Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Staged operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High efficiency interleaved solar power supply system

ActiveUS9397497B2Easy to operateIncrease working voltageElectric signal transmission systemsPhotovoltaicsEngineeringPhase control

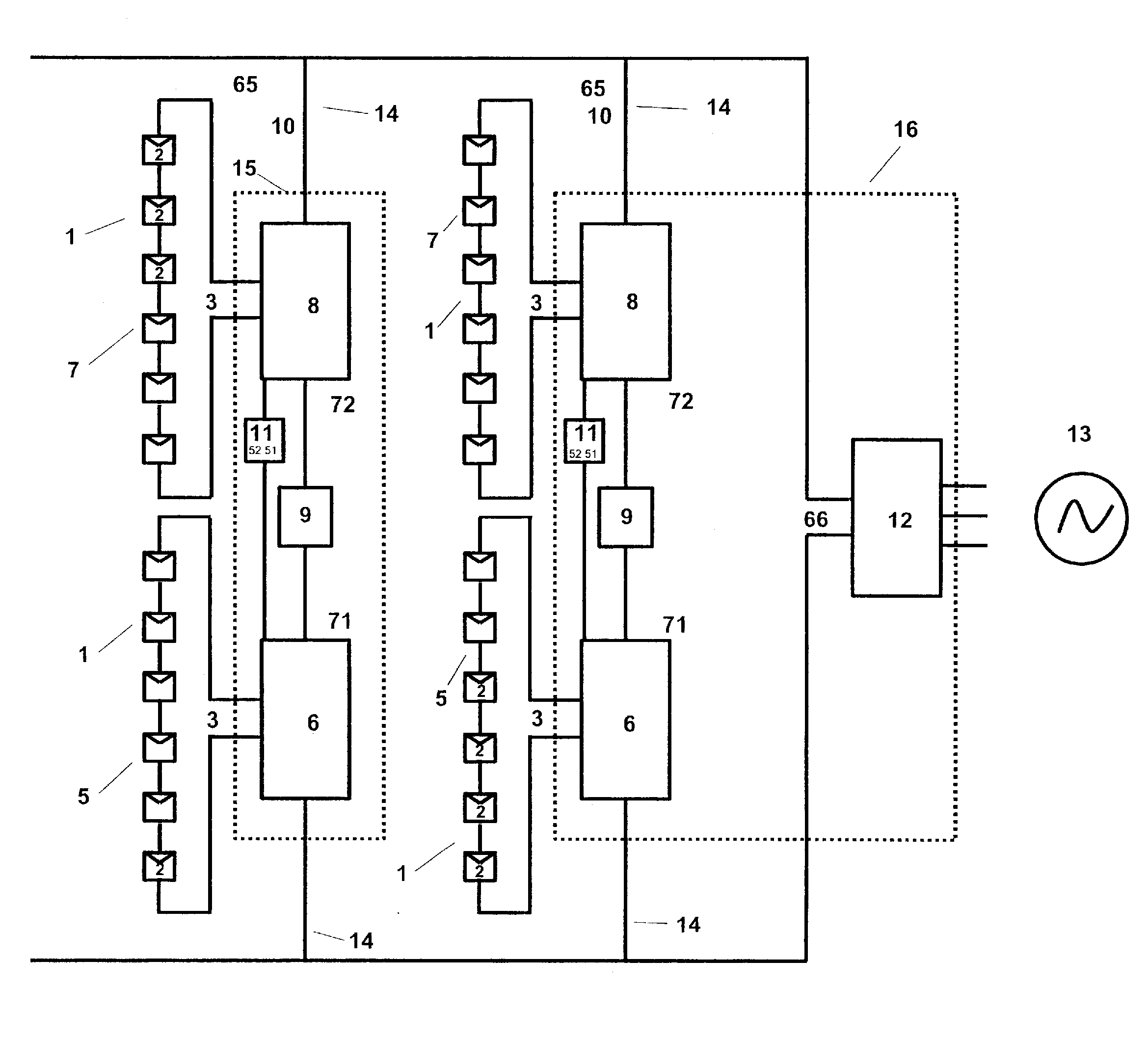

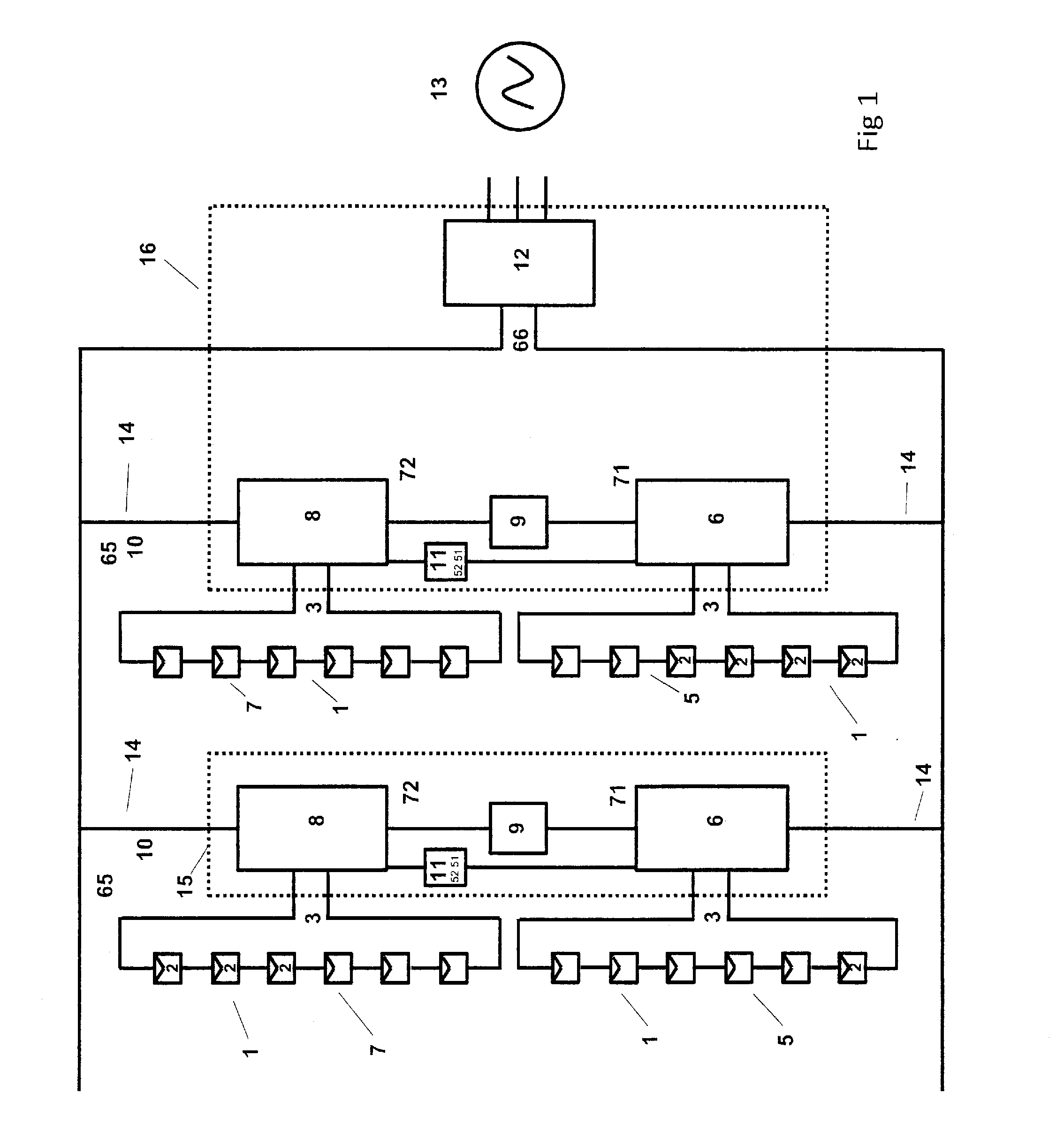

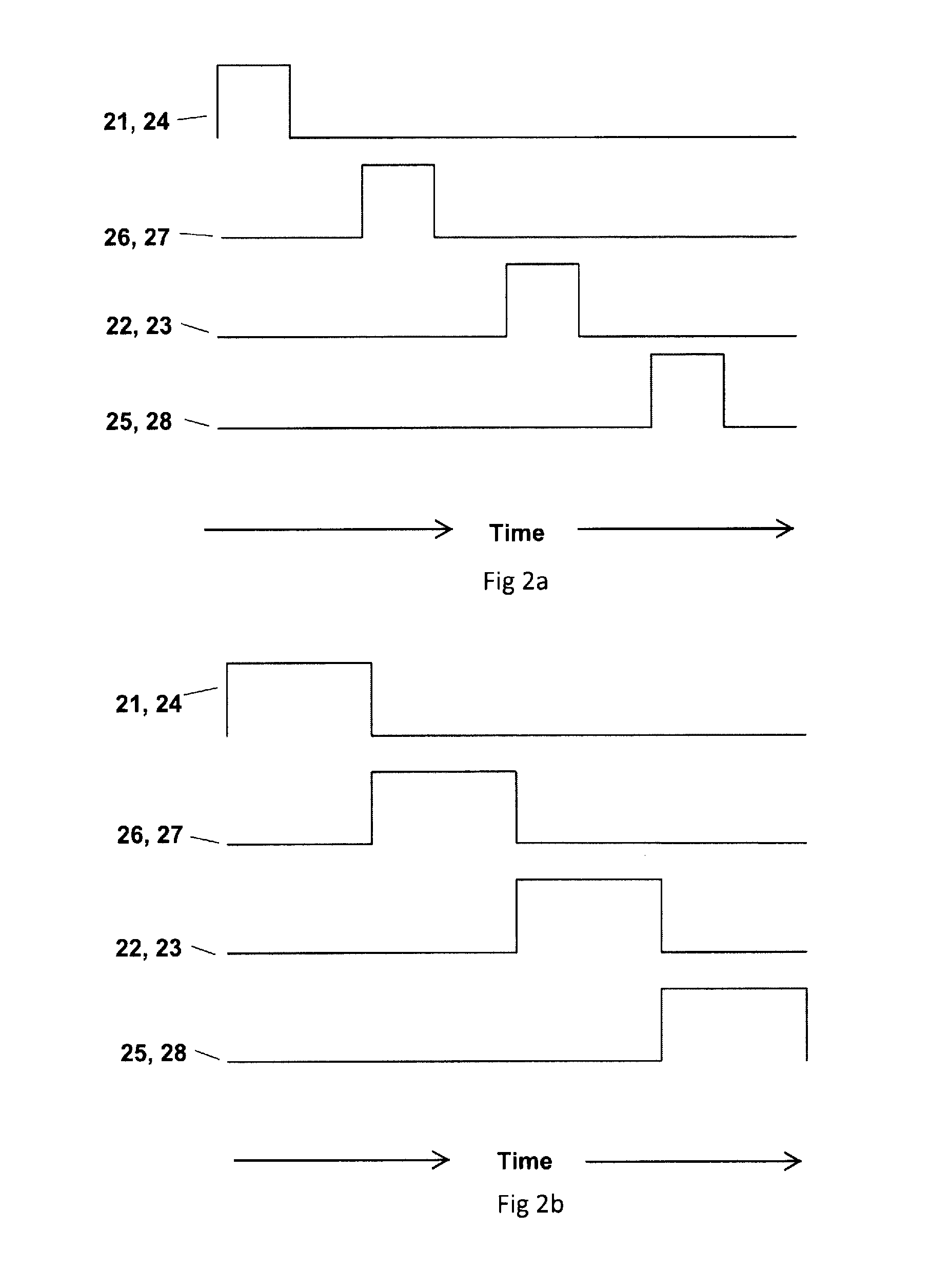

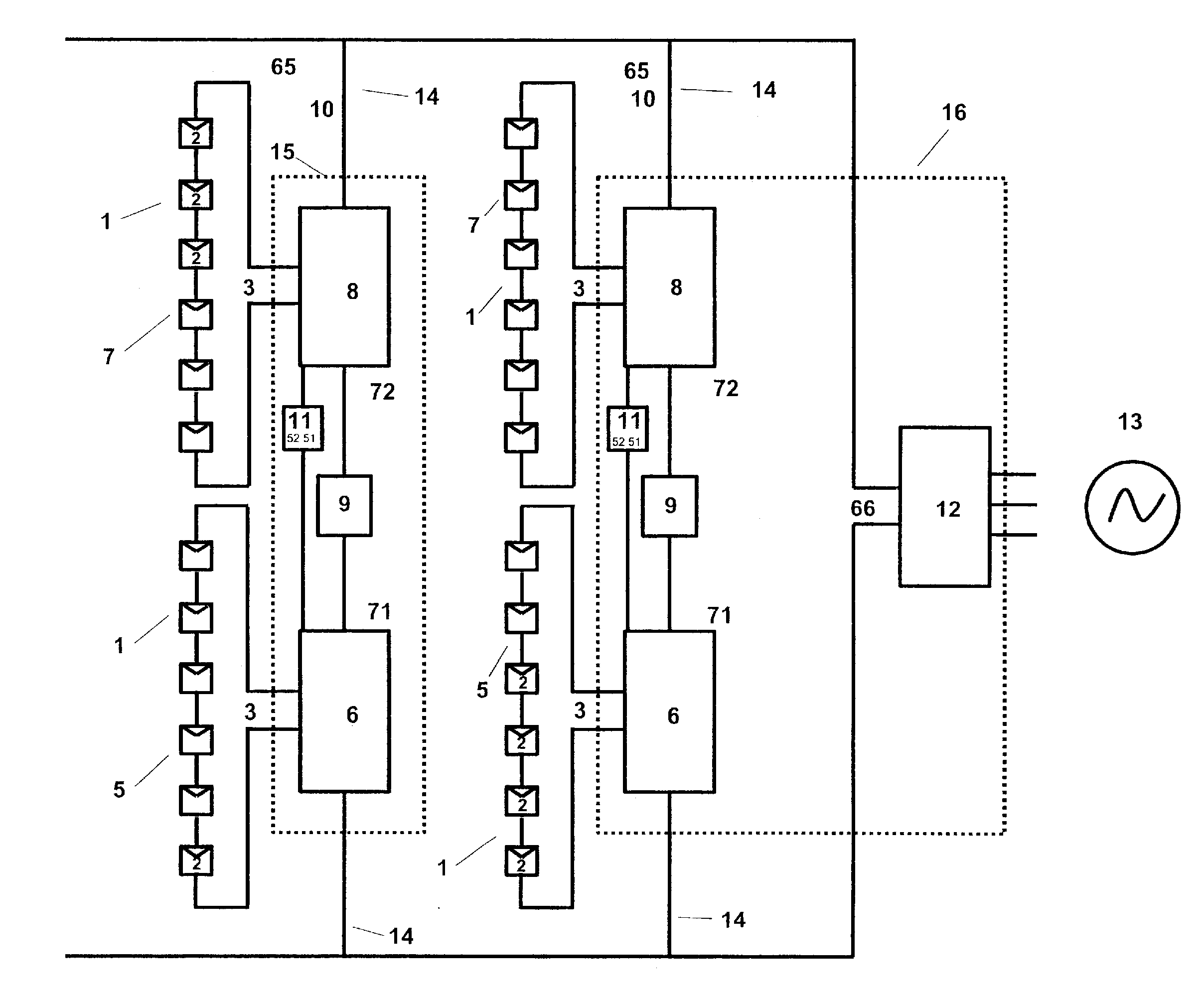

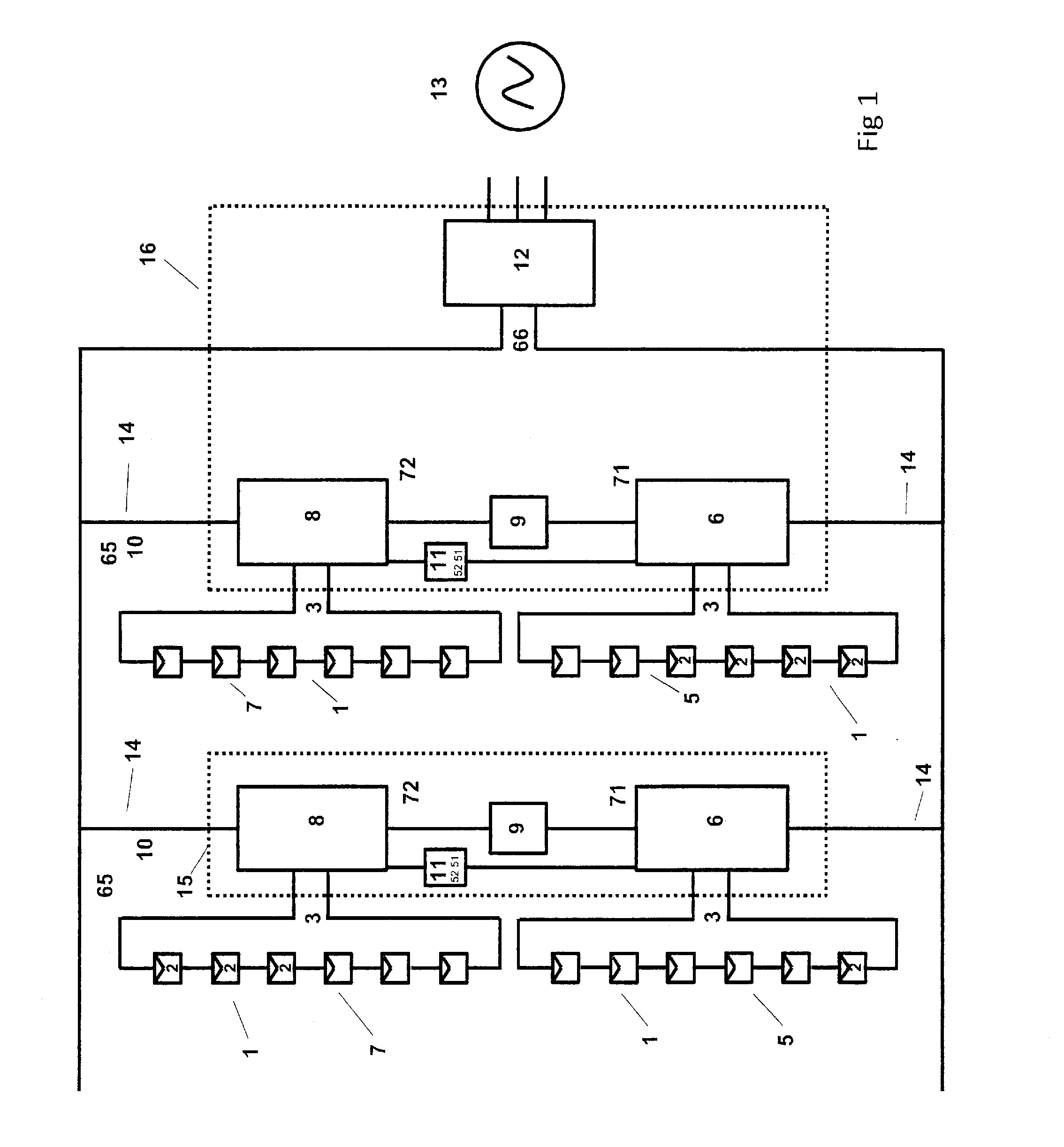

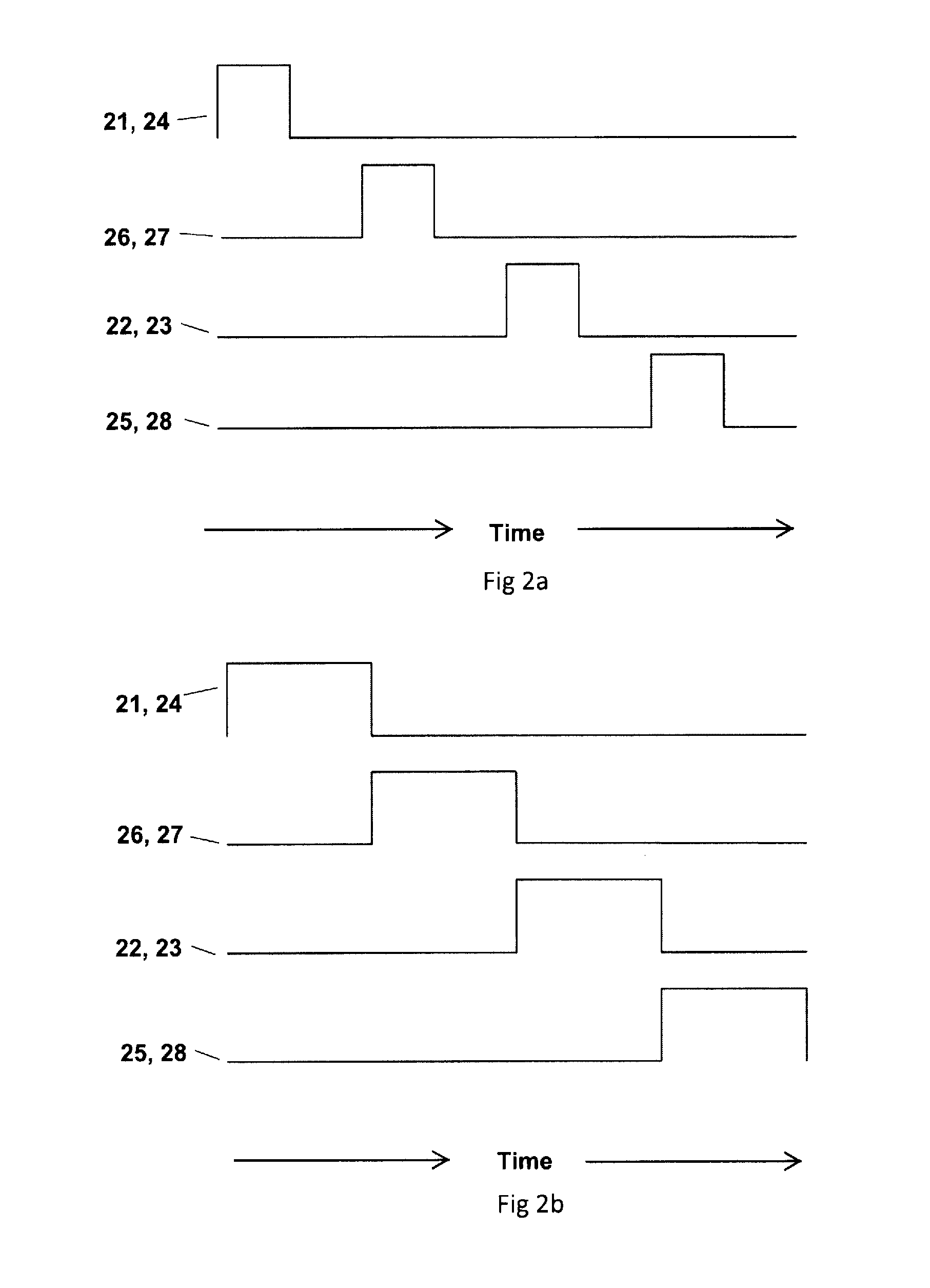

A high efficiency solar power system combining photovoltaic sources of power (1) can be converted by a base phase DC-DC photovoltaic converter (6) and an altered phase DC-DC photovoltaic converter (8) that have outputs combined through low energy storage combiner circuitry (9). The converters can be synchronously controlled through a synchronous phase control (11) that synchronously operates switches to provide a conversion combined photovoltaic DC output (10). Converters can be provided for individual source conversion or phased operational modes, the latter presenting a combined low photovoltaic energy storage DC-DC photovoltaic converter (15) at string or individual panel levels.

Owner:AMPT

Posture identification method and device based on near-infrared TOF camera depth information

InactiveCN104463146AThe detection process is fastAccurate detectionImage analysisCharacter and pattern recognitionHuman bodyStaging operation

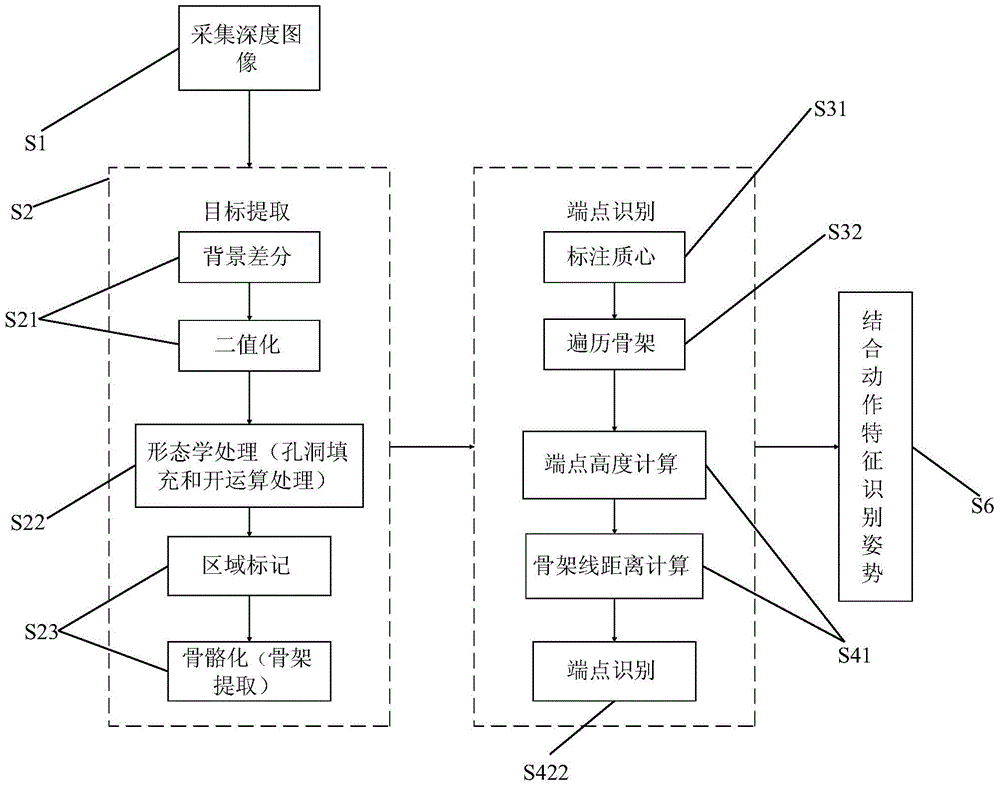

