Modified reinforced flame-retardant PBT material and preparation method thereof

A PBT resin and modification technology, which is applied in the field of modified and enhanced flame-retardant PBT materials and its preparation, can solve the problems of poor comprehensive performance of PBT materials, achieve low deflection, and broaden the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh each raw material according to the raw material formula in Table 1, wherein the TH6100 melt index of PBT resin is 23-32g / 10min (235°C / 2.16kg, tested according to the national standard GB / T3682-2000), the tensile strength is 50-60MPa, and the fracture Elongation >200%; glass fiber is alkali-free glass long fiber, particle size is 14μm; flame retardant is brominated epoxy resin and antimony trioxide (purity: 99.99%) compounded by mass ratio of 3:1 Compound, wherein the weight percentage of bromine in the brominated epoxy resin is 51-53%, the molecular weight of the epoxy resin is 3000-6000; the anti-dripping agent is polytetrafluoroethylene masterbatch, which is ground into powder when used , wherein the weight percentage of polytetrafluoroethylene is 50%; the inorganic filler is nano-active calcium carbonate, and the particle size is 3000 mesh; the coupling agent is γ-mercaptopropyltrimethoxysilane; the toughening agent is ethylene- Methyl acrylate-glycidyl methacr...

Embodiment 2

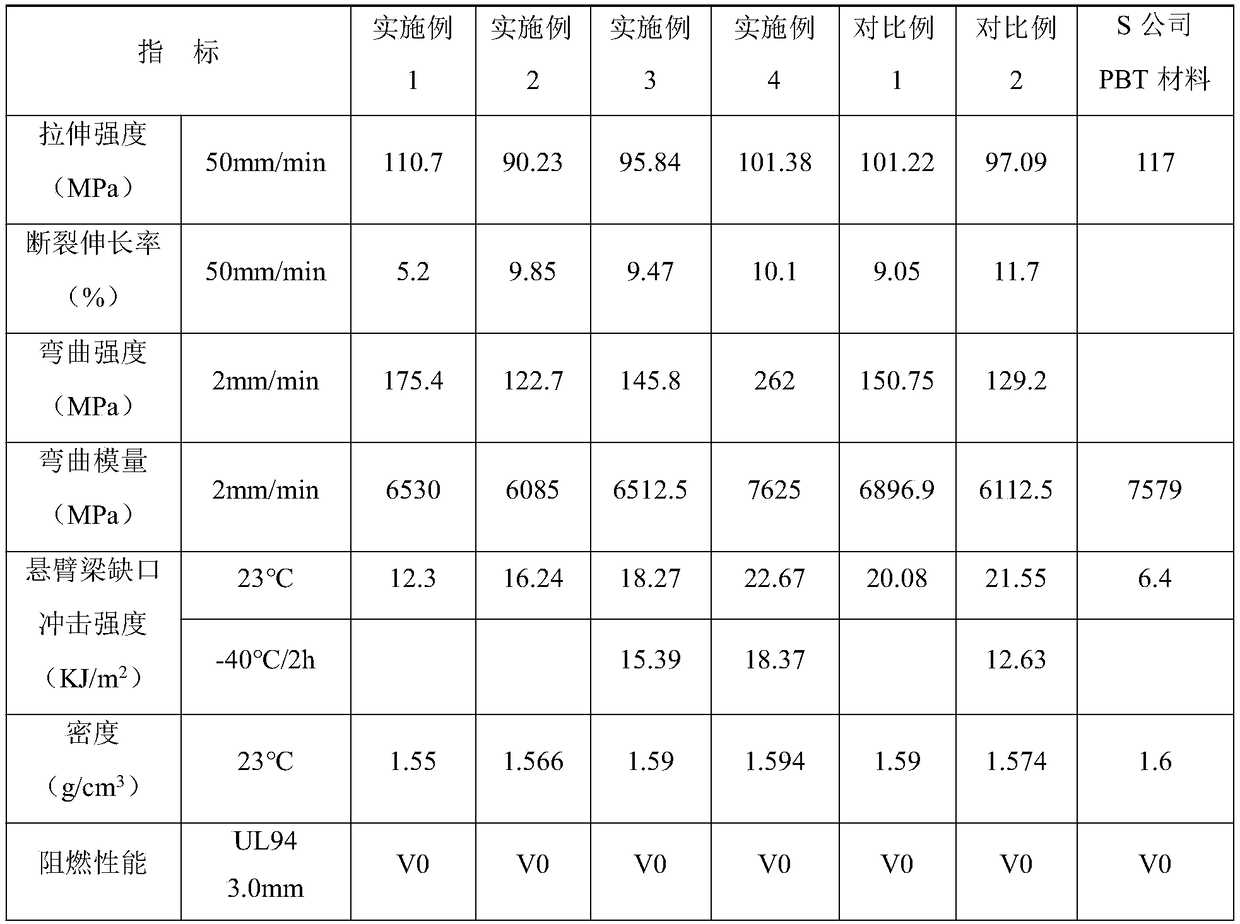

[0026] The preparation method of Examples 2-4 is the same as that of Example 1, and the specific raw material ratio is shown in Table 1, wherein the ratio of Example 2 is exactly the same as that of Example 1, the only difference is that the particle size of the glass fiber in Example 2 is 11 μm The product of embodiment 2-4 is tested according to national standard, and product performance data is as shown in table 2~5.

[0027] The preparation method of Comparative Example 1-2 is the same as that of Example 1, and the specific raw material ratio is shown in Table 1, wherein the alkali-free glass fibers in Comparative Example 1-2 are chopped fibers with a particle size of 8 μm; Comparative Example 1-2 The products are tested according to the national standard, and the product performance data are shown in Table 2.

[0028] Table 1 Raw materials and raw material ratios of modified reinforced flame-retardant PBT materials (unit: part)

[0029] components

Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com