Method for extracting chromium from chromium-containing waste liquor

A technology of waste liquid and ferrochrome, which is applied in the field of comprehensive utilization of sewage resources, can solve the problems of high cost and low efficiency, and achieve the effects of convenient operation, cost reduction, and efficient separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

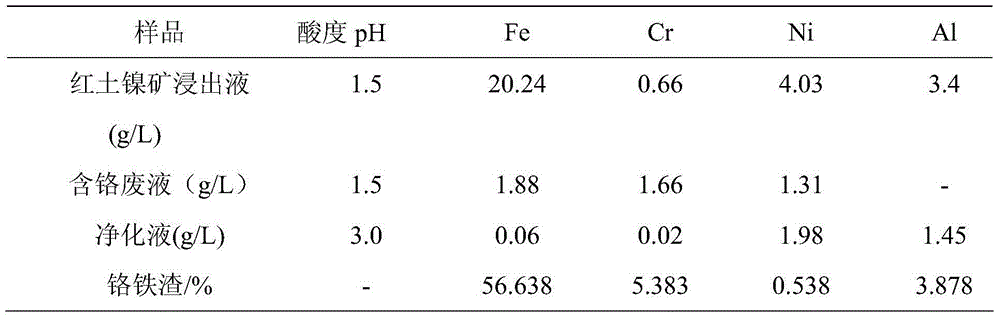

[0037] Using this process to process Cr 3+ The chromium-containing waste liquid with a mass concentration of 1.66g / L, the laterite nickel ore leachate used contains 20.24g / L of iron.

[0038] Preparation of magnetic fluid: crush the magnetite powder with a purity of more than 90% to less than 38 microns, and sieve it through a 400-mesh standard Taylor sieve. The ore (containing more than 55wt% iron) is mixed at a mass ratio of 5:1, and ground for 30 minutes in a ceramic ball mill, so that the hematite is coated on the surface of the magnetic crystal nucleus, and the magnetic material and water are mixed at a mass ratio of 1:2. Proportionally mixed to obtain the magnetic fluid.

[0039] Add 5g / L magnetic fluid into a reaction kettle containing 0.5L distilled water and stir, add an appropriate amount of dilute H 2 SO 4solution so that the pH of the solution is around 3. Mix the laterite nickel ore sulfuric acid leaching solution with the chromium-containing waste solution at...

Embodiment 2

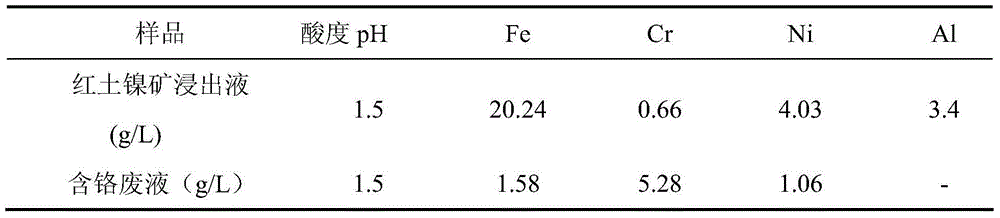

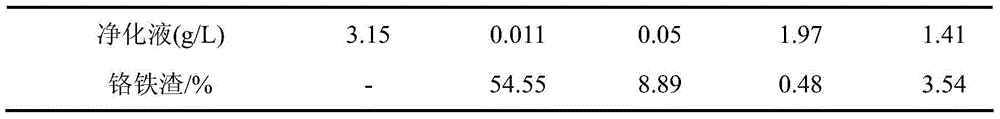

[0043] Using this process to process Cr 3+ Chromium-containing waste liquid with a mass concentration of 5.28g / L, laterite nickel ore leaching solution Fe 3+ The mass concentration is 20.24g / L.

[0044] Preparation of magnetic fluid: crush the magnetite powder with a purity of more than 90% to less than 38 microns, and sieve it through a 400-mesh standard Taylor sieve. The ore (containing more than 55wt% iron) is mixed at a mass ratio of 5:1, and ground for 35 minutes in a ceramic ball mill, so that the hematite is coated on the surface of the magnetic crystal nucleus, and the magnetic material and water are mixed at a mass ratio of 1:3. Proportionally mixed to obtain the magnetic fluid.

[0045] Add 8g / L magnetic fluid into the reaction kettle containing 0.5L distilled water and stir, add appropriate amount of dilute H 2 SO 4 solution so that the pH of the solution is around 3. Mix lateritic nickel ore leaching liquid with chromium-containing waste liquid in a ratio of 1...

Embodiment 3

[0050] Using this process to process Cr 3+ Chromium-containing waste liquid with a mass concentration of 10.64g / L, laterite nickel ore leaching solution Fe 3+ The mass concentration is 20.24g / L.

[0051] Preparation of magnetic fluid: crush the magnetite powder with a purity of more than 90% to less than 38 microns, and sieve it through a 400-mesh standard Taylor sieve. The ore (containing more than 55% iron) is mixed at a mass ratio of 4:1, and ground in a ceramic ball mill for 40 minutes, so that the hematite is coated on the surface of the magnetic crystal nucleus, and the magnetic material and water are mixed at a mass ratio of 1:2.5 Proportionally mixed to obtain the magnetic fluid.

[0052] Add 10g / L magnetic fluid into a reaction kettle containing 0.5L distilled water and stir, add an appropriate amount of dilute H 2 SO 4 solution so that the pH of the solution is around 2.7. Mix the laterite-nickel ore leaching solution with the chromium-containing waste solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com