Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Spray Suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bacillus subtilis and its application

The invention discloses a Bacillius subtilis strain, and the culture preservation code for the Bacillius subtilis at China General Microbiological Culture Collection Center (CGMCC) is CGMCC No.1982. Dry-powder microbial inoculum prepared by the strain can be applied to prevention and cure of wheat scab, rice blast, corn southern leaf blight, sclerotium disease germ of garlic, anthracnose germ of cucumber and other germs that cause diseases to agricultural crops and vegetables; the microbial inoculum can also be applied to preservation of fresh fruits such as peaches, apples, grapes, pears, etc. Rice and corn leaves processed with suspension liquid of Bacillus subtilis strain can prevent the corresponding lesion disease; the cucumber seeds or seedlings processed by mixing the seeds with powder, burying the powder around the root or spraying suspension liquid of Bacillus subtilis strain can not only prevent cucumber anthracnose, but also accelerate the growth of the plants. The production of safe and pollution-free vegetables is capable. Fresh peaches processed with suspension liquid of Bacillus subtilis strain are rot-resistance, and the preservation time is prolonged. The preparation process for the microbial inoculum is simple, applicable to commercial production.

Owner:LIAOCHENG SUBILIER FERTILIZER

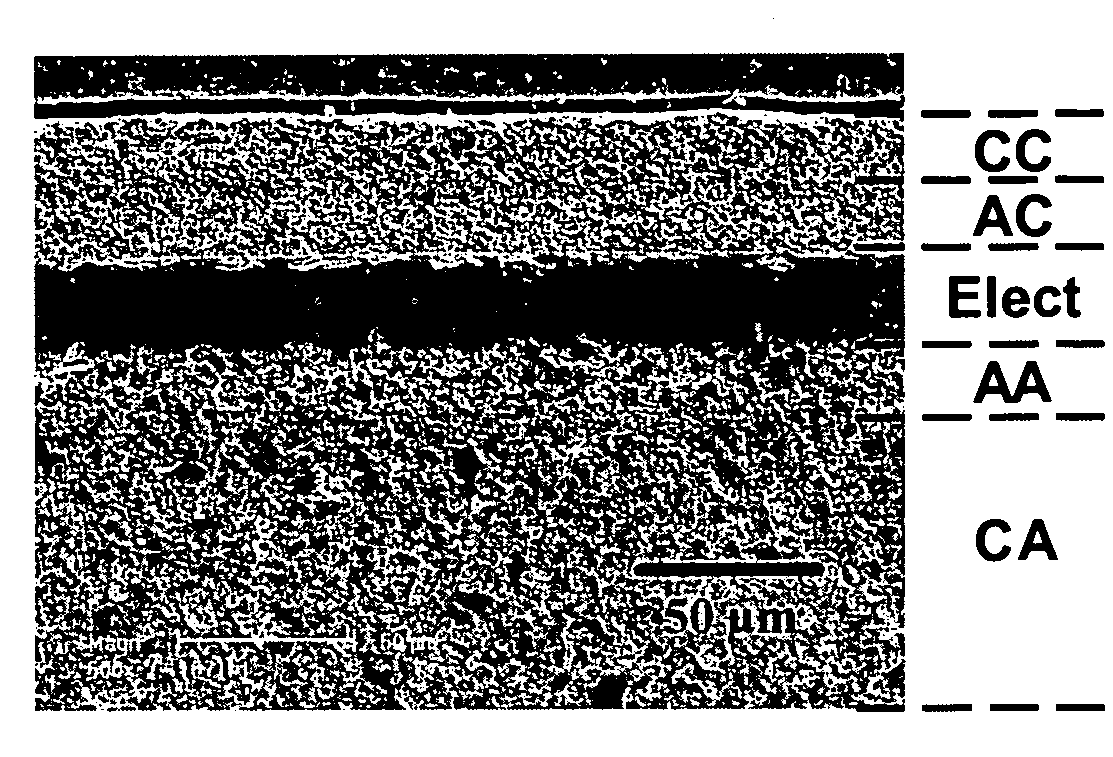

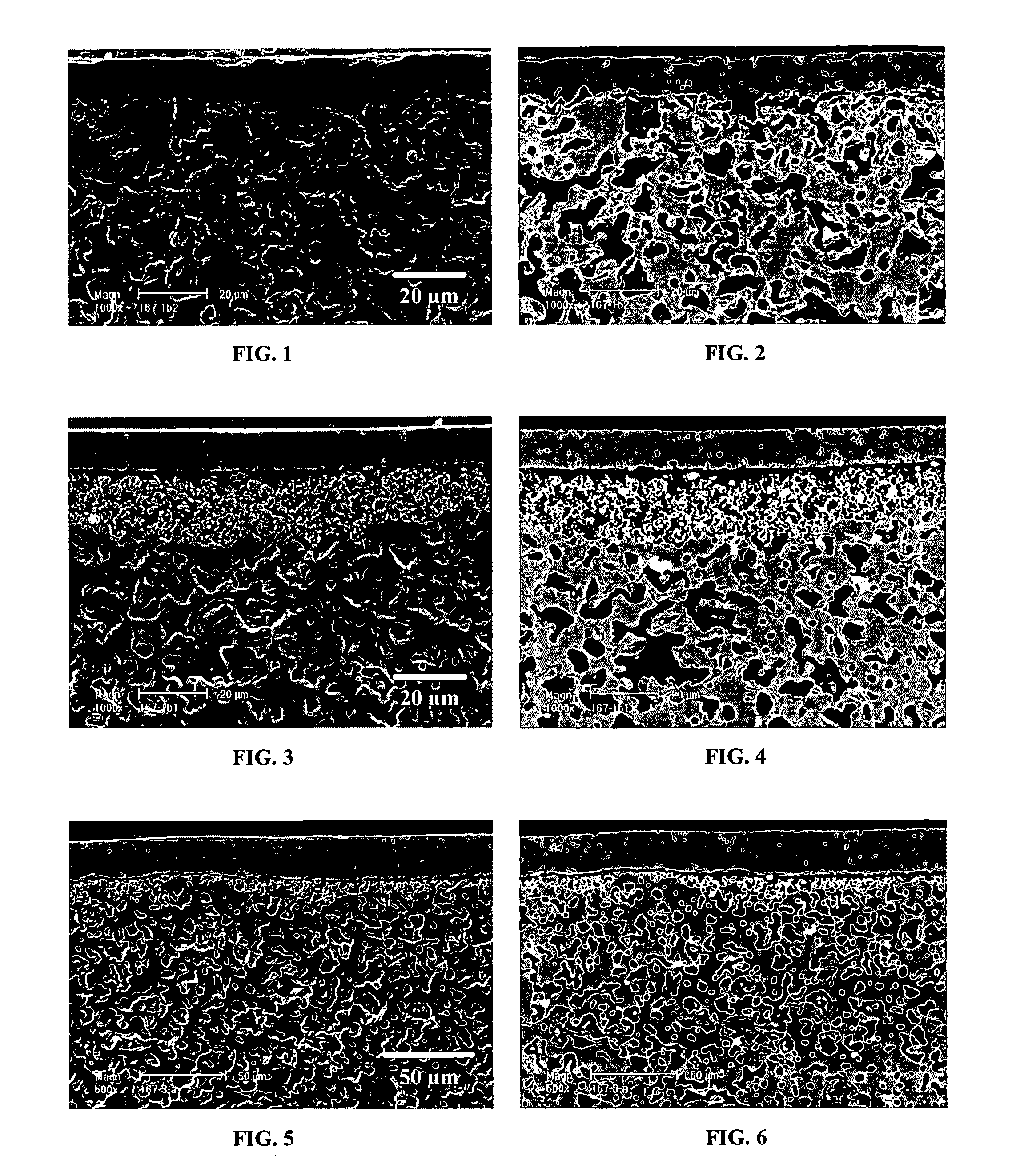

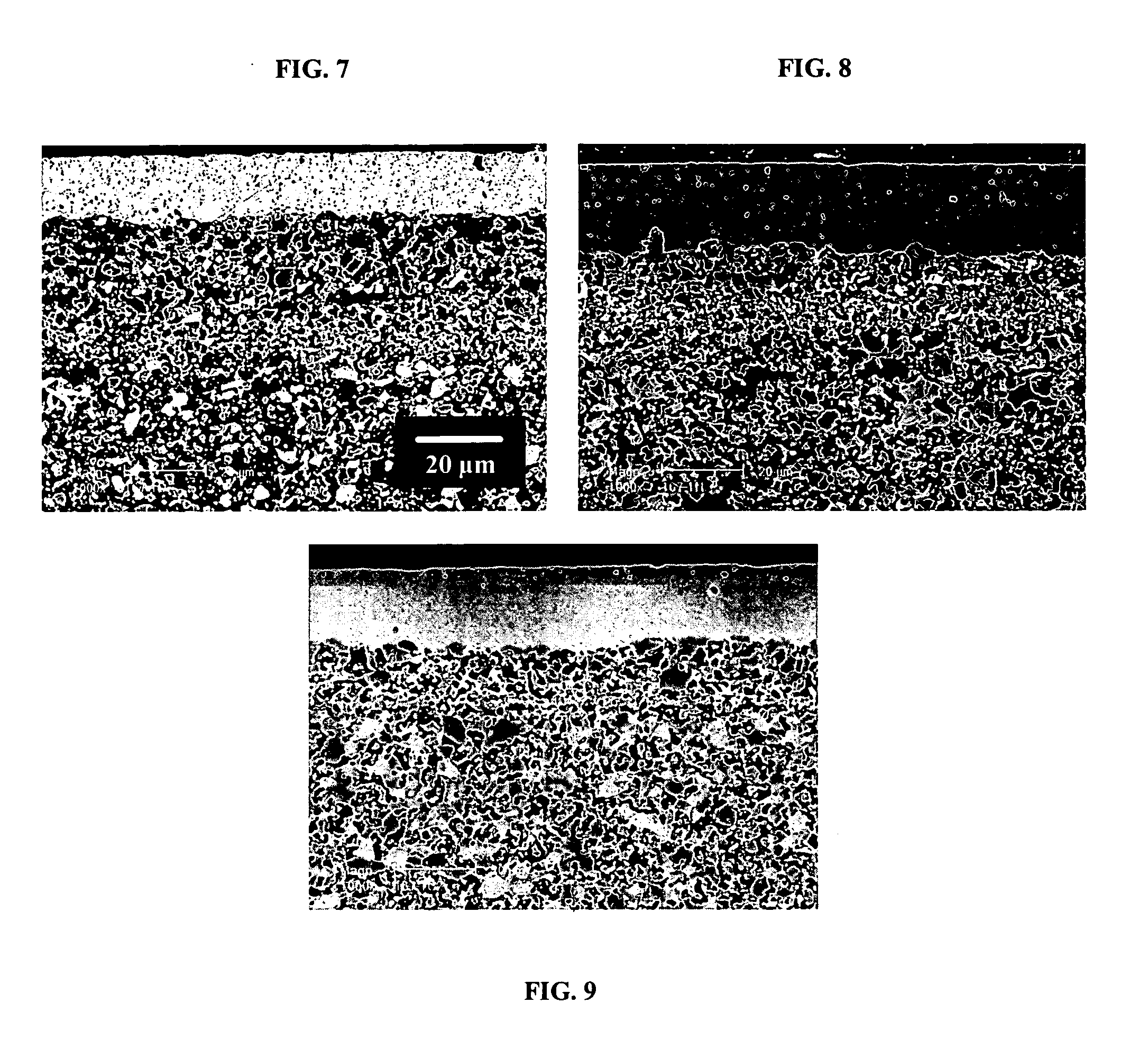

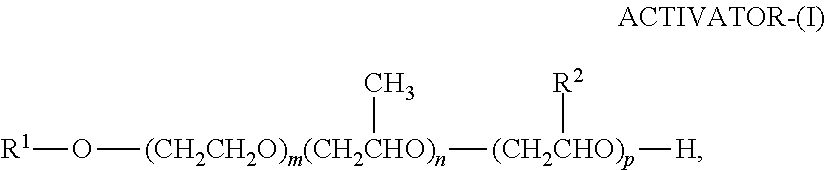

Nonazeotropic terpineol-based spray suspensions for the deposition of electrolytes and electrodes and electrochemical cells including the same

A family of spray suspensions for aerosol deposition of green ceramic layers that subsequently can be sintered to produce both dense and porous ceramic layers. The suspensions comprise a nonazeotropic solvent mixture, a ceramic powder, a dispersant, and a an organic binder. The invention also includes methods for depositing coatings of these ceramic suspensions on a substrate, either singly or sequentially, to form electrochemically efficient multilayer structures that can be economically co-sintered. The suspensions and deposition approach allow formation of thin layers of varying microstructure and composition in the sintered state. The suspensions and deposition approach are likely to be useful in the fabrication of electrochemical devices.

