Rapid self-repairing materials and application thereof

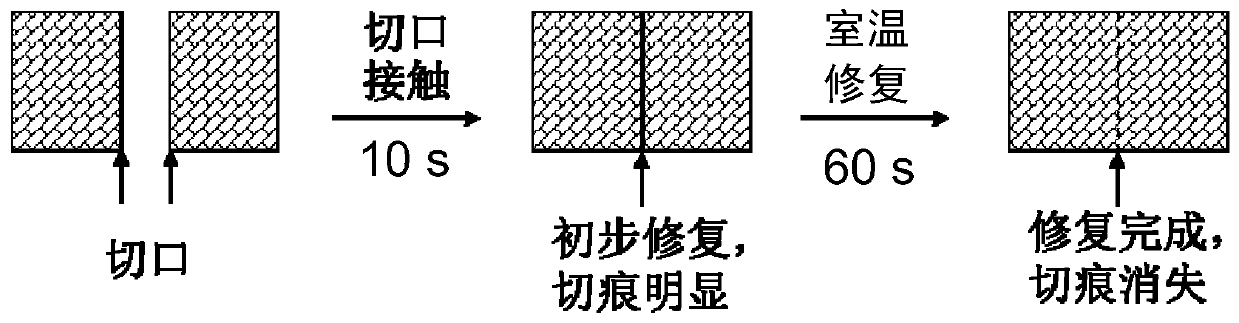

A self-healing material and self-healing technology, applied in the field of self-healing materials, can solve problems such as poor processability, difficulty in recycling and recycling, and ecological environment pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

