DC parallel-serial transition electric power system

A technology of power supply system and DC power supply, which is applied to conversion equipment without intermediate conversion to AC, electric traction, electric vehicles, etc. The effect of series conversion, increasing cycle life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

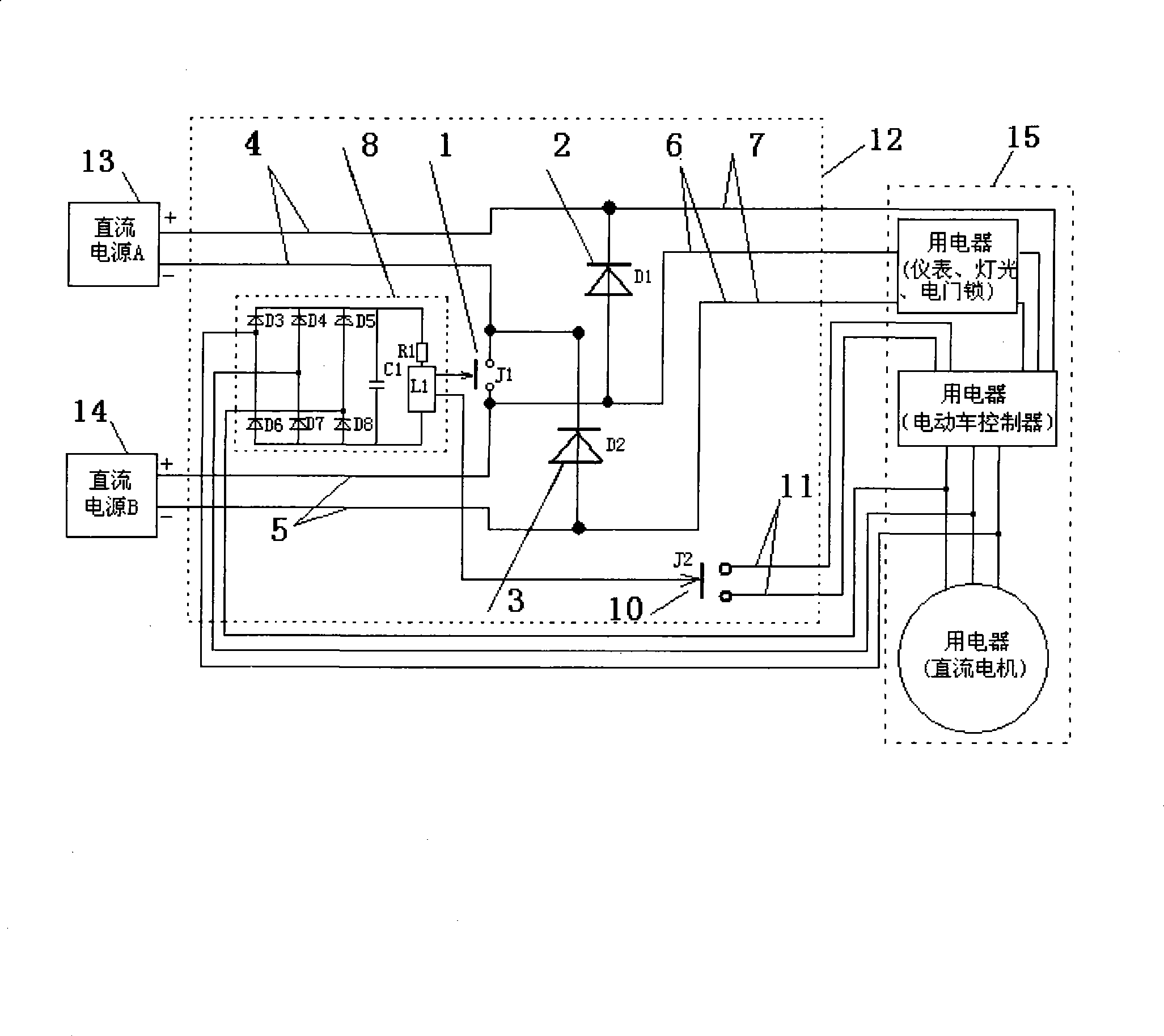

[0032] 1. Make a DC parallel converter 12: Make a DC parallel converter according to the DC parallel converter 12 shown in the figure, and the control switch circuit 8 is provided with 3 connecting wires to accept the feed from the phase line induction when the motor rotates, and Through the three-phase bridge rectification circuit, it is converted into direct current and connected to the logic device, and the logic device judges the motor speed and triggers switch 1 and switch 10 . The two contacts of the switch 1 are connected with the negative wire of the DC power connection 4 and the positive wire of the DC power connection 5 .

[0033] 2. Connection and installation: Connect the positive and negative wires of DC power supply A13 to DC power supply wiring 4 according to the figure, connect the positive and negative wires of DC power supply B14 to DC power supply wiring 5; connect the motor phase wire of electrical appliance 15 to control signal wire 9 The positive wire of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com