Patents

Literature

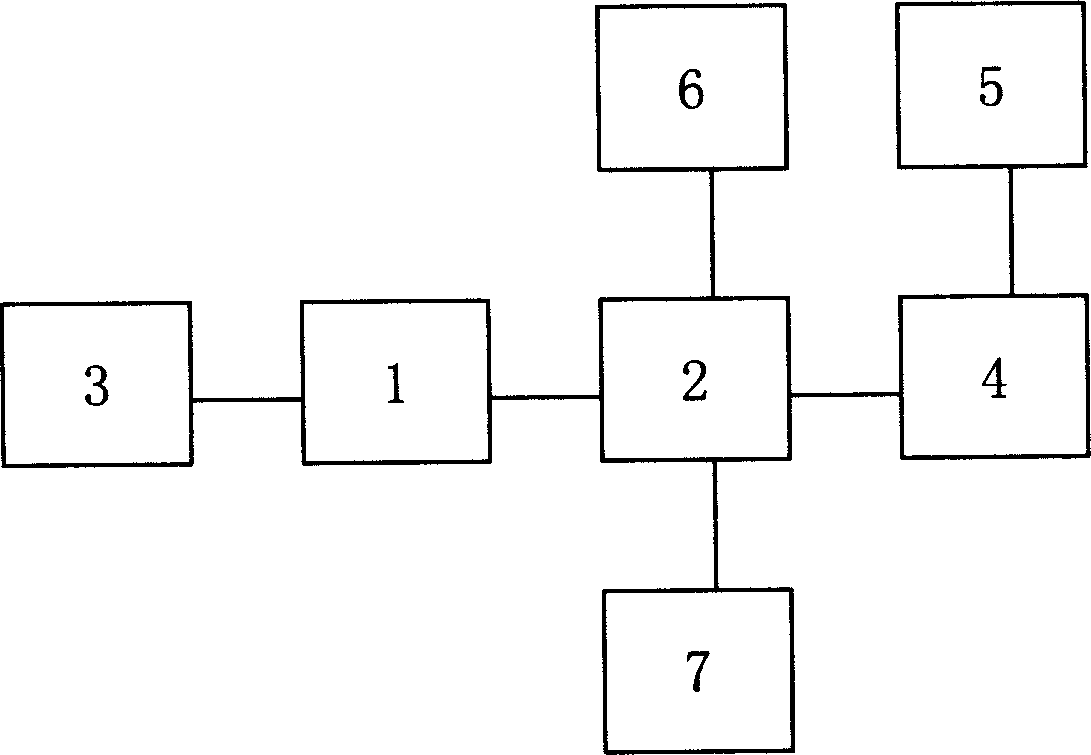

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188 results about "Self-cleaning glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

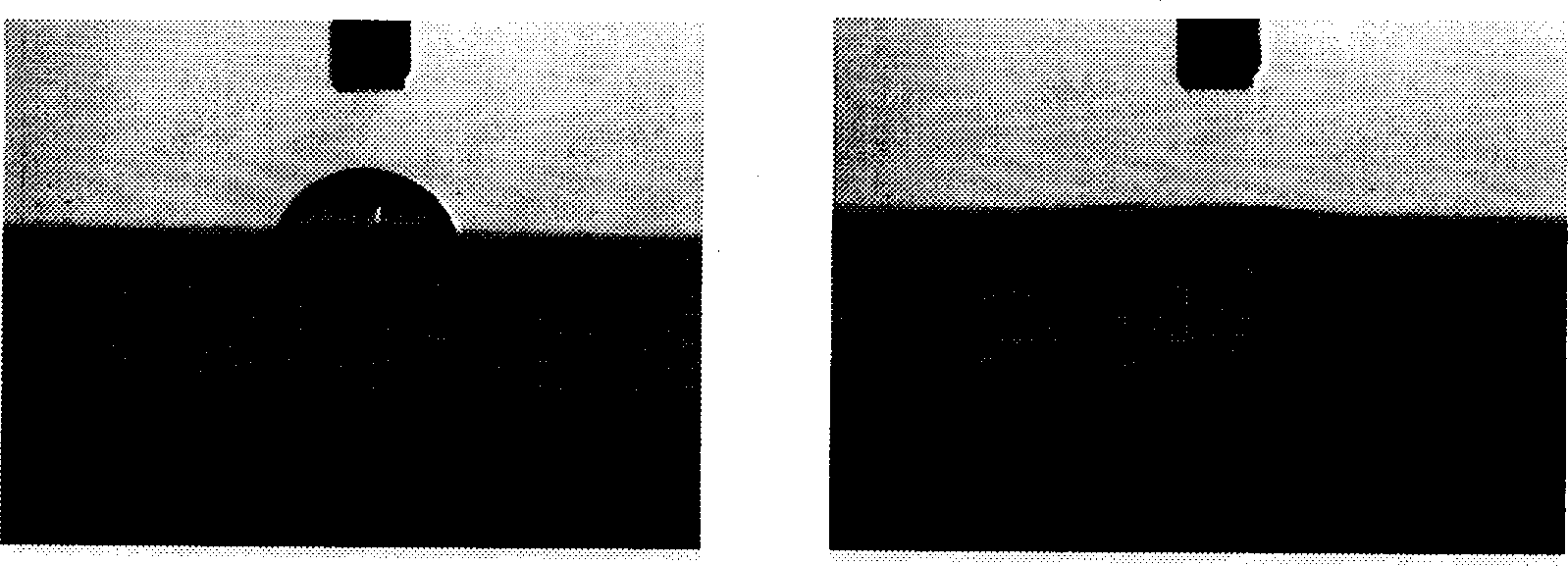

Self-cleaning glass is a specific type of glass with a surface that keeps itself free of dirt and grime. The field of self-cleaning coatings on glass is divided into two categories: hydrophobic and hydrophilic. These two types of coating both clean themselves through the action of water, the former by rolling droplets and the latter by sheeting water that carries away dirt. Hydrophilic coatings based on titania (titanium dioxide), however, have an additional property: they can chemically break down absorbed dirt in sunlight.