Owner:DAY MICHAEL J +1

Water-free antiperspirant non-aerosols in which active substances are more readily released

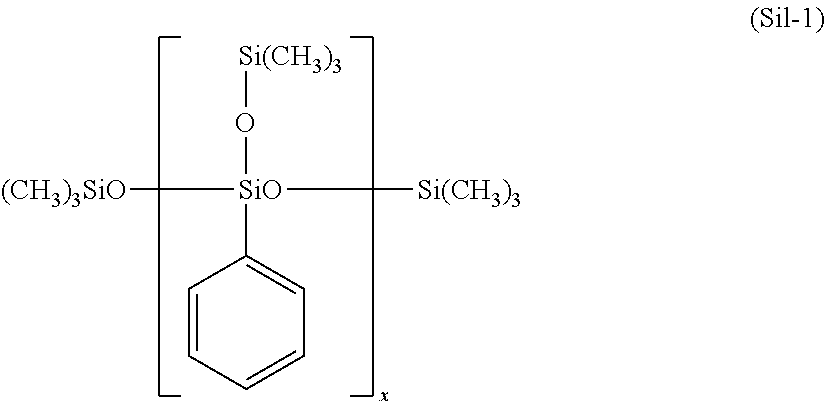

Antiperspirant compositions for personal body care are produced as a non-aerosol, stick, soft solid, cream, gel, non-sprayable suspension, non-sprayable solution, or impregnated on a substrate and include at least one antiperspirant, at least one oil as a carrier, said oil being liquid in normal conditions, 0-7 percent by weight of free water relative to the weight of the composition, and at least one selected alkyl-modified polyether.

Owner:HENKEL KGAA

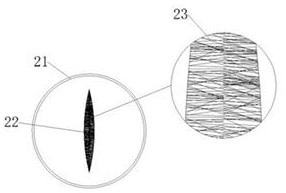

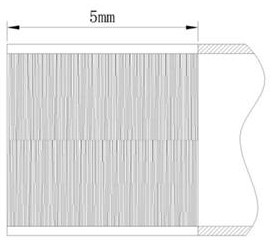

Equipment for preparing continuous functionalized carbon fiber enhanced thermoplastic resin base prepreg tape

The invention discloses equipment for preparing continuous functionalized carbon fiber enhanced thermoplastic resin base prepreg tape. The equipment comprises a yarn rack, a yarn guiding device, a spraying device, a hot press moulding device, and a reeling roller; and the yarn rack, the yarn guiding device, the spraying device, the hot pressing moulding device, and the reeling roller are sequentially arranged from the front to the rear. A functionalized carbon fiber splitting device is arranged between the yarn guiding device and the spraying device, and the spraying device is used to spray thermoplastic resin powder suspension over the splitted functionalized carbon fibers. A splitting device is added before the spraying device and the spraying device is used to spray suspension containing thermoplastic resin powder over the functionalized carbon fibers to effectively control the prepreg tape resin content so as to prepare uniform and low porosity continuous functionalized carbon fiber enhanced thermoplastic prepreg tape. The equipment has the advantages of simple structure and good production continuity.

Owner:DONGHUA UNIV

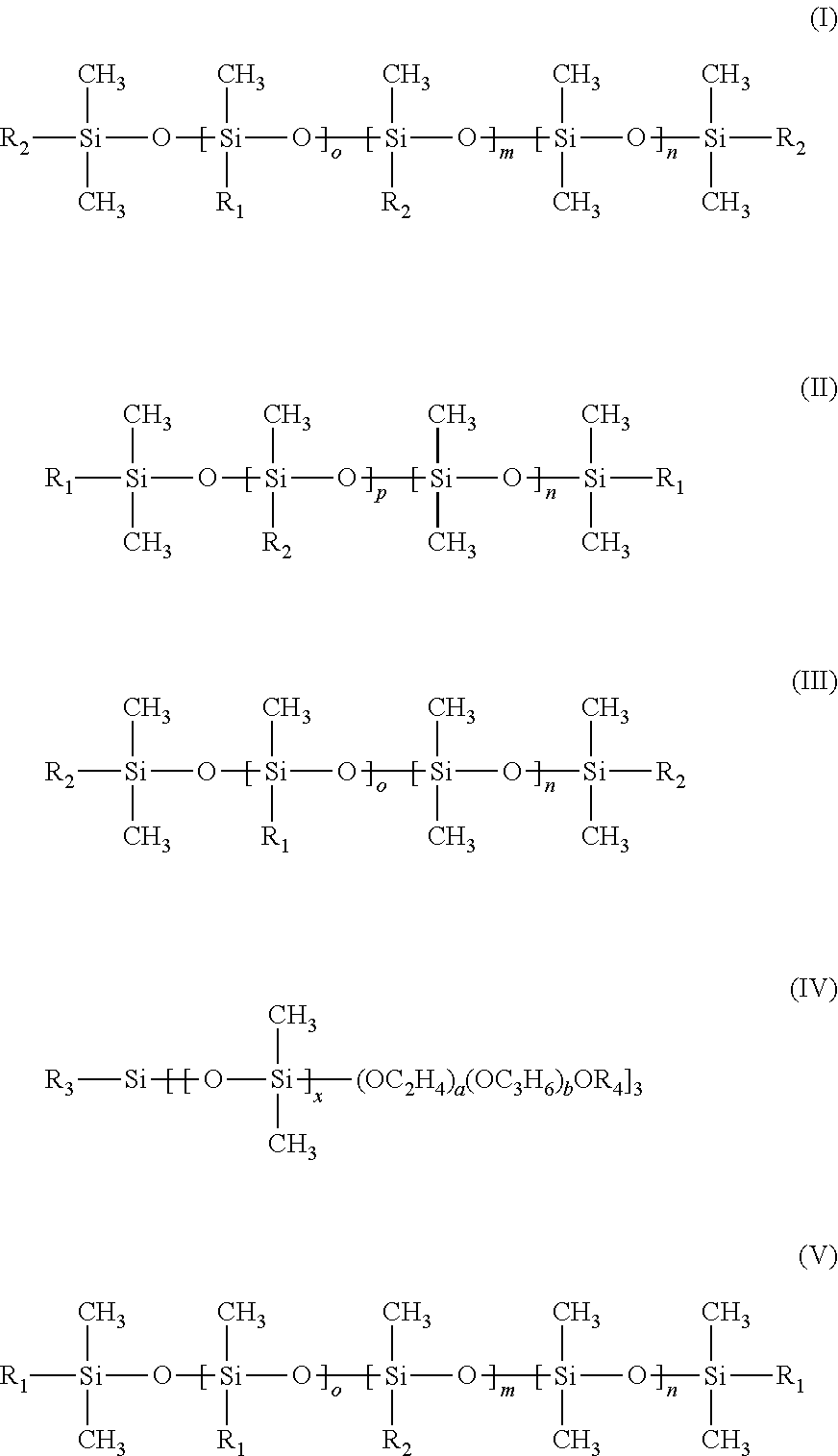

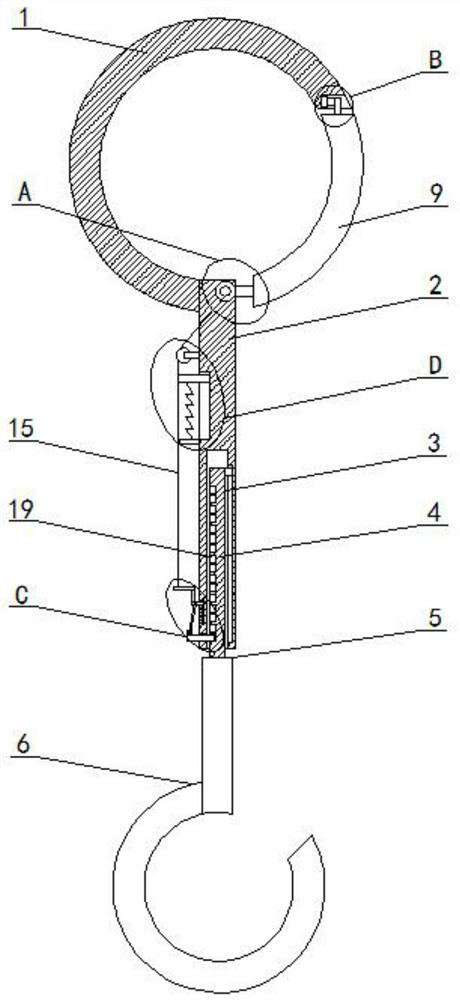

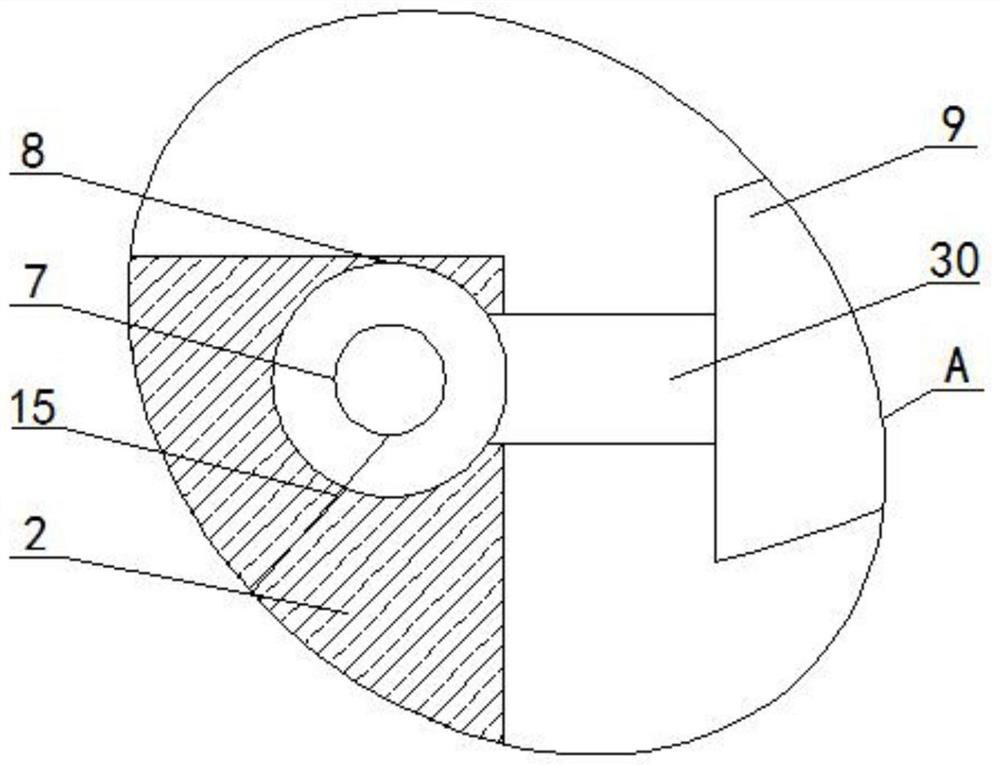

Automatic rotating paint-spraying suspension device

InactiveCN104209210ASmooth rotationHarm reductionSpraying apparatusClassical mechanicsStructural engineering

