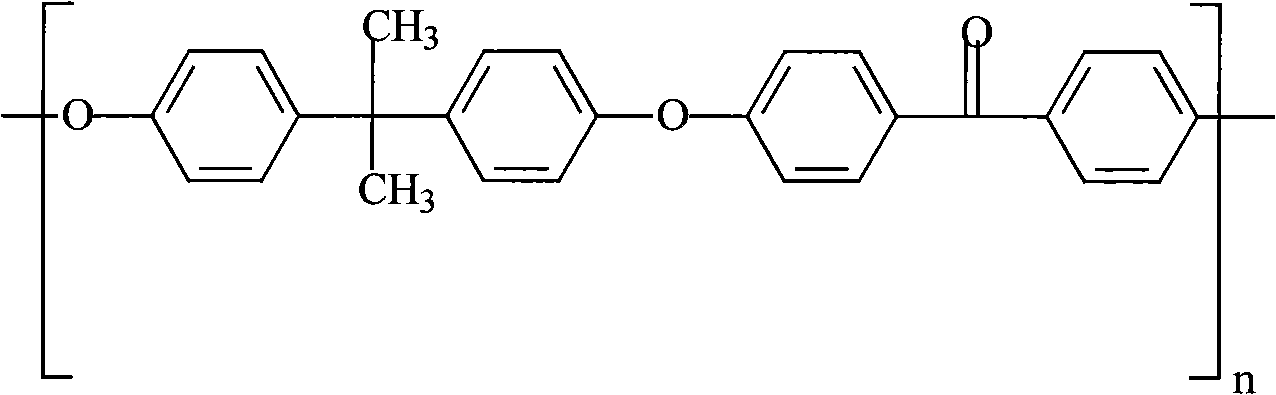

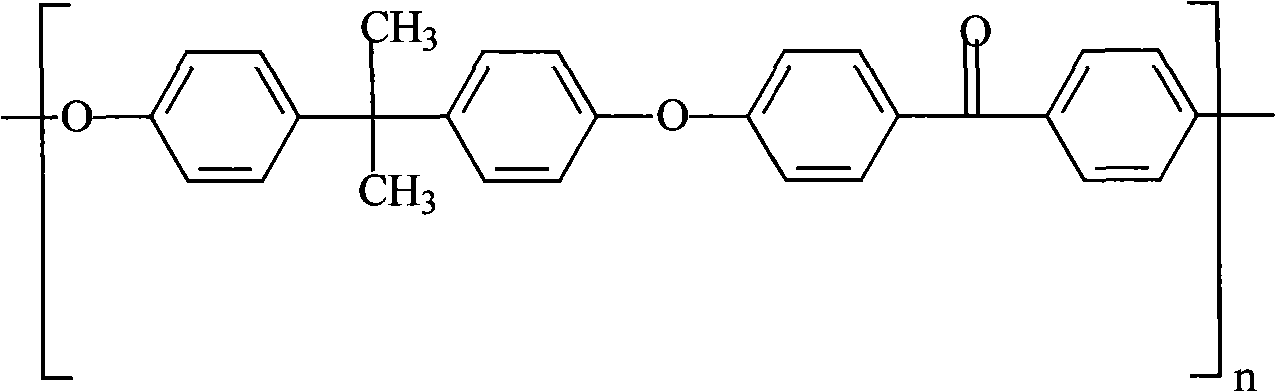

Bisphenol A type polyaromatic ether ketone water-based fluid dispersion and preparation thereof

A water-based dispersion, polyaryletherketone technology, applied in the direction of polyether coatings, coatings, etc., can solve the problems of no crosslinking reaction and high processing temperature, and achieve the effect of reducing costs and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 4 g of polyvinylpyrrolidone (PVP) was dissolved in 240 ml of chloroform, and then 72 g of bisphenol A type polyaryletherketone was dissolved in the above solution.

[0028] Dissolve 8g of sodium dodecylbenzenesulfonate in 280ml of deionized water; pour the aqueous solution of sodium dodecylbenzenesulfonate into the colloid mill, then slowly add the bisphenol A polyaryletherketone solution into the colloid mill , dispersed to prepare bisphenol A polyaryletherketone emulsion.

[0029] Pour the prepared bisphenol A polyaryletherketone emulsion containing an organic solvent into a 1000 ml three-necked flask equipped with a ventilation device, a stirring device, and a condensing device, and heat the three-necked flask in a water bath, and the temperature is controlled at 50 to 55 ℃ for 2-3 hours, then continue to heat up to 64-65°C until no organic solvent evaporates; then raise the temperature to 66-75°C, keep the temperature for 0.5-1 hour, stop heating, stir and discharge...

Embodiment 2

[0031] Dissolve 72g of bisphenol-A polyaryletherketone in 240ml of chloroform to prepare a bisphenol-A polyaryletherketone solution.

[0032] Dissolve 8 g of sodium dodecylbenzenesulfonate in 280 ml of deionized water. Pour the sodium dodecylbenzene sulfonate aqueous solution into the colloid mill, then slowly add the bisphenol A polyaryletherketone solution into the colloid mill, and disperse to prepare the bisphenol A polyaryletherketone emulsion.

[0033] Pour the prepared bisphenol A polyaryletherketone emulsion containing an organic solvent into a 1000 ml three-necked flask equipped with a ventilation device, a stirring device, and a condensing device, and heat the three-necked flask in a water bath, and the temperature is controlled at 50 to 55 ℃ for 2-3 hours, then continue to heat up to 64-65°C until no organic solvent evaporates; then raise the temperature to 66-75°C, keep the temperature for 0.5-1 hour, stop heating, stir and discharge to obtain bisphenol A polystyre...

Embodiment 3

[0035] 0.6 g of polyvinylpyrrolidone (PVP) was dissolved in 130 ml of chloroform, and then 11.4 g of bisphenol A type polyaryletherketone was dissolved in the above solution.

[0036] Dissolve 1.2g of sodium dodecylbenzenesulfonate in 100ml of deionized water; pour the aqueous solution of sodium dodecylbenzenesulfonate into the colloid mill, then slowly add the bisphenol A polyaryletherketone solution into the colloid mill In, dispersed, prepared bisphenol A type polyaryletherketone emulsion.

[0037] Pour the prepared bisphenol A polyaryletherketone emulsion containing an organic solvent into a 1000 ml three-necked flask equipped with a ventilation device, a stirring device, and a condensing device, and heat the three-necked flask in a water bath, and the temperature is controlled at 50 to 55 ℃ for 2-3 hours, then continue to heat up to 64-65°C until no organic solvent evaporates; then raise the temperature to 66-75°C, keep the temperature for 0.5-1 hour, stop heating, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com