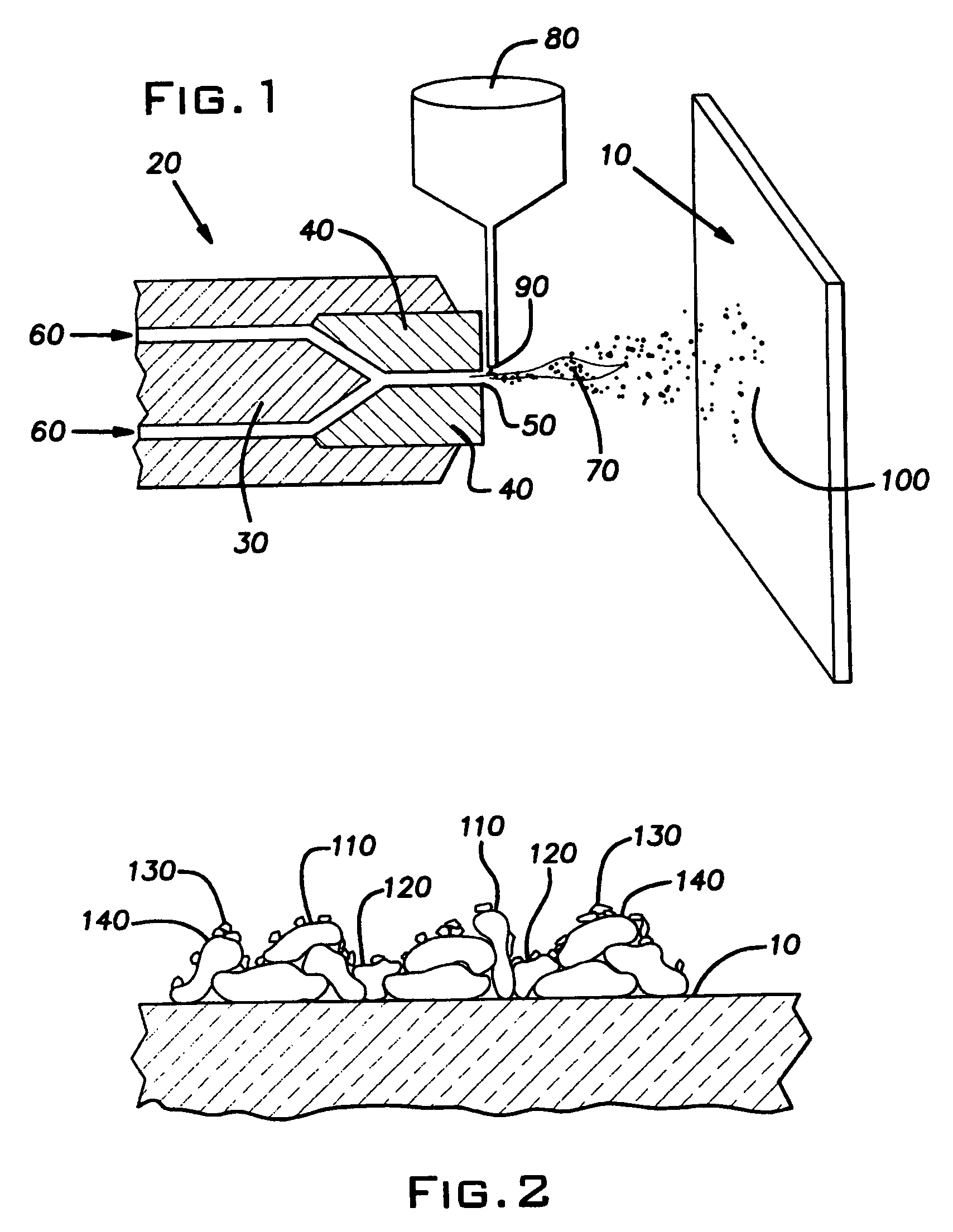

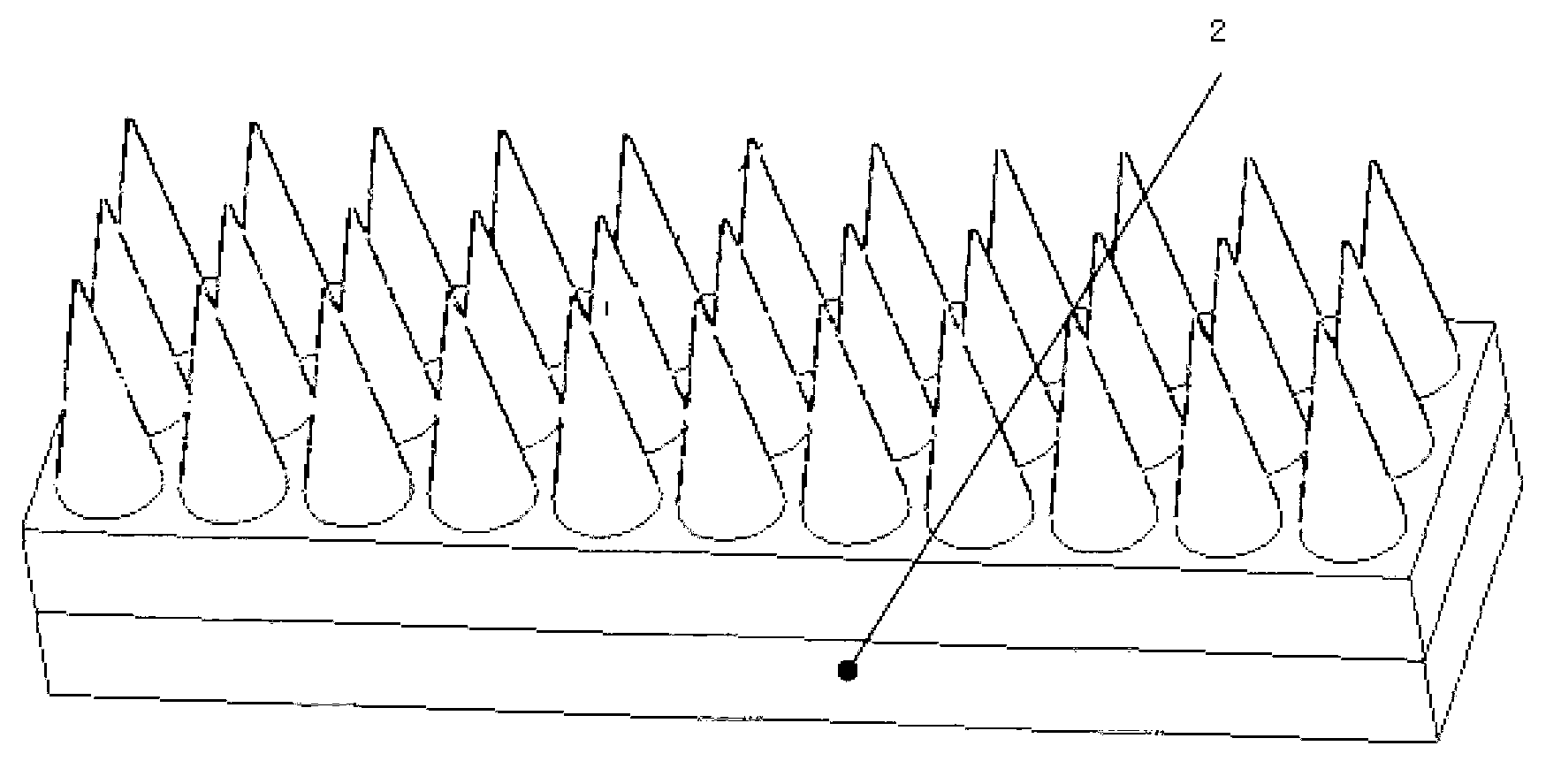

Process for structuring self-cleaning glass surfaces

A plasma spray process for structuring self-cleaning glass surfaces and self-cleaning glass surfaces formed according to the process. Molten or heat softened particles of inorganic material are plasma spray deposited onto the surface of a substrate to create a micro-rough surface. If desired, a hydrophobic top coating layer can optionally be applied to the micro-rough surface. The micro-structured surface formed according to the invention is durable and self-cleaning.

Owner:FERRO CORP

Low-temperature prepn process of self-cleaning nano Tio2 glass

InactiveCN1417147AImprove superhydrophilicityImprove photocatalytic performanceRoom temperatureFree cooling

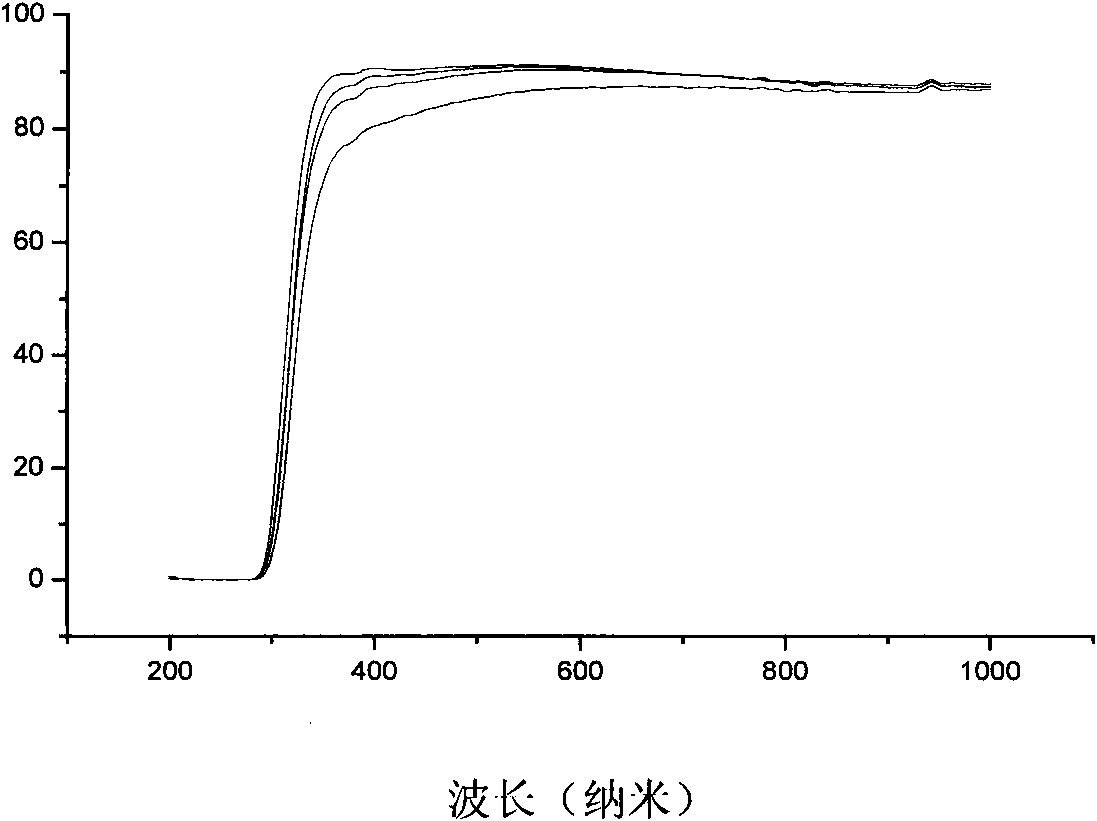

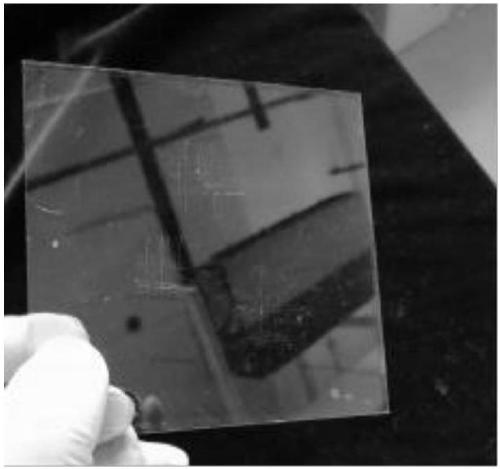

The present invention relates to a low temperature treating process of self-cleaning TiO2 nanoglass. By using silica and anatase type nanosol as basic components and through pulling process, film is formed on the surface of glass plate. The film is dried at room temperature and cured or treated at temperature below 300 deg.c and cooled naturally. The prepared self-cleaned glass has excellent photocatalytic property, superhydrophilic property, high and homogeneous transparency. The said process is simple, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

Permanent self-cleaning glass with visible light responsibility and preparation method thereof