The invention discloses an automatic rotating paint-spraying suspension device and belongs to the field of paint spraying. The device comprises a bracket, a guide rail and a pothook, wherein the guide rail is connected with the pothook through a rotating mechanism; a driving belt, a spring adjusting rod and a lateral plate are arranged on each of two sides of the rotating mechanism; the driving belts are fixed on the lateral plates through the spring adjusting rods; the lateral plates are fixed on the bracket. The rotating mechanism is connected between the pothook and the guide rail and the driving belts are used for rubbing the rotating mechanism to rotate, so that the paint-spraying pothook is rotated at a uniform speed, the paint-spraying efficiency and the paint-spraying quality are increased, and the harm to a human body caused by near-distance paint-spraying is reduced.

Owner:ANQING TIANRUN ENG MACHINERY

Paint-spraying suspension device

InactiveCN107297292AHeight adjustableMeet the needs of useSpraying apparatusEngineeringSpray Suspension

The invention discloses a paint-spraying suspension device. The paint-spraying suspension device comprises a guide rail and a tackle, wherein wheels are mounted at the top ends of the inner side of the tackle, a support is mounted at the bottom end of the tackle, an ejector pin is mounted at the bottom end of the support, a sleeve sleeves the bottom end of the outer wall of the ejector pin, an insertion rod is mounted at the left end of a retaining plate, an insertion groove is arranged in the right outer wall of the ejector pin, support rods are mounted on the left and right sides of the bottom end of the sleeve, and hooks are mounted at the bottom ends of the support rods. The paint-spraying suspension device has the advantages that by the coordination of the tackle, the insertion rod and the insertion groove, the tackle can slide leftwards and rightwards at the bottom end of the guide rail, a pull rod is driven to move rightwards by pulling a handle rightwards, the pull rod drives the insertion rod to move rightwards to leave the insertion groove through the retaining plate, the sleeve can move up and down on the outer wall of the ejector pin to regulate the height of the hooks, the retaining plate drives the insertion rod to move leftwards under the elastic effect of a first compression spring when the handle is released, the insertion rod is leftwards inserted into the insertion groove, and the sleeve is fixed; the height of the hooks can be regulated conveniently, and the use requirements of users can be satisfied.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

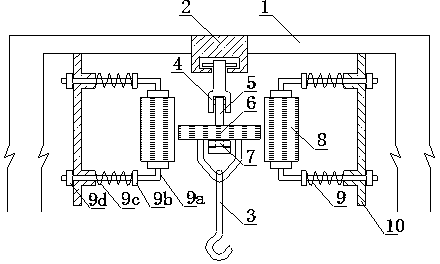

Preparation method of metal oxide suspension and method for spraying suspension to form high-specific-surface-area gas-sensitive coating under liquid material flame

InactiveCN109850934APromote meltingImprove work efficiencyLiquid surface applicatorsZinc oxides/hydroxidesRoom temperatureSpherical morphology

The invention discloses a preparation method of a metal oxide suspension capable of being applied to industrial production and a method for spraying the suspension to form a high-specific-surface-areagas-sensitive coating under a liquid material flame. The method utilizes a composite soft template method to synthesize a hollow spherical metal oxide suspension having hollow spherical morphology with a wall thickness thicker than that of a conventional hollow spherical morphology (structural strength of the hollow sphere is improved, and the intrinsic morphology after colliding with a substratecan be preserved), and the gas-sensitive coating is prepared by using the suspension as a liquid material and adopting a liquid material precursor flame spray (LPFS) technique with a milder flame speed and temperature. According to the method provided by the invention, the prepared gas-sensitive coating is a gas-sensitive coating having hollow spherical morphology, and has high sensitivity, faster response / recovery time and good long-term stability to a specific gas at under low temperature or even room temperature condition.

Owner:扬州睿德石油机械有限公司 +1

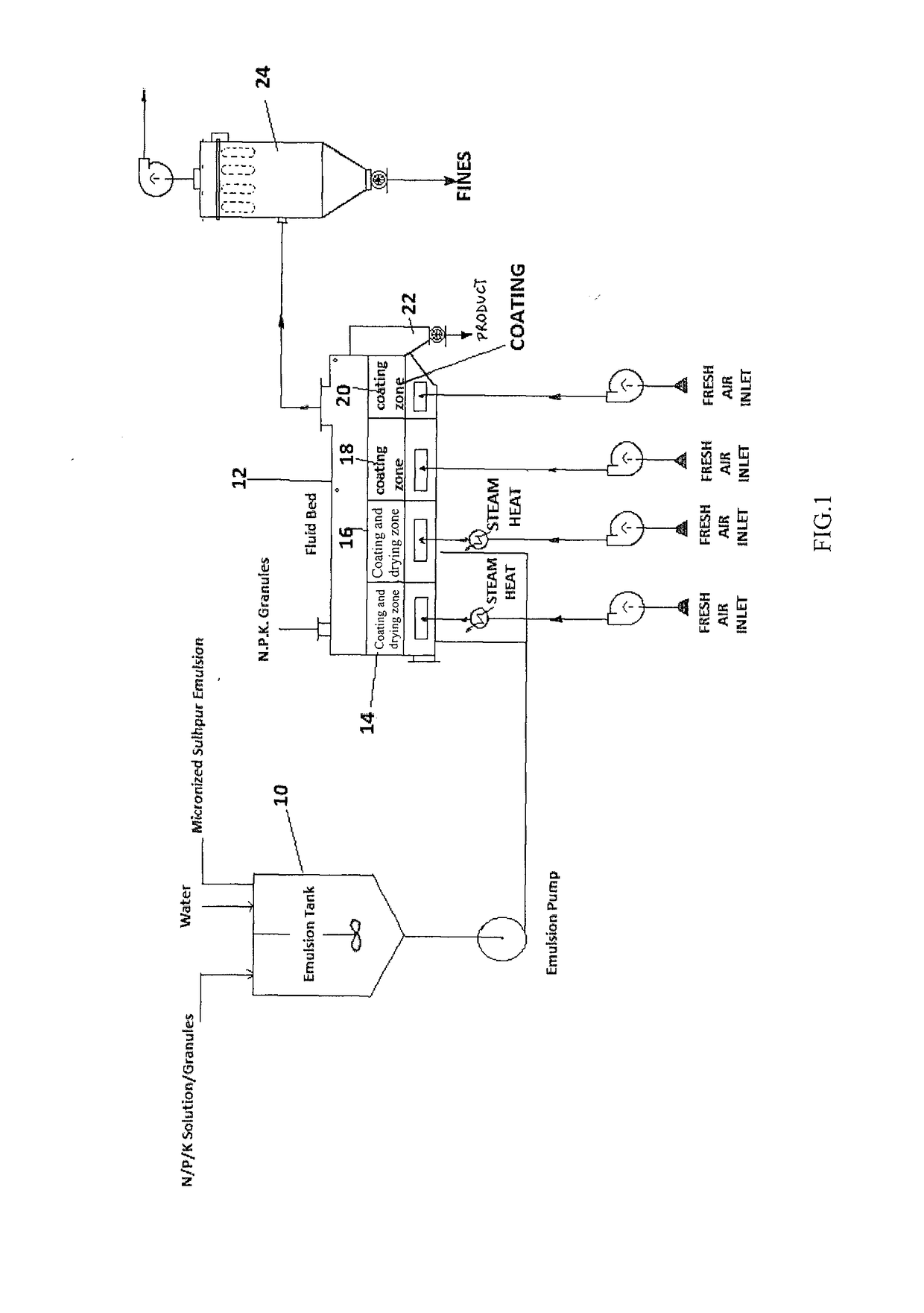

Spray coated fertilizer composition

InactiveUS20190039965A1Increase concentrationEfficient coatingGranule coatingAlkali orthophosphate fertiliserChemistryFertilizer

A fertilizer composition includes a seed particle spray coated with a fertilizer material including a soluble fertilizer and micronized sulphur particles. A method of producing a fertilizer composition includes the steps of producing a seed particle; preparing a sprayable suspension comprising a solution of a fertilizer material in water, a suspended insoluble fertilizer material, and a dispersant; and using the suspension to spray coat a layer of a mixture of the soluble and insoluble fertilizer material onto the seed particle.

Owner:SULVARIS INC

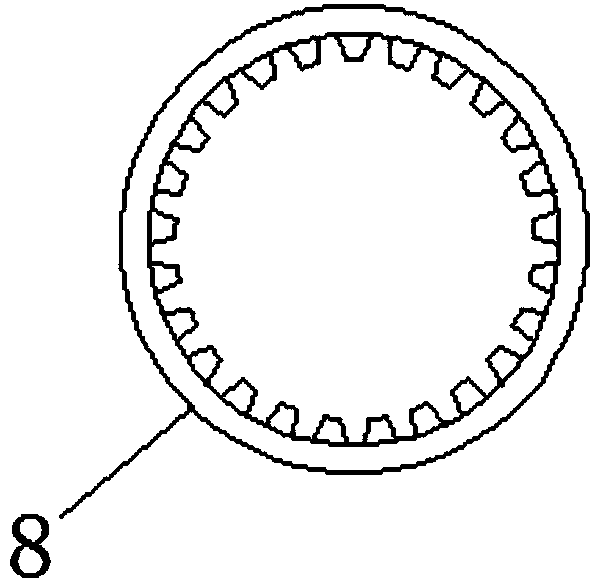

Shock absorber paint spraying suspension rack high in efficiency

InactiveCN107583791AFacilitate large-scale productionReduce wasteSpraying apparatusProduction lineGear drive

The invention discloses a shock absorber paint spraying suspension rack high in efficiency. The shock absorber paint spraying suspension rack comprises a rotary cylinder, a suspension rack body and asuspension rack arm, wherein a second supporting rod is arranged on the suspension rack body, a fixed fluted disc is welded at the top of the second supporting rod, a suspension rack arm is welded onthe side face of the rotary cylinder, a second gear is in meshed connection with the fixed fluted disc, a first gear is in transmission connection with a fixing hook through a first supporting rod, and the bottom of the rotary cylinder is in meshed connection with a third gear through an inner gear. In the shock absorber paint spraying suspension rack, the rotary cylinder can rotate under the transmission effect of a motor, the second gear drives the first supporting rod to rotate under the rotating effect of the rotary cylinder, and accordingly rotation of the fixing hook is indirectly controlled. By adopting the structure, a shock absorber can be fixed to the fixing hook at a time, a paint spraying process can be efficiently completed through rotation and revolution, large production line operation of a factory is facilitated, the labor cost is reduced, and the paint cost is reduced.

