Polypropylene material with high gloss and low linear expansion coefficient and preparation method thereof

A low linear expansion, polypropylene material technology, applied in the field of polypropylene materials and their preparation, can solve the problems of poor mechanical properties, expensive raw materials, affecting the color of products, etc., to achieve excellent performance, improve processing and molding properties and mechanical properties. Performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

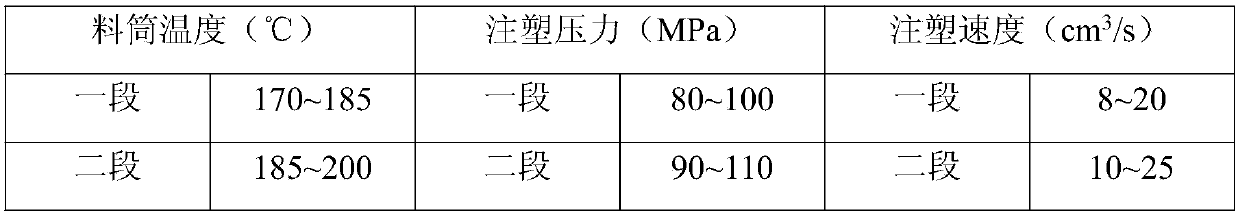

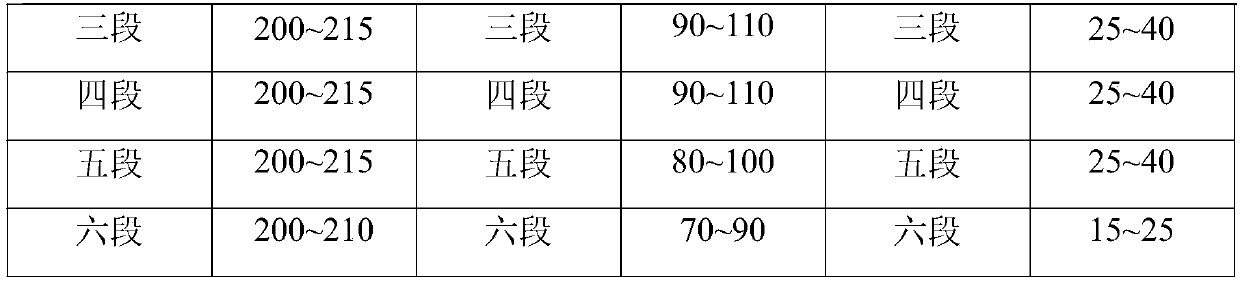

[0046] The present invention also provides the preparation method of the polypropylene material with high gloss and low linear expansion coefficient described in the appeal, the method comprises the following steps:

[0047] A. Take each material according to the ratio, mix polypropylene resin, polyethylene and color masterbatch, and stir and mix at a speed of 3000-5000r / min for 1-3 minutes;

[0048] B. Then add aluminum powder, pearl powder, nucleating agent, lubricant, antioxidant and light stabilizer, first stir at a speed of 500-2000r / min for 3-5min, and then proceed at a speed of 3000-5000r / min Stir for 5-10 minutes, mix well and then discharge at a speed of 500-2000r / min to obtain a premix;

[0049] C. Add the premixed material into the twin-screw extruder, melt extrude, granulate, and cool to obtain a polypropylene material with high gloss and low linear expansion coefficient.

[0050] In the above method, stirring can generally be carried out in a high-speed mixer, wh...

