Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Sodium complex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis method of hydroquinone

InactiveCN102351656BMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Angiotensin receptor antagonist and creatine phosphate sodium complex and uses thereof

ActiveCN106474479AGood treatment effectStable in natureMetabolism disorderGroup 5/15 element organic compoundsTasosartanValsartan

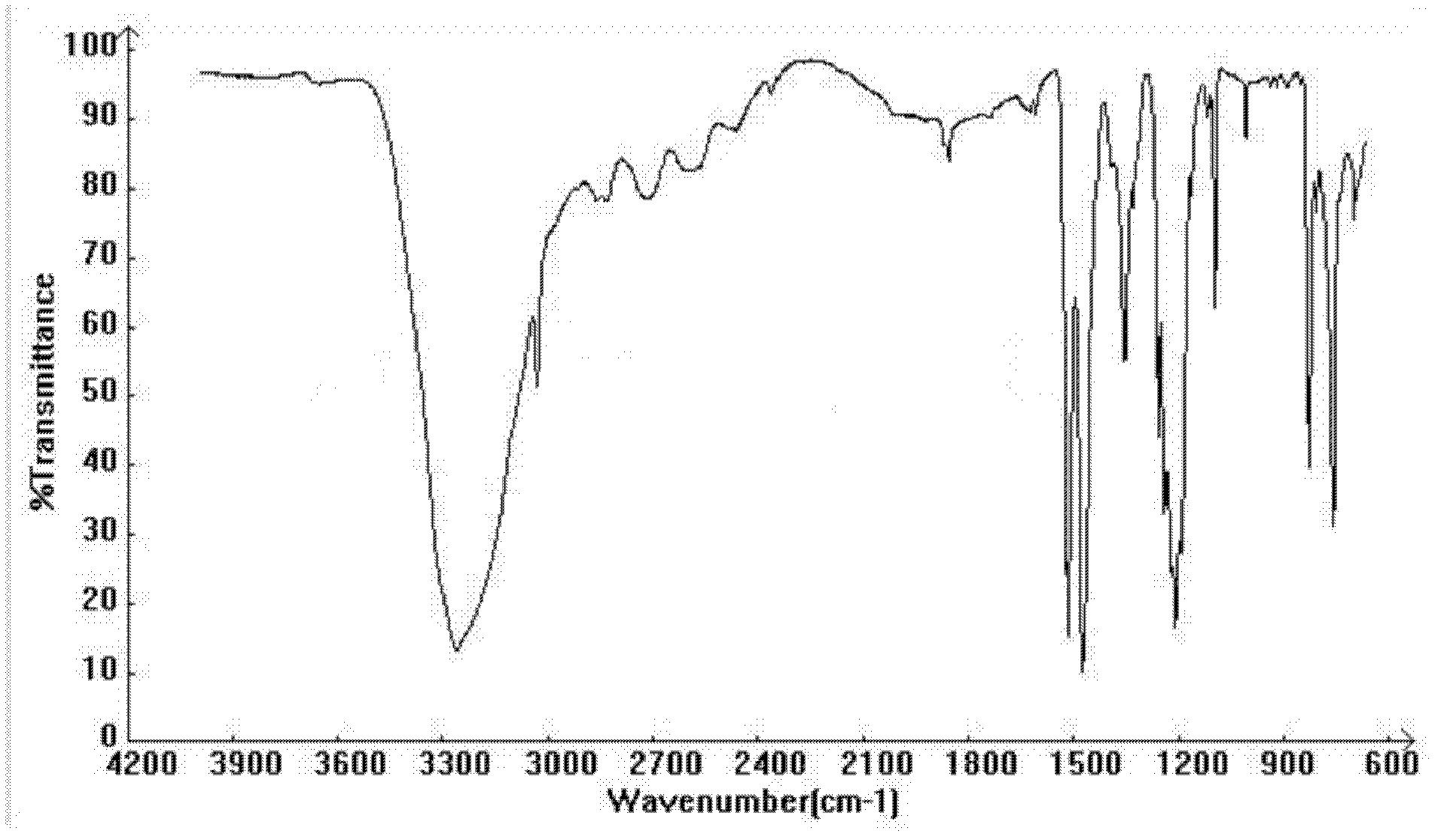

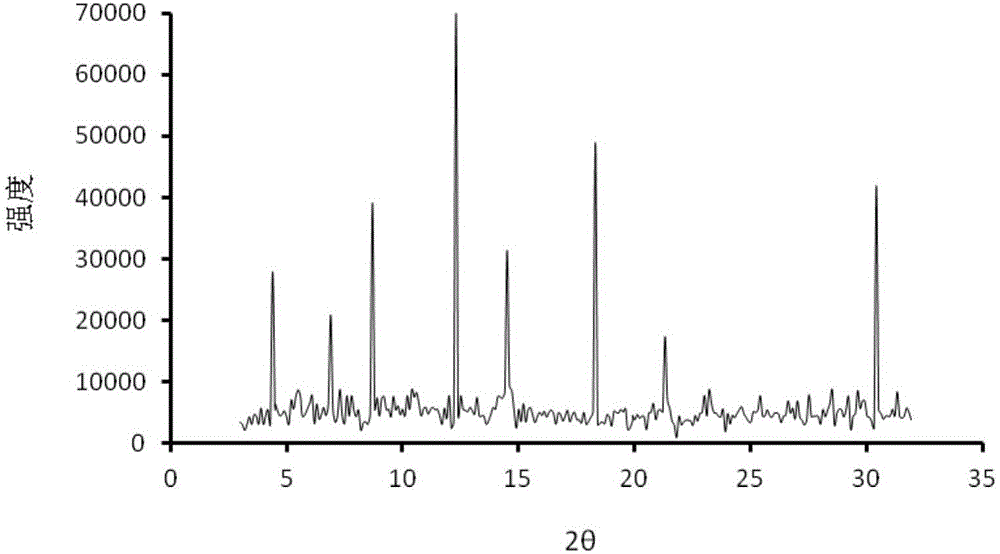

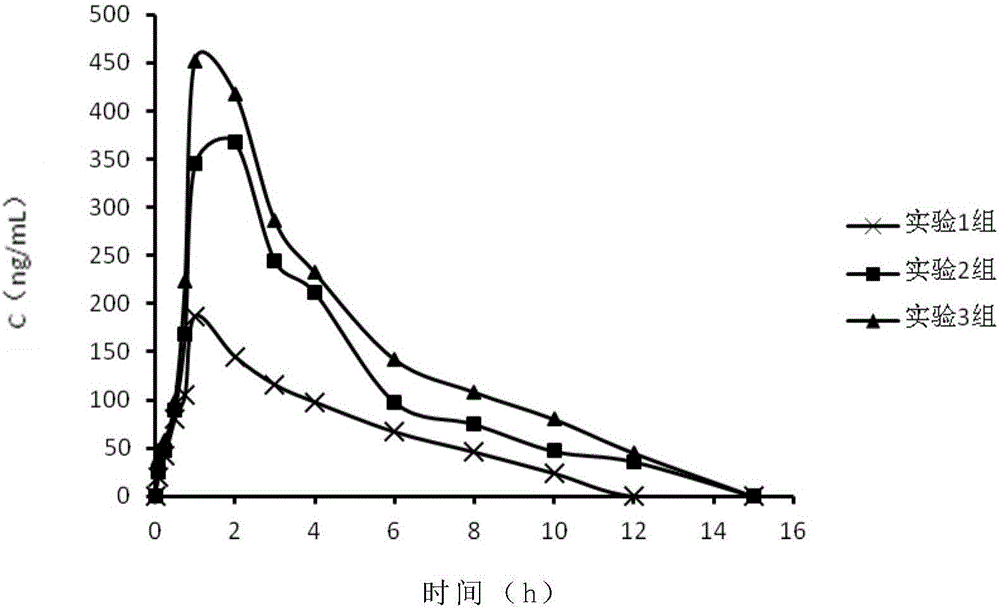

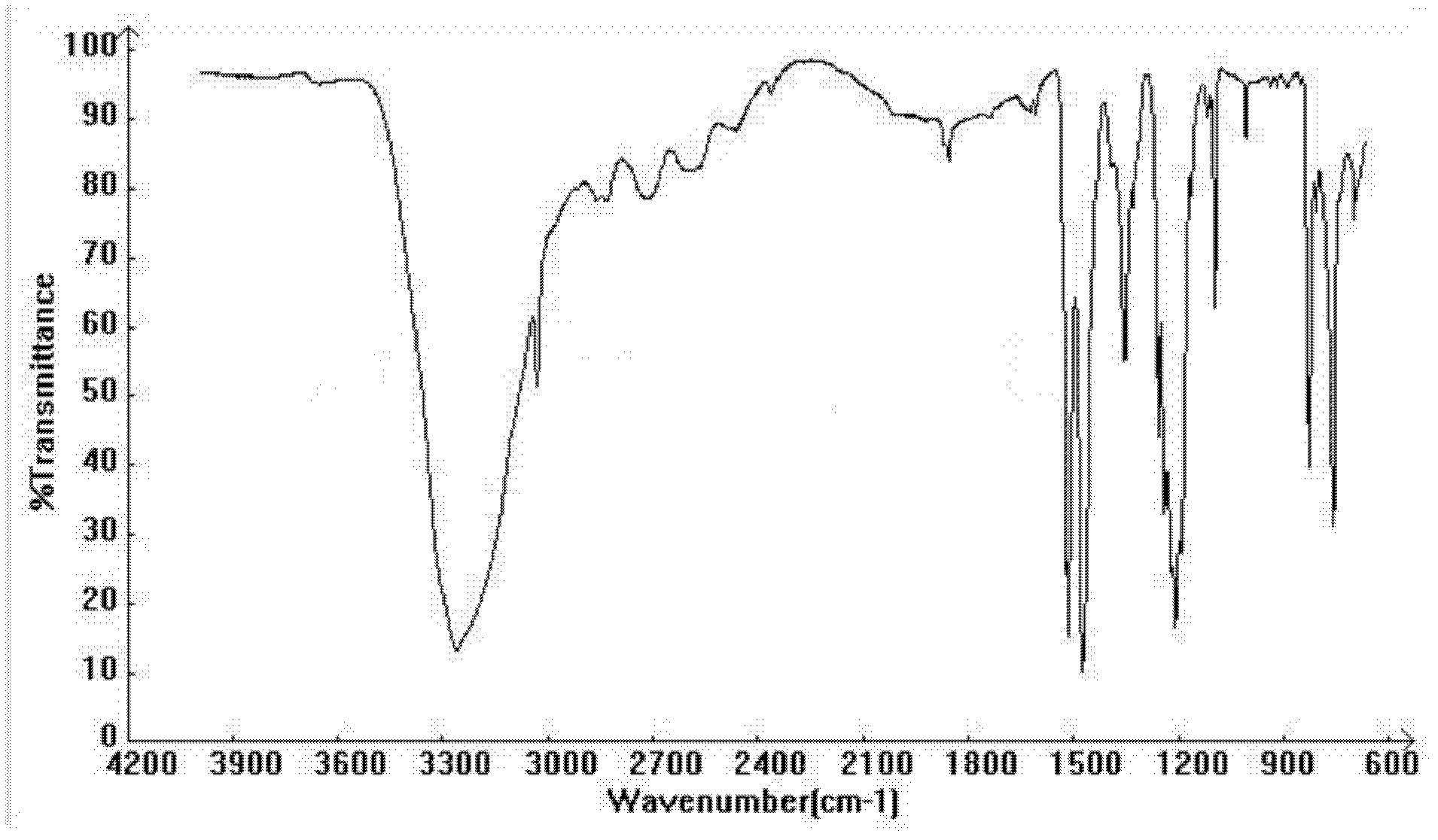

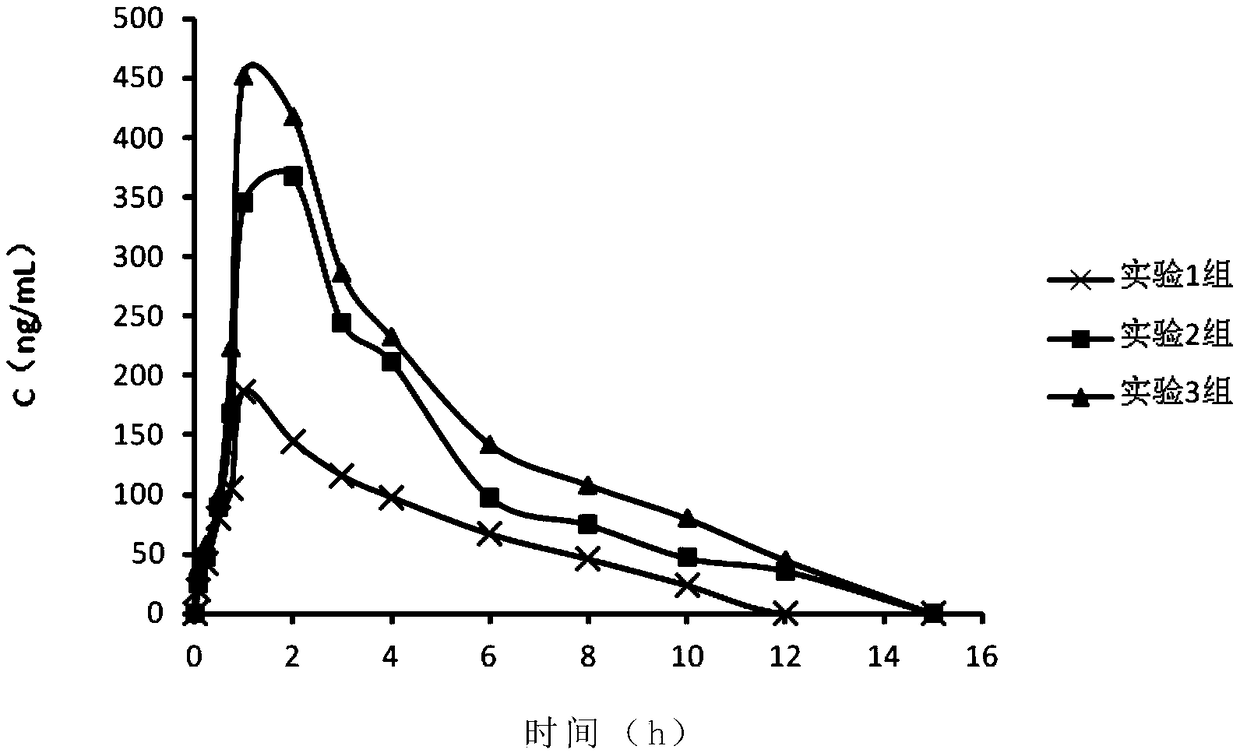

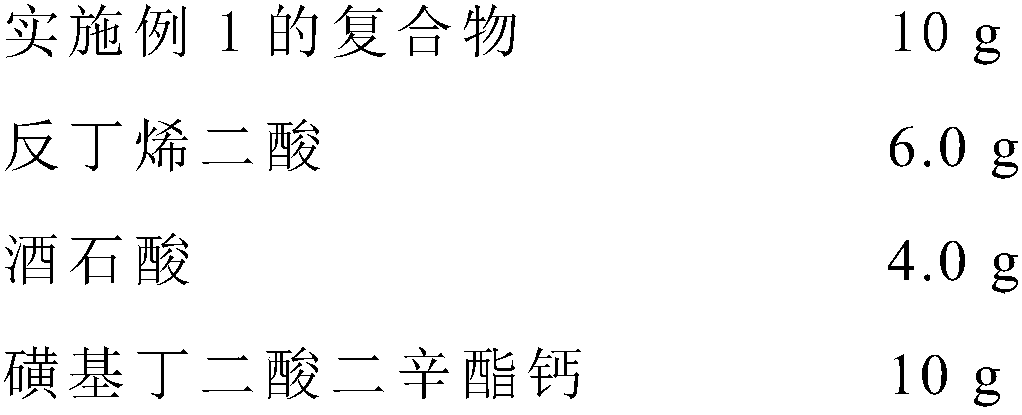

The present invention provides a an angiotensin receptor antagonist and creatine phosphate sodium complex and uses thereof, wherein the complex comprises an angiotensin receptor antagonist and creatine phosphate sodium, a molar ratio of the angiotensin receptor antagonist to the creatine phosphate sodium is 1:1-2, and the angiotensin receptor antagonist is selected from valsartan, losartan, irbesartan, telmisartan, eprosartan, candesartan, olmesartan, saprisartan, tasosartan, and elisartan. According to the present invention, the complex is formed by compounding the angiotensin receptor antagonist and the creatine phosphate sodium, and provides the unexpected double effect and the synergistic effect for treatment of heart failure and high blood pressure, the cocrystallization salt hydrate formed by linking the hydrogen bond has the stable characteristic, the pharmacokinetic property is significantly provided, and the positive application prospects are provided in the fields of anti-high blood pressure treatment and anti-heart failure treatment.

Owner:珠海赛隆药业股份有限公司(长沙)医药研发中心

Synthesis method of hydroquinone

InactiveCN102351656AMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

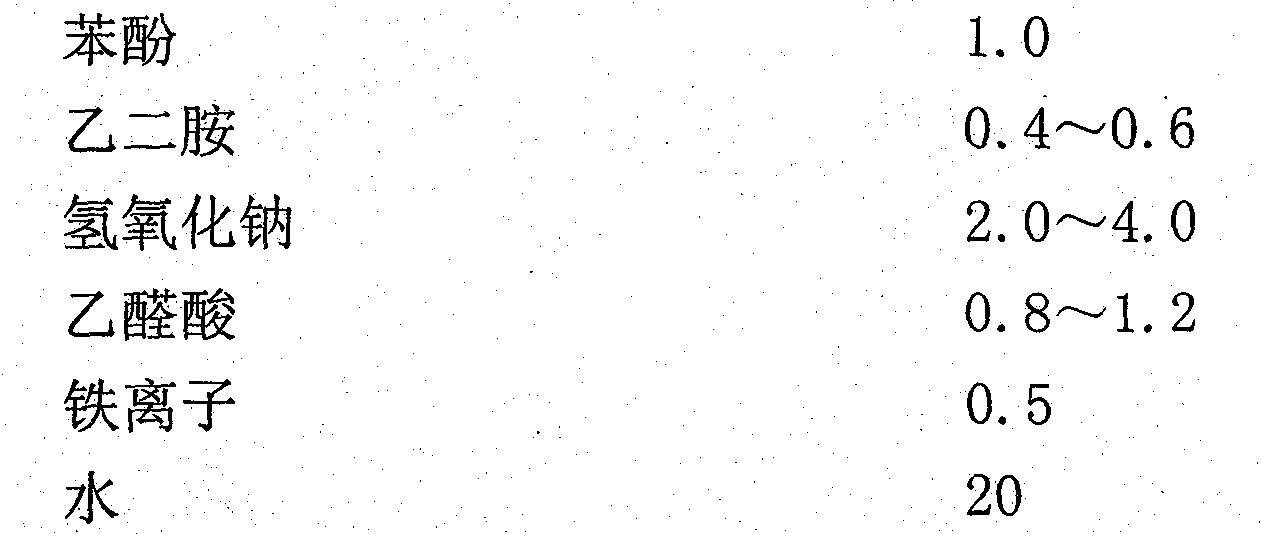

Production process for synthetizing EDDHA (Ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex) Ferrochel with one-step method

InactiveCN102050753AShort processHigh yieldOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineWater insoluble

The invention provides a production process for synthetizing EDDHA Ferrochel with a one-step method, comprising the following process steps of: weighing the following raw material components in the molar ratio: 1.0% of phenol, 0.4-0.6% of quadrol, 2.0-4.0% of sodium hydroxide, 0.8-1.2% of glyoxylic acid, 0.5% of iron ion and 20% of water; firstly, synthetizing EDDHA aqueous solution; then reacting with ferric salt to synthetizing EDDHA Ferrochel solution; and drying to finally obtain the EDDHA Ferrochel. The production process has the advantages of short process flow, high yield, low production cost, no pollution and low energy consumption and does not need organic solvent. The iron content of the EDDHA Ferrochel is more than 7%, when the EDDHA Ferrochel is dissolved in water, the content of the water insoluble is less than 0.1%, and EDDHA Ferrochel is stable when PH is between 3 and 10. The EDDHA Ferrochel is mainly used as fertilizer.

Owner:SICHUAN TONGFENG TECH

Fruit and vegetable nutrient solution

InactiveCN108033842AFull of nutritionPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserContinuous croppingPhosphate

The invention discloses a fruit and vegetable nutrient solution. The fruit and vegetable nutrient solution comprises a solution A and a solution B, wherein the solution A mainly consists of the following components: calcium nitrate, potassium nitrate, ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex (EDDHA-Fe), ethylene diamine tetraacetic acid disodium ferric salt (EDTA-Fe); and the solution B mainly consists of the following components: magnesium sulfate heptahydrate, potassium sulfate, potassium dihydrogen phosphate, manganese sulfate tetrahydrate, boric acid, zincsulfate heptahydrate, copper sulphate pentahydrate, and ammonium molybdate. The fruit and vegetable nutrient solution is rich in nutrients, does not contain harmful substances, promotes crop growth,is suitable for hydroponic and substrate culture, and is suitable for large-scale popularization; and the culture solution and matrix of the nutrient solution are easy to renew, and pathogenic bacteria are also easy to remove, so that disease and pest control and soil disinfection are almost not needed, and continuous cropping obstacle can be avoided.