The invention discloses a posture identification method based on near-infrared TOF camera depth information. The posture identification method includes the steps that a depth image is obtained through an SR4000, earlier-stage operation processing is carried out on the depth image, a human body object is obtained and skeletonized, then coordinates of end points of the head, the hands, the feet and the mass center of the human body target are obtained, the heights between the end points and the ground and the skeleton line distances between the end points and the mass center are calculated, the attributes of the end points are identified according to the skeleton line distances and the ground heights, and then posture identification is achieved in cooperation with motion characteristics and the depth information. In this way, the target tracking difficulty and the algorithm complexity are lowered, the identification effective rate and the target division accuracy are improved, and convenience is brought to real-time embedded transplanting. The invention further discloses a device used for implementing the posture identification method.

Owner:SOUTH CHINA NORMAL UNIVERSITY

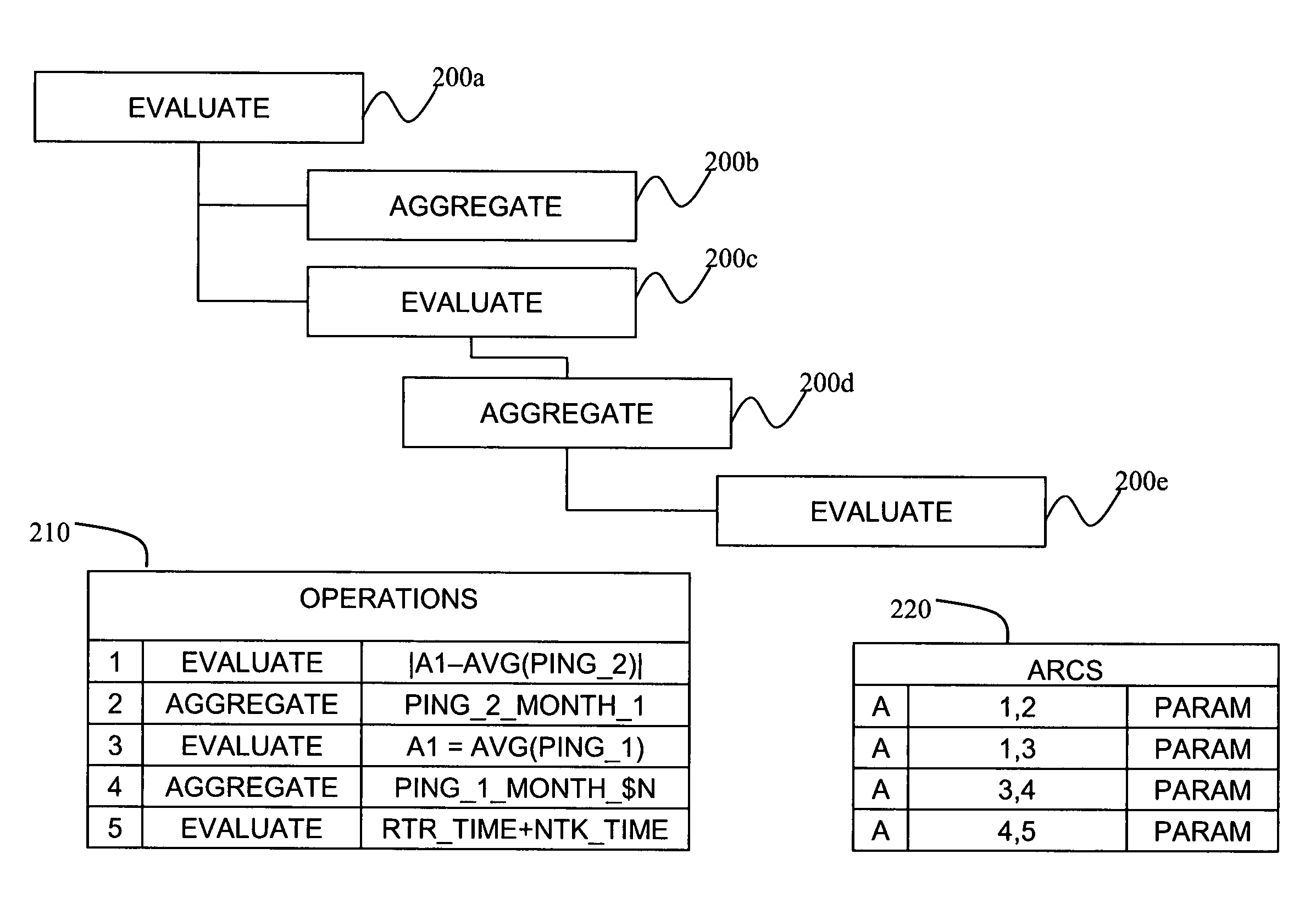

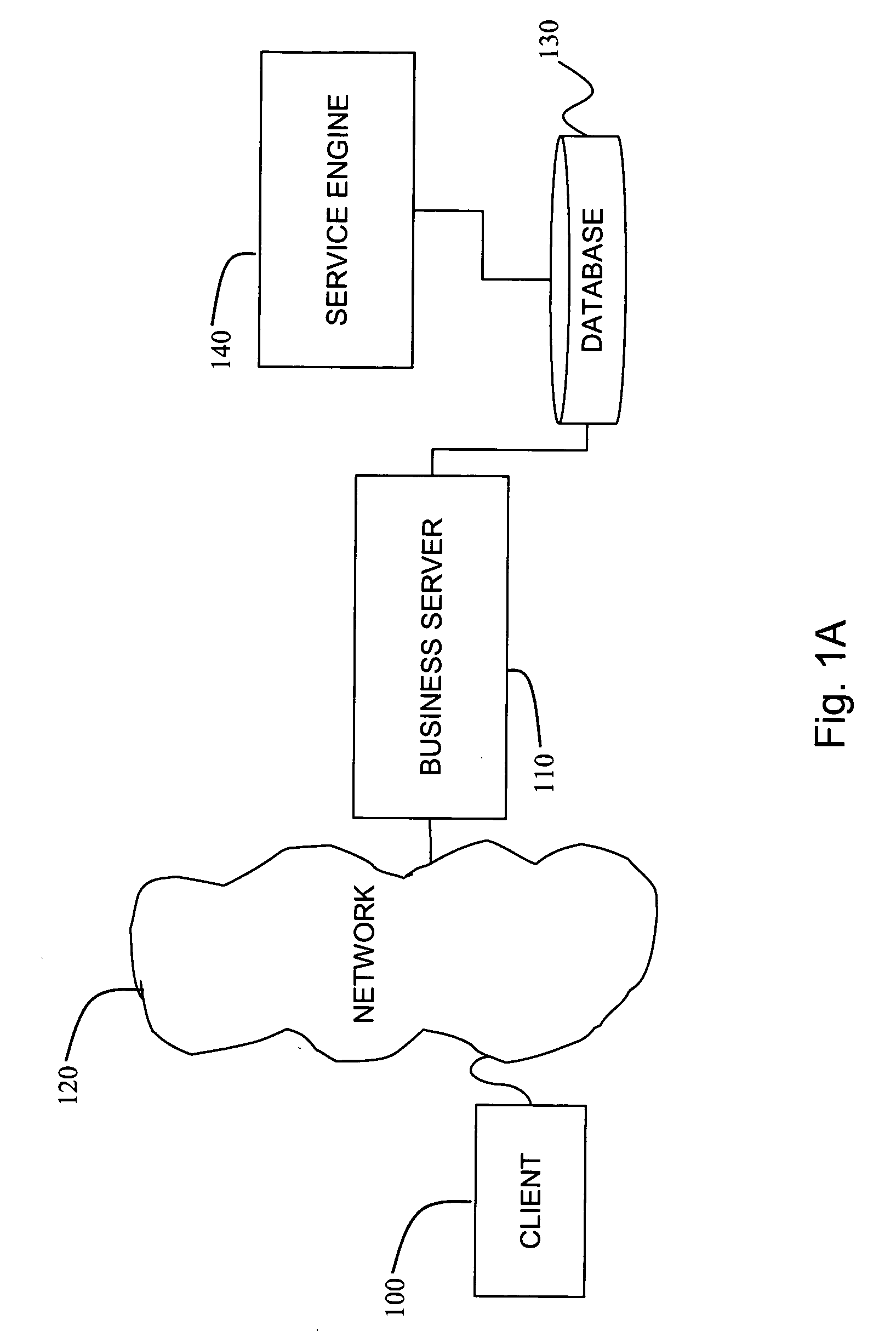

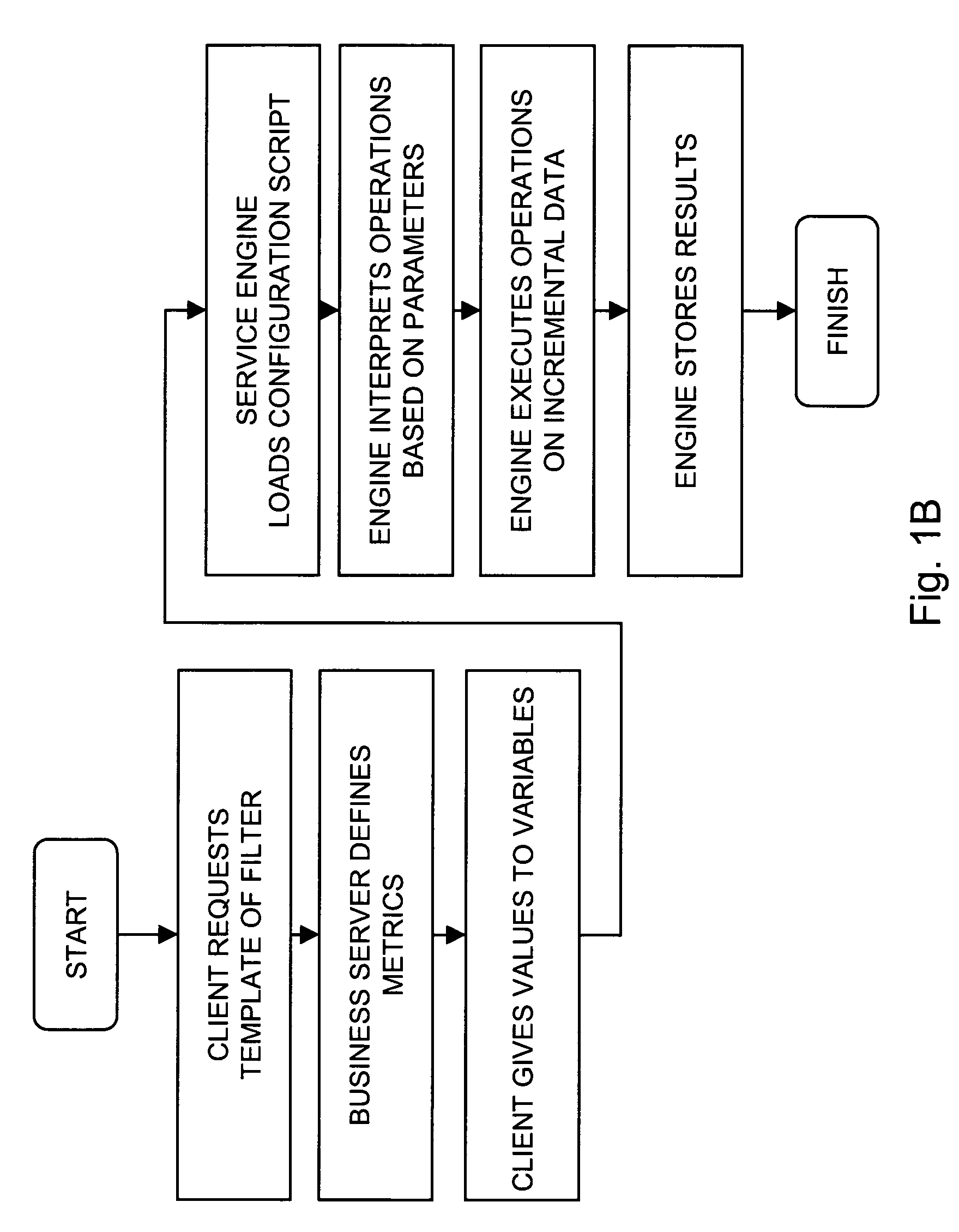

System for interpretation of streaming data filters

InactiveUS20060197766A1Digital data information retrievalProcessor architectures/configurationStreaming dataStaging operation

A method for processing streaming data, including selecting a flow having a plurality of operations configured to be applied to streaming data, and executing any of the operations defined in the flow, where the operations are executed on the streaming data, where the operations are executed in a series of discrete stages, during each stage performing a discrete function in a multi-stage operation, and where the operations are executed incrementally, processing each new part of the streaming data as it becomes available for processing.

