Hypergravity rotating bed for polymer devolatilization granulation and application method of hypergravity rotating bed

A supergravity rotating bed, polymer technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc. The effect of devolatilization process and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

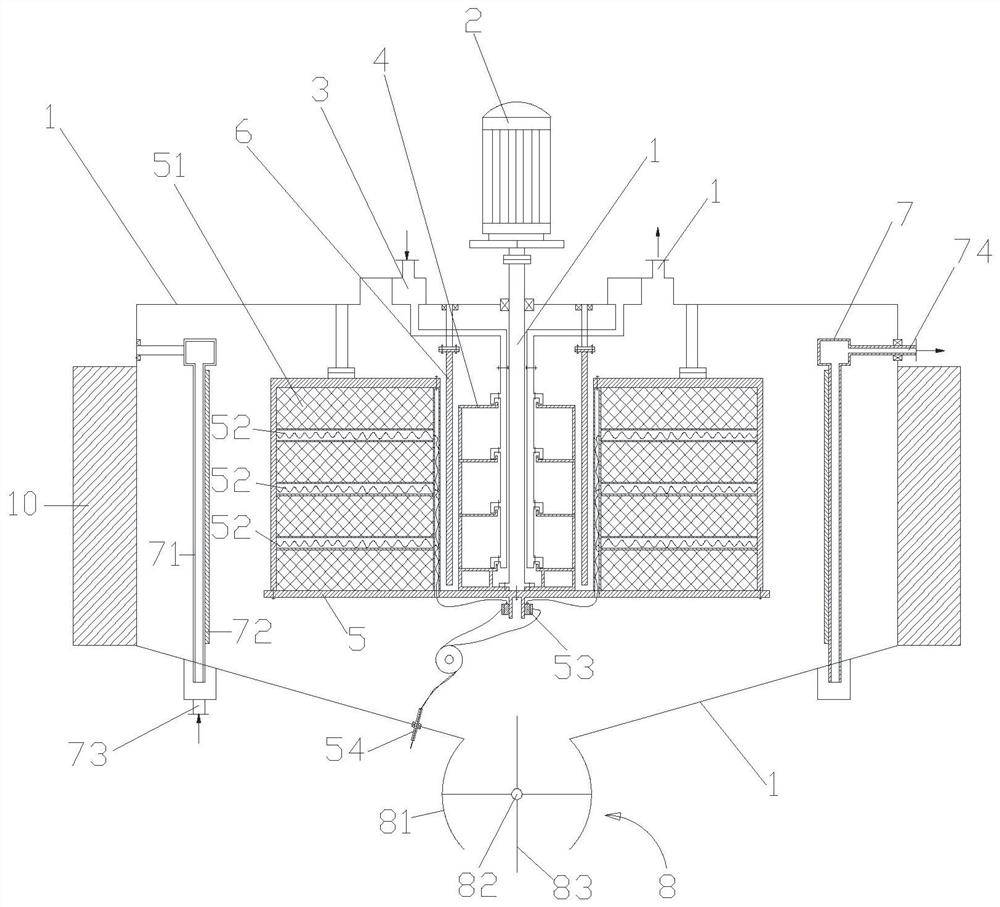

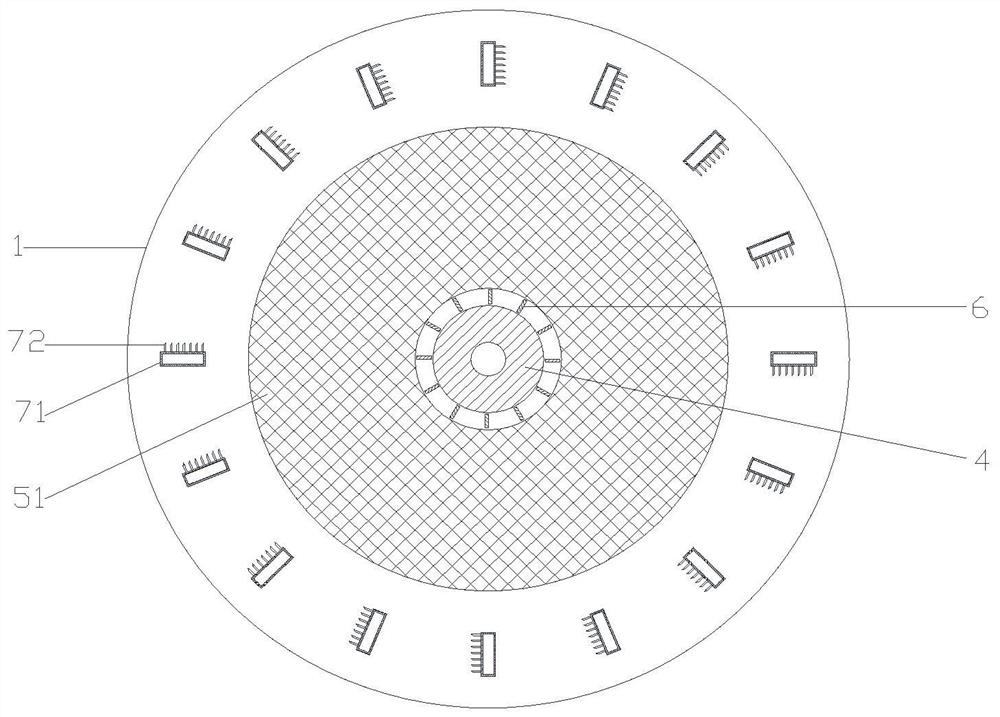

Method used

Image

Examples

Embodiment 1

[0108] This device is used to remove the volatile TDI in the polyurethane prepolymer. The experimental conditions are as follows: the rotation speed of the rotating bed is 200-2000r / min, the volume flow rate of the material is 50L / h, the devolatilization temperature is 110°C (the boiling point of TDI under vacuum is about 110°C), and the vacuum degree in the rotating bed is 0.99 MPa, the viscosity of the material is about 1Pa·s. The TDI content in the polyurethane prepolymer before and after devolatilization is detected by gas chromatography. At the speed of 2000r / min, this device can remove 80% of the TDI content in the polyurethane prepolymer, and the final TDI content is 800-1200ppm.

Embodiment 2

[0110] The device in Example 1 is adjusted to adjust the surface structure of the disc distributor, respectively image 3 As shown, it is found that the removal rate of final TDI has been improved to varying degrees. The devolatilization effect of the surface structure is straight baffle type > arc baffle type > spiral groove type > concentric groove type > cubic convex type. The removal rate of the optimal straight baffle type can be increased by 85%, and the TDI content can be reduced to 600-1000ppm.

Embodiment 3

[0112] On the basis of Example 2, a straight disc is used to further adjust the structure of the static deflector, which are respectively Figure 4 structure shown. The final TDI removal rate has been improved to varying degrees, and the best effect is the flexible plate structure, the flexible plate part is made of silica gel, the removal rate can be increased to 88%, and the TDI content can be reduced to 400-700ppm; followed by Straight plate type, again arc plate type structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com