Owner:贵州华以农业科技有限公司

Preparation method of polyamide reverse osmosis membrane containing amphoteric carboxymethylcellulose sodium complex

ActiveCN104028118BImprove transmission efficiencyImprove hydrophilicitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisInorganic saltsCarboxymethyl cellulose

The invention discloses a preparation method of a polyamide reverse osmosis membrane containing an amphoteric carboxymethylcellulose sodium complex. The preparation method comprises the steps: firstly, preparing an amphoteric cationic polymer by a free radical polymerization method, then preparing an amphoteric carboxymethylcellulose sodium complex by an ionic crosslinking method, adding the amphoteric carboxymethylcellulose sodium complex into an aqueous phase monomer solution for preparing a polyamide membrane, and thus obtaining the polyamide reverse osmosis membrane containing the amphoteric carboxymethylcellulose sodium complex through an interfacial polymerization method. With utilization of good hydrophilicity, contamination resistance and a unique nanoparticle structure of the amphoteric carboxymethylcellulose sodium complex, the water permeation flux and contamination resistance of the membrane are greatly improved while the high salt interception rate of the polyamide membrane on an inorganic salt is kept. Under an operating pressure of 1.5 MPa at the temperature of 25 DEG C, the interception rate of the reverse osmosis membrane on NaCl is more than 97%, and the water permeation flux is more than 30 L.m<-2>.h<-1>. Therefore, the prepared polyamide reverse osmosis membrane containing the amphoteric carboxymethylcellulose sodium complex has high salt interception rate, water permeability and contamination resistance.

Owner:ZHEJIANG UNIV

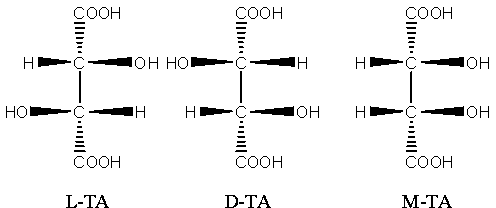

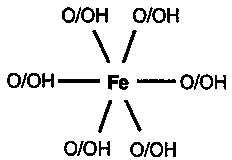

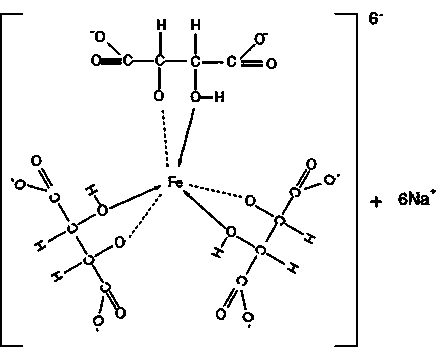

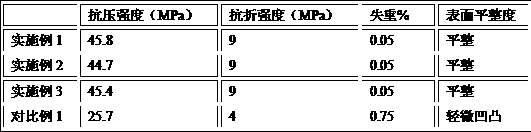

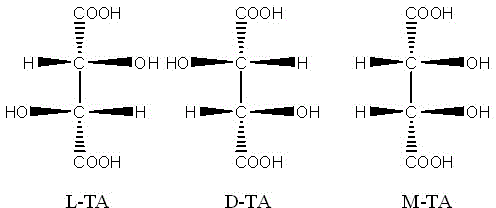

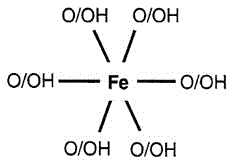

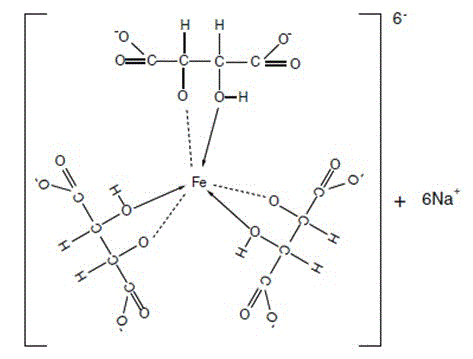

Preparation method of iron-tartaric acid-sodium complex

ActiveCN103382151AEasy to prepareMild reaction conditionsCarboxylic acid salt preparationAcid concentrationRoom temperature

The invention discloses a preparation method of an iron-tartaric acid-sodium complex. The preparation method comprises following steps: (1) water and dextrotartaric acid are added into a high-pressure reaction vessel, wherein the dextrotartaric acid concentration of the solution is more than 5 wt%; the solution is stirred, heated to 155 to 175 DEG C, and reacted for 8 to 48h at the temperature of 155 to 175 DEG C; (2) the contents of the ingredients in the high-pressure reaction vessel are determined, and the reaction is stopped when more than 30 wt% of dextrotartaric acid is converted to mesotartaric acid; (3) the ingredients in the high-pressure reaction vessel are cooled to room temperature, and then the solution is discharged; (4) a solution containing Fe3<+> is added into the solution with stirring; and (5) a solution containing Na<+> is added into the solution with stirring, the mixture is stirred until appearance is clear, color is uniform, no precipitate is generated and no stratification is causes, and then the iron-tartaric acid-sodium complex is obtained. Reaction conditions of the preparation method are mild; the preparation method is simple; consumption of raw materials is less; no pollution is caused; the preparation method is suitable for industrial production; and the stability of the iron-tartaric acid-sodium complex is much higher than that of complex prepared by existing methods.

