Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Polymer engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of polymers, compounding and processing of polymers and description of major polymers, structure property relations and applications.

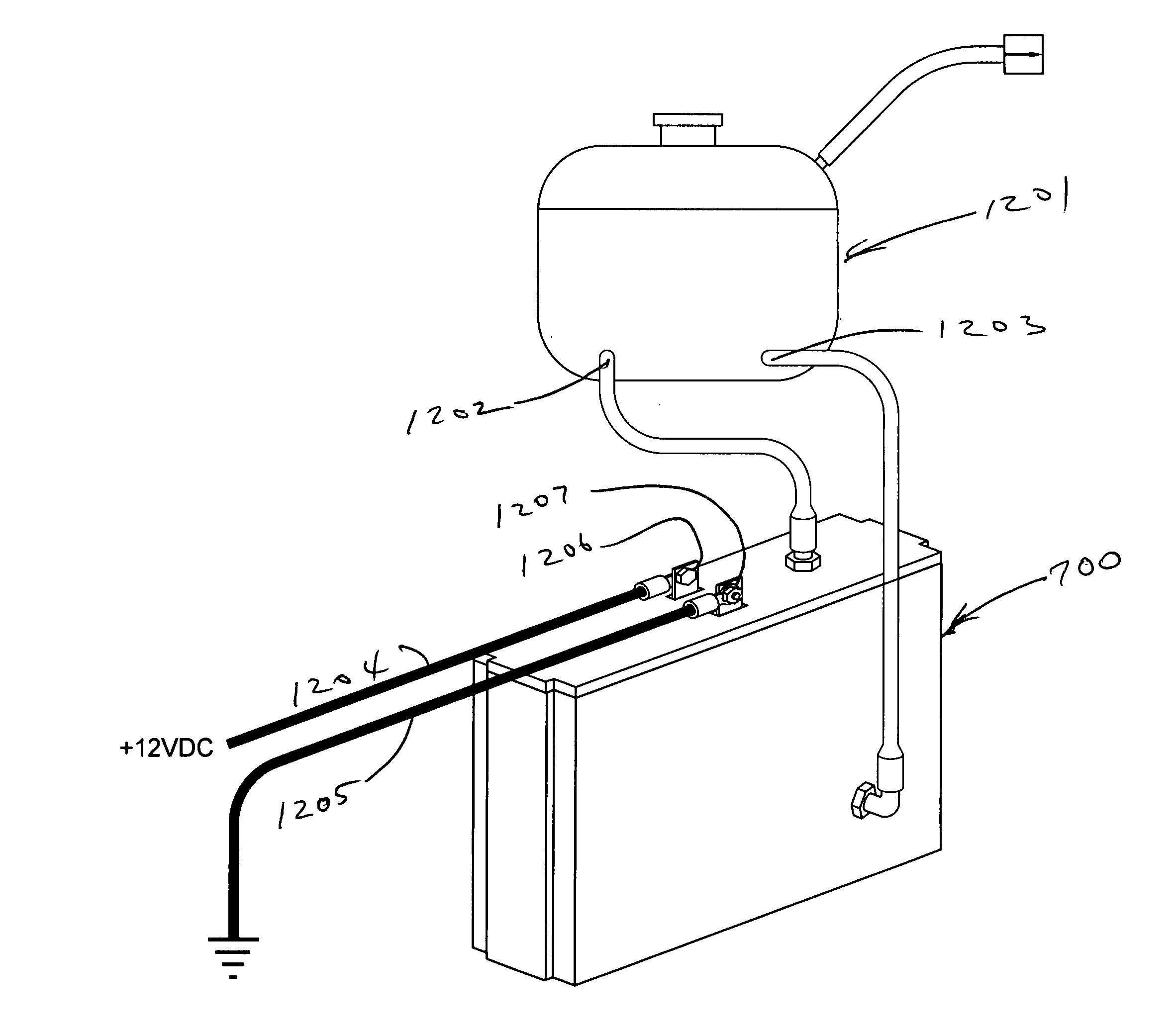

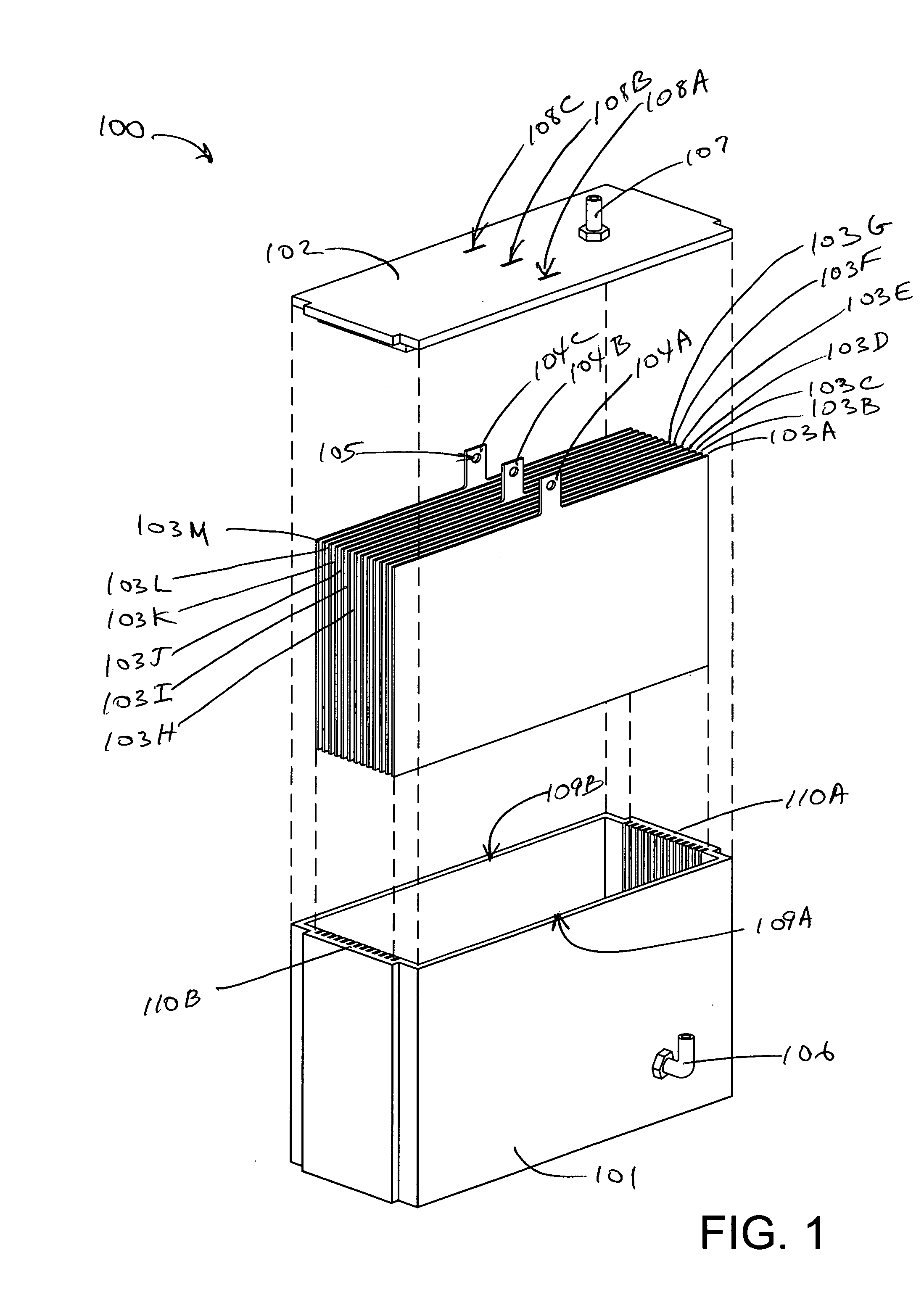

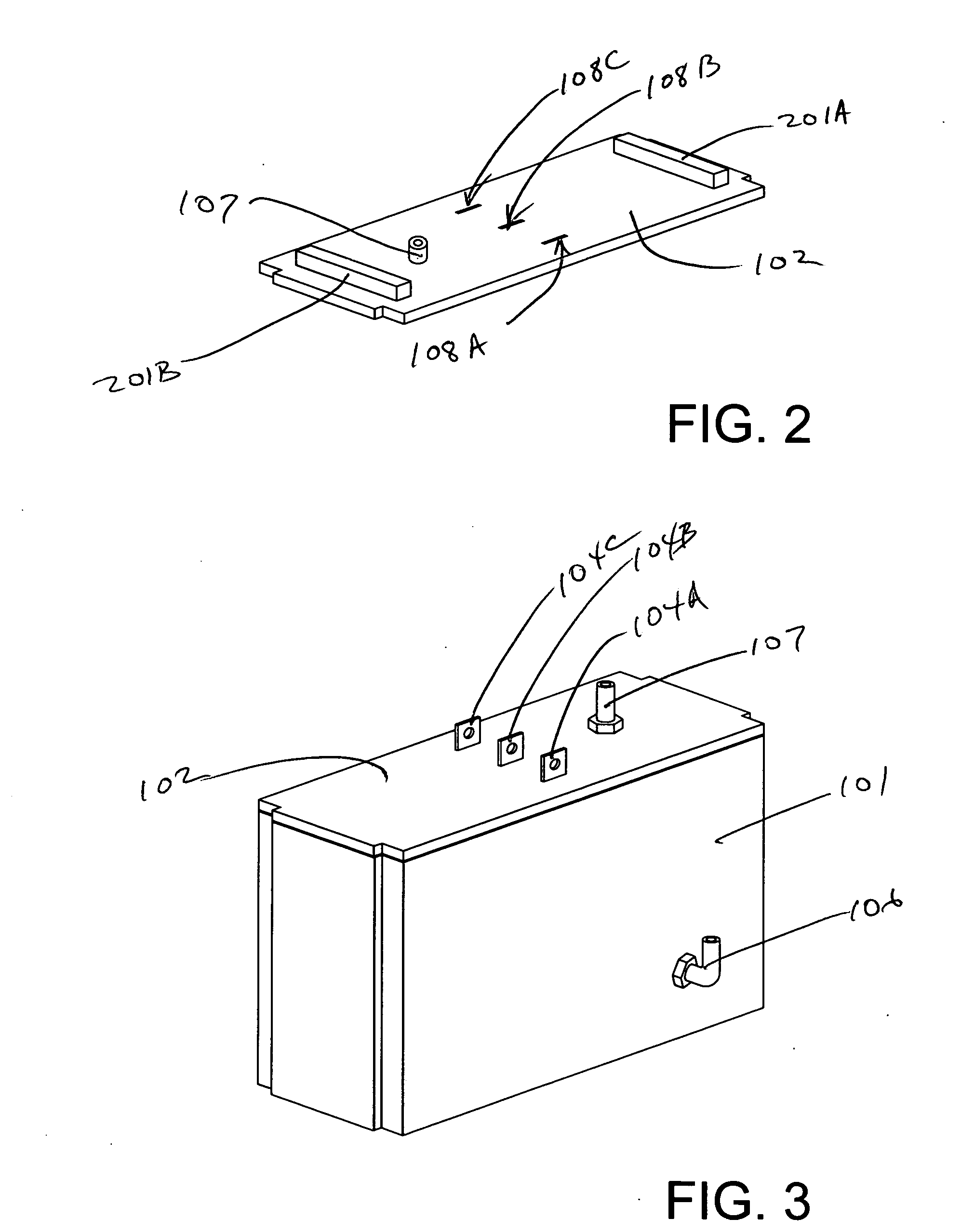

Hydrogen and oxygen generator having semi-isolated series cell construction

InactiveUS20100065419A1Improve sealingFirmly connectedCellsPhotography auxillary processesThermoplasticHysteresis

Owner:RICHARDSON DAVID THOMAS

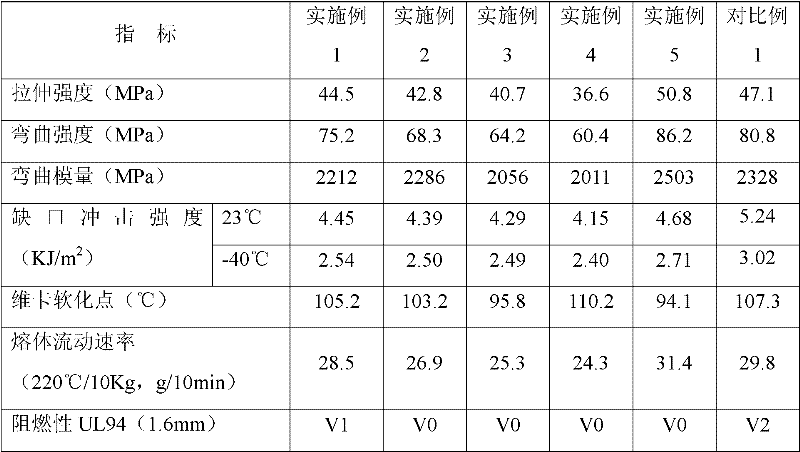

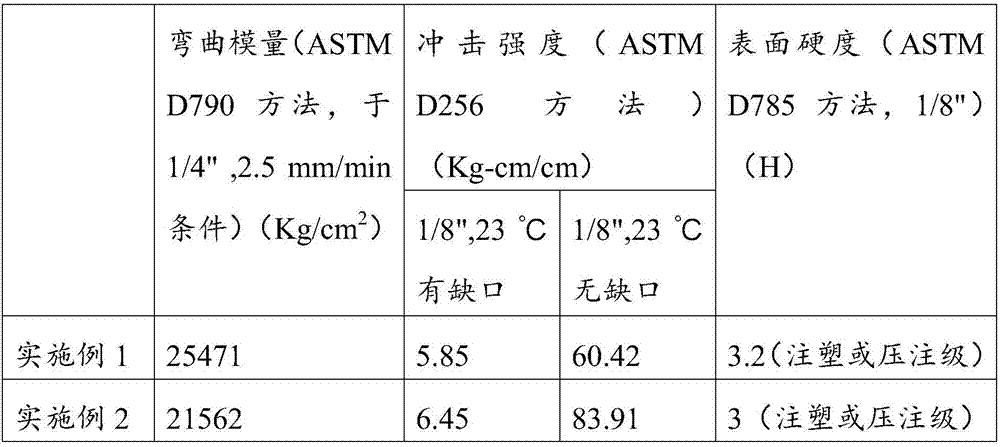

Polycarbonate (PC) resin/acrylonitrile-butadiene-styrene (ABS) alloy and preparation method thereof

The invention relates to the technical field of polymer engineering plastics, in particular to polycarbonate (PC) resin / acrylonitrile-butadiene-styrene (ABS) alloy and a preparation method thereof, and provides high-impact-strength halogen-free flame retardant PC resin / ABS alloy. The PC resin / ABS alloy is prepared from the following raw materials in part by weight: 20 to 50 parts of ABS resin, 30 to 60 parts of PC resin, 2 to 20 parts of halogen-free flame retardant, 1 to 15 parts of compatilizer, and 3 to 30 parts of toughening agent. The ratio of ABS to PC in the alloy material can be adjusted reasonably, the added halogen-free flame retardant ensures that the flame retardant property of the alloy material can reach the American UL94V-0-grade requirement, does not contain halogen, does not release a large amount of dense smoke or corrosive toxic gas when combusted, and has the advantages of high safety and environment-friendliness and the like. The added compatilizer and toughening agent can obviously improve the mechanical property and impact strength of the alloy material, and ensures that the ABS / PC alloy material has high toughness at low temperature of -40 DEG C.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

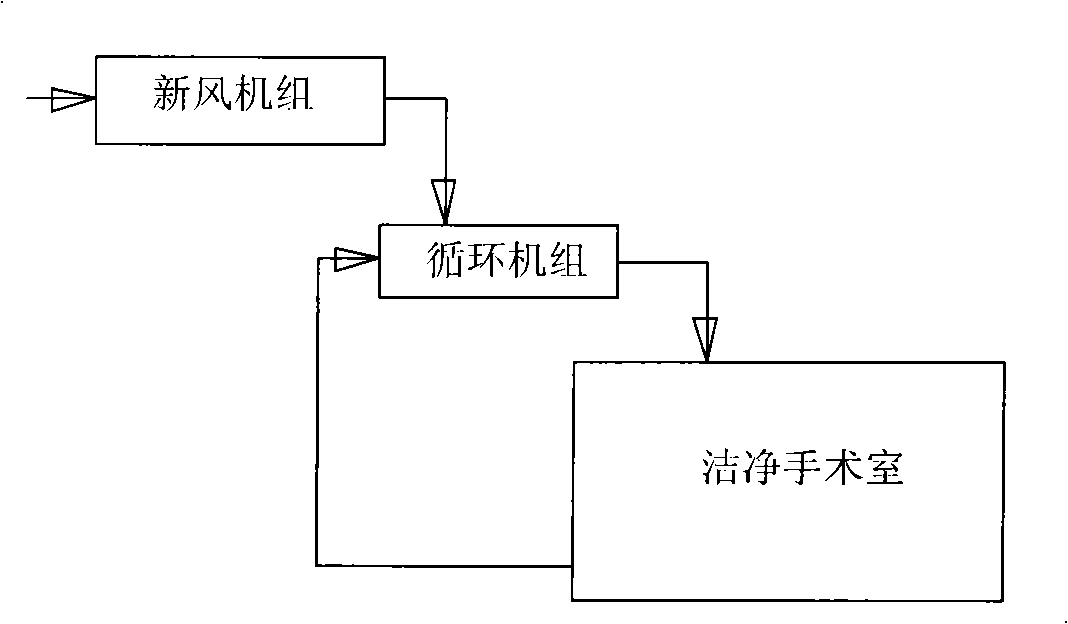

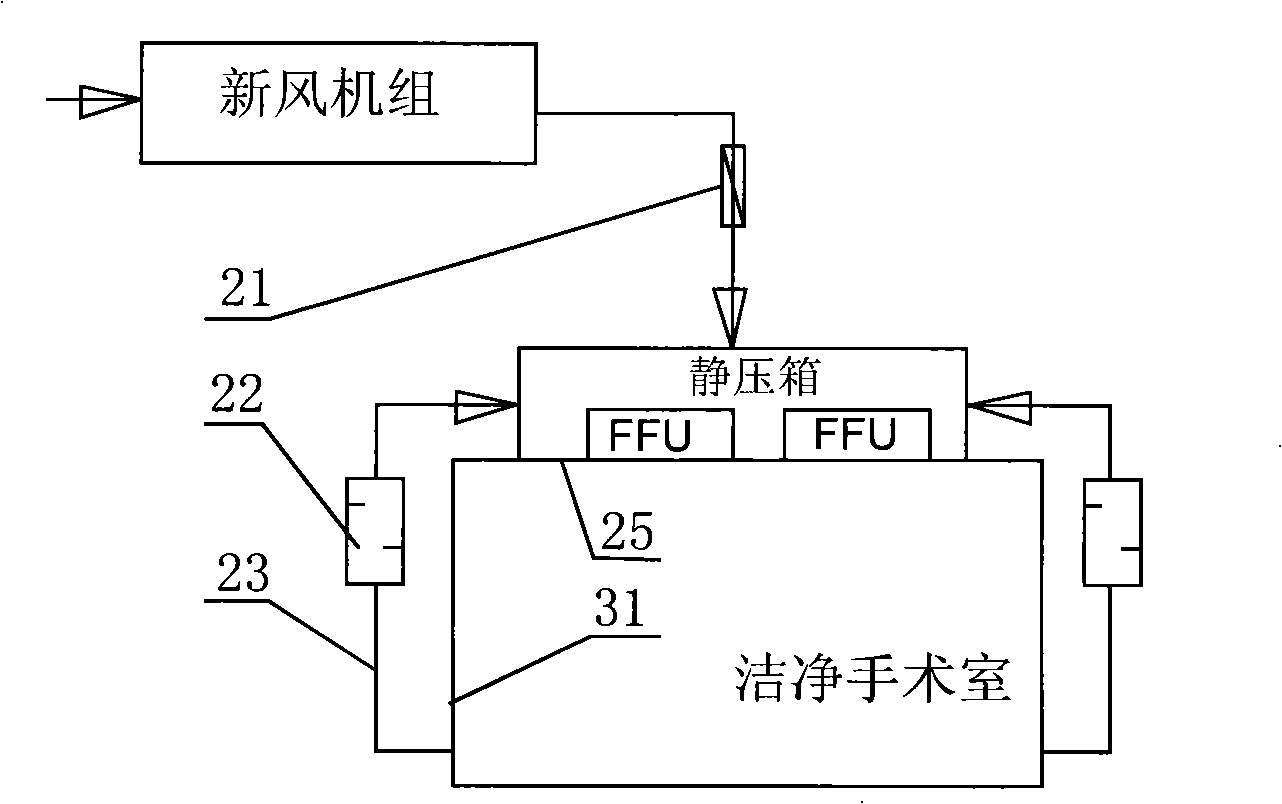

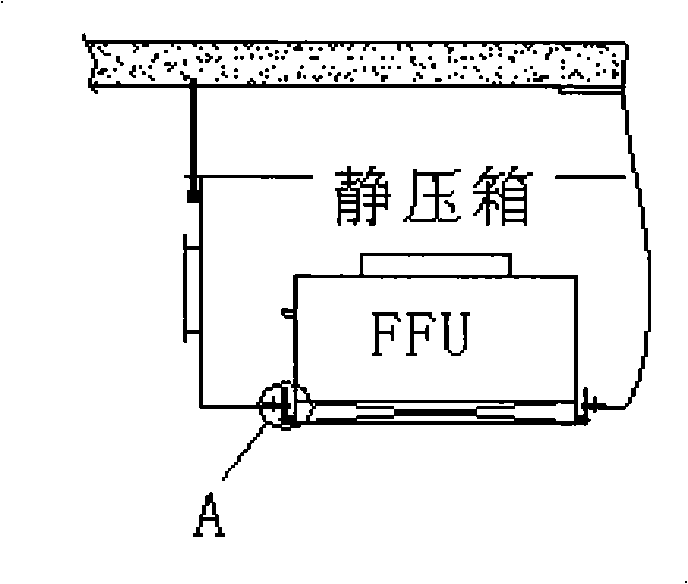

Assembling type dried work condition operating cleaning operation room and wind process method thereof

