Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Nickel hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

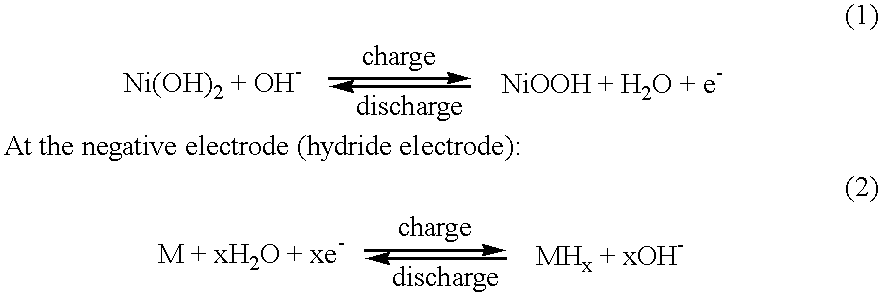

Nickel hydride describes both inorganic compounds of the formula NiHₓ as well as a variety of coordination complexes.

Method to make nickel positive electrodes and batteries using same

InactiveUS20010012586A1Large capacityImprove high temperature performanceElectrode manufacturing processesAlkaline accumulator electrodesAlkaline earth metalConductive polymer

This invention discloses a method to make a positive electrode and the nickel hydride battery using same. The positive electrode at least comprises a nickel hydroxide plus 1-15 wt. % of fine additive powders selected from the group consisting of Co / CoO, Ni, Cu, Zn, ZnO, C, Mg, Al, Mn, silver oxide, hydride, conductive polymer, and combinations thereof. Said positive electrode further comprises one, two or more additives, 0.01-10 wt. %, selected from the group of MgCl2, CaCl2, SrCl2, SrF2, BaCl2, BaF2, MgF2, and other fluorides / chlorides of alkali metals, alkaline earth metals, Al, Y, Sn, Sb, Ag, transition metals, rare earth metals, and composite metal oxide / halide to improve the performance of said positive electrode at high temperature.