Owner:HUNAN XUETIAN FINE CHEM IND

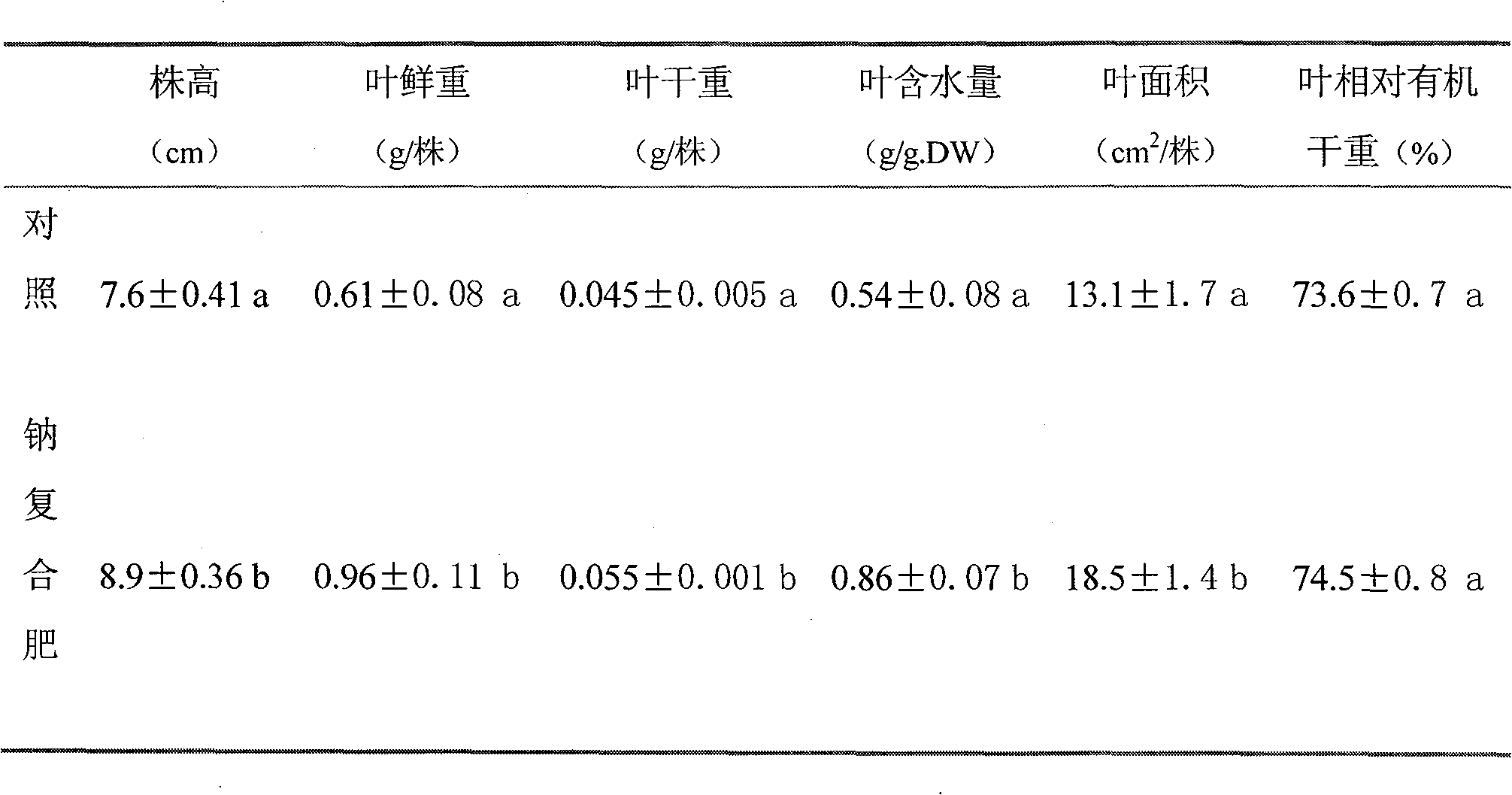

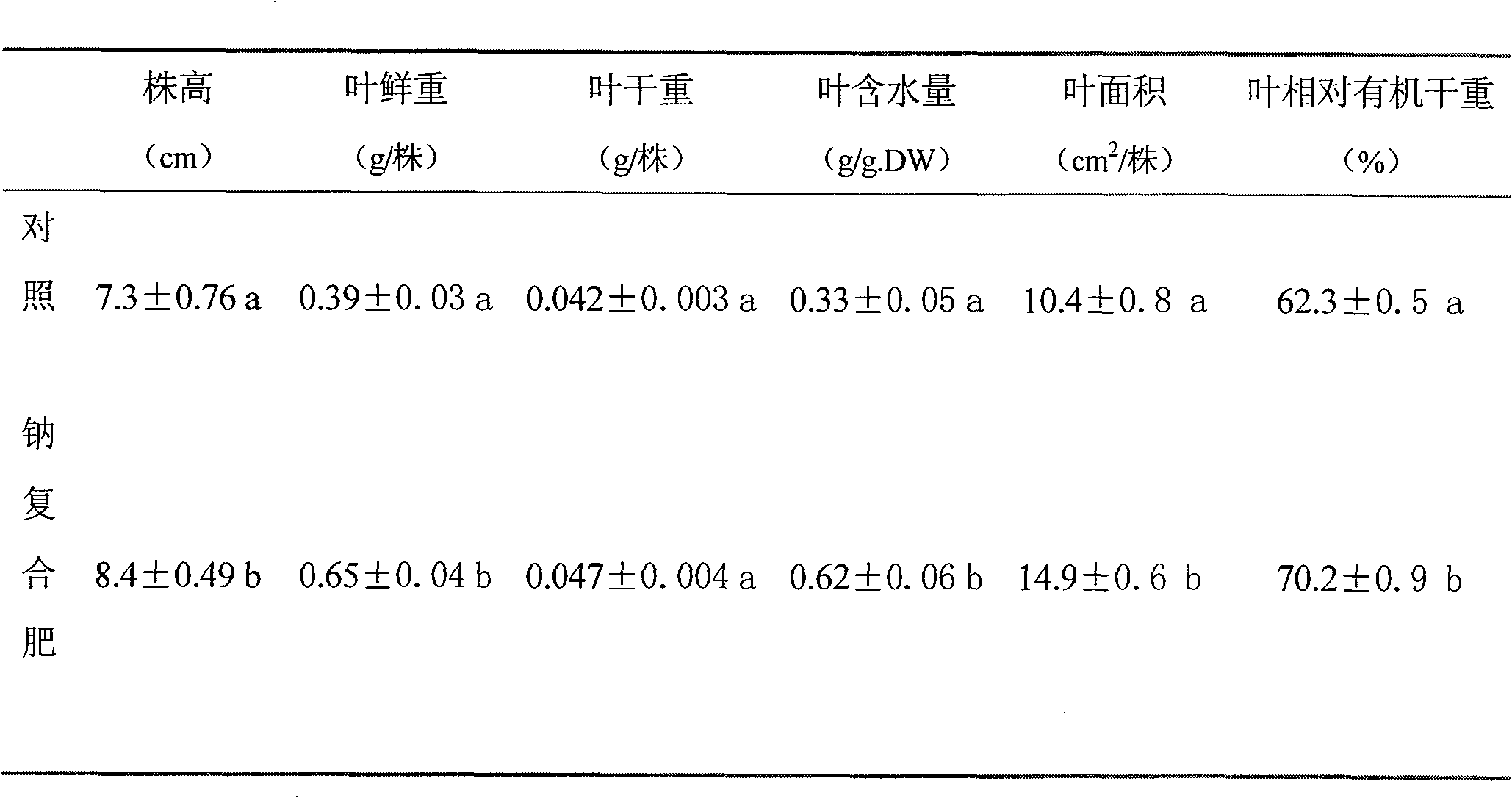

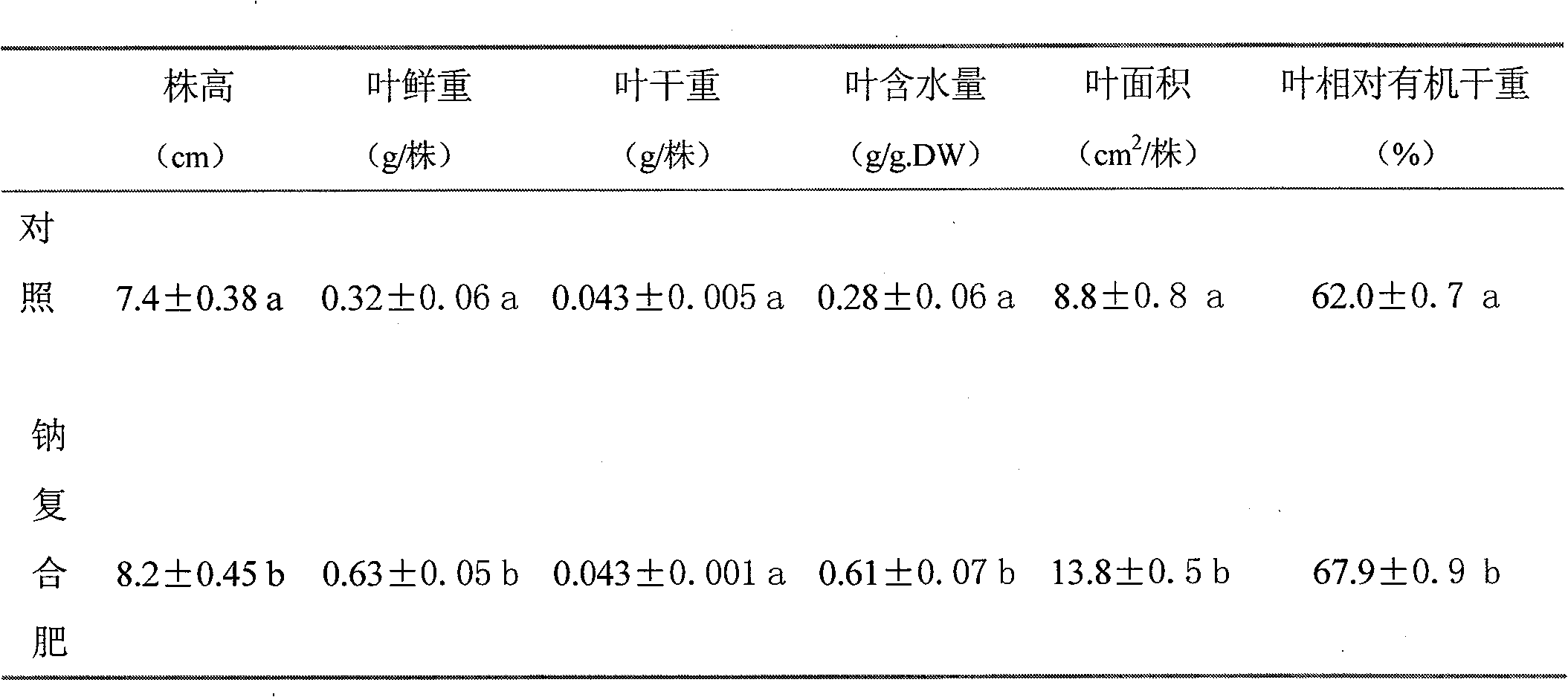

Sodium complex fertilizer, uses and employing method thereof

InactiveCN101172901APromote growthImprove stress resistanceNitrate fertilisersFertilizer mixturesPlant growthSodium nitrate

The invention mainly relates to a sodium compound fertilizer which can promote the growth of desert plants and improve their drought resistance and its application and application method. A sodium compound fertilizer is characterized by comprising the following raw materials by weight percentage: 0%-85% of sodium nitrate, 0%-22% of sodium dihydrogen phosphate, 0%-99% of sodium silicate, and 0% of sodium chloride -90%; the application of sodium compound fertilizer can be directly applied to vegetation in desert areas, or used for seedling raising of desert plants or in sand or hydroponics for desert plants; the application method of sodium compound fertilizer is sodium The amount of compound fertilizer applied to desert soil is 6kg-60kg per mu of land, or 0.2-3g of fertilizer is directly applied to 1kg of soil, or 0.2-3g of fertilizer is first dissolved in 0.05-0.3kg of water, and then The water-fertilizer mixture solution was applied to 1 kg of soil. By providing sodium compound fertilizers and their uses that can promote the growth of desert plants and improve their drought resistance, we can further expand the coverage of vegetation in desert areas, solve the problem of expanding desertification, and promote vegetation restoration and ecosystem reconstruction.

Owner:LANZHOU UNIVERSITY

Propylene glycol anhydrous type coolant

InactiveCN104830286AImprove stabilityImprove antifouling performanceHeat-exchange elementsAcetic acidDiethylenetriamine

The present invention discloses a propylene glycol anhydrous type coolant, which comprises the following raw materials by weight: 100 parts of 1,2-propylene glycol, 0.1-0.5 part of methyl benzotriazole, 0. 5-1.5 parts of polyaminoacid, 0.1-0.5 part of diethylenetriamine pentaacetic acid iron-sodium complex, 0.5-1.5 parts of sodium benzoate and 0.1-0.3 part of dimethicone. The propylene glycol anhydrous type coolant provided by the present invention has high stability, overcomes the technical defect of easy boiling of the traditional aqueous coolant, and helps the operation of engine at full load and high load.