Owner:DIGITAL FUEL TECH

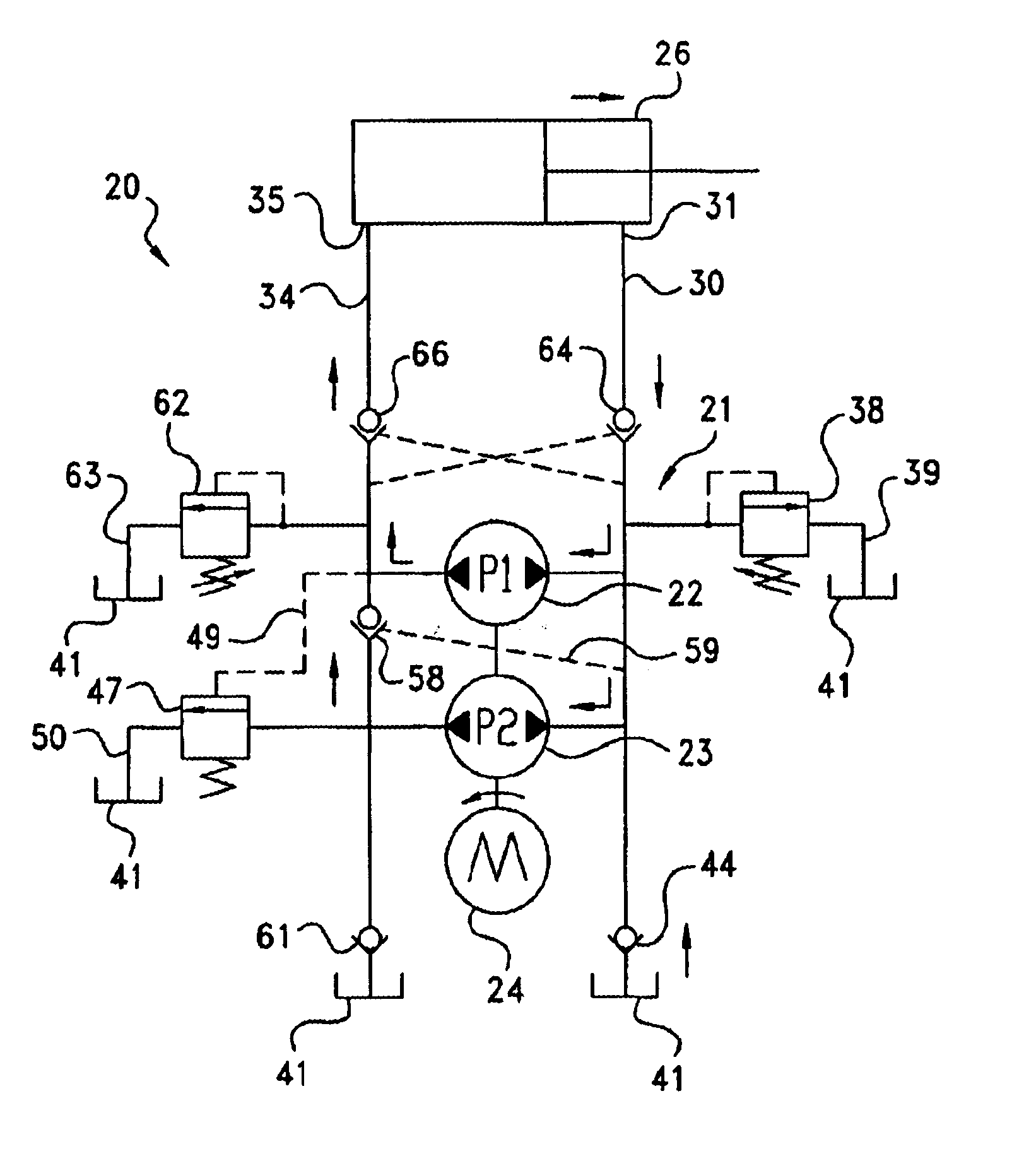

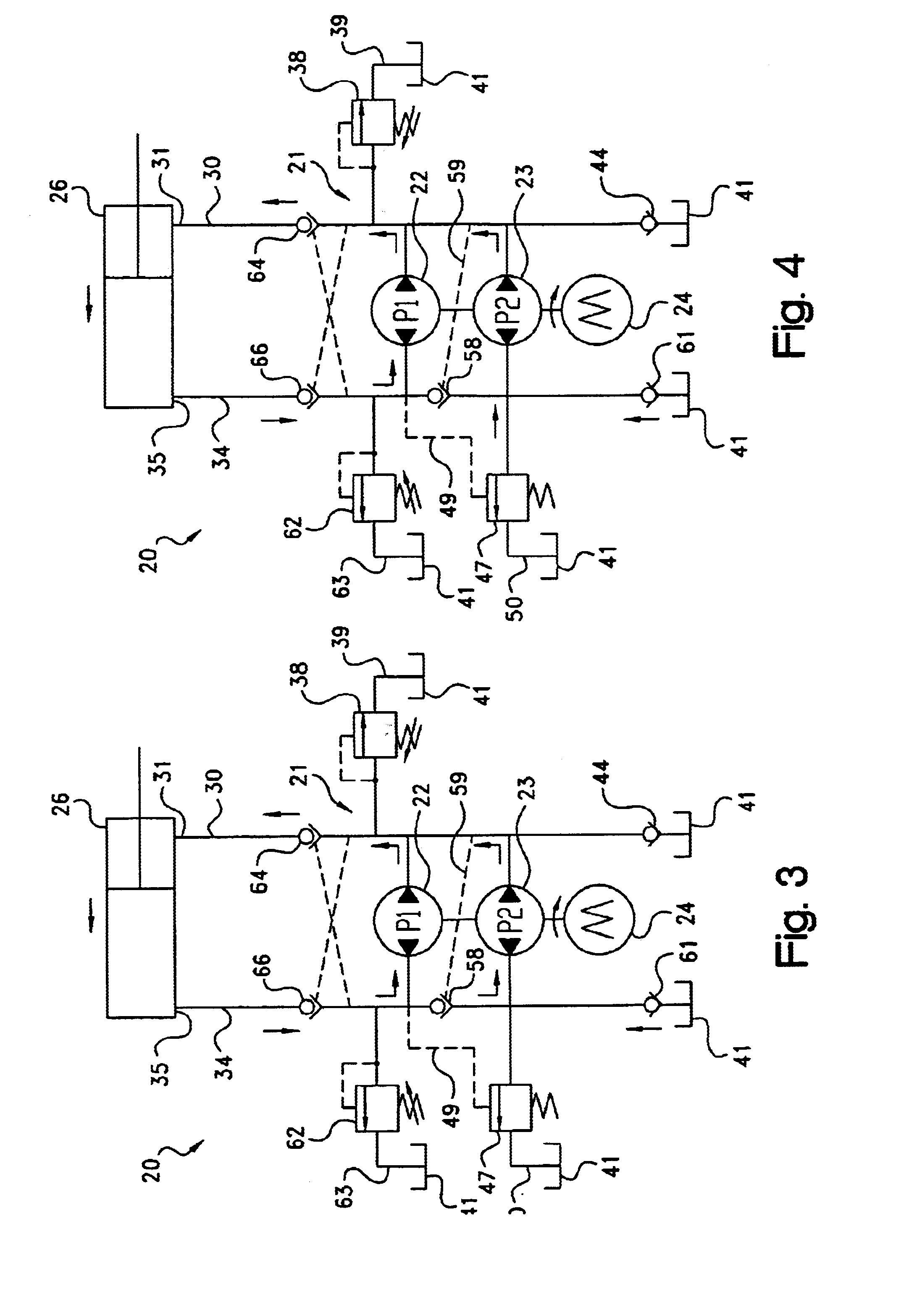

Bi-rotational, two-stage hydraulic system

InactiveUS6886332B2Low costSimple and compactFluid couplingsPropulsion power plantsStaging operationEngineering

A hydraulic system for an actuator provides staged operation during extend and retract. A pair of reversible pumps are conjointly driven by a reversible motor. A relief valve in the retract circuit directs fluid to tank when fluid pressure increases above a predetermined value. An unloader valve in the extend circuit is responsive to pressure at a first stage pump to direct flow to tank when the pressure increases above a second predetermined value. A non-return check valve connected between the pumps in the extend circuit closes the flow circuit to the second stage pump during high loads, so that the flow from the second stage pump goes to tank, and the return flow from the actuator goes only to the first stage pump. The non-return check valve is responsive (via a signal line to the retract circuit portion) to the pressure in the extend and retract circuit portions.

Owner:PARKER INTANGIBLES LLC

Washing machine and its washing method

A washing machine adopting a clutch structure wherein a power switching motor for controlling a brake band and a clutch lever in multi-stage is separately applied from a drainage motor, such that various kinds of water currents can be embodied according to the multi-control of the power switching motor and a washing method adequate to needs of cloth protection and coping with varying cloths can be provided to thereby enable to protect damage of cloths in advance, the washing machine comprising: a spin-dry tub rotably disposed in a water tub and connected to a dram and a gear case via a power line; a pulsator rotably disposed in a spin-dry tub and connected to a driving shaft coupling and a driving shaft via power line; a brake band for braking and releasing the rotation of the drum; a clutch spring for disconnecting and connecting the power of the driving shaft coupling and the gear case; and power switching motor for controlling in multi-stage operations of clutch sprig and the brake band, the washing method comprising: a first water current control method therein pulsator only rotates in forward / backward direction; a second water current control method wherein a spin-dry tub repeats forward / backward netations is opposition to those of the pulsator; a third water current control method wherein the pulsator and the spin-dry tub rotates in forward direction only; and a fourth water current control method wherein the second water current control is alternatively operated under the third water current control state.

Owner:SAMSUNG ELECTRONICS CO LTD

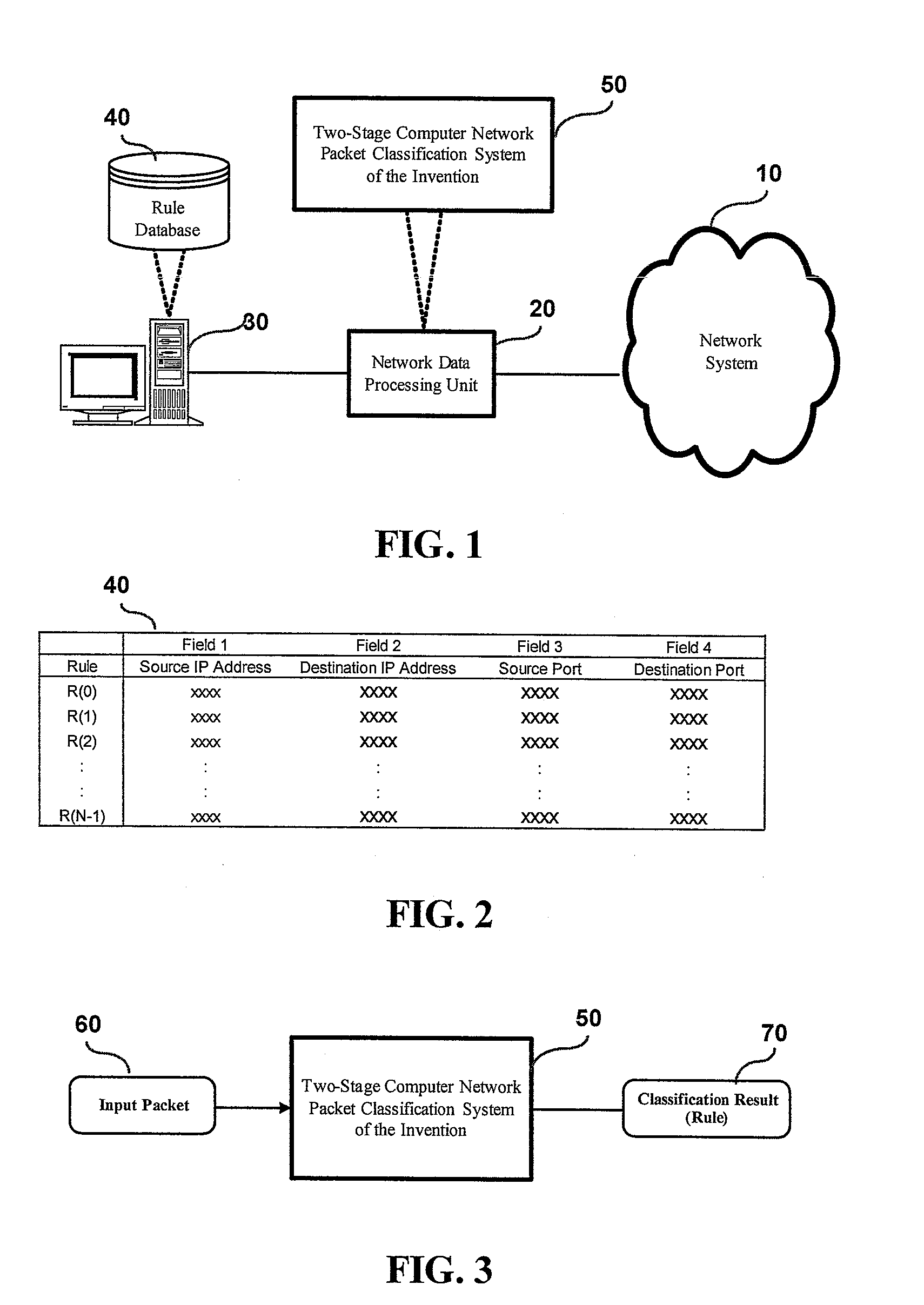

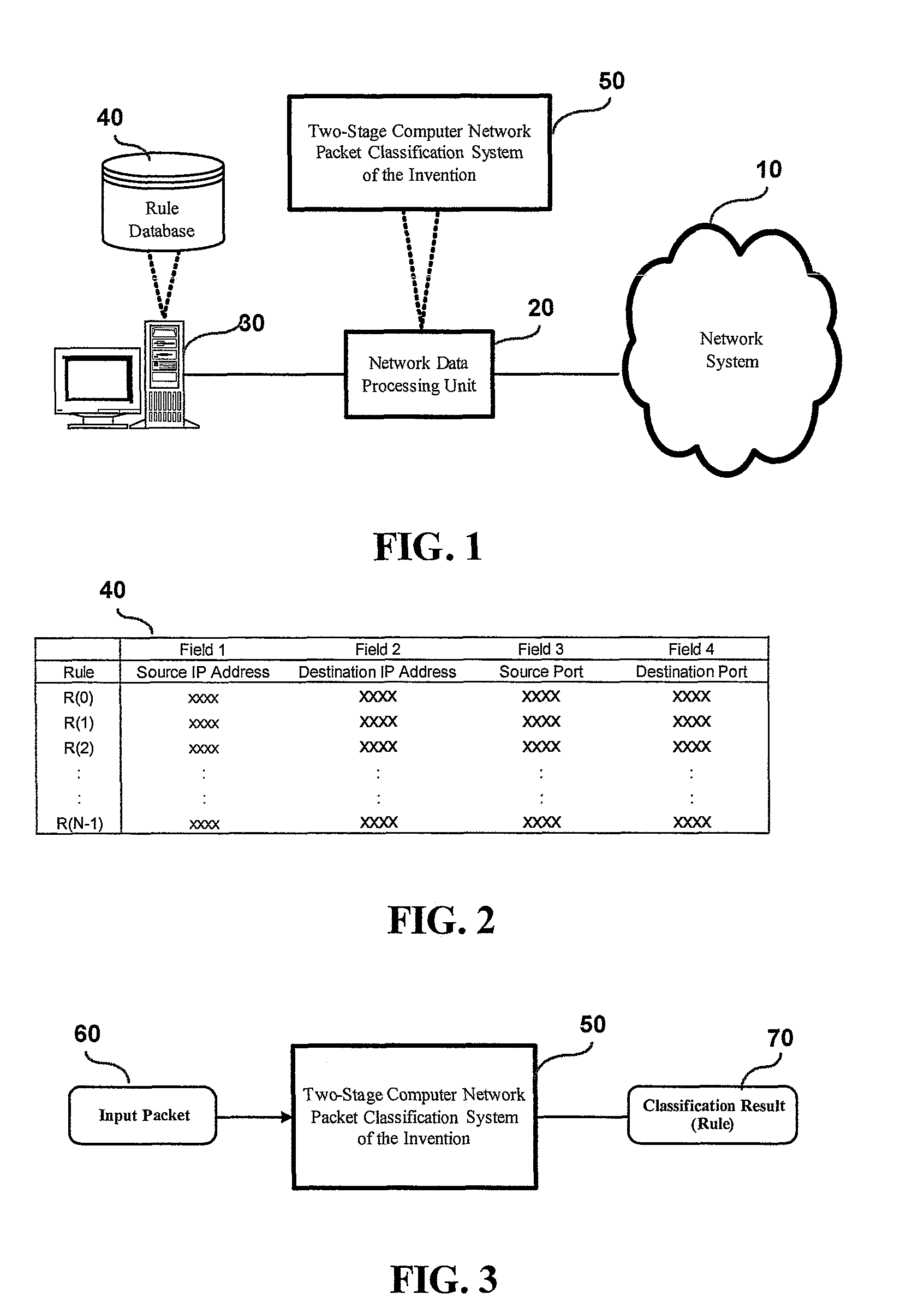

Two-stage computer network packet classification method and system

InactiveUS20090190592A1Improve performanceEasy to useData switching by path configurationNetworked systemClassification methods

A two-stage computer network packet classification method and system is proposed, which is designed for integration to a network system for classification of packets within the network system. The proposed method and system is characterized by the use of a two-stage operation for packet classification; wherein the first-stage operation involves the use of a decision-tree data module whose leaf nodes are used to store a bit vector that represents a cluster of rule groups that are located within a particular cut region in a multidimensional Euclidean space that is mapped to the field values of the input packet; and the second-stage operation involves the use of a bit-vector lookup table data module to retrieve a set of bit vectors which represent a set of possible rules in each rule group and which are intersected to find a matched rule for the input packet. This feature allows the packet classification to be implemented with low memory requirement and enhanced system performance.