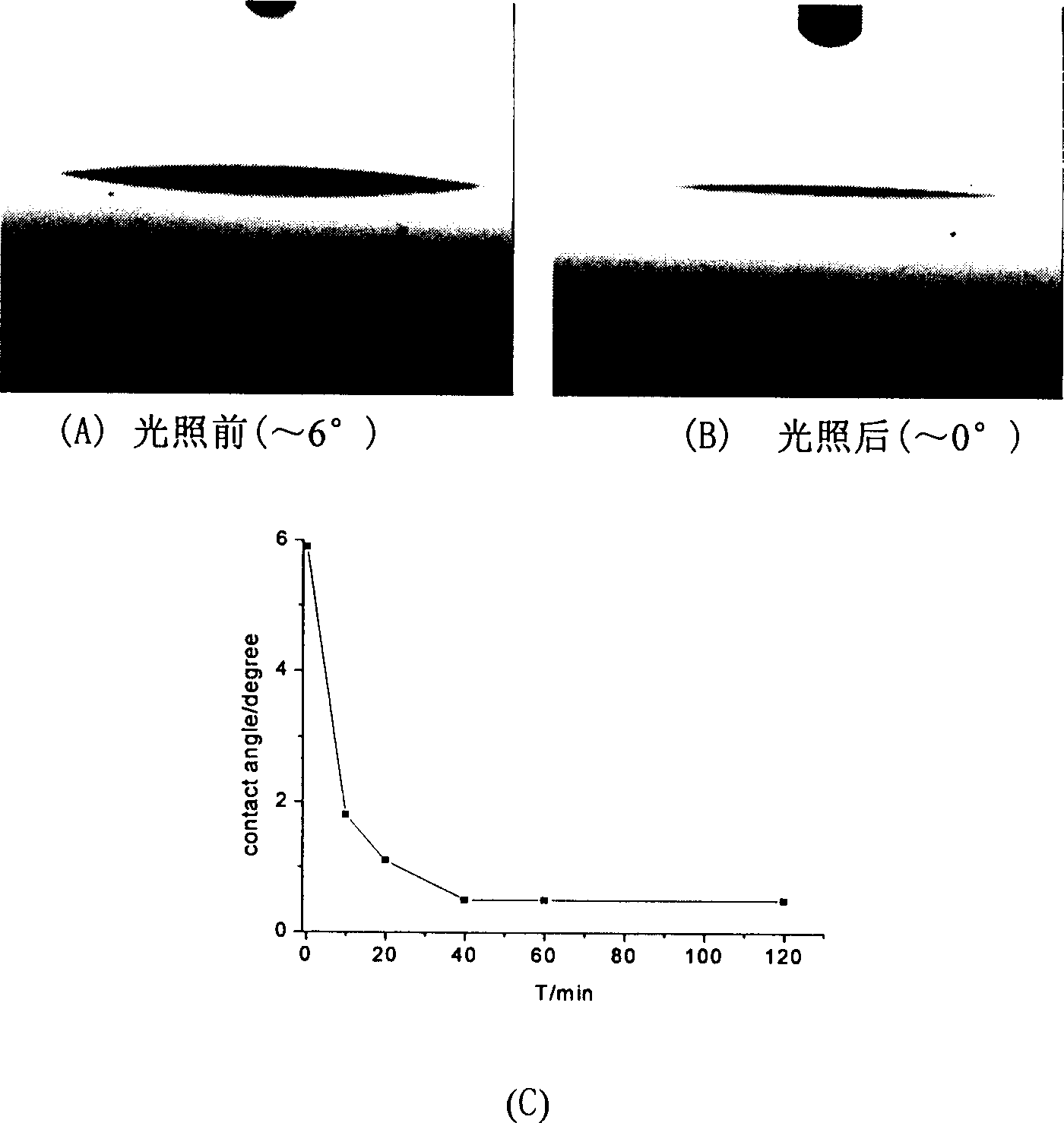

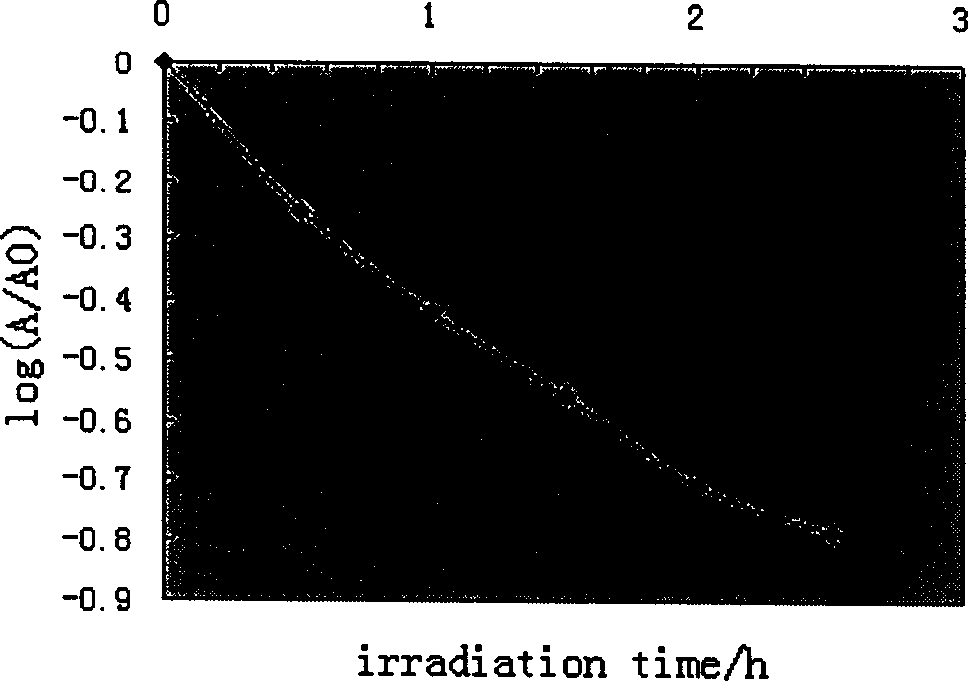

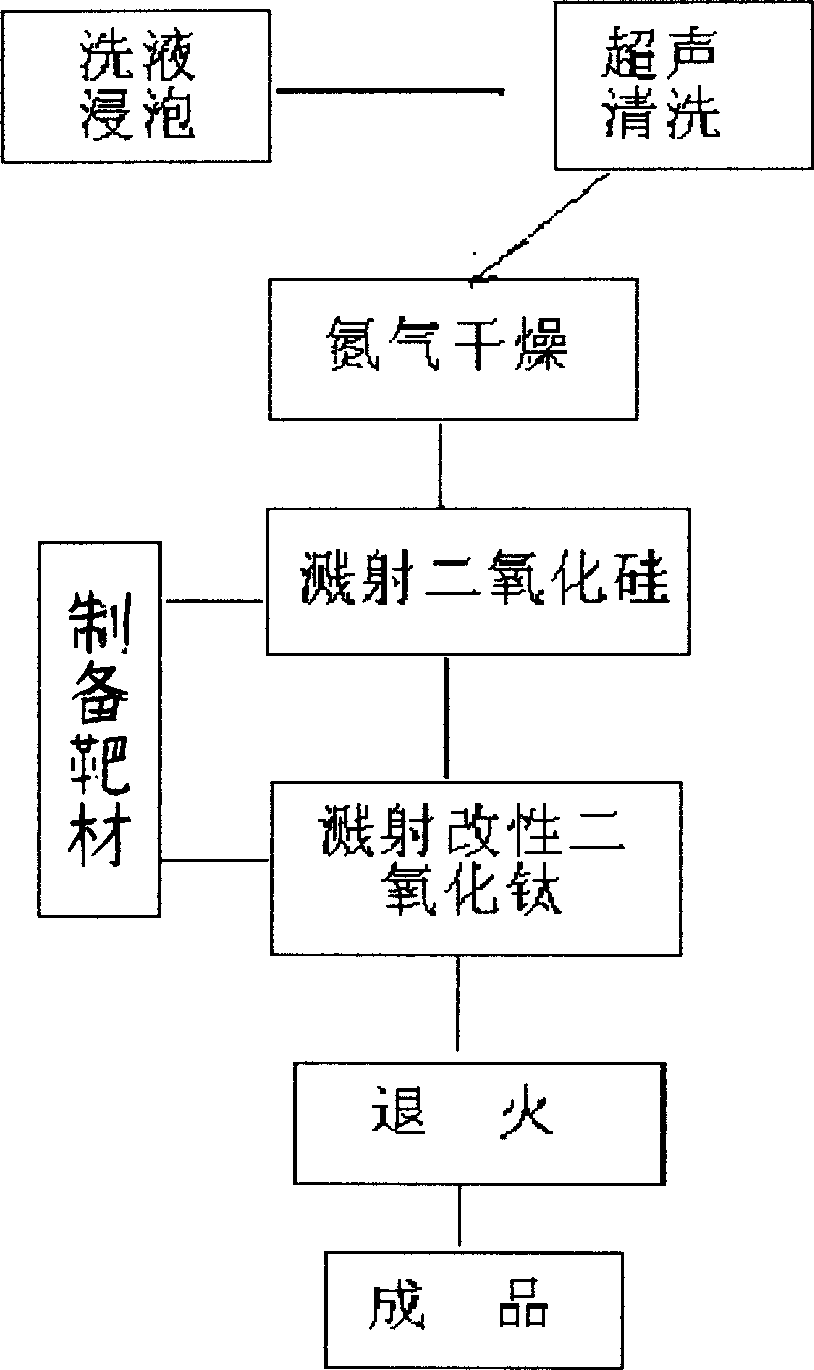

The invention belongs to functional material technology and glass processing field, concretely discloses a permanent self-cleaning glass with visible light response and method for making it. Firstly, sputtering silica dioxide film on the surface of glass, sputtering a layer of titanium oxide film with anion and cation codoping on the surface of silica dioxide film, annealing the glass with twin layer films at 500-600 DEG C, cooling by radiation in sintering stove, to get the product. The self-cleaning glass has good photocatalysis property and photo-induced hydrophilicity, stable performance, almost perpetual availability, high light transmittance ratio and transparency. It is widly used in glass curtain wall of skyscrapers, automobile glass, road lamp shade, kitchen galss and antifog glass, avoiding artificial cleaning indoor and outdoor glass of skyscrapers, saving manual power and material, reducing corrosion destruction of cleaning agent to glass and building machinery, embodying environment protection notion.

