Directional porous monatomic carbon membrane electrode and preparation method and application thereof

An atomic carbon, membrane electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of electrode material shedding, blocking electrode and electrolyte, high hydrogen production rate, and achieve good industrial application value, high activity and stability. The effect of high conductivity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

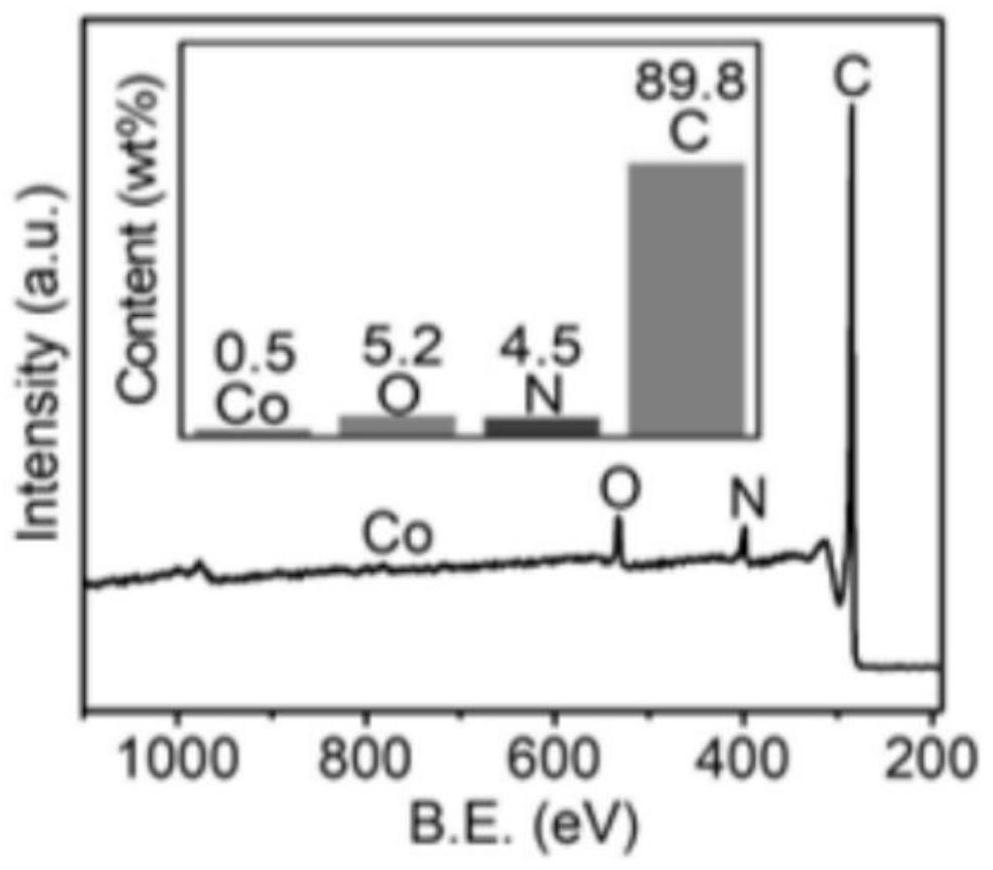

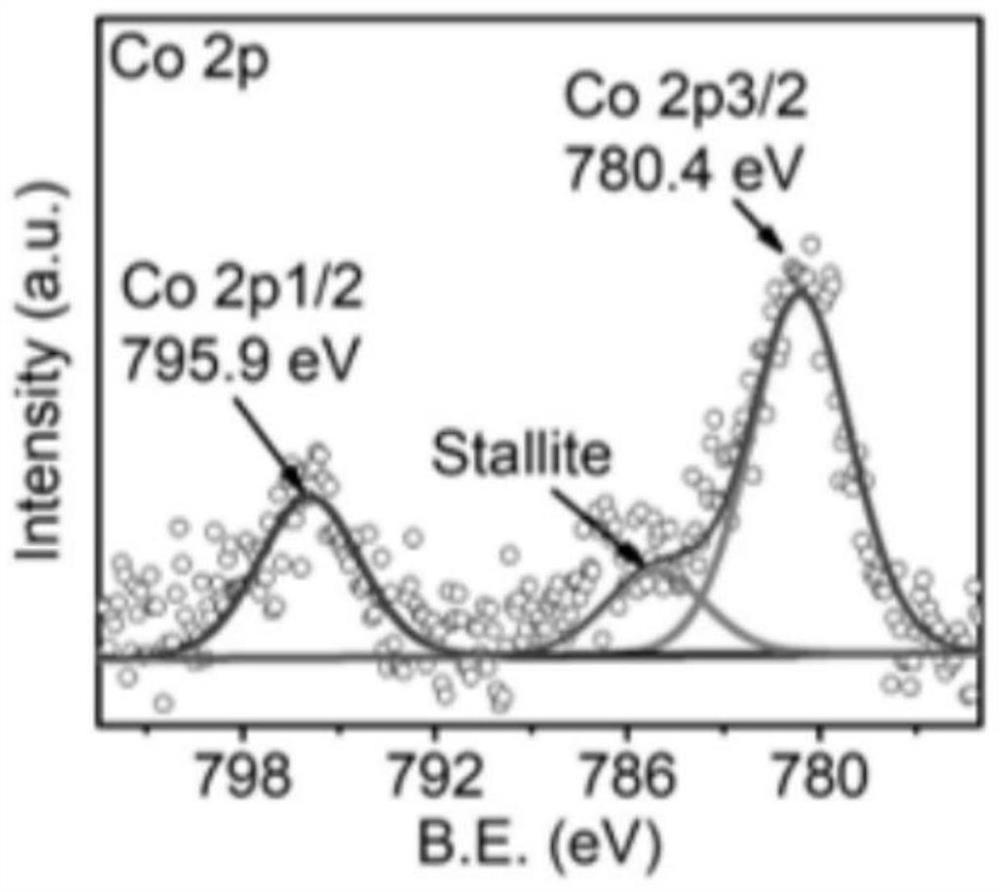

[0066] A kind of preparation method of oriented porous monoatomic carbon film electrode (Co-NC-AF) of the present invention, comprises the following steps:

[0067] (1) Preparation of O-MWCNTs (oxidized multi-walled carbon nanotubes)

[0068] O-MWCNTs are synthesized by oxidizing MWCNTs (multi-walled carbon nanotubes) under strong acid and oxidizing conditions. First, MWCNTs (150mg) were dispersed in 36mLH 2 SO 4 (98wt%), add 4mLH after stirring for 1h 3 PO 4 (85wt%), then stirred for 15min;

[0069] Then slowly add KMnO 4 (750mg), reacted at 65°C for 2h, cooled to room temperature naturally, poured into the solution containing 5mLH while stirring 2 o 2 (30 wt%) in 100 mL ice water; the precipitate was washed several times with HCl (10 vol%), ethanol, and water until the pH value reached about 7.0; finally, the precipitate was diluted with water to obtain the desired concentration of O-MWCNTs aqueous solution.

[0070] (2) Preparation of Co-NC-AF (Co-N-C modified orien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com