Large-section earth pressure balancing rectangular jacking pipe joint of motor vehicle tunnel and method for constructing large-section earth pressure balancing rectangular jacking pipe

A technology of earth pressure balance and rectangular pipe jacking, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of loss of use function, large section, small bearing capacity, etc., and achieve simple structure, convenient manufacture and use, and enhanced The effect of load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the present invention, along the length direction of the tunnel, the direction of pipe jacking is taken as the forward direction, and vice versa as the backward direction.

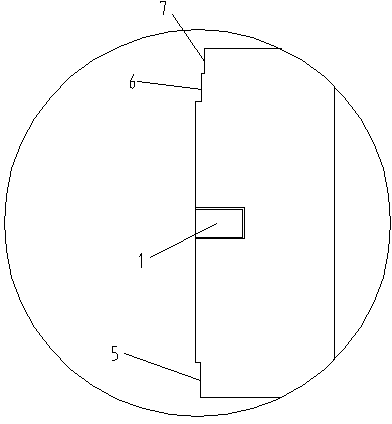

[0021] Such as Figure 1 to Figure 5 shown ( figure 2 , Figure 4 and Figure 5 The direction indicated by the middle arrow is the forward direction of pipe jacking during construction), the invention discloses a rectangular pipe jacking joint with earth pressure balance in a large-section motor vehicle tunnel, and the pipe jacking joints are arranged at intervals along the circumferential direction in the middle of the outer wall surface. There are grouting holes 2 radially penetrating the pipe wall. Two hoisting holes 1 are provided in the middle of the four faces of the pipe jacking joint. Radial thixotropic mud grouting holes 4 on the pipe wall. The thixotropic mud grouting hole 4 is used to reduce the jacking resistance, which is a prior art, so it is not shown enlarged in the figure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com