Owner:JIEYANG HONGGUANG COATED GLASS

Process for structuring self-cleaning glass surfaces

Owner:FERRO CORP

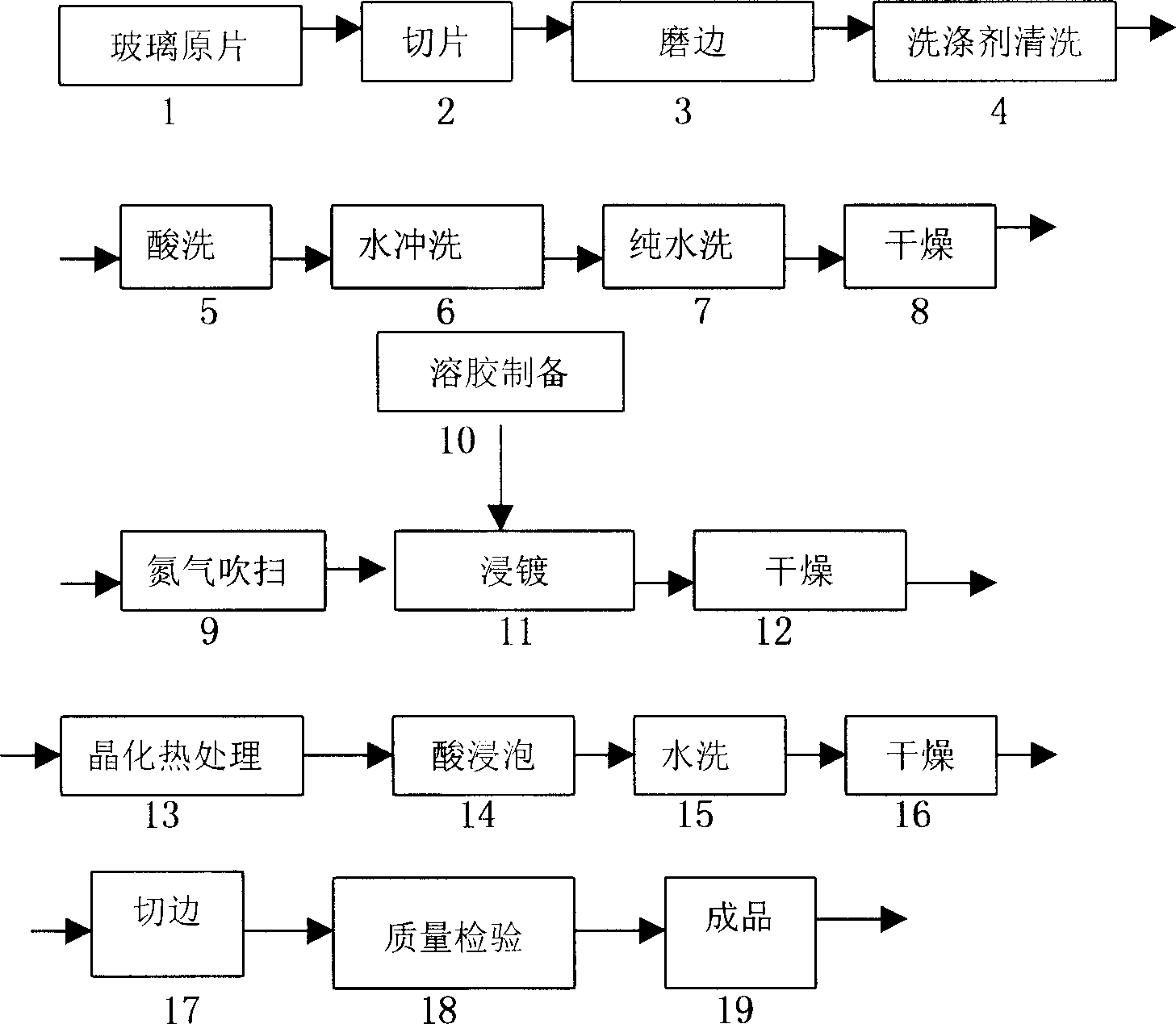

Method for preparing high-activity titanium dioxide film self-cleaning glass material

InactiveCN1400185AImprove photocatalytic activityEasy to effectively control product qualityIon contentAfter treatment

The method for preparing high-activity titanium dioxide film self-cleaning glass material, applicable to the fields of building glass, car glass and optical glass, uses general glass as base body forcoating film and includes the following steps: cleaning glass surface, drying, sweeping with nitrogen gas, sol preparation, impregnating and coating, drying, crystallization heat treatment, pickling and surface after-treatment. The sodium ion content of titanium dioxide film can be controlled in 0.3%, carbon content of film surface is reduced, surface hydroxy content is increased and the optical catalytic activity of glass can be greatly raised. Said invention adopts line production process, and can effectively control product quality.

Owner:WUHAN UNIV OF TECH +1

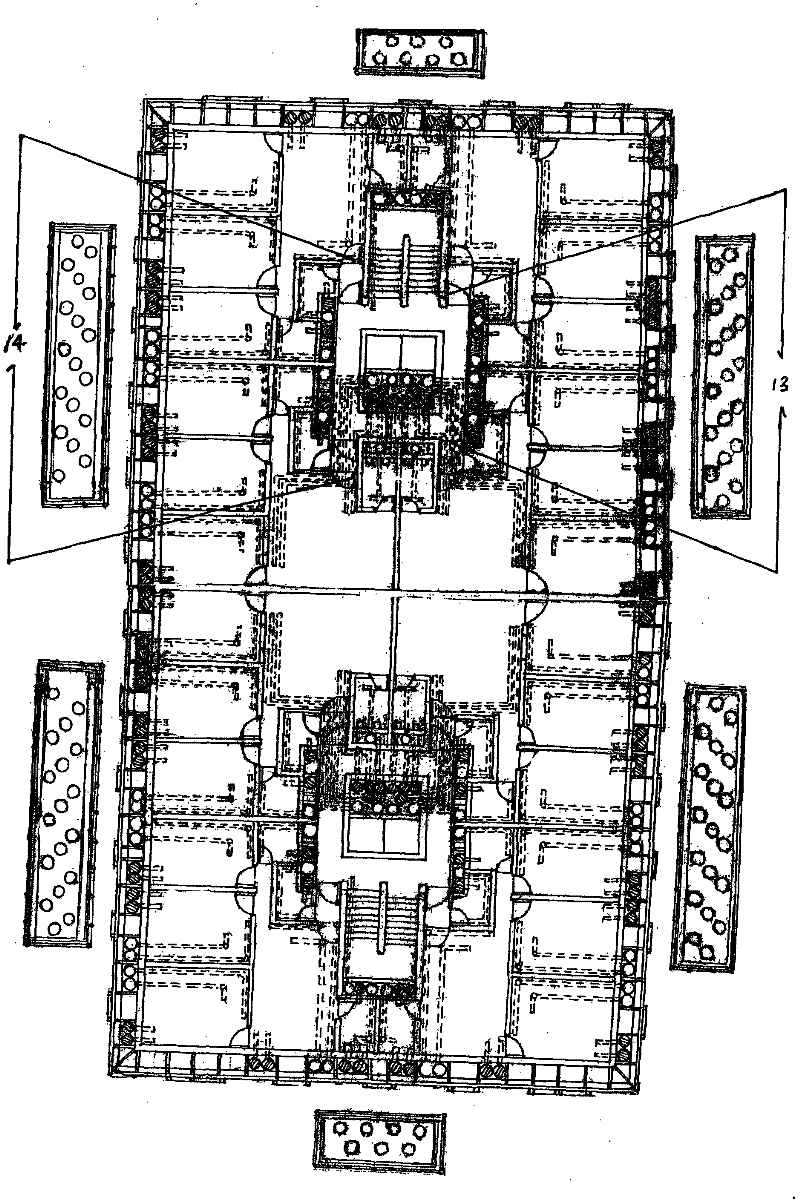

Intelligent self-cleaning glass window

ActiveCN105231953AClean InstantAvoid safety hazardsWindow cleanersSpecial door/window arrangementsMotor driveSprayer

An intelligent self-cleaning glass window comprises a window frame and a glass plate, wherein a self-cleaning mechanism is mounted on the window frame. The self-cleaning mechanism comprises two guide rods capable of rotating around respective axes. The two ends of each guide rod are connected with the window frame. A power interface, a microprocessor and a motor driving the guide rods to rotate are mounted on the window frame. Each guide rod is sleeved with a guide sleeve capable of conducting up-down reciprocating movement along the guide rod. The two guide sleeves are connected through a connecting beam. A windscreen wiper and a support are mounted on the connecting beam. A second cross shaft sleeved with an electric brush is arranged in the support. A gear motor is mounted on the support and connected with the electric brush through a gear belt. A cleaning solution box is mounted on the connecting beam. A micro pump is arranged on the cleaning solution box. The cleaning solution box is communicated with one end of an infusion tube. Multiple sprayers are arranged on the infusion tube. The electric brush, the gear motor, the micro pump and the motor driving the guide rods to rotate are all in signal connection with the microprocessor. The self-cleaning glass window can clean itself in time to keep bright like a new window, and avoids potential safety hazards existing in manual cleaning.

Owner:兰州泰坦互联网信息科技服务有限公司

Method for preparing self-cleaning toughened glass

The invention belongs to the technical field of functional materials, particularly relating to the offline and online production technology for normal temperature and pressure nano self-cleaning glass, especially to a manufacturing method for normal temperature self-cleaning tempered glass. The invention will first enables the nano-coating with visible light activity to be pre-crystalled, and coat the pre-crystalled coating on the surface of the glass, then form crystal rapidly under the condition of 700 DEG C transient high temperature treatment required in the tempered glass preparation process, so as to achieve tempering and simultaneously realize super-hydrophilicity and photocatalytic activity on the glass surface. The nano-self-cleaning coating on the glass surface is more strengthened through transient high temperature, so as to improve the service life of the self-cleaning coating.

Owner:北京中科华纳技术发展有限公司

Titanium dioxide photo-catalyzed film and preparation method thereof

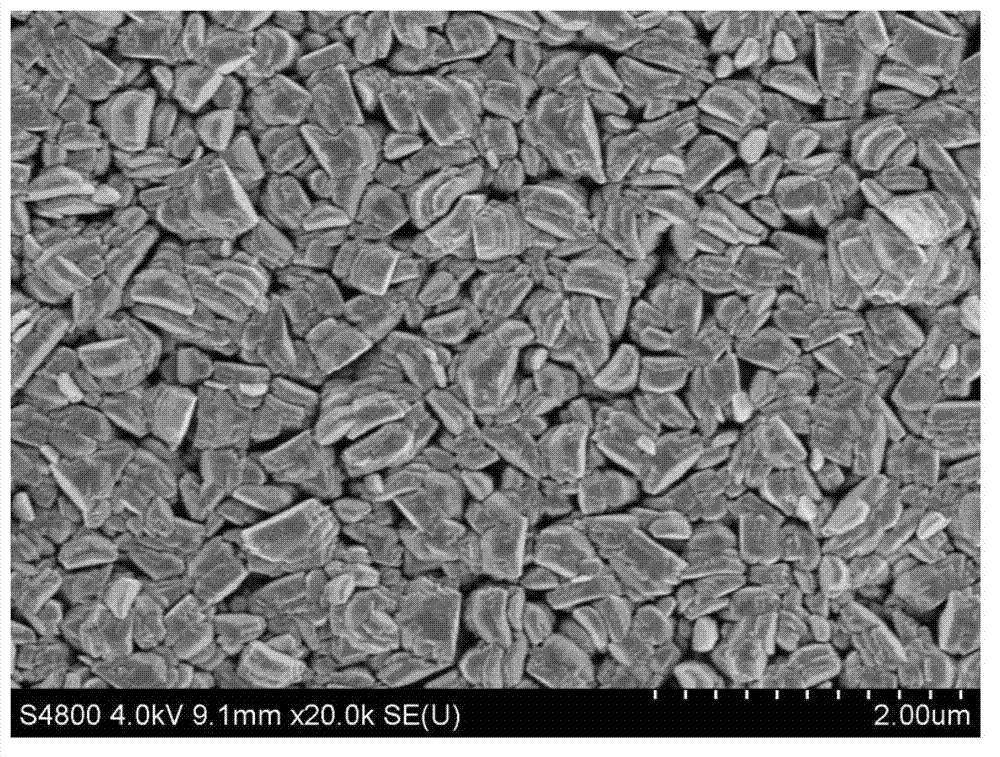

ActiveCN102864481ALarge specific surface areaGood light transmissionSurface reaction electrolytic coatingVacuum evaporation coatingPhotocatalytic reactionHeat treated