InactiveCN101354164ASimple structureQuick assembly and useAir heatersAir conditioning systemsFresh airAir treatment

The invention discloses an assembling-typed clean operating room operated in dry condition and the air treatment method thereof. The assembling-typed clean operating room comprises side walls, a roof plate and a fresh air unit. A static pressure box is arranged above the roof plate and is connected with an air supply pipeline of the fresh air unit; a wind returning pipeline is connected between the lower part of the side wall and the static pressure box, and the wind returning pipeline is provided with a circulating fan or the static pressure box is provided with an FFU; the side walls, the roof plate, the static pressure box, the FFU, the circulating fan, the wind returning pipeline, the fresh air unit and the air supply pipeline of the fresh air unit are connected with each other in a detachable manner. The circulating fan or the FFU operates in dry condition. The whole system has safety, high efficiency and simple structure. The assembling-typed clean operating room can be obtained by assembling polymer engineering plastics or color steel plates, Syntex plates, nanometer cloth and PVC strong material and the like together and the fast on-site assembling can be realized. The invention ensures that the exiting operating room can become a product instead of an engineering project, leading to standardization, normalization, speed-up and energy conservation of manufacturing and assembling.

Owner:赵阿萌 +1

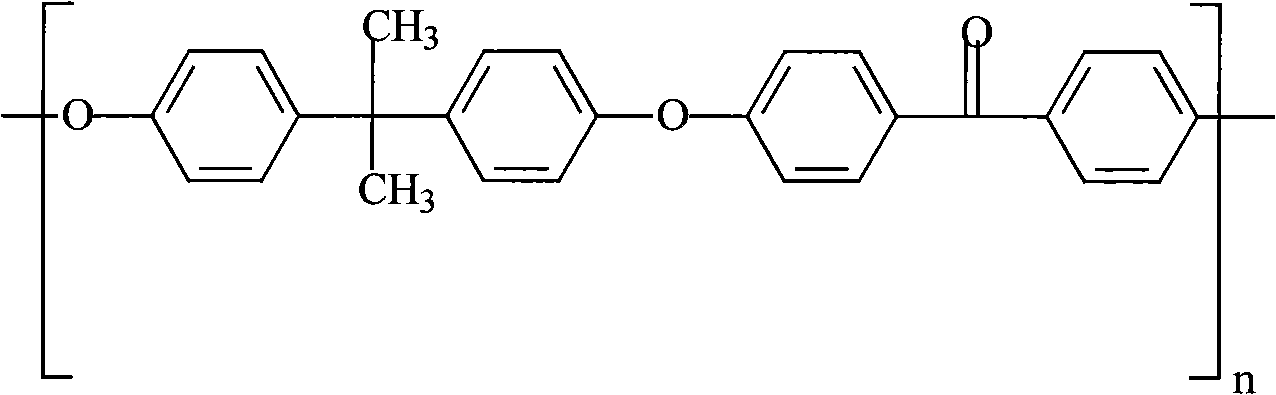

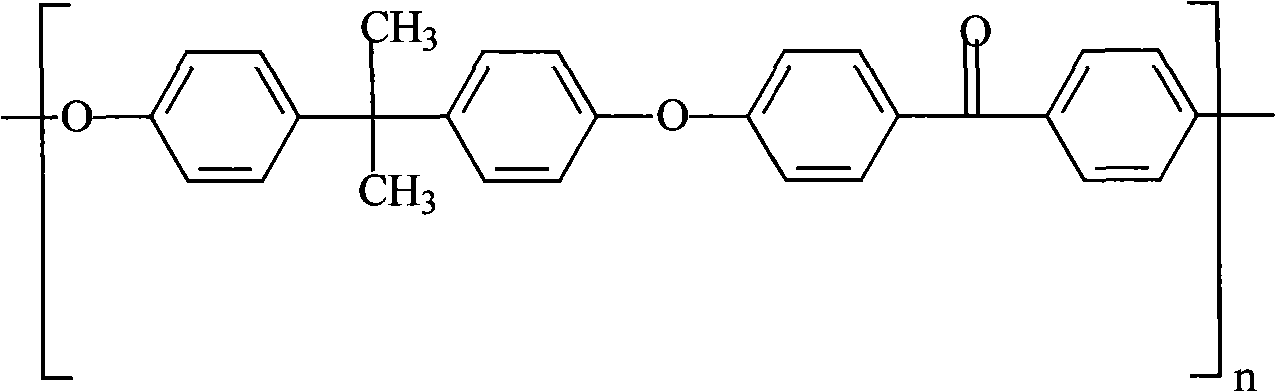

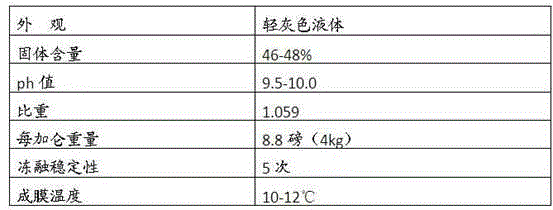

Bisphenol A type polyaromatic ether ketone water-based fluid dispersion and preparation thereof

The invention provides a bisphenol-A poly (aryl ether ketone) water-based dispersion and a method for preparing the same, belonging to the polymer water-based paint technical field. The compositions of the bisphenol-A poly (aryl ether ketone) water-based dispersion comprises bisphenol-A poly (aryl ether ketone), surface active agent and water, wherein, the surface active agent is dodecyl benzene sulfonate or dodecyl sodium sulfate. The preparing method comprises the following steps of: preparing bisphenol-A poly (aryl ether ketone) polymer solution, preparing latex and steaming organic solvent. The bisphenol-A poly (aryl ether ketone) water-based dispersion can be used during preparing heat-resisting paint or paint polymer, and can be combined with fluor resin to prepare various paints, thereby improving the service temperature and the solvent resistance of bisphenol-A poly (aryl ether ketone) paint. The bisphenol-A poly (aryl ether ketone) water-based dispersion and the method for preparing the same enlarge the application range of bisphenol-A poly (aryl ether ketone) polymer engineering materials, and meet the requirement of environmental protection.

Owner:JILIN UNIV

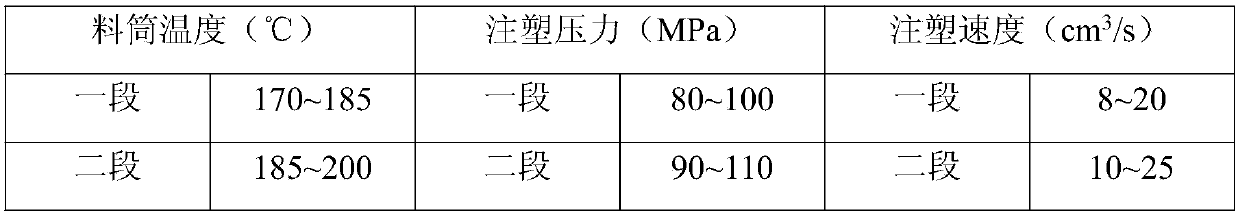

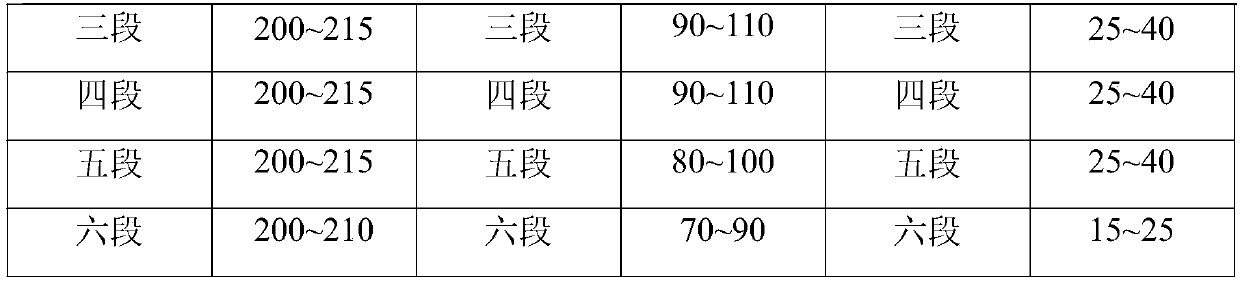

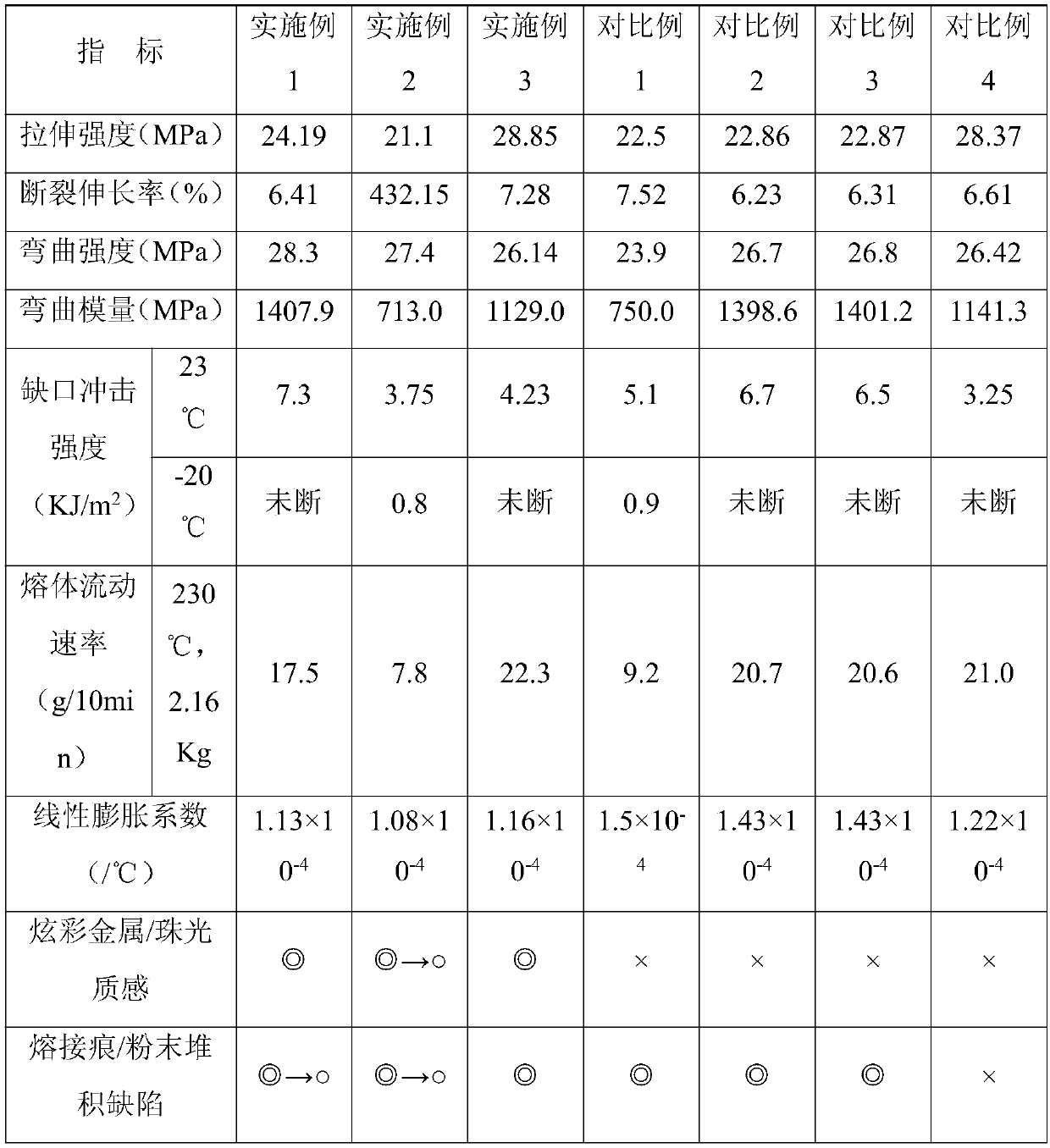

Polypropylene material with high gloss and low linear expansion coefficient and preparation method thereof

InactiveCN107722446AHas a low coefficient of linear expansionWith spray-freePolypropyleneMechanical property

The invention discloses a polypropylene material with high gloss and low linear expansion coefficient and a preparation method of the polypropylene material, and belongs to the technical field of polymer engineering plastics. The polypropylene material with high gloss and low linear expansion coefficient comprises the following components by mass: 70-95 parts of polypropylene resin, 5-20 parts ofpolyethylene, 0.2-2 parts of aluminite powder, 0.3-2 parts of pearl powder, 0.05-0.6 part of nucleating agent, 0.2-0.6 part of light stabilizer, 0.1-0.5 part of lubricant, 0.2-0.4 part of antioxygen,and 1-6 parts of color masterbatch. By reasonably controlling the proportion of the components and the ingredients in the formula, the polypropylene material achieves the metallic pearl effect of theplastic material and has the advantages of being free from spraying, saving the energy and protecting the environment, the processing and molding performances and the mechanical property of the material are improved, and the polypropylene material further has the advantages of high fluidity, high gloss, and low linear expansion coefficient.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

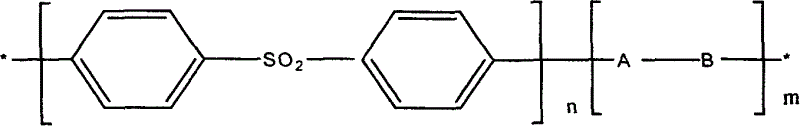

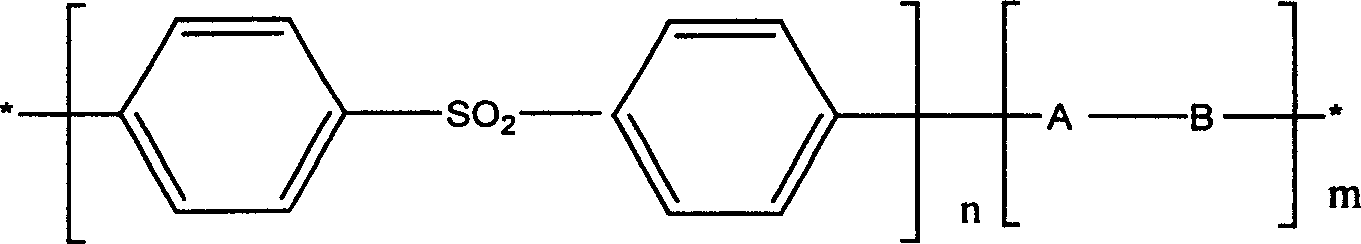

Aqueous polyarylethersulphones dispersion liquid and process for preparing same

The invention relates to water-based polyarylether sulfone dispersion and the preparing method, belonging to the high molecular polymer field.The elementary composition is polyarylideneethersulfone with repetitive units or polyarylideneethersulfone with repetitive units and with side group, the dispersion containing surface active agent, the sodium dodecylbenzene sulfonate.The preparing process comprising putting the polyarylether sulfone into the mixed solution of organic solvent and assisting solvent; preparing emulsion, evaporating the organic solvent and getting the water-based polyarylether sulfone dispersion.Prepared product can be used as heat resisting paint or coating polymer, and can combine with fluoro-resin to prepare coating material. The invention enlarges the application area of the polyarylethersulfone, which is a kind of engineering material, and can recovery the organic solvent during the process, adapted for environmental protection.

Owner:JILIN UNIV

Hydrolysis-resistant glass fiber reinforced polyamide 66 (PA66) composite material and preparation method thereof

InactiveCN102585495AImprove hydrolysis resistanceGood physical and mechanical propertiesGlass fiberAntioxidant

The invention relates to the field of modification of polymer engineering plastic, in particular to a method for preparing a hydrolysis-resistant glass fiber reinforced polyamide 66 (PA66) composite material. The composite material is characterized by consisting of the following materials in part by weight: 55 to 65 parts of PA66, 0.1 to 2 parts of hydrolysis-resistant agent, 30 to 40 parts of glass fibers, 1 to 3 parts of nanoparticles, 0.5 to 2 parts of antioxidant and 0.5 to 2 parts of lubricating agent. According to the preparation method, extrusion granulation is performed by a double screw extruder. By introducing the high-efficiency hydrolysis-resistant agent, the hydrolysis resistance of the PA66 is improved, and the physical and mechanical properties of the glass fiber reinforced PA66 in a high-humidity environment are enhanced; and meanwhile, by introducing the nanoparticles, the mechanical properties such as tensile strength, hardness and the like of the PA66 are further enhanced, the wear resistance of the PA66 is enhanced, and the application range of the PA66 is further expanded.