Owner:山东中坤石油科技股份有限公司

Preparation method of automobile windshield cleaning agent

InactiveCN107723127AEfficient removalNo corrosionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPhosphatePotassium

The invention discloses a preparation method of an automobile windshield cleaning agent. Sodium, tripolyphosphate, ethanol, potassium sorbate, ethyl cellulose, 3-phosphoglyceric acid, anionic surfactant 1, sodium tripolyphosphate, nonionic surfactant 1, isopropanol and nano titanium sol were mixed and Stir evenly, and then use an emulsifier to mix at high speed. The beneficial effects of the present invention are: the present invention can effectively remove the stains on the windshield, and it has the advantages of strong cleaning ability, short cleaning time, no corrosion to the base material, no stimulation to the human body, no trace left after use, etc., and It can form a protective film on the outer surface of the windshield to prevent dust accumulation and prevent water stains from remaining for a certain period of time.

Owner:成都凯斯恩科技有限公司

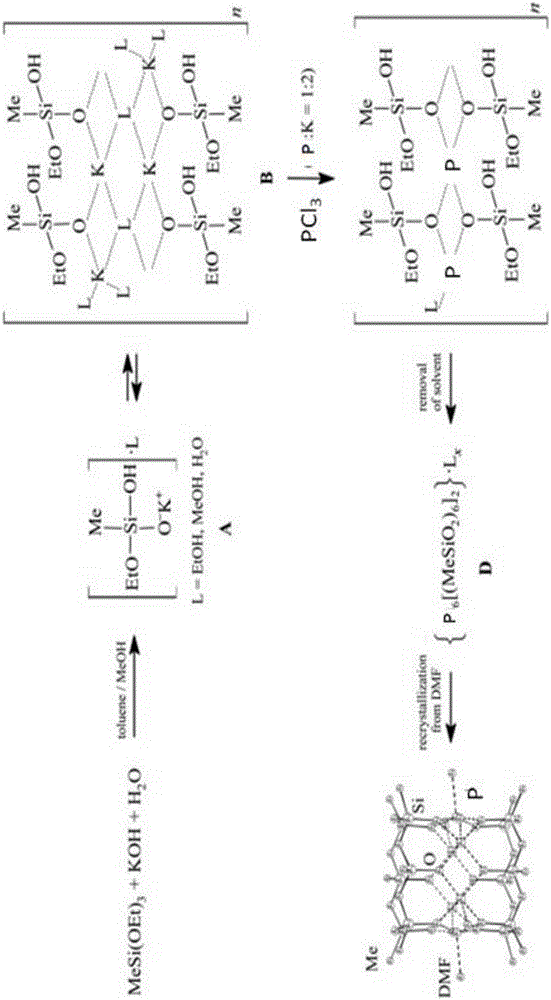

Preparation method of novel silicane fire retardant

InactiveCN105038819ANot generatedEasy to separatePhosphorus organic compoundsReaction temperaturePotassium hydroxide

The invention relates to a preparation method of novel silicane fire retardant. The method includes the following steps of firstly, dissolving siloxane in organic solvent with the siloxane as raw materials, adding a potassium hydroxide catalyst, and conducting heating reflux for 15-30 minutes after the mixture is stirred to be uniform so that sodium complex can be obtained; secondly, adding phosphorus trichloride for substitution after the phosphorus trichloride is slightly cooled, conducting reflux again for 25-40 minutes, and converting the phosphorus trichloride into phosphorus complex; thirdly, conducting filtering after cooling, cooling filtrate to -5 DEG C after the filtrate is concentrated, and generating white crystals; fourthly, flushing the white crystals obtained in the third step through methyl alcohol, placing the white crystals in a room-temperature vacuum oven to be dried for 0.6-1.5 hours, and obtaining the silicane fire retardant. Compared with the prior art, the reaction condition is gentle, the reaction temperature is moderate, the obtained finished product can be quite easily separated from a reaction system, the flame retardant property and the oxidation resistance can be effectively improved, and meanwhile the mechanics performance, the insulating performance and the heat resistance are not influenced.

Owner:SHANGHAI PUYANG NEW MATERIAL TECH CO LTD

Asphalt anti-aging agent applied to tropical coastal area and preparation method of asphalt anti-aging agent

The invention discloses an asphalt anti-aging agent applied to a tropical coastal area. The anti-aging agent has a good flame-retardant smoke-suppressing effect through combined interaction of micro-nano-sized brucite powder with raw vermiculite powder and flame-retardant polyamide 66 composite fiber in a combustion process, so that the flammability of asphalt is reduced effectively, and the safety of use and construction of asphalt pavements is improved; meanwhile, the impact of high temperature on asphalt can be reduced effectively through addition of the brucite powder and the flame-retardant polyamide 66 composite fiber, and corrosion of chloride ions and other inorganic salts in sea water to asphalt pavement materials can be resisted through addition of an iron diethylene triamine pentaacetate-sodium complex; and the anti-aging agent is obtained mainly through grinding of natural minerals, has no phosphorus, no halogen, no adverse effects on the environment, and has significant environment-friendly benefits.

Owner:山西云度知识产权服务有限公司

Asphalt aging inhibitor applied to northeast coastal areas, and preparation method thereof

InactiveCN109651828AImprove low temperature resistanceReduce flammabilityBuilding insulationsFiberPolyamide

The invention discloses an asphalt aging inhibitor applied to northeast coastal areas. The common action of propylene glycol, nano-scale spinel powder, raw vermiculite powder and flame-retardant polyamide 66 composite fibers achieves excellent flame retardation and smoke suppression effects in the combustion process, so the flammability of asphalt is effectively reduced, and the use safety and theconstruction safety of an asphalt pavement are improved; the addition of propylene glycol can improve the low temperature resistance of the aging inhibitor, and an added iron-sodium diethylenetriaminepentaacetate complex can resist the corrosion of chloride ions and other inorganic salts in seawater to the asphalt pavement; and the aging inhibitor is mainly prepared by grinding natural minerals,is free from phosphorus and halogen, has no adverse effects on the environment, and has a remarkable environmental protection benefit.

Owner:山西云度知识产权服务有限公司

A detergent for toilet disinfection

InactiveCN106566723AExcellent decontaminationImprove the bactericidal effectBiocideFungicidesSodium metasilicateSodium polymetaphosphate

A detergent for toilet disinfection is disclosed. The detergent comprises following components by mass: 5-7 parts of sodium metasilicate pentahydrate, 2-4 parts of oxalic acid, 3-4 parts of sodium hexametaphosphate, 5-7 parts of a sodium complex, 6-7 parts of sodium silicate, 9-11 parts of tea dregs, 4-8 parts of tri(propylene glycol) butyl ether, 6-10 parts of linseed oil, 6-8 parts of tri(propylene glycol) methyl ether, 4-6 parts of urea, and 1-2 parts of a brightening agent. The detergent is used for toilet cleaning, deodorizing and disinfection.

Owner:孙静

Preparation method of automobile cleaning agent

InactiveCN107828540AEfficient removalNo corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsTectorial membranePhosphate

The invention discloses a preparation method of an automobile cleaning agent, comprising preparing C8-10 fatty alcohol polyoxyethylene ether phosphoric acid monoester, diethylenetriaminepentaacetate iron-sodium complex, sodium dodecylbenzenesulfonate, three Polyphosphate, ethanol, potassium sorbate, ethyl cellulose, 3-phosphoglyceric acid, anionic surfactant 1, sodium tripolyphosphate, nonionic surfactant 1, isopropanol and nano-titanium sol are mixed and stirred evenly, Then use an emulsifier for high-speed shear mixing. The beneficial effects of the present invention are: the present invention can effectively remove the stains on the outer surface of the automobile, and it has the advantages of strong cleaning ability, short cleaning time, no corrosion to the substrate, no stimulation to the human body, no trace left after use, etc., and can Form a protective film on the outer surface of the car to prevent dust from accumulating for a certain period of time.

Owner:成都凯斯恩科技有限公司

Ceramic tile detergent

InactiveCN106753879APromote reductionExtended service lifeAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsTurpentineDiethylenetriamine

The invention relates to the field of detergents, in particular to a ceramic tile detergent which consists of the following substances in parts by weight: 6-12 parts of nitrilotriacetic acid trisodium salt, 15-20 parts of turpentine, 8-12 parts of propylene glycol monomethyl ether, 15-25 parts of a lacquer thinner, 15-25 parts of oxalic acid, 4-6 parts of 2-amino-2-methyl-1-propyl alcohol, 1-3 parts of lauryl sodium sulfate, 15-25 parts of citric acid, 5-10 parts of glycolic acid, 2-3 parts of coconut fatty acid diethanol amine, 2-5 parts of polyoxyethylene fatty acid, 15-20 parts of hydroxyethyl cellulose, 1-2 parts of a diethylenetriamine pentaacetic acid iron-sodium complex, 5-8 parts of a waterproof agent, 3-5 parts of a corrosion inhibitor, 5-8 parts of perfume and 50-60 parts of water. The ceramic tile detergent provided by the invention is thorough in washing, the original feature of a ceramic tile can be rapidly recovered, a surface protection agent is available, a layer of a protection membrane is generated on the surface of the ceramic tile, due to addition of the waterproof agent, the phenomenon of slipping can be effectively avoided after the ceramic tile is washed, and due to addition of the corrosion inhibitor, the service life of the ceramic tile can be prolonged.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Preparation method of iron-tartaric acid-sodium complex

ActiveCN103382151BEasy to prepareMild reaction conditionsCarboxylic acid salt preparationAcid concentrationRoom temperature

The invention discloses a preparation method of an iron-tartaric acid-sodium complex. The preparation method comprises following steps: (1) water and dextrotartaric acid are added into a high-pressure reaction vessel, wherein the dextrotartaric acid concentration of the solution is more than 5 wt%; the solution is stirred, heated to 155 to 175 DEG C, and reacted for 8 to 48h at the temperature of 155 to 175 DEG C; (2) the contents of the ingredients in the high-pressure reaction vessel are determined, and the reaction is stopped when more than 30 wt% of dextrotartaric acid is converted to mesotartaric acid; (3) the ingredients in the high-pressure reaction vessel are cooled to room temperature, and then the solution is discharged; (4) a solution containing Fe3<+> is added into the solution with stirring; and (5) a solution containing Na<+> is added into the solution with stirring, the mixture is stirred until appearance is clear, color is uniform, no precipitate is generated and no stratification is causes, and then the iron-tartaric acid-sodium complex is obtained. Reaction conditions of the preparation method are mild; the preparation method is simple; consumption of raw materials is less; no pollution is caused; the preparation method is suitable for industrial production; and the stability of the iron-tartaric acid-sodium complex is much higher than that of complex prepared by existing methods.

Owner:HUNAN XUETIAN FINE CHEM IND

Sodium complex fertilizer, uses and employing method thereof

InactiveCN101172901BPromote growthImprove stress resistanceNitrate fertilisersFertilizer mixturesVegetation coverSodium silicate

The invention relates to sodium composite fertilizer which can promote the growth of desert plants and increase the drought resistance performance of the desert plants, as well as the application and the fertilizing method thereof. The sodium composite fertilizer is characterized in that the fertilizer consists of the raw materials as follow in weight percent: 0 to 85 percent of sodium nitrate, 0to 22 percent of monobasic sodium phosphate, 0 to 99 percent of sodium silicate, and 0 to 90 percent of sodium chloride. The application of sodium composite fertilizer is that the sodium composite fertilizer can be directly fertilized in plants grown in desert areas or can be used for seeding the desert plants or can be used in the sand cultivation or water cultivation of the desert plants. The sodium composite fertilizer has the fertilizing method that the sodium composite fertilizer is fertilized into the desert soil with 6 kg to 60 kg for one acre, or 0.2 to 3 g of fertilizer is directly fertilized into 1 kg of the soil, or 0.2 to 3 g fertilizer is firstly dissolved with water, and the water-fertilizer mixed solution is fertilized into 1 kg of the soil. The invention has the advantagesof further expanding the vegetation-covered areas of desert areas by providing the sodium composite fertilizer which can promote the growth of the desert plants and increase the drought resistance performance of the desert plants, as well as the application thereof, thereby solving the problem of continuously expanding desertification, and promoting the recovery of the plants and the reestablishment of the ecological system.

Owner:LANZHOU UNIVERSITY

Propylene Glycol Anhydrous Coolant

InactiveCN104830286BImprove stabilityImprove antifouling performanceHeat-exchange elementsDiethylenetriamineBenzotriazole

The present invention discloses a propylene glycol anhydrous type coolant, which comprises the following raw materials by weight: 100 parts of 1,2-propylene glycol, 0.1-0.5 part of methyl benzotriazole, 0. 5-1.5 parts of polyaminoacid, 0.1-0.5 part of diethylenetriamine pentaacetic acid iron-sodium complex, 0.5-1.5 parts of sodium benzoate and 0.1-0.3 part of dimethicone. The propylene glycol anhydrous type coolant provided by the present invention has high stability, overcomes the technical defect of easy boiling of the traditional aqueous coolant, and helps the operation of engine at full load and high load.