Owner:CHENGDU KECHUANGGU TECH CO LTD

High pressure spray system

ActiveUS6886784B1Universal adaptabilityIncrease productivityPower installationsLiquid spraying apparatusPropellerHigh pressure

A combination of an aircraft and spraying apparatus for spraying suspensions or solutions having predetermined characteristics independent of the speed of the aircraft, the apparatus consisting of a mounting frame attached to the underside of the aircraft, a plurality of bearing braces attached to the frame and a propeller shaft mounted through the bearing braces. A full feathering propeller is mounted on the forward end with a control running to the cockpit of the aircraft, and a rotary piston type high pressure pump connected to the aft end of the propeller. The input of the pump is connected to a supply tank in the aircraft and the output is connected to a spray boom. The spray nozzles consist of high pressure impingement nozzles.

Owner:SKYPATH LLC

Soft hard alternate composite coating used for surface of bearing bush material and preparation method of soft hard alternate composite coating

InactiveCN106222656AImprove wear resistance and antifriction performanceImprove carrying capacitySuperimposed coating processWorking lifeMetallurgy

The invention provides a soft hard alternate composite coating used for the surface of a bearing bush material and a preparation method of the soft hard alternate composite coating. The composite coating comprises a Cu coating, a WC coating and a MoS2 coating which are sequentially arranged from the surface to the outside of the bearing bush material. The preparation method comprises the steps that flames are sprayed on the surface of the bearing bush material, and the Cu coating and the WC coating are sequentially prepared; and then the MoS2 coating is prepared by spraying suspension liquid to the WC coating, so that the composite coating is obtained. The soft hard alternate composite coating used for the surface of the bearing bush material and the preparation method of the soft hard alternate composite coating have the following beneficial effects that the soft hard alternate coating is prepared on the bearing bush material, so that the abrasion resistance, the antifriction performance, the bearing capacity and the embedding performance of the bearing bush are improved, the working life of the bearing bush is prolonged, and the anti-lock performance of the bearing bush is improved.

Owner:SHANGHAI JIAO TONG UNIV

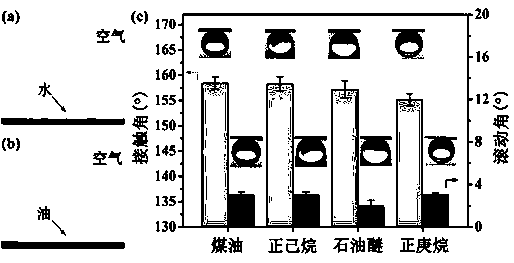

Preparation for titanium dioxide-AP stainless steel net and application thereof in water body remediation

InactiveCN108675386AImprove separation efficiencyImprove mechanical propertiesLiquid surface applicatorsFatty/oily/floating substances removal devicesALUMINUM PHOSPHATESolvent

The invention discloses a preparation method for a TiO2-AP stainless steel net. The preparation method comprises the following steps: uniformly spraying suspension liquid containing TiO2 nanoparticlesand an aluminum phosphate binder on the surface of a stainless steel net, drying and solidifying, to obtain the TiO2-AP stainless steel net. The TiO2-AP stainless steel net has the excellent emulsionseparation capacity, aiming at oil-in-water emulsion containing a surfactant, separation efficiency is higher than 99.8%. The TiO2-AP stainless steel net still has 99.5% of the high separation efficiency even if 500 times of scratching tests are performed. The TiO2-AP stainless steel net further has the very good mechanical durability and chemical stability, and is capable of enduring more severeconditions, such as sand impact circulation, 24 hours of a solvent soaking test and ultrasonic wave treatment. In addition, the TiO2-AP stainless steel net is capable of efficiently degrading organicdye, and can be extensively applied to the water body remediation.

Owner:NORTHWEST NORMAL UNIVERSITY

Water-free antiperspirant non-aerosols in which active substances are more readily released

Antiperspirant compositions for personal body care are produced as a non-aerosol, stick, soft solid, cream, gel, non-sprayable suspension, non-sprayable solution, or impregnated on a substrate and include at least one antiperspirant, at least one oil as a carrier, said oil being liquid in normal conditions, 0-7 percent by weight of free water relative to the weight of the composition, and at least one selected alkyl-modified polyether.

Owner:HENKEL KGAA

3D spray suspension projection imaging device suitable for installation in various scenes

InactiveCN109799668AImprove ease of useAvoid deviation of projection effectProjectorsStands/trestlesCamera lensProjection image

The invention discloses a 3D spray suspension projection imaging device suitable for installation in various scenes. The device comprises a shell, and two groups of loudspeakers and a jack board are mounted on the end surface of the shell. The jack board is located between the two loudspeakers, and an infrared receiving window and a lens are installed at the upper portion of the shell. The infrared receiving window is located at one side of the lens, and a threaded through hole is formed in the inner side wall of the lens, and a drainage pipe is installed in the threaded through hole. A wiringboard is installed at the rear end of the shell. The position of the device provided by the invention can be adjusted after fixing, so as to adapt to various working environments and facilitate the cleaning of the heat dissipation window. The water gathered in the lens can be discharged, and the projection effect of the 3D spray suspension projection imaging device is prevented from deviating dueto refraction of the water.

Owner:甘肃修森网络信息科技有限公司

Preparation method of super-hydrophobic plate membrane for oil-water separation

InactiveCN107583312AImprove hydrophobicityImprove lipophilicityLiquid separationSeparation technologyMicroparticle

The invention relates to a preparation method of a super-hydrophobic plate membrane for oil-water separation and belongs to the technical field of chemical separation. The preparation method is characterized in that a stainless steel microparticle sintered perforated plate is taken as a substrate, a water mixture of polyphenylene sulfide and polytetrafluoroethylene is taken as a first-layer spraysuspension, a water mixture of polytetrafluoroethylene is taken as a second-layer spray suspension, and the super-hydrophobic plate membrane for oil-water separation is prepared with a double-layer spray and high-temperature plastification method. The super-hydrophobic plate membrane for oil-water separation has the advantages of good hydrophobic and oleophilic effects, high strength, high pressure resistance and the like and further has good chemical corrosion resistance and higher oil-water separation efficiency; the preparation method is simple and convenient and has wide application prospect in the fields of petrochemicals, environmental protection and the like.

Owner:DALIAN UNIV OF TECH

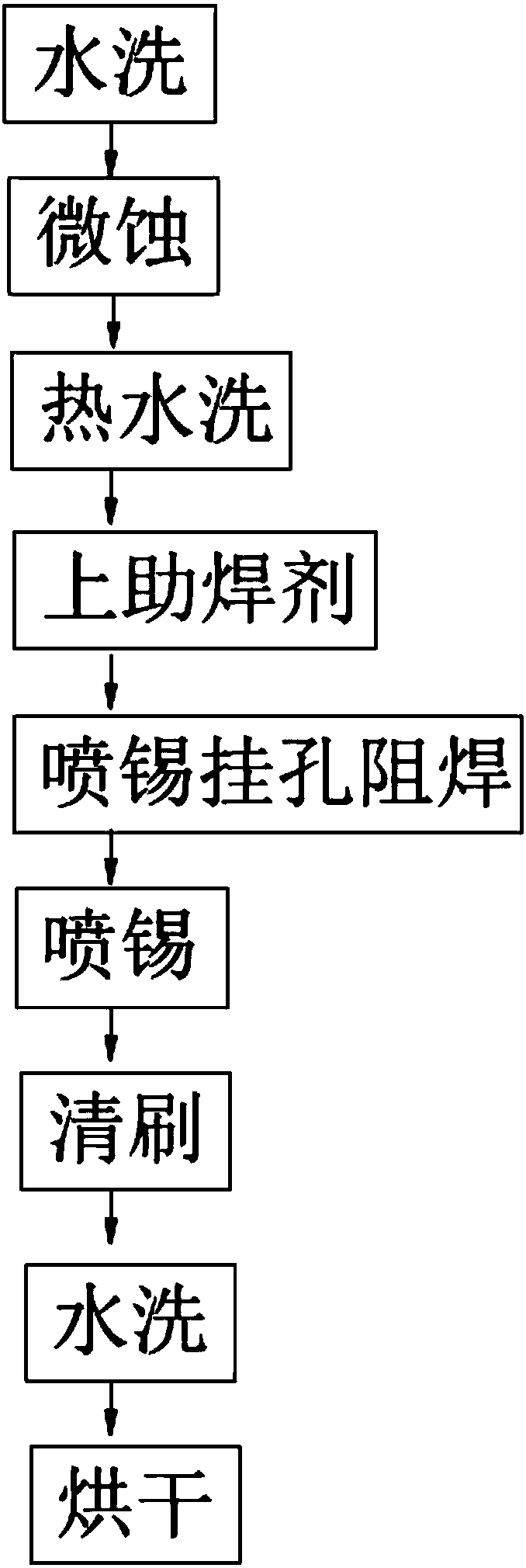

Negative sheet PCB tin spraying process

ActiveCN107683029APrevent the problem of tin accumulationSimple processing methodPrinted circuit assemblingEtchingSoldering

The invention provides a negative sheet PCB tin spraying process. The process comprises the following steps of A performing water washing; B performing micro etching; C performing hot water washing; Dusing soldering flux; E performing solder resisting on tin-sprayed suspension holes; F performing tin spraying; G performing cleaning and brushing; H performing water washing; and I performing drying. According to the negative sheet PCB tin spraying process, a measure of solder resisting is performed on the tin-sprayed suspension holes before tin spraying; the position of the tin-sprayed suspension holes is coated with solder resisting printing oil, and the printing oil is subjected to exposure, developing and baking to form a layer of solder resisting layer, so that the problem of tin accumulation in the position of the tin-sprayed suspension holes caused by the fact that the tin material is cured in the tin-sprayed suspension holes in the tin spraying operation can be prevented; the printing oil forms the solder resisting layer in the tin-sprayed suspension holes, so that tin material attachment in the tin-sprayed suspension holes in tin spraying can be avoided, and the tin-sprayedsuspension holes are tidy and leveled; a smooth, uniform and bright solder coating layer is obtained around the position of the tin-sprayed suspension holes; the process is simple in method, convenient to operate and capable of effectively preventing tin accumulation in the position of the tin-sprayed suspension holes; and the positions of the tin-sprayed suspension holes are tidy and uniform.