Owner:HONG KUOCHIH +1

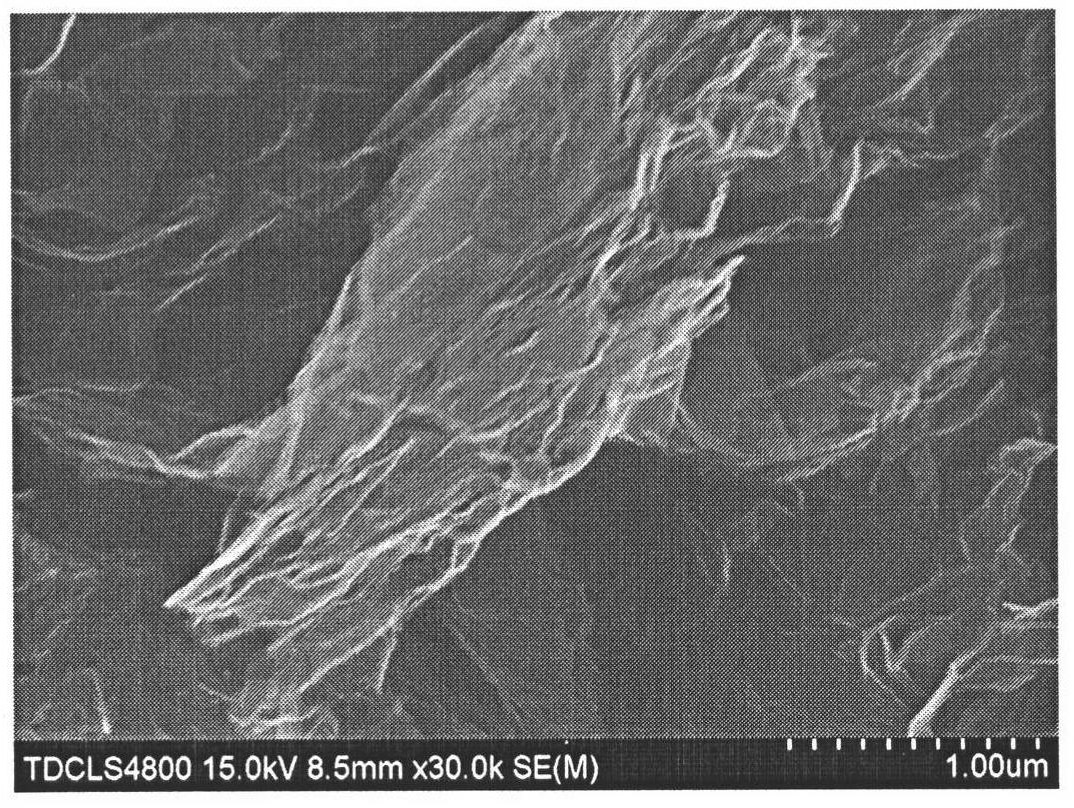

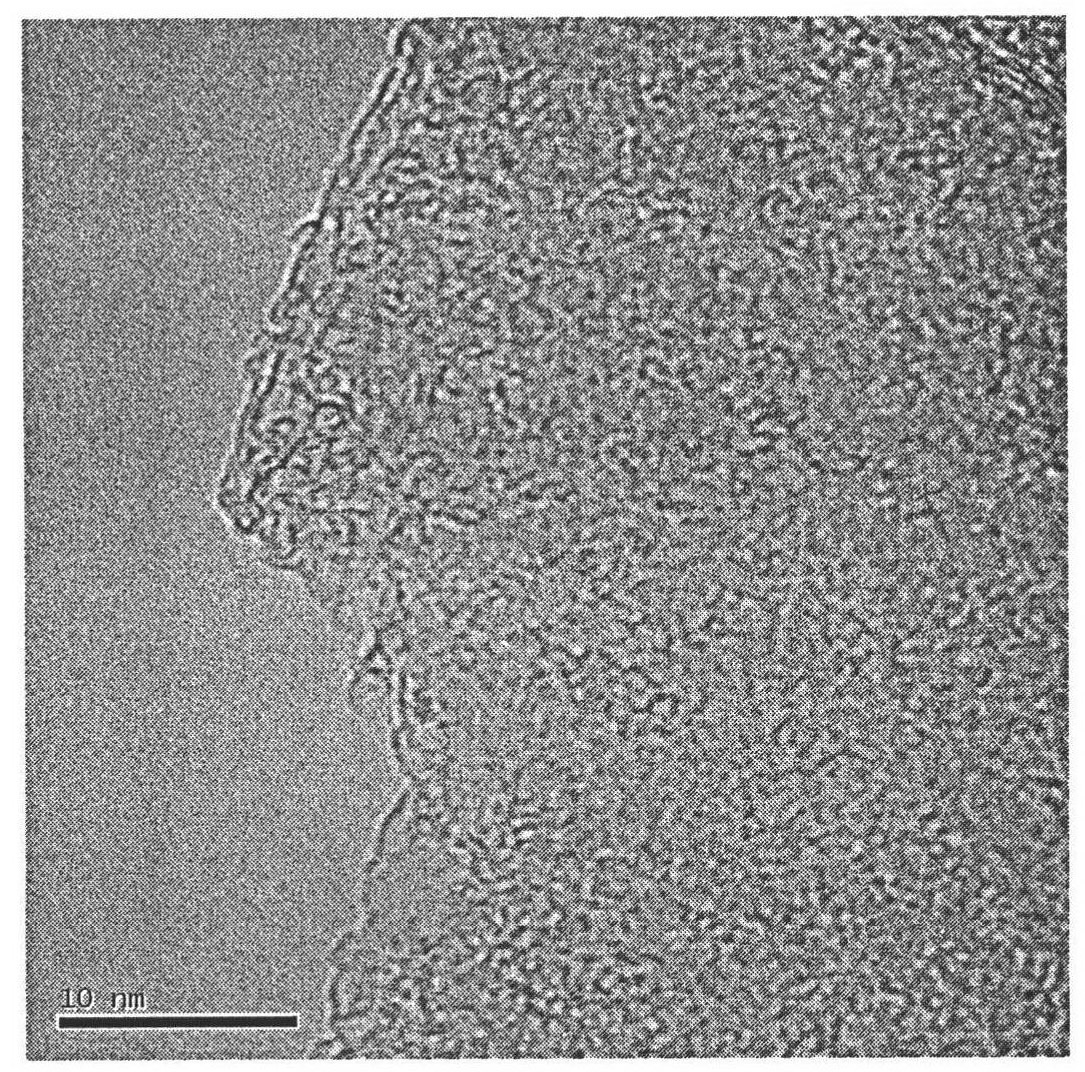

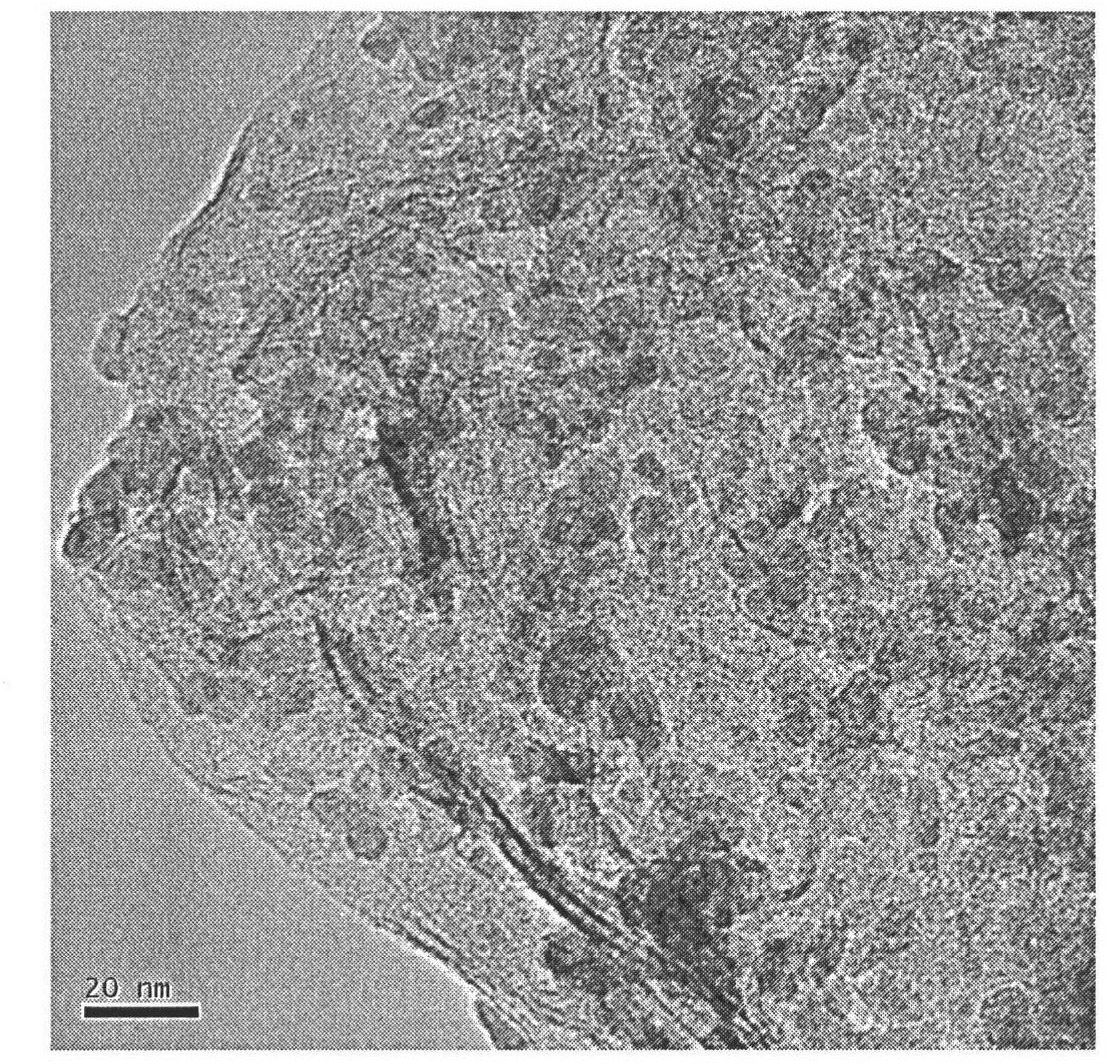

Preparation method of graphene loaded with anatase type nano titanium dioxide and application thereof

InactiveCN102324505ASmall sizeEvenly dispersedAlkaline accumulator electrodesNanotechnologyFlake graphiteSODIUM DODECYL BENZENE SULFONATE

The invention discloses a preparation method of graphene loaded with anatase type nano titanium dioxide and an application thereof. The preparation method comprises the following steps: preparing graphite oxide from crystalline flake graphite; carrying out reduction reaction on the graphite oxide to obtain graphene by taking hydrazine hydrate as a reducing agent and sodium dodecyl benzene sulfonate as a dispersing agent; preparing titanium hydroxide colloidal solution by taking tetrabutyl titanate as a titanium source; mixing the ethanol solution of graphene and the titanium hydroxide colloidal solution, stirring and calcining to prepare the graphene loaded with anatase type nano titanium dioxide. The graphene loaded with anatase type nano titanium dioxide prepared by the method can be mixed with copper powder to prepare the negative electrode of a nickel-hydride secondary battery. The method provided by the invention has the advantages of simple preparation process and low cost and is easy to operate. When the prepared graphene loaded with anatase type nano titanium dioxide is used as the active material of the cathode of the secondary battery, the effects of high discharge specific capacity and good circulation stability are achieved.