The invention discloses a titanium dioxide photo-catalyzed film and a preparation method thereof. The titanium dioxide photo-catalyzed film has a spongy porous structure; the length of holes along the growth direction is 200nm-800nm; and the maximal width of the holes along the direction vertical to the growth direction is 10nm-300nm. The preparation method for the titanium dioxide photo-catalyzed film comprises the following steps: depositing a columnar structural titanium film on a substrate by adopting a magnetron sputtering method, wherein the depositing pressure is 0.1-1Pa; preparing the titanium dioxide having a porous structure by anodizing the titanium film; sputtering the deposited titanium film as an anode and taking graphite as a cathode; taking a mixed solution of ammonium fluoride, water and organic saturate alcohol as an electrolyte; keeping a constant voltage at 25-50V; and thermally treating, thereby obtaining the titanium dioxide photo-catalyzed film. The titanium dioxide photo-catalyzed film provided by the invention has the characteristics of high light transmission and high photo-catalytic reaction rate constant and meets the requirements of photo-catalyzed materials, such as self-cleaning glass, air and waste water purifier, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing porous nano TiO2

The invention discloses a method for preparing porous nano TiO2. The method includes steps: according to the weight ratio of titanic acid ester, sublimable compound template, organic solvent, acid and deionized water, (0.001%-80%):(0.00001%-50%):(0.001%-95%):(0.001%-90%):(0.001%-95%), mixing the titanic acid ester, the sublimable compound, the organic solvent and the acid till completely dissolved, adding the deionized water, scattering with ultrasonic for 0.1-20 hours, reacting under stirring at 25-85 DEG C for 0.1-50 hours, ageing for 1-48 hours at room temperature to obtain TiO2 sol containing the sublimate template, removing solvent by means of reduced pressure distillation, drying at 60-130 DEG C, roasting at 150-240 DEG C for 0.1-20 hours, roasting at 250-340 DEG C for 0.1-20 hours, roasting at 350-440 DEG C for 0.1-20 hours, roasting at 450 DEG C for 0.1-20 hours, cooling naturally and grinding to obtain porous nano TiO2 solid powder. The porous nano TiO2 solid powder can be applied to photocatalytic hydrogen production by water decomposition, photocatalytic organic pollutant degradation, ultrasonic absorbing materials, textiles, self-cleaning glass, sunscreen cream, paint, printing ink, food packaging materials, paper industry, space industry and lithium batteries and has wide application prospect. The method is simple and feasible in process, low in investment and beneficial to popularization and application.

Owner:NANJING FORESTRY UNIV

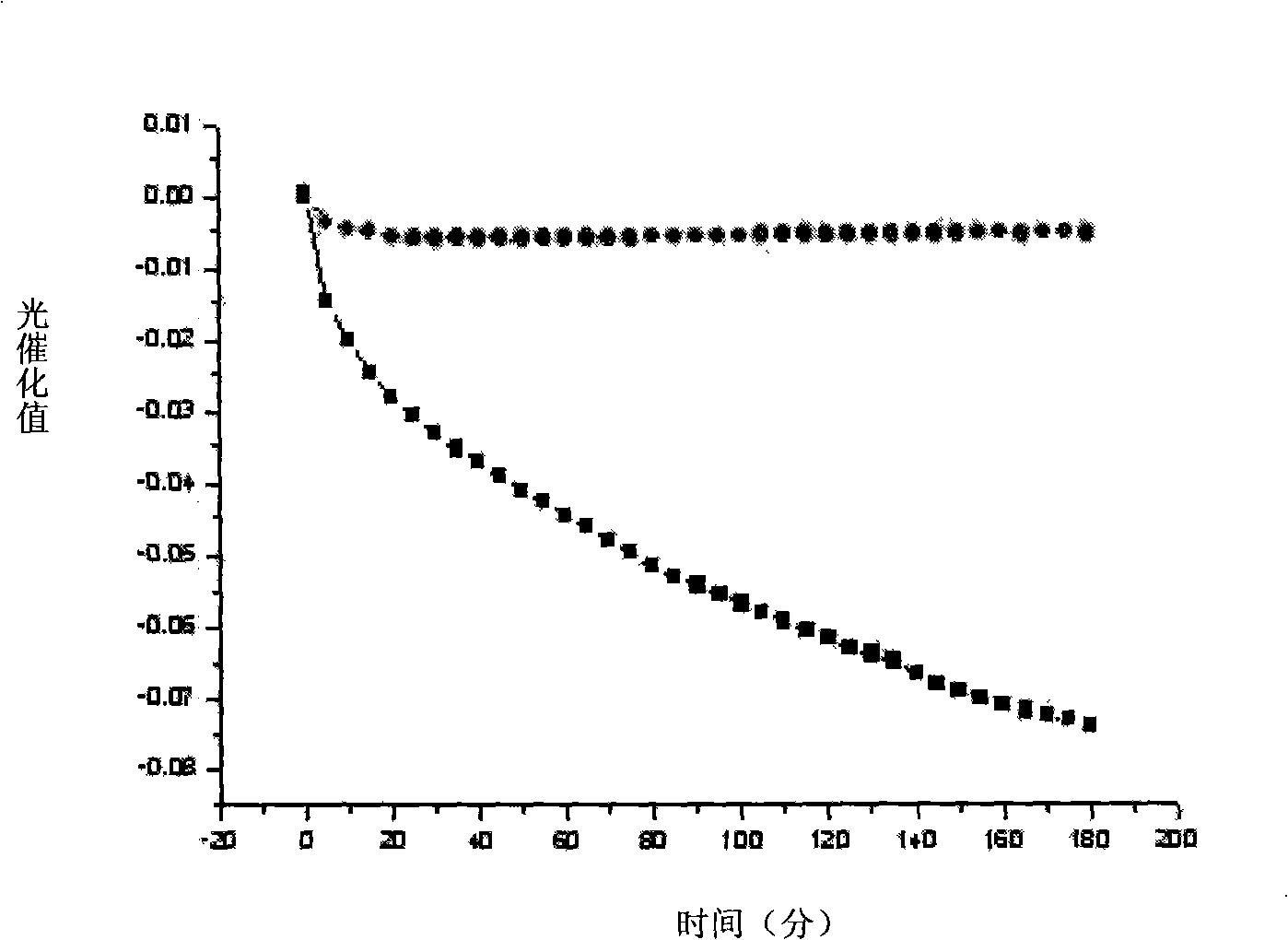

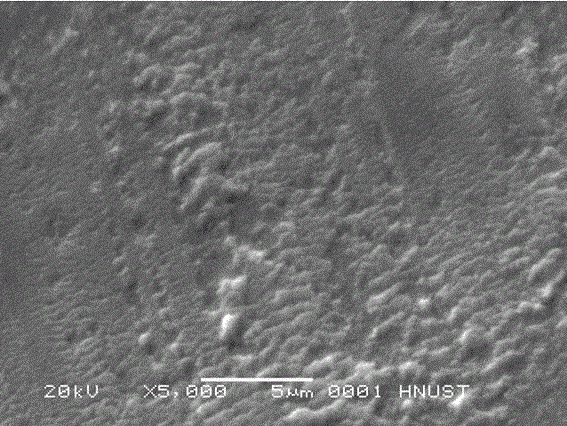

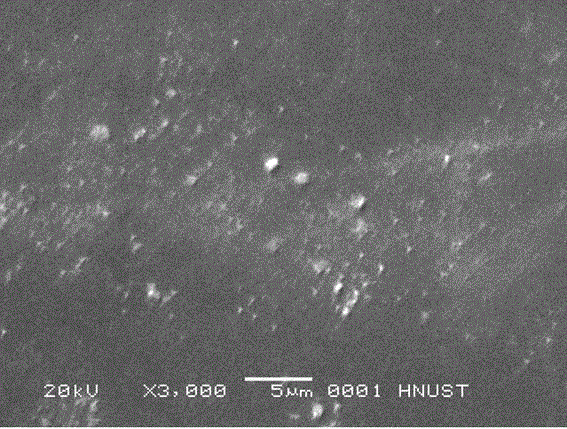

Method for raising titanium dioxide film self-cleaning glass photocatalytic activity

InactiveCN1400186AFacilitates the control of surface microstructureImprove photocatalytic activityOptical glassSelf-cleaning glass

The method for raising optical catalytic activity of titanium dioxide film self-cleaning glass is applicable to the fields of building window, car glass and optical glass, uses glass as base body forcoating film and includes the following steps: using sol-gel method to prepare titanium dioxide film, impregnating glass surface and coating film, acid treating surface of titanium dioxide film, washing with water and drying, the sodium ion of titanium dioxide film surface can be controlled in 0.3%, carbon content of film surface is reduced, hydroxy content of surface is increased, so that the optical catalytic activity of the glass can be greatly raised. It features signal method, effective and easy-to-control glass quality.

Owner:WUHAN UNIV OF TECH +1

Method for manufacturing self-cleaning glass plated with photocatalysis layer and antibacterial metal ions

The invention relates to a method for manufacturing self-cleaning photocatalysis antibacterial glass plated with a titanium dioxide photocatalysis layer and antibacterial metal ions. The method comprises the following steps: using a sol-gel method to prepare a photocatalysis film; performing cleaning pretreatment to the surface of glass; preparing titanium dioxide sol through titanium alkoxide hydrolysis; dispersing antibacterial nanometer metal ions in the titanium dioxide sol; adopting a dipping-pulling method to plate the glass; drying and then sintering the plated glass at a high temperature; and plating the glass for thickening. The method is characterized by simple process, no toxicity, quality control easiness, strong photocatalytic activity, high hardness, durability and the like.

