Polymer engineering plastic and preparation method and applications thereof

A technology of engineering plastics and polymers, applied in the chemical industry, can solve the problems of high bending degree and flexural modulus, low thermal deformation temperature of polymer engineering plastics, high tensile strength of polymer engineering plastics, etc., to achieve bending and bending The effect of high modulus, excellent thermal stability, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

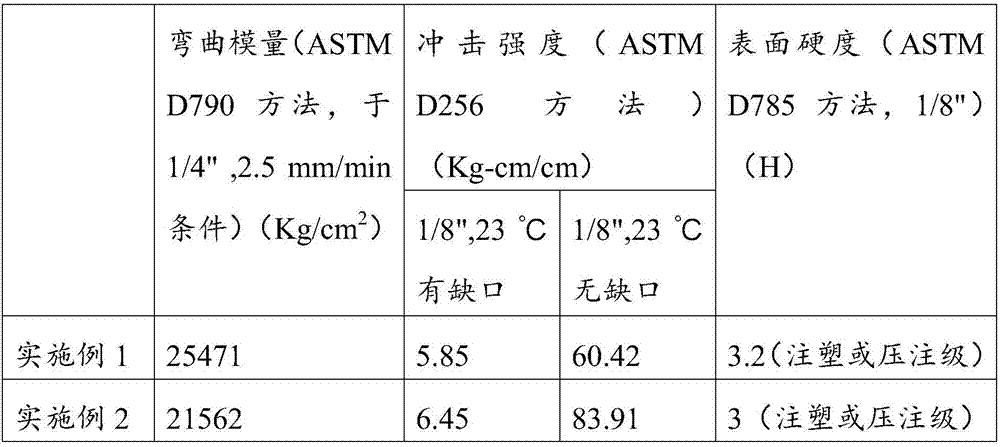

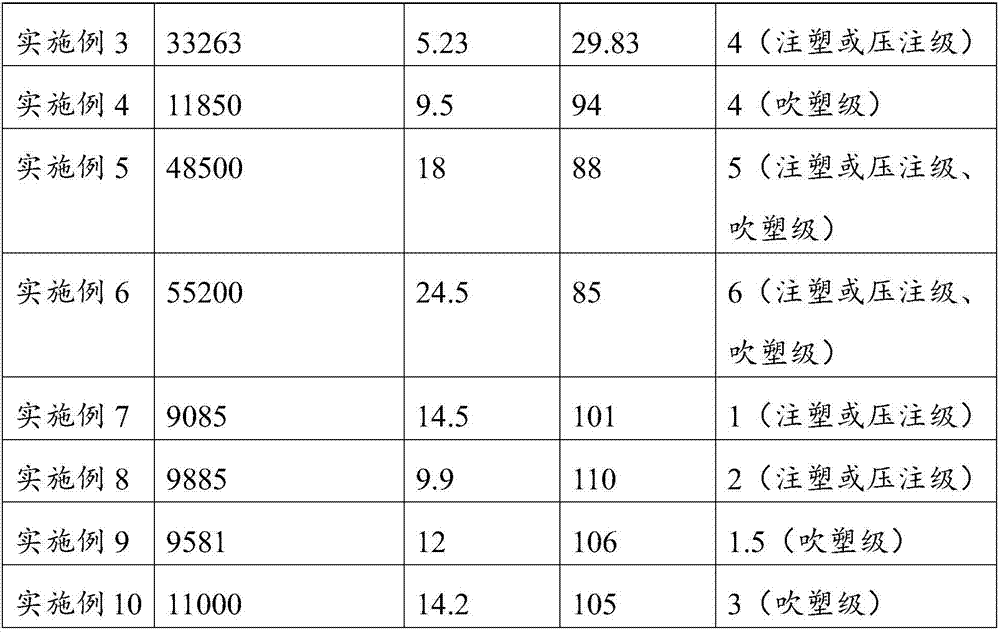

Embodiment 1

[0041] Weigh each raw material in parts by weight, weigh 48 parts of polypropylene, 4.5 parts of antioxidant and 1 part of composite material and mix evenly to obtain a mixture; then weigh 3 parts of compatibilizer, 6 parts of talcum powder and 2.5 parts of toughening agent 34 parts of nano-silica 1 / 6000-25000 fineness and 8 parts of glass fiber were mixed uniformly, then added the mixed material and stirred Mix evenly to obtain the mixed total material, and then extrude the mixed total material through a twin-screw machine, injection molding or pressure injection, and then inject the material after injection molding or pressure injection under vacuum conditions (in the mold, under vacuum conditions). Gamma ray irradiation, that is.

Embodiment 2

[0043] Weigh each raw material in parts by weight, weigh 54.4 parts of polypropylene, 2 parts of antioxidant and 4.5 parts of composite material and mix evenly to obtain a mixture; then weigh 2 parts of compatibilizer, 5 parts of talcum powder and 1 part of toughening agent 30 parts of nano-silica 1 / 6000-25000 fineness and 11 parts of glass fiber were mixed uniformly, then added the mixed material and stirred Mix evenly to obtain the mixed total material, and then extrude the mixed total material through a twin-screw machine, injection molding or pressure injection, and then inject the material after injection molding or pressure injection under vacuum conditions (in the mold, under vacuum conditions). Gamma ray irradiation, that is.

Embodiment 3

[0045] Weigh each raw material in parts by weight, weigh 47 parts of polypropylene, 1 part of antioxidant and 3 parts of composite material and mix evenly to obtain a mixture; then weigh 2 parts of compatibilizer, 5 parts of talcum powder and 1 part of toughening agent 1 / 6000-25000 fineness of nano-silica and 10 parts of glass fiber and mix uniformly, then add the mixed material and stir Mix evenly to obtain the mixed total material, and then extrude the mixed total material through a twin-screw machine, injection molding or pressure injection, and then inject the material after injection molding or pressure injection under vacuum conditions (in the mold, under vacuum conditions). Gamma ray irradiation, that is.

[0046] The polymer engineering plastics prepared in Example 1-3 were placed at a high temperature of 120°C for 6 hours, and the polymer engineering plastics produced had no obvious deformation; then the polymer engineering plastics prepared in Examples 1-3 were place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com