Process of quickly regulating alkalinity of LF (ladle furnace) slag

A rapid adjustment and slag basicity technology, applied in the field of metallurgy, can solve the problems of unfavorable molten steel purity, poor adsorption capacity of molten steel inclusions, excessive content, etc., and achieve the effect of stable and rapid adjustment of basicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

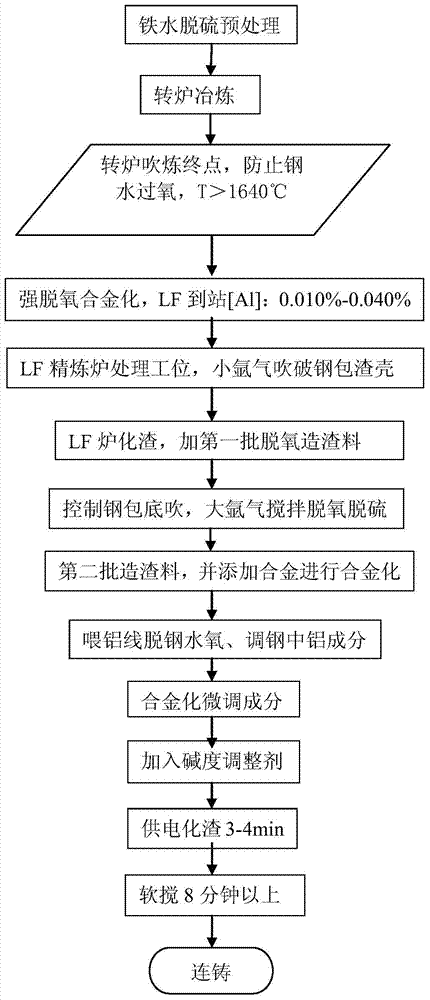

[0048] The LF refining furnace ladle top slag alkalinity rapid adjustment process, through the high-temperature tapping of the converter, strong deoxidation in the tapping process and large slag operation in the ladle, the LF refining furnace rapidly produces high alkalinity and strong reducing white slag in the early stage, and deoxidizes during the refining process , Desulfurization slagging and bottom blowing argon process optimization, adding an appropriate amount of alkalinity regulator in the middle and later stages of refining, reducing the alkalinity to within 4-6, and realizing stable and rapid adjustment of alkalinity in the LF ladle refining furnace smelting process.

[0049] In this embodiment, a 150t converter and an LF refining furnace are selected to smelt Q960 steel. The finished product has higher requirements on the purity of molten steel and strict composition design. The entire smelting process is controlled as follows:

[0050] (1) Converter blowing

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com