Owner:林旺

Preparation method of self-cleaning coating and self-cleaning glass

ActiveCN103468109AHas super hydrophilic effectEfficient removalPolyether coatingsWeather resistancePolyethylene glycol

The invention relates to a preparation method of a self-cleaning coating and a self-cleaning glass. The preparation method includes: firstly preparing a SiO2 sol; then mixing the SiO2 sol with polyethylene glycol, ammonium perchlorate and n-butanol evenly to obtain the self-cleaning coating; and spraying the self-cleaning coating on the surface of a clean glass, then carrying out curing treatment, or performing toughening treatment according to a toughened glass process, thus obtaining the self-cleaning curtain wall glass. The self-cleaning film layer formed in the invention is a porous SiO2 structure, is firmly combined with a glass substrate and has excellent weather resistance. The prepared self-cleaning glass surface has a superhydrophilic effect, so that surface dirt can be effectively removed. With good weather resistance, the self-cleaning glass can be used in the curtain wall glass filed.

Owner:佛山中科邦达无机功能材料有限公司

Anti-reflection and self-cleaning glass and manufacturing method thereof

The invention discloses anti-reflection and self-cleaning glass and a manufacturing method of the glass. A nanocone array structure with sub-wavelength is formed on an impressing material on the glass surface by a nanometer impressing process based on a band soft mould or a nanocone array structure with sub-wavelength is etched on the glass surface by a hard mask, a nanometer impressing with an impressing material based on a band soft mould and a hard mask transferring etching process. The anti-reflection and self-cleaning glass can be applied to the fields of solar battery panels, glass curtain walls, automobile windshields, optical elements and instruments, large-size high-definition panel displays, infrared detectors and the like. The anti-reflection and self-cleaning glass disclosed by the invention has the advantages of high anti-reflection and self-cleaning performance, good durability, high stability, strong severe environment adaptation and low cost, and in particular, the efficient and low-cost mass production of the anti-reflection and self-cleaning glass with extra-large area can be realized.

Owner:QINGDAO BONA PHOTOELECTRIC EQUIP

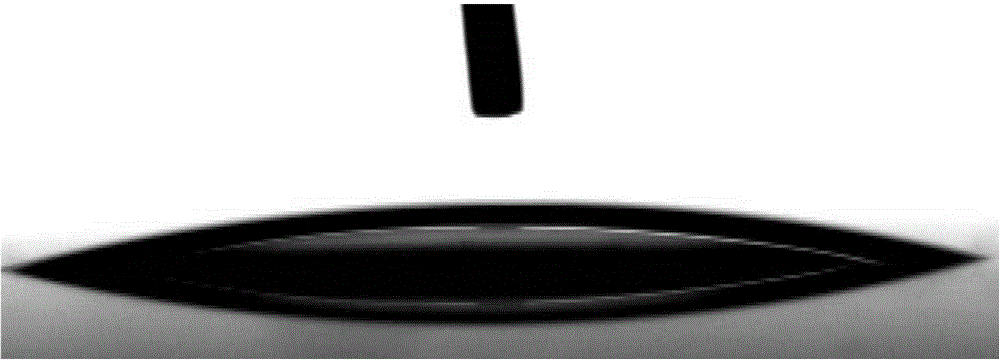

Method for preparing superhydrophobic and self-cleaning glass

ActiveCN105130206AExcellent superhydrophobic propertiesImprove stabilityPolymer scienceHydrophobic polymer

The invention relates to a method for preparing superhydrophobic and self-cleaning glass. The method comprises the following steps of submerging common glass in a piranha solution for surface hydroxylation treatment, putting the glass subjected to surface hydroxylation treatment in toluene, adding a silane coupling agent, of which terminal groups are double bonds, into the toluene for surface terminal double-bond treatment, then, covalently grafting a hydrophobic polymer to the surface of the glass by an in-situ polymerization or spraying method, and carrying out cleaning and airing, thereby preparing the superhydrophobic and self-cleaning glass. According to the method for preparing the superhydrophobic and self-cleaning glass, disclosed by the invention, a uniform and chemically-grafted polymer coating can be formed on the surface of the common glass and has good super-hydrophobicity, stability and light transmittance and excellent self-cleaning performance.

Owner:佛山市维宁新材料有限公司

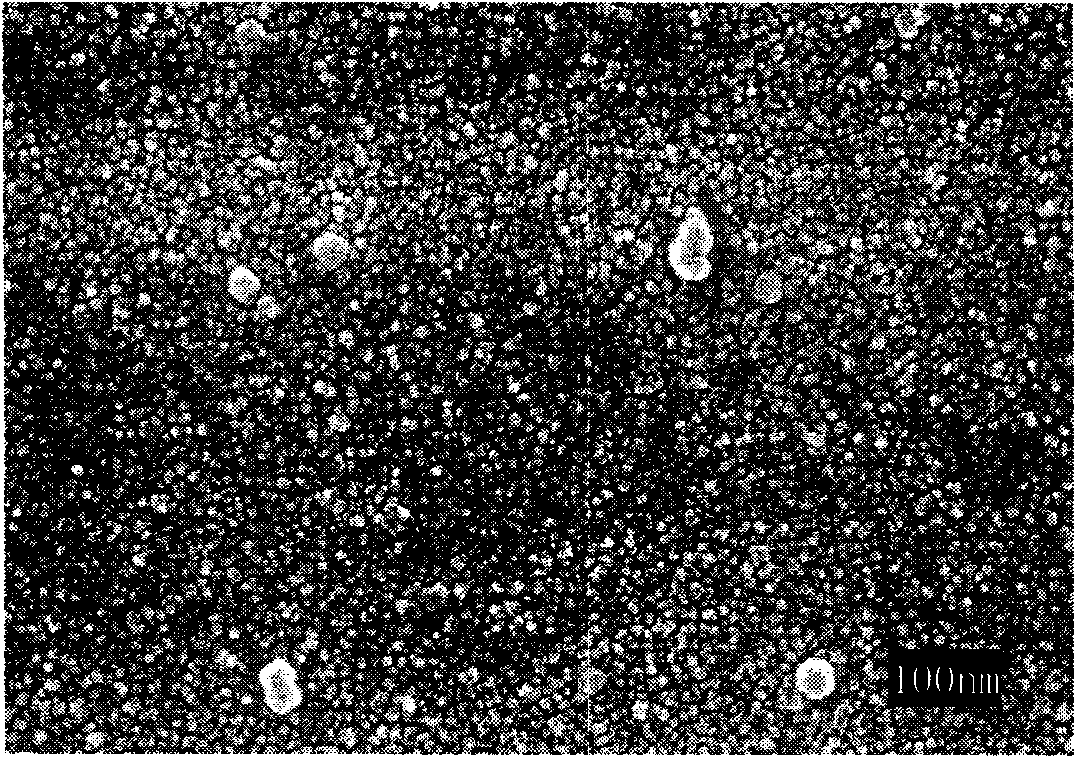

Self-cleaning glass and preparation method thereof

InactiveCN101985390AIncrease profitImprove photocatalytic efficiencyGlass/slag layered productsPhoto catalysisNanometre

The invention provides a self-cleaning glass. The self-cleaning glass comprises a glass base, a nano sliver layer and a titanium dioxide layer in turn, wherein the nano sliver layer is distributed between the glass base and the titanium dioxide layer; and the titanium dioxide layer is a photo-catalyst layer. The invention also provides a preparation method for the self-cleaning glass. Because the nano sliver layer is distributed on the glass and the titanium dioxide layer is distributed on the nano sliver layer, the self-cleaning glass can effectively improve the utilization rate of sunlight and improve the photo-catalysis efficiency of a TiO2 film so that the photo-catalysis efficiency of the self-cleaning glass is improved. In the preparation method for the self-cleaning glass, the nano sliver layer with strong bonding force with glass is formed on the surface of the glass by adopting a magnetron sputtering method, and the titanium dioxide layer which is not easy to fall from the glass is formed on the nano sliver layer by a sol-gel method, so the service life of the glass is long; and meanwhile, the preparation method has simple process and the reaction condition is easy to control.

Owner:BYD CO LTD

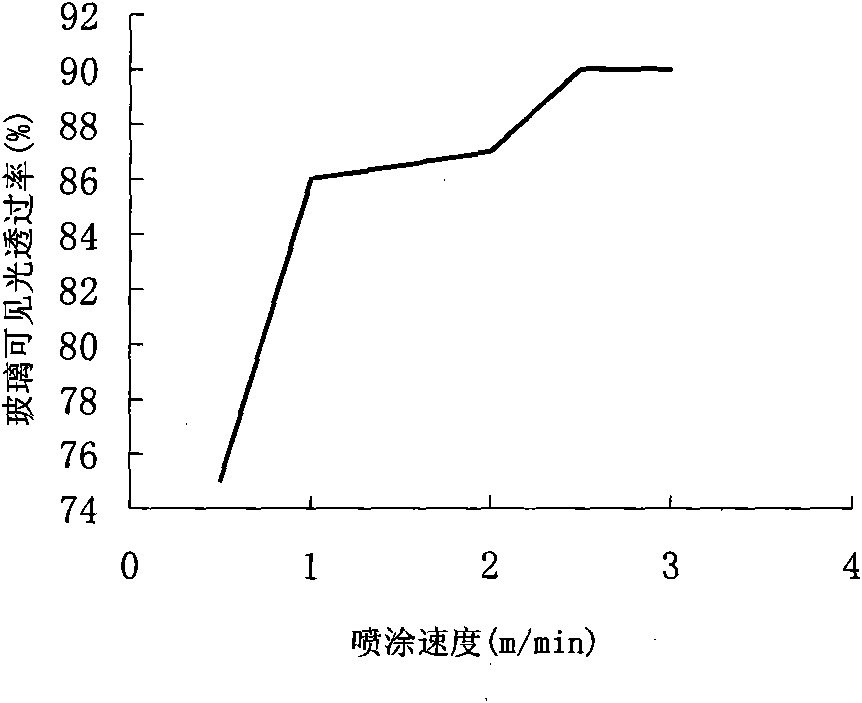

Production of self-cleaning glass

Production of self-cleaning glass is carried out by cleaning glass substrate, drying, pouring the prepared TiO2 sol into atomizer, spraying glass substrate surface with TiO2 composite sol at 1.0-2.5m / min, drying at 60-150 degrees C, and aging at 300 degrees C to obtain self-cleaning glass with TiO2 self-cleaning membrane. It has better super-hydrophilic property and self-cleaning ability.

