Low-temperature prepn process of self-cleaning nano Tio2 glass

A nano-titanium dioxide, self-cleaning technology, applied in the chemical industry, can solve the problems of expensive equipment, necessary vacuum system, restricting the practical process of nano-TiO2 thin film materials, etc., to achieve the effect of simple equipment, small investment and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

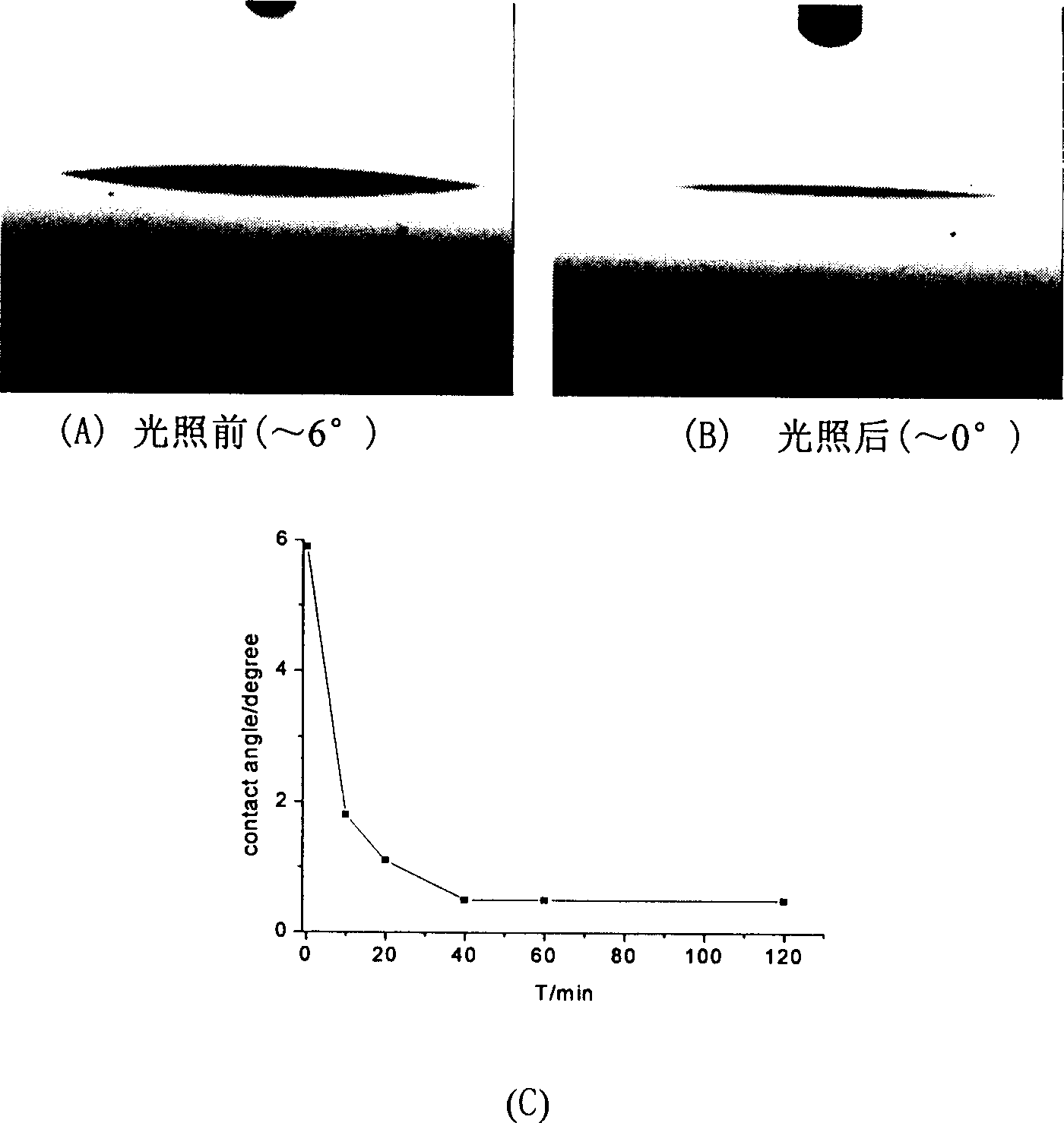

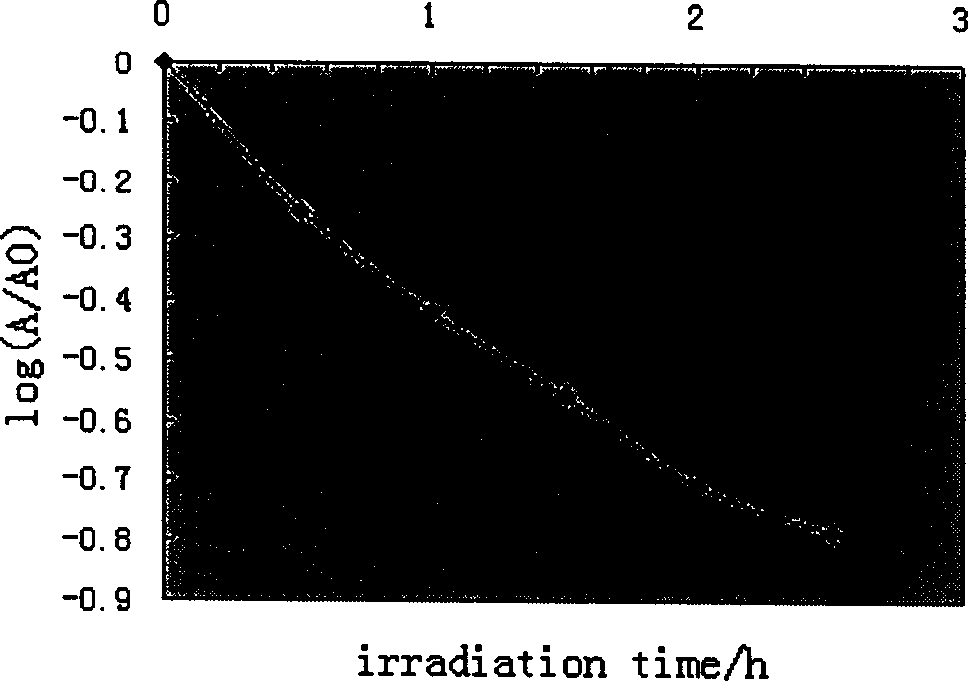

[0019] Embodiment 1: with 9.2ml anatase type TiO 2 Colloid, 3ml water-soluble silica sol and 47.8ml deionized water are mixed and stirred evenly; put the cleaned glass substrate prepared in advance into the colloid vertically, then pull it up at a uniform speed, place it in a clean environment, and place it in the Dry and solidify at room temperature or cool naturally after treatment at 300°C or less. The self-cleaning glass thus prepared has a wavelength of 254nm and an optical power density of 200μW / cm 2 After 40 minutes of exposure to high-grade ultraviolet light, the contact angle dropped from 54° to less than 1°, close to 0°, which has obvious anti-fog function.

Embodiment 2

[0020] Example 2: After mixing 4ml of tetraethyl orthosilicate and 50ml of absolute ethanol (≥99.7%) and stirring for 4 hours, add a mixture of deionized water (4ml) and HCl (0.12ml) and stir for 2 hours; Then anatase TiO diluted with absolute ethanol (50ml) 2 Colloid (20ml) was added therein and mixed evenly with a sonicator. Put the pre-prepared clean glass substrate into it, and pull it up vertically at a constant speed, and place it in a clean environment to dry and cure naturally or cool it naturally after processing at 300°C or less. The self-cleaning glass thus prepared has a wavelength of 254nm and an optical power density of 160μW / cm 2 After 40 minutes of exposure to ultraviolet light, the contact angle to water dropped from 13° to below 1°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com