Owner:上海聚威新材料股份有限公司

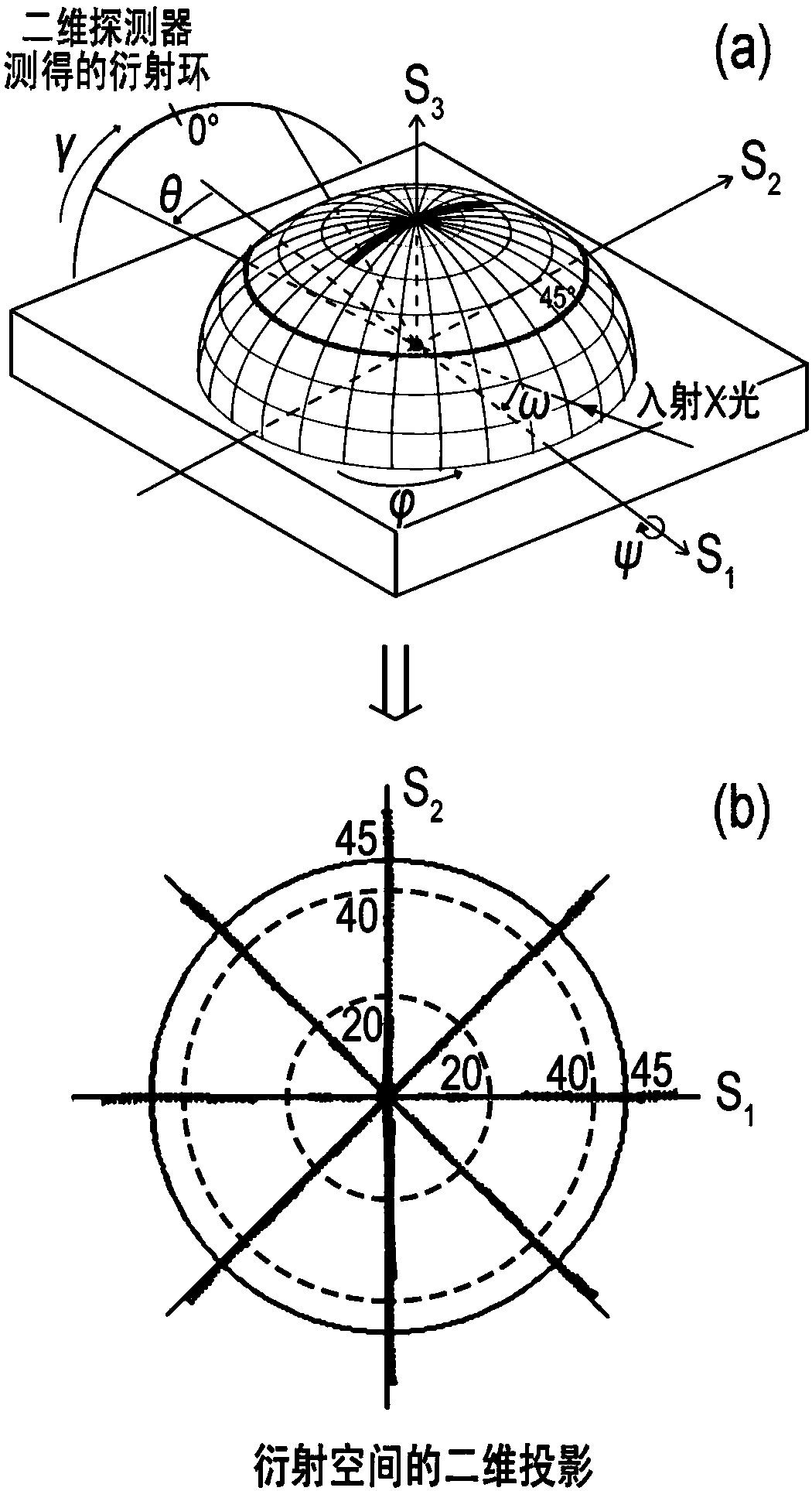

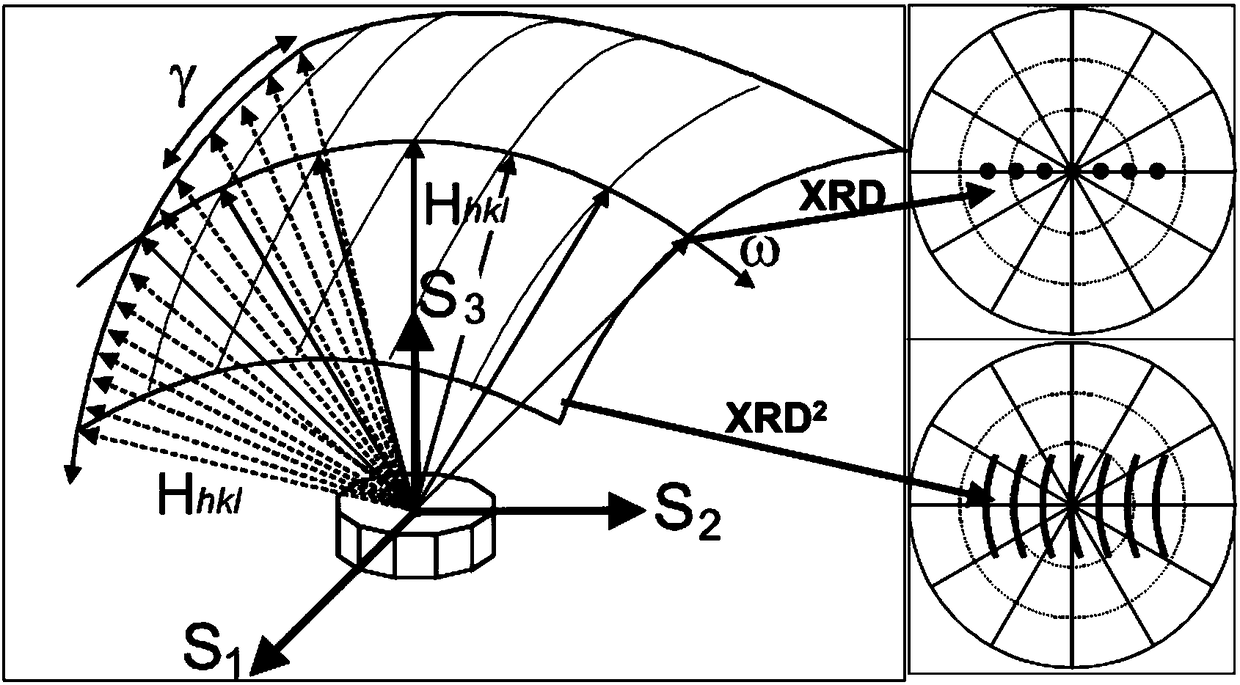

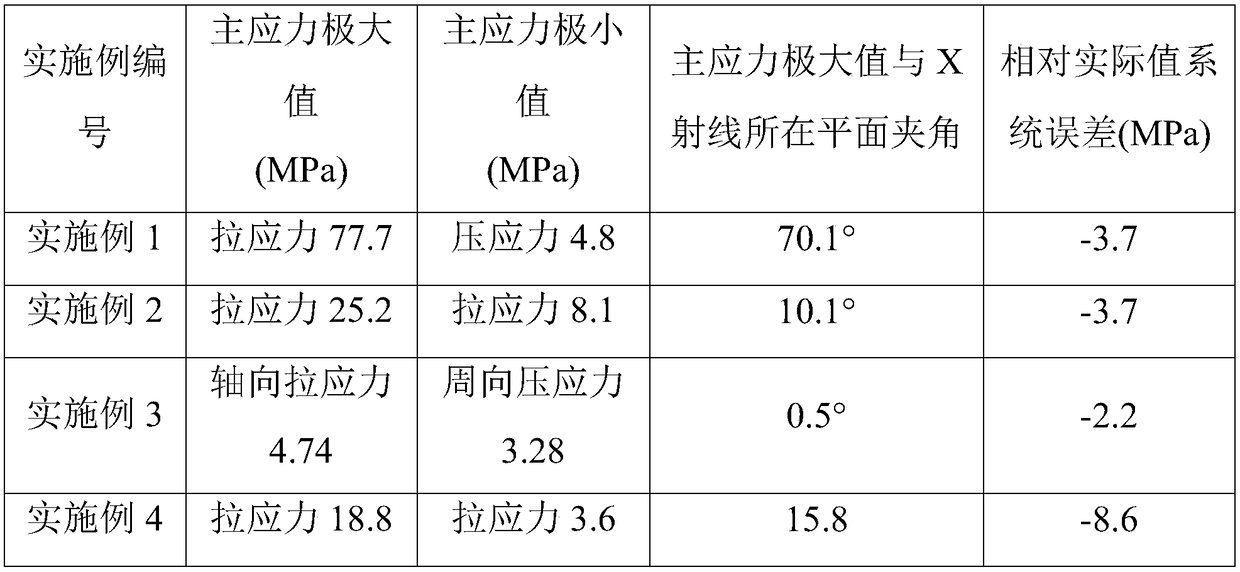

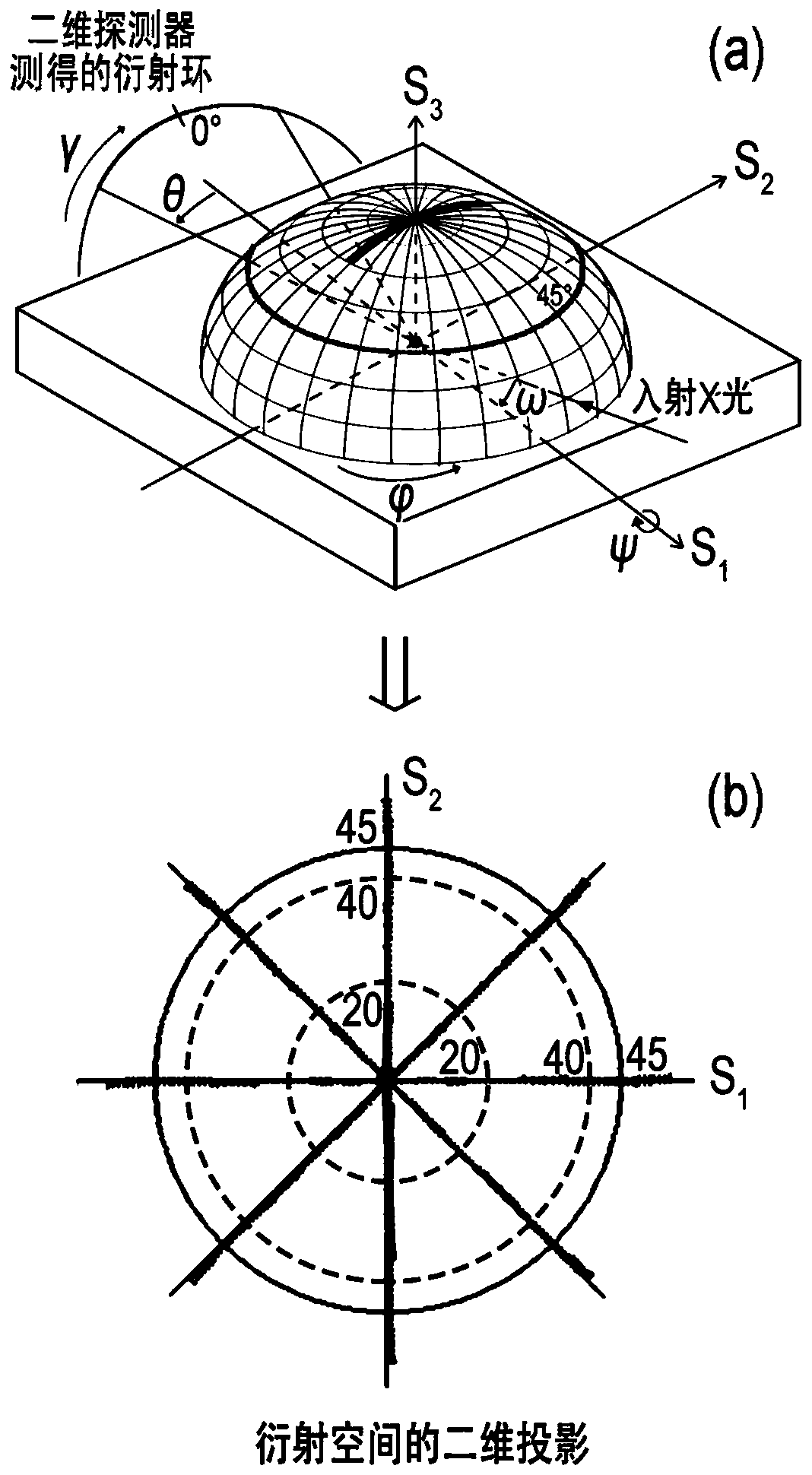

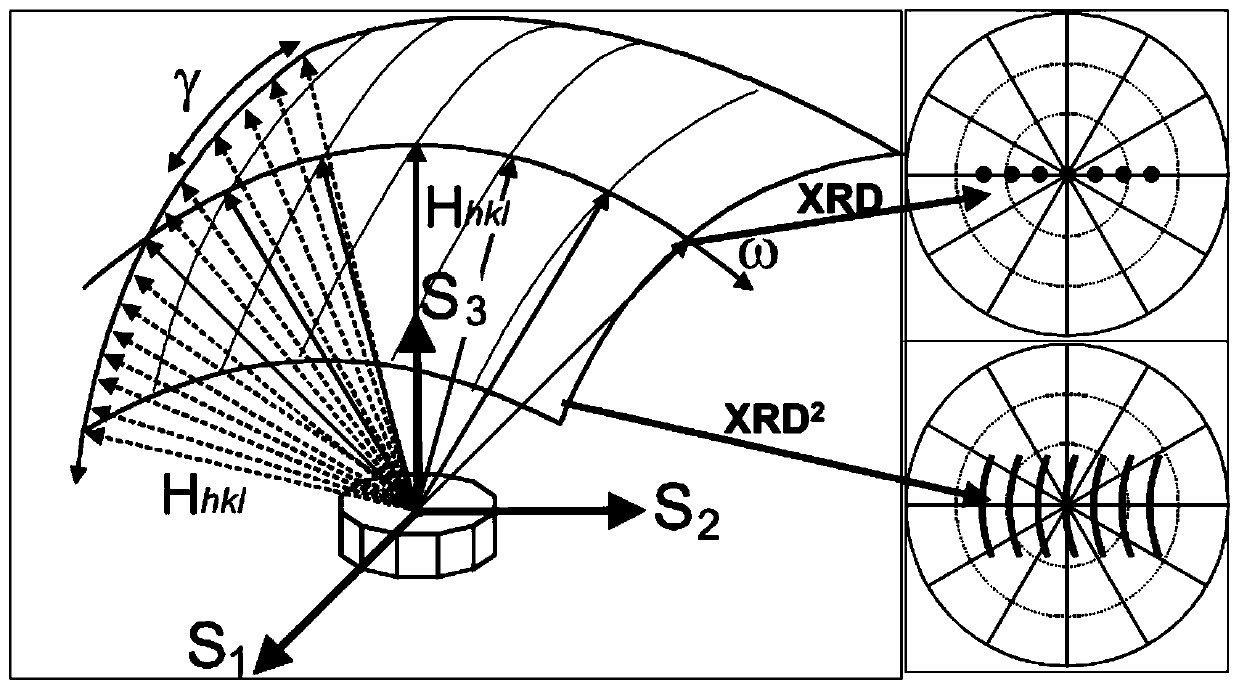

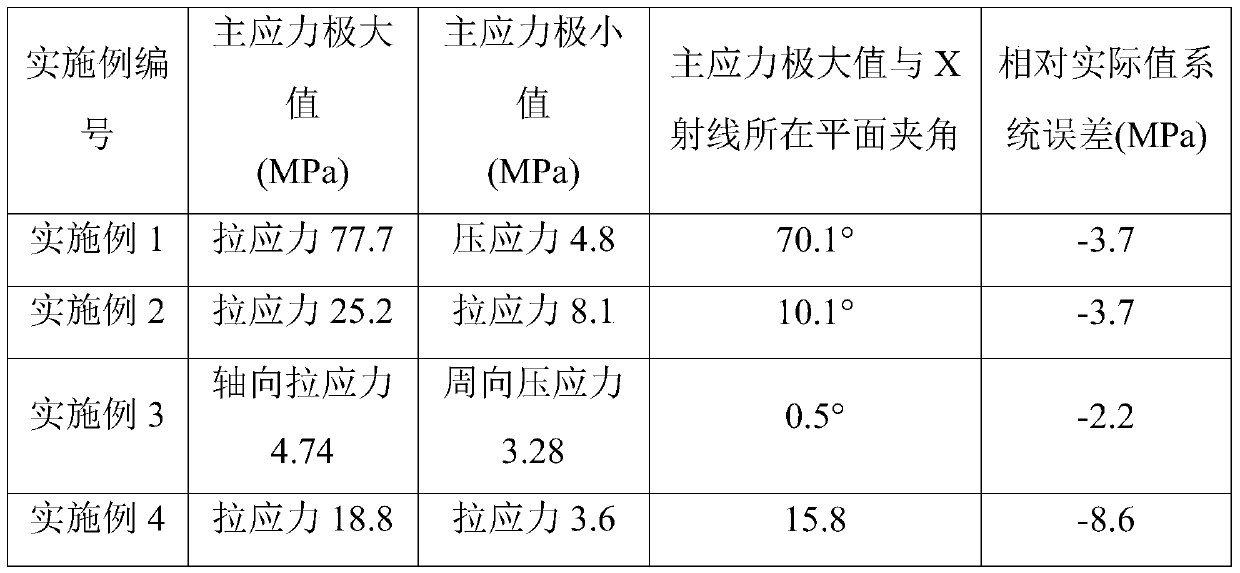

Method of detecting residual principal stress of polymer product

ActiveCN109141706AImprove accuracyEasy to operateMaterial analysis using wave/particle radiationApparatus for force/torque/work measurementPrincipal stressStress measurement

The invention relates to the field of stress measurement of polymer materials and discloses a method of detecting the residual principal stress of a polymer product. The method adopts a two-dimensional X-ray diffraction method to quantitatively detect the residual principal stress of the polymer product, the polymer material adopts a crystalline region and an amorphous region, and in the presenceof the residual stress, the crystalline region and the amorphous region have the same strain. The method provided in the invention succeeds in application of the two-dimensional X-ray diffraction method to the residual principal stress detection on a polymer engineering material, the limitations that the traditional two-dimensional X-ray diffraction method can only be applied to detection on the residual stress of a polycrystalline metal material are broken, and the detection method is simple and controllable, the application range is wide, the detection errors are small, and the application prospect is broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano magnesium carbonate modified fire protection engineering plastic and preparation method thereof

InactiveCN101967275AReduce dosageImprove rigidityPigment treatment with macromolecular organic compoundsEngineering plasticFire protection engineering

The invention belongs to the technical field of polymer engineering materials and relates to magnesium carbonate modified halogen-free fire protection engineering plastic and a preparation method thereof. The engineering plastic comprises the following components in percentage by mass: 1 to 20 percent of nano magnesium carbonate, 1 to 15 percent of aids, 1 to 15 percent of synthetic resin and the balance of plastic. The nano magnesium carbonate is added into a fire resistant agent and the mechanical property of engineering plastic is not greatly influenced, and in addition, the added nano magnesium carbonate can also improve the rigidity and heat resistance of engineering plastic. A magnesium carbonate fire retardant is obtained by performing in-situ dispersion polymerization on the nano magnesium carbonate and alkyd resin. As the alkyd resin is compatible with nano magnesium carbonate, the dispersibility of nano magnesium carbonate in a polymer is improved and the alkyd resin is compatible with the synthetic resin.

