High-temperature-resistance hydrographics transfer printing coating composition and preparing method thereof

A composition and warm water technology, applied in the field of coatings, can solve the problems of incomplete transfer, damage, slow speed, etc., and achieve the effects of avoiding incomplete transfer, improving production efficiency, and good gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

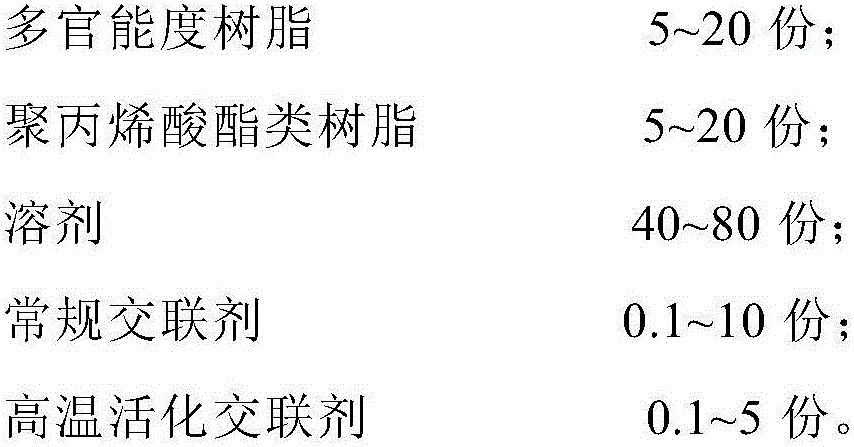

Method used

Image

Examples

Embodiment 1

[0024] The high temperature-resistant water transfer printing coating composition and preparation method thereof involved in this embodiment comprise the following process steps:

[0025] 1. Put all the solvents, i.e. 30 kg of methyl ethyl ketone and 50 kg of toluene into the reaction kettle and stir;

[0026] 2. Keep stirring and put 10 kg of polymethyl methacrylate and 10 kg of acrylate-epoxy resin graft copolymer into the reaction kettle in turn, and stir for about 1 hour;

[0027] 3. After mixing evenly, slowly put 2 kg of pyromellitic anhydride and 0.5 kg of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (bis-25) into the reaction kettle;

[0028] 4. When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0029] 5. Measure the solid content and adjust it to the theoretical value;

[0030] 6. Stir slowly for about 1 hour, cool down, weigh and pack.

Embodiment 2

[0032] The high temperature-resistant water transfer printing coating composition and preparation method thereof involved in this embodiment comprise the following process steps:

[0033] 1. First put all the solvents, i.e. 10 kg of n-propyl acetate and 50 kg of methyl ethyl ketone into the reaction kettle and stir;

[0034] 2. Keep stirring and put 15 kg of methyl methacrylate-n-butyl methacrylate copolymer and 20 kg of silicone epoxy resin into the reaction kettle in turn, and stir for about 2.5 hours;

[0035] 3. After mixing evenly, slowly put 0.2 kg of pyromellitic anhydride and 0.1 kg of triallyl isocyanurate (TAIC) into the reaction kettle;

[0036] 4. When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0037] 5. Measure the solid content and adjust it to the theoretical value;

[0038] 6. Stir slowly for about 2.5 hours, cool down, weigh and pack.

Embodiment 3

[0040] The high temperature-resistant water transfer printing coating composition and preparation method thereof involved in this embodiment comprise the following process steps:

[0041] 1. First put all the solvents, i.e. 45 kg of methyl ethyl ketone and 5 kg of n-butyl acetate into the reactor to stir;

[0042] 2. Keep stirring and put 20 kg of hydrogenated bisphenol A epoxy resin and 10 kg of methyl methacrylate into the reaction kettle in turn, and stir for about 0.5 hours;

[0043] 3. After mixing evenly, slowly put 3 kg of isobutyl triethoxy silicon and 5 kg of triallyl isocyanurate (TAIC) into the reaction kettle;

[0044] 4. When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0045] 5. Measure the solid content and adjust it to the theoretical value;

[0046] 6. Stir slowly for about 0.5 hours, cool down, weigh and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com