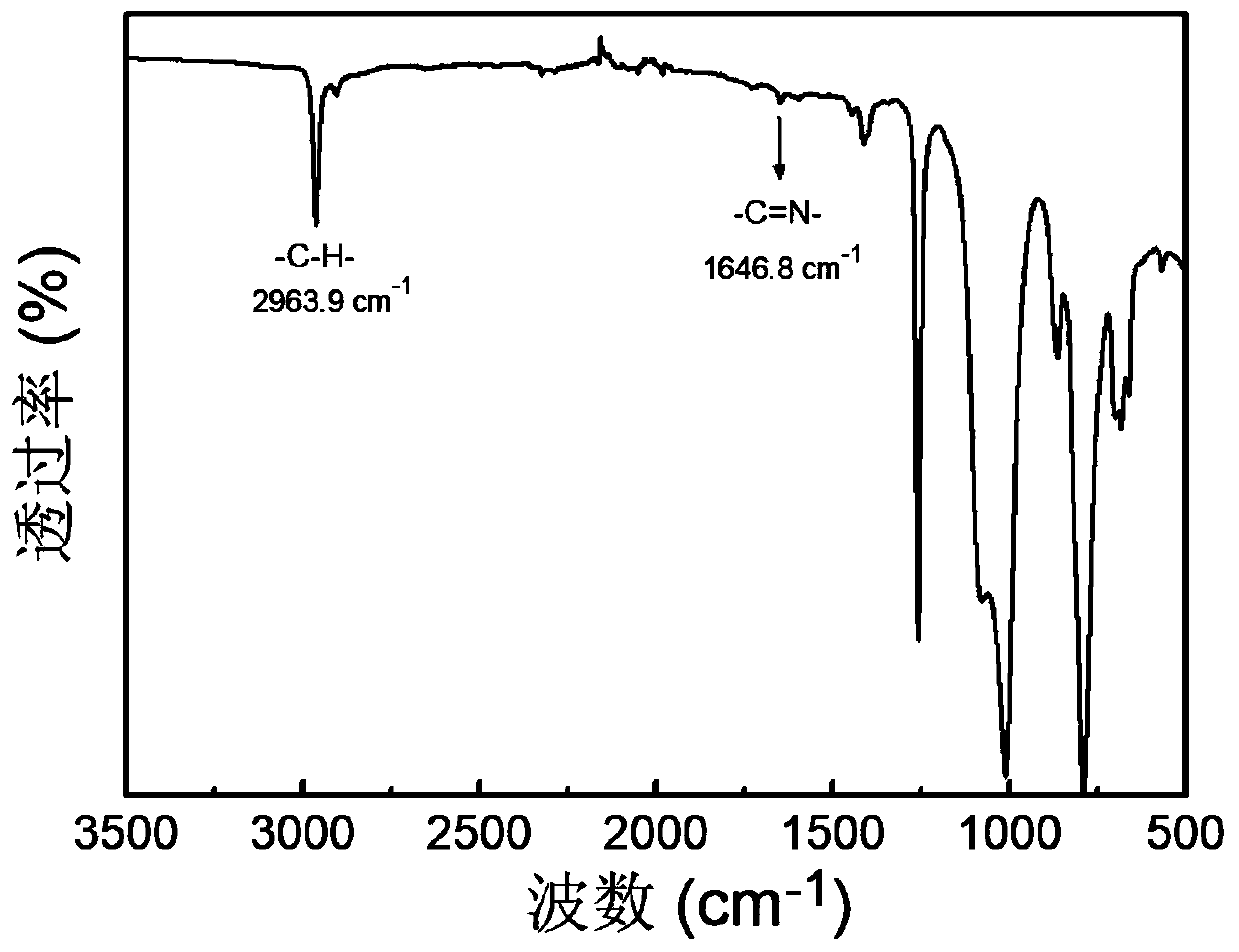

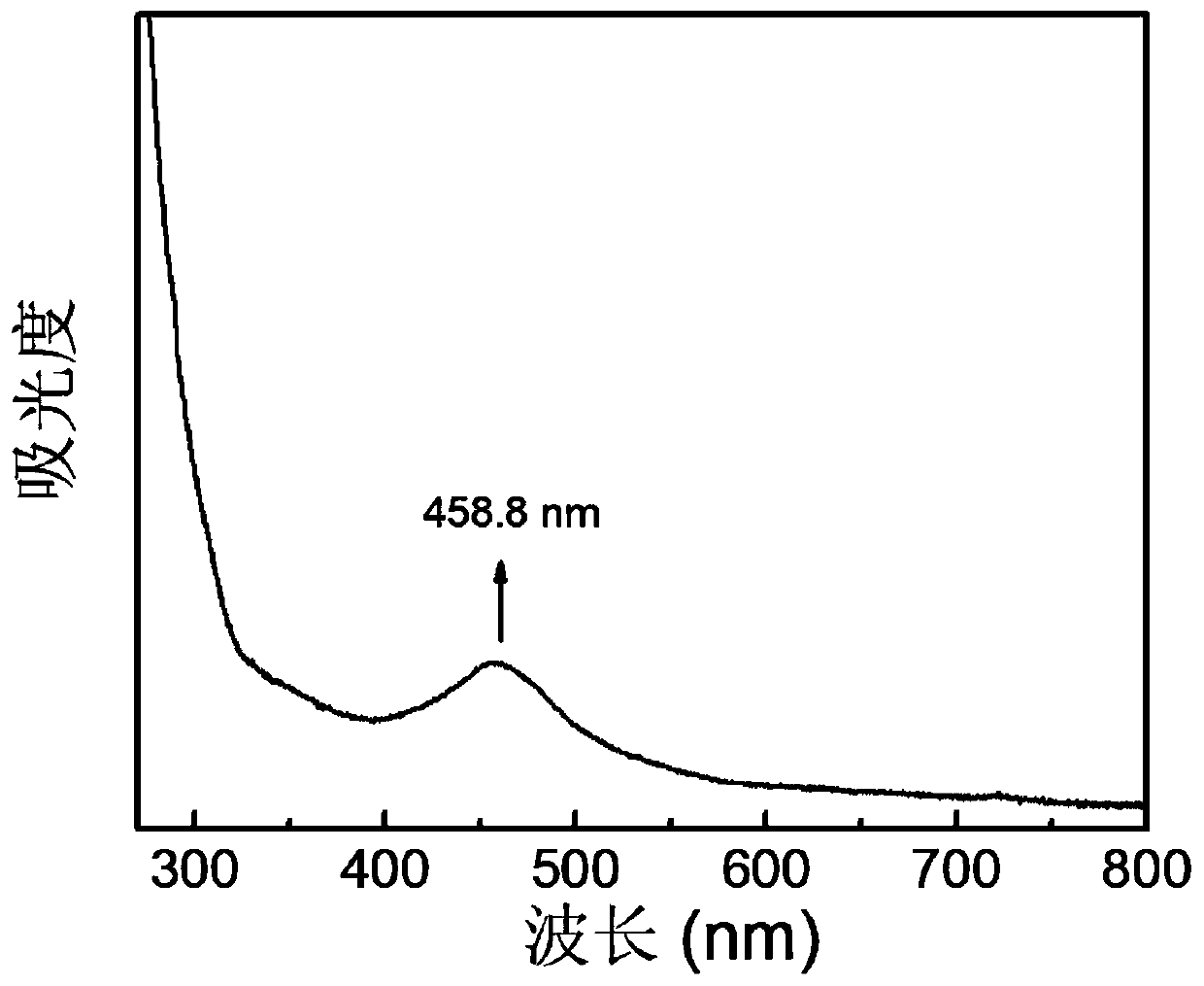

[0059] Synthesis of a novel fast self-healing material (1), the structure is as follows:

[0060]

[0061] Specific steps:

[0062] In a dry four-neck flask equipped with a thermometer, a condenser, a dropping funnel, and a nitrogen inlet, add 1000 g of anhydrous toluene, start stirring, and mix 3,3',5,5'-tetraaldehyde-4,4' -Dihydroxybiphenyl solid powder in batches (Z 1 = Z 4 =-OH,Z 2 = Z 3 = Z 5 = Z 6 =-H, 0.30g, 1.00mmol) was added in anhydrous toluene, and then slightly excess 50g of amodimethicone (p 1 =q 1 =3,G 1 =G 2 =G 3 =G 4 =G 5 =G 6 =-CH 3 ,n 1 =300-350, 2.25mmol) into the mixed reaction system. Then add 60g of 4A molecular sieve into the reaction solution to act as a water absorbing agent. Finally, 30 mg of p-toluenesulfonic acid monohydrate catalyst (10 g of toluene solution) was added dropwise into the reaction system. After the dropwise addition, the temperature was raised and controlled to 120° C., the condensed water was turned on, and the...

Embodiment 2

[0068] Synthesis of a novel fast self-healing material (2), the structure is as follows:

[0069]

[0070] Specific steps:

[0071] In a dry four-necked flask equipped with a thermometer, a condenser, a dropping funnel, and a nitrogen inlet, add 1000g of anhydrous toluene, start stirring, and mix 5-chloro-2-hydroxyisophthalaldehyde solid powder in batches (Y 1 =-OH,Y 2 =Y 3 =-H,Y 4 =-Cl, 1.84g, 10.00mmol) was added in anhydrous toluene, and then slightly excess 150g of