Owner:TIANJIN UNIV

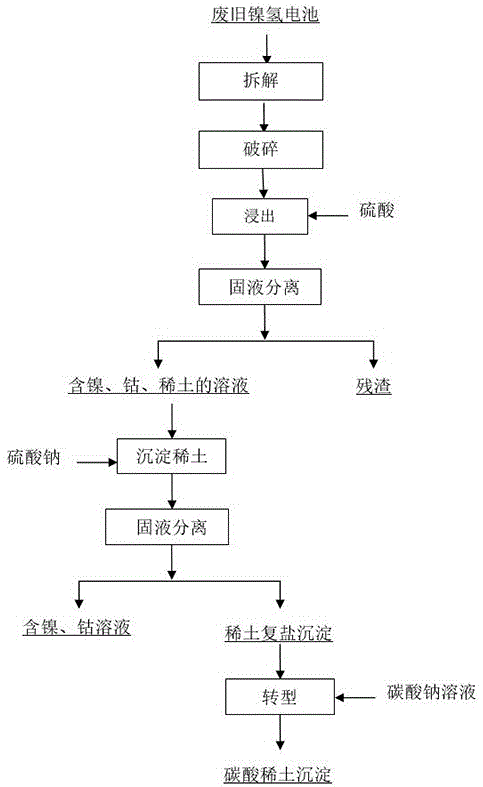

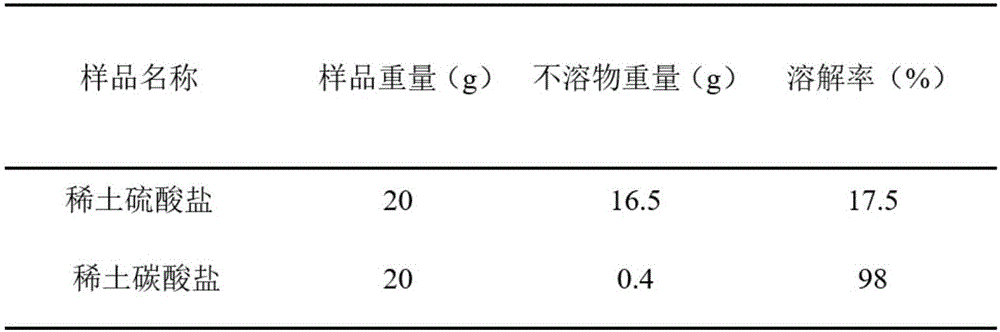

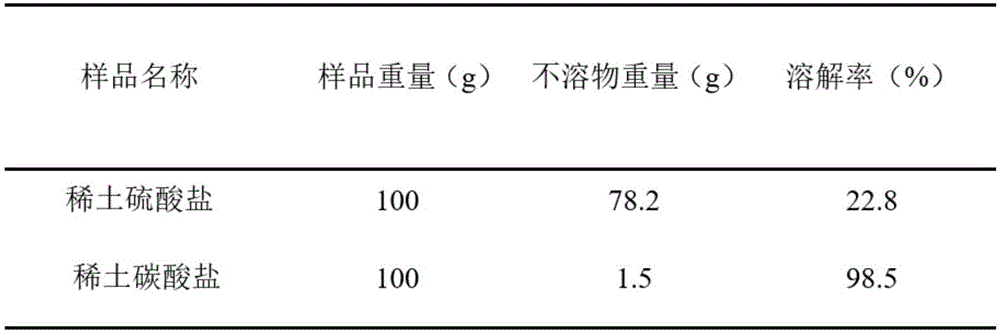

Method for recycling rare earth from waste nickel-hydride battery and conducting transformation

ActiveCN106222456AEasy to recycleImprove solubilityWaste accumulators reclaimingProcess efficiency improvementReaction temperatureRare earth

The invention discloses a method for recycling rare earth from a waste nickel-hydride battery and conducting transformation. The method comprises seven steps including the first step of crushing treatment, the second step of acid leaching treatment, the third step of primary solid-liquid separation, the fourth step of primary sedimentation treatment, the fifth step of secondary solid-liquid separation, the sixth step of sulfuric acid rare earth double salt transformation treatment and the seventh step of rare earth sedimentation extraction. Compared with rare earth sulfate, carbonic acid rare earth sediment is easy to dissolve, the carbonic acid rare earth sediment can be better conducted to further deep processing and can be well separated from nickel and cobalt in the waste nickel-hydride battery, recycling of the rare earth is facilitated, and other valuable metal can be recycled. The reaction is conducted under the normal pressure, the reaction temperature is low, and therefore energy consumption is low. The waste nickel-hydride battery is crushed under the temperature condition of 15 DEG C, volatilization of harmful substances of the waste nickel-hydride battery can be reduced, and the waste nickel-hydride battery can be easier to crush; and to prevent temperature rise of the waste nickel-hydride battery due to collisions in the crushing process, it is most proper to crush the waste nickel-hydride battery in winter.

