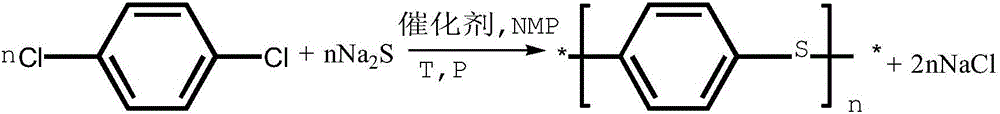

Method for preparing polyphenylene sulfide by using composite catalyst

A technology of composite catalyst and polyphenylene sulfide, which is applied in the field of polymer engineering, can solve problems affecting normal production, poor product quality, and poor catalytic effect, and achieve the effects of improving catalytic effect, reducing dosage, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take by weighing industrial grade pentahydrate crystalline sodium sulfide 1500Kg (according to the main content, this is the quantitative benchmark), take by weighing industrial grade p-dichlorobenzene, composite catalyst (lithium chloride The molar ratio to sodium acetate is 0.3:1), solvent N-methylpyrrolidone, caustic soda, and polymerize in a reactor. The evaporative dehydration temperature is 195°C, the first stage polymerization temperature is 225±2°C, the time is 45 minutes, the stirring speed is 25rpm, the second stage polymerization temperature is 262±2°C, the time is 150 minutes, the stirring speed is 40rpm. After the polymerization reaction, the reaction material was cooled to 165° C., separated, washed and dried to obtain 850 kg of polyphenylene sulfide product with a yield of 88.17%. After analysis, the melting point of the product is 280°C, the melt flow rate is 185g / min, and the ash content is 0.3%. The product can be used for spinning and injection moldin...

Embodiment 2

[0027] Take by weighing 3 water crystalline sodium sulfide 1350Kg (according to the main content, this is the quantitative benchmark), take by weighing industrial grade p-dichlorobenzene in molar ratio 1:0.995:0.42:6.0:0.025, composite catalyst (lithium chloride and acetic acid The molar ratio of sodium is 0.5:1), the solvent N-methylpyrrolidone and caustic soda are polymerized in the reactor. The evaporative dehydration temperature is 190°C, the first stage polymerization temperature is 224±2°C, the time is 60 minutes, the stirring speed is 20rpm, the second stage polymerization temperature is 265±2°C, the time is 120 minutes, the stirring speed is 35rpm. After the polymerization reaction, the reaction material was cooled to 170° C., separated, washed and dried to obtain 920 kg of polyphenylene sulfide product with a yield of 83.29%. After analysis, the melting point of the product is 280°C, the melt flow rate is 180g / min, and the ash content is 0.25%. The product can be used...

Embodiment 3

[0029] Take by weighing 800Kg of crystalline sodium sulfide pentahydrate, 700Kg of crystalline sodium sulfide trihydrate (according to the main content, this is the quantitative benchmark), take by weighing industrial grade p-dichlorobenzene with a molar ratio of 1:0.990:0.50:6.5:0.025, compound The catalyst (the molar ratio of lithium chloride to sodium acetate is 0.2:1), the solvent N-methylpyrrolidone and caustic soda are polymerized in a reactor. The evaporative dehydration temperature is 192°C, the first stage polymerization temperature is 224±2°C, the time is 50 minutes, the stirring speed is 35rpm, the second stage polymerization temperature is 265±2°C, the time is 130 minutes, the stirring speed is 55rpm. After the polymerization reaction, the reaction material was cooled to 170° C., separated, washed and dried to obtain 935 kg of polyphenylene sulfide product with a yield of 86.02%. After analysis, the melting point of the product is 282°C, the melt flow rate is 220g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com