Owner:山东中坤石油科技股份有限公司

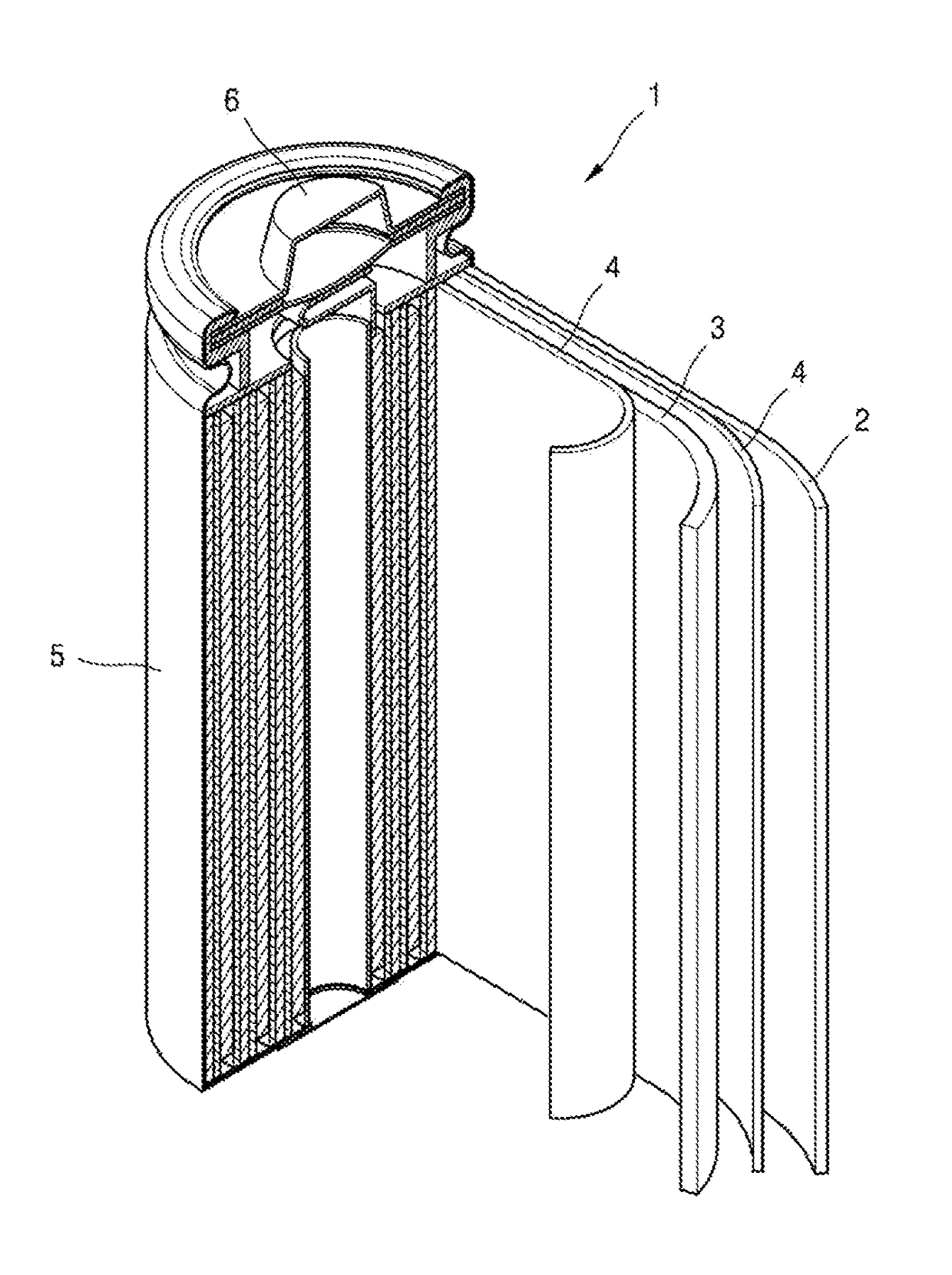

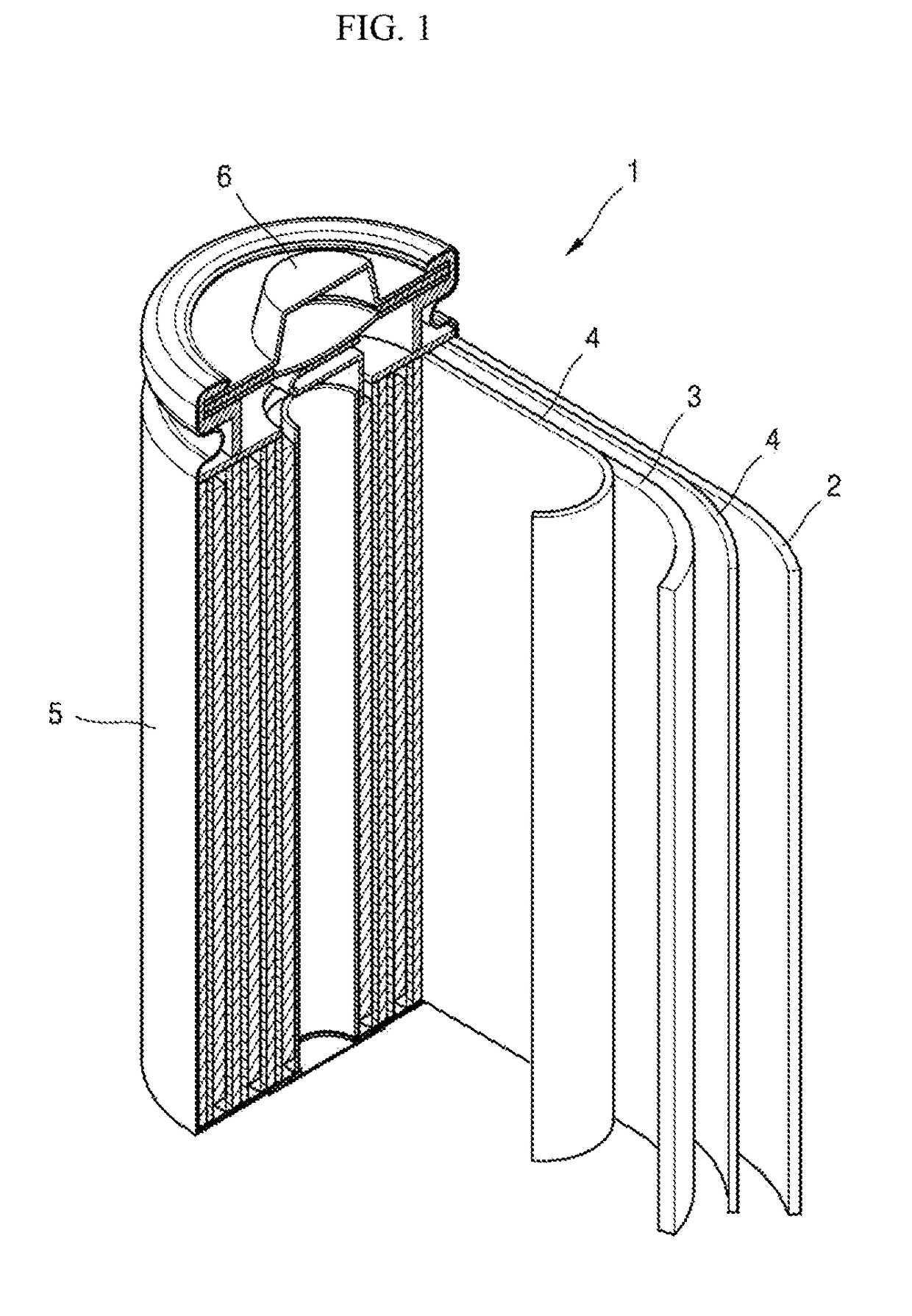

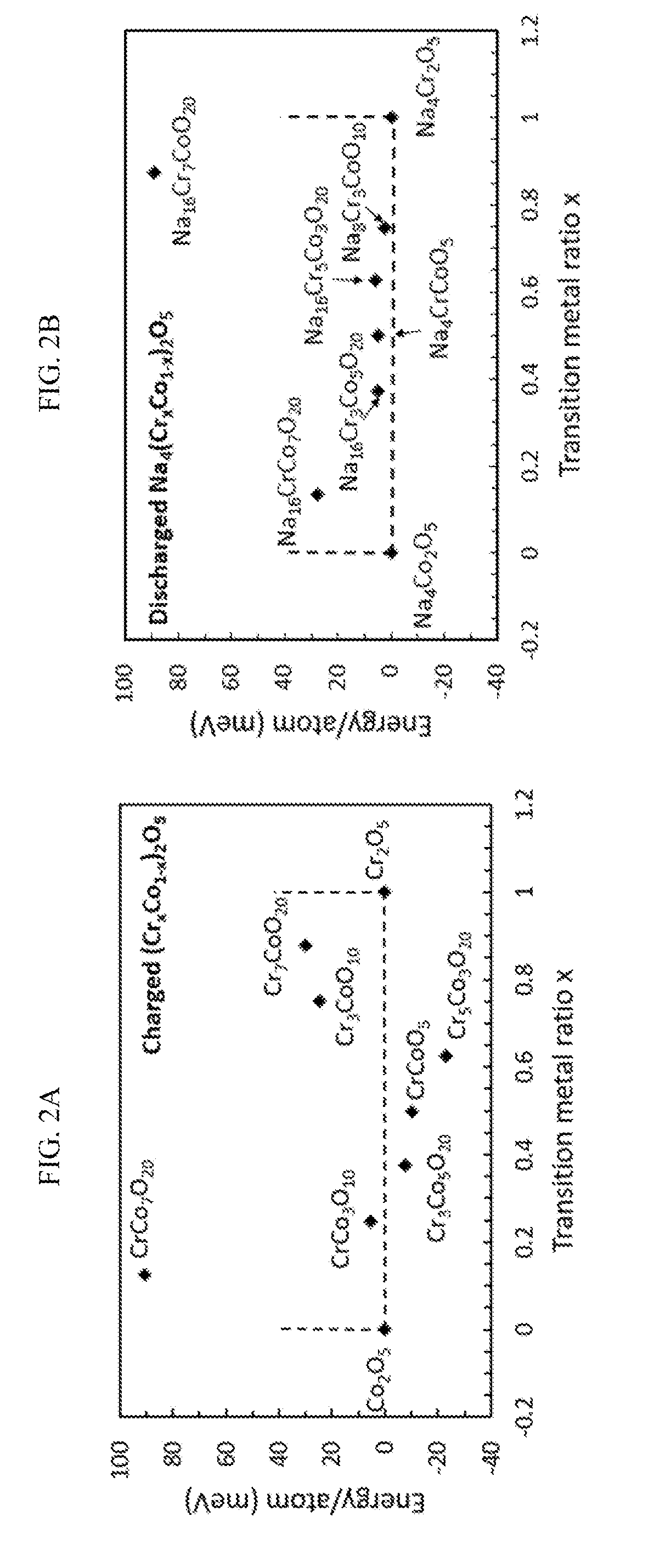

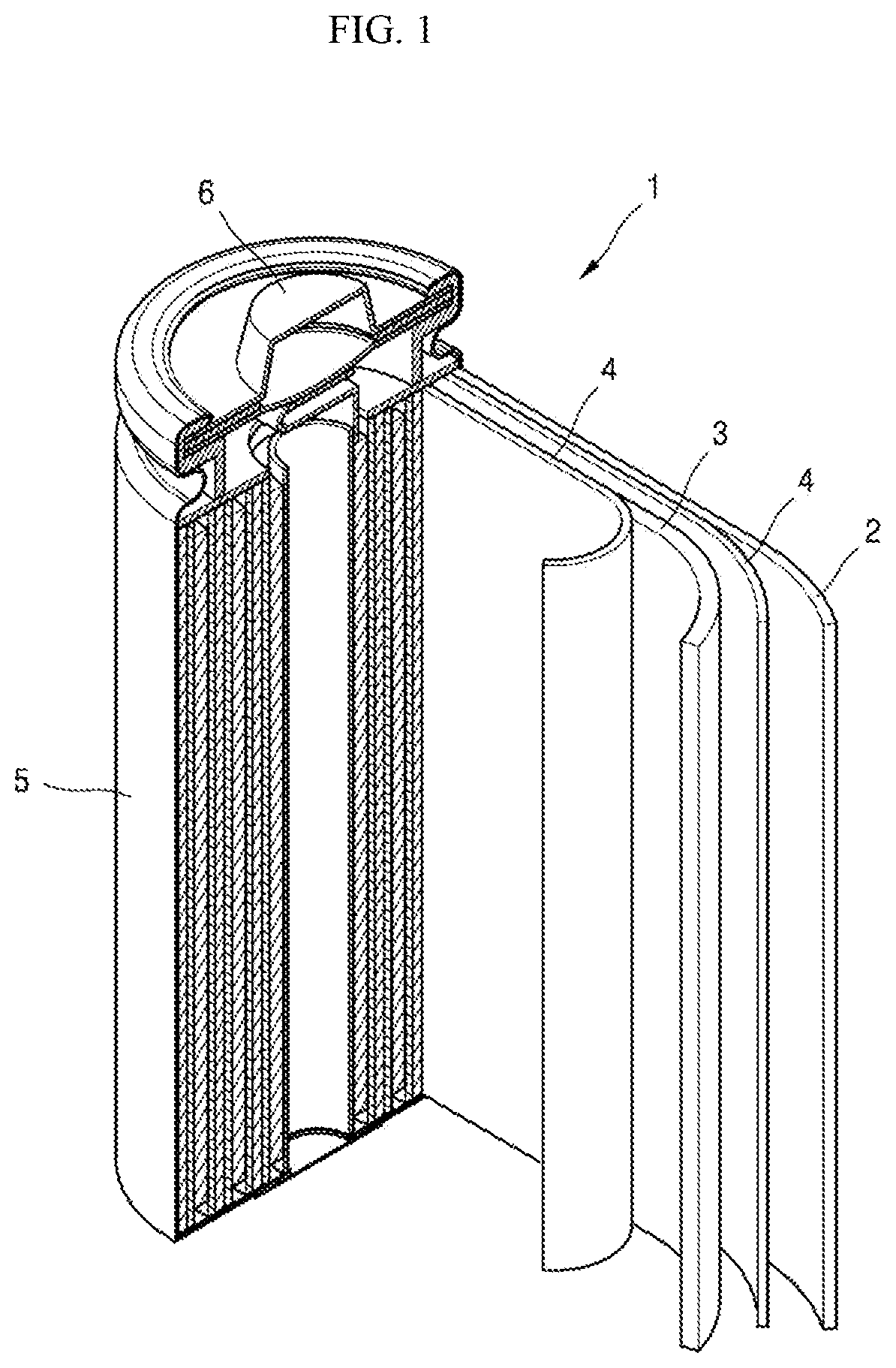

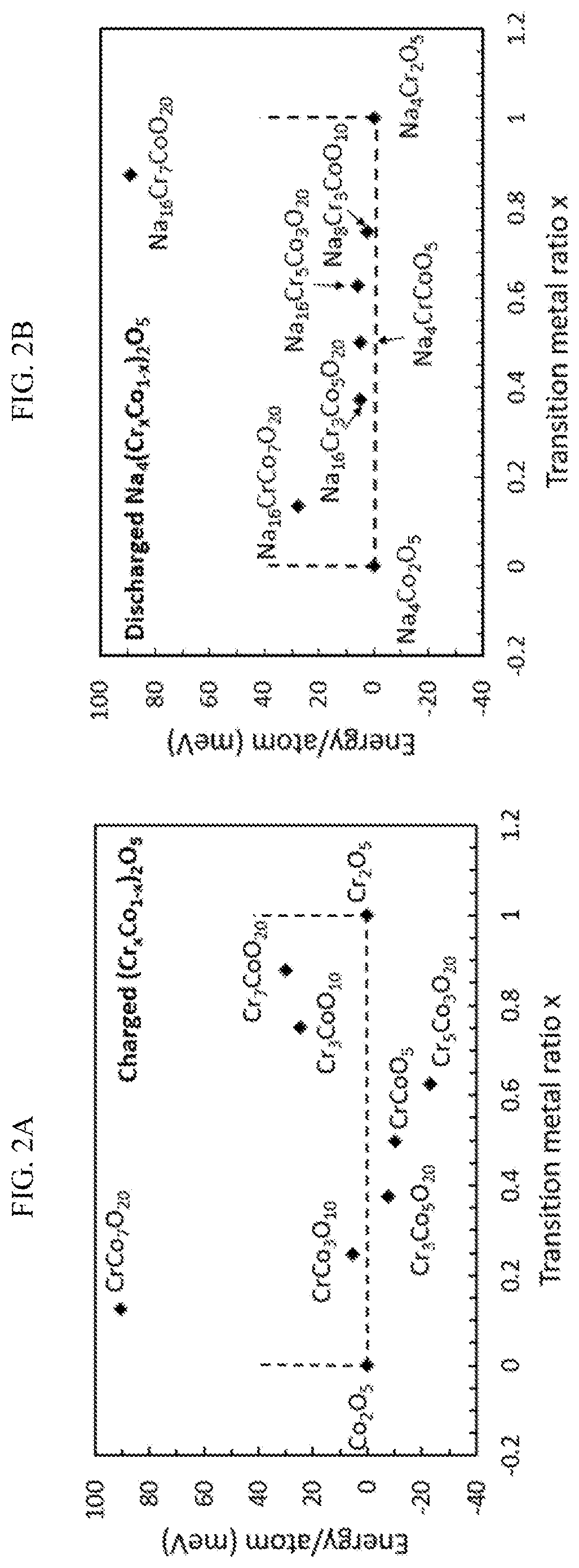

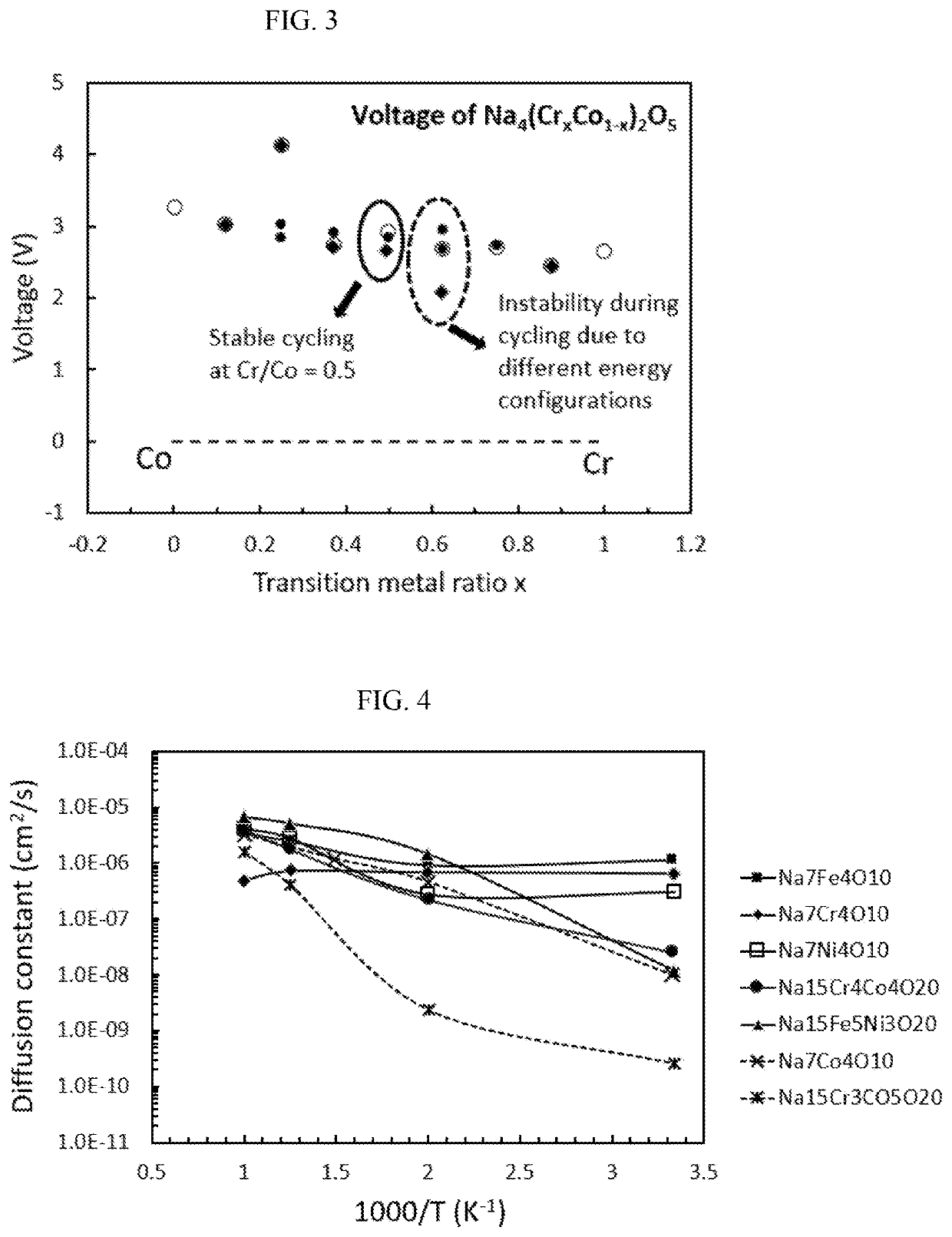

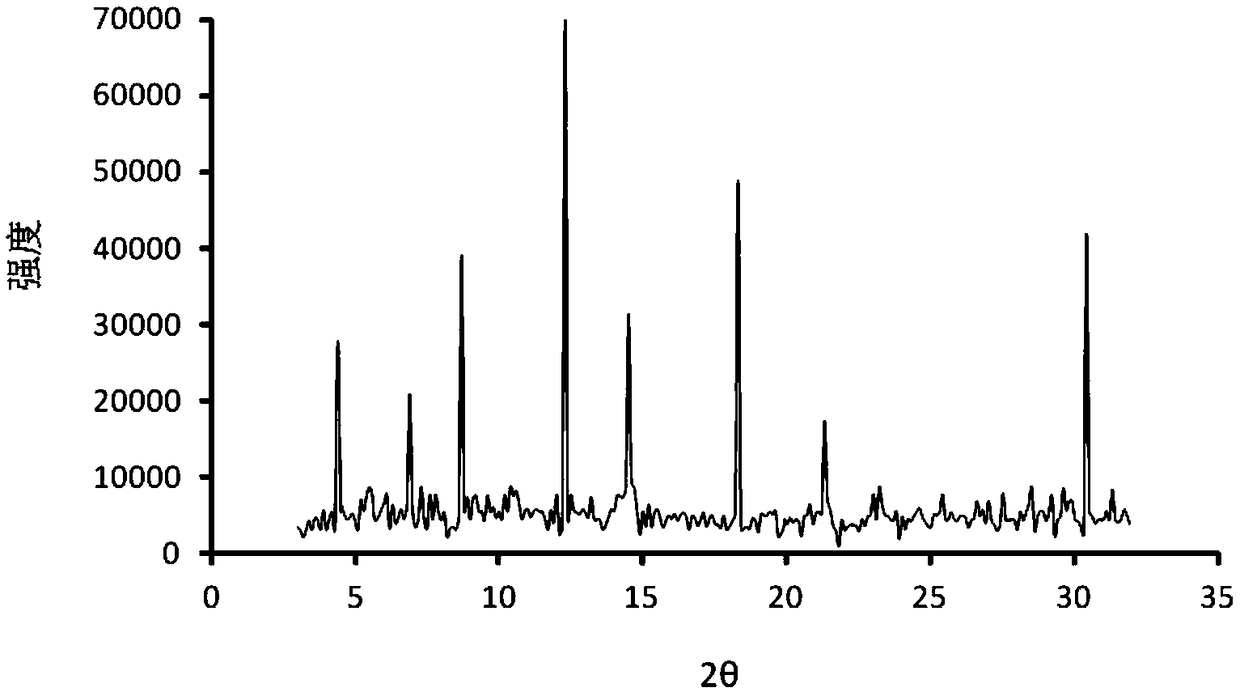

High capacity sodium-ion battery positive electrode material

ActiveUS20180294480A1Increase capacitySimple materialAlkaline accumulatorsElectrode thermal treatmentSodium-ion batterySodium complex

A positive electrode active material for a sodium ion battery includes a sodium complex oxide of the formula Na4(M1aM21−a)2O5 having an orthorhombic crystal structure, wherein M1 and M2 are each independently Ti, Cr, Fe, Co, Ni, Mn, V, or a combination there of provided that M1 and M2 are different from each other; and 0≤a≤1.

Owner:SAMSUNG ELECTRONICS CO LTD

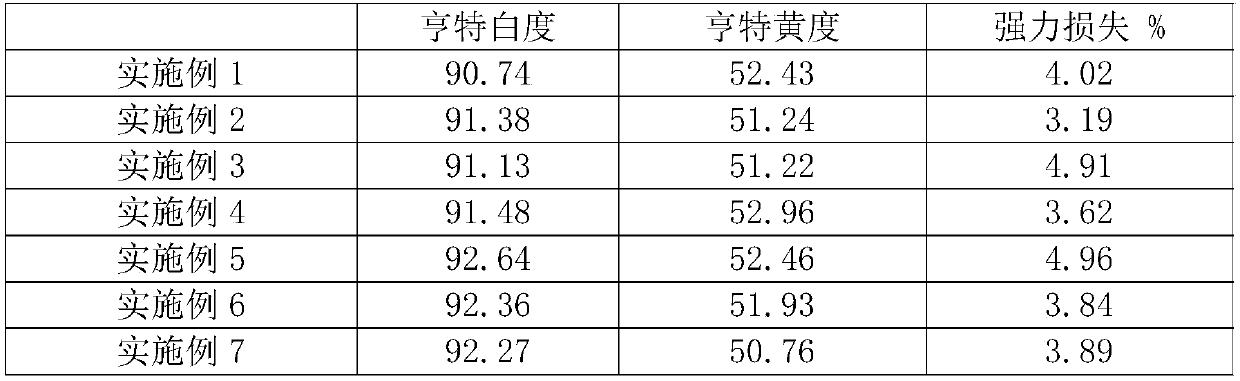

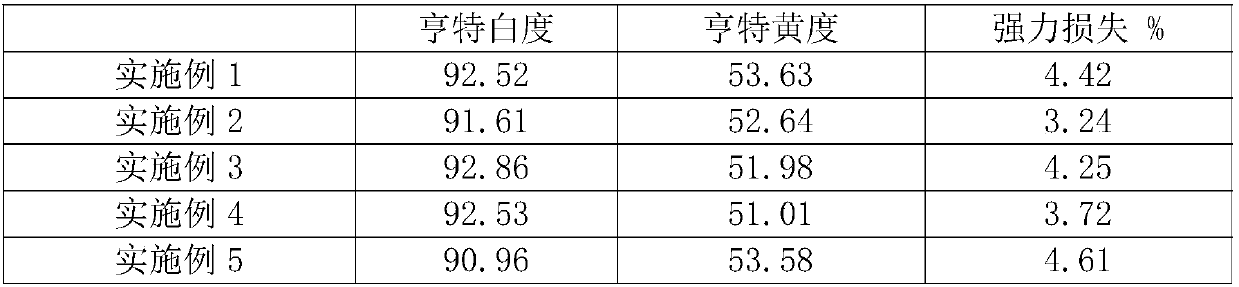

A kind of glycerin-carboxymethylcellulose sodium composite type hydrogen peroxide bleaching stabilizer and its application

ActiveCN106120295BStrong heat and alkali resistance and oxidation resistanceEasy to useLiquid/gas/vapor fibres/slivers/rovings treatmentFiberCarboxymethyl cellulose

The invention discloses a glycerinum-carboxymethylcellulose compound hydrogen peroxide bleaching stabilizer and an application thereof. The compound hydrogen peroxide bleaching stabilizer is prepared from the following components in parts by weight, 1-1.5 parts of glycerinum, 0.1-2 parts of carboxymethylcellulose, 2-2.7 parts of soluble starch and 10-14 parts of water. A preparation method of the compound hydrogen peroxide bleaching stabilizer includes the steps: mixing the water with the glycerinum and heating the water and the glycerinum to 100 DEG C; adding the soluble starch into mixed boiling solution and uniformly stirring the solution; slowly dripping carboxymethylcellulose solution and then performing low-temperature standing. The compound hydrogen peroxide bleaching stabilizer is applied to the bleaching process of linen rove and a fabric thereof. The hydrogen peroxide bleaching stabilizer has the function of efficiently stabilizing hydrogen peroxide, is low in fiber material damage, high in heat resistance, alkali resistance and oxidation resistance, easy to use, good in compatibility with other auxiliaries, low in cost and ideal, and reduces environmental pollution.