Owner:NAT TAIWAN UNIV

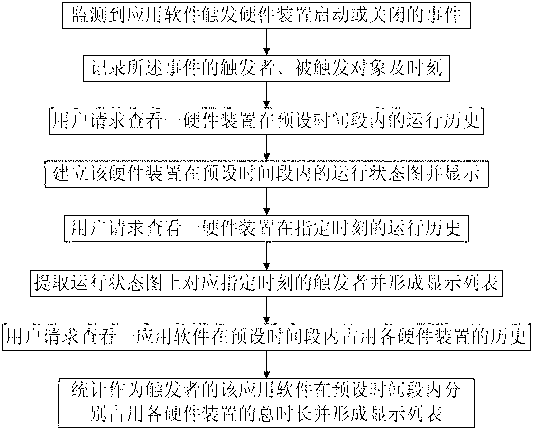

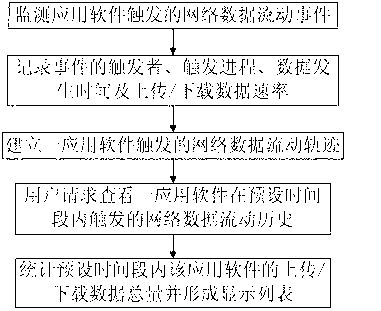

Data monitoring method and data monitoring system for software behavior of mobile terminal

ActiveCN103106130AReduce power lossEnergy efficient ICTHardware monitoringStaging operationState diagram

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

High Efficiency Interleaved Solar Power Supply System

ActiveUS20150130284A1Improve efficiencyOperating efficiency greatDc network circuit arrangementsPhotovoltaicsStored energyPhase control

A high efficiency solar power system combining photovoltaic sources of power (1) can be converted by a base phase DC-DC photovoltaic converter (6) and an altered phase DC-DC photovoltaic converter (8) that have outputs combined through low energy storage combiner circuitry (9). The converters can be synchronously controlled through a synchronous phase control (11) that synchronously operates switches to provide a conversion combined photovoltaic DC output (10). Converters can be provided for individual source conversion or phased operational modes, the latter presenting a combined low photovoltaic energy storage DC-DC photovoltaic converter (15) at string or individual panel levels.

Owner:AMPT

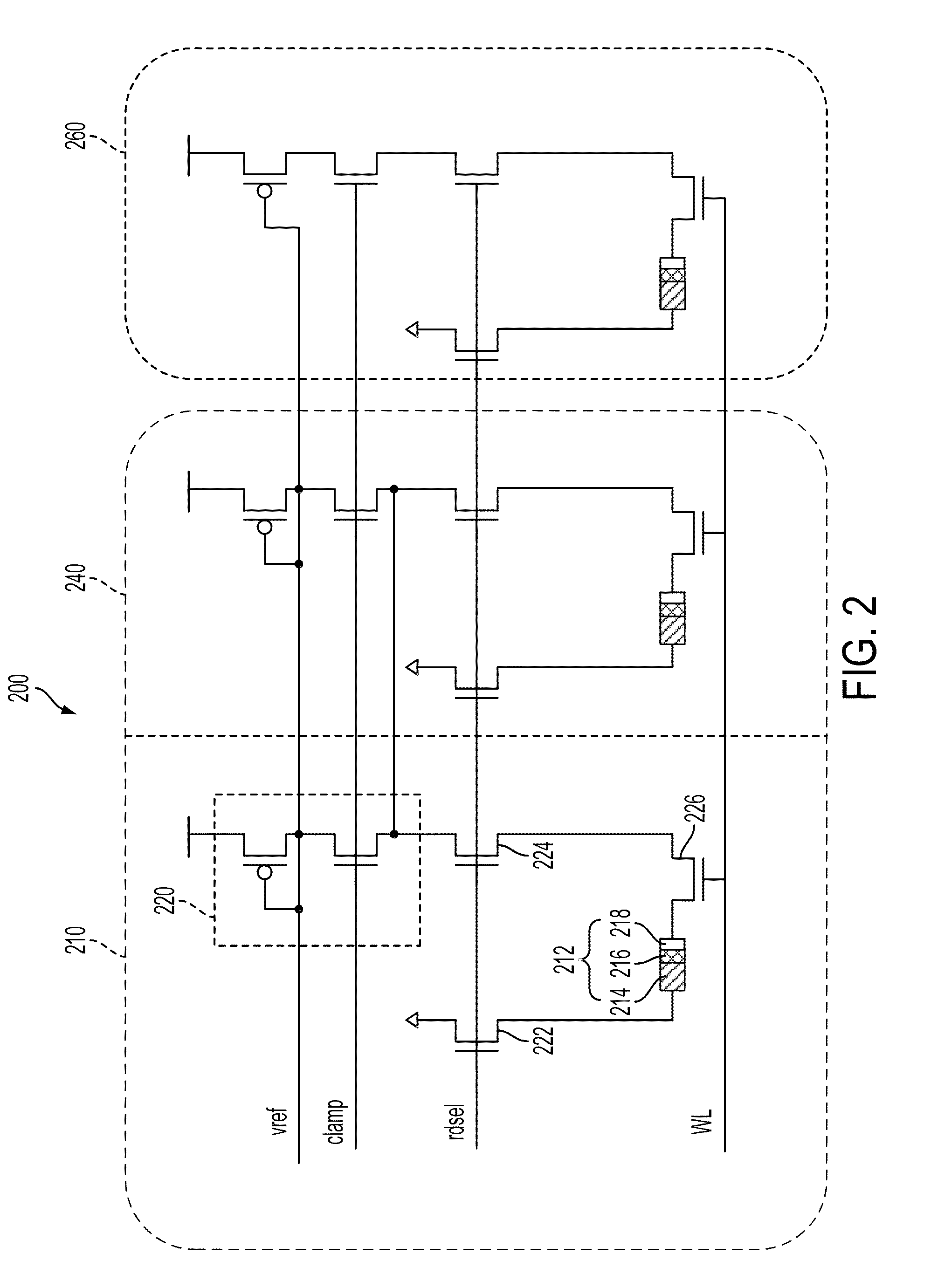

Offset canceling dual stage sensing circuit

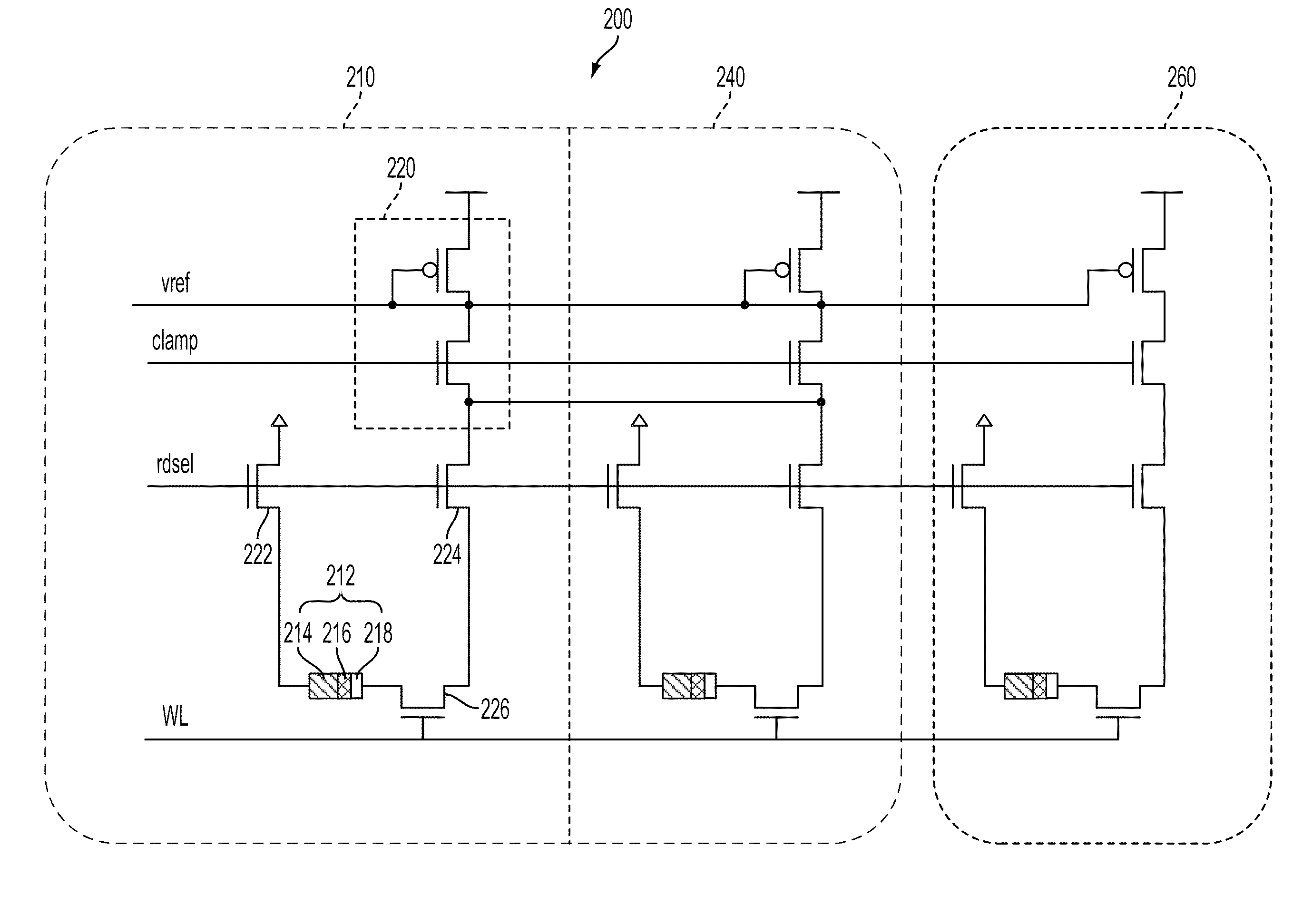

An offset canceling dual stage sensing method includes sensing a data value of a resistive memory data cell using a first load PMOS gate voltage generated by a reference value of a resistive memory reference cell in a first stage operation. The method also includes sensing the reference value of the resistive memory reference cell using a second load PMOS gate voltage generated by the data value of the resistive memory data cell in a second stage operation of the resistive memory sensing circuit. By adjusting the operating point of the reference cell sensing, an offset canceling dual stage sensing circuit increases the sense margin significantly compared to that of a conventional sensing circuit.

Owner:QUALCOMM INC +1

Large-section earth pressure balancing rectangular jacking pipe joint of motor vehicle tunnel and method for constructing large-section earth pressure balancing rectangular jacking pipe

ActiveCN103061782AImprove carrying capacitySufficient carrying capacityUnderground chambersTunnel liningStaging operationEngineering

The invention discloses a large-section earth pressure balancing rectangular jacking pipe joint of a motor vehicle tunnel. The large-section earth pressure balancing rectangular jacking pipe joint is characterized in that a jacking direction of a jacking pipe is defined as a forward direction, grouting holes which radially penetrate through a pipe wall are peripherally arranged in the middle of the outer wall surface of the jacking pipe joint at intervals, lifting holes are arranged in middles of four surfaces of the jacking pipe joint, and radial thixotropic mud grouting holes which penetrate through the pipe wall are peripherally arranged in the front of the outer wall surface of the jacking pipe joint at intervals; and the top of the jacking pipe joint is arched, and four corners of the section of the pipe joint are of arc chamfer structures. The invention further discloses a method for constructing the jacking pipe joint. The large-section earth pressure balancing rectangular jacking pipe joint and the method have the advantages that a earth pressure balancing pipe jacking process can be applied to the field of motor vehicle tunnels, the long-term technical difficult problem that the earth pressure balancing pipe jacking process cannot be applied to constructing the motor vehicle tunnels is solved, the stability requirement that the pipe joint is prevented from being staggered under the condition of long-term unbalanced dynamic loads of motor vehicles on the tunnel is met assuredly, a permanent waterproofing function is realized, and the cost for later-stage operation and maintenance is greatly lowered.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

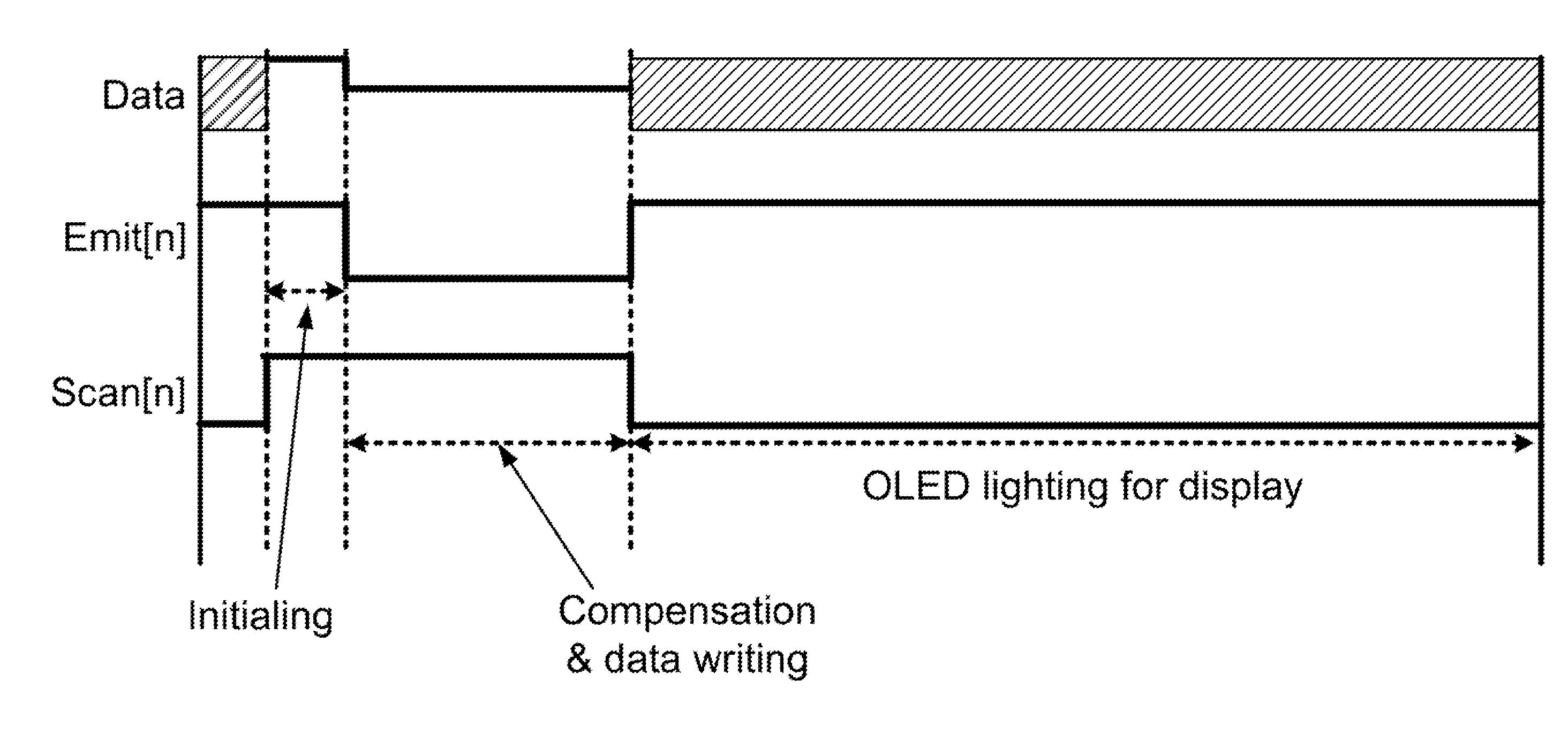

Pixel circuit of light emitting diode display and driving method thereof

InactiveUS20120242712A1Large display sizeIR dropCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceHemt circuits

The gate of the first TFT in the present invention is discharged through the first TFT and the OLED in the compensation and data writing stage operation. As in cases that the usage time of the display pixel extends and the threshold voltage of the first TFT increases and the mobility thereof decreases, the voltage of the OLED increases, or the size of the display becomes larger to induce IR drop, the present invention enables to reduce the discharge voltage (charge current) to raise the gate voltage of the first TFT for compensating the OLED current drop. Meanwhile, the fifth TFT has characteristic of the threshold voltage increase. As the threshold voltage of the fifth TFT increases with usage time, the compensation of the OLED luminous efficiency drop can be realized.

