A method for rapidly decomposing sedimentary rare earth ore

A rare earth ore, sedimentary technology, applied in the analysis of materials, thermal excitation analysis, material excitation analysis, etc., can solve the problem of no better decomposition method of sedimentary rare earth ore, poor air tightness of the sample solution tank, no better, etc. problem, to achieve the effect of good sealing, strong solvent resistance and short use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Weigh 0.050g (accurate to 0.001g) of CJX1# sample into the polyphenylene inner tank of the closed sample dissolver, add 1mL HNO 3 , 3 g NH 4 HF 2 Solid, cover the polyphenylene inner tank lid, put it into the steel sleeve, and tighten the steel sleeve cover.

[0041] 2. Place the sample dissolving device in an oven at 160°C for 1 hour, then rise to 250°C for 9 hours.

[0042] 3. Take it out, open the lid after cooling, take out the inner tank, add 0.25mL H 2 SO 4 , steamed on a hot plate at 220°C to H 2 SO 4 Smoke dry.

[0043] 4. Add 3mL distilled water, 1.25g solid tartaric acid, 2mL (1+1) HCl in sequence, and heat on a hot plate for 15 minutes until the solution is clear.

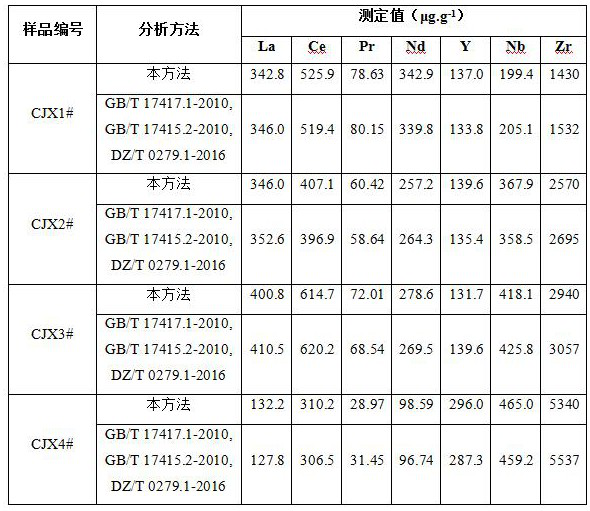

[0044] 5. Take off the cooling tube and adjust the volume to 25mL. At the same time as a blank test. According to the actual content, dilute different times to determine by ICP-OES / ICP-MS. The measurement results are shown in Table 1.

Embodiment 2

[0046] The operation mode of this embodiment is the same as that of embodiment 1, the difference is that the sample CJX1# is changed to the sample CJX2#. The measurement results are shown in Table 1.

Embodiment 3

[0048] 1. Weigh 1.000g (accurate to 0.001g) of CJX2# sample into the polyphenylene inner tank of the closed sample dissolver, add 2mL HNO 3 , 1 g NH 4 HF 2 Solid, cover the polyphenylene inner tank lid, put it into the steel sleeve, and tighten the steel sleeve cover.

[0049] 2. Place the sample dissolving device in an oven at 150°C for 2 hours, then raise it to 240°C for 11 hours.

[0050] 3. Take it out, open the lid after cooling, take out the inner tank, add 0.5mL H 2 SO 4 , steamed on a hot plate at 200°C to H 2 SO 4 Smoke dry.

[0051] 4. Add 2mL of distilled water, 1.75g of solid tartaric acid, and 3mL of (1+1) HCl in sequence, and heat on a hot plate for 10 minutes until the solution is clear.

[0052] 5. Take off the cooling tube and adjust the volume to 25mL. At the same time as a blank test. According to the actual content, dilute different times to determine by ICP-OES / ICP-MS. The measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com