amodimethicone (p 1 =q 1 =3,G 1 =G 2 =G 3 =G 4 =G 5 =G 6 =-CH 3 ,n 1 =200-220, 12.00mmol) into the mixed reaction system. Then add 60g of 4A molecular sieve into the reaction solution to act as a water absorbing agent. Finally, 30 mg of p-toluenesulfonic acid monohydrate catalyst (10 g of toluene solution) was added dropwise into the reaction system. After the dropwise addition, the temperature was raised and controlled at 120°C, the condensed water was turned on, and the reflux was continued f...

Embodiment 3

[0076] Synthesis of a novel fast self-healing material (3), the structure is as follows:

[0077]

[0078] Specific steps:

[0079] In a dry four-necked flask equipped with a thermometer, a condenser, a dropping funnel, and a nitrogen feed inlet, add 500g of anhydrous toluene, start stirring, and 5-chloro-2-hydroxy isophthalaldehyde solid powder in batches ((Y 1 =-OH,Y 2 =Y 3 =-H,Y 4 =-Cl, 1.84g, 10.00mmol) was added in anhydrous toluene, and then slightly excess 40g of amino-terminated polyethylene glycol (p 2 =q 2 =1,n 2 =100-120, 12.50mmol) into the mixed reaction system. Then add 20g of 4A molecular sieve into the reaction solution to act as a water absorbing agent. Finally, 10 mg of p-toluenesulfonic acid monohydrate catalyst (10 g of toluene solution) was added dropwise into the reaction system. After the dropwise addition, the temperature was raised and controlled to 120° C., the condensed water was turned on, and the reflux reaction was continued for 32 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com