Owner:格兰特工程玻璃(中山)有限公司

Fluorosilicate self-cleaning glass nanophase material and producing method thereof

The invention discloses a silicon fluoride self-cleaning glass nano-material, which is composed of solvent and active ingredients; the active ingredients are fluorinated modified silicone nano-particles, and the reaction raw materials comprise ortho-silicon ester and fluorine modified alkyl silane, with the ratio volume and dosage reaching 1.5-3:0.15-1.8. The invention also discloses a manufacturing method for the silicon fluoride self-cleaning glass nano-material, comprising two steps: synthesizing the surface modification of silica nano-particles, silica nano-particles; the ratio between volume and dosage for each added reactant is as follows: solvent: water: ortho-silicon ester: fluorine modified alkyl silane equals to 100: 1.5-3: 1.5-3: 0.15-1.8. The invention has simple production process, stable product performance, higher storage stability, excellent chemical properties, low surface energy and good tolerance against pollution, which is used for glass surface treatment; the contact angle between water and coating is greater than 110 degrees.

Owner:GUANGZHOU BAIYUN CHEM IND

Novel preparation method of nanometer self-cleaning glass

The invention provides a novel preparation method of nanometer self-cleaning glass with low refractive index. The preparation method comprises the following steps: 1) uniformly spraying a nanometer self-cleaning paint onto the surface of glass; 2) drying the self-cleaning glass obtained from the step 1) under the normal temperature or heating condition so as to obtain self-cleaning glass with a nanometer self-cleaning film; and 3) spraying a solvent A onto the surface of the self-cleaning glass obtained from the step 2), standing, removing the nano-pore-forming agent-dissolved solvent A, and drying to form a nanometer concave-convex structure on the film. The self-cleaning glass prepared by the method has raised self-cleaning ability and high light transmittance, also has enhanced super-hydrophilic property and antifogging property, and has wider applicability.

Owner:江纳股份公司

A method of nano self-cleaning glass production in the float glass production line

The invention relates to a method of nano self-cleaning glass production in the float glass production line. At the end of annealing kiln and above the area between the emergency transverse cutting machines in the float glass production line, the method need add the on-line spray equipment for spraying the nano self-cleaning paint across the float glass production line; evenly and directly spray the nano self-cleaning paint in fine mist on the non-tin surface of the glass at temperature 60-120 DEG C obtained at the end of the annealing kiln to form the nano self-cleaning coating; and then continue to follow the cold end manufacturing process of the float glass line to perform the on-line production to eventually obtain the nano self-cleaning glass. The method of invention saves the glass cleaning process before painting the nano self-cleaning paint during the traditional self-cleaning glass manufacturing. It uses the on-line clean glass obtained at end of the annealing kiln, directly sprays the nano self-cleaning paint on the non-tin glass surface to form the film; and saves the glass cleaning process as well as the resources.

Owner:北京中科华纳技术发展有限公司

Antifogging self-cleaning glass, and preparation method

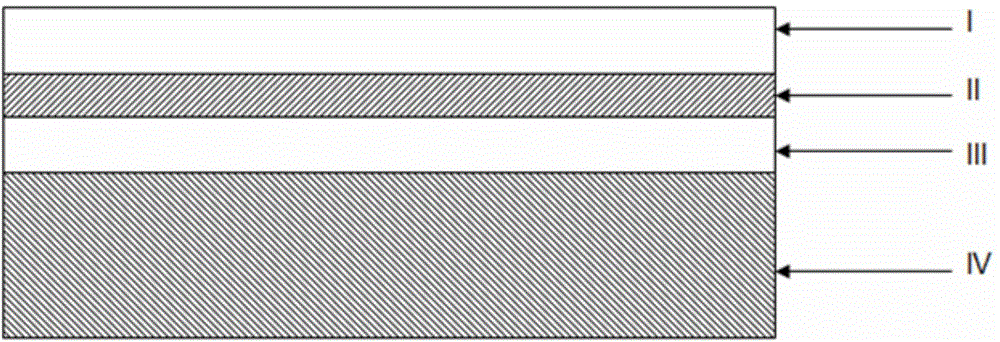

InactiveCN1872758AImprove hydrophilicityOvercome the disadvantage of strong dependenceRadio frequency magnetron sputteringTriple layer

This invention provides a method for mass production of fog-proof and self-cleaning glass. The method comprises: coating TiO2 and SiO2 onto a cleaned glass substrate by DC reactive magnetron sputtering technology and radiofrequency magnetron sputtering technology using pure titanium target and pure silicon dioxide (quartz) target respectively, thus obtaining TiO2 / SiO2 double-layer fog-proof and self-cleaning glass or SiO2 / TiO2 / SiO2 triple-layer fog-proof and self-cleaning glass. The obtained product has better hydrophilicity, lower initial wetting angle, and longer maintaining time after stopping UV radiation than those of TiO2 single-layer glass, and overcomes the shortcoming of strong dependence on environment of present fog-proof and self-cleaning glasses.

Owner:HUBEI UNIV

Preparation method of super-hydrophilic self-cleaning glass

The invention discloses a preparation method of super-hydrophilic self-cleaning glass and belongs to the technical field of film coating on glass. The provided preparation method adopts a liquid phase deposition method to deposit a photoinduced super-hydrophilic TiO2 membrane on glass surface, and uses metatitanic acid, silicon dioxide, hydrofluoric acid, ammonia, boracic acid and the like as the raw materials to prepare solution, wherein the concentration of titanium ion is 0.01-0.5M, the mol ratio of silicon and titanium is 0-1, the mol ratio of boron and titanium is 2-6, the pH value of the solution is 1.0-4.0; and a washed glass substrate is soaked in the solution vertically at the solution temperature of 20-80 DEG C, then taken out and washed after 1-20h of deposition, and air-dried at the temperature of 80-200 DEG C, thus obtaining the photoinduced super-hydrophilic TiO2 coated glass. The preparation method has the advantages of simple equipment, convenient operation, easily available raw materials, low cost, and the like.

Owner:张国栋

Super-hydrophilic self-cleaning coating material composition and preparation method thereof, and super-hydrophilic self-cleaning glass and preparation method thereof

PendingCN110093050ALow shrinkageHigh bonding strengthAntifouling/underwater paintsPaints with biocidesWeather resistancePhotocatalytic degradation

The invention relates to the field of self-cleaning glass, and discloses a super-hydrophilic self-cleaning coating material composition and a preparation method thereof, and a super-hydrophilic self-cleaning glass and a preparation method thereof. The super-hydrophilic self-cleaning coating material composition comprises a modified nanometer silica sol, an anatase type nanometer titanium dioxide sol and water, and based on the total amount of the solid-state sol, the mole fraction of the modified nanometer silica sol is 40-70%, and the mole fraction of the anatase type nanometer titanium dioxide sol is 30-60%. The structure of the super-hydrophilic self-cleaning glass sequentially comprises a coating formed by the super-hydrophilic self-cleaning coating material composition, and a glass plate from top to bottom. The present invention further provides a super-hydrophilic self-cleaning coating material composition and a preparation method thereof, and a super-hydrophilic self-cleaning glass and a preparation method thereof. According to the present invention, the super-hydrophilic self-cleaning coating material composition has characteristics of excellent super-hydrophilic property,excellent photocatalytic degradation property, reflection reducing, weathering resistance and good self-cleaning performance, the coating process is simple to construct and operate, and the large-areaconstruction application in multiple fields can be achieved.

Owner:MATERIAL & IND TECH RES INST BEIJING

Self-air-supply ash-filtering cooling silencing closable fireproof tall building with solar warming water heater

InactiveCN102364016AQuality improvementAvoid enteringShutters/ movable grillesFireproof doorsCollection systemFire extinguisher

The invention discloses a self-air-supply ash-filtering cooling silencing closable fireproof tall building with a solar warming water heater. An air supply system consists of a blind window with self-cleaned glass, a spraying water pipe, an air inlet main pipe which extends to an underground garage and then is sealed at a roof, air inlet branch pipes and valve covers which extend to each room, a stainless wind energy fan which extends from the underground garage to a place which is 6 m higher than the roof or a pipe orifice with a rain shade, an air exhaust main pipe of which the lower end is sealed, and air exhaust branch pipes and the valve covers which extend to each room. A heat preservation system consists of an internal door, windows, rolling gates which are arranged outside the windows, anti-theft fences, a heat preservation layer which is arranged on the external wall, an air relative isolation layer which is arranged outside the heat preservation layer, and a ceramic partition wall which is arranged outside the air relative isolation layer. Preferably, the solar warming water heater which is arranged on a shelf is connected with an indoor electric water heater and metal pipes under the floor to form a heat collection system. The invention has the advantages that: a livable environment which is dustless, quiet, warm in winter, cool in summer and fresh in air is created; and when a fire alarm is given, the doors, the windows, air inlet pipelines and air outlet pipelines are closed to eliminate a chimney effect, and with no need of escaping, people can wear gas masks, carry oxygen bottles and hold fire extinguishers to effectively extinguish fire.

Owner:郭厚德

Sunlight controlled self cleaning glass and its producing method

The present invention discloses one kind of sunlight controlled self-cleaning glass and its making process. The sunlight controlled self-cleaning glass includes three layers, the first layer of glass plate, the second layer of sunlight controlled layer and the third layer of the outmost self-cleaning layer. The first layer is Si-Na-Ca glass; the second layer consists of at least one of the oxide of Fe, Cr, Cu, Co, Ti, Mn, Ni, V, Al, Mg, Sn and Ca; and the third layer consists of TiO2 with or without dopant. The sunlight controlled self-cleaning glass has both sunlight control and self-cleaning functions, and is made through on-line high temperature pyrolysis spraying process.