Owner:JINCHUAN GROUP LIMITED

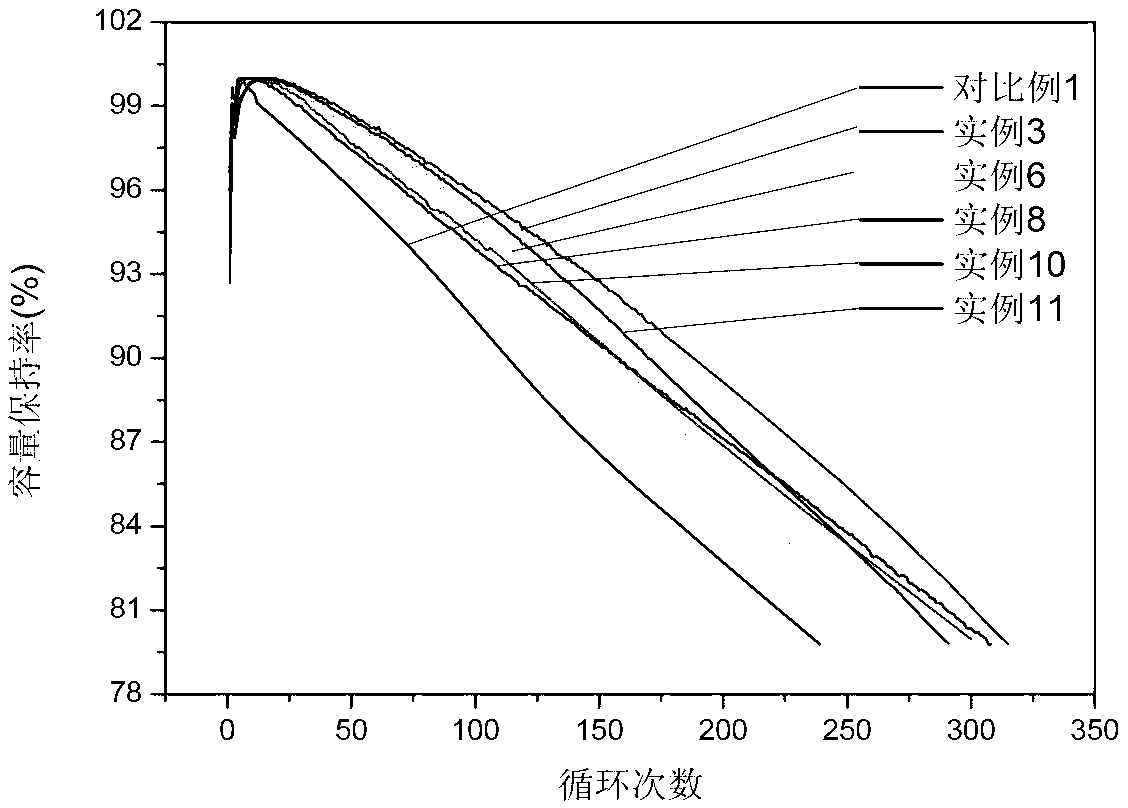

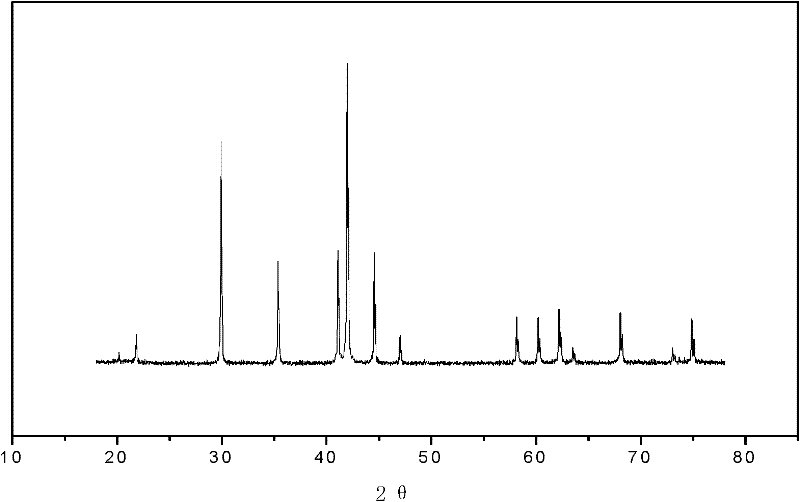

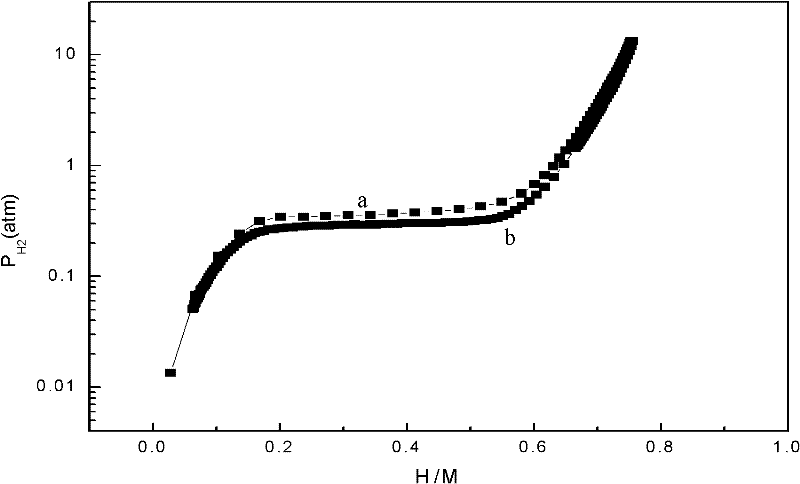

A2B7 hydrogen storage alloy for nickel-hydride battery and preparation method thereof

ActiveCN103326004AImprove cycle lifeImprove low temperature performanceCell electrodesRare-earth elementLanthanum

The invention discloses an A2B7 hydrogen storage alloy for nickel-hydride battery and a preparation method thereof. The A2B7 hydrogen storage alloy has a structure formula of LnaMgbNixYyZz in which Ln is at least one element selected from rare earth elements; Y is at least one element selected from Al, Co, Nb, V, Fe, Cu, Zn, As, Ga, Mo, Sn, In, W, Si and P; and Z is at least one element selected from Ag, Sr and Ge at least. X, Y and Z shall satisfy 0.5 <=a (2, 0 (b (1, 5 (x+y+z (9, 0 (y (3, 0 (z (1. In the invention, the A2B7 hydrogen storage alloy for superlattice nickel-hydrogen battery is prepared by weighing raw materials such as metal lanthanum, neodymium, nickel, magnesium, aluminum and silver according to the structure formula (LnaMgbNixYyZz) and performing induction smelting. The phase content of A2B7 in the hydrogen storage alloy shall be over 90% through strict control of the alloy composition and the proper annealing treatment. In the invention, B side elements are replaced by Ag, Sr and Ge etc., the cycle life of hydrogen storage alloy is prolonged without effecting discharge capacity, and the low-temperature performance thereof is improved.