Owner:DIGITAL PRINTED CIRCUIT BOARD CO LTD

Portable 3D spray suspension projection imaging equipment

InactiveCN109669314AEasy to carryEasy to transportProjectorsBiochemical engineeringProtection mechanism

The invention discloses portable 3D spray suspension projection imaging equipment, which comprises an equipment main body, wherein a square opening is formed in the equipment main body; a heat radiation net is fixedly arranged in the square opening; a round hole is formed in the square opening; a dismountable top plate is arranged in the square opening; the lower surface of the dismountable top plate is provided with a small cylinder; the dismountable top plate is fixedly connected with the square opening through the small cylinder; a square groove is formed in the dismountable top plate; oneend of the equipment main body is fixedly provided with a carrying handle mechanism; the front end of a prime number equipment main body is provided with a projection lens; a protection mechanism sleeves the projection lens. The portable 3D spray suspension projection imaging equipment has the advantages that the top plate can be dismounted; the heat radiation efficiency can be conveniently maintained in a high-temperature environment; if the equipment is not used, the lens is protected, so that the damage due to scratch is avoided, and the equipment transportation and carrying when being needed by a user are convenient.

Owner:甘肃修森网络信息科技有限公司

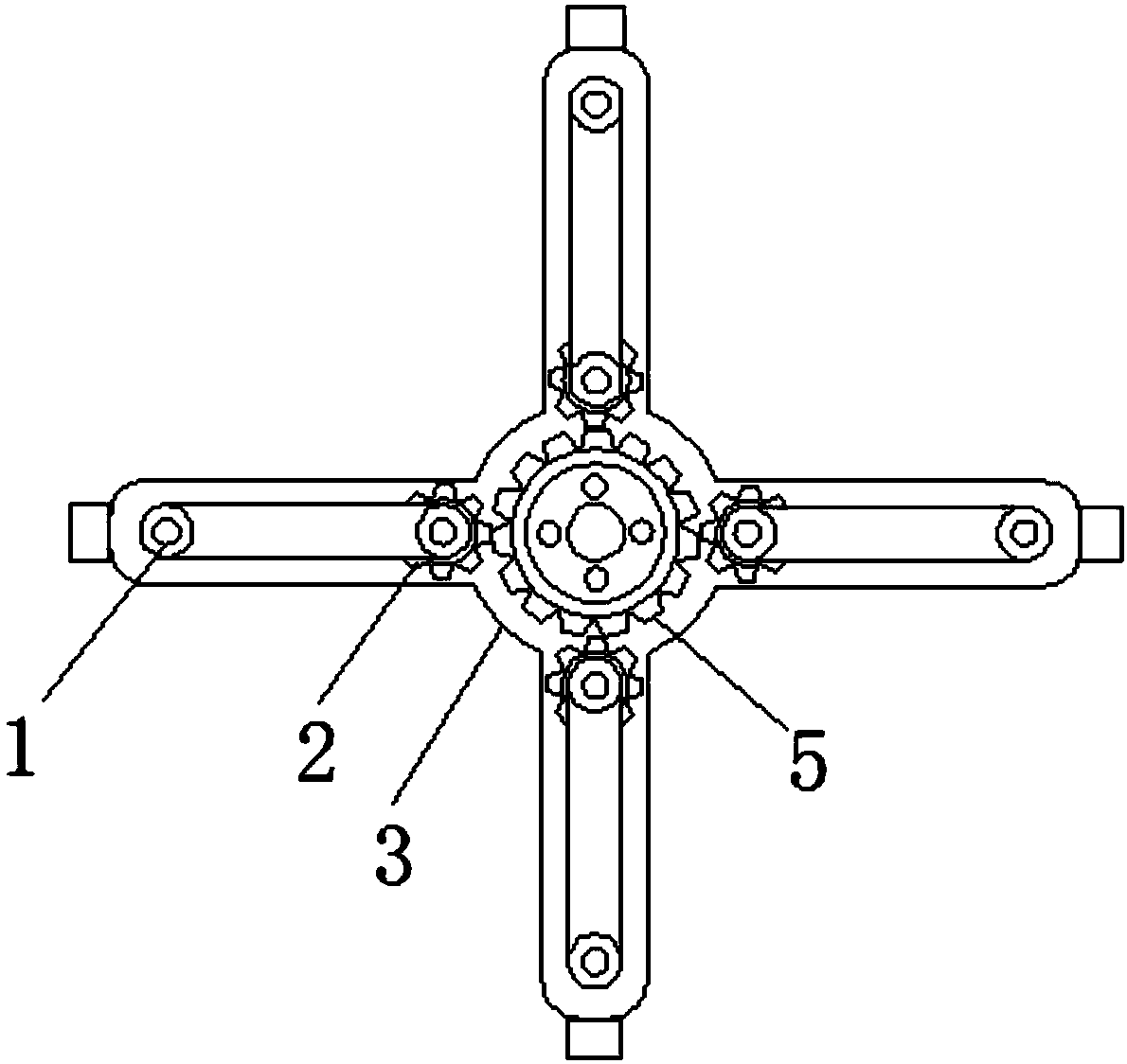

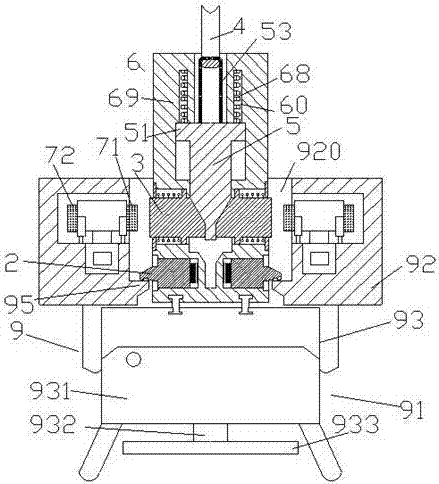

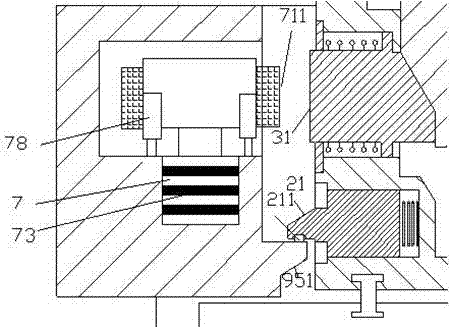

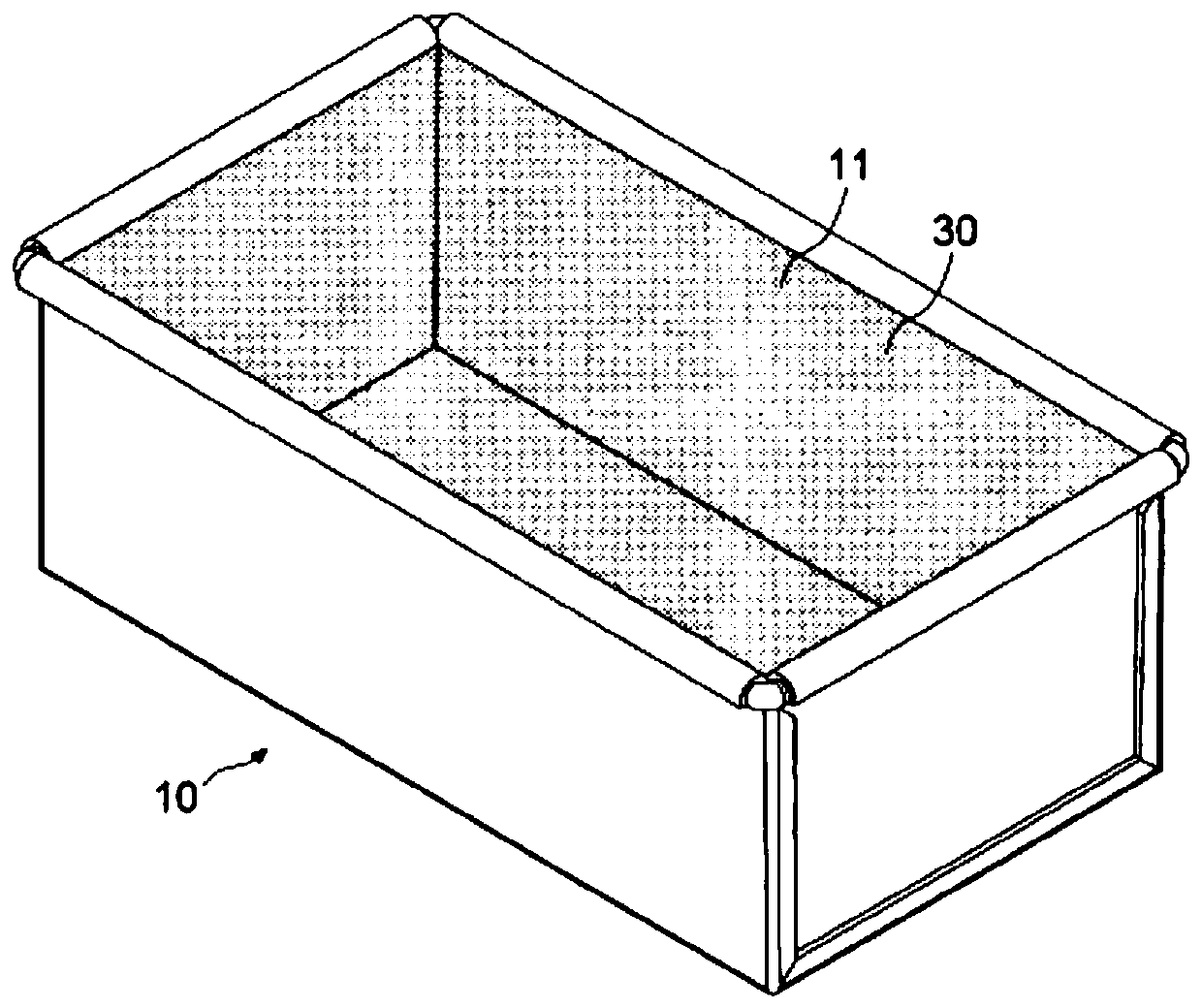

Convenient spraying device for transporting greenhouses pesticide

A convenient greenhouse pesticide conveying and spraying device, used for conveying spraying equipment (93), comprising a spraying equipment sliding area (91) and a top beam body (92) located above the spraying equipment sliding area (91) The fixing frame (9) and the spraying suspension device (6) which is fixedly connected with the spraying equipment (93) and can move in the suspension channel (920) of the top beam body (92), wherein , the spraying suspension device (6) includes a main body (69), elastic and telescopic sliding support blocks (2) and joint members (3) for front and rear driving that are symmetrically arranged on both sides of the main body (69). .