Owner:FUYAO GLASS IND GROUP CO LTD

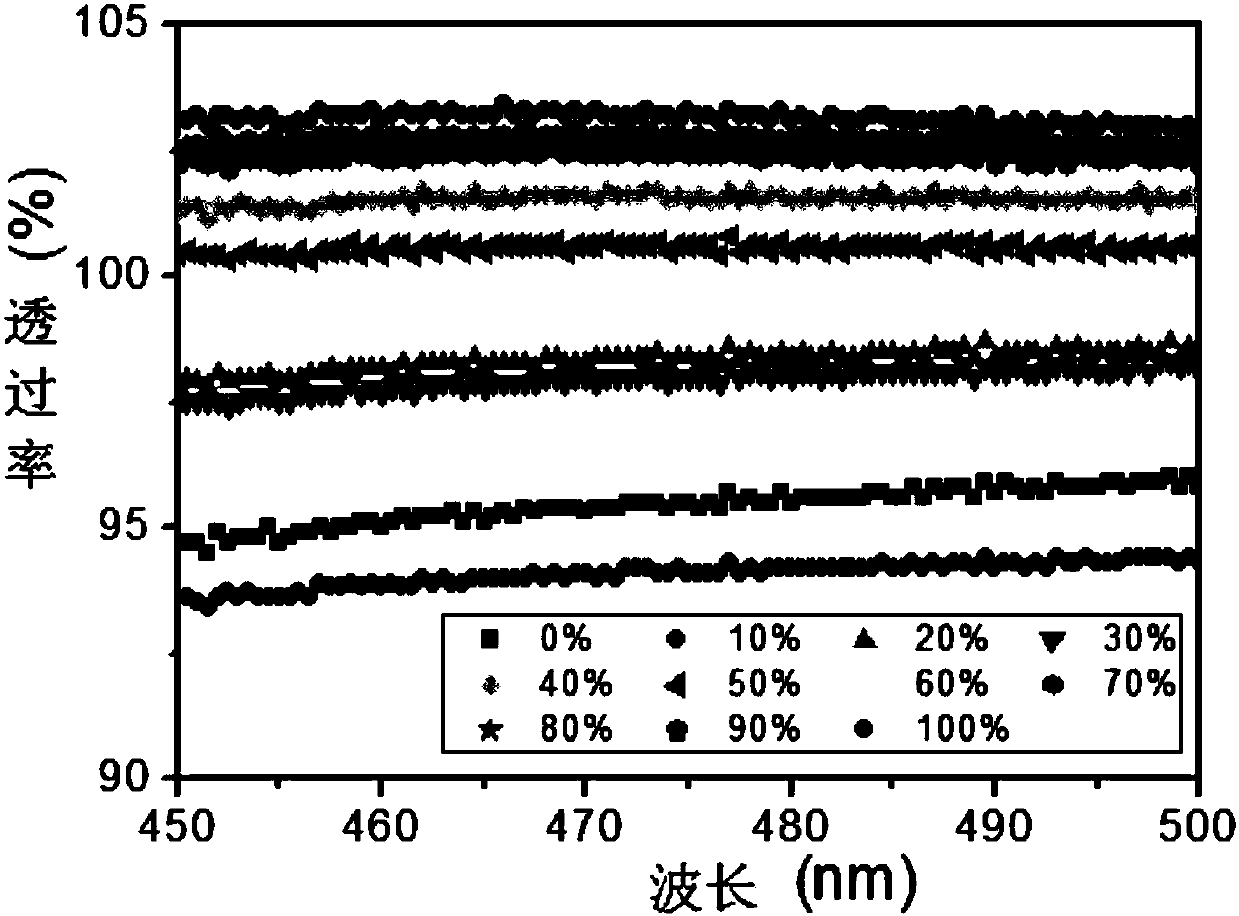

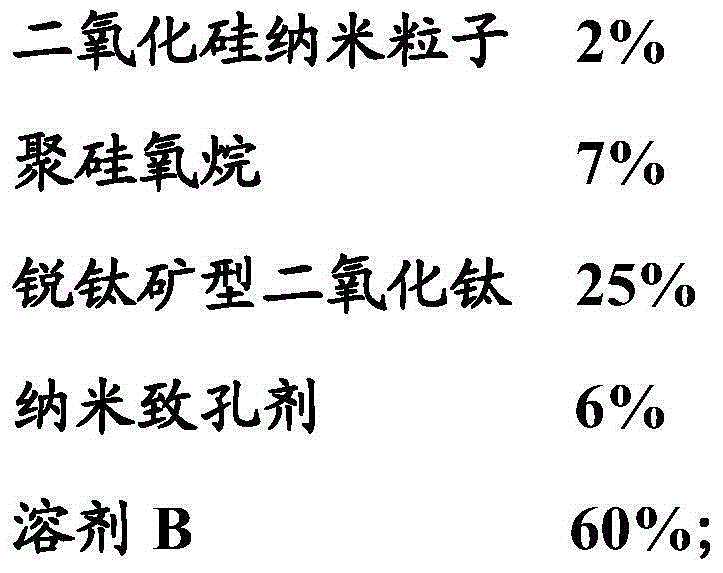

Novel nanometer self-cleaning paint and nanometer self-cleaning glass containing coating formed by paint

ActiveCN104673090ALow refractive indexImprove self-cleaning abilityCoatingsFoaming agentTransmittance

The invention provides a novel nanometer self-cleaning paint and nanometer self-cleaning glass containing coating formed by the paint. The paint comprises the following components: (a) silicon dioxide nanoparticles, (b) polysiloxane, (c) anatase type titanium dioxide, (d) a nanometer pore-foaming agent and (e) a solvent B. The self-cleaning glass has improved self-cleaning capacity and high light transmittance and also has enhanced super-hydrophilic property and antifogging property and wide applicability.

Owner:北京中科华纳技术发展有限公司

Method for preparing self-cleaning glass

The invention discloses a method for preparing self-cleaning glass, which comprises the following steps: cleaning and air-drying a glass substrate; performing the mixing preparation of TiO2 composite sol according to the following components in the weight ratio of TiO2 to SiO2 to CeO2 to H2O being 20-30: 0.1-1: 0.02-0.1: 65-70; then pouring the prepared TiO2 composite sol into an atomizer, and spray-coating the TiO2 composite sol onto the surface of the glass substrate at a speed of between 1.0 and 2.5m / min; drying the position on the glass substrate spray-coated with the TiO2 composite sol at a temperature of between 60 and 150 DEG C; and aging the glass substrate at a temperature of 300 DEG C to obtain the self-cleaning glass coated with a TiO2 self-cleaning film. The TiO2 self-cleaning film has super-hydrophilicity under visible light conditions; and the surface of the glass can form an intact water film when encountering water, and has self-cleaning capability.

Owner:格兰特工程玻璃(中山)有限公司

Self-cleaning glass and its production

InactiveCN1939857AReduced activityPhotocatalyticPlane surface grinding machinesCooking & bakingAlcohol

A self-cleaning glass and its production are disclosed. The glass consists of glass raw sheet and light catalyst coating set on surface of glass raw sheet, which comprises anatase nano-titanium dioxide, isopropyl alcohol, sodium dodecyl benzene sulfonate, silicon sol, alcohol and water. The process is carried out by concentrating for glass raw sheet, cutting, polishing, edging, surface washing by acid, washing by pure water, baking and drying at high temperature and tempering treating. It's smooth and transparent, has excellent light catalytic and sterilizing functions, strong oxidative performance, and higher degradation rate.

Owner:HUAXIA SAFETY GLASS SCI & TECH SHENZHEN

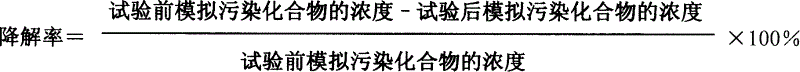

Titanium dioxide thin film self-cleaning glass optical catalytic activity inspection method

InactiveCN1621844AGood test methodEasy to operateAnalysing fluids using sonic/ultrasonic/infrasonic wavesScattering properties measurementsPhotocatalytic reactionProduct gas

The process of testing the photocatalytic activity of self-cleaning glass with titania film includes the following steps: preparing glass sample; connecting photocatalytic reactor with opto-acoustic-infrared gas monitoring instrument, setting near ultraviolet lamp and mini fan inside the photocatalytic reactor, and connecting drier with the photocatalytic reactor and mini vacuum pump; setting the sample inside the photocatalytic reactor and injecting the simulating pollutant into the photocatalytic reactor; homogenizing the components inside the photocatalytic reactor, controlling the initial concentration of pollutant and vapor and test temperature; regulating light strength and the concentration of the degraded medium and degraded product; continuous on-line monitoring with the opto-acoustic-infrared gas monitoring instrument and outputting test result; and calculating degradation rate. The present invention has easy operation and convenient detection.

Owner:HUBEI SANXIA NEW BUILDING MATERIALS CO LTD +1

Method for producing nano antibiotic far infrared self cleaning glass and its product

The present invention discloses a kind of nanometer antibiotic self-cleaning glass and its production process. The recipe includes main material comprising ZrO2, SiO2, Al2O3, Na2O, TiO2, ZnO and Fe2O3, and supplementary material comprising CaO, Cr2O3, CuO, MnO2, Se, Cd and CoO. The present invention can produce various kinds of color far infrared antibiotic self-cleaning glass, glass utensils and microporous glass products. The far infrared antibiotic self-cleaning glass may be used as building glass for high grade building, decoration glass, etc, as main material for microporous glass filter, and in making glass utensil and container. The products of the present invention possess antibiotic, degrading and self-cleaning effects.

Owner:刘明前

High-light-transmittance and low-radiation self-cleaning glass

The invention discloses self-cleaning glass which has high visible light transmittance and high infrared ray reflectivity. The self-cleaning glass is provided with a cladding layer prepared by a magnetron sputtering processes on one side, and the cladding layer structurally comprises a medium layer 1, a medium layer 2, a medium layer 3 and a glass substrate layer, wherein the medium layer 1 adopts a rare earth element-containing titanium oxide layer with the thickness of 15-200nm, the medium layer 2 adopts a titanium oxide / silicon oxide blend layer with the thickness of 10-150nm, and the medium layer 3 adopts a metal oxide or metal fluoride layer with the thickness of 5-350nm. By the magnetron sputtering processes, the whole production process of the self-cleaning glass is safe, environment-friendly and free of pollution to the environment; by adopting a structural design of a glass film layer, the surface water contact angle is less than 2 degrees, and in a visible light waveband, the light transmittance is 2% higher and the visible light reflectivity is 5% lower than those of cladding-layer-free glass with the same specification respectively; the self-cleaning glass has the infrared reflectivity of 70%; through a design of a film system of the cladding layer, the self-cleaning glass provided by the invention overcomes contradictions of the conventional titanium-oxide-coating self-cleaning glass in aspects of high light transmittance and low radiation, and can be widely used as a high-end building material and photovoltaic glass.

Owner:HEFEI JIAWEI DECORATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com