Owner:HANNSTAR DISPLAY CORPORATION

Zoning Control Method of Anti-fatigue Life of Steam Turbine Rotor

InactiveCN102278152AGuaranteed economyOptimal Rate of ChangeMachines/enginesEngine startersLow loadPeak value

A steam turbine rotor anti-fatigue life partition control method, the method is the following steps: (1), start the steam turbine unit of the power plant, record the structural size and operating parameters of the steam turbine rotor; (2), finite element modeling, Thermal calculations and simulation calculations under variable working conditions; (3), peak stress calculations in different temperature zones, and material fatigue characteristics analysis; (4), formulating rush rotation, medium-speed warm-up, constant-speed warm-up, grid-connected low-load warm-up, Six-stage optimized operation control plan for cutting cylinders and entering sliding pressure operation; (5) Draw optimized start-up curves, and organize construction personnel to operate the start-up and operation of steam turbine units on site. The invention reasonably distributes the anti-fatigue life loss, optimizes the change rate of operating parameters under variable working conditions, shortens the start-up time, ensures the economy of the start-up process, and meets the flexibility requirements of the peak-shaving demand of the power grid.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD ELECTRIC POWER SCI RES INST +1

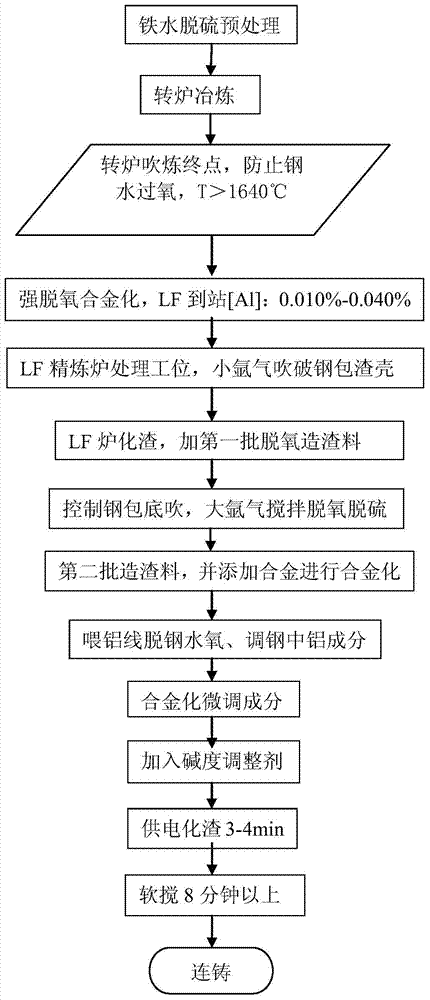

Process of quickly regulating alkalinity of LF (ladle furnace) slag

The invention discloses a process of quickly regulating alkalinity of LF slag. The process comprises a molten iron desulfurization pretreatment and converter smelting process and an LF refining smelting process, wherein the molten iron desulfurization pretreatment and converter smelting process comprises the following steps: 1) end point operation, 2) slag stopping operation and 3) implementation of a system for tapping, deoxidizing and slagging; the LF refining smelting process comprises the following steps: 1) LF early-stage operation: adding a first batch of deoxidizing and slagging material; 2) implementation of an LF middle-stage deoxidization and desulfuration process: adding a second batch of deoxidizing and slagging material, alloying according to components of a steel grade; if the sulfur content of a second sample meets the component requirements of the steel grade, feed aluminum wires; if the components of the second sample fail to meet the component requirements of the steel grade, adding a third batch of deoxidizing and slagging material until the requirements are met, and then feeding the aluminum wires to supplement the aluminum content in the molten steel; 3) LF middle-later stage quick alkalinity regulation: at the end of feeding of the aluminum wires to supplement the aluminum content in the molten steel, adding an alkalinity regulator to optimize a slag system and ending the process. According to the process of quickly regulating the alkalinity of top slag of an LF steel ladle in stages, the requirements for refining furnace molten steel desulfuration and the impurity removal are both met to achieve the molten steel refining effects, so that the internal quality of continuous casting is improved.

Owner:SHANGLUO UNIV

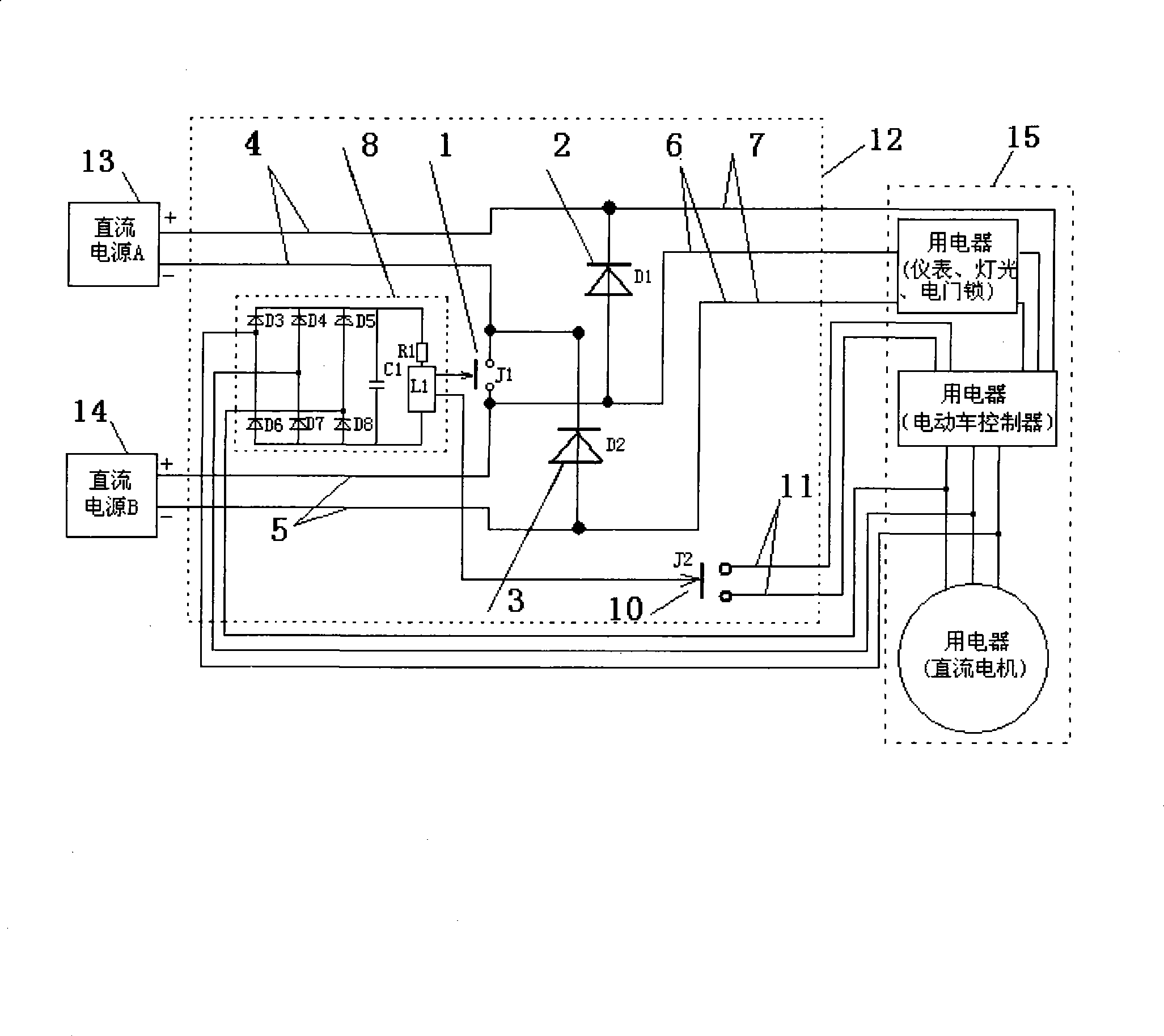

DC parallel-serial transition electric power system

ActiveCN101442259ASimple structureWork reliablyApparatus without intermediate ac conversionVehicular energy storageDischarge efficiencyLow speed

The invention relates to the technical field of supplying electricity to a power utilization device after two groups of direct current power supplies are parallelly or serially connected, in particular to technology of supplying electricity to electric bicycles and electric automobiles, which comprises a direct current parallel-serial connection converter (12), wherein the direct current parallel-serial connection converter (12) is provided with a direct current power supply connection wire (4) and a direct current power supply connection wire (5) which can be connected with a direct current power supply (A13) and a direct current power supply B14, and is provided with a pair of positive and negative conducting wire direct current output connection wires (7) which are connected with a positive connection wire and a negative connection wire of the power utilization device. The technology has the advantages that the technology realizes the conversion of parallel-serial connection only by a switch, and solves common problems of conversion failure and battery short-circuit caused by non-synchronized switches when a plurality of switches realize the conversion of the parallel-serial connection, has a simple structure and reliable work, reduces the damage of heavy current to batteries through the normal parallel low-voltage output of the two groups of direct current power supplies and the serial high-voltage output when needing to be used, reduces the quantity of usable batteries in waste battery packs, reduces the count of rechargeable serial batteries, improves the discharging efficiency of the batteries, is favorable for the safety due to the adoption of high and low speed staged operation, and can meet different power supply demands at any time.

Owner:无锡德博尼新能源科技有限公司

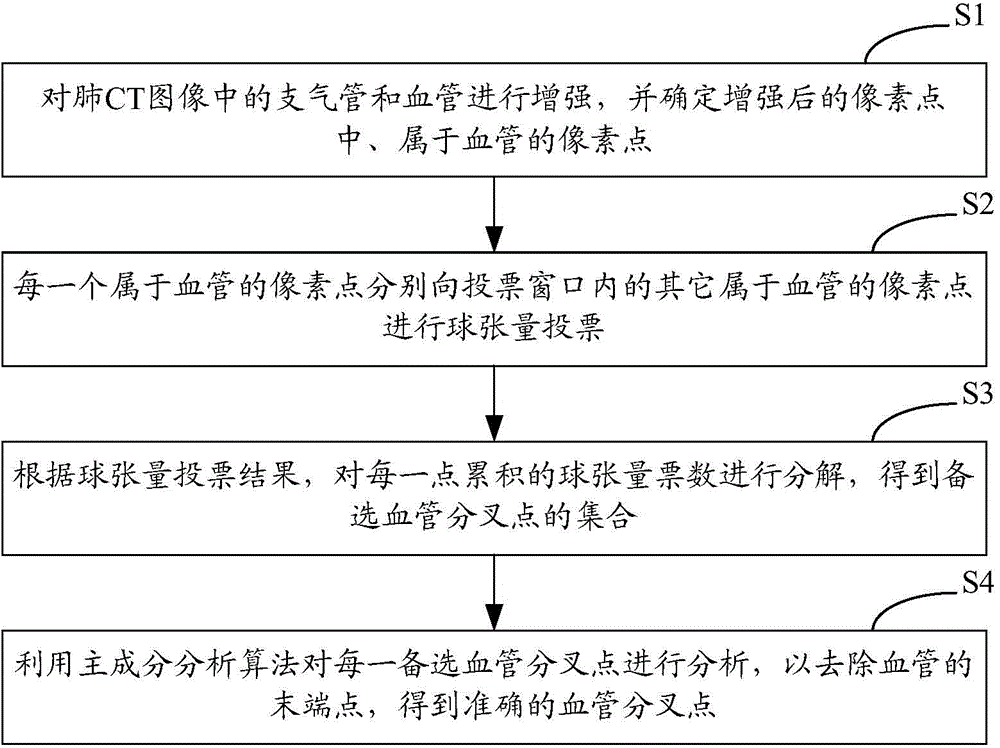

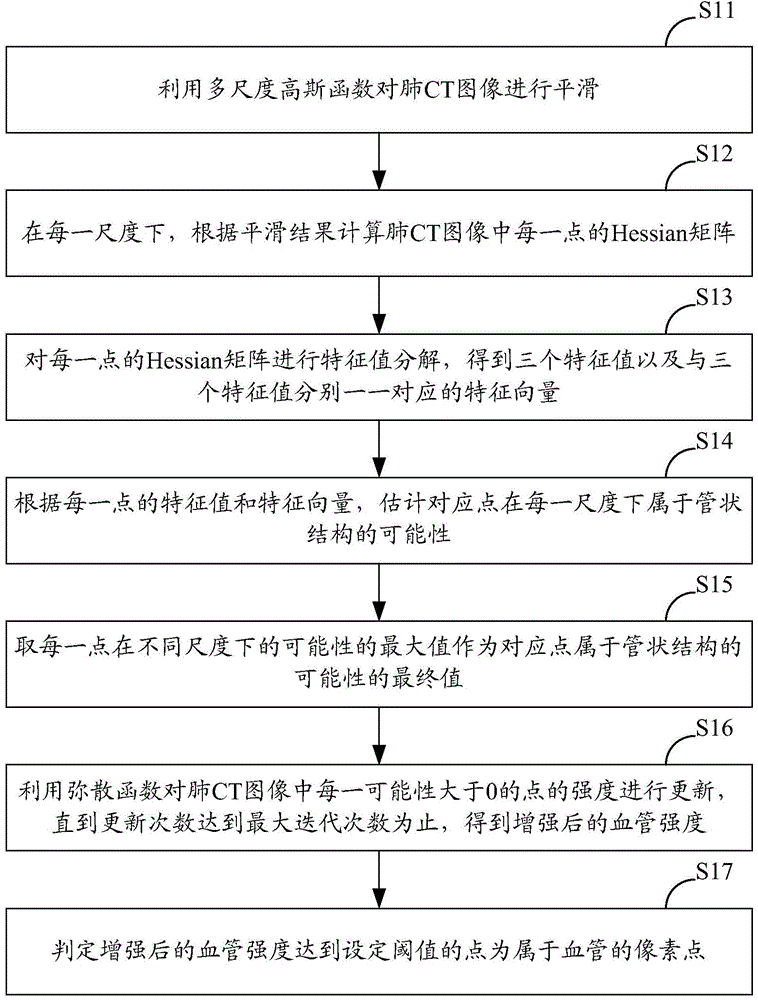

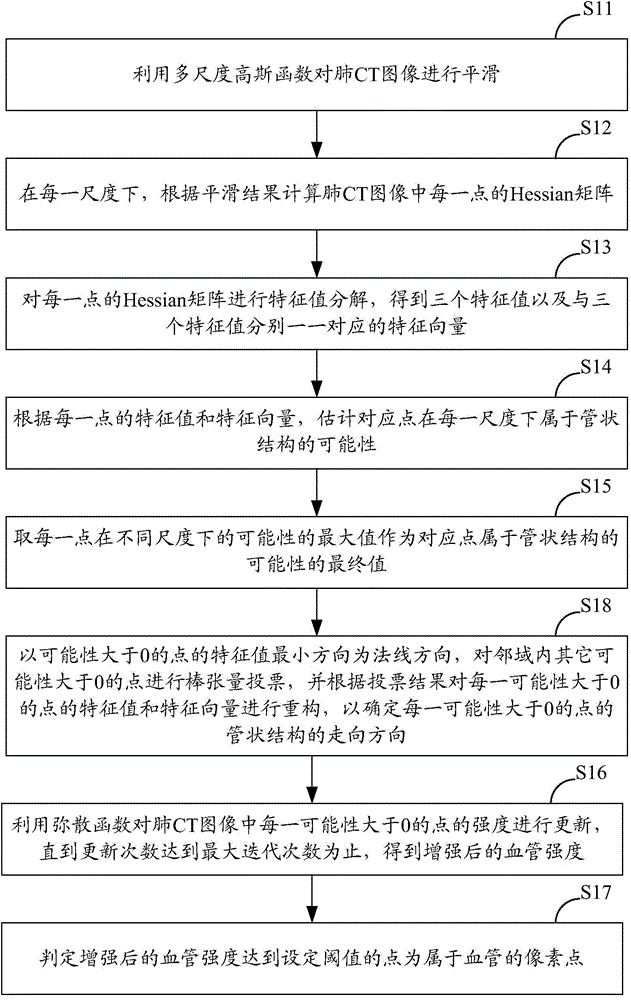

Blood vessel bifurcation extracting method and system of lung CT picture

ActiveCN104574413AEasy to analyzeImprove robustnessImage enhancementImage analysisStaging operationClinical diagnosis

The invention belongs to the field of picture processing, and provides a blood vessel bifurcation extracting method and system of a lung CT picture. The spherical characteristic of the blood vessel bifurcation on a geometrical structure and the accumulation performance of tensor voting are fully used, spherical tensor voting is carried out on pixel points, belonging to a blood vessel, on the reinforced lung CT picture, the partial maximum value of a spherical tensor significance coefficient is solved to obtain an alternative blood vessel bifurcation, then the tail end points of the blood vessel are removed through a main component analysis algorithm, and an accurate lung blood vessel bifurcation is obtained. The method and system do not need earlier stage operation of the picture, has high robustness on noise, provides important basis for later picture registration and lung movement, is favorable for later lung CT picture analysis, and assists in clinical diagnosis and treatment.