Owner:汪涛

A tin-spraying process for negative pcb board

ActiveCN107683029BPrevent the problem of tin accumulationSimple processing methodPrinted circuit assemblingEtchingSolder mask

The invention provides a negative sheet PCB tin spraying process. The process comprises the following steps of A performing water washing; B performing micro etching; C performing hot water washing; Dusing soldering flux; E performing solder resisting on tin-sprayed suspension holes; F performing tin spraying; G performing cleaning and brushing; H performing water washing; and I performing drying. According to the negative sheet PCB tin spraying process, a measure of solder resisting is performed on the tin-sprayed suspension holes before tin spraying; the position of the tin-sprayed suspension holes is coated with solder resisting printing oil, and the printing oil is subjected to exposure, developing and baking to form a layer of solder resisting layer, so that the problem of tin accumulation in the position of the tin-sprayed suspension holes caused by the fact that the tin material is cured in the tin-sprayed suspension holes in the tin spraying operation can be prevented; the printing oil forms the solder resisting layer in the tin-sprayed suspension holes, so that tin material attachment in the tin-sprayed suspension holes in tin spraying can be avoided, and the tin-sprayedsuspension holes are tidy and leveled; a smooth, uniform and bright solder coating layer is obtained around the position of the tin-sprayed suspension holes; the process is simple in method, convenient to operate and capable of effectively preventing tin accumulation in the position of the tin-sprayed suspension holes; and the positions of the tin-sprayed suspension holes are tidy and uniform.

Owner:DIGITAL PRINTED CIRCUIT BOARD CO LTD

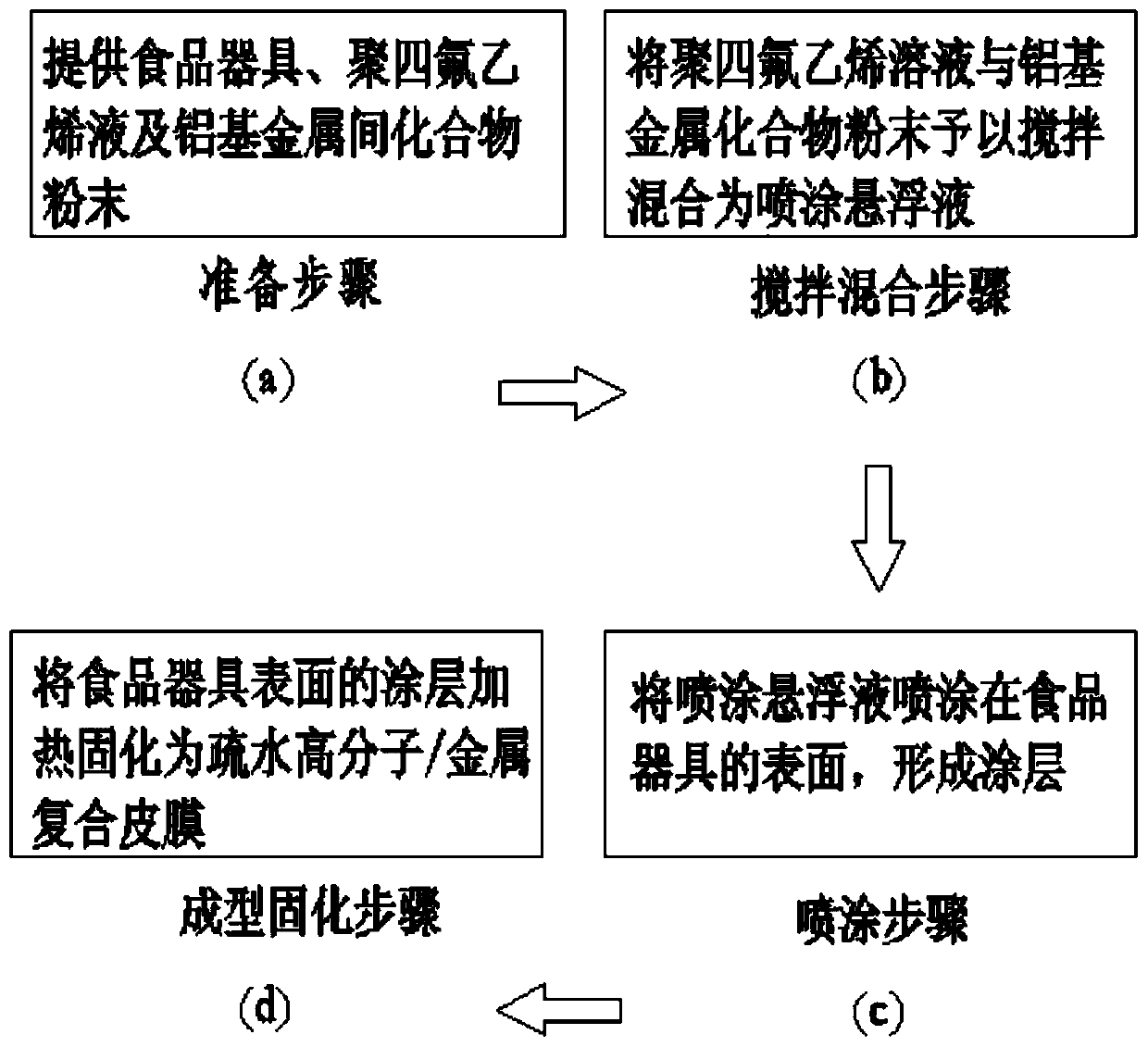

Method for covering the surface of food utensils with hydrophobic polymer metal composite film

ActiveCN109807042BNot easy to cleanImprove overall performancePretreated surfacesCoatingsPolymer sciencePolymer metal

The invention relates to a method for covering the surface of a food utensil with a hydrophobic polymer metal composite film, comprising the following steps: a) a preparation step, providing a treated food utensil, a specific amount of polytetrafluoroethylene solution and a specific amount of aluminum base intermetallic compound powder; b) stirring and mixing step, stirring and mixing the polytetrafluoroethylene solution and the aluminum-based intermetallic compound powder to form a spray suspension; c) spraying step, spraying the spray suspension on the surface of the food utensil above, forming at least one coating on the surface of the food utensil; d) molding and curing step, heating and curing the coating of the food utensil to form a hydrophobic polymer / metal composite film; the invention provides a food utensil surface covered with a hydrophobic polymer The method of metal composite film makes the load-bearing surface of food utensils have many characteristics such as high hydrophobicity, high anti-sticking property and better surface wear resistance.

Owner:SAN NENG BAKE WARE WUXI

Delivery spraying device used for greenhouse pesticide spraying

InactiveCN107087577AAvoid interferenceAvoid damageInsect catchers and killersGreenhouseSpray Suspension

A conveying and spraying device for pesticide spraying in greenhouses, used for conveying spraying equipment (93), comprising a spraying equipment sliding area (91) and a top beam body ( 92) fixed frame (9) and the spray suspension device (6) which is fixedly connected with the spray equipment (93) and can move in the suspension channel (920) of the top beam body (92) , wherein the spraying suspension device (6) includes a main body (69), elastic and telescopic sliding support blocks (2) and front and rear driving joint members ( 3).

Owner:汪涛

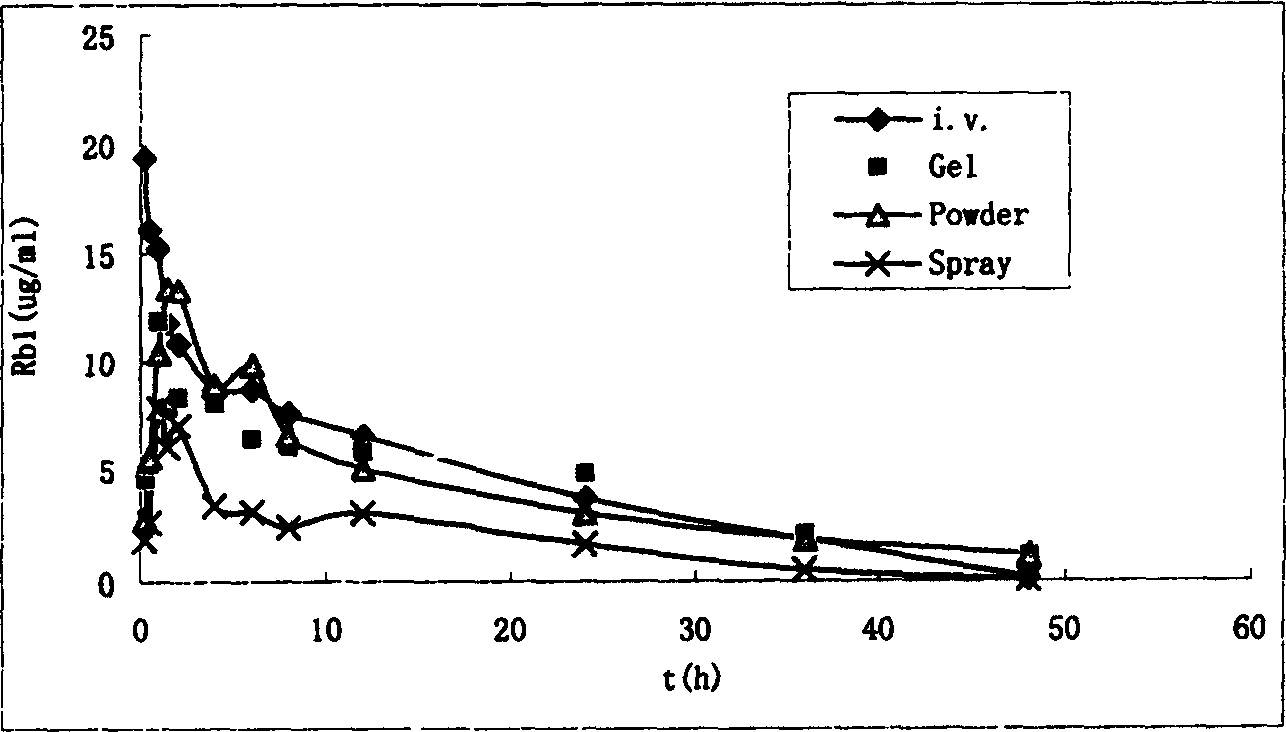

Chinese medicine prepn containing arasaponin and its prepn process

InactiveCN1199646COrganic active ingredientsPharmaceutical delivery mechanismOral medicationIrritation

The invention belongs to the field of traditional Chinese medicine pharmacy, and in particular relates to a traditional Chinese medicine preparation containing Panax notoginseng saponins and a preparation method thereof. The present invention adopts the total saponins of Panax notoginseng as the active ingredient, adds dry powder agent and gel agent agent, and freeze-dries to prepare dry powder sprays, gel sprays and suspension sprays of other non-injection routes of administration other than oral administration. new dosage forms. Animal tests of the present invention prove that the bioavailability is high, the administration is convenient, the administration site is non-irritating, and the patient's compliance is good.