Owner:SHENZHEN HALCYON NEW MATERIALS +1

Modified polyphenylene sulfide or modified polyphenylene ether foaming bead and preparation method of modified polyphenylene sulfide or modified polyphenylene ether foaming bead

The invention relates to the technical field of polymer engineering materials, in particular to modified polyphenylene sulfide or a modified polyphenylene ether foaming bead and a preparation method of the modified polyphenylene sulfide or the modified polyphenylene ether foaming bead. The modified polyphenylene sulfide or the modified polyphenylene ether foaming bead is prepared from the following components in parts by weight: 20-80 parts of polyphenylene sulfide or polyphenylene ether, 20-80 parts of a modified polymer, 10-25 parts of a compatibilizer, 10-20 parts of a toughening agent, 5-10 parts of a flame retardant, 1-5 parts of an antioxidant, 1-5 parts of an assistant anti-oxidant, 1-5 parts of a lubricant, 1-5 parts of a coupling agent and 1-10 parts of a dispersant. According tothe modified polyphenylene sulfide or the modified polyphenylene ether foaming bead and the preparation method of the modified polyphenylene sulfide or the modified polyphenylene ether foaming bead, the problems of uneven particle size distribution, small magnification and low closure rate of the modified polyphenylene sulfide or the modified polyphenylene ether foaming bead in the prior art can be solved.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

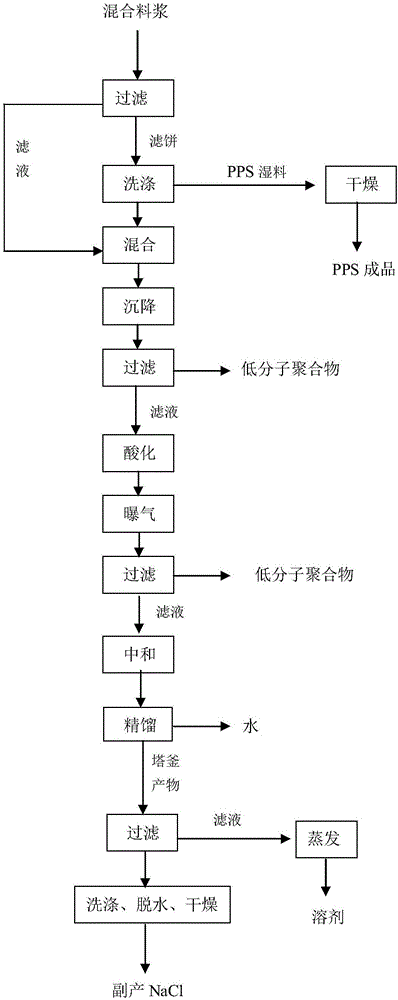

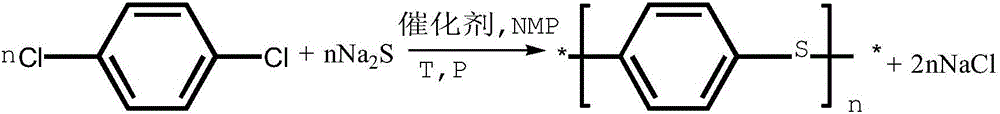

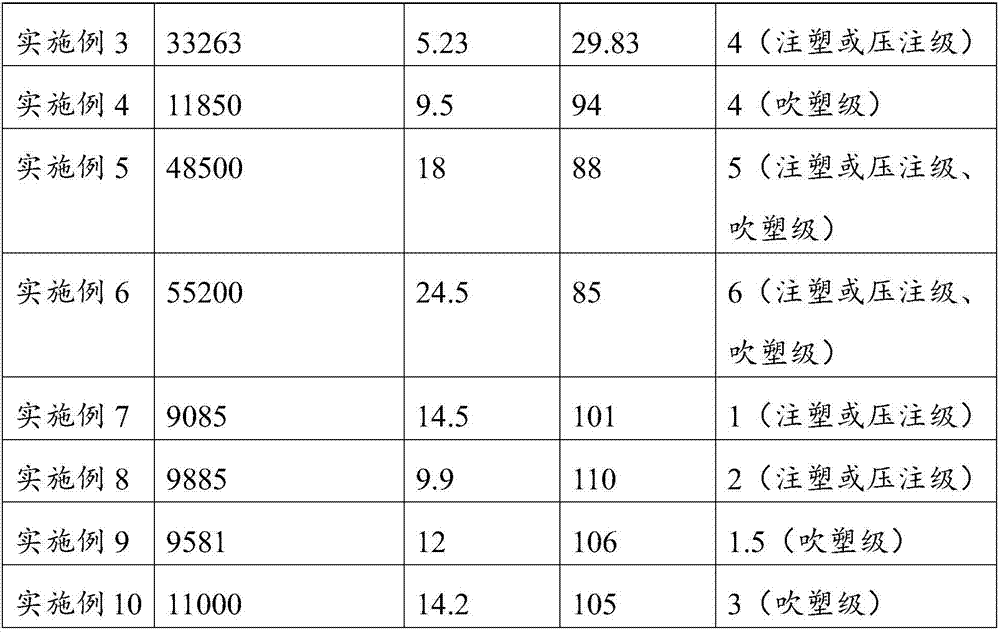

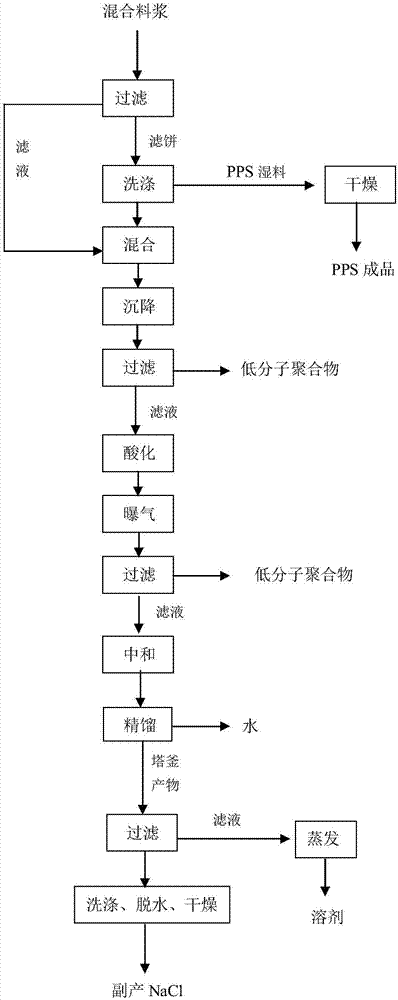

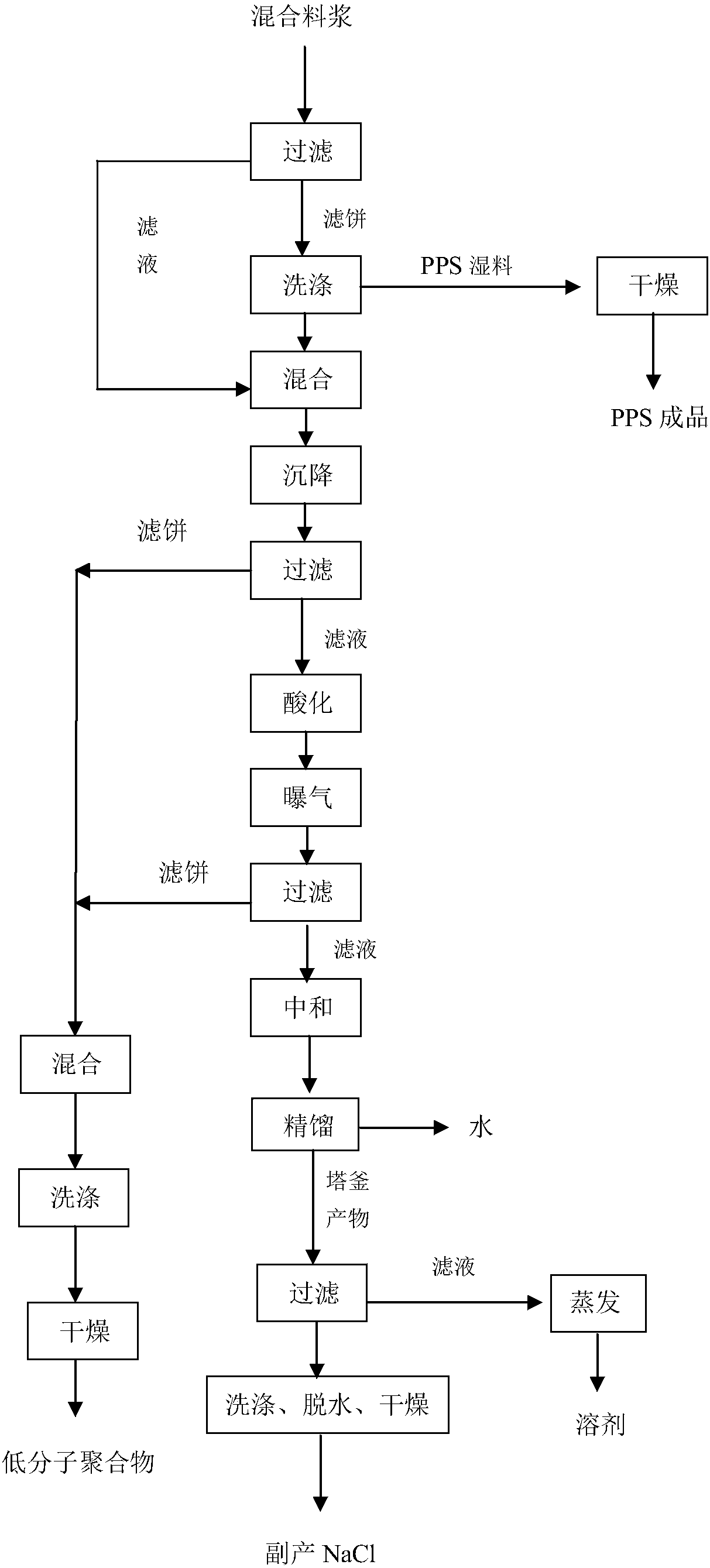

Recovery method of by-product sodium chloride in production process of polyphenylene sulfide

ActiveCN106395862AMeet the use requirementsReduce energy consumptionAlkali metal chloridesAlkali metal halide purificationRecovery methodSlurry

Belonging to the field of polymer engineering, the invention in particular relates to a recovery method of by-product sodium chloride in the production process of polyphenylene sulfide (PPS). The method includes the steps of: filtering the mixed slurry obtained at the end of polymerization reaction to obtain a filter cake and a by-product slurry, washing the filter cake with deionized water to obtain washing liquid and a PPS wet material, mixing the washing liquid and the by-product slurry, then carrying out filtering, acidification, aeration, filtration, neutralization, dehydration and refiltering, thus obtaining the byproduct sodium chloride. The sodium chloride recovered by the method provided by the invention has purity of not less than 99.55wt%, and a low molecular polymer content of less than or equal to 0.3wt%, thus meeting the quality requirements of industrial salt. Therefore, no waste salt is generated in the production process of PPS.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

ABS (Acrylonitrile Butadiene Styrene) thermoplastic resin and preparation method thereof

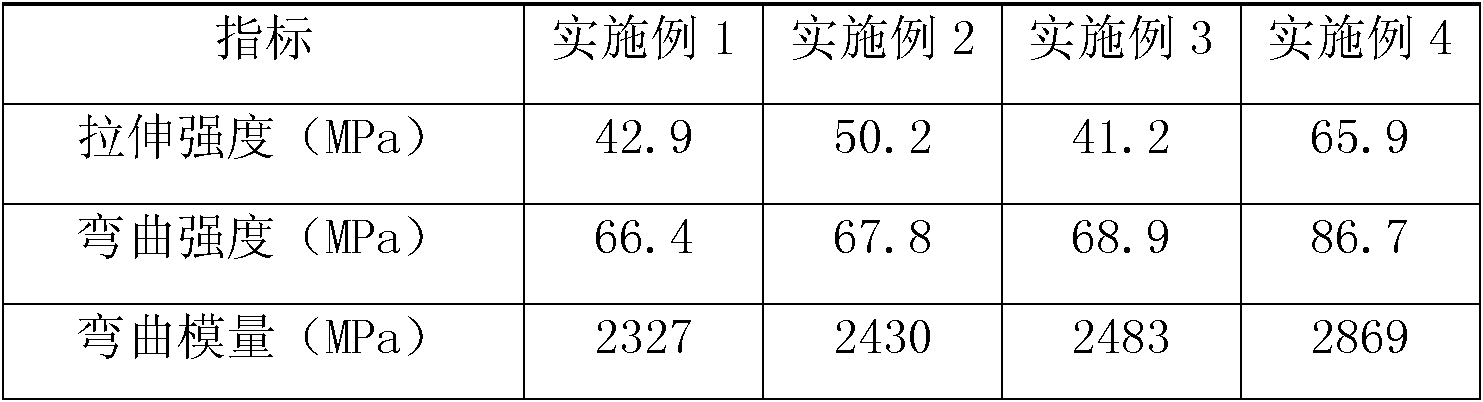

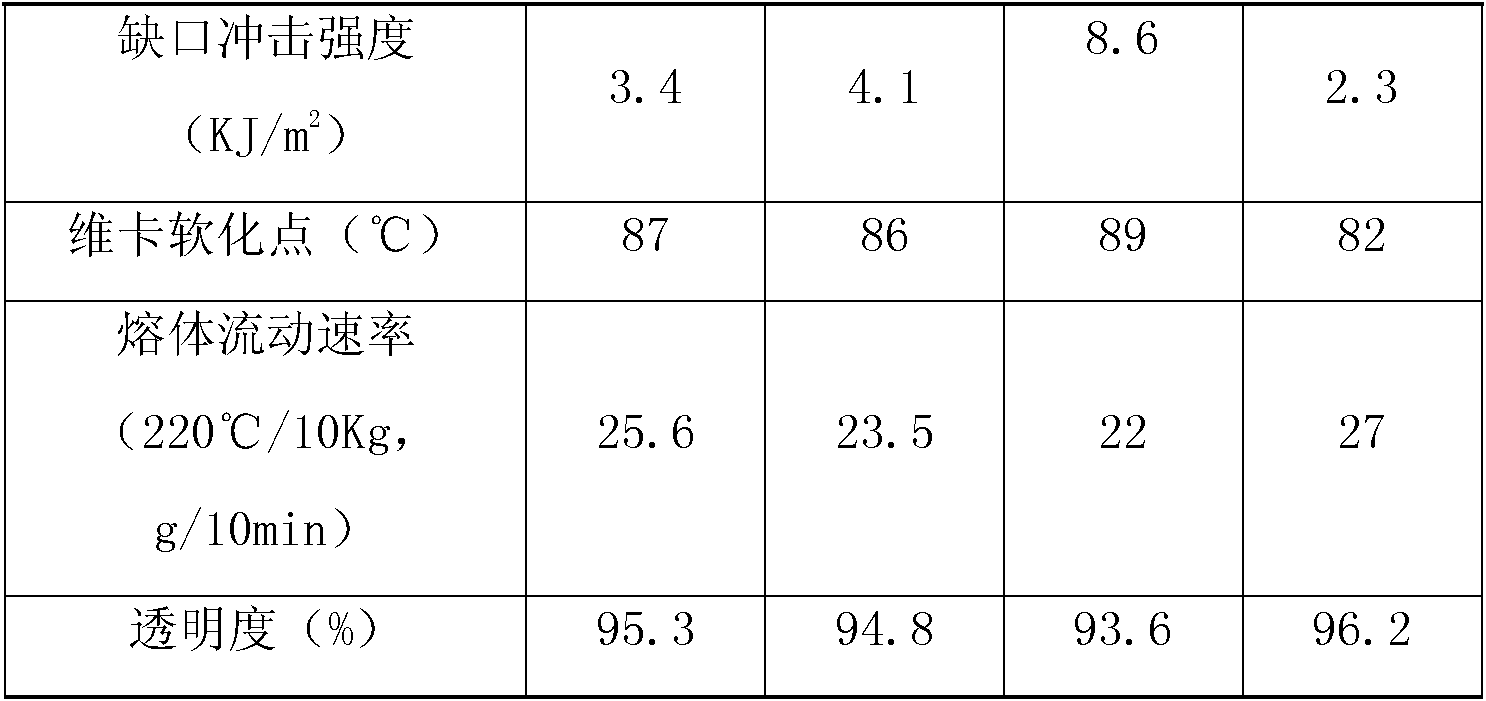

The invention belongs to the technical field of polymer engineering plastics and particularly relates to an ABS (Acrylonitrile Butadiene Styrene) thermoplastic resin and a preparation method thereof. The invention solves the technical problem to provide an ABS thermoplastic resin with high fluidity and high transparency. The ABS thermoplastic resin is prepared from the raw materials in parts by weight: 20-75 parts of SAN (Styrene Acrylonitrile) resin, 20-60 parts of PMMA (Polymethylmethacrylate) resin, 2-25 parts of MBS (Methacrylate-butadiene-stryrene) resin, 0.2-04 part of antioxidant, 0.05-0.2 part of light stabilizer, 0.05-0.2 part of whitening agent and 0.05-0.2 part of lubricant. The ABS thermoplastic resin has the advantages of good surface glossiness, good rigidity, good transparency, good mechanical property and good forming and processing property, and each key index of the ABS thermoplastic resin exceeds that of commonly used transparent plastics such as transparent ABS and the like.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

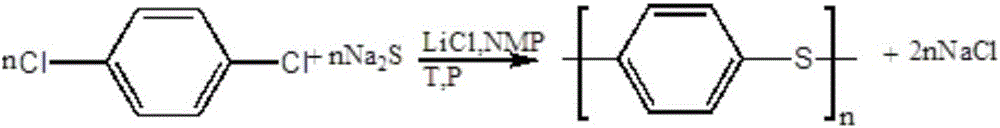

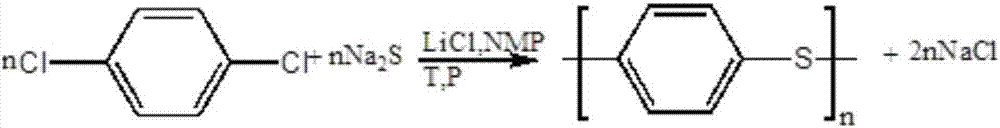

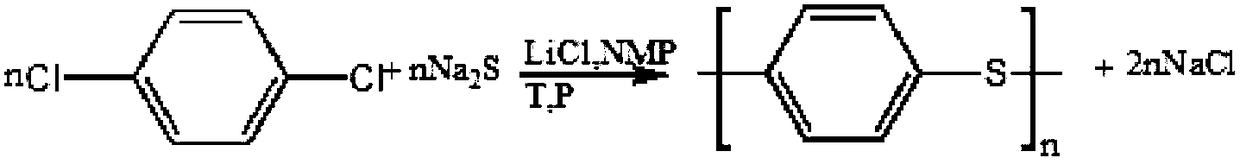

Method for preparing polyphenylene sulfide by using composite catalyst

The invention relates to the technical field of polymer engineering, in particular to a method for preparing polyphenylene sulfide by using a composite catalyst. The method comprises the steps: adding a sodium sulfide crystal, a solvent and caustic soda into a reaction container, heating under the protection of nitrogen, completely dissolving the added materials, and evaporating part of water and solvent; dissolving paradichlorobenzene and the composite catalyst into the solvent, adding the solution into a reactor, heating and performing polymerization reaction to prepare the polyphenylene sulfide. When the polyphenylene sulfide is prepared by the method, scaling is avoided after the polymerization reaction and in the process of cooling the materials, the reaction byproducts are easy to separate, and the comprehensive performance and the yield of the product are high.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