Owner:SHENZHEN UNIV

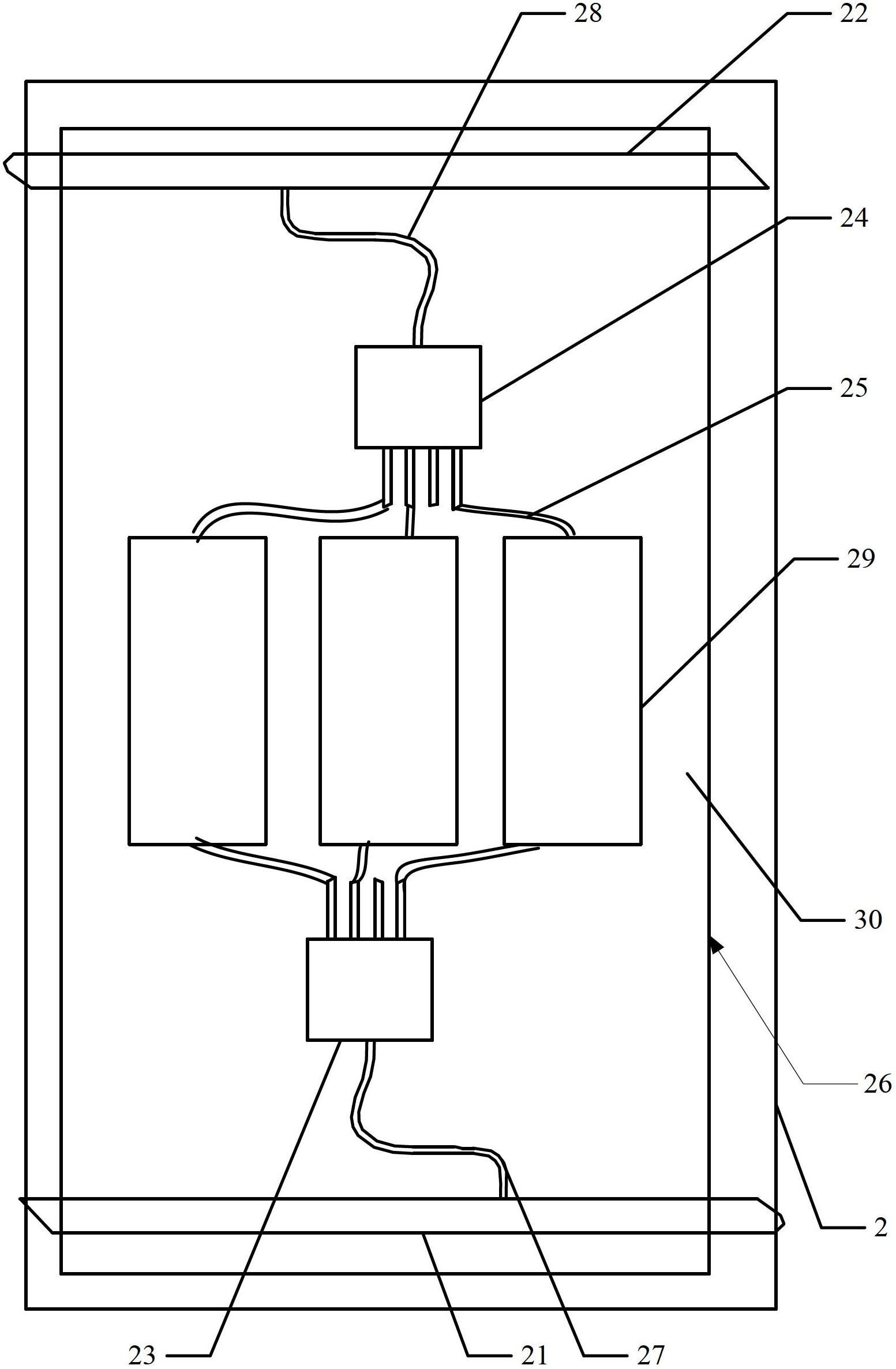

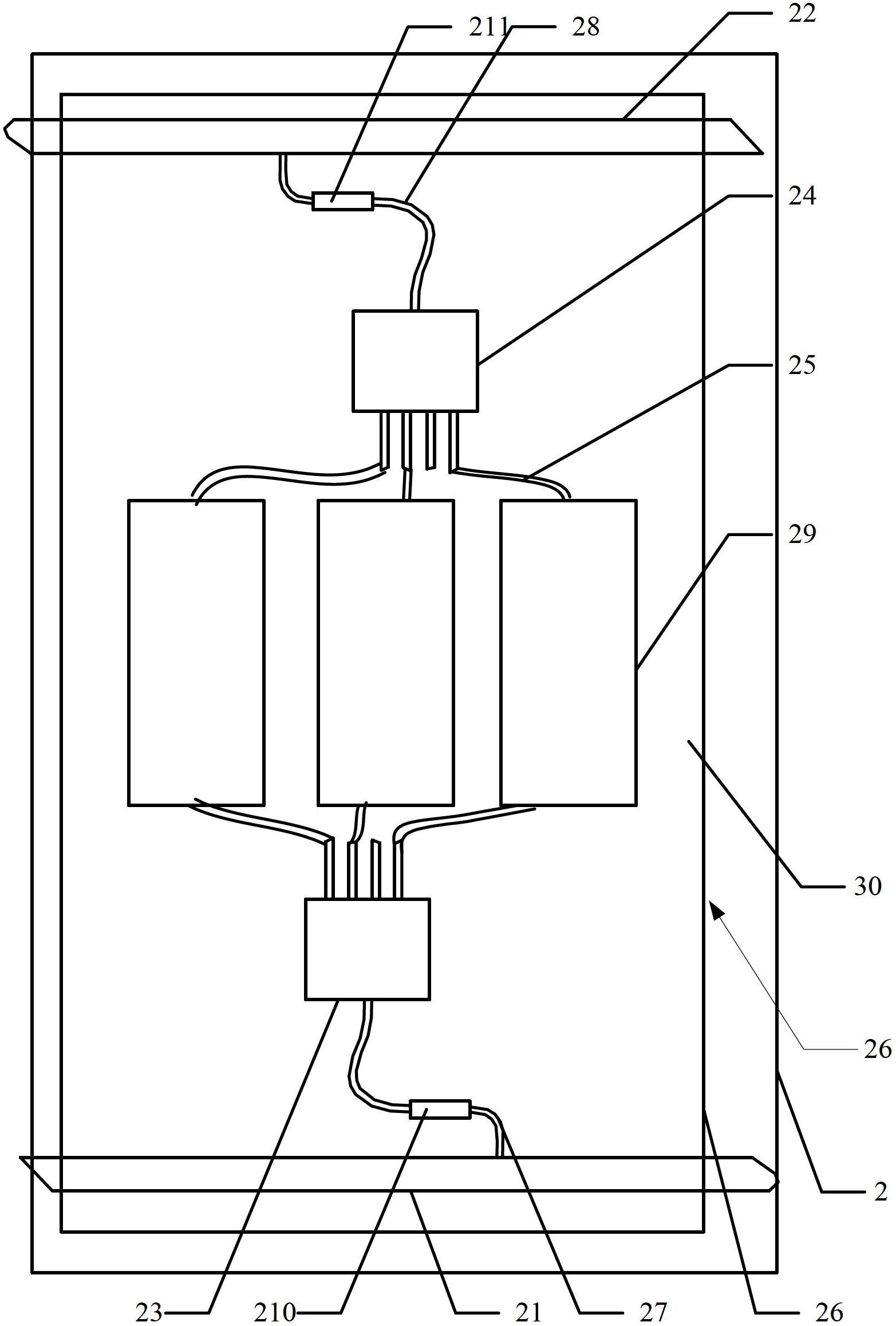

Liquid cooling system and equipment cabinet of electronic equipment

InactiveCN102695404ASimplify the pre-operation processReduce workloadCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersLiquid cooling systemStaging operation

The invention discloses a liquid cooling system of electronic equipment. The liquid cooling system comprises a water-cooling heat radiation device, a main water inlet pipe, a main water outlet pipe, a first flow distributor, a second flow distributor and a plurality of water transmission pipes. The first flow distributor is arranged inside an equipment cabinet, and comprises a water inlet and a plurality of water outlets; the water inlet of the first flow distributor is communicated with the main water inlet pipe through a first hose; the second flow distributor is arranged inside the equipment cabinet, and comprises a water outlet and a plurality of water inlets; the water outlet of the second flow distributor is communicated with the main water outlet pipe through a second hose; a water inlet of a water-cooling board is communicated with one of the water outlets of the first flow distributor through z water transmission pipe; and a water outlet of the water-cooling board is communicated with one of the water inlets of the second flow distributor through a water transmission pipe. The liquid cooling system disclosed by the invention has the advantages of simplifying front-stage operation of maintaining or replacing the inside of the equipment cabinet or a power device, shortening operation time, and reducing the working load of an operator. The invention further discloses the equipment cabinet of the electronic equipment.

Owner:SHENZHEN INVT ELECTRIC

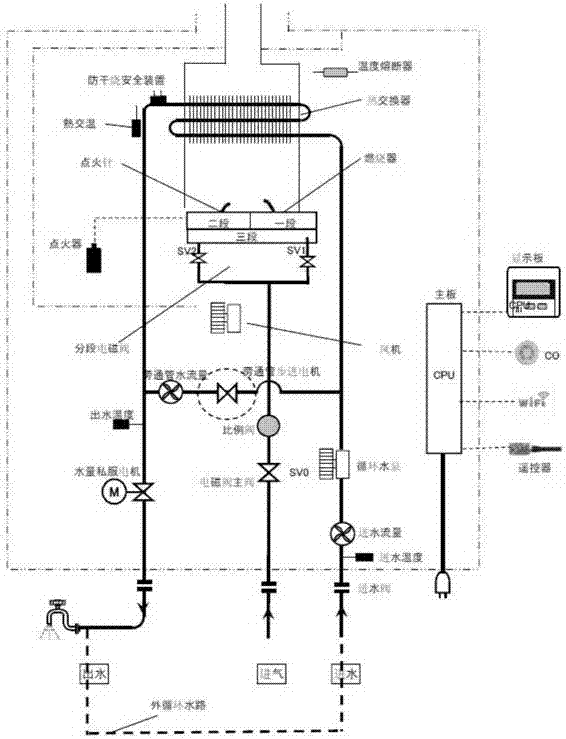

Combustion control method of gas water heater based on oxygen sensor

The invention relates to a combustion control method of a gas water heater based on an oxygen sensor. The gas water heater comprises a first electromagnetic proportional valve, a second electromagnetic proportional valve, a fan, an igniter, a combustor and a main valve which are used for adjusting combustion parameters and also comprises a main control panel, wherein the main control panel has three operation modes; each operation mode has corresponding combustion parameters; the first electromagnetic proportional valve is switched on under a first-stage operation mode; the second electromagnetic proportional valve is switched on under a second-stage operation mode; both the first electromagnetic proportional valve and the second electromagnetic proportional valve are switched on under a third-stage operation mode. The combustion control method of the gas water heater has the characteristics of by judging the size of actual combustion power and ignition power, then further judging whether the oxygen concentration value detected by the oxygen sensor is deviated from the preset normal oxygen concentration value, and then dynamically adjusting the combustion parameters of the gas water heater so as to ensure that the combustor is not blown out when the wind pressure is excessively high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

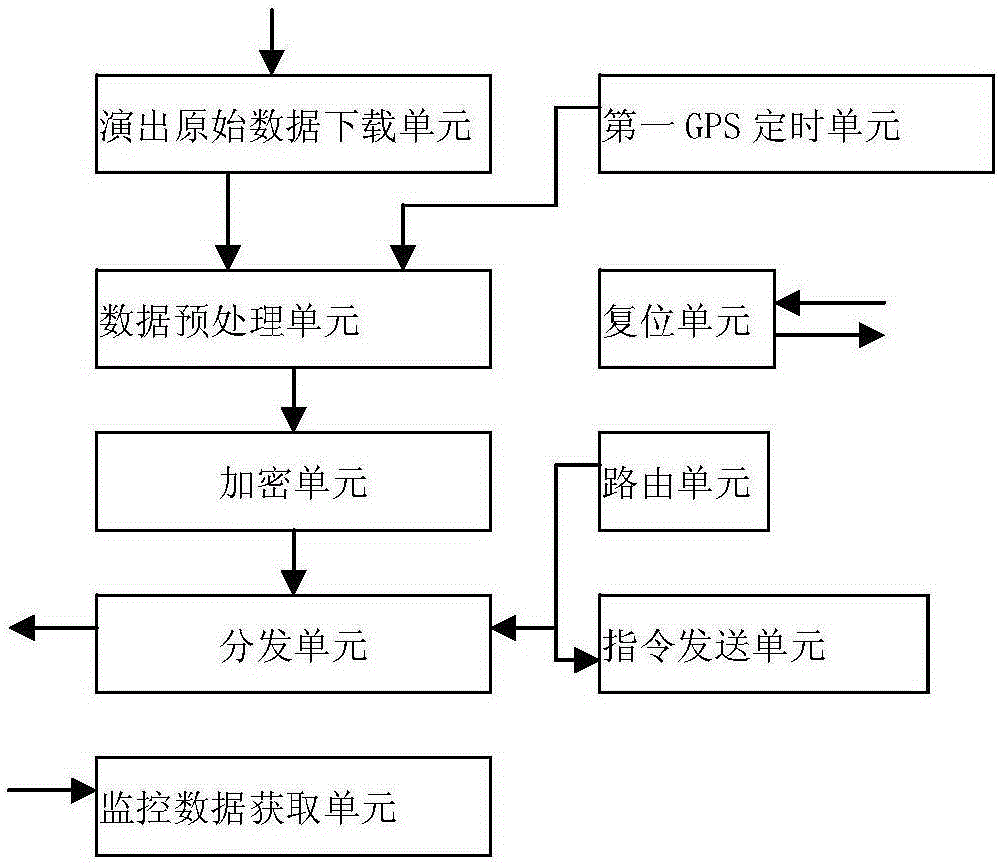

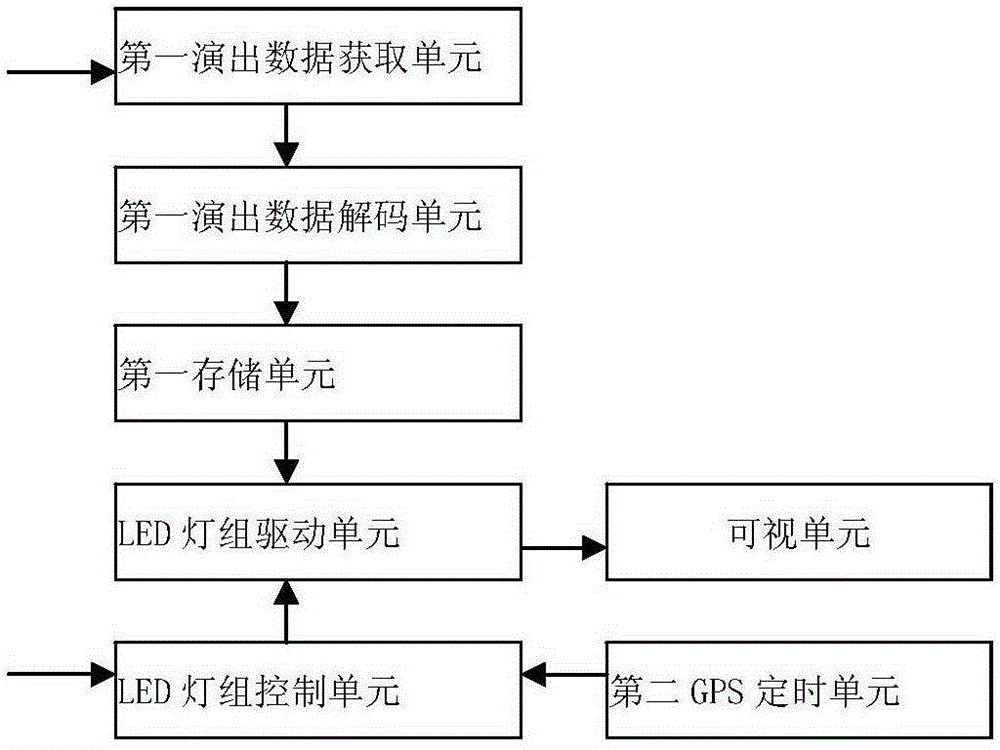

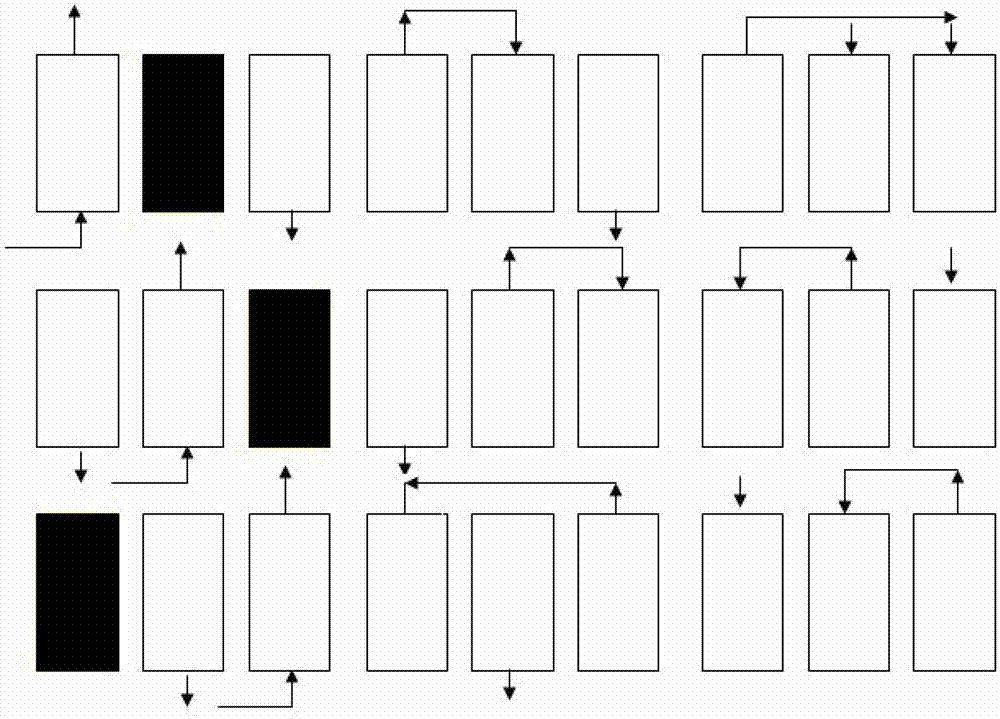

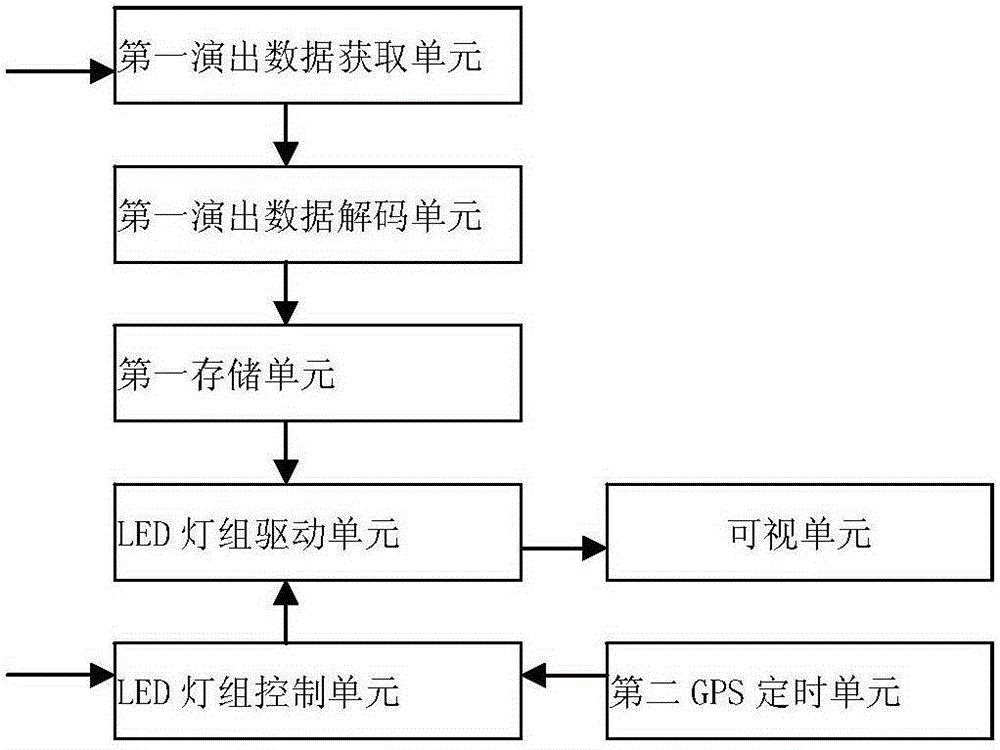

Stage control system

ActiveCN105159154AImprove performanceImprove work efficiencyProgramme control in sequence/logic controllersSynchronous controlControl system

Disclosed is a stage control system. The stage control system comprises a cloud server, a master control unit, a slave control unit and a stage safety monitoring subsystem. The system provided by the invention realizes concentrated monitoring, unified management and synchronous control of multiple systems of a stage, improves the stage performance effect and the work efficiency and realizes self safety protection of stage operation.