Owner:绍兴市荣士达衬布有限公司

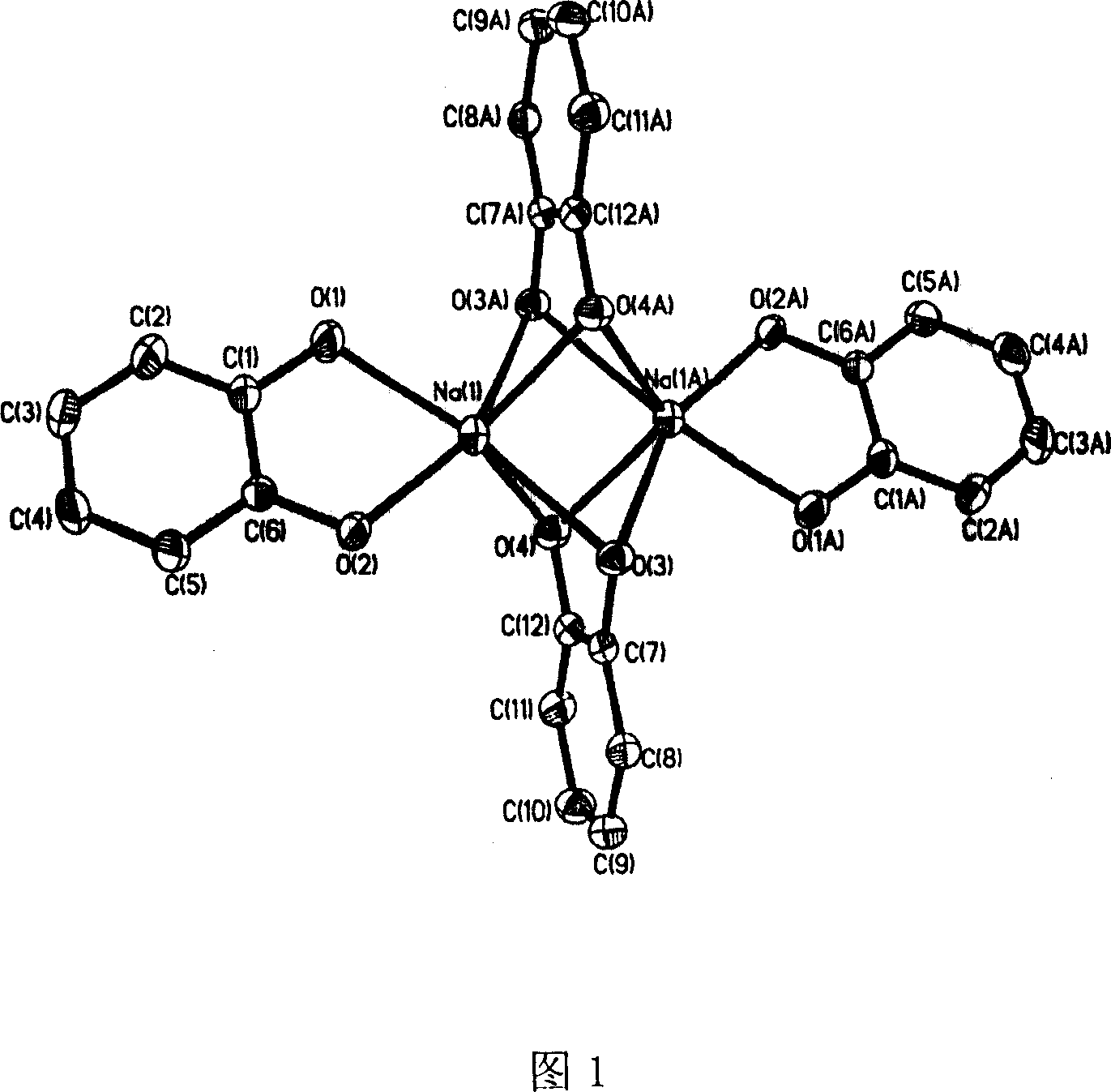

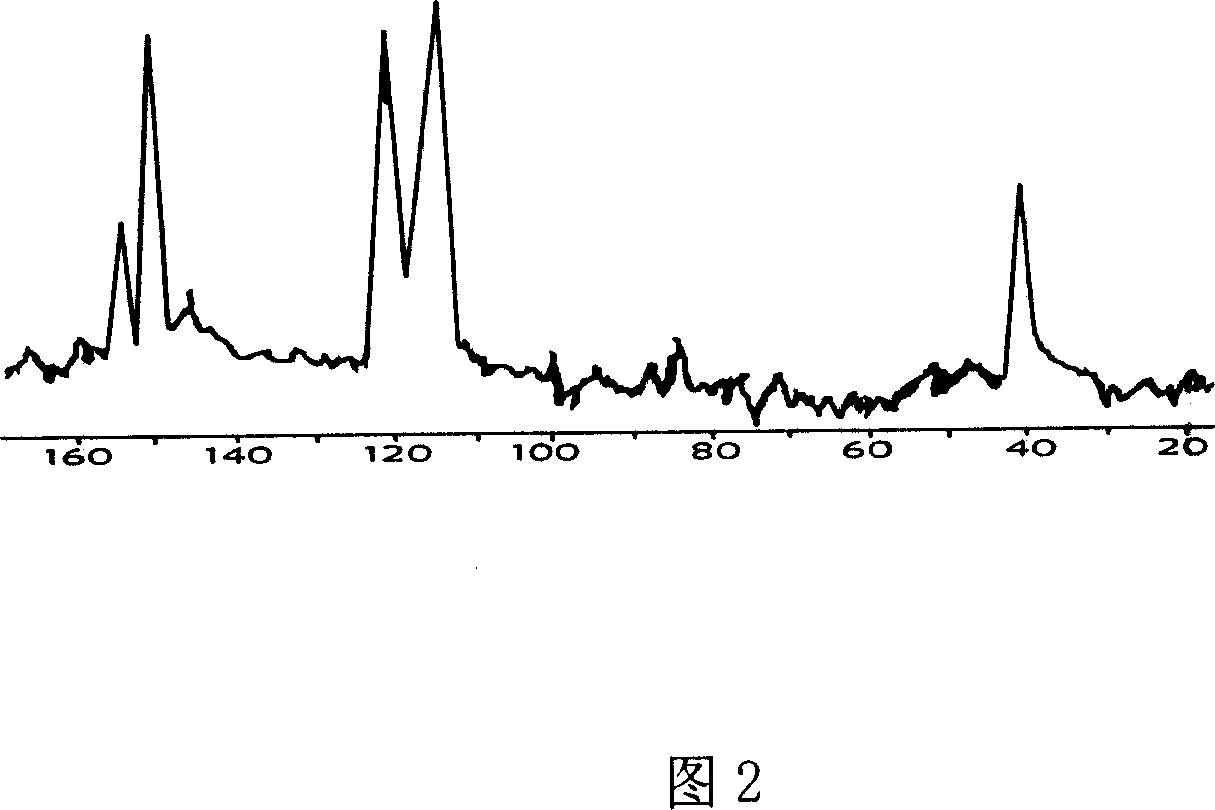

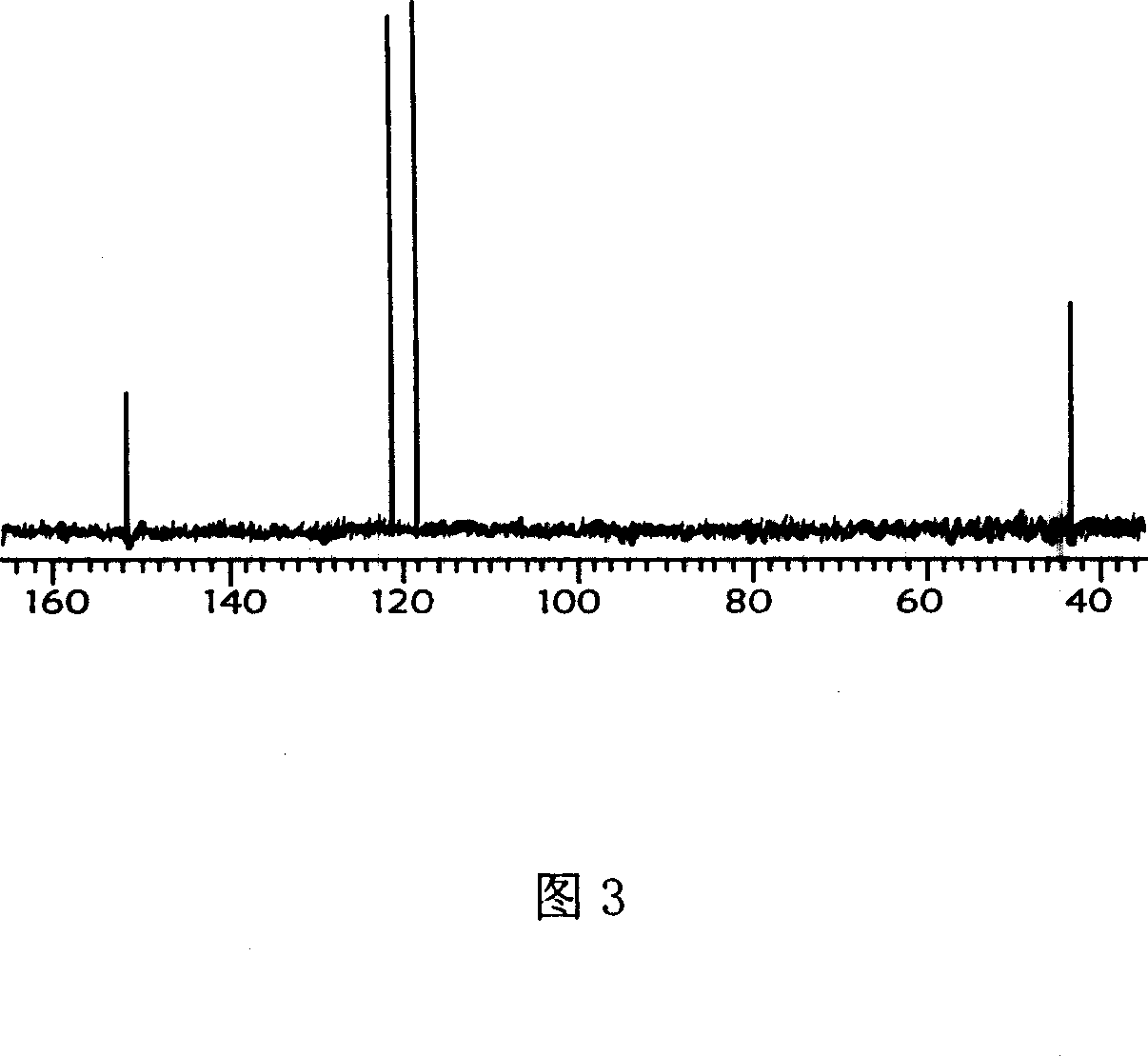

Catechol sodium complex and its prepn and application in medicine for preventing and treating cancer and tumor

InactiveCN100349899CRaw materials are easy to getLow costOrganic active ingredientsSodium organic compoundsAbnormal tissue growthDisease

The catechol sodium complex has both catechol with latent anticancer and antitumor capacity and low toxicity sodium ion, and their cooperation makes the complex possess excellent water solubility and liposolubility and can enter effectively the disease focus part in life system to treat cancer and tumor. The catechol sodium complex may be used alone as anticancer and antitumor medicine or as the active component of anticancer and antitumor. The preparation process is to complex inorganic salt containing metal sodium ion and catechol ligand to form the catechol sodium complex inside water phase, organic phase or mixed phase in the presence of organic amine. The preparation process has easy-to-obtain material, low cost, separated crystal product, high product purity, high yield and high stability of the product under natural state.

