Preparation method of self-extinguishing, super-hydrophilic and underwater super-oleophobic coating

An underwater super-oleophobic and super-hydrophilic technology, used in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of poor mechanical durability, unstable performance, slow response, etc., and achieve a wide range of applications. Prospect, simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

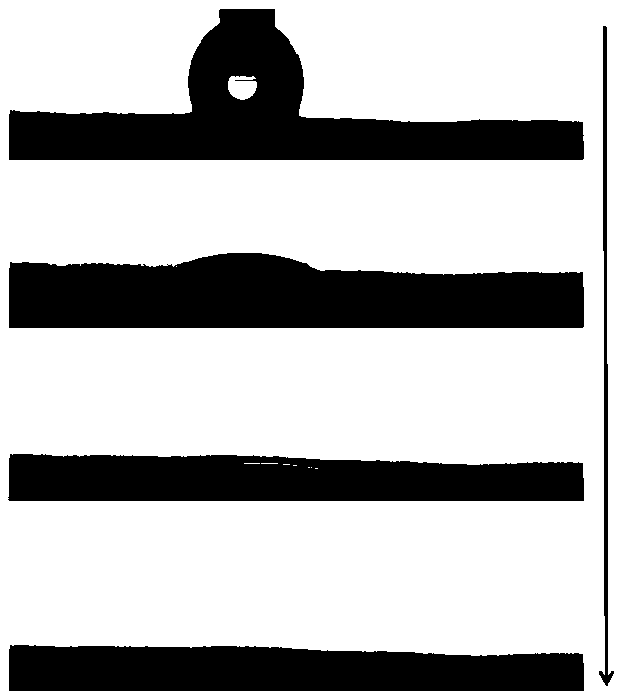

Image

Examples

Embodiment 1

[0029] (1) Prepare a cationic polyelectrolyte (polyethyleneimine PEI) aqueous solution with a concentration of 4 mg / mL, an anionic polyelectrolyte (ammonium polyphosphate APP) with a concentration of 10 mg / mL, and an anion with a mass concentration of 8%. Polyelectrolyte (phytic acid PA) aqueous solution. The PET fabric was washed several times with water and ethanol, and then immersed in a 5 wt% NaOH aqueous solution for 10 minutes to make it negatively charged.

[0030] (2) The PET fabric treated with the NaOH aqueous solution was immersed in the PEI aqueous solution (4 mg / mL) for 10 minutes to load the PEI layer. The PEI coated fabric was then washed with deionized water and squeezed to remove excess water. Then it was soaked in PA aqueous solution (8 wt%) for 10 minutes and washed with water. Then the PEI / PA coated fabric is dried in an oven at 50°C to completely remove the excess water, and finally PEI / PA@PET fabric is obtained.

[0031] (3) Immerse the PEI / PA@PET fabric in...

Embodiment 2

[0038] (1) Prepare a cationic polyelectrolyte (polyethyleneimine PEI) aqueous solution with a concentration of 4 mg / mL, an anionic polyelectrolyte (ammonium polyphosphate APP) with a concentration of 10 mg / mL, and an anion with a mass concentration of 8%. Polyelectrolyte (phytic acid PA) aqueous solution. The iron net (4 cm*4 cm) was washed several times with water and ethanol, and then immersed in a 5 wt% NaOH aqueous solution for 10 minutes to make it negatively charged.

[0039] (2) Immerse the iron mesh in the PEI aqueous solution (4 mg / mL) for 10 minutes to load the PEI layer. Then wash with deionized water. Then it was soaked in PA aqueous solution (8 wt%) for 10 minutes and washed with water. Then the PEI / PA coated iron mesh was dried in an oven at 50°C to completely remove excess water, and finally PEI / PA @ SS mesh was obtained.

[0040] (3) Immerse the PEI / PA @ SS mesh in the PEI solution again for 10 minutes, then wash with deionized water. Then soak it in the aqueous...

Embodiment 3

[0053] (1) Prepare a cationic polyelectrolyte (polyethyleneimine PEI) aqueous solution with a concentration of 6 mg / mL, an anionic polyelectrolyte (ammonium polyphosphate APP) with a concentration of 15 mg / mL, and an anion with a mass concentration of 6%. Polyelectrolyte (phytic acid PA) aqueous solution. The sponge (4 cm*4 cm) was washed several times with water and ethanol, and then immersed in a 5 wt% NaOH aqueous solution for 10 minutes to make it negatively charged.

[0054] (2) Immerse the sponge in a PEI aqueous solution (6 mg / mL) for 10 minutes to load the PEI layer. Then wash with deionized water. Then it was soaked in PA aqueous solution (6 wt%) for 10 minutes and washed with water. Then the PEI / PA coated sponge was dried in an oven at 50°C to completely remove excess water, and finally PEI / PA@sponge was obtained.

[0055] (3) Immerse the PEI / PA@ sponge in the PEI solution again for 10 minutes, and then wash with deionized water. Then soak it in the aqueous APP (15mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com