Polybutylene terephthalate/glass fiber composite and preparation method thereof

A polybutylene terephthalate and glass fiber technology is applied in the field of polybutylene terephthalate/glass fiber composite materials and their preparation, and can solve the toughness of polybutylene terephthalate. , processing performance and poor appearance quality and other problems, to achieve good processing performance, solve the effect of color, notched impact strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

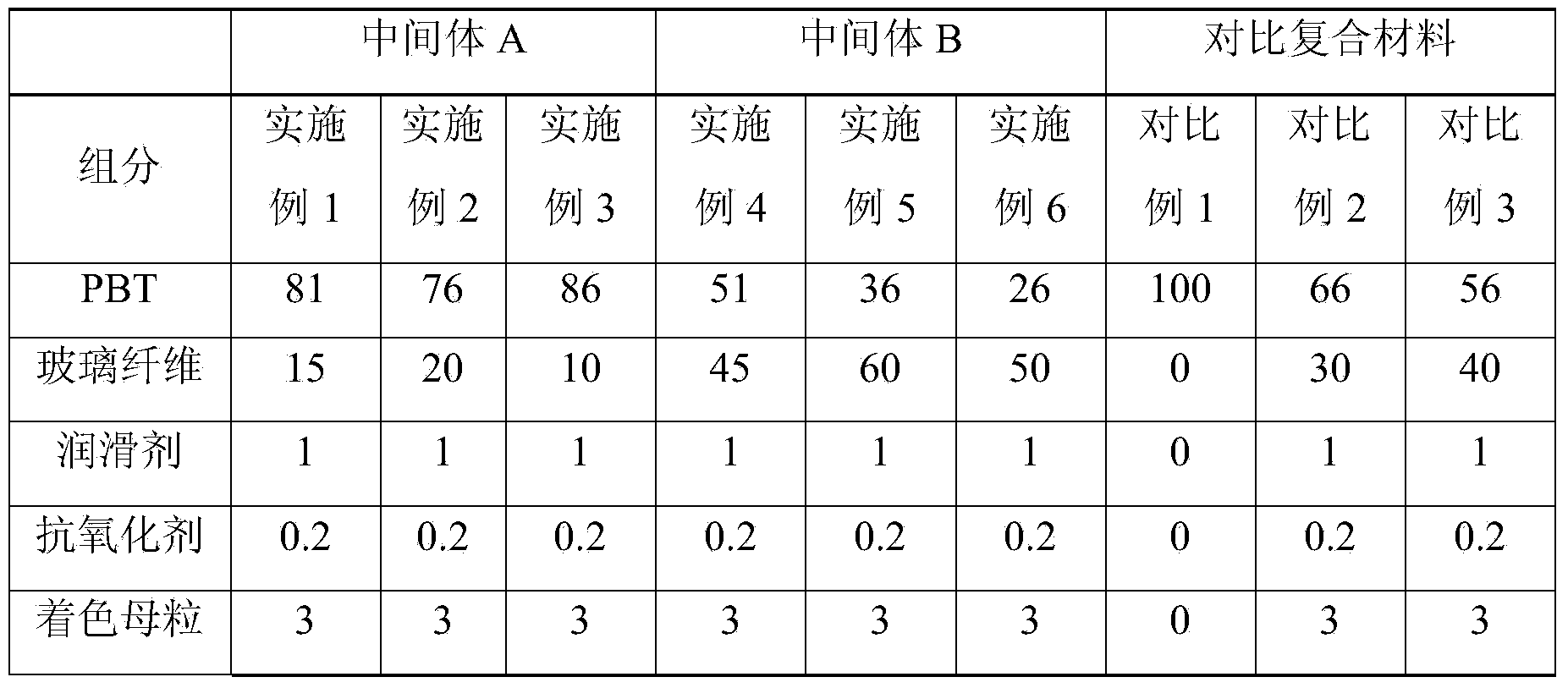

[0033] The preparation of embodiment 1~6 intermediate A and intermediate B

[0034] Intermediate A weighs various raw materials according to the raw material ratio in Table 1, and intermediate B weighs various raw materials according to the raw material ratio in Table 1.

[0035] Among them, PBT resin (molecular weight: 25000) was dried at 120°C for 5 hours before use, and various raw materials were added to a high-speed mixer and mixed at high speed for 3 minutes, and then discharged at a low speed. The mixed material is extruded and granulated to obtain intermediate A and intermediate B. Extrusion granulation conditions are: host screw speed 350r / min, feeding speed 30r / min, heating temperature range: 1 stage / 220°C, 2 stages / 230°C, 3 stages / 240°C, 4 stages / 250°C, 5 stages / 260°C, 6 stages / 250°C, 7 stages / 240°C, 8 stages / 230°C, 9 stages / 230°C, head temperature: 240°C.

