Anti-skid cement mortar and preparation method thereof

A technology of cement mortar and cement, which is applied in the field of cement mortar, can solve the problems of poor friction performance, high energy consumption, and long construction period, and achieve the effects of excellent performance, reducing road surface water, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of antiskid cement mortar and preparation method thereof,

[0052] Its components include: high molecular polymer, cement, water, engineering fine sand;

[0053] Its weight percent of each component is:

[0054] High molecular polymer 10%;

[0055] Cement 20%;

[0056] water 40%;

[0057] Engineering fine sand 30%;

[0058] The sum of the percentages of the above components is 100%;

[0059] The above water is clean natural water;

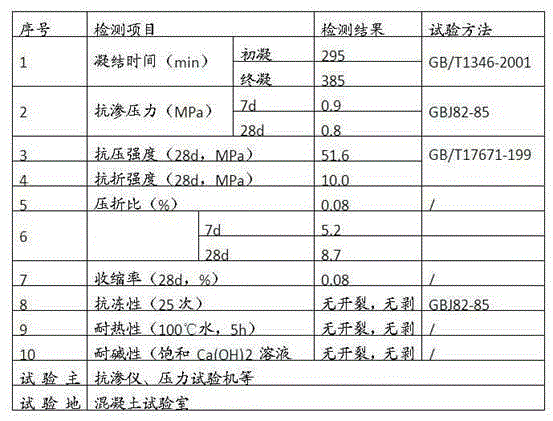

[0060] The above-mentioned cement is not less than 42.5R cement, which is composed of clinker mineral components, magnesium oxide, sulfur trioxide, free calcium oxide, alkali, etc.; the setting time of cement is ≥1 hour for initial setting and ≤10 hours for final setting ; Dry shrinkage rate of cement ≤ 0.10%; Abrasion resistance of cement is 3.60 kg / ㎡;

[0061] The above engineering fine sand is 20-40 mesh;

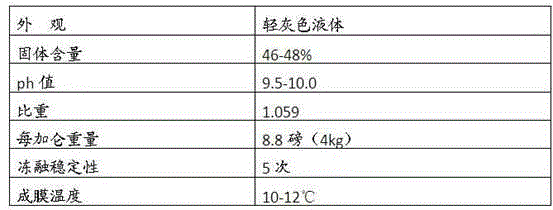

[0062] The above-mentioned high molecular polymer is prepared from high molecular polymer monomer, initiator, emulsifi...

Embodiment 2

[0073] A kind of antiskid cement mortar and preparation method thereof,

[0074] Its components include: high molecular polymer, cement, water, engineering fine sand;

[0075] Its weight percent of each component is:

[0076] High molecular polymer 20%;

[0077] Cement 10%;

[0078] water 30%;

[0079] Engineering fine sand 40%;

[0080] The sum of the percentages of the above components is 100%;

[0081] The above water is clean natural water;

[0082] The above-mentioned cement is not less than 42.5R cement, which is composed of clinker mineral components, magnesium oxide, sulfur trioxide, free calcium oxide, alkali, etc.; the setting time of cement is ≥1 hour for initial setting and ≤10 hours for final setting ; Dry shrinkage rate of cement ≤ 0.10%; Abrasion resistance of cement is 3.60 kg / m2;

[0083] The above-mentioned engineering fine sand is 40-90 mesh;

[0084] The above-mentioned high molecular polymer is prepared from high molecular polymer monomer, initiato...

PUM

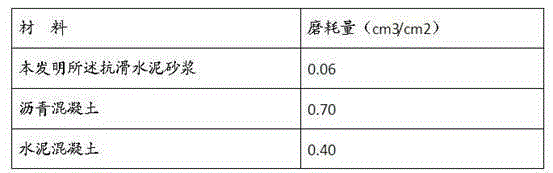

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com