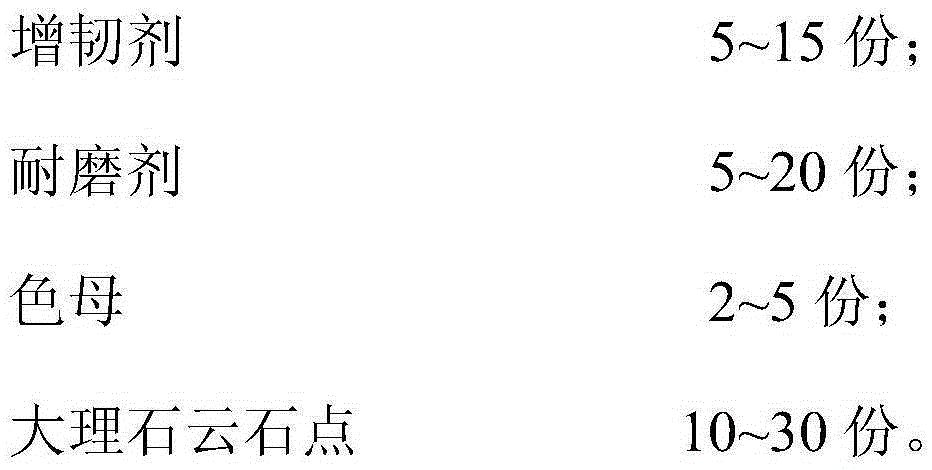

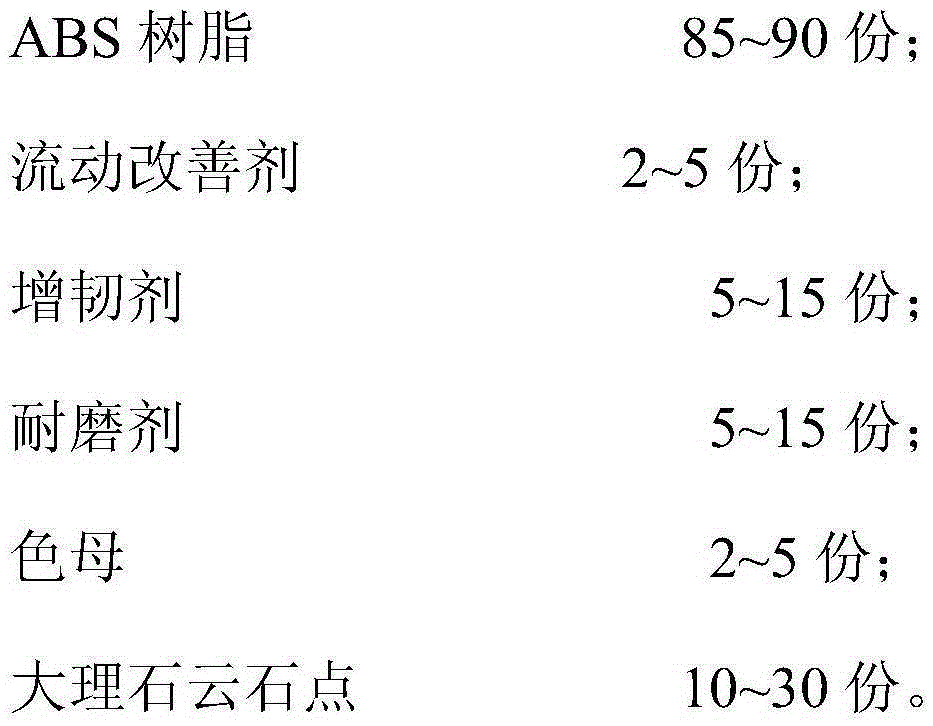

Marble-imitated ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

ActiveCN105255093AImitation marble effect is obviousPromote environmental protectionTougheningAcrylonitrile butadiene styrene

The invention relates to the field of polymer engineering plastics, and provides a marble-imitated ABS (acrylonitrile butadiene styrene) composite material and a preparation method thereof, which are used for solving the problem that current marble-imitated ABS composite materials are poor in performance. The marble-imitated ABS composite material comprises the following raw materials in parts by weight: 85-100 parts of ABS resin, 1-5 parts of a flow improver, 5-15 parts of a toughening agent, 5-20 parts of a wear-resisting agent, 2-5 parts of color masterbatch, and 10-30 parts of marble points. According to the technical scheme of the invention, by designing the proportions of the ABS, the flow improver and the marble-imitated filler in the composite material, due to the addition of the marble-imitated filler, the marble-imitated effect of the ABS composite material is more obvious, and the ABS composite material has the advantages of good environmental friendliness and paint spraying avoidance, and the like.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

