Polybutylene terephthalate/glass fiber composite material and preparation method thereof

A technology of polybutylene terephthalate and glass fiber, which is applied in the field of polybutylene terephthalate/glass fiber composite material and its preparation, can solve the toughness of polybutylene terephthalate , processing performance and poor appearance quality, etc., to achieve good processing performance, solve the effect of enhancing the color and notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

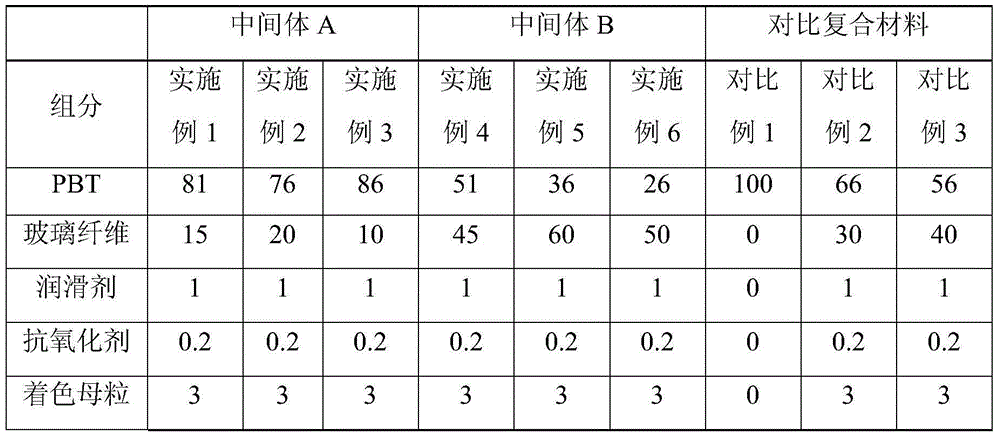

[0033] The preparation of embodiment 1~6 intermediate A and intermediate B

[0034] Intermediate A weighs various raw materials according to the raw material ratio in Table 1, and intermediate B weighs various raw materials according to the raw material ratio in Table 1.

[0035] Among them, PBT resin (molecular weight: 25000) was dried at 120°C for 5 hours before use, and various raw materials were added to a high-speed mixer and mixed at high speed for 3 minutes, and then discharged at a low speed. The mixed material is extruded and granulated to obtain intermediate A and intermediate B. Extrusion granulation conditions are: host screw speed 350r / min, feeding speed 30r / min, heating temperature range: 1 stage / 220°C, 2 stages / 230°C, 3 stages / 240°C, 4 stages / 250°C, 5 stages / 260°C, 6 stages / 250°C, 7 stages / 240°C, 8 stages / 230°C, 9 stages / 230°C, head temperature: 240°C.

Embodiment 7~9

[0040] The preparation of embodiment 7~9 polybutylene terephthalate / glass fiber composite material

[0041] The compositions of Examples 7-9 are shown in Table 2. Intermediate A and Intermediate B were uniformly mixed at a weight percentage of 1:1 to obtain a polybutylene terephthalate / glass fiber composite material.

[0042] Table 2 Composition and preparation of polybutylene terephthalate / glass fiber composites

[0043] product

Embodiment 10

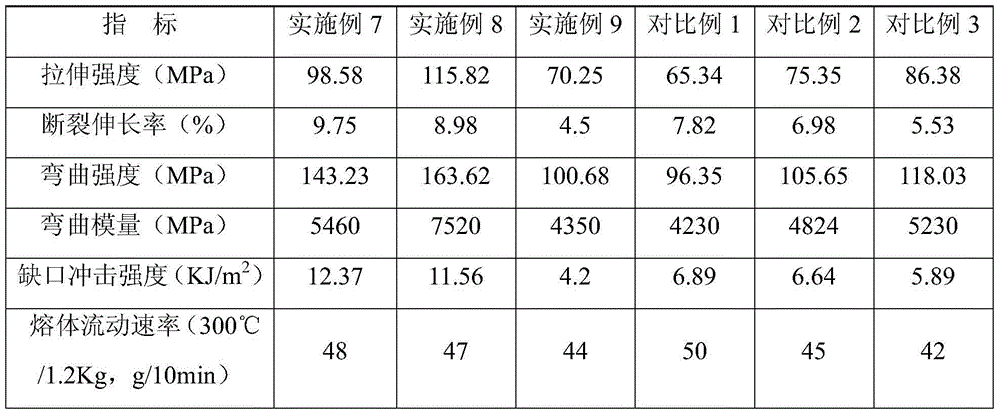

[0044] Embodiment 10 performance comparison

[0045] The tensile strength and elongation at break of the products obtained in Comparative Examples 1 to 3 and the products obtained in Examples 7 to 9 were tested according to the national standard GB / T1040.2-2006; the flexural strength and flexural modulus were tested according to the national standard GB / T9341- Tested in 2000; Izod notched impact strength was tested in accordance with national standard GB / T1843-2008; melt flow rate was tested in accordance with national standard GB / T3682-2000. The performance comparison data of the products are shown in Table 3.

[0046] Table 3 Properties of polybutylene terephthalate / glass fiber composites

[0047]

[0048] As can be seen from table 1 and table 2, the product of embodiment 7 is identical with the glass fiber content of comparative example 2, and the product of embodiment 8 is identical with the glass fiber content of comparative example 3, as can be seen from table 3, by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com