Marble-imitated ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

A technology of imitating marble and composite materials, applied in the field of ABS composite materials with imitation marble effects and its preparation, can solve the problems of poor performance of ABS composite materials, achieve good environmental protection, good toughness, improve mechanical properties and impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

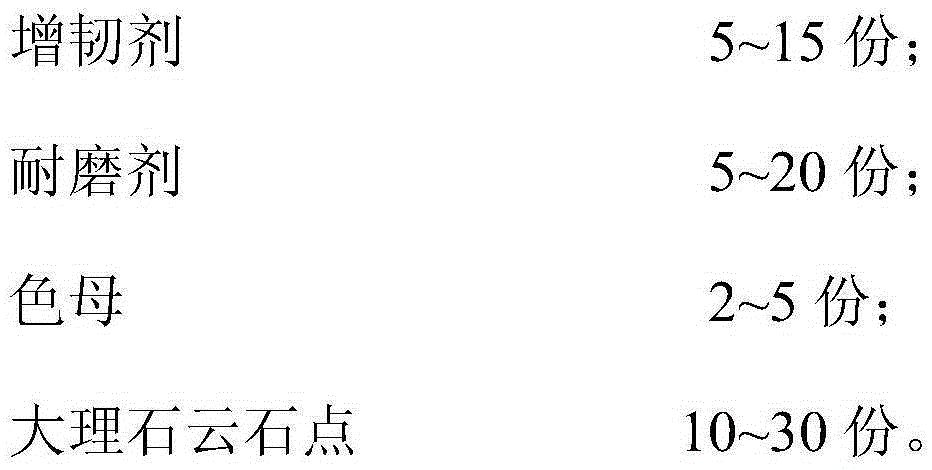

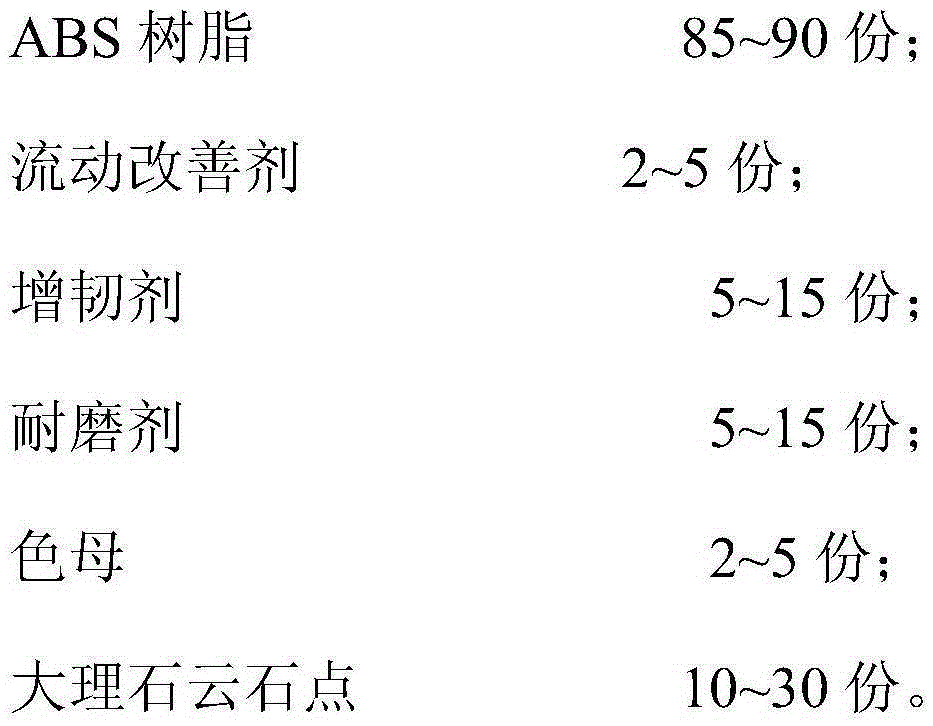

Method used

Image

Examples

Embodiment 1

[0031] According to the raw material composition of Example 1 in Table 1, various raw materials are weighed, including: ABS resin (under the condition of 200 ℃ / 5Kg, its melt index is at 8.5g / 10min, and its refractive index is 1.57), wear-resistant agent (a methyl acrylate-styrene acrylonitrile polymer, wherein the weight percent content of methyl methacrylate is 40%), toughening agent (methyl acrylate-butadiene-styrene terpolymer, wherein methyl acrylate The weight percentage content is 25%, the butadiene content is 15%, the styrene content is 50%), marble dot filler (including white, yellow, brick red, brown); before use, the ABS resin is heated at 80°C Drying at low speed for 4 hours; Add various raw materials (including auxiliary materials) into the high-speed mixer and mix at high speed for 2 minutes, and then discharge at low speed. The mixed material is melted and granulated to obtain an ABS composite material with a marble-like effect. The test data of the product prope...

Embodiment 2

[0033] Various raw materials are weighed according to the raw material composition of Example 2 in Table 1, including: ABS resin (under the condition of 200 ℃ / 5Kg, its melt index is at 8.5g / 10min, and the refractive index is 1.57), wear-resistant agent (formazy methyl acrylate-styrene acrylonitrile polymer, wherein the weight percent content of methyl methacrylate is 40%), toughening agent (methyl acrylate-butadiene-styrene terpolymer, wherein methyl acrylate The weight percentage content is 25%, the butadiene content is 15%, the styrene content is 50%), marble dot filler (including white, yellow, brick red, brown); before use, the ABS resin is heated at 80°C Drying at low speed for 4 hours; Add various raw materials (including auxiliary materials) into the high-speed mixer and mix at high speed for 2 minutes, and then discharge at low speed. The mixed material is melted and granulated to obtain an ABS composite material with a marble-like effect. The test data of the product ...

Embodiment 3

[0035] Various raw materials are weighed according to the raw material composition of Example 3 in Table 1, including: ABS resin (under the condition of 200 ℃ / 5Kg, its melt index is at 8.5g / 10min, and the refractive index is 1.57), wear-resistant agent (formazy methyl acrylate-styrene acrylonitrile polymer, wherein the weight percent content of methyl methacrylate is 40%), toughening agent (methyl acrylate-butadiene-styrene terpolymer, wherein methyl acrylate The weight percentage content is 25%, the butadiene content is 15%, the styrene content is 50%), marble dot filler (including white, yellow, brick red, brown); before use, the ABS resin is heated at 80°C Drying at low speed for 4 hours; Add various raw materials (including auxiliary materials) into the high-speed mixer and mix at high speed for 2 minutes, and then discharge at low speed. The mixed material is melted and granulated to obtain an ABS composite material with a marble-like effect. The test data of the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com