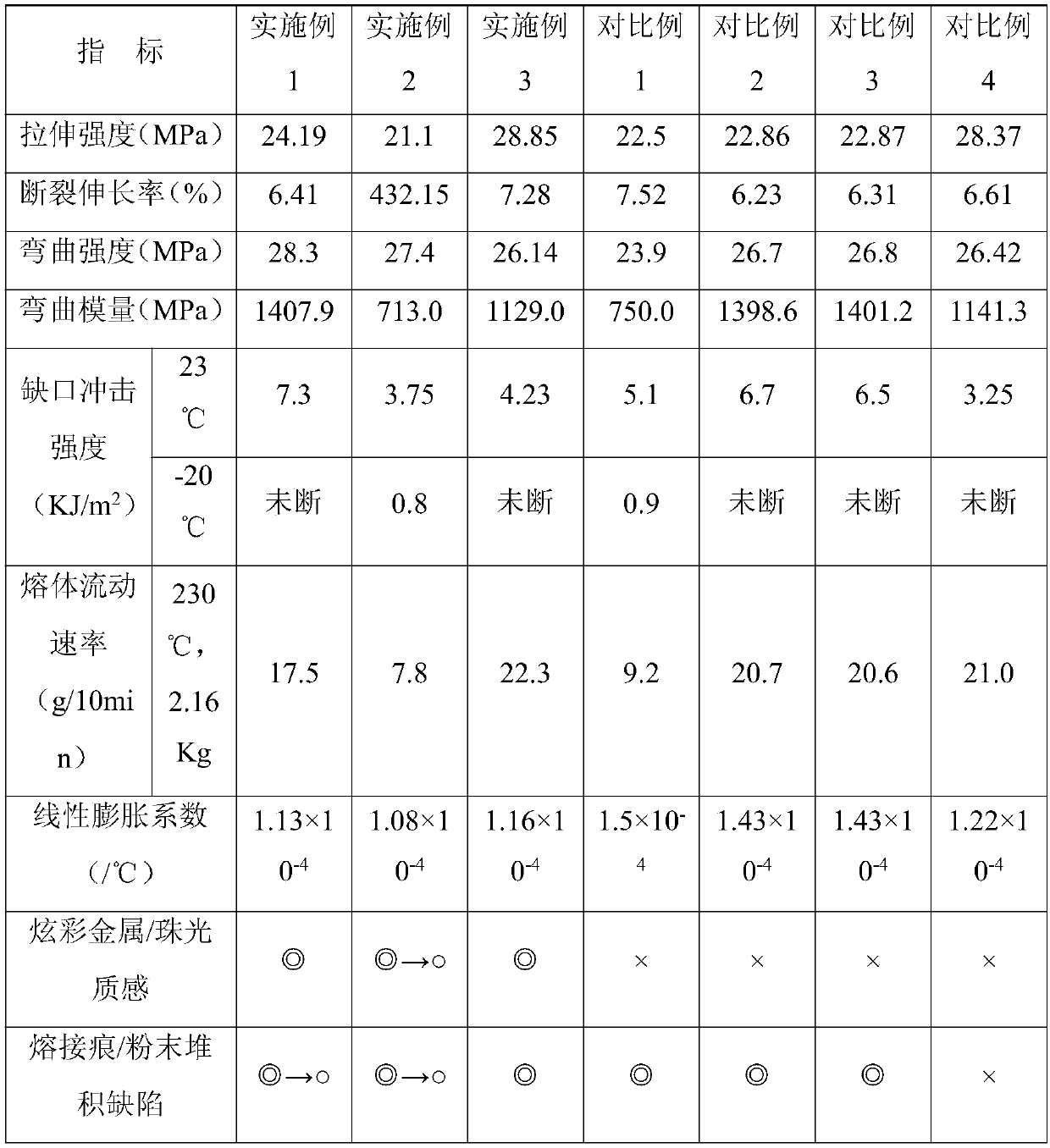

Embodiment 1

[0058] The polypropylene material with high gloss and low linear expansion coefficient in this embodiment contains the following components by mass:

[0059] Polypropylene resin: 83.3 parts, its melt index is 21g / 10min under the conditions of 230°C and 2.16kg load;

[0060] Polyethylene: 10 parts, with a density of 0.94 and a melt index of 25g / 10min at 230°C and a load of 2.16kg;

[0061] Aluminum powder: 1 part, with a flake structure, a particle size of 6um, and the surface is coated with PE wax;

[0062] Pearl powder: 1 part, which is irregular 3D silver-coated glass powder with a particle size of 15um;

[0063] Nucleating agent: 0.2 parts, sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate;

[0064] Light stabilizer: 0.2 parts, UV-770, molecular formula is C 28 h 50 N 2 o 4 ;

[0065] Lubricant: 0.1 parts, white oil;

[0066] Antioxidant: 0.2 parts, the compound of 1010 and 168, the weight ratio is 1010:168=1.5:1;

[0067] Color masterbatch: 4 parts, blue...

Embodiment 2

[0074] The polypropylene material with high gloss and low linear expansion coefficient in this embodiment contains the following components by mass:

[0075] Polypropylene resin: 77.3 parts, its melt index is 9g / 10min under the condition of 230℃ and 2.16kg load;

[0076] Polyethylene: 16 parts, with a density of 0.93 and a melt index of 5.3g / 10min at 230°C and a load of 2.16kg;

[0077] Aluminum powder: 1.4 parts, which has a flake structure with a particle size of 18 μm, and the surface is coated with PE wax;

[0078] Pearl powder: 0.6 parts, which is irregular 3D shape silver-coated glass powder, and its particle size is 30um

[0079] Nucleating agent: 0.2 parts, sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate;

[0080] Light stabilizer: 0.2 parts, UV-770, molecular formula is C 28 h 50 N 2 o 4 ;

[0081] Lubricant: 0.1 parts, white oil;

[0082] Antioxidant: 0.2 parts, the compound of 1010 and 168, the weight ratio is 1010:168=1:1;

[0083] Color master...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com