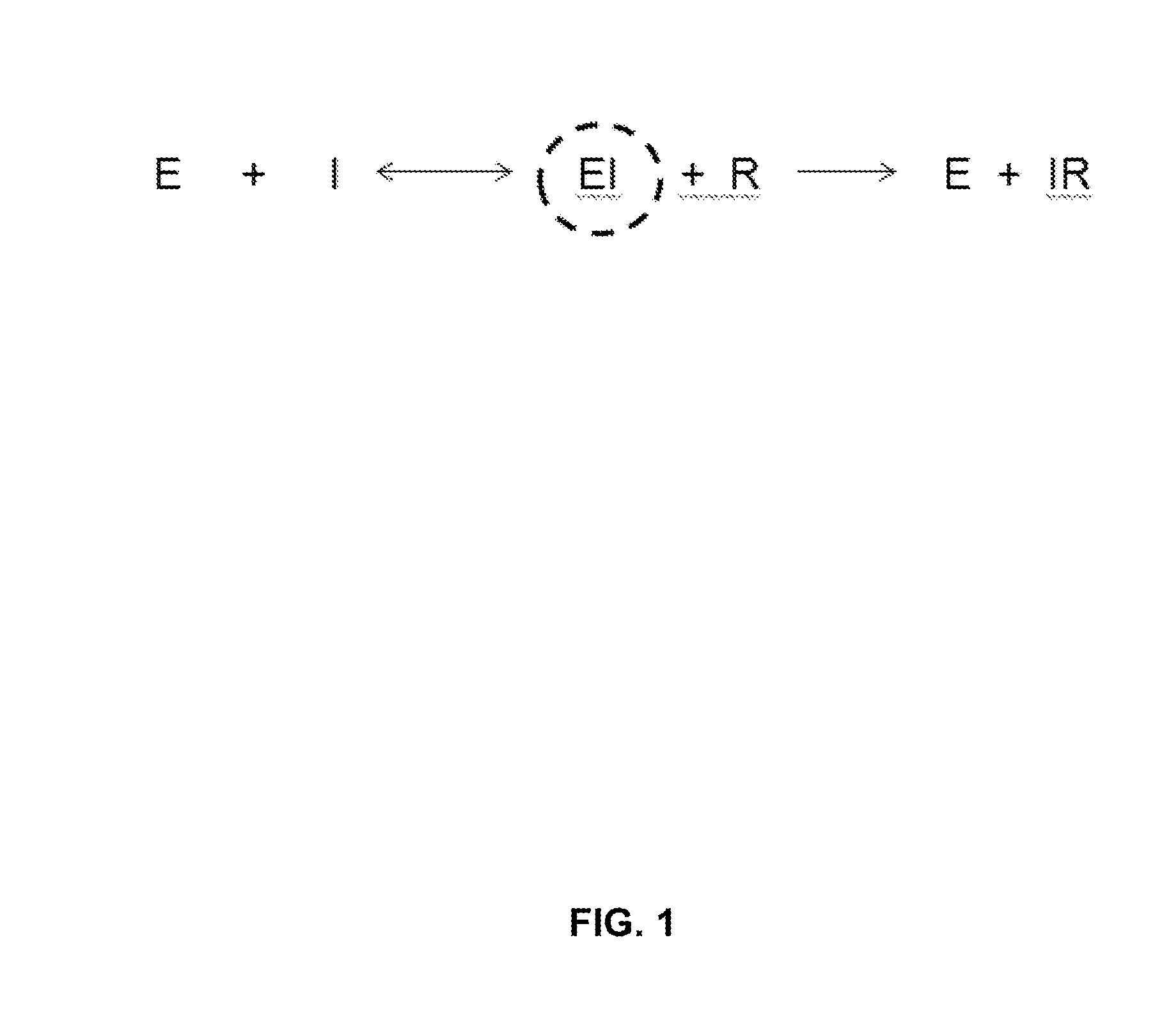

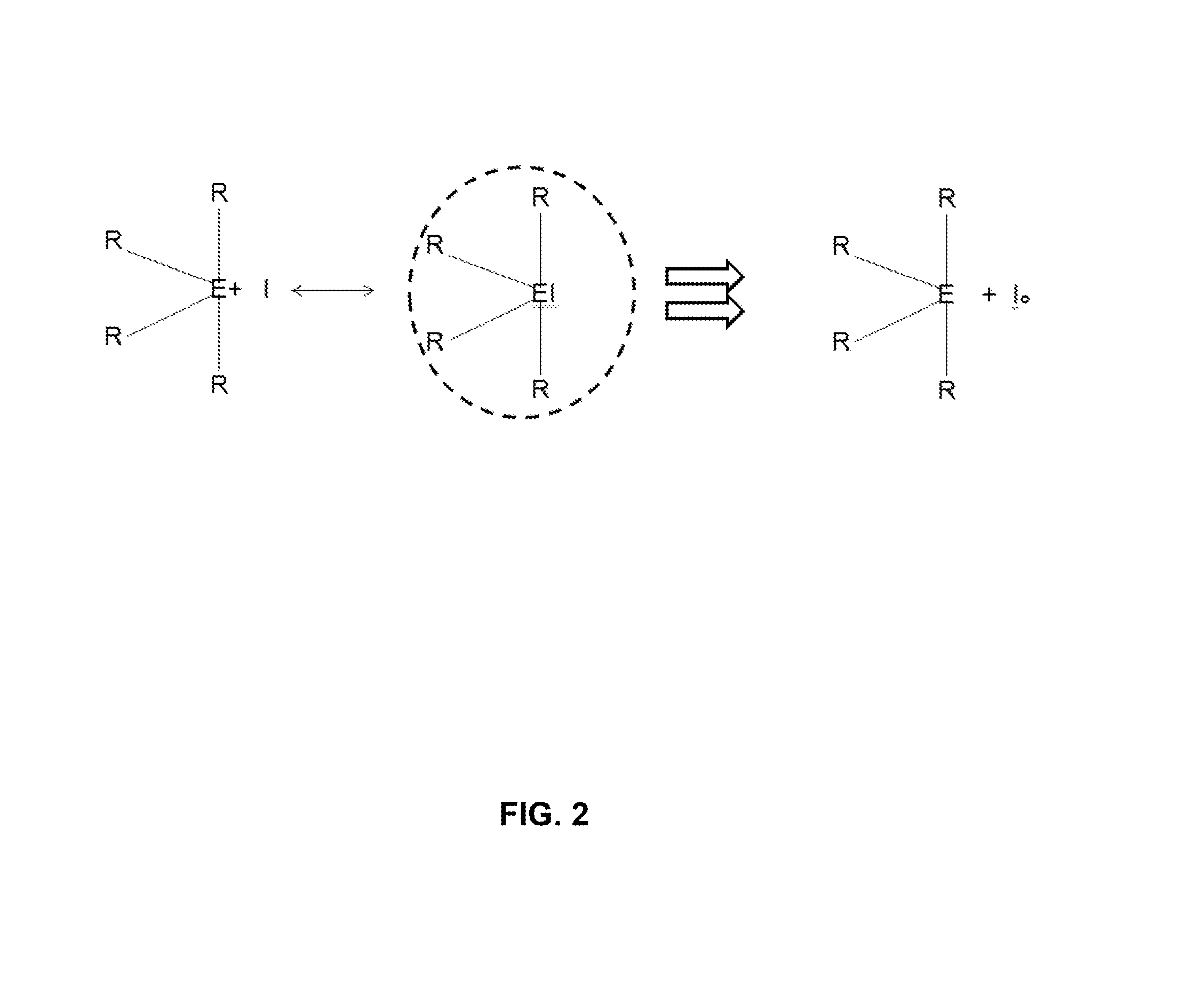

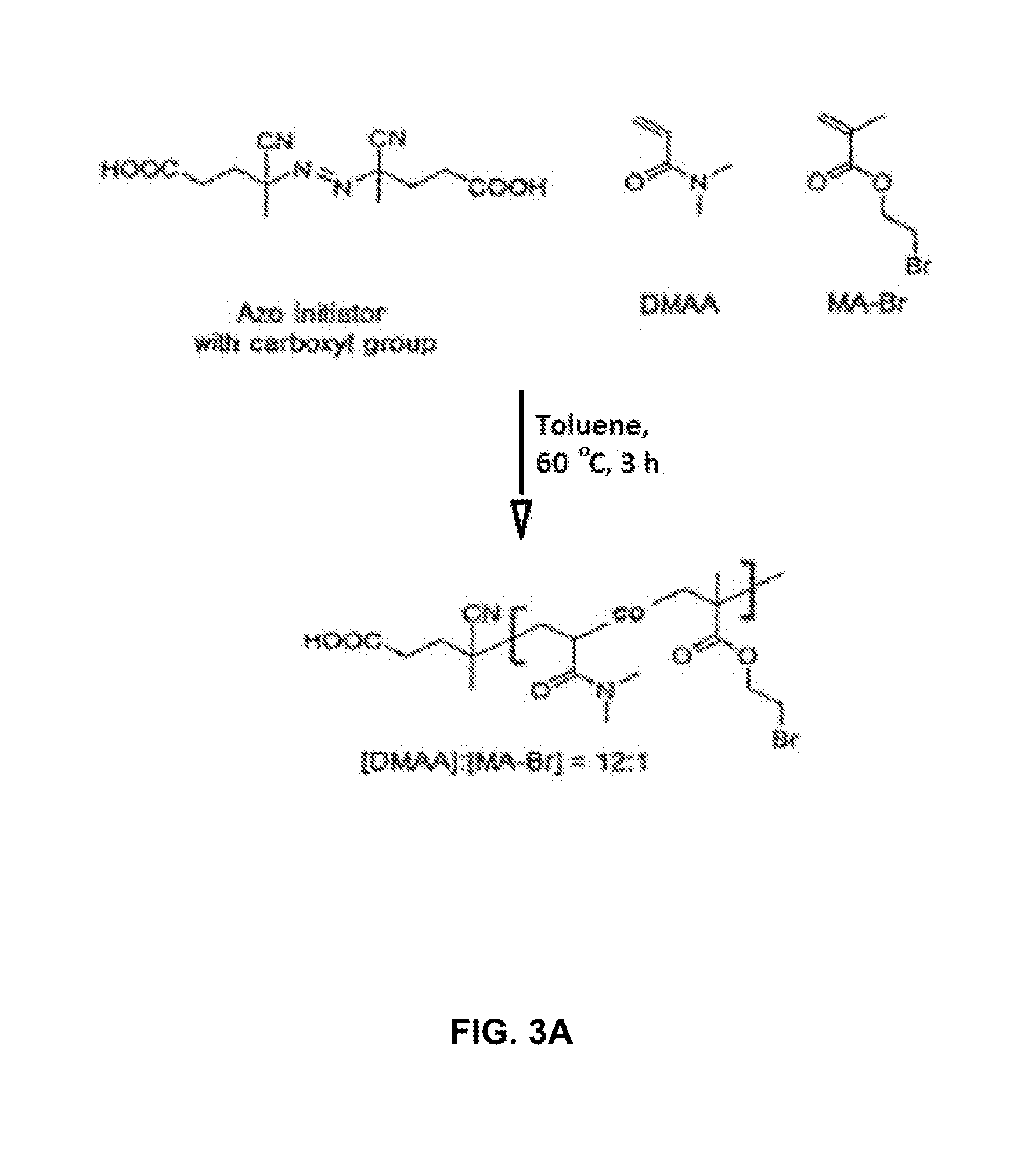

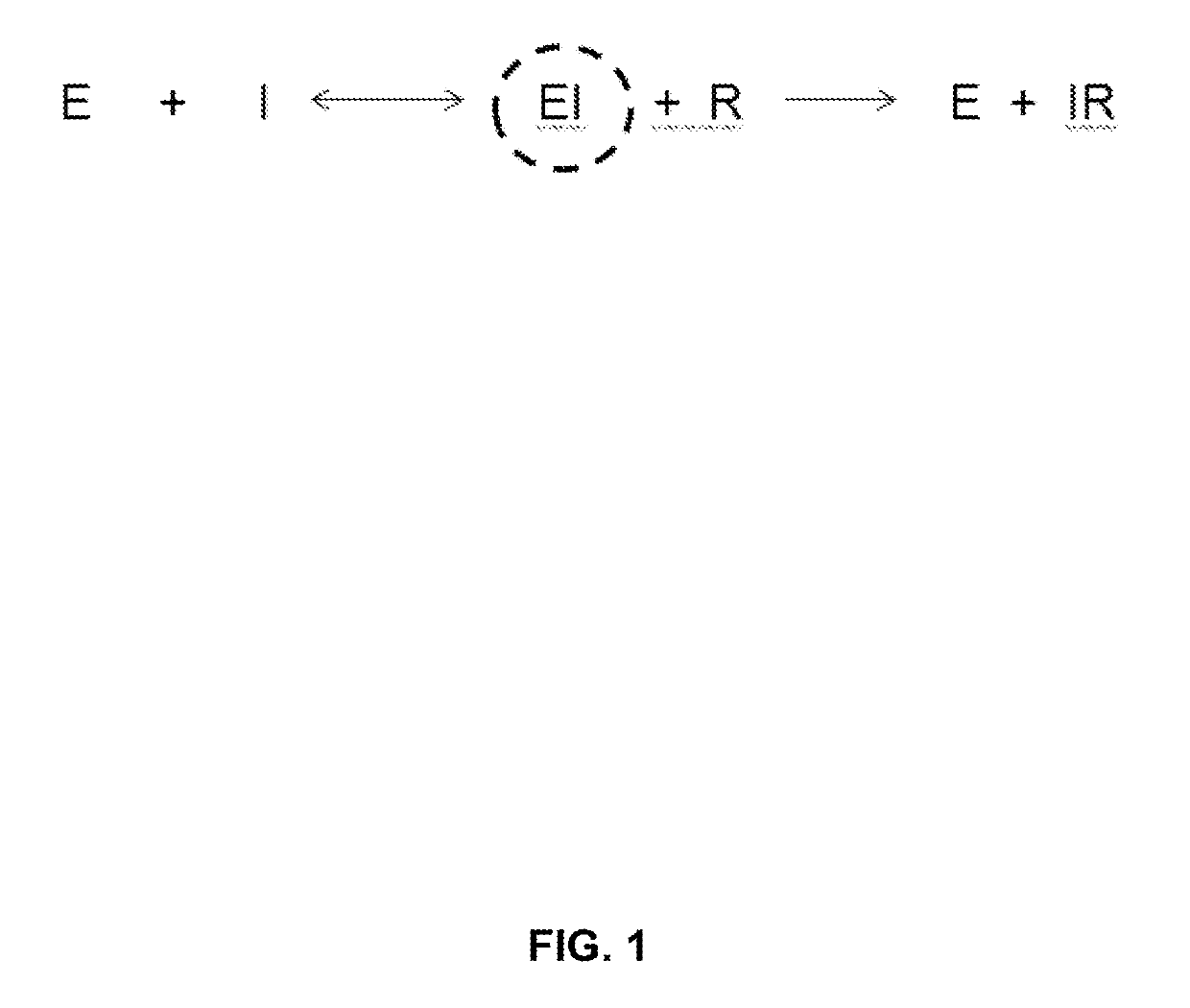

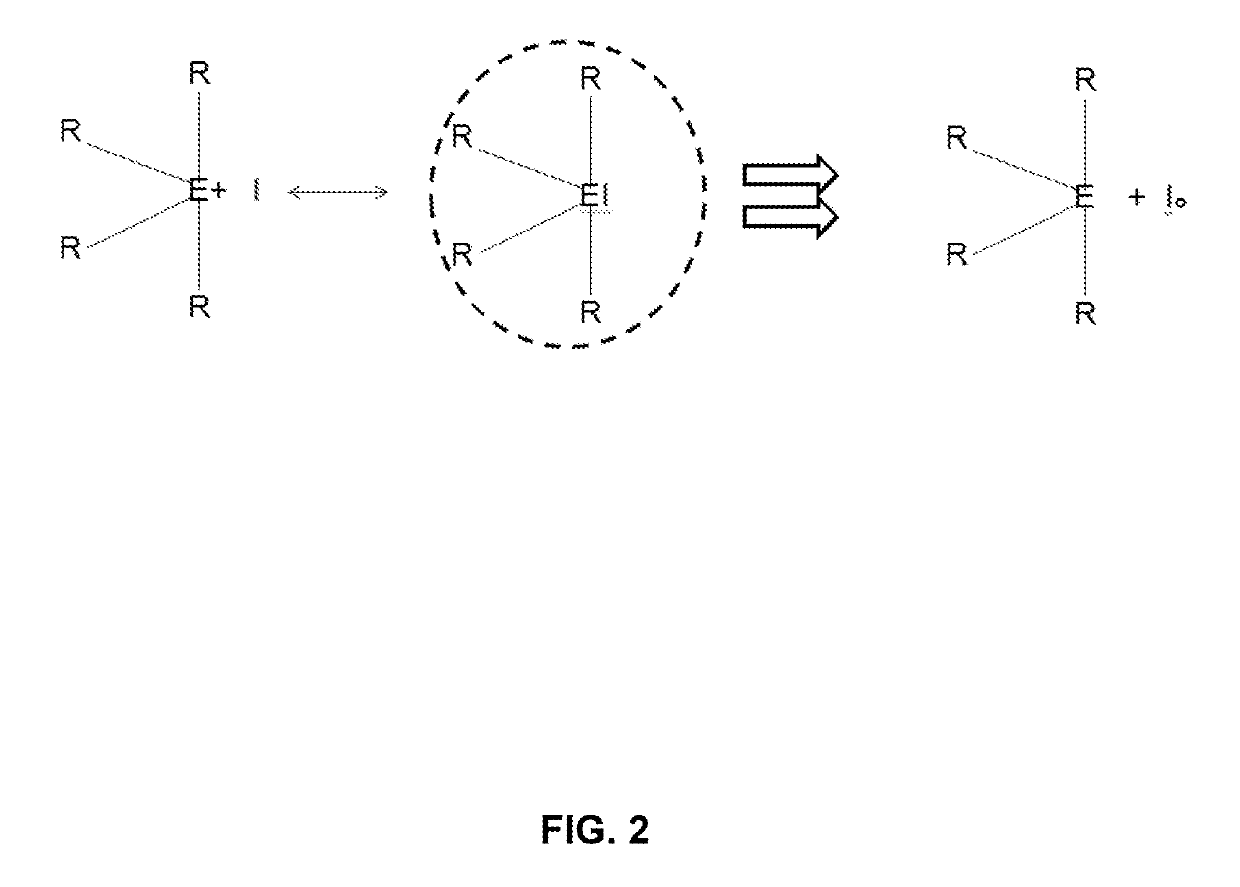

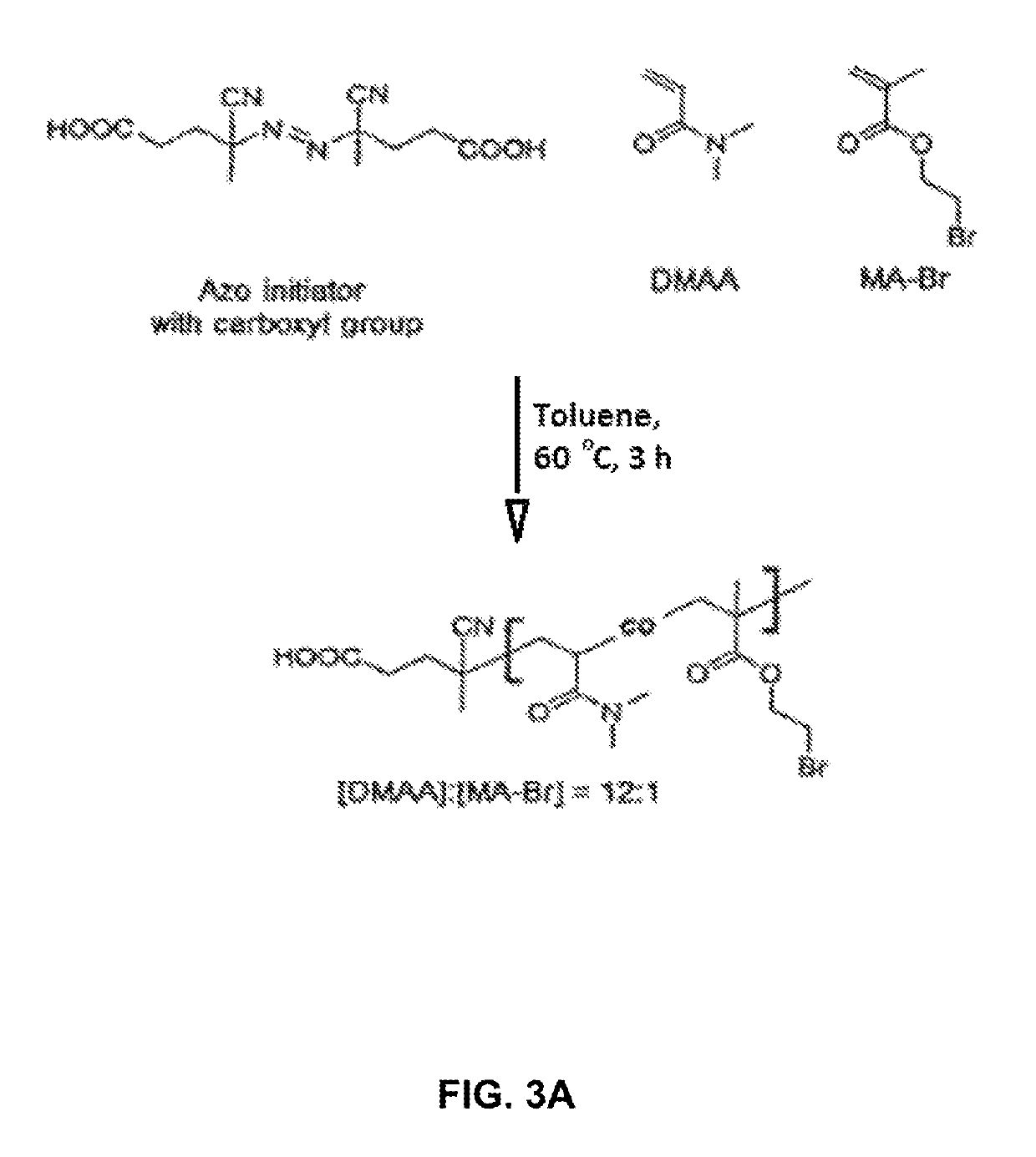

Polymer engineered regenerating bioscavengers

ActiveUS20160244741A1Extended service lifeReduce clearancePeptide/protein ingredientsEnzyme stabilisationPolymer scienceOxime

Owner:CARNEGIE MELLON UNIV

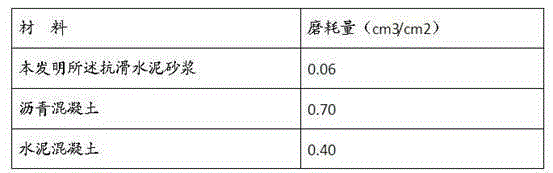

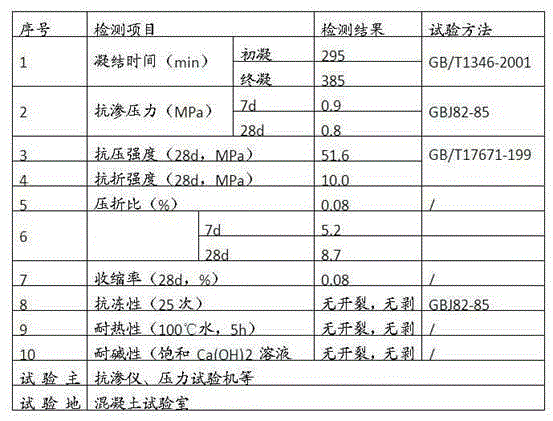

Anti-skid cement mortar and preparation method thereof

InactiveCN104556883AHigh mechanical strengthImprove friction performanceCement mortarPolymer chemistry

The invention relates to anti-skid cement mortar and a preparation method thereof. The anti-skid cement mortar comprises the following components in percentage by weight: 10-40 percent of high-molecular polymer, 10-40 percent of cement, 20-50 percent of water and 30-60 percent of engineering fine sand. The sum of the percentages of the components is 100%. The preparation method of the anti-skid cement mortar comprises the following steps: (1) pouring water, cement, high-molecular polymer and engineering fine sand into a clean agitation vat in proportion in sequence; (2) uniformly agitating the cement mortar raw materials for 30min in a normal-temperature environment with an agitator fixed above the agitation vat; and (3) pouring fully and uniformly agitated cement mortar into a charging bucket for use. The anti-skid cement mortar and the preparation method thereof overcome the defects of poor friction performance, high possibilities of skidding, cracking and corrosion and poor ductility of conventional cement mortar material, and solve the problems of high energy consumption, severe environmental pollution and long construction period during preparation of the conventional cement mortar material.

Owner:李林声

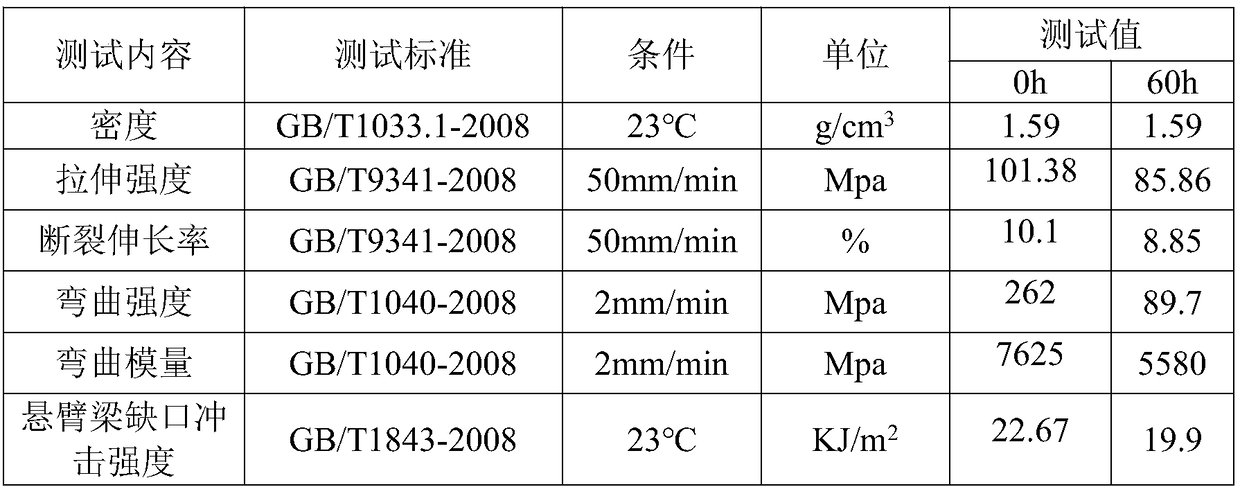

Polymer engineering plastic and preparation method and applications thereof

The invention relates to a polymer engineering plastic and a preparation method and applications thereof. The polymer engineering plastic comprises the following raw materials in parts by weight: 40 to 70 parts of nano silica with fineness of 1 / 6000-25000, 5 to 10 parts of talcum powder, 30 to 60 parts of crosslinking agent, 1 to 5 parts of antioxidant, 1 to 5 parts of composite material, 2 to 5 parts of compatilizer, 1 to 3 parts of flexibilizer, and 8 to 20 parts of glass fiber. The preparation method comprises following steps: weighing raw materials according to a proper weight ratio, stirring and mixing, and finally carrying out injection molding or press injection. The polymer engineering plastic is used to produce industrial products. The polymer engineering plastic has the advantages of resistance to high temperature and low temperature, high tensile strength, high bending degree, high bending modulus, and resistance to impact and wear, and is suitable for being applied to construction materials.

Owner:郭兆来

A kind of recovery method of by-product sodium chloride in the production process of polyphenylene sulfide

ActiveCN106395862BMeet the use requirementsReduce energy consumptionOrganic chemistryOrganic compound preparationRecovery methodSulfide production

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

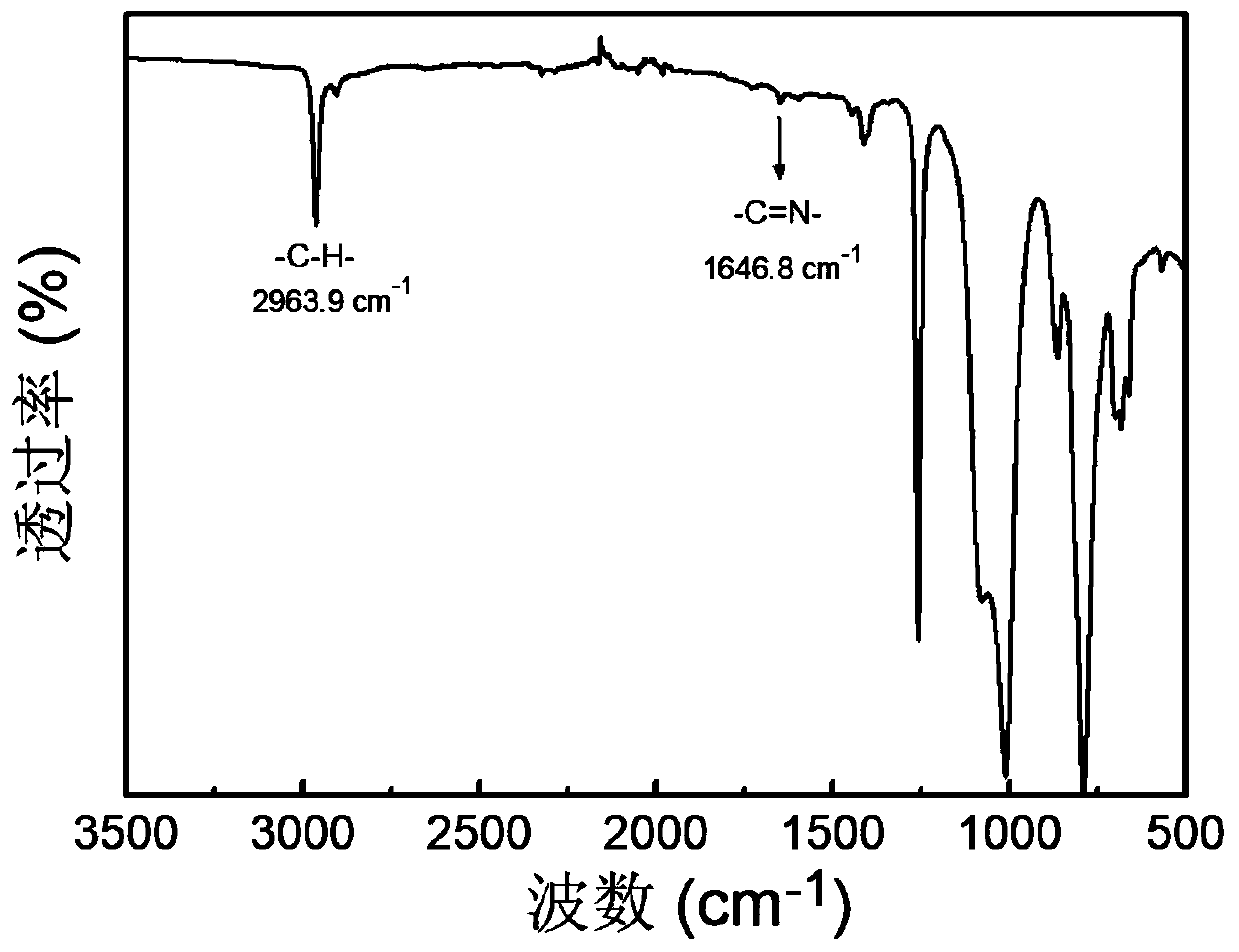

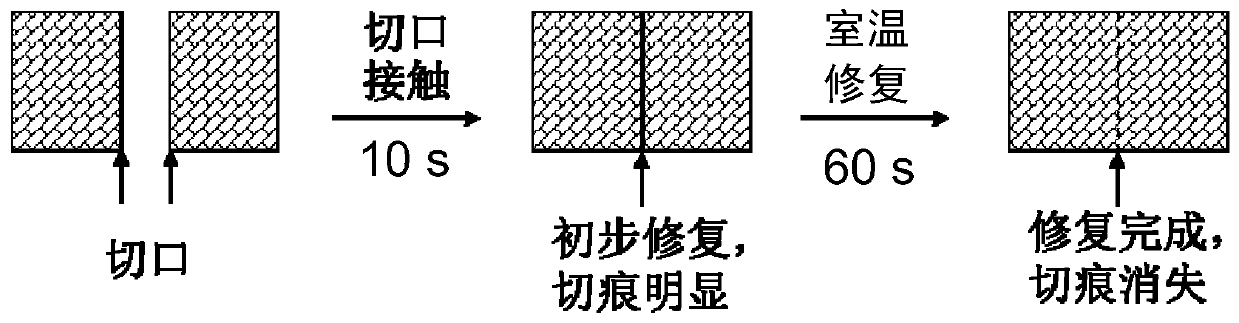

Rapid self-repairing materials and application thereof

ActiveCN110283317AImprove liquidityExcellent self-healing performancePolymer scienceRoom temperature

The present invention provides rapid self-repairing materials in view of the problems existing in the field of polymer engineering. A fast exchanged imine bond is combined with an amino-terminated polymer having a good chain fluidity, and the proportions of the imine bond and the amino-terminated polymer material are controlled, so the prepared rapid self-repairing materials have an excellent self-repairing property; and after the materials are continuously damaged by the outside, the materials can recover excellent tensile property, sealing performance and bonding performance at room temperature in just 1-30 min, and can be recycled.

