A kind of glycerin-carboxymethylcellulose sodium composite type hydrogen peroxide bleaching stabilizer and its application

A technology of sodium carboxymethyl cellulose and hydrogen peroxide, which is applied in liquid/gas/steam fiber/sliver/roving treatment, textile and papermaking, and textile material treatment, and can solve the problem of hydrogen peroxide bleaching stabilizer raw materials Complicated, unable to improve fabric whiteness, poor metal ion chelation, etc., to achieve good and stable hydrogen peroxide, efficient and stable hydrogen peroxide, and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

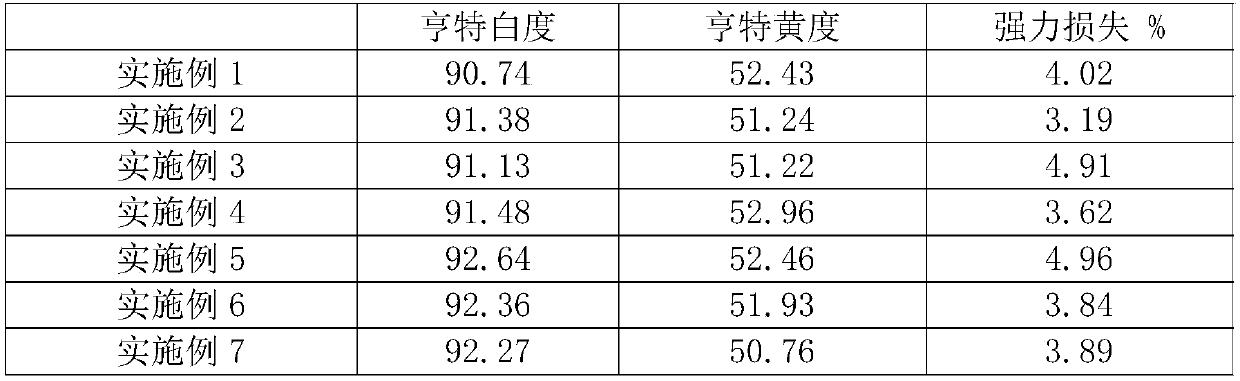

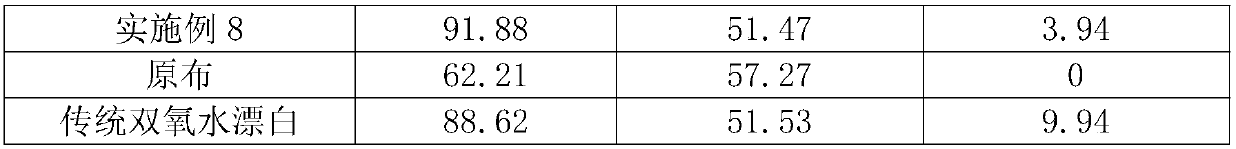

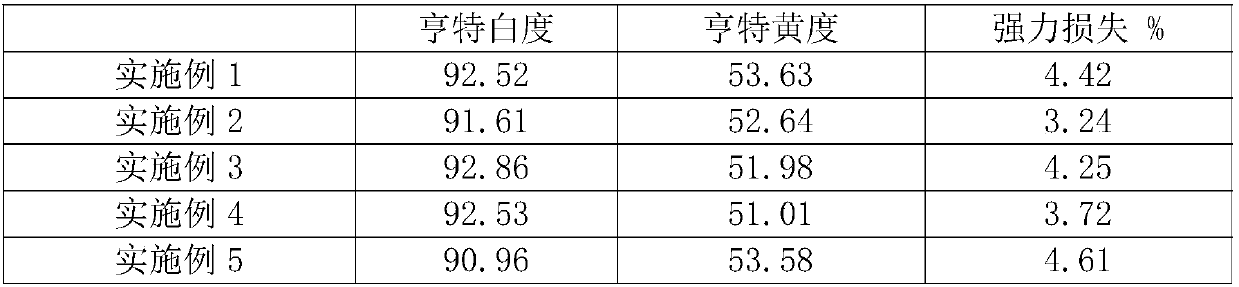

Examples

Embodiment 1

[0026] A glycerol-sodium carboxymethyl cellulose composite hydrogen peroxide bleaching stabilizer, which consists of the following components in parts by weight: 1 part of glycerin, 0.1 part of sodium carboxymethyl cellulose, 2 parts of soluble starch, and 10 parts of water share.

Embodiment 2

[0028] A glycerin-carboxymethylcellulose sodium composite hydrogen peroxide bleaching stabilizer, which consists of the following components in parts by weight: 1.5 parts of glycerin, 2 parts of sodium carboxymethylcellulose, 2.7 parts of soluble starch, 14 parts of water share.

Embodiment 3

[0030] A glycerol-sodium carboxymethyl cellulose composite hydrogen peroxide bleaching stabilizer, which consists of the following components in parts by weight: 1 part of glycerin, 2 parts of sodium carboxymethyl cellulose, 2 parts of soluble starch, 14 parts of water share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com