Embodiment 7~9

[0040] The preparation of embodiment 7~9 polybutylene terephthalate / glass fiber composite material

[0041] The compositions of Examples 7-9 are shown in Table 2. Intermediate A and Intermediate B were uniformly mixed at a weight percentage of 1:1 to obtain a polybutylene terephthalate / glass fiber composite material.

[0042] Table 2 Composition and preparation of polybutylene terephthalate / glass fiber composites

[0043] product

Embodiment 10

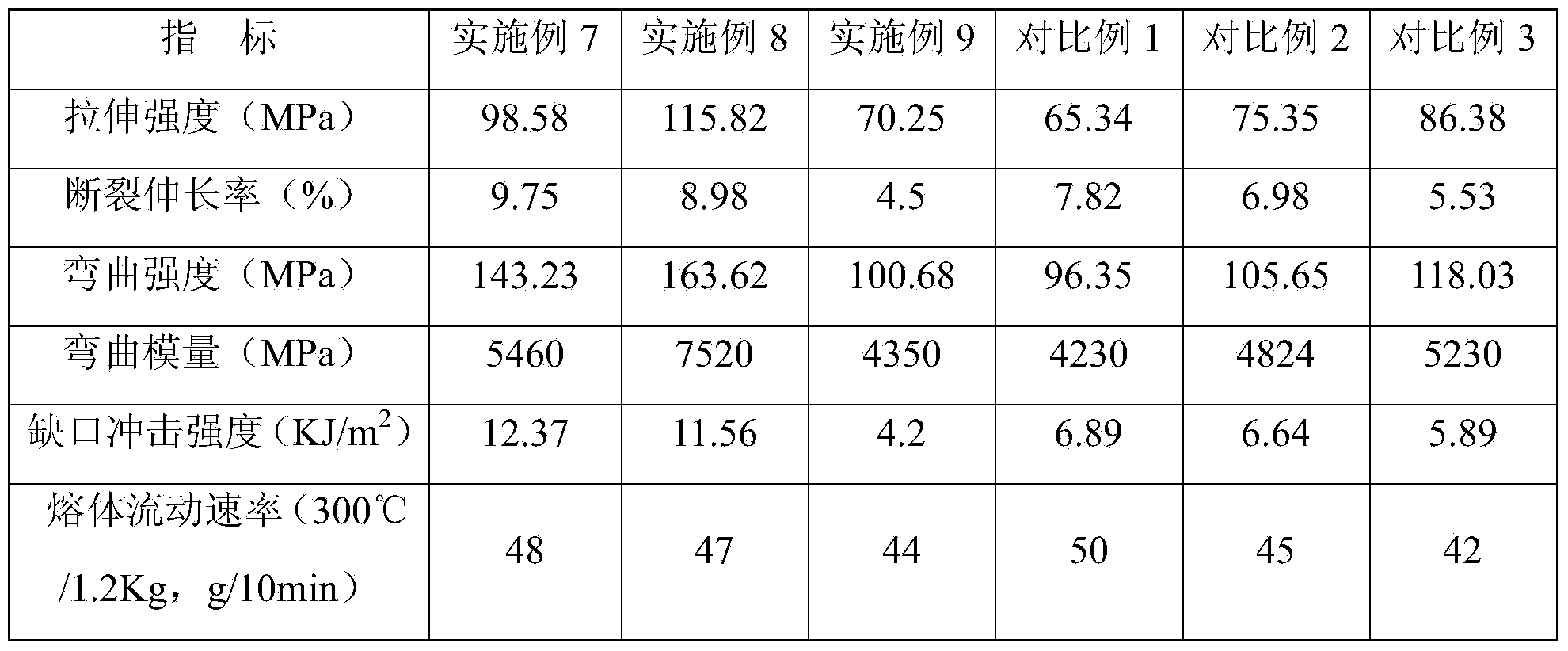

[0044] Embodiment 10 performance comparison

[0045] The tensile strength and elongation at break of the products obtained in Comparative Examples 1 to 3 and the products obtained in Examples 7 to 9 were tested according to the national standard GB / T1040.2-2006; the flexural strength and flexural modulus were tested according to the national standard GB / T9341- Tested in 2000; Izod notched impact strength was tested in accordance with national standard GB / T1843-2008; melt flow rate was tested in accordance with national standard GB / T3682-2000. The performance comparison data of the products are shown in Table 3.

[0046] Table 3 Properties of polybutylene terephthalate / glass fiber composites

[0047]

[0048] As can be seen from table 1 and table 2, the product of embodiment 7 is identical with the glass fiber content of comparative example 2, and the product of embodiment 8 is identical with the glass fiber content of comparative example 3, as can be seen from table 3, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com