Owner:SIHUI DABOWEN IND CO LTD +1

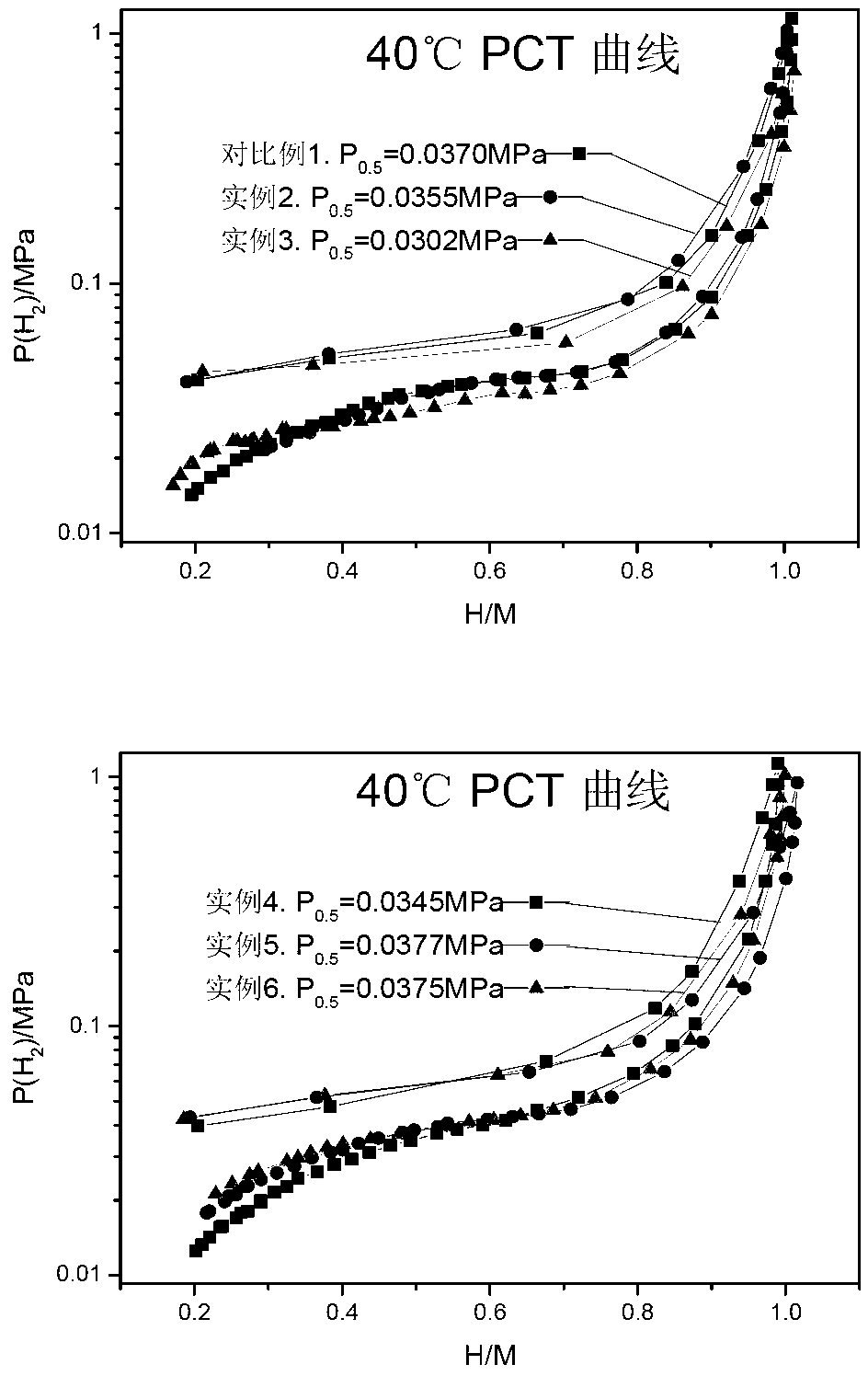

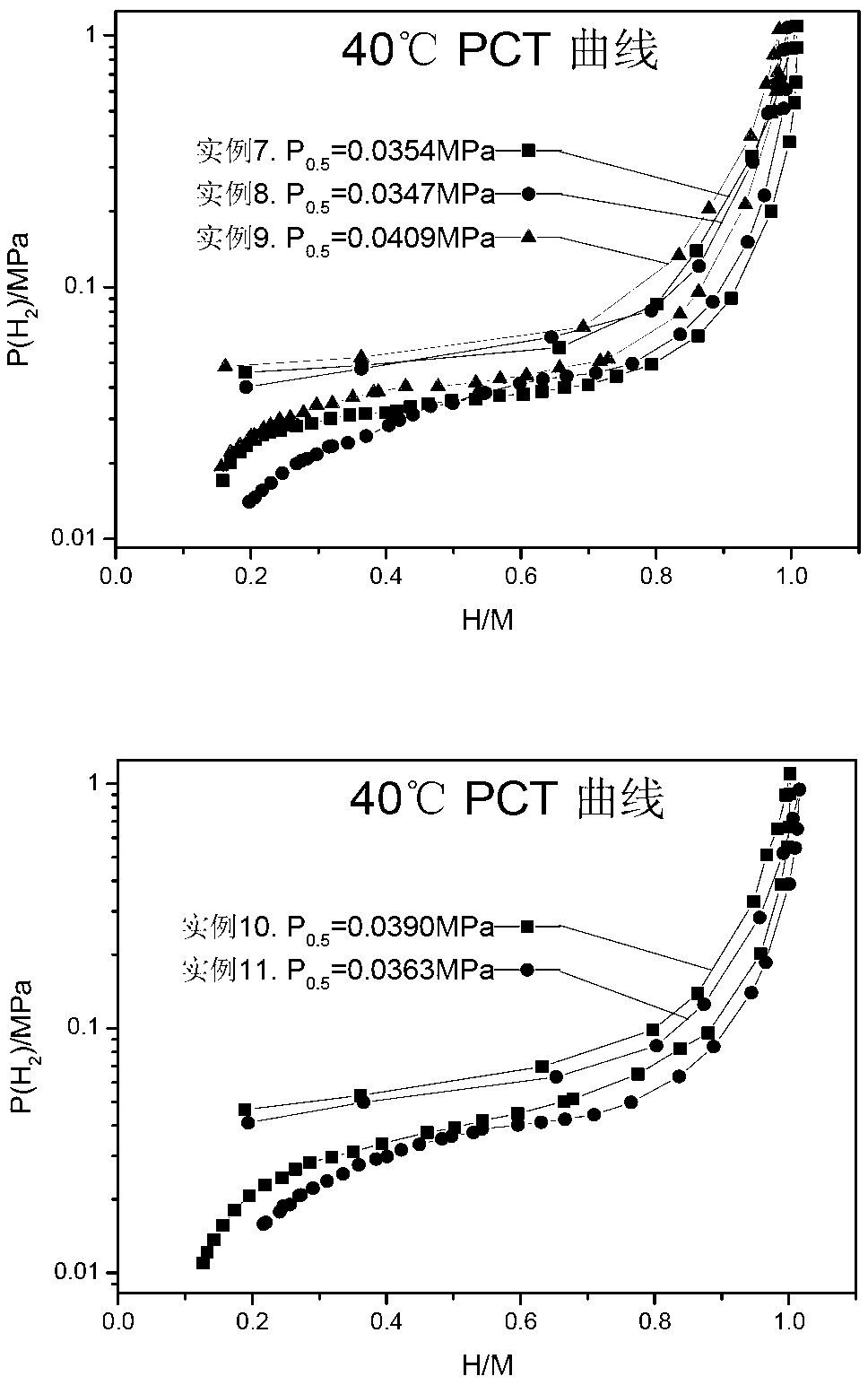

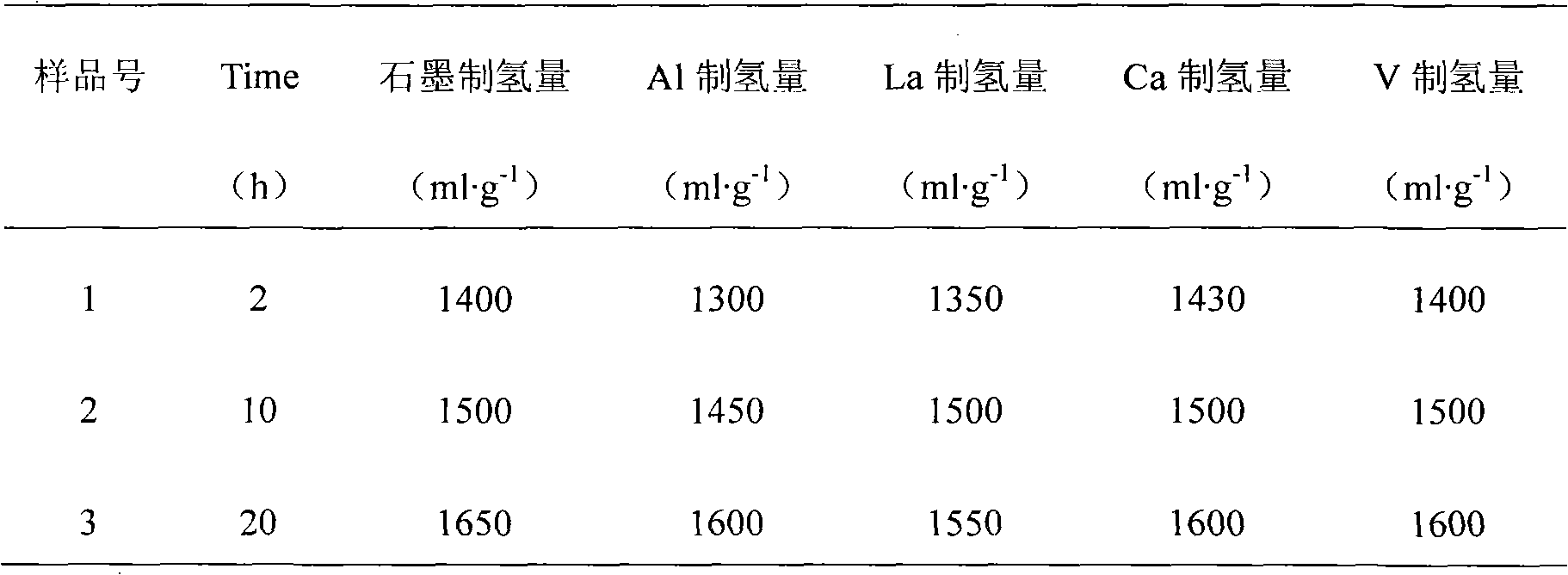

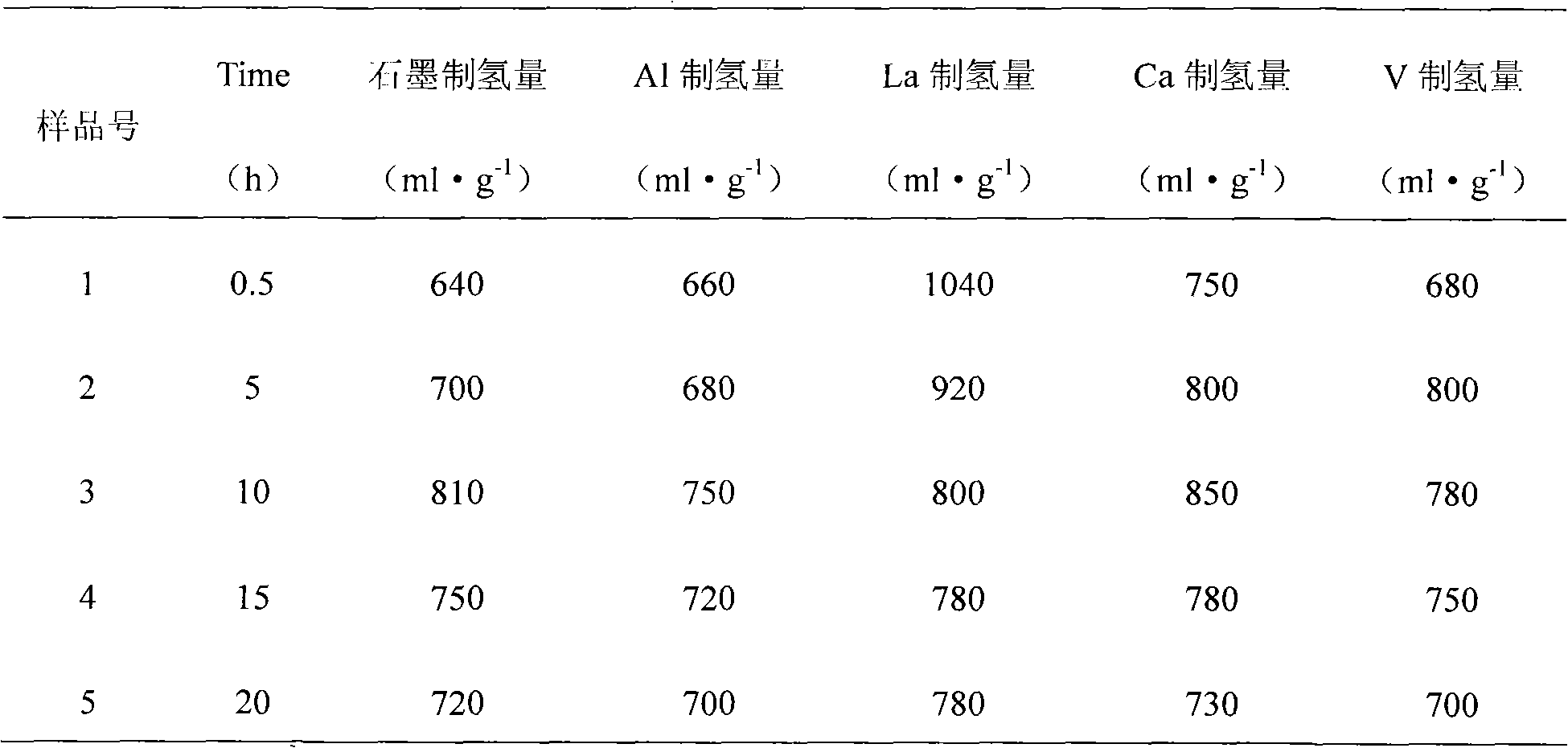