Owner:CAPITAL NORMAL UNIVERSITY

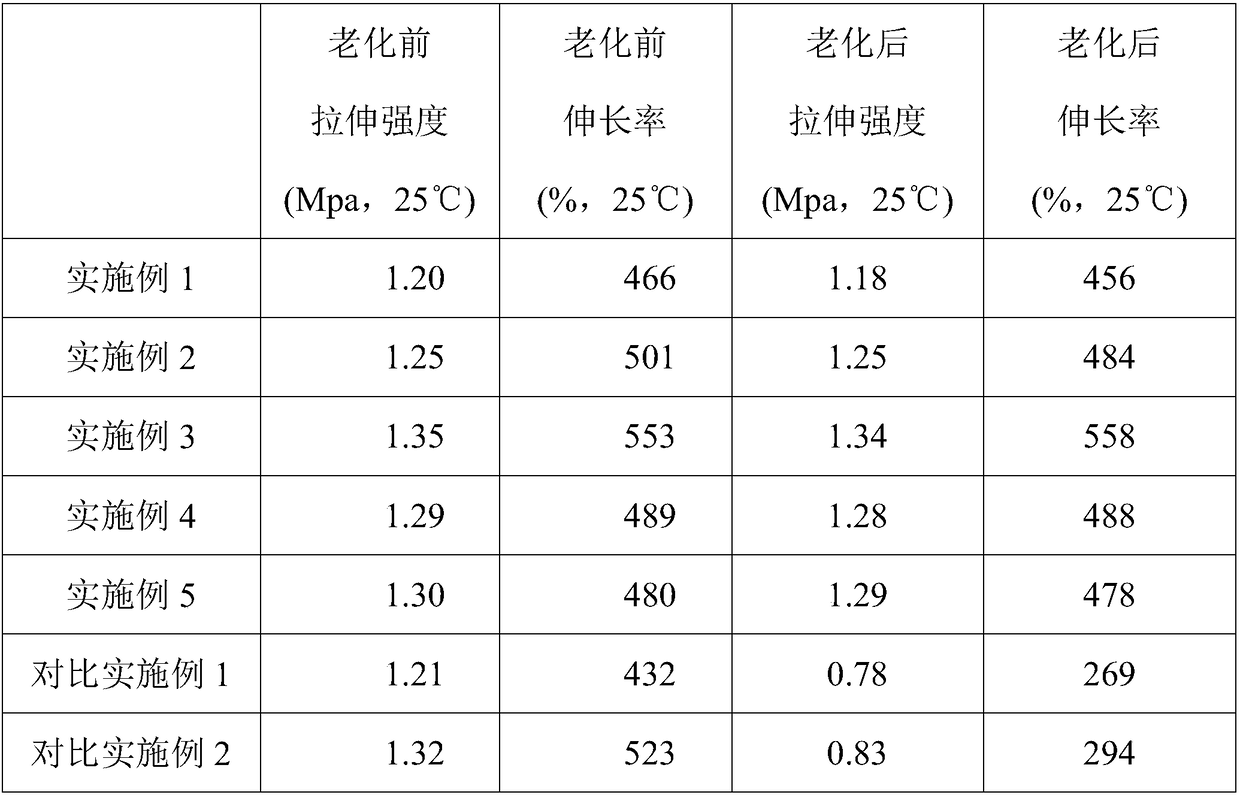

Surface modification method of anti-oxidation nano-calcium carbonate for silicone sealant

ActiveCN105482500BGood compatibilityHigh mechanical strengthNon-macromolecular adhesive additivesPigment physical treatmentSlurryOxidation resistant

The invention discloses a surface modification method of anti-oxidation nanometer calcium carbonate used for a silicone sealant. The method comprises the following steps: 1, preparing a material: preparing a nanometer calcium carbonate slurry; 2, carrying out surface treatment: adding fatty acid and diethylenetriaminepentaacetic acid ferric-sodium complex mixed saponification liquor to the nanometer calcium carbonate slurry, and stirring to prepare a modified nanometer calcium carbonate slurry; 3, dehydrating and drying: carrying out dehydrating and drying treatment on the modified nanometer calcium carbonate slurry; and 4, crushing the obtained material to obtain a nanometer calcium carbonate product. The nanometer calcium carbonate product modified through the method has good compatibility to a silicone adhesive system, and a filled sealant has good mechanical strength and very good anti-oxidation characteristic. The product has the advantages of good dispersibility, less agglomeration, good thixotropy and processability, and effective increase of the tensile strength and the elongation at break of the silicone sealant. The above preparation method has the advantages of simplicity, low production cost and good economic benefit.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Cleaning wet tissue for liquid crystal screen

InactiveCN107312631AEasy to useQuick cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsMonomethyl etherEthylene glycol monoethyl ether

The invention discloses cleaning wet tissue for a liquid crystal screen. The cleaning wet tissue comprises spunlaced nonwoven cloth and cleaning liquid, and the cleaning liquid is composed of 6-15% of dodecyl glucoside, 5-10% of tripropylene glycol monomethyl ether, 5-10% of ethylene glycol monoethyl ether, 3-5% of N-methyl-2-pyrrolidone, 0.2-0.4% of DTPA iron-sodium complex, 0.2-0.4% of trisodium N-iminodiacetate and the balance of deionized water. The cleaning wet tissue is convenient to use, capable of quickly cleaning oil stain and dirty marks on the screen, free of residue and free of damage to the screen.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

Easy-to-clean floor detergent

InactiveCN106085643AEasy to cleanIncrease aromaInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIrritationOleic Acid Triglyceride

The invention discloses an easy-to-clean floor detergent which is prepared from, by weight, 6-11 parts of lauryl alcohol polyoxyethylene ether, 7-10 parts of sodium xylene sulfonate, 1.5-2.3 parts of dimethoxybenzene, 4-6 parts of o-methylphenyl acetic acid, 1-4 parts of ethylparaben, 12-17 parts of dimethyl silicon oil, 2.4-5 parts of oleic acid, 8-11 parts of potassium silicate, 3-5 parts of diethyltriaminepentaacetate iron-sodium complex, 0.5-1.2 parts of methylisothiazolinone, 8-13 parts of lauramidopropyl betaine, 3-8 parts of triethanolamine, 2.3-5 parts of 45% methanol, 3.2-5.4 parts of citric acid and 1.3-2.7 parts of ethylene glycol butyl ether. The easy-to-clean floor detergent has the advantages of being capable of deeply cleaning various stains in floors, low in foam, easy to clean, good in aromatic smell and free of irritation.

Owner:青岛千帆高新技术有限公司

High capacity sodium-ion battery positive electrode material

ActiveUS10916772B2Alkaline accumulatorsElectrode thermal treatmentPhysical chemistrySodium-ion battery

A positive electrode active material for a sodium ion battery includes a sodium complex oxide of the formula Na4(M1aM21−a)2O5 having an orthorhombic crystal structure, wherein M1 and M2 are each independently Ti, Cr, Fe, Co, Ni, Mn, V, or a combination there of provided that M1 and M2 are different from each other; and 0≤a≤1.

Owner:SAMSUNG ELECTRONICS CO LTD

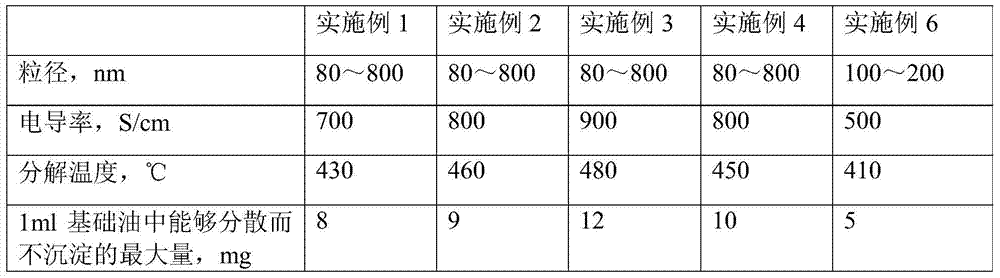

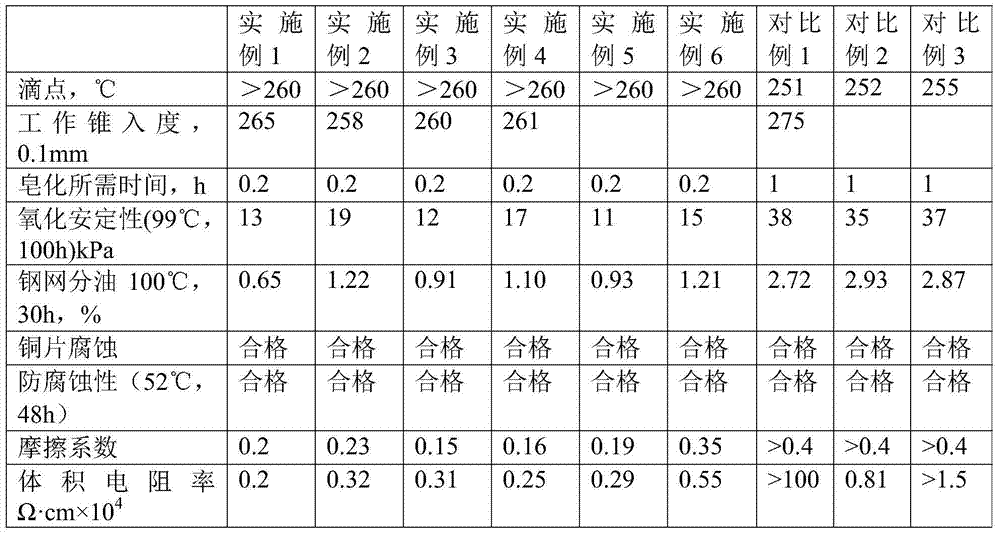

A kind of composite sodium base lubricating grease and preparation method thereof

ActiveCN104560315BImprove antioxidant capacityImprove high drop pointThickenersHeat resistanceGraphene

The invention discloses a composite sodium-based lubricating grease and a preparation method thereof. Based on the grease weight, the complex sodium-based grease includes the following components: 65-95% lubricating base oil, 5-30% complex sodium-based thickener, and 0.2-15% graphene. The composite sodium-based lubricating grease of the present invention has excellent properties such as high temperature resistance, water resistance, adhesion, colloid stability, extreme pressure and wear resistance, lubrication life, corrosion resistance and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process for synthetizing EDDHA (Ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex) Ferrochel with one-step method

InactiveCN102050753BShort processHigh yieldOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineWater insoluble

The invention provides a production process for synthetizing EDDHA Ferrochel with a one-step method, comprising the following process steps of: weighing the following raw material components in the molar ratio: 1.0% of phenol, 0.4-0.6% of quadrol, 2.0-4.0% of sodium hydroxide, 0.8-1.2% of glyoxylic acid, 0.5% of iron ion and 20% of water; firstly, synthetizing EDDHA aqueous solution; then reacting with ferric salt to synthetizing EDDHA Ferrochel solution; and drying to finally obtain the EDDHA Ferrochel. The production process has the advantages of short process flow, high yield, low production cost, no pollution and low energy consumption and does not need organic solvent. The iron content of the EDDHA Ferrochel is more than 7%, when the EDDHA Ferrochel is dissolved in water, the content of the water insoluble is less than 0.1%, and EDDHA Ferrochel is stable when PH is between 3 and 10. The EDDHA Ferrochel is mainly used as fertilizer.

Owner:SICHUAN TONGFENG TECH

Formula of automobile windscreen cleaning agent

InactiveCN107974360AEfficient removalNo corrosionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsTectorial membraneIrritation

The invention discloses a formula of an automobile windscreen cleaning agent. The formula of the automobile windscreen cleaning agent is prepared from the following raw materials in parts by weight: 4-13 parts of C8-10 fatty alcohol polyoxyethylene ether phosphate monoester, 6-12 parts of a diethylenetriamine pentaacetic acid iron-sodium complex, 5-8 parts of sodium dodecyl benzene sulfonate, 6-10parts of tripolyphosphate, 4-6 parts of alcohol, 8-12 parts of potassium sorbate, 2-4 parts of ethyecellulose, 3-6 parts of 3-phosphoglyceric acid, 1-2 parts of an anionic surfactant I, 5-9 parts ofsodium tripolyphosphate, 2-3 parts of an anionic surfactant II, 1-3 parts of isopropanol and 1-2 parts of nano-titanium sol. The formula of the automobile windscreen cleaning agent has the beneficialeffects that the cleaning agent is capable of effectively cleaning stains on the windscreen, the cleaning agent has the advantages of high cleaning capability, short washing time, no corrosion to substrate, no irritation to human body and no trace after being used, a protection layer can be formed on the outer surface of the windscreen, and the cleaning agent is capable of preventing dust accumulation in a certain time and preventing water stain residue.

Owner:成都凯斯恩科技有限公司

Complex of angiotensin receptor antagonist and creatine sodium phosphate and use thereof

The present invention provides a an angiotensin receptor antagonist and creatine phosphate sodium complex and uses thereof, wherein the complex comprises an angiotensin receptor antagonist and creatine phosphate sodium, a molar ratio of the angiotensin receptor antagonist to the creatine phosphate sodium is 1:1-2, and the angiotensin receptor antagonist is selected from valsartan, losartan, irbesartan, telmisartan, eprosartan, candesartan, olmesartan, saprisartan, tasosartan, and elisartan. According to the present invention, the complex is formed by compounding the angiotensin receptor antagonist and the creatine phosphate sodium, and provides the unexpected double effect and the synergistic effect for treatment of heart failure and high blood pressure, the cocrystallization salt hydrate formed by linking the hydrogen bond has the stable characteristic, the pharmacokinetic property is significantly provided, and the positive application prospects are provided in the fields of anti-high blood pressure treatment and anti-heart failure treatment.

Owner:赛隆药业集团股份有限公司(长沙)医药研发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com