Method for preparing self-cleaning toughened glass

A tempered glass, self-cleaning technology, applied in the field of functional materials, can solve the problems of unstable performance of self-cleaning glass, high heat treatment temperature, low photocatalytic activity, etc., and achieve good photo-induced hydrophilicity, high light transmittance, high performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Remove all labels and dirt on the glass surface to ensure that the glass surface is clean, and then wash off the dust on the glass surface with water. Use glass polishing powder of about 400 mesh (the mixing ratio of polishing powder and deionized water is 1:10) to polish the glass surface with a rotating disk, then rinse the dirt and polishing powder on the glass surface with water, and use a fan with a filter to clean the surface of the glass. Dry the moisture on the glass surface to ensure that the glass surface is clean without any dust, and then use high-purity nitrogen to purge the glass surface. Use a spray gun to evenly spray nano self-cleaning coating with a concentration of 10g / l on the glass surface (speed 1 m / s), and cure at normal temperature and pressure to obtain super-hydrophilic self-cleaning glass.

[0036] Then acid-treat the surface of the cured self-cleaning glass. The acid used is 0.5M HCl aqueous solution. The soaking time is 1 hour. After taking i...

Embodiment 2

[0040] Clean the original glass sheet, dry the surface with a hair dryer, and evenly spray the self-cleaning nano-coating with a concentration of 25g / l on the glass surface (speed 2.5 m / s) with a spray gun. If there is too little cleaning coating, the film formation is not good, resulting in a significant decrease in its photocatalytic activity.

Embodiment 3

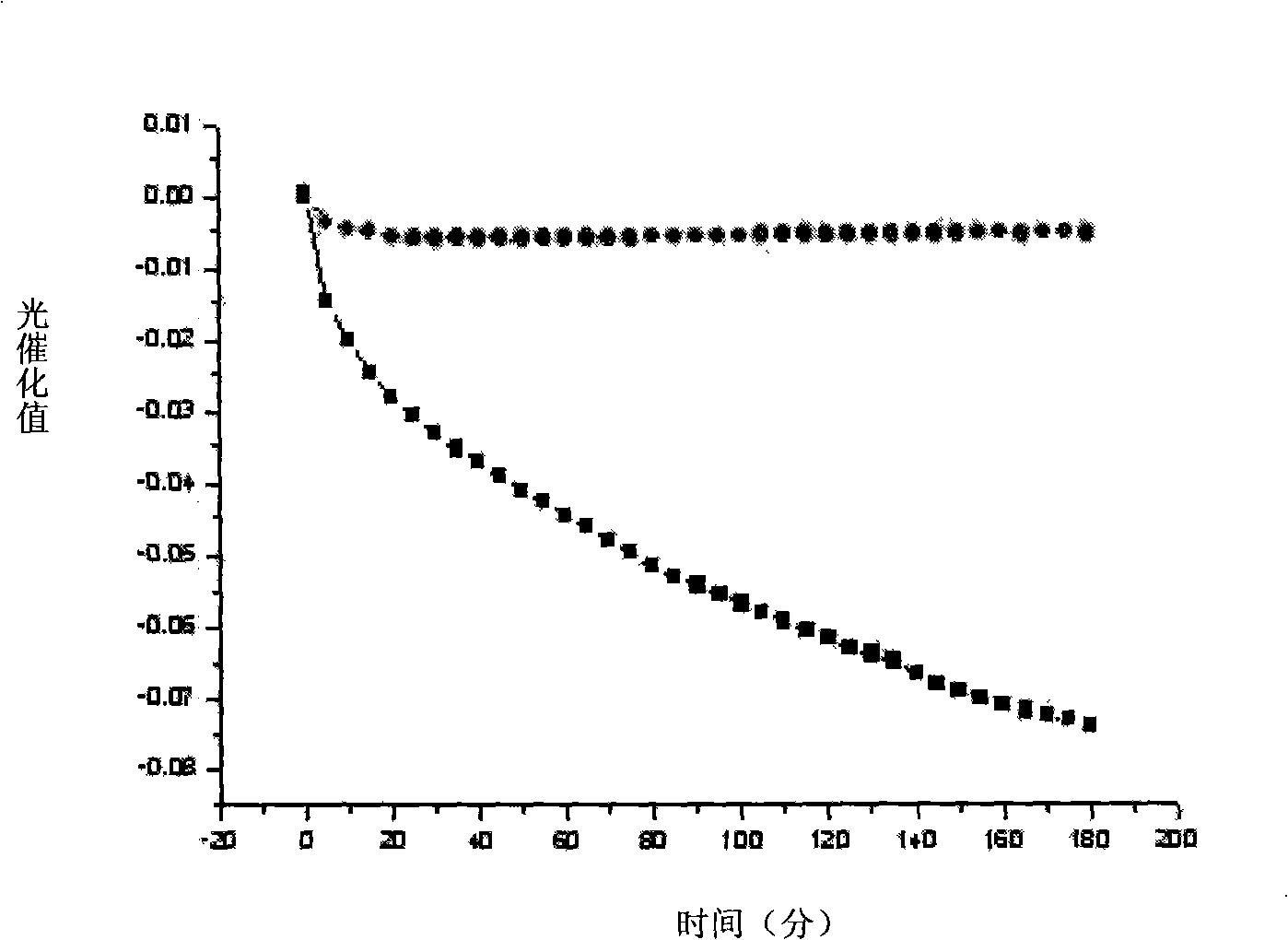

[0042] Use 400-mesh glass polishing powder to polish the glass surface with a rotating disc, then rinse the dirt and polishing powder on the glass surface with water, dry it naturally in a clean place, and spray the self-cleaning nano-coating with a concentration of 20g / l evenly with a spray gun Superhydrophilic self-cleaning glass can be obtained by curing at normal temperature and pressure on the glass surface (speed 0.9 m / s). Then acid-treat the surface of the cured self-cleaning glass. The acid used is 3M acetic acid aqueous solution. The soaking time is 2 hours. After taking it out, rinse it with tap water, rinse it with deionized water, and dry it under natural conditions. Then the prepared self-cleaning glass was tempered at 700°C for 550 seconds. The treated self-cleaning glass maintained good superhydrophilic properties and photocatalytic properties, but due to the slow spraying speed, the light transmittance of the glass surface was significantly reduced. However, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com