Sectional-type secondary mirror high-stability support structure

A technology with high stability and support structure, which is applied in the field of aerospace optical remote sensors, can solve the problems of heavy weight and large gravity deformation of the three-bar support technology, and achieve the effects of improving thermal environment adaptability, reducing weight, and ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

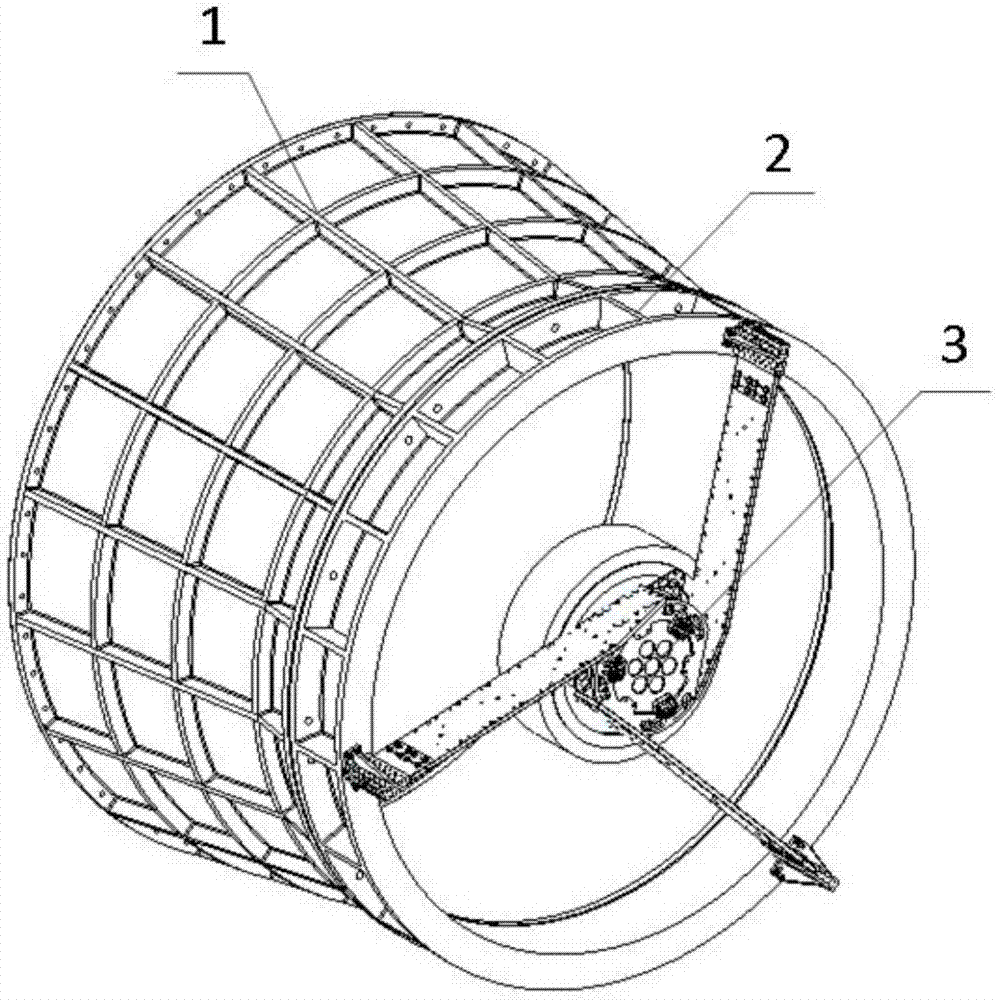

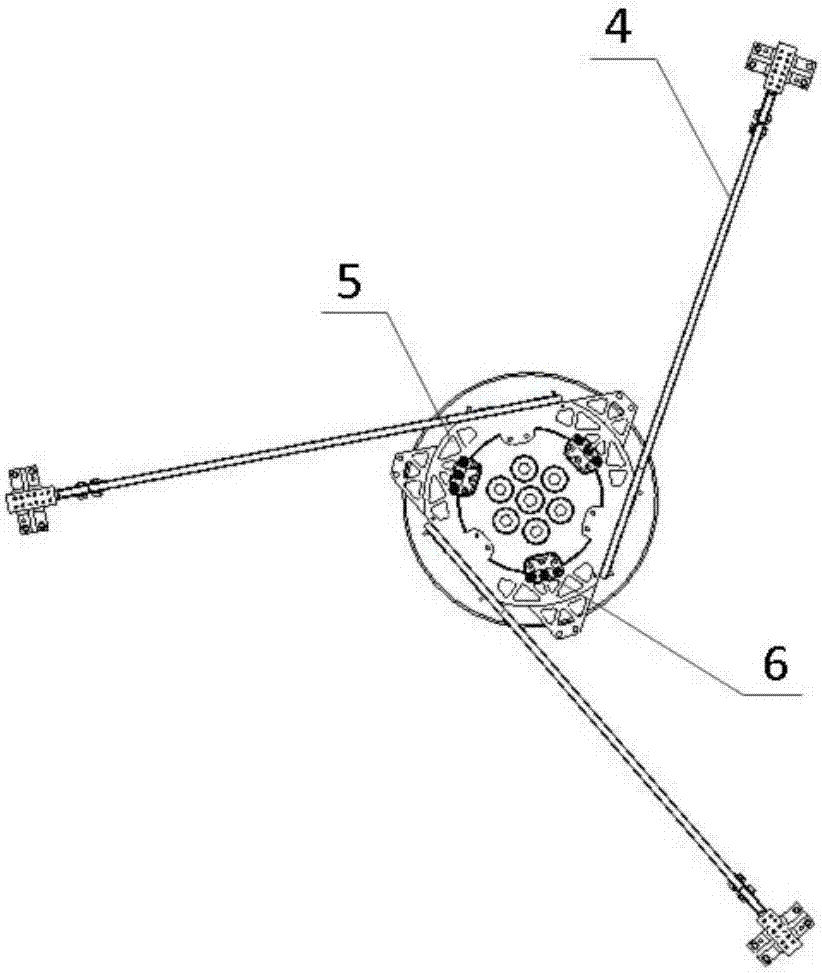

[0023] Such as figure 1 As shown, a segmented secondary mirror high-stability support structure includes a first front lens barrel 1 , a second front lens barrel 2 and a secondary mirror support assembly 3 .

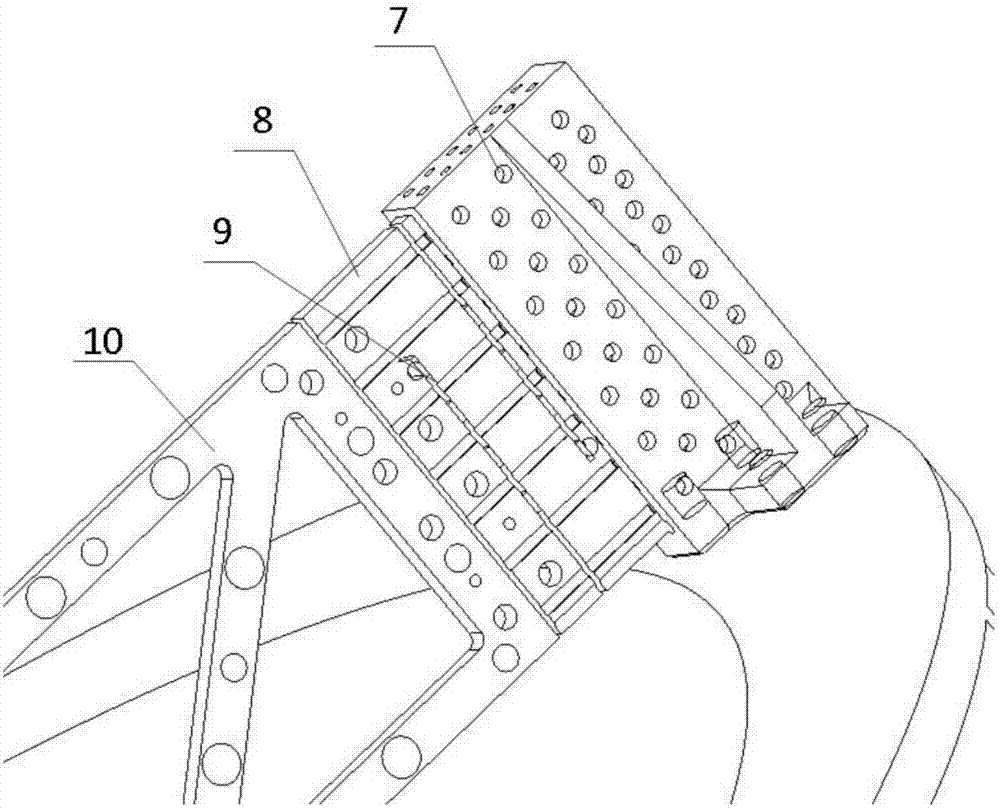

[0024] The first front lens barrel 1 and the second front lens barrel 2 are load-bearing lens barrels installed between the primary and secondary mirrors for supporting the secondary mirror assembly. The first front lens barrel 1 is a truncated cone, and the second front lens barrel 2 is cylindrical; the end flange of the large end of the first front lens barrel 1 is installed on the front load-bearing frame by screws, and the small end is connected to the second front lens One end of the barrel 2 is connected; the flange at the other end of the second front lens barrel 2 is connected to three sets of flexible webs 10 in the secondary mirror support assembly 3 for supporting the secondary mirror assembly. Due to the high specific stiffness of the C / SiC composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com