Owner:NANJING UNIV

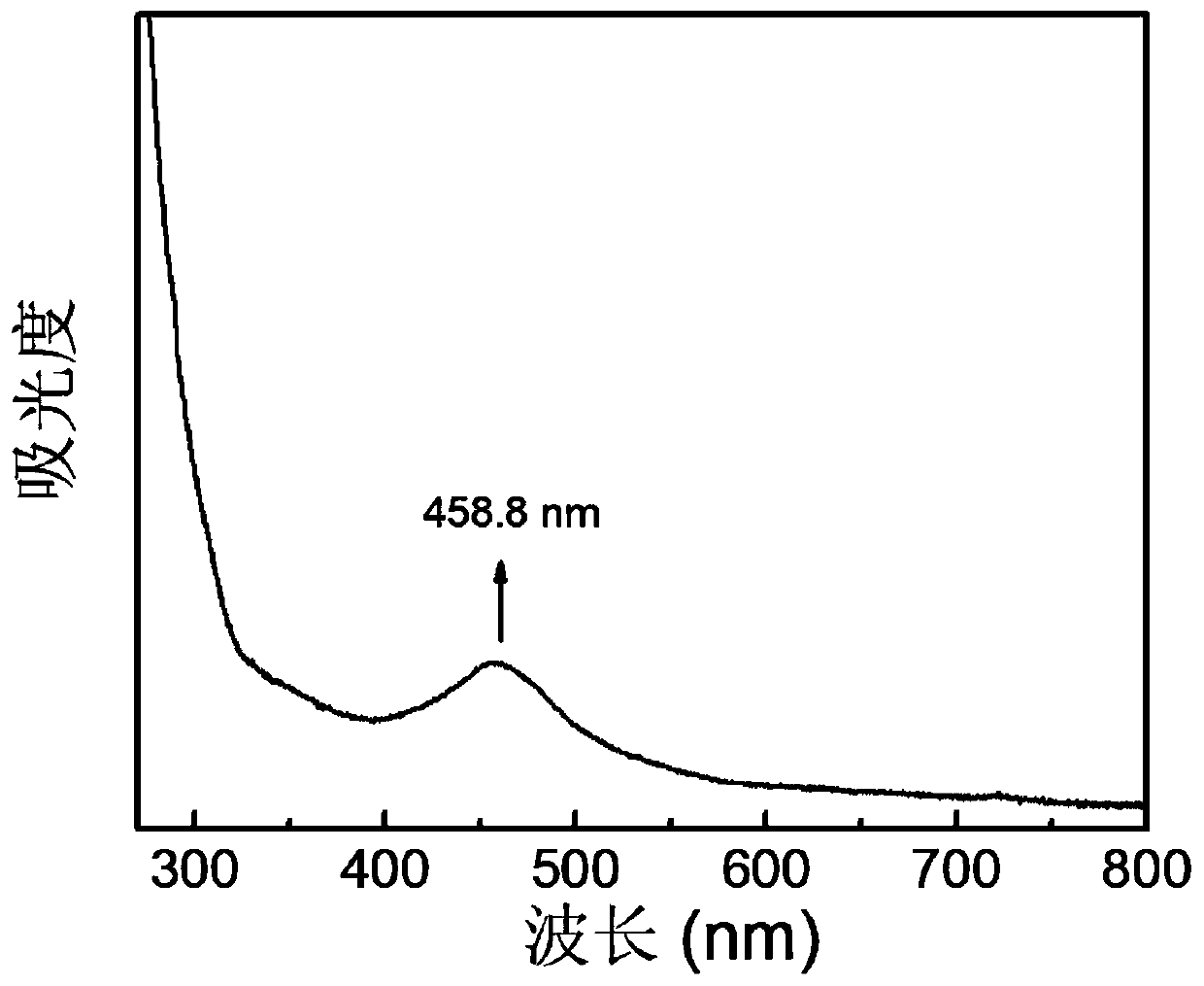

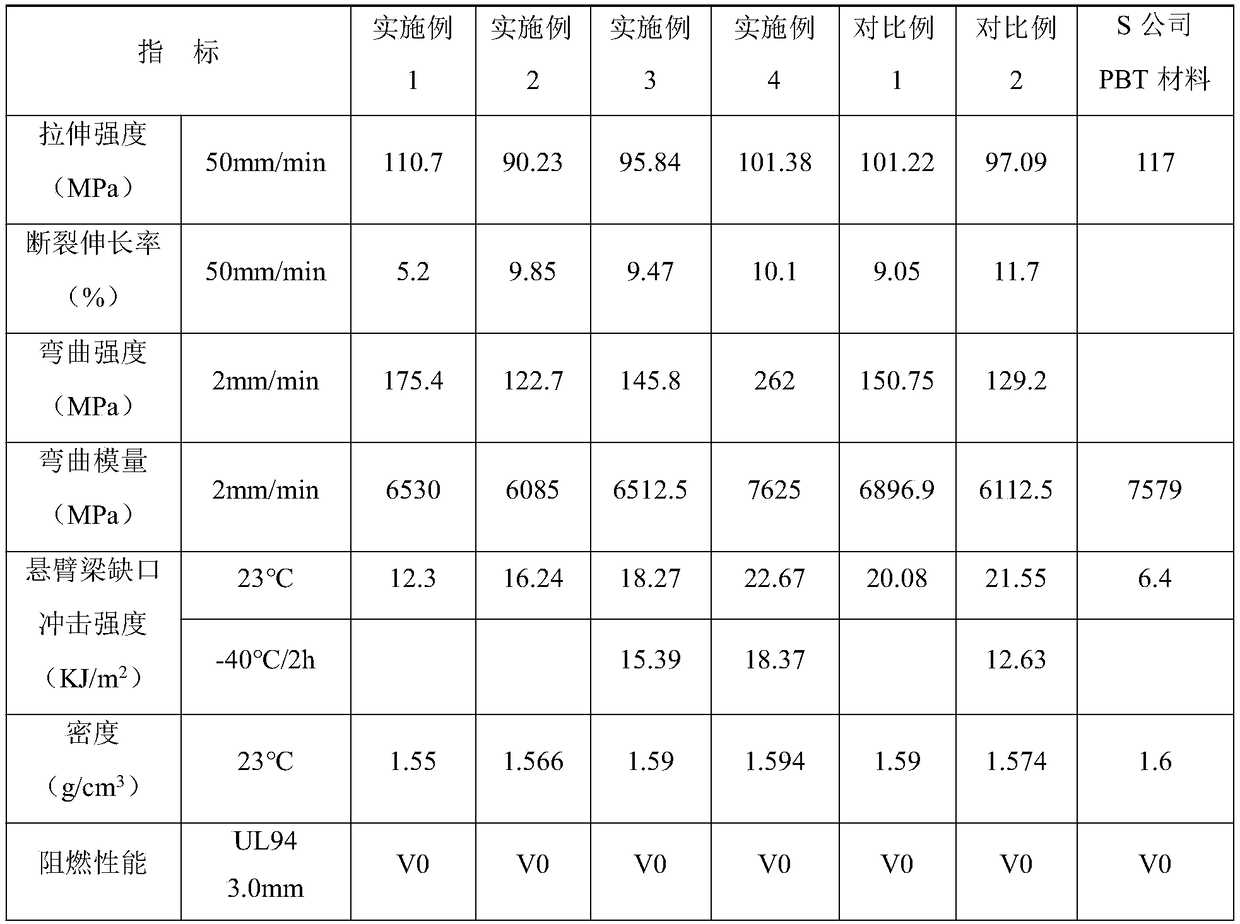

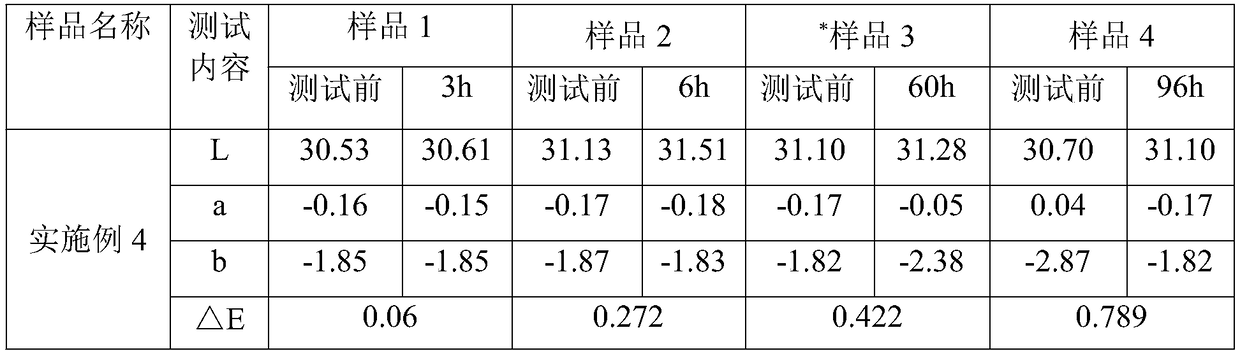

Modified reinforced flame-retardant PBT material and preparation method thereof

The invention discloses a modified reinforced flame-retardant PBT material and a preparation method thereof, and belongs to the technical field of polymer engineering plastic modification. The modified reinforced flame-retardant PBT material comprises the following components in parts by weight: 40-45.5 parts of a PBT resin, 25-30 parts of a glass fiber, 12-15 parts of a flame retardant, 0.3-0.5 part of an anti-drip agent, 0-5 parts of an inorganic filler, 0-2 parts of a coupling agent, 3-10 parts of a toughening agent, 0-3 parts of a lubricant, 0.2-0.5 part of a light stabilizer, 0.1-0.4 partof an ultraviolet absorber and 0.2-0.4 part of an antioxidant. The modified reinforced flame-retardant PBT material having the advantages of high weather resistance, high impact resistance, low deflection and scratch resistance is prepared by reasonably controlling the components in the formulation and the component matching in a low-cost manner, and can be widely applied to electronic appliances, outdoor high weather-proof products.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Yellowing-resistant and bottom-impermeable polymer engineering membrane

ActiveCN112519360AImprove flatnessImprove the finishNon-macromolecular adhesive additivesBio-packagingPolymer sciencePolyurethane adhesive

The invention relates to a yellowing-resistant and bottom-impermeable polymer engineering membrane. The glue of the engineering membrane used at the present stage is mainly polyurethane glue, and mainly has the problem of intolerance to yellowing, so that chromatic aberration exists, and the use and attractiveness are influenced. The membrane is characterized by comprising a PET surface layer, a glue layer, an outer milky-white master batch layer, an inner milky-white master batch layer and a base membrane, wherein the outer milky-white master batch layer comprises LDPE and milky white masterbatch, the inner milky-white master batch layer comprises LLDPE and milky white master batch, the glue layer is prepared from the following materials in parts by weight: 90 parts of acrylic acid glue,8-12 parts of tackifying resin, 0.1-0.5 part of a curing agent, 10 parts of waterborne polyurethane resin, 15 parts of modified nano silicon dioxide and 70-90 parts of a solvent, and the solvent is selected from ethyl acetate or methylbenzene. The membrane has the advantages of excellent flatness, smooth finish, few crystal points, strong covering property, no bottom penetration and no color penetration. By improving a glue formula and combining the milky-white master batch layer, a better yellowing-resistant effect is achieved, and no color difference is generated after long-term use.

Owner:浙江华清包装材料有限公司

Polymer engineered regenerating bioscavengers

ActiveUS10400232B2Keep for a long timeAdsorption is slowPeptide/protein ingredientsEnzyme stabilisationPolymer sciencePolymer

Owner:CARNEGIE MELLON UNIV

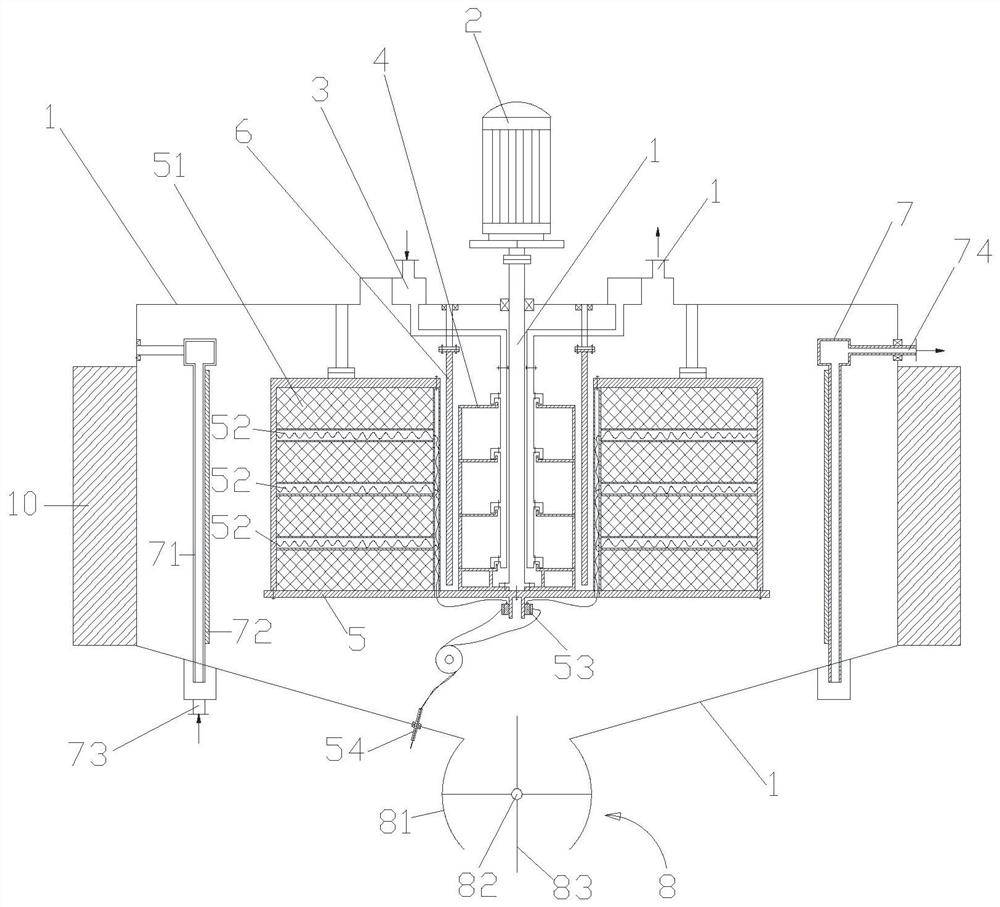

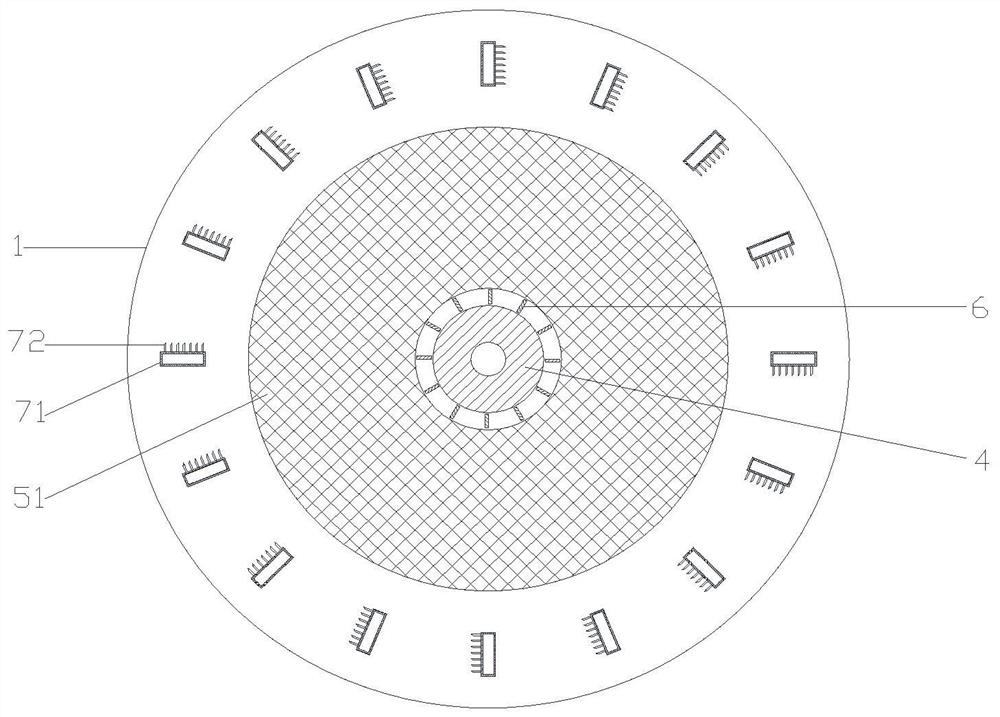

Hypergravity rotating bed for polymer devolatilization granulation and application method of hypergravity rotating bed

ActiveCN112339158AChange physical propertiesEnhanced devolatilization processChemical industryPlastics engineeringElectric machine

The invention discloses a hypergravity rotating bed for polymer devolatilization granulation and an application method of the hypergravity rotating bed. The hypergravity rotating bed comprises a shell, a motor, a liquid inlet cavity, a multi-layer disc distributor, a rotor, a static flow guide piece, a granulation component, a discharging component and a gas outlet. According to the hypergravity rotating bed, the integrated process of volatile compound removal, granulation and discharging of thermoplastic polymers under the vacuum condition can be achieved, the series connection process of anexternal granulation device in the traditional plastic industry is avoided, and the occupied area and energy consumption are remarkably reduced. Meanwhile, the advantages of the hypergravity rotatingbed are exerted, so that volatile components are removed more thoroughly, and the granulated particle size is more uniform. By adjusting the structure of the granulation device and matching with different rotating speeds of the rotating bed, the morphology and the size of the granules can be controlled. The device and the method have important significance in the fields of plastic engineering, polymer engineering and hypergravity reactors.