Owner:FUDAN UNIV

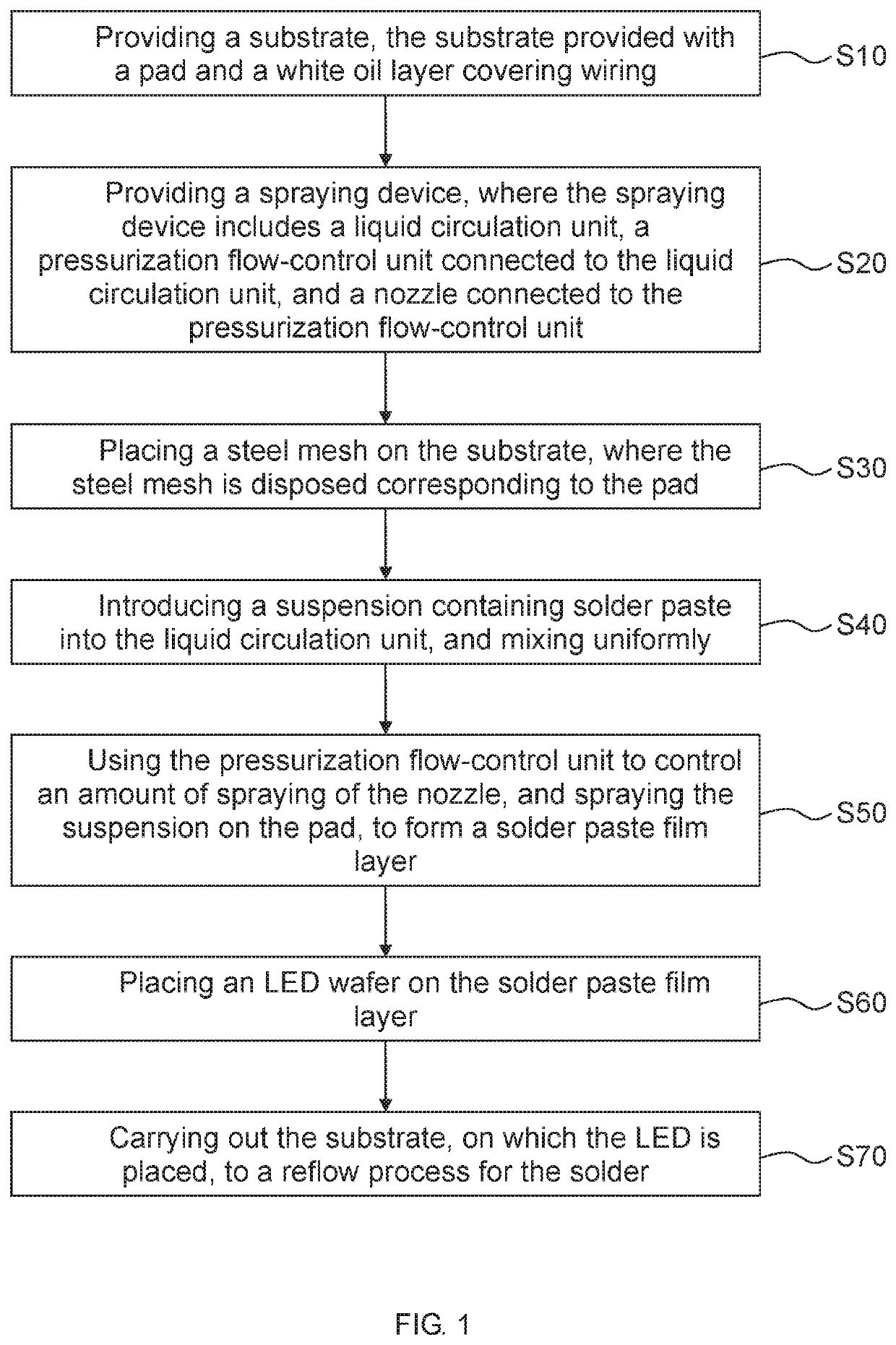

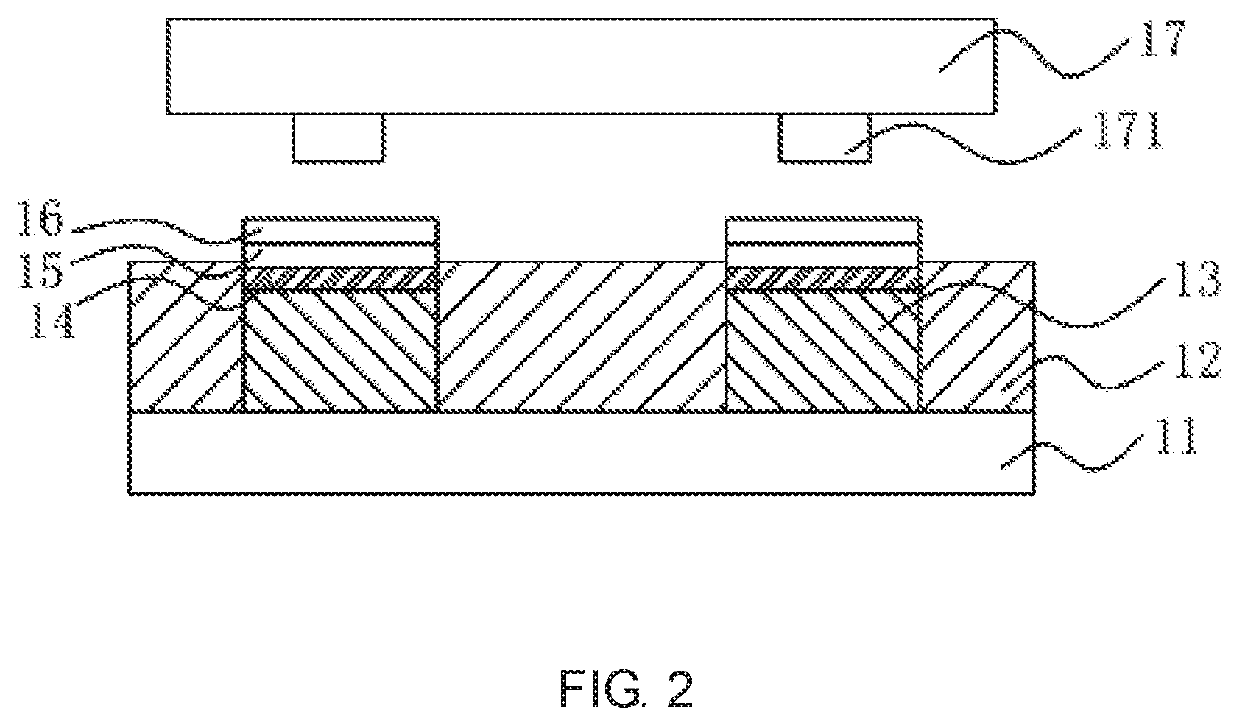

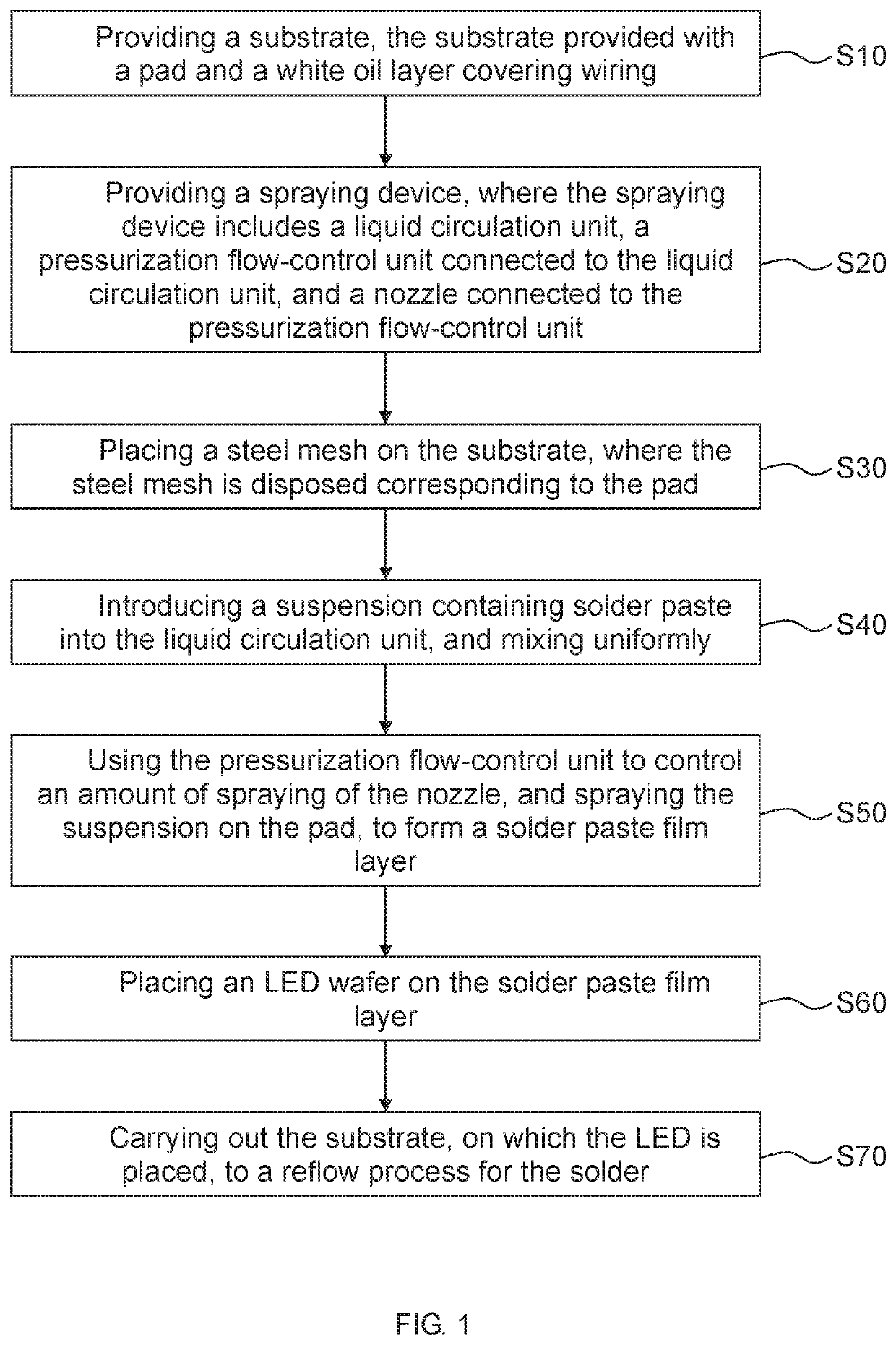

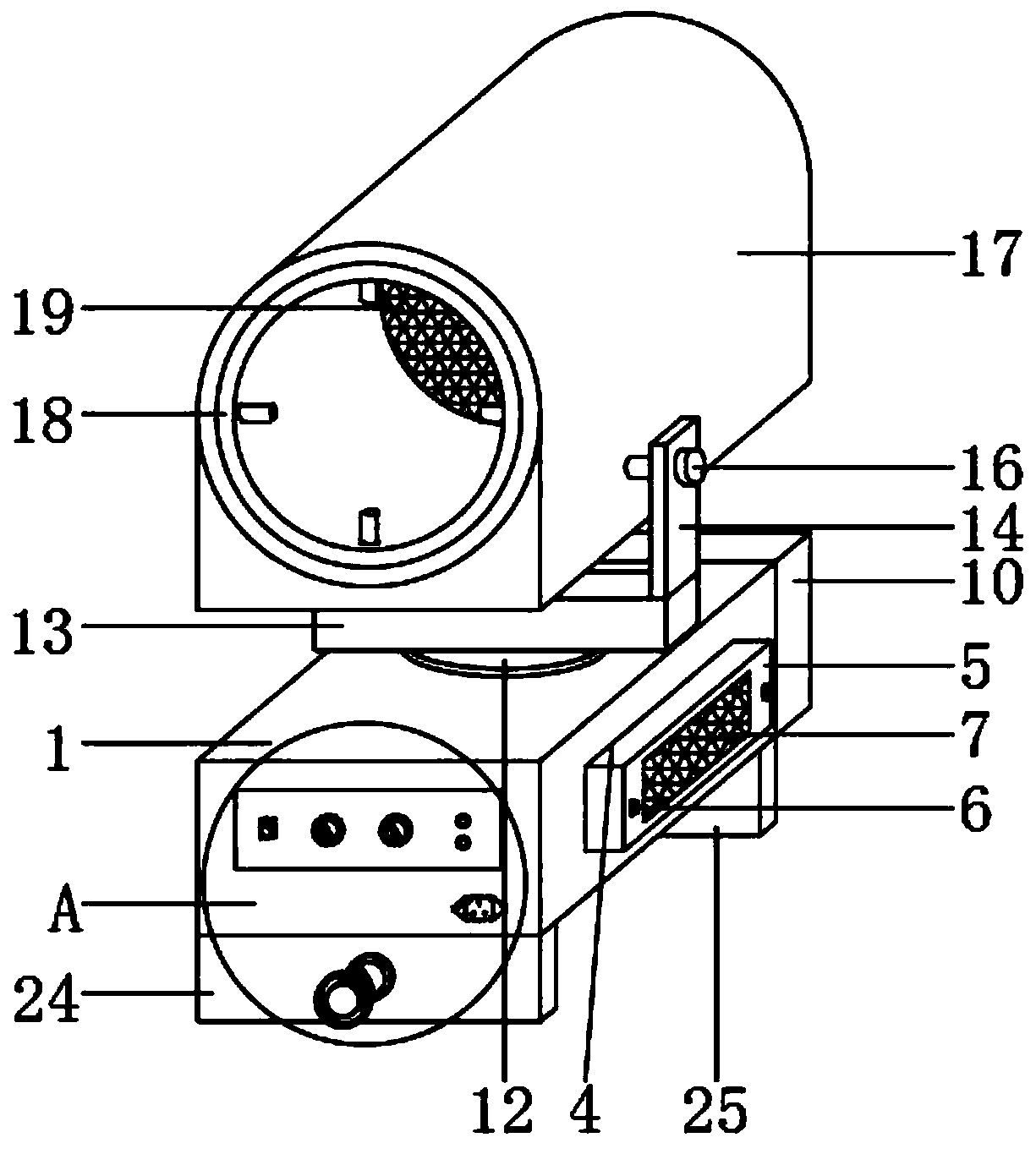

Die-bonding method and spraying device for LED

ActiveUS20210217924A1Improve luminous efficiencyBlocking phenomenonSemiconductor/solid-state device detailsSolid-state devicesWaferingSolder paste

A die-bonding method and a spraying device for an LED include: providing a substrate provided with a pad and a white oil layer covering wiring, placing a steel mesh on the substrate, and then spraying suspension containing solder paste on the pad by the spraying device, to form a solder paste film layer. Finally, a reflow process for the solder is performed. The solder paste is prepared on the pad by spraying, so that a crystal wafer is prevented from being tilted or short-circuited due to pulling or dragging of the solder paste during the reflow process for the solder, thereby improving uneven brightness of the surface light source.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A suspension device for spraying magnesium-aluminum alloy profiles

ActiveCN111438014BReduce storage space requirementsLower requirementSpraying apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of suspension devices, and discloses a suspension device for spraying magnesium-aluminum alloy profiles, including a main hook, a main hanging rod is fixedly installed at the bottom of the main hanging rod, and a telescopic groove is opened at the bottom of the main hanging rod. A telescopic rod is slidingly installed in the telescopic slot. The bottom end of the telescopic rod extends to the bottom of the main hanging rod and is fixedly installed with an auxiliary hanging rod. The bottom end of the auxiliary hanging rod is fixedly installed with an auxiliary hook. There is a rotating shaft, the outer fixed sleeve of the rotating shaft is provided with a rotating wheel, a mounting plate is fixedly installed on the rotating wheel, and an arc-shaped plate is fixedly installed on the end of the mounting plate away from the rotating wheel. The suspension device for magnesium-aluminum alloy profile spraying has strong practicability. Through the cooperation of the arc-shaped plate and the main hook, the rigidity of the main hook is enhanced, and the bending and deformation of the main hook are prevented. The storage space requirement is low, and the difficulty of taking and placing is reduced at the same time, which meets the needs of use.

Owner:四川齐飞新材料科技有限公司

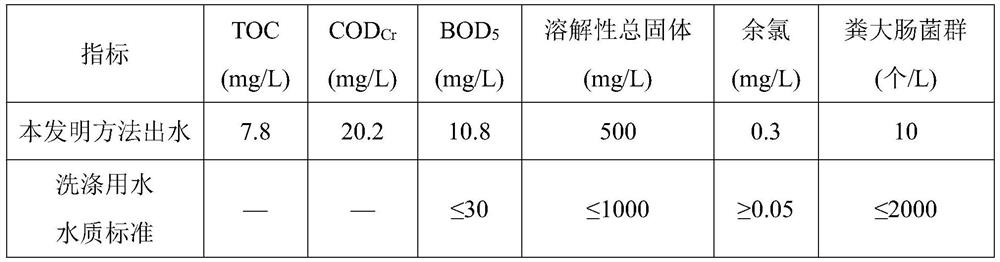

Advanced treatment and reuse method of biochemical effluent from chemical wastewater

ActiveCN106882896BReduce iron ionsAchieve reductionWater/sewage treatment by irradiationWater treatment compoundsEcological safetyWastewater

The invention relates to a method for advanced treatment and reuse of chemical wastewater biochemical effluent, comprising the following steps: (1) preparing high-loaded Fe by spray suspension polymerization 3 O 4 (2) Utilize the magnetic resin prepared in step (1) to carry out advanced treatment to the chemical wastewater biochemical effluent, and add 3~5mmol / L H in the chemical wastewater biochemical effluent 2 O 2 , mixed reaction, and the reaction time is 60 to 600 minutes; (3) the mixed wastewater treated in step (2) is first subjected to solid-liquid separation, and then the separated chemical wastewater biochemical effluent is disinfected. The advanced treatment and reuse method of chemical wastewater and biochemical effluent provided in the above technical scheme can effectively remove refractory organic pollutants in wastewater and reduce their toxicity, meet the requirements of water quality standards for reuse, and can ensure ecological protection during the reuse process. Safety.

Owner:NANJING UNIV +1

Die-bonding method and spraying device for LED

ActiveUS11417795B2Improve luminous efficiencyBlocking phenomenonSemiconductor/solid-state device detailsSolid-state devicesWaferingSolder paste

A die-bonding method and a spraying device for an LED include: providing a substrate provided with a pad and a white oil layer covering wiring, placing a steel mesh on the substrate, and then spraying suspension containing solder paste on the pad by the spraying device, to form a solder paste film layer. Finally, a reflow process for the solder is performed. The solder paste is prepared on the pad by spraying, so that a crystal wafer is prevented from being tilted or short-circuited due to pulling or dragging of the solder paste during the reflow process for the solder, thereby improving uneven brightness of the surface light source.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

3D spray suspension projection imaging equipment with good waterproof performance