Owner:ZHEJIANG DAFENG IND

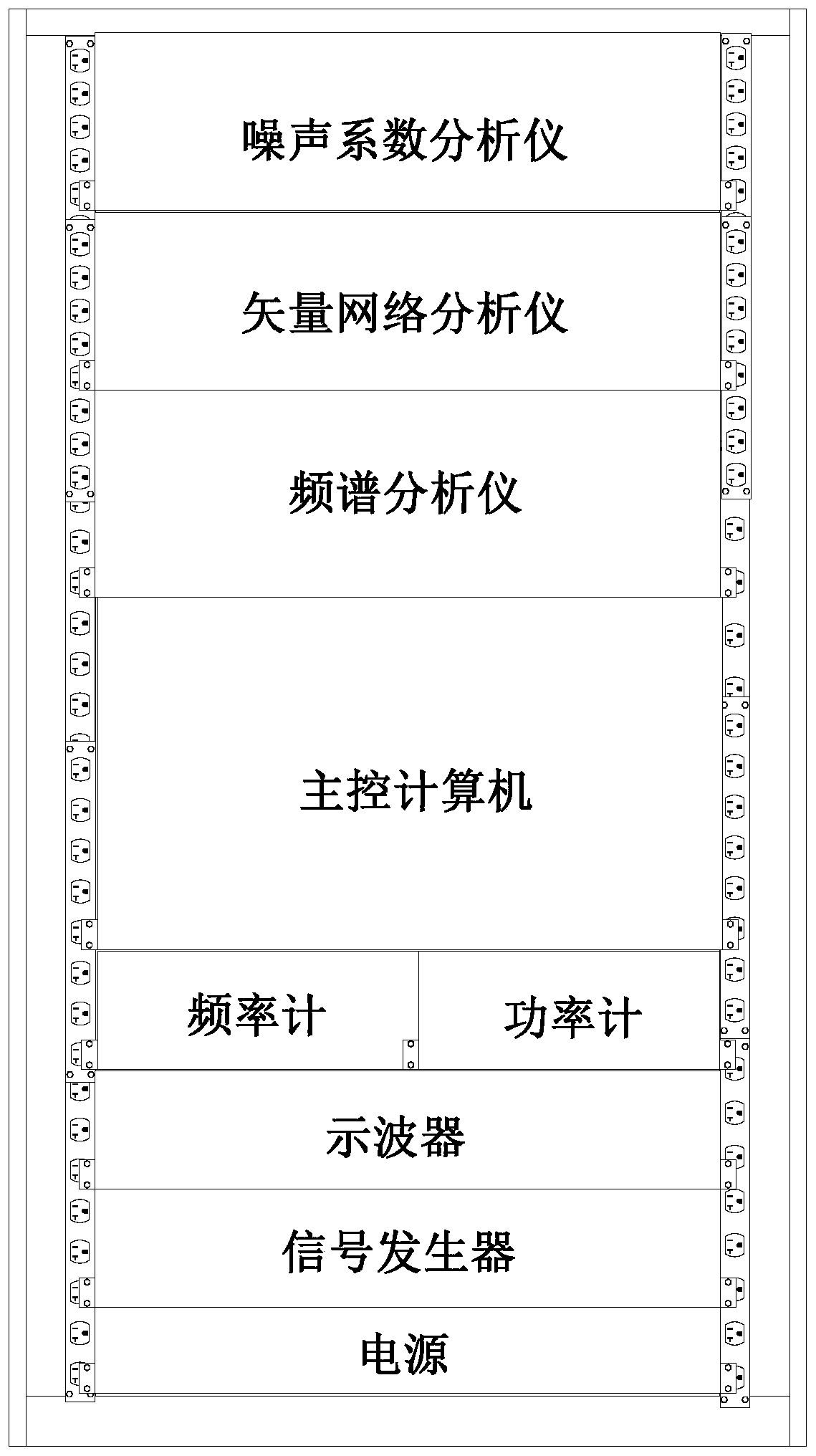

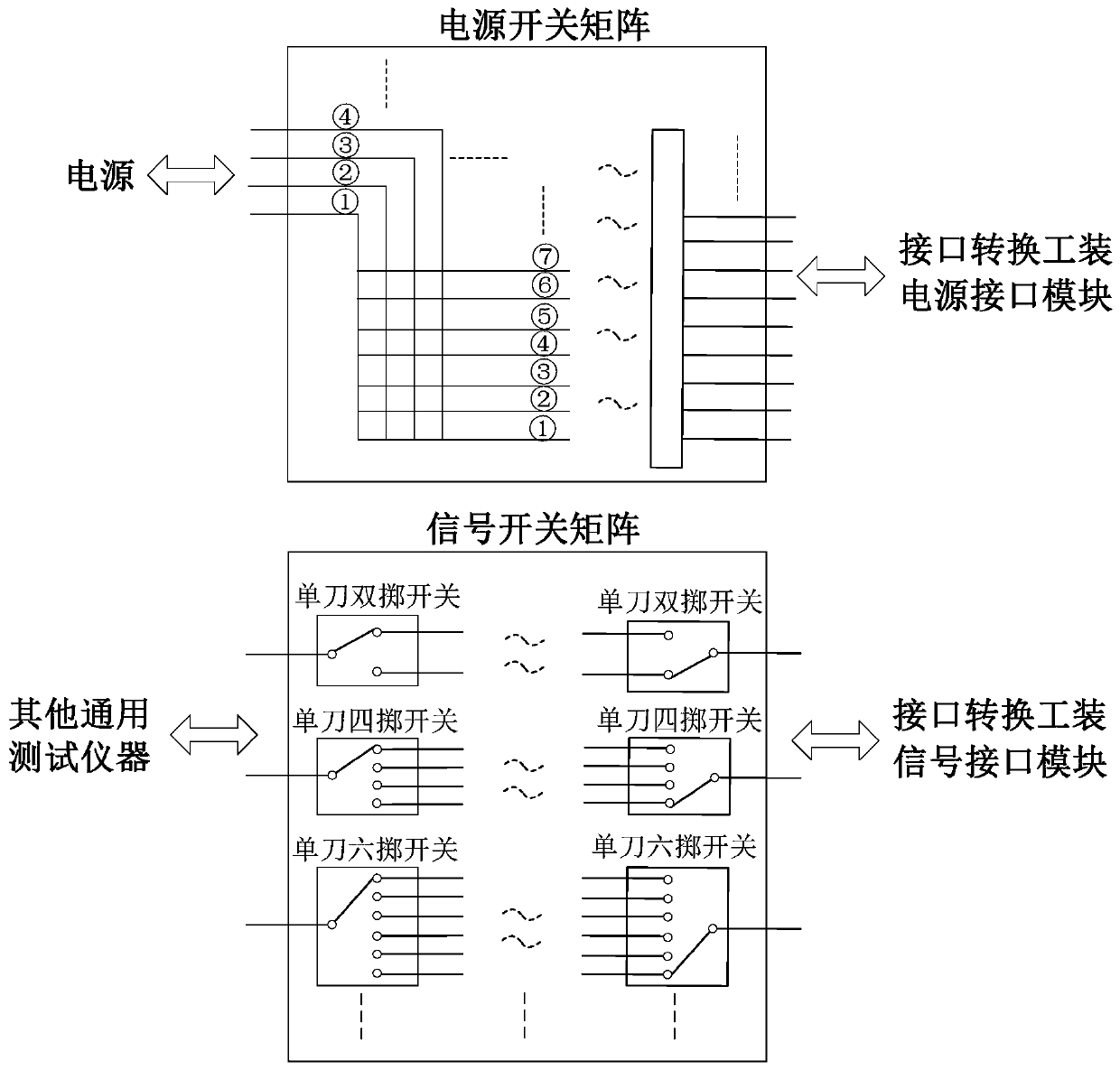

General automatic test system for radio frequency assembly

InactiveCN110514929AImprove test efficiencyComprehensive parametersTransmitters monitoringReceivers monitoringControl signalAnalysis center

The invention provides a general automatic test system for a radio frequency assembly. The general automatic test system comprises a main control computer, a general test instrument, a switching and control device and an interface conversion tool; the main control computer is the control analysis center of the system, controls the general test instrument, the switching and control device, collectsthe data of the general test instrument to complete the calibration of the test system and the parameter test of the radio frequency assembly, performs post-stage operation including test data processing and analysis, and generates a test report; the general test instrument comprise a plurality of testers; and the switching and control device responds to the switching and control signals of the main control computer in real time, so that the interface conversion tool can be connected with a specified tester, and then the specified tester is in signal connection with the radio frequency assembly. With the general automatic test system of the invention adopted, the serialization and generalization requirements of testing are met; manpower is saved; the testing efficiency of the radio frequency assembly is improved; and testing cost is reduced. The system has the advantages of high safety, high stability, high reliability, high practicability and bright application prospect.

Owner:SHANGHAI RADIO EQUIP RES INST

Method and device for maintaining textile machine assembly

InactiveCN1498993AEasy to removeRemove maintenance operationsPiercing arrangementsContinuous wound-up machinesBobbinControl system

A spinning assembly with a series of identical stations is maintained by a maintenance process using equipment which moves from station to station. The maintenance operation is esp. split into a first preliminary operation, followed by manual maintenance, or vice versa. The spinning assembly is shut down prior to maintenance. Prior to maintenance, the feed roller is reversed. Prior to a new batch, all bobbins are removed and are replaced by empty units, and other elements may be replaced. Cleaning takes place in the first-stage operation. Also claimed is a commensurate spinning assembly (2) with a semi-automated maintenance system having a control panel (4), release devices (41, 42), moving maintenance unit (3), control system (30), reel changers (8) and magazines (80, 81) for interchangeable components.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

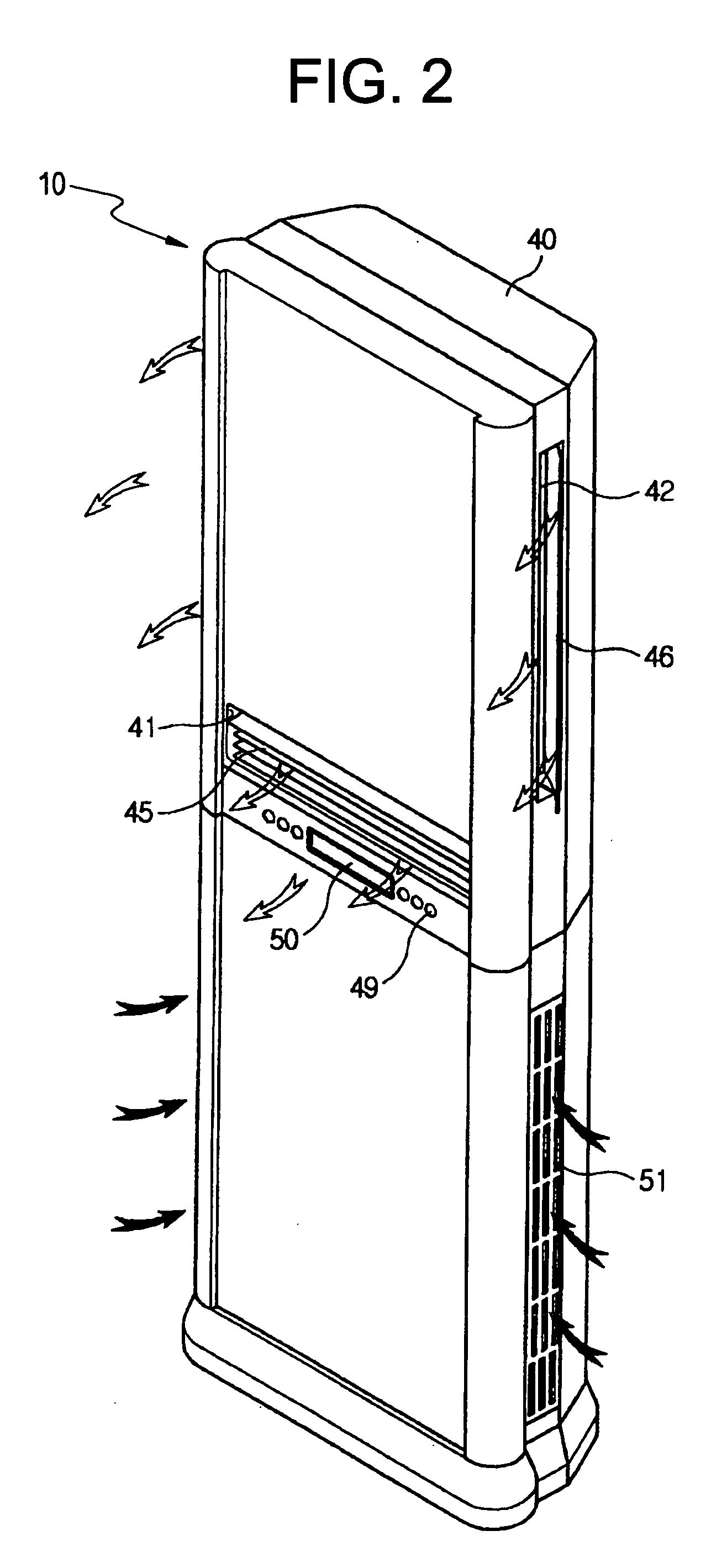

Multi-stage operation type air conditioner

InactiveUS20050257560A1Space heating and ventilation safety systemsSpace heating and ventilation control systemsStaging operationEngineering

A multi-stage operation type air conditioner which can be operated in various cooling or heating capacities. The multi-stage operation type air conditioner includes a first discharge port, a first opening / closing device for opening or closing the first discharge port, a second discharge port having a size different from that of the first discharge port, a second opening / closing device for opening or closing the second discharge port, and a controller for controlling the air conditioner such that the air conditioner may be operated with one of the first and second discharge ports opened, in an operation with a lower cooling or heating load, and the air conditioner may be operated with both the first and second discharge ports opened, in an operation with a higher cooling or heating load.

Owner:SAMSUNG ELECTRONICS CO LTD

Hydraulic hand pump with pivoting links

InactiveUS20070253846A1Piston pumpsPositive-displacement liquid enginesLocking mechanismStaging operation

A method and apparatus is provided that includes a hand pump having a handle locking mechanism, a counter bored nut, pivoting links, and unloading valve assembly. The unloading valve assembly allows a pump operator to pump a larger volume of hydraulic fluid and / or to pump to higher pressures in first stage operation than a conventional pump which employs a direct-acting relief valve. The unloading valve also decreases the effort required to pump the handle during second stage operation. The handle locking mechanism allows the pump handle from moving during transporting and storing of the hand pump. The counter bored nut allows for more reservoir room than conventional hand pumps. The pivoting link allows for greater leverage of the handle during pumping.

Owner:SPX CORP

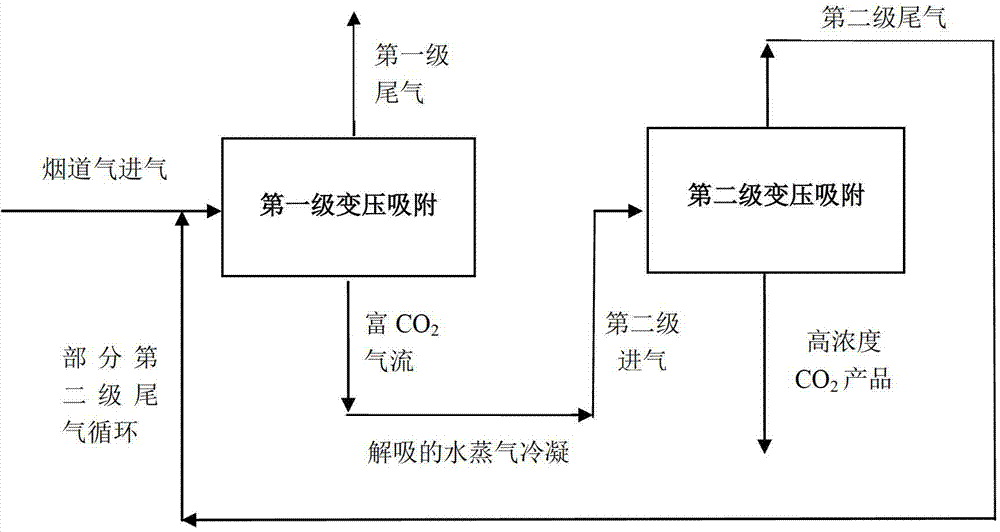

System and method for trapping carbon dioxide from flue gases in multi-stage manner

ActiveCN103071364ALow costImprove adsorption capacityDispersed particle separationBy adsorptionSorbentWater vapor

The invention relates to a system and a method for trapping carbon dioxide from flue gases in a multi-stage manner. The system comprises at least two groups of pressure swing adsorption devices; each group of pressure swing adsorption devices comprise at least one adsorbent bed; the adsorbent bed of the first-stage pressure swing adsorption device is made of hydrophobic adsorption material; the adsorbent beds of the other stages of pressure swing adsorption devices are made of carbon dioxide adsorption material; the method aims to allow the flue gases to pass through the system. The multi-stage VSA process is designed by simple circulation steps. In the first-stage step, the hydrophobic adsorption materials are adopted, so that the CO2 concentration is increased from 12 percent to 40-60 percent, and the CO2 recovery rate is guaranteed to be higher than 90 percent. After the first-stage operation is finished, most of steam directly penetrates the adsorbent beds to be discharged. In the other stage operation, 13X is adopted as an adsorbent, so that the CO2 is purified easily to achieve the purpose that the concentration is increased from 40-60% to more than 95%.

Owner:GUODIAN NEW ENERGY TECH INST

Energy-saving processing method and device of terminal and terminal

InactiveCN106200867AReduced operating power consumptionReduce standby power consumptionPower supply for data processingIdle timeStaging operation

Embodiments of the invention provide energy-saving processing method and device of a terminal and the terminal. The method comprises the following steps of: detecting whether the terminal is located in an idle state or not; if the terminal is located in the idle state, obtaining an idle time length of the terminal and determining a stage operation strategy corresponding to the idle time length; and carrying out corresponding frequency reduction processing and / or nuclear reduction processing on a central processing unit CPU of the terminal according to the stage operation strategy, so as to reduce the operation power consumption of the terminal. By adoption of the method, device and terminal, the operation power consumption of the terminal can be reduced and the practicability of the terminal is strengthened.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Stage control system realizing independent operation and coordinated operation of multiple units

InactiveCN105159152ARealize centralized monitoringRealize self-safety protectionProgramme control in sequence/logic controllersControl systemSynchronous control

The invention discloses a stage control system realizing independent operation and coordinated operation of multiple units. The system comprises a cloud server, a master control unit, a slave control unit and a stage safety monitoring sub system. The system provided by the invention realizes concentrated monitoring, unified management and synchronous control of multiple systems of a stage, improves the stage performance effect and the work efficiency and realizes self safety protection of stage operation.