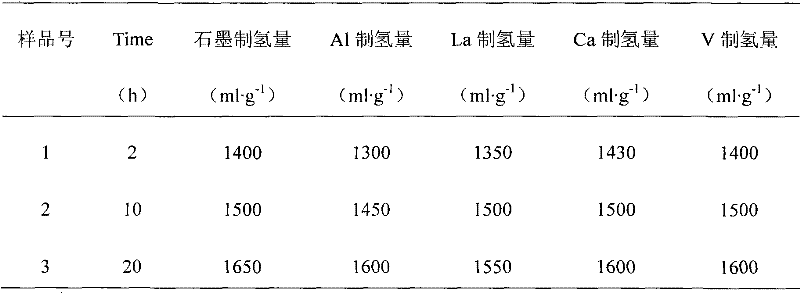

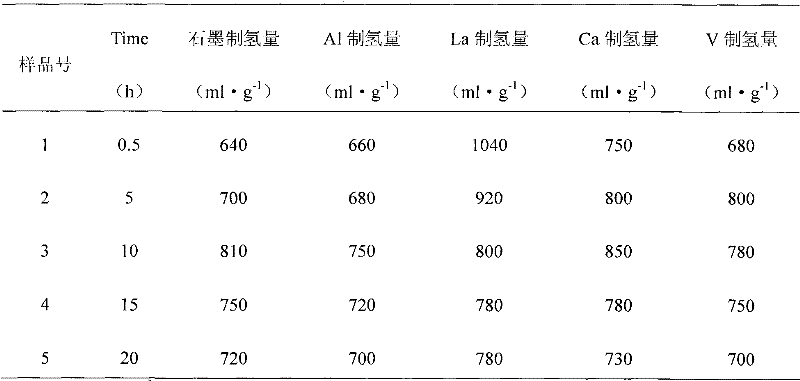

Magnesium base hydride composite system for hydrolysis hydrogen production and preparation method and application thereof

