A method for recovering low-molecular polymers in the production process of polyphenylene sulfide

A production process, polyphenylene sulfide technology, applied in the field of polymer engineering, can solve problems such as environmental pollution, increased difficulty and safety risks, and achieve the effect of no pollution to the environment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

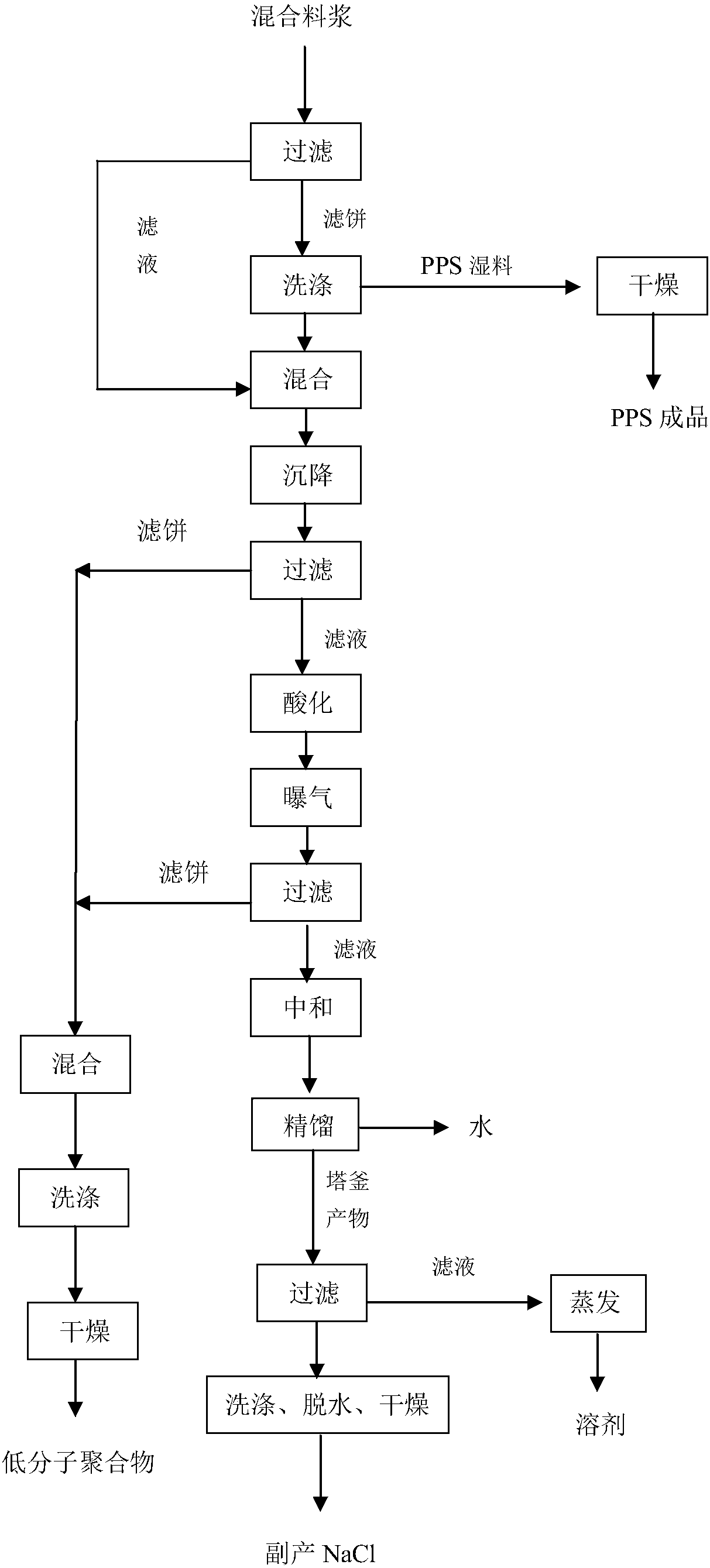

Method used

Image

Examples

Embodiment 1

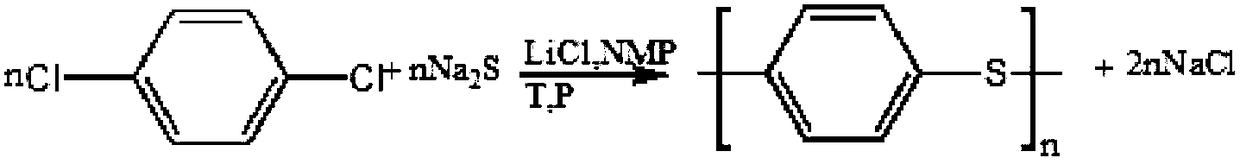

[0025] Weigh 1700Kg of crystalline sodium sulfide pentahydrate, 1430Kg of p-dichlorobenzene, 175Kg of catalyst, and 7000Kg of solvent (2000Kg is used for dissolving p-dichlorobenzene, and 5000Kg is used for dehydration), and polymerize in a reactor. During the polymerization reaction, the pre-polymerization temperature is 225±2°C for 45 minutes, and the polymerization temperature is 265±2°C for 150 minutes. After the polymerization reaction is completed, the temperature of the mixed slurry is cooled to 90° C., and filtered with a continuous centrifuge to obtain filter cake and by-product slurry. Wash the filter cake with 8000Kg deionized water to obtain PPS wet material and washing water, and dry the PPS wet material in a dryer to obtain the finished PPS product. The washing water is mixed with the above-mentioned by-product slurry, and then settled in the settling tank, and the settling time is 30 minutes. The supernatant in the settling tank is filtered with a plate and fra...

Embodiment 2

[0027] Weigh 1500Kg of crystalline sodium sulfide pentahydrate, 1250Kg of p-dichlorobenzene, 165Kg of catalyst, and 5700Kg of solvent (1200Kg is used for dissolving p-dichlorobenzene, and 4500Kg is used for dehydration), and polymerize in a reactor. During the polymerization reaction, the pre-polymerization temperature was 223±2°C for 60 minutes, and the polymerization temperature was 262±2°C for 180 minutes. After the polymerization reaction is completed, the temperature of the mixed slurry is cooled to 80° C., and filtered with a continuous centrifuge to obtain filter cake and by-product slurry. Wash the filter cake with 7500Kg deionized water to obtain PPS wet material and washing water, and dry the PPS wet material in a dryer to obtain the finished PPS product. The washing water is mixed with the above-mentioned by-product slurry, and then settled in the settling tank, and the settling time is 45 minutes. The supernatant in the settling tank is filtered with a plate-and-f...

Embodiment 3

[0029] Weigh 1350Kg of crystalline sodium sulfide pentahydrate, 1230Kg of p-dichlorobenzene, 140Kg of catalyst, and 5500Kg of solvent (1000Kg is used for dissolving p-dichlorobenzene, and 4500Kg is used for dehydration), and polymerize in a reactor. During the polymerization reaction, the pre-polymerization temperature is 225±2°C for 45 minutes, and the polymerization temperature is 265±2°C for 150 minutes. After the polymerization reaction, the temperature of the mixed slurry was cooled to 85° C., and filtered with a continuous centrifuge to obtain filter cake and by-product slurry. Wash the filter cake with 7500Kg deionized water to obtain PPS wet material and washing water, and dry the PPS wet material in a dryer to obtain the finished PPS product. The washing water is mixed with the above-mentioned by-product slurry, and then settled in the settling tank, and the settling time is 60 minutes. The supernatant in the settling tank is filtered with a plate-and-frame filter, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com