PVC (Polyvinyl Chloride) diaphragm and manufacturing method thereof

A manufacturing method and technology of PVC resin, applied in the field of PVC diaphragm manufacturing, can solve the problems of expensive reinforcing agent and high production cost, improve melt strength and uniformity, prevent low temperature cracking, slow down melt fracture and seepage out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

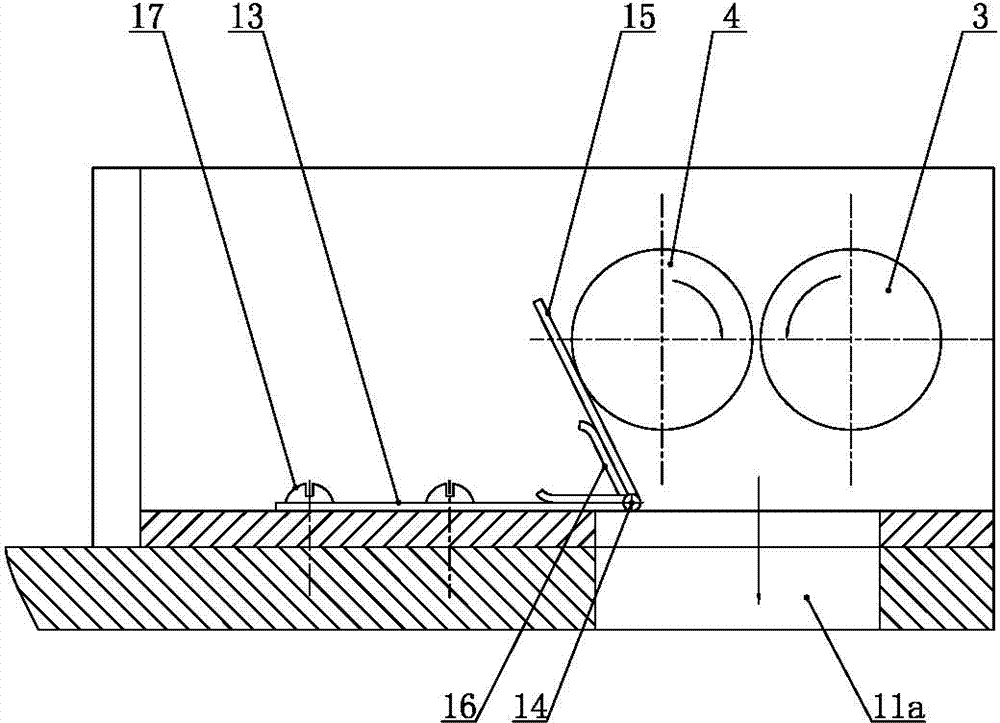

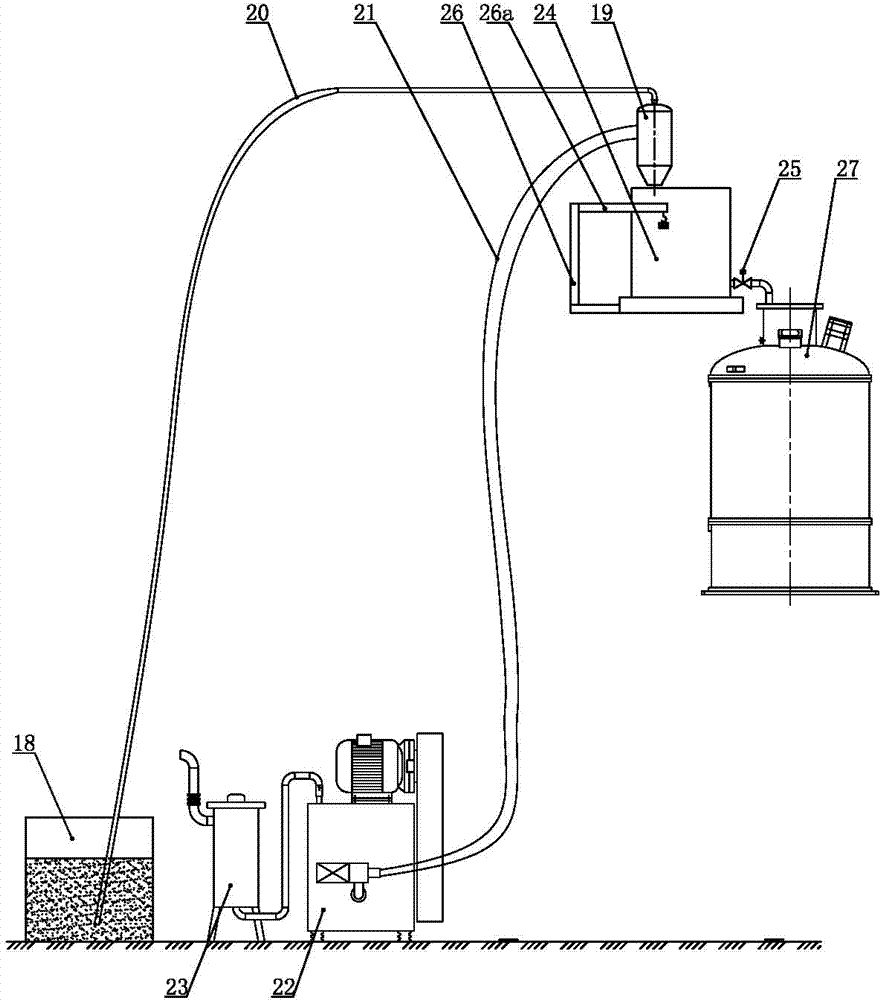

[0021] The manufacturing method of the PVC diaphragm of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, PVC resin: 100 parts; 719 type oxidized polyethylene wax: 1.0 part; auxiliary stabilizer: 0.015 parts ; MBS resin: 3.5 parts; processing aid ACR: 0.9 part; solid internal lubricant: 0.45 part; external lubricant: 0.1 part; polyvinyl chloride resin PX1000: 0.3 part; ultramarine blue pigment: 0.011 part; part; the auxiliary stabilizer is composed of methyl tin and antimony mercaptide, and the weight ratio of the two is 1:4; (2) First, put each raw material into the kneading pot and knead until uniform, and the discharge temperature of the kneading pot is 80°C ;Then let the mixed material enter the cooling pot to cool down and stir, and the temperature of the cold pot is 60°C; then the mixed material is extruded and plasticized into a paste by a screw extruder, and the extrusion temp...

Embodiment 2

