Assembling type dried work condition operating cleaning operation room and wind process method thereof

A dry working condition, operating room technology, applied in the field of air purification, can solve the problems of unfavorable assembly and use, complex structure, relatively fixed, etc., and achieve the effect of facilitating rapid assembly and use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

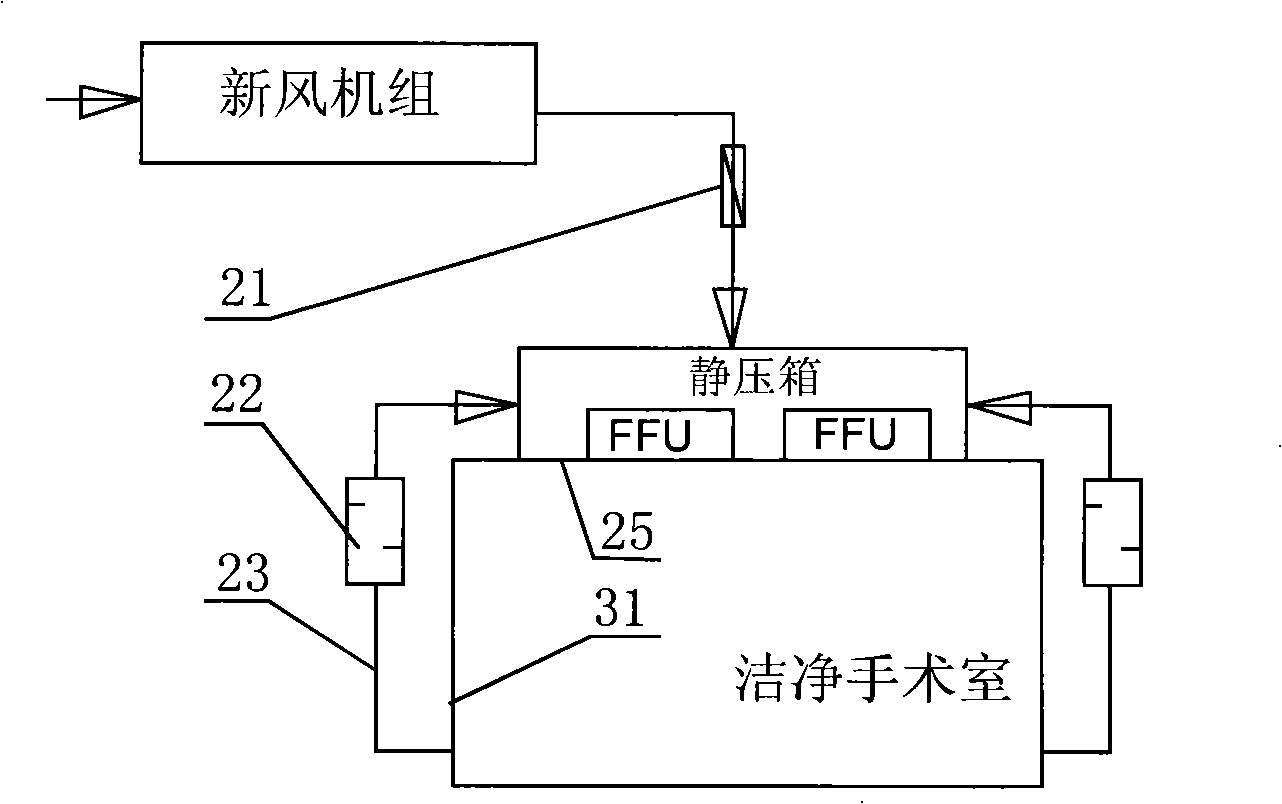

[0020] Specific embodiment one, such as figure 2 Shown:

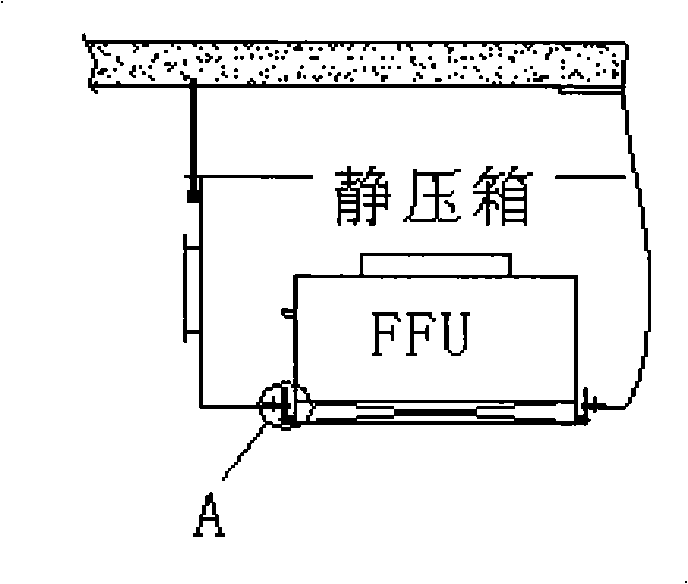

[0021] Including the side wall 31, the top plate 25, and the fresh air unit, a static pressure box is installed above the top plate 25, and an FFU (fan filter unit) is installed in the static pressure box. , 2 or more FFUs.

[0022] The air supply pipeline of the fresh air unit is connected to the static pressure box of the clean operating room, and a return air pipeline 23 may be connected between the side wall 31 of the clean operating room and the static pressure box, and a double-layer air return pipeline may be arranged on the return air pipeline 23 The coarse-effect filter 22 connected in series is used to filter the return air. The fresh air processed by the fresh air unit enters the plenum and mixes with the return air from the return air pipeline 23, and then enters the clean operating room through the FFU.

[0023] The side wall 31, the top plate 25, the static pressure box, the FFU, the return air pipelin...

specific Embodiment 2

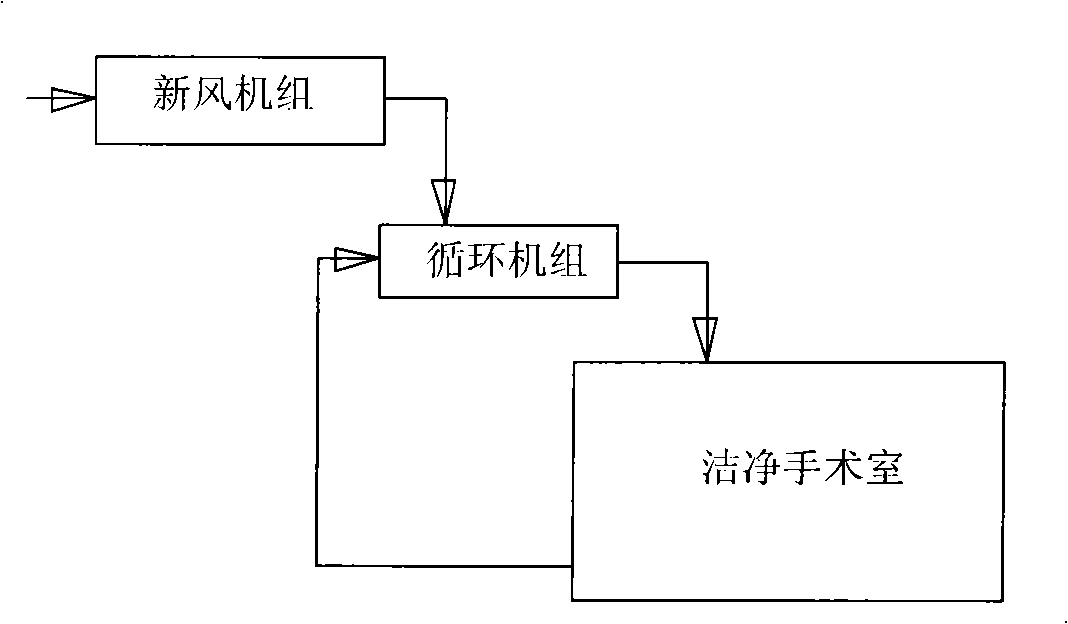

[0028] Specific embodiment two, such as Figure 5 Shown:

[0029] The circulation unit (circulation fan) operating in dry working condition is installed on the return air pipeline, and the connection between the circulation unit and the return air pipeline is detachable. Dry working condition operation means that the circulation unit does not perform humid heat treatment on the circulating air. The technical parameters of the air used in the clean operating room are all processed by the fresh air unit, and the circulating air in the return air line is a dry working condition circulation. In this way, the bulky circulating unit in the prior art can be replaced by a small circulating fan, without having to set up a functional section for humid heat treatment, so that the structure is simple, and the functional section is simplified to only set a coarse and medium-efficiency filter section, a fan section, and a flow equalization section. Section, to ensure the air volume require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com