Owner:BEIJING UNIV OF CHEM TECH

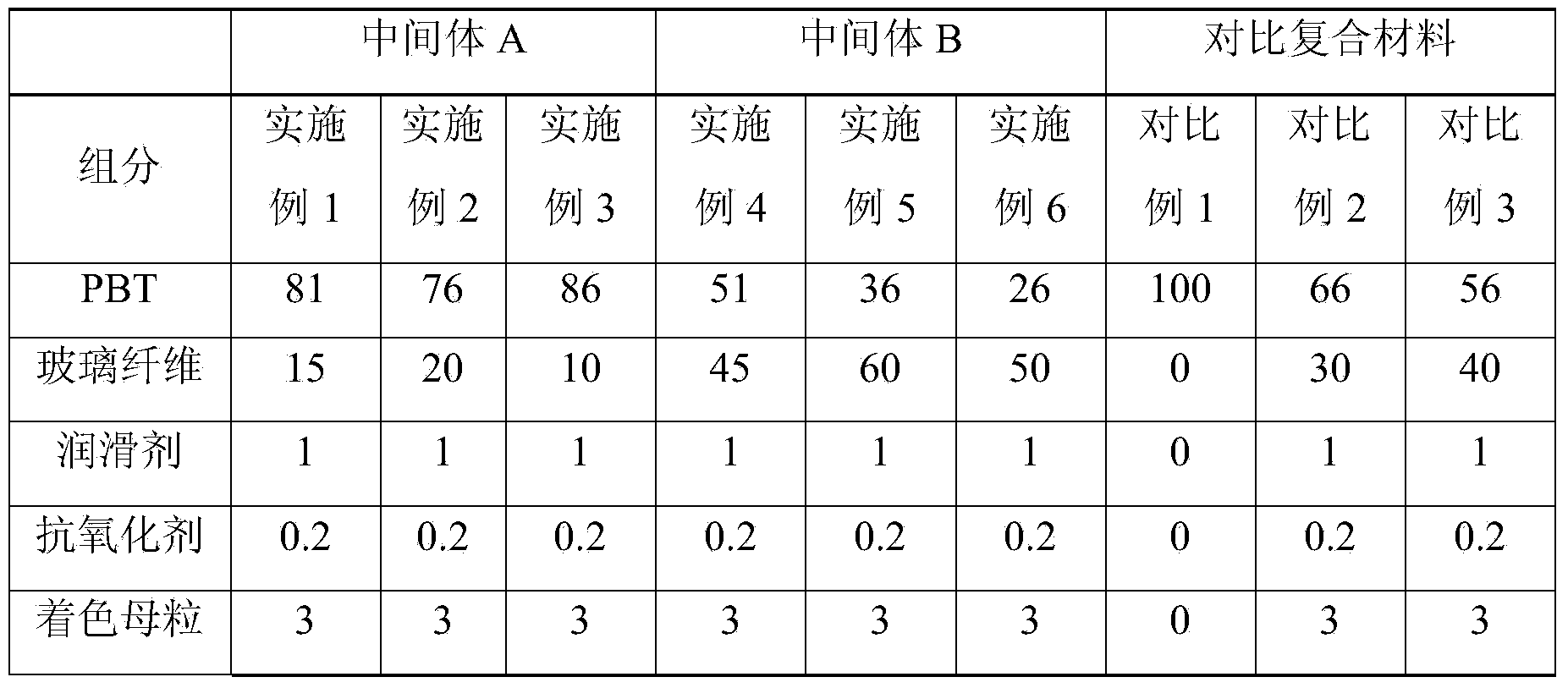

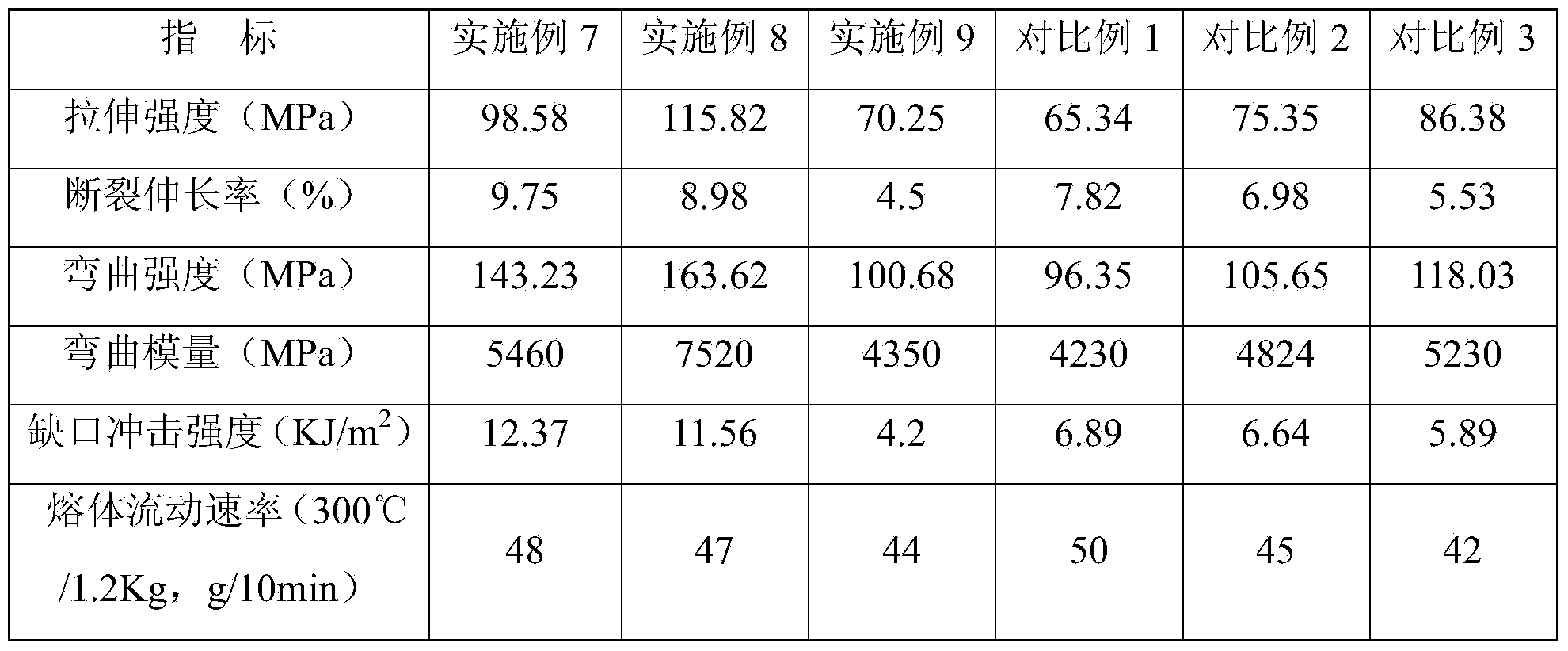

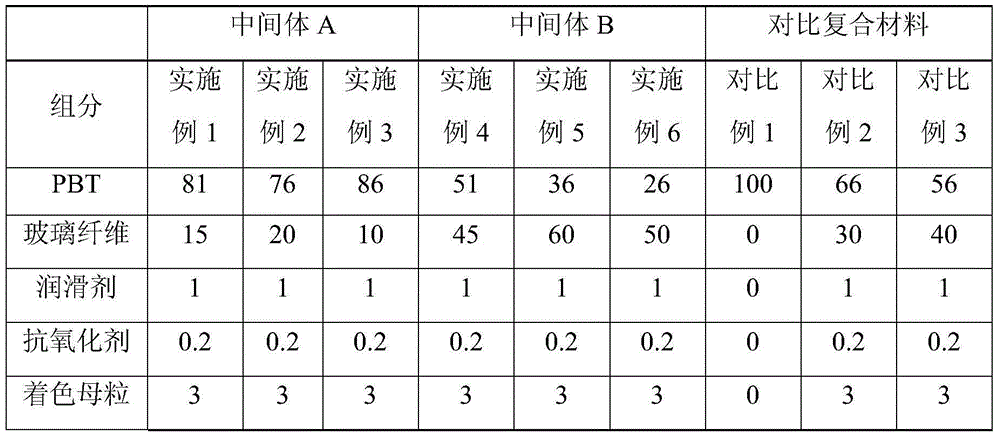

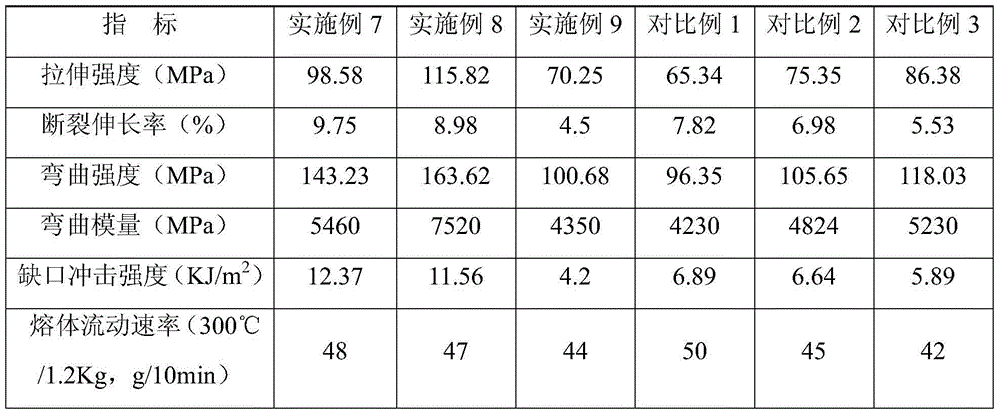

Polybutylene terephthalate/glass fiber composite and preparation method thereof

ActiveCN103642179AFix color problemsSolve surface floating fiber phenomenonGlass fiberPolytetramethylene terephthalate

The invention belongs to the technical field of polymer engineering plastics, in particular relates to a polybutylene terephthalate / glass fiber composite and a preparation method thereof and aims to solve the technical problems that the toughness, the processability and the appearance quality of the polybutylene terephthalate are poor due to the addition of a glass fiber. According to the technical scheme of the invention, the polybutylene terephthalate / glass fiber composite with high strength and high toughness is provided, the polybutylene terephthalate / glass fiber composite is prepared by uniformly mixing intermediates A and B according to the mass ratio of 1:1, and carrying out extrusion pelletization. The polybutylene terephthalate / glass fiber composite has stronger strength, stronger toughness, good processability and good appearance effect and can be widely applied to various fields of the electronic field, the automobile field, the household appliance field and the like.

Owner:MIANYANG SHENGYU NEW MATERIALS

Magnesium carbonate modified fireproof plastic and preparation method thereof

InactiveCN105038176AIncrease heat absorptionImprove mechanical propertiesHeat resistanceSynthetic resin

The invention relates to the technical field of polymer engineering materials, and discloses magnesium carbonate modified fireproof plastic and a preparation method thereof. The magnesium carbonate modified fireproof plastic is composed of magnesium carbonate, nanoscale magnesium hydrate, synthetic resin, additives and plastic. The magnesium carbonate modified fireproof plastic has good mechanical performance and heat resistance and is good in flame retarding effect.

Owner:韦海棉

Polybutylene terephthalate/glass fiber composite material and preparation method thereof

ActiveCN103642179BHigh tensile strengthImprove bending strengthPolytetramethylene terephthalateGlass fiber

The invention belongs to the technical field of polymer engineering plastics, in particular relates to a polybutylene terephthalate / glass fiber composite and a preparation method thereof and aims to solve the technical problems that the toughness, the processability and the appearance quality of the polybutylene terephthalate are poor due to the addition of a glass fiber. According to the technical scheme of the invention, the polybutylene terephthalate / glass fiber composite with high strength and high toughness is provided, the polybutylene terephthalate / glass fiber composite is prepared by uniformly mixing intermediates A and B according to the mass ratio of 1:1, and carrying out extrusion pelletization. The polybutylene terephthalate / glass fiber composite has stronger strength, stronger toughness, good processability and good appearance effect and can be widely applied to various fields of the electronic field, the automobile field, the household appliance field and the like.

Owner:MIANYANG SHENGYU NEW MATERIALS

A method for recovering low-molecular polymers in the production process of polyphenylene sulfide

ActiveCN106432019BEfficient separation and recoveryNo pollution in the processOrganic chemistryOrganic compound preparationPolymer scienceSulfide production

The invention belongs to the field of polymer engineering and in particular provides a method for recovering a low molecular polymer in the polyphenylene sulfide (PPS) production process. The method comprises the following steps: filtering mixed slurry obtained through polymerization of PPS resin to obtain filtrate and a filter cake, washing the filter cake with deionized water to obtain washing liquor and a PPS wet material, mixing the washing liquor with the filtrate and then carrying out filtration, acidification, aeration and refiltration, thus obtaining the low molecular polymer. The method can be used for effectively separating and recovering the low molecular polymer generated in the PPS production process and has the effect of reducing environmental pollution.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

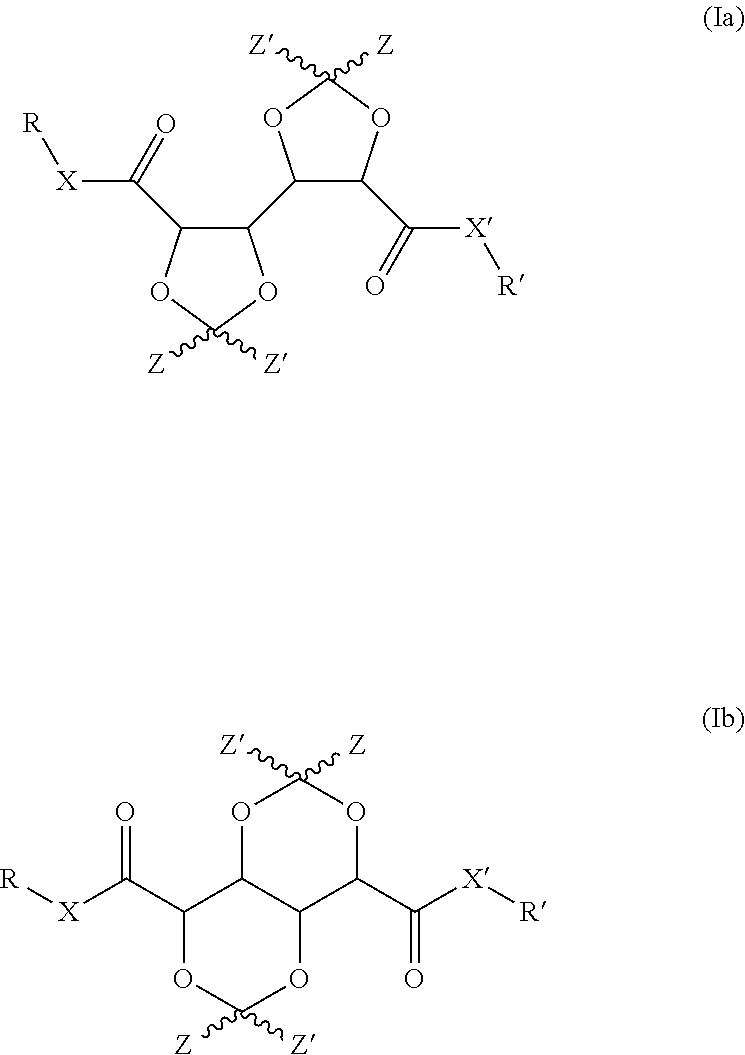

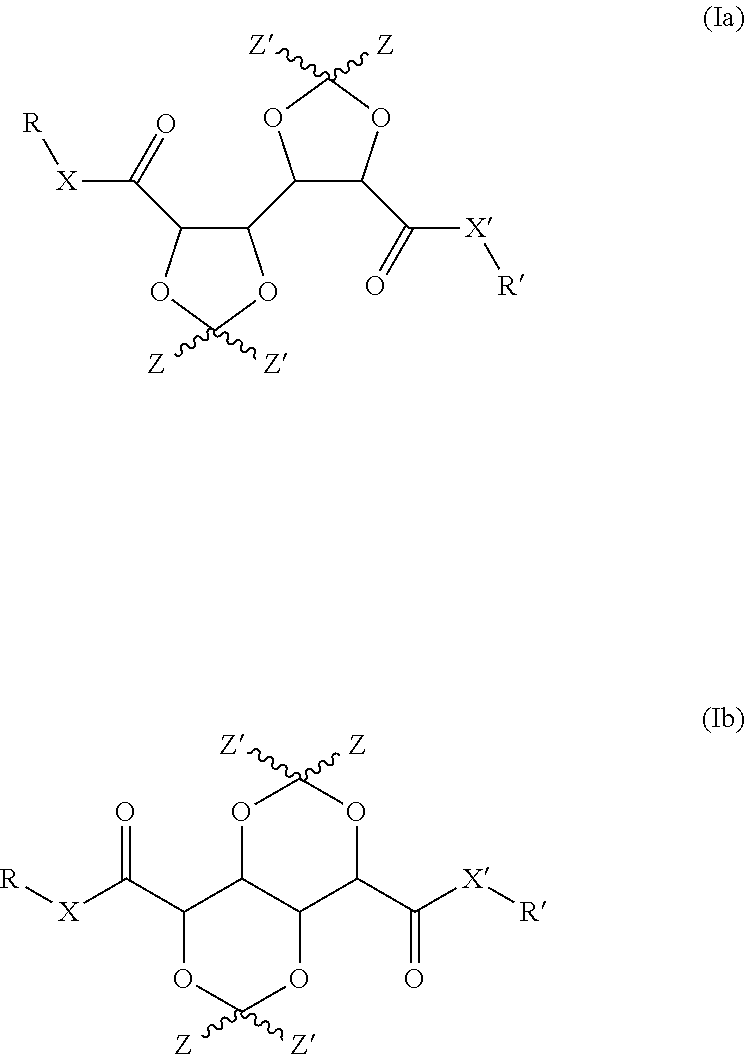

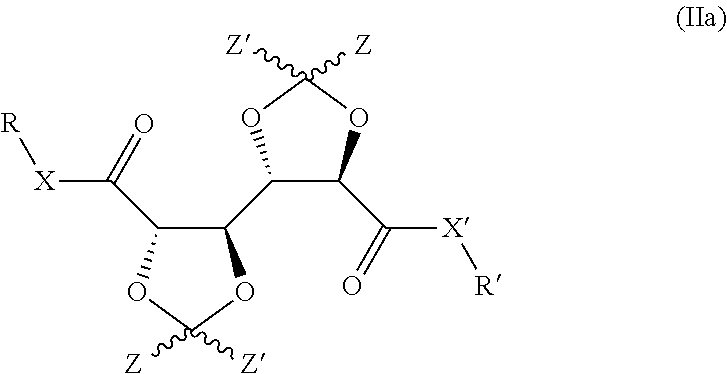

Bis-diox(OL)ane compounds

ActiveUS20190284201A1Convenient introductionImprove efficiencyEsterified saccharide compoundsSugar derivativesCross-linkStructural unit

The present invention relates to new bi-functional and polyfunctional bis-dioxolanes and bis-dioxanes. The present inventors have established that the bis-dioxolanes and bis-dioxanes of the invention are highly advantageous as building blocks, cross-linking and / or coupling agents in polymer engineering. They can be derived from biomass sources in a highly efficient manner. The production of the present bis-dioxolanes and bis-dioxanes from biomass has the particular advantage that it facilitates the introduction of desired functionality in a highly flexible manner. Hence, the present invention provides novel bi- or polyfunctional bis-dioxolanes and bis-dioxanes, their production from renewable (biomass) sources, as well as their use in the engineering of polymers.

Owner:KONINK COOPERATIE COSUN U A

Method for detecting residual principal stress of polymer material products

ActiveCN109141706BImprove accuracyEasy to operateMaterial analysis using wave/particle radiationApparatus for force/torque/work measurementCrystallographyMetallic materials

The invention relates to the field of stress measurement of polymer materials and discloses a method of detecting the residual principal stress of a polymer product. The method adopts a two-dimensional X-ray diffraction method to quantitatively detect the residual principal stress of the polymer product, the polymer material adopts a crystalline region and an amorphous region, and in the presenceof the residual stress, the crystalline region and the amorphous region have the same strain. The method provided in the invention succeeds in application of the two-dimensional X-ray diffraction method to the residual principal stress detection on a polymer engineering material, the limitations that the traditional two-dimensional X-ray diffraction method can only be applied to detection on the residual stress of a polycrystalline metal material are broken, and the detection method is simple and controllable, the application range is wide, the detection errors are small, and the application prospect is broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

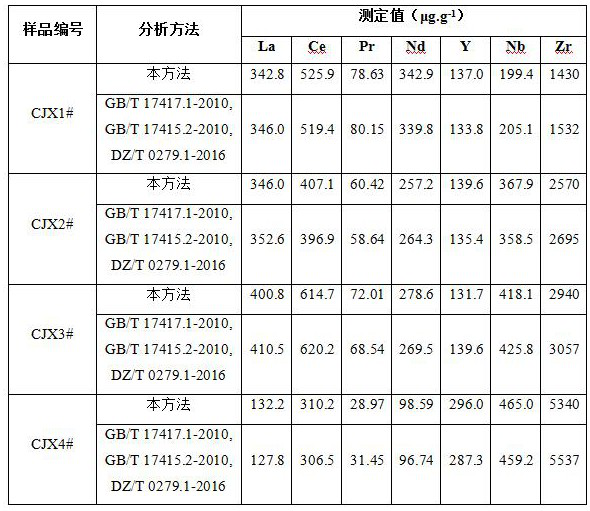

A method for rapidly decomposing sedimentary rare earth ore

ActiveCN110595851BHigh decomposition temperatureCorrosion resistant to strong acid and alkaliPreparing sample for investigationMaterial analysis by electric/magnetic meansEngineering plasticFluoride

The present invention proposes a novel method for quickly decomposing sedimentary rare earth ores for specific sedimentary clay-type rare earth ores in the Bijie-Liupanshui area of Guizhou, that is, high-strength polyphenylene polymer engineering plastics are used as the material for the inner tank for digestion. NH with high boiling point 4 HF 2 Instead of HF, use NH 4 HF 2 and HNO 3 Perform a high-pressure closed digestion program at 240-250 °C. Digest solution with 0.25~0.5mL H 2 SO 4 Catching acid to destroy rare earth fluorides, using 5% HCl~5% tartaric acid as the dissolution medium, realized the rapid and complete decomposition of rare earth, Zr, and Nb in sedimentary rare earth ores. The decomposition effect of this method on zircon and rutile in sedimentary rare earth ores in Bijie-Liupanshui area, Guizhou Province is equivalent to that of the closed polytetrafluoroethylene digestion method, but the temperature used is higher, the pressure is higher, and the time is shortened by nearly 2 / 3, which reflects It has the advantages of fast, efficient, green and energy saving.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com