[0023] The manufacturing method of the PVC diaphragm of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, PVC resin: 100 parts; 719 type oxidized polyethylene wax: 1.1 parts; auxiliary stabilizer: 0.016 parts ; MBS resin: 3.7 parts; processing aid ACR: 1.0 part; solid internal lubricant: 0.50 part; external lubricant: 0.15 part; polyvinyl chloride resin PX1000: 0.35 part; ultramarine blue pigment: 0.012 part; parts; the auxiliary stabilizer is composed of methyl tin and antimony mercaptide, and the weight ratio of the two is 1:4; (2) First, put all the raw materials into the kneading pot and knead until uniform, and the discharge temperature of the kneading pot is 85°C ; Then make the mixed material enter the cooling pot to cool down and stir, the temperature of the cold pot is 65 ° C; then the mixed material is extruded and plasticized into a paste by a screw extruder, and the extrus...

Embodiment 3

[0025] The manufacturing method of the PVC diaphragm of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, PVC resin: 100 parts; 719 type oxidized polyethylene wax: 1.2 parts; auxiliary stabilizer: 0.017 parts ; MBS resin: 4.0 parts; processing aid ACR: 1.1 parts; solid internal lubricant: 0.55 parts; external lubricant: 0.2 parts; polyvinyl chloride resin PX1000: 0.4 parts; ultramarine blue pigment: 0.013 parts; parts; the auxiliary stabilizer is composed of methyl tin and antimony mercaptide, and the weight ratio of the two is 1:4; (2) firstly put each raw material into the kneading pot and knead until uniform, and the discharge temperature of the kneading pot is 90°C ;Then make the mixed material enter the cooling pot to cool down and stir, the temperature of the cooling pot is 70°C; then the mixed material is extruded and plasticized into a paste by the screw extruder, and the extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com