Method and device for maintaining textile machine assembly

A maintenance device and textile machine technology, which is applied in the direction of textiles and papermaking, spinning machines, jointing devices, etc., and can solve the problems that air spinning machines cannot produce yarn and waste time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

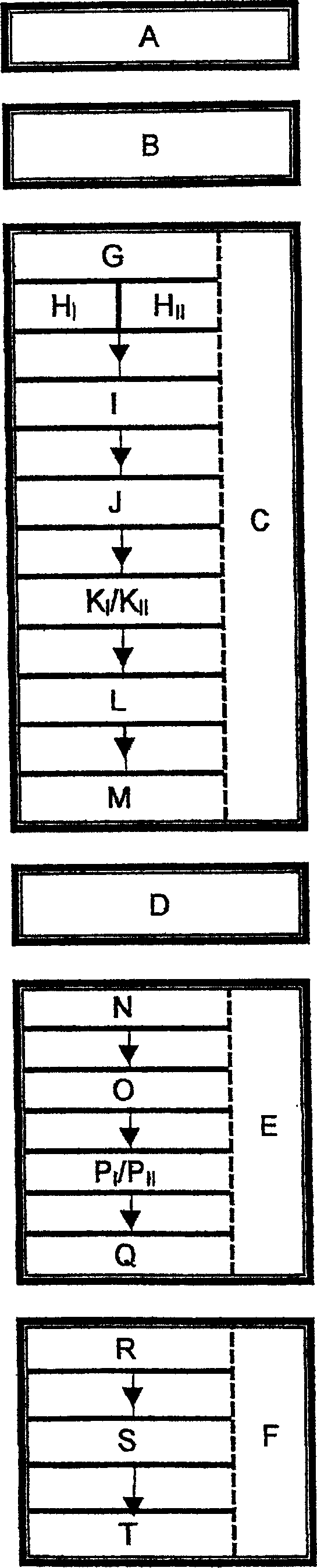

[0020] figure 2 An air spinning machine 1 is schematically shown, which comprises a plurality of spinning positions 10 arranged side by side, each of which has a spinning device 2 and a bobbin device (Spurvorrichtung) arranged thereon to form a bobbin Tube S P .

[0021] To e.g. eliminate yarn breaks or use empty bobbins H during normal spinning operation L Replacing a fully loaded bobbin S P To maintain each spinning position 10, a maintenance device 3 is provided, which patrols back and forth along the corresponding spinning position 10 and performs required maintenance on the relevant spinning position 10. The maintenance device 3 has a control device 30 which is connected to the control center 4 by means of a control line 300 . Its control center is located on one of the end frames 11 of the air spinning machine 1 and also has a switching device 40 with a first switching element 400 for switching on and a switch for the air spinning machine 1. Another switching eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com