Die-bonding method and spraying device for LED

a spraying device and die-bonding technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical devices, etc., can solve the problems of deteriorating surface light mixing uniformity and tilting of solid-state wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

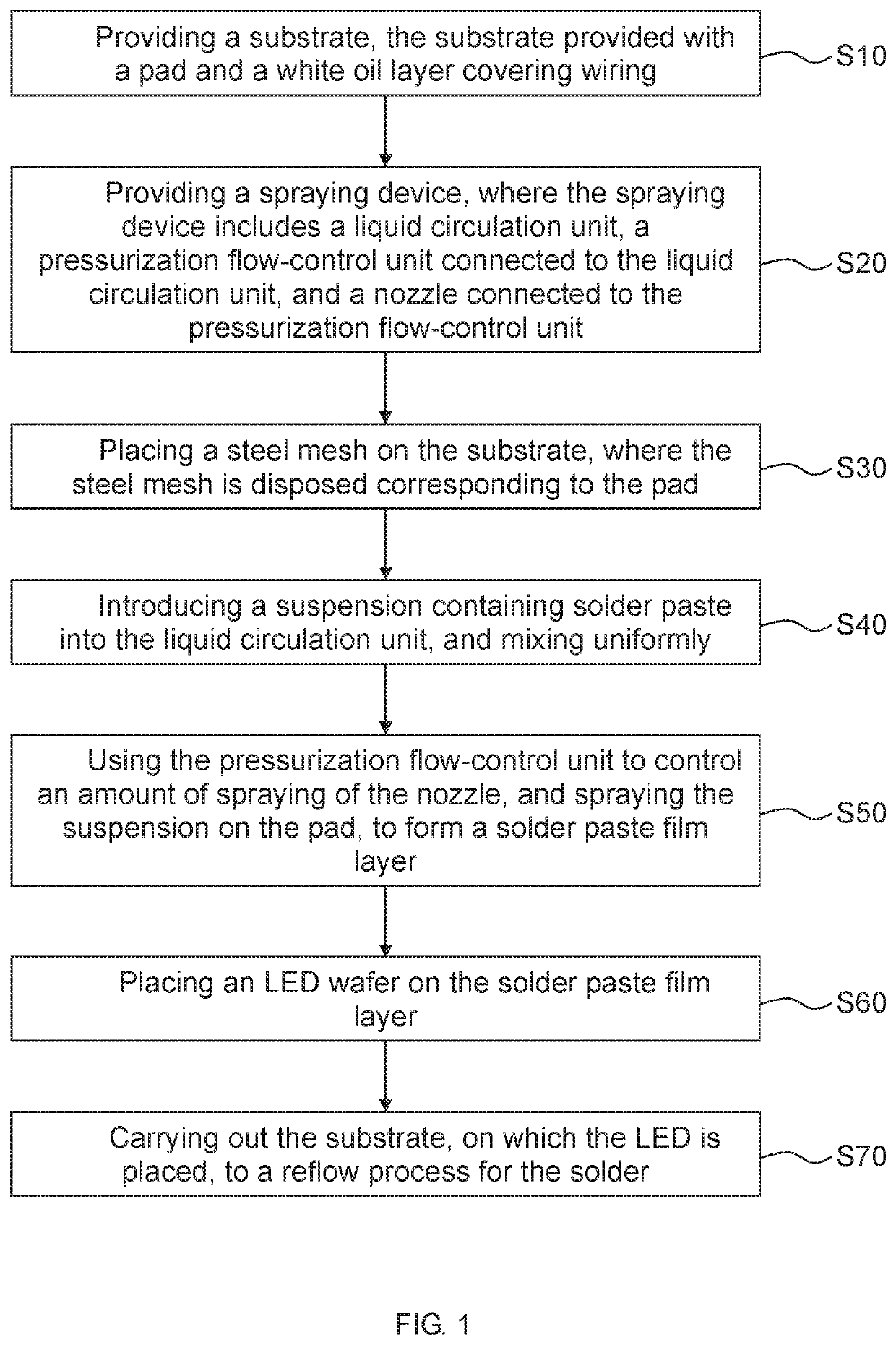

[0053]The following description of the embodiments is with reference to the drawings and is provided to illustrate the specific embodiments of the invention. The directional terms mentioned in the present invention, such as ‘upper’, ‘lower’, ‘front’, ‘back’, ‘left’, ‘right’, ‘top’, ‘bottom’, etc., are only the directions in the drawings. Therefore, the directional terminology used is for the purpose of illustration and understanding of the invention rather than limiting the invention. In the figures, structurally similar elements are denoted by the same reference numerals.

[0054]The invention is directed to the technical problem of the existing die-bonding method for the LED as follows: Due to the solder paste brushing / coating method used for soldering the LED to the pad, the crystal wafer tilts due to pulling and dragging of the solder paste during the subsequent reflow process for the solder; thereby, the light-emitting direction of the wafer is changed, and the uniformity of light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vertical distance | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| boiling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com