The invention discloses 3D spray suspension projection imaging equipment with a good waterproof performance. The equipment comprises an equipment housing and a projection lamp, and a protection coveris arranged on the equipment housing. Heat dissipation openings are formed in the top end of the equipment housing. A protection net is arranged at the top end of the equipment housing and located between the heat dissipation openings. A cooling fan is arranged in the protection net in the equipment housing, and a lens cone is arranged at the front end of the equipment housing. The projection lampis arranged in the lens cone, and a level is arranged at the rear end of the equipment housing. An adjusting device is arranged at the bottom end of the equipment housing, and a fixing rod is arranged on the adjusting device. According to the invention, the protection cover can prevent water mist from entering the equipment, so the equipment has a better waterproof function; the level can serve as a reference for adjusting a projector, and the adjusting device can flexibly adjust the projection equipment at multiple angles.

Owner:甘肃修森网络信息科技有限公司

3D spraying suspension projection spraying device convenient to install

The invention discloses a 3D spraying suspension projection spraying device convenient to install, which comprises a high-pressure pump box, two groups of adjusting rotating shafts, a fixed rotating shaft, a supporting plate and an adjusting screw rod, wherein a control panel and a power supply slot are installed on the end face of the high-pressure pump box; the power supply slot is positioned below the control panel; a heat dissipation window and a heat dissipation box are arranged on one side of the high-pressure pump box; the heat dissipation box covers the heat dissipation window; a waterstorage tank is installed at the rear end of the high-pressure pump box; and a water inlet pipe is installed at the rear end of the water storage tank. The 3D spraying suspension projection sprayingdevice convenient to install can be conveniently installed and used, the heat dissipation speed of the high-pressure pump box can be increased, the situation that the internal structure of the 3D spraying suspension projection spraying device is heated and damaged due to slow heat dissipation is avoided, mist can be prevented from being mixed with dust in the spraying process, and the dust is prevented from influencing the using effect of the 3D spraying suspension projection.

Owner:甘肃修森网络信息科技有限公司

Method for covering surface of food ware with lyophobic macromolecule metal composite skin film

ActiveCN109807042AEasy to cleanImprove overall performancePretreated surfacesSpecial surfacesBearing surfaceSpray Suspension

The invention relates to a method for covering the surface of food ware with a lyophobic macromolecule metal composite skin film. The method comprises the following steps that a, preparation is made,and the treated food ware, a specific amount of polytetrafluoroethylene solution and a specific amount of aluminum-base intermetallic compound powder are provided; b, stirring and mixing are carried out, and the polytetrafluoroethylene solution and the aluminum-base intermetallic compound powder are stirred and mixed to form spraying suspension liquid; c, spraying is carried out, the spraying suspension liquid is sprayed to the surface of the food ware, and thus at least one coating is formed on the surface of the food ware; and d, forming and curing are carried out, and the coating of the food ware is heated and cured to form the lyophobic macromolecule metal composite skin film. According to the method for covering the surface of food ware with the lyophobic macromolecule metal compositeskin film, the bearing surface of the food ware has multiple characteristics of having high hydrophobicity, high viscosity resisting performance, better surface abrasion resisting ability and the like.

Owner:SAN NENG BAKE WARE WUXI

Underwater waterproof socket

InactiveCN114865372ASuperhydrophobicAvoid enteringCouplings bases/casesVehicular energy storagePolymer scienceNanofiber

The invention discloses an underwater waterproof socket, which comprises a plug box and a plug, and is characterized in that the plug comprises pins and insulating rubber; the insertion box is provided with an insertion hole and an external power line, and the insertion hole is composed of a sealing ring, a hydrophobic insertion hole and multiple layers of hydrophobic nanofibers; the multiple layers of hydrophobic nanofibers are arranged in the hydrophobic insertion holes, and the super-hydrophobic nanofibers are formed by spraying suspension liquid containing SiO2-NPs and hydrophobic compound isocyanate on the surface of the cotton fiber base material. The invention has the following beneficial effects: the nanofiber material has super-hydrophobicity and can prevent moisture in the external environment from entering the insertion box; and meanwhile, the nanofiber also has a sealing effect, so that water is prevented from entering the insertion box.

Owner:HUBEI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com