InactiveCN101811667ASimple processEase of industrial mass productionAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen productionCombustionGraphite

The invention discloses a magnesium base hydride composite system for hydrolysis hydrogen production and a preparation method and application thereof. The composite system is prepared by a method comprising the following steps of: taking magnesium powder and nickel powder in a mole ratio of 30:1-49:1; performing hydrogenation combustion synthesis under the action of a catalyst and an organic dispersant which account for 3 to 10 percent of the total weight of the mixture of the magnesium powder and the nickel powder; and performing strong mechanical ball milling. The magnesium hydride in the prepared magnesium base hydride composite system for the hydrolysis hydrogen production accounts for 95 to 98 percent of the weight of hydride, and the magnesium nickel hydride accounts for 2 to 5 percent; the catalyst is one of graphite, B, Al, La, Ca, V, Ce and Nb; the magnesium hydride is MgH2; and the magnesium nickel hydride is a mixture of Mg2NiH4 and Mg2NiH0.3 in any ratio. The theoretical hydrogen production amount of the composite system is up to 1,600 ml / g, and a preparation process of the magnesium base hydride composite system is time-saving, energy-saving and simple and is easy for industrial production.

Owner:NANJING UNIV OF TECH

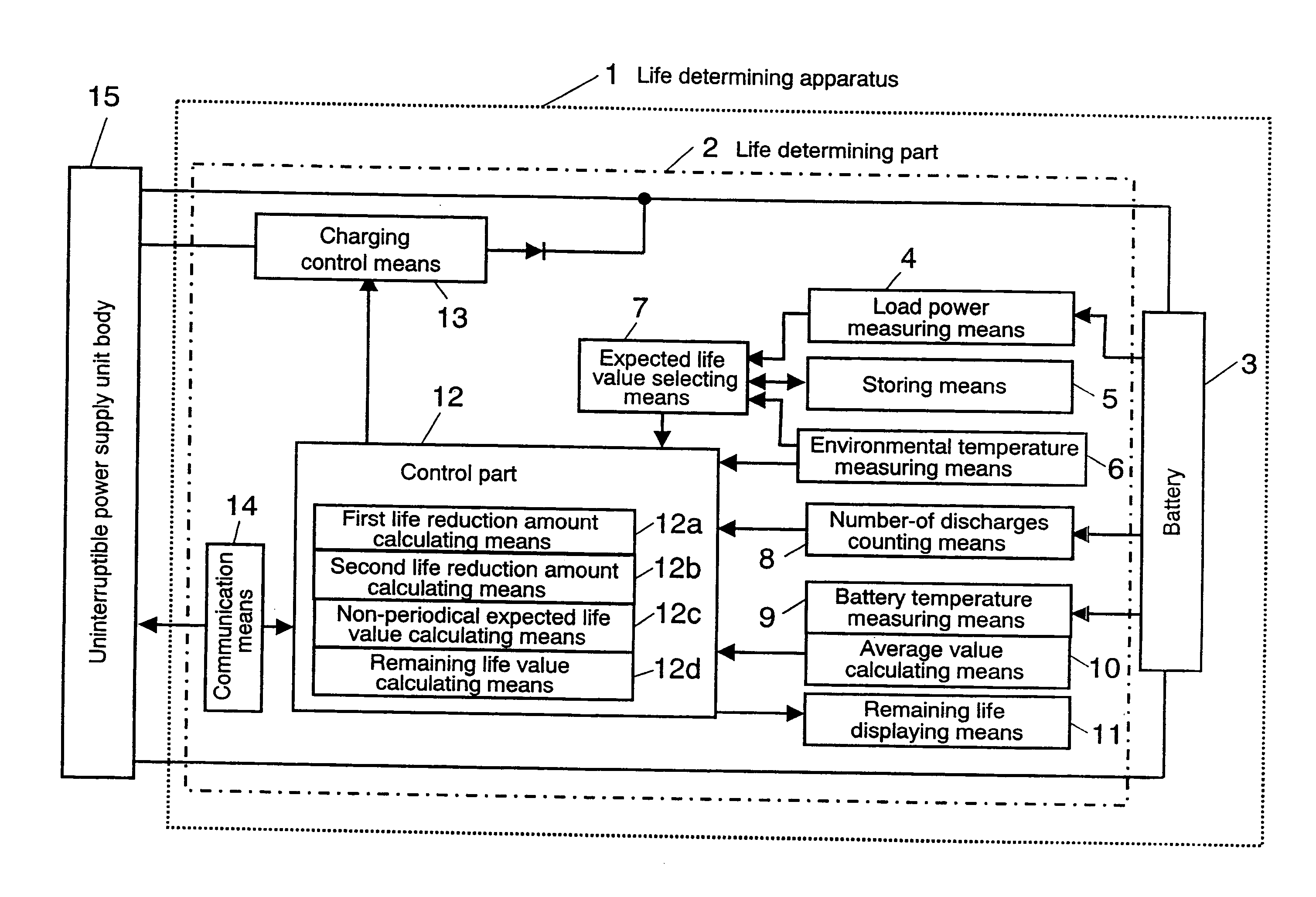

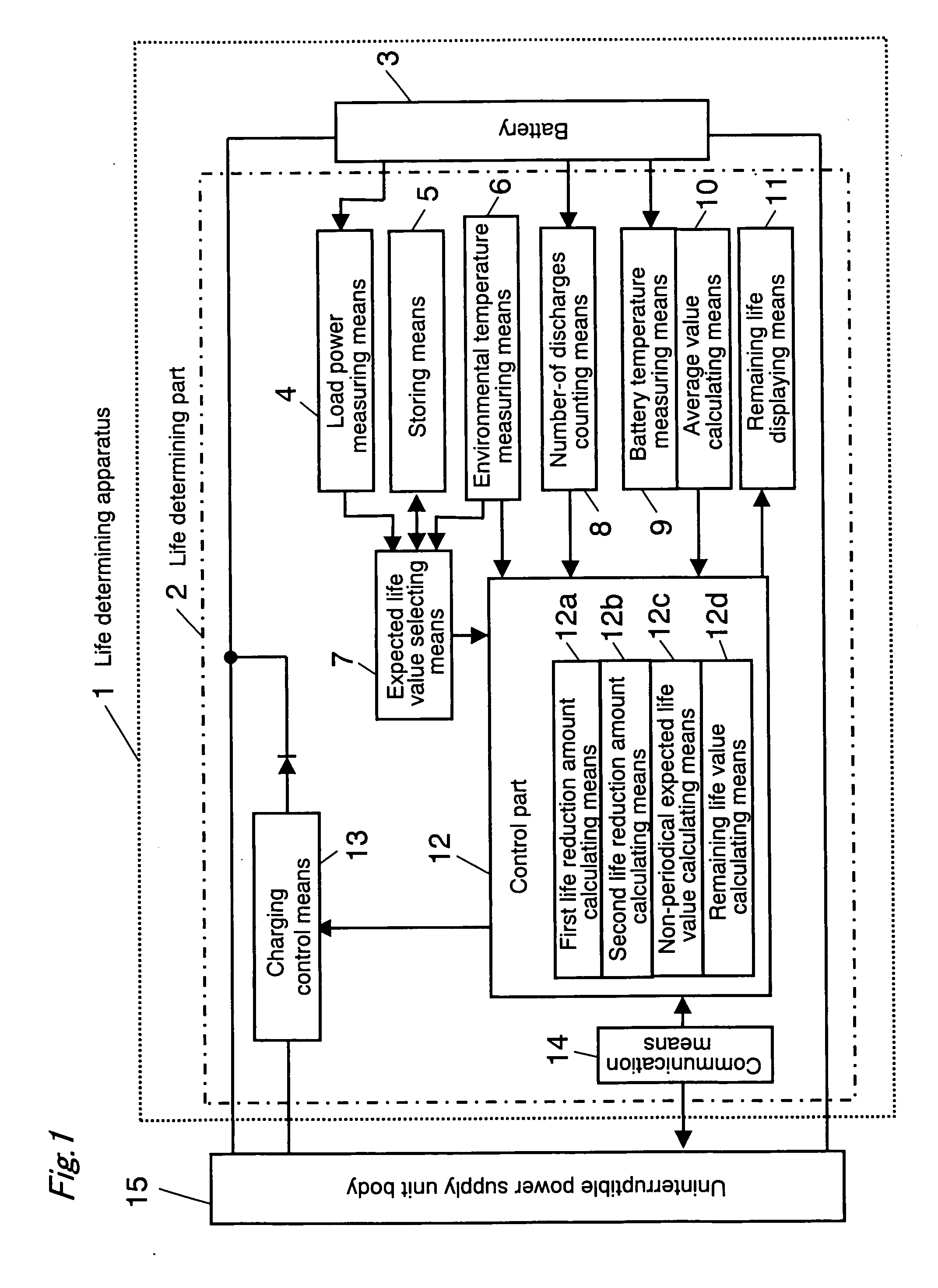

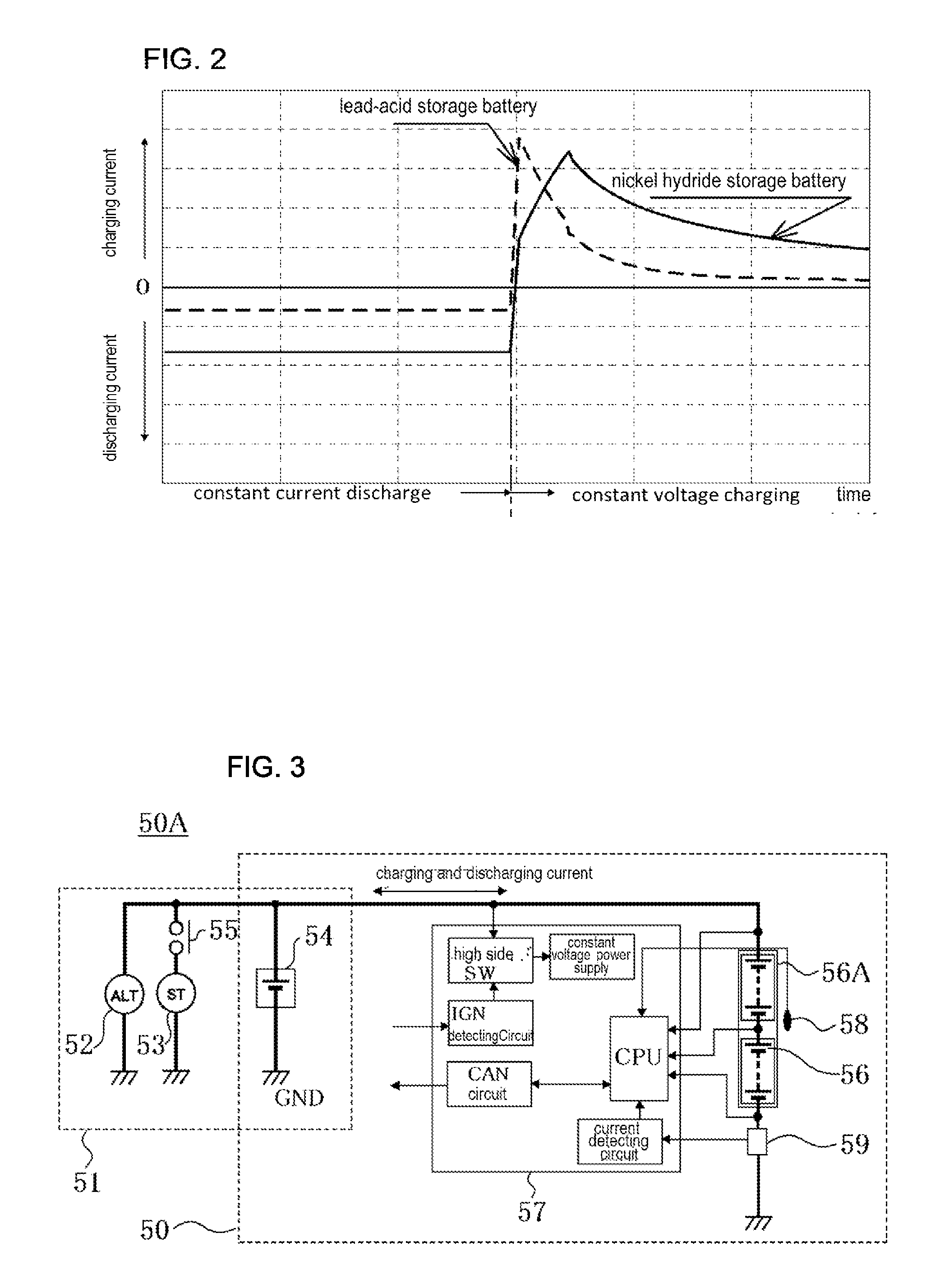