Owner:ZHEJIANG DAFENG IND

Two-stage computer network packet classification method and system

InactiveUS7782868B2Reduce memory requirementsImprove system performanceTime-division multiplexData switching by path configurationNetworked systemClassification methods

A two-stage computer network packet classification method and system is proposed, which is designed for integration to a network system for classification of packets within the network system. The proposed method and system is characterized by the use of a two-stage operation for packet classification; wherein the first-stage operation involves the use of a decision-tree data module whose leaf nodes are used to store a bit vector that represents a cluster of rule groups that are located within a particular cut region in a multidimensional Euclidean space that is mapped to the field values of the input packet; and the second-stage operation involves the use of a bit-vector lookup table data module to retrieve a set of bit vectors which represent a set of possible rules in each rule group and which are intersected to find a matched rule for the input packet. This feature allows the packet classification to be implemented with low memory requirement and enhanced system performance.

Owner:NAT TAIWAN UNIV

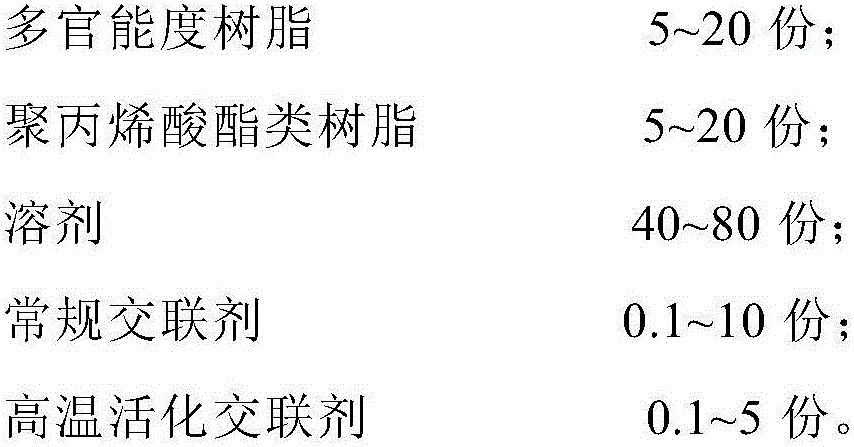

High-temperature-resistance hydrographics transfer printing coating composition and preparing method thereof

The invention provides a high-temperature-resistance hydrographics transfer printing coating composition and a preparing method thereof. The coating composition comprises polyfunctionality resin, polyacrylate resin, a solvent, a conventional cross-linking agent and a high-temperature activation cross-linking agent. The preparing method comprises the steps of placing the polyfunctionality resin, the polyacrylate resin, the conventional cross-linking agent and the high-temperature activation cross-linking agent into the solvent in sequence, conducting uniform mixing, and then conducting curing; adjusting solid content to be 10-50% after curing ends, and conducting stir-discharging, so that the high-temperature-resistance hydrographics transfer printing coating composition is obtained. The high-temperature-resistance hydrographics transfer printing coating composition and the preparing method thereof have the advantages that a bi-component formula is adopted, and a good luster effect can be maintained in the later-stage high-temperature baking process; film forming property is high, and the problem of integral transfer failure can be solved to a large extent during transfer printing; the tolerance of later-stage operation to a concave-convex interface is high; waiting is not needed in each step of operation interval, and production efficiency is improved greatly.

Owner:SHANGHAI CHENGYING NEW MATERIALS

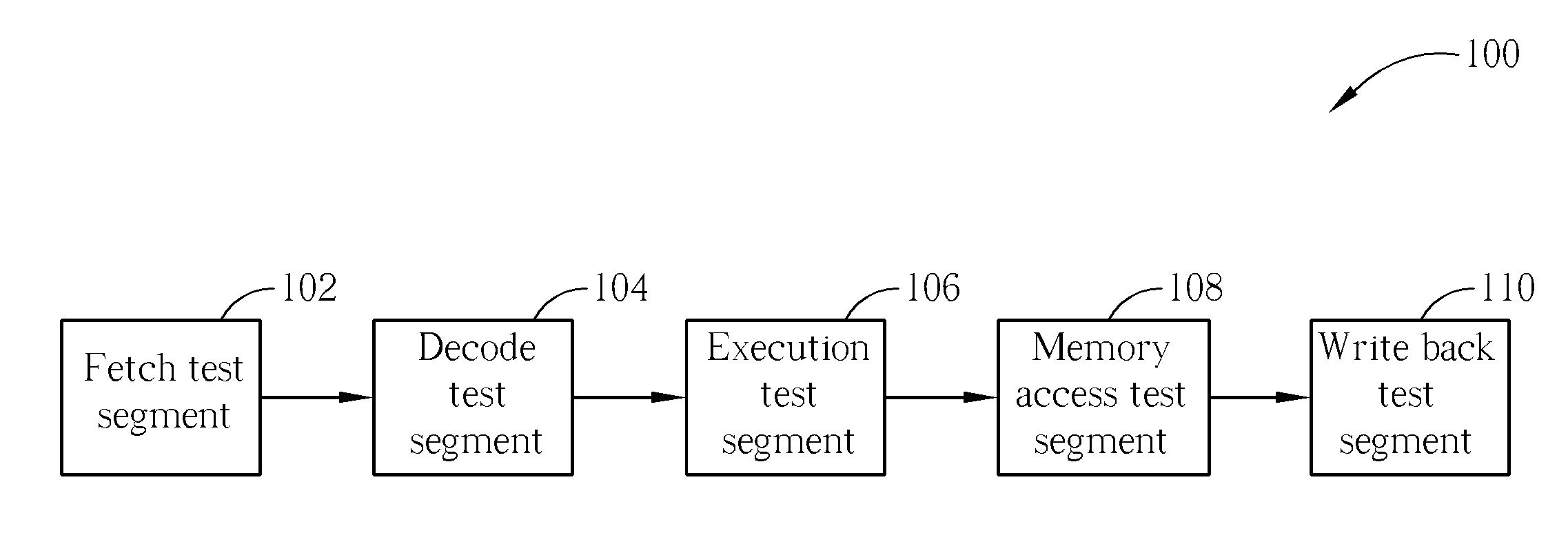

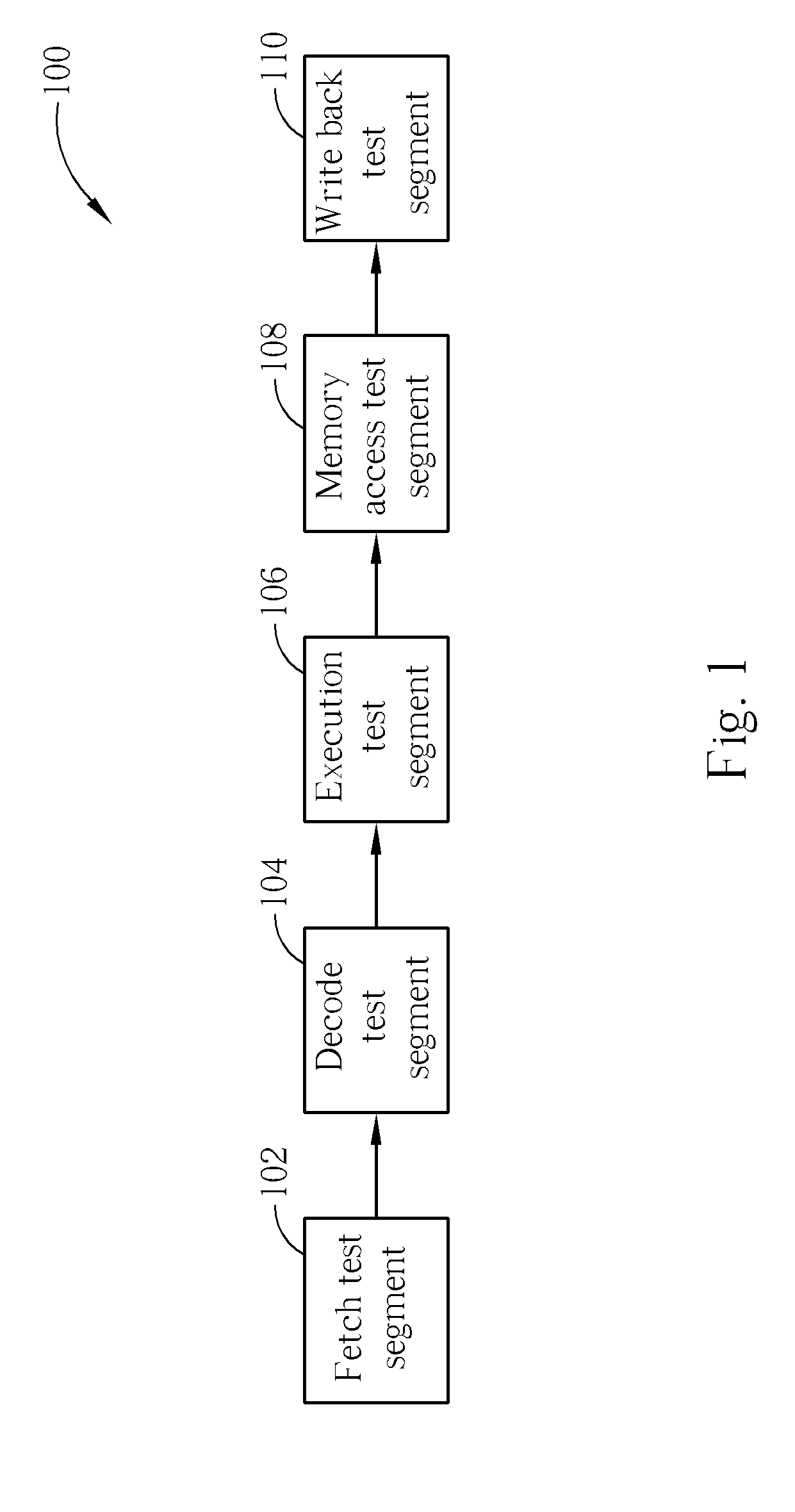

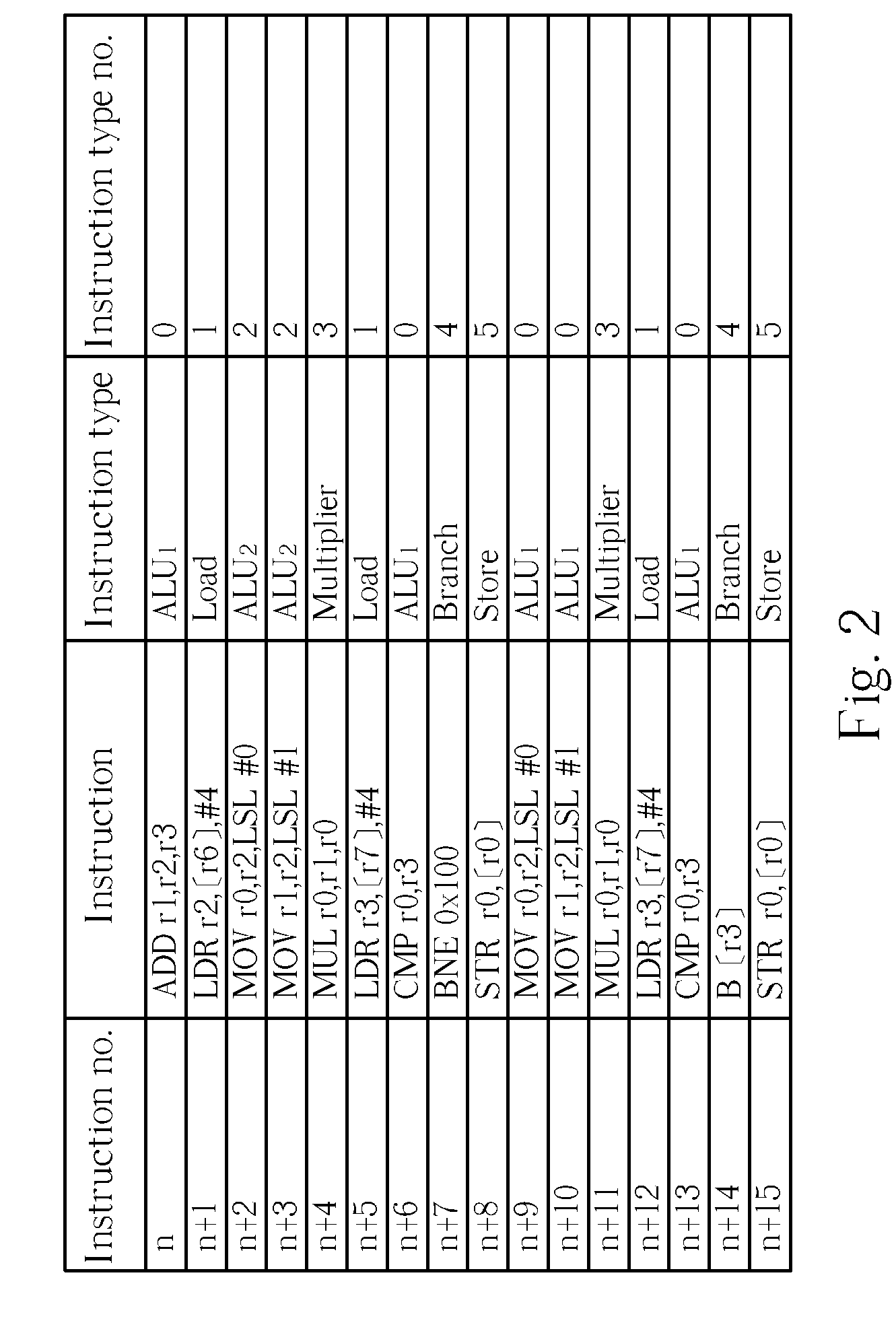

Digital logic test method to systematically approach functional coverage completely and related apparatus and system

InactiveUS20060161828A1Electronic circuit testingResistance/reactance/impedenceStaging operationTest segment

A digital logic test method for systematically testing a pipeline-structured integrated circuit chip is disclosed. The method includes the steps of: providing an integrated circuit chip capable of executing a plurality of instructions during a period of time, each of the instructions being executed according to a plurality of sequentially ordered operation segments, sorting the instructions, and designing a plurality of test patterns to test the integrated circuit according to the sorting result and STAGE test segments corresponding to the STAGE operation segments.

Owner:FARADAY TECH CORP

Waterlogging modeling and analysis method based on FCM

ActiveCN107563096AImprove analytical performanceGood reference valueSpecial data processing applicationsSimulationModelling analysis

The invention discloses an FCM-based waterlogging modeling and analysis method, which constructs an FCM model of waterlogging through modeling, and analyzes the occurrence of waterlogging based on the urban rainfall variation trend and waterlogging depth of waterlogging-prone points obtained therefrom. The method proposed by the present invention combines the strong fuzzy information expression and reasoning ability of the fuzzy cognitive map, and the gene-level operation of the DNA-encoded genetic algorithm technology to construct the waterlogging FCM model; the constructed waterlogging FCM model carries out the historical waterlogging data Integrate analysis and utilization, so that the ability of analysis is enhanced. Theoretically, the construction of this model is not restricted by the geographical location of waterlogging occurrence, and only needs to combine the parameter changes of a single waterlogging point under actual conditions to obtain the dynamic change trend of each parameter; therefore, it has great reference value.

Owner:中电科新型智慧城市研究院有限公司

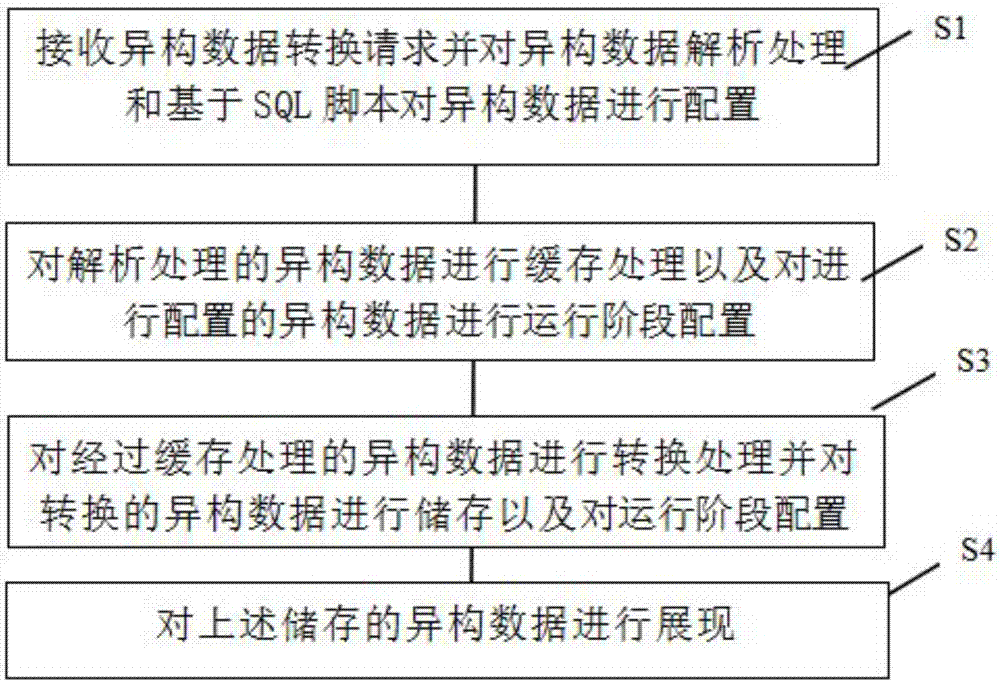

Big data conversion method and system based on adapter

InactiveCN107315743AReduce logic errorsImprove exchange efficiencyOther databases browsing/visualisationSpecial data processing applicationsData acquisitionStaging operation

The invention relates to a big data conversion method and system based on an adapter. The big data conversion method based on the adapter comprises the following steps that: receiving a heterogeneous data conversion request, carrying out analysis processing on the heterogeneous data, and configuring the heterogeneous data on the basis of an SQL (Structured Query Language) script; carrying out cache processing on the heterogeneous data subjected to the cache processing, and carrying out operation stage configuration on the configured heterogeneous data; carrying out conversion processing on the heterogeneous data subjected to the cache processing, storing the converted heterogeneous data, and carrying out operation stage operation on the heterogeneous data subjected to the operation stage configuration; and displaying the stored heterogeneous data. By use of the method, a batch data conversion script set is automatically executed, conversion script execution result information is stored, and then, an application analysis report is generated. When the method is adopted, logic errors generated when the heterogeneous data is converted can be reduced, conversion efficiency among the heterogeneous data is improved, and data collection and analysis cost of the heterogeneous data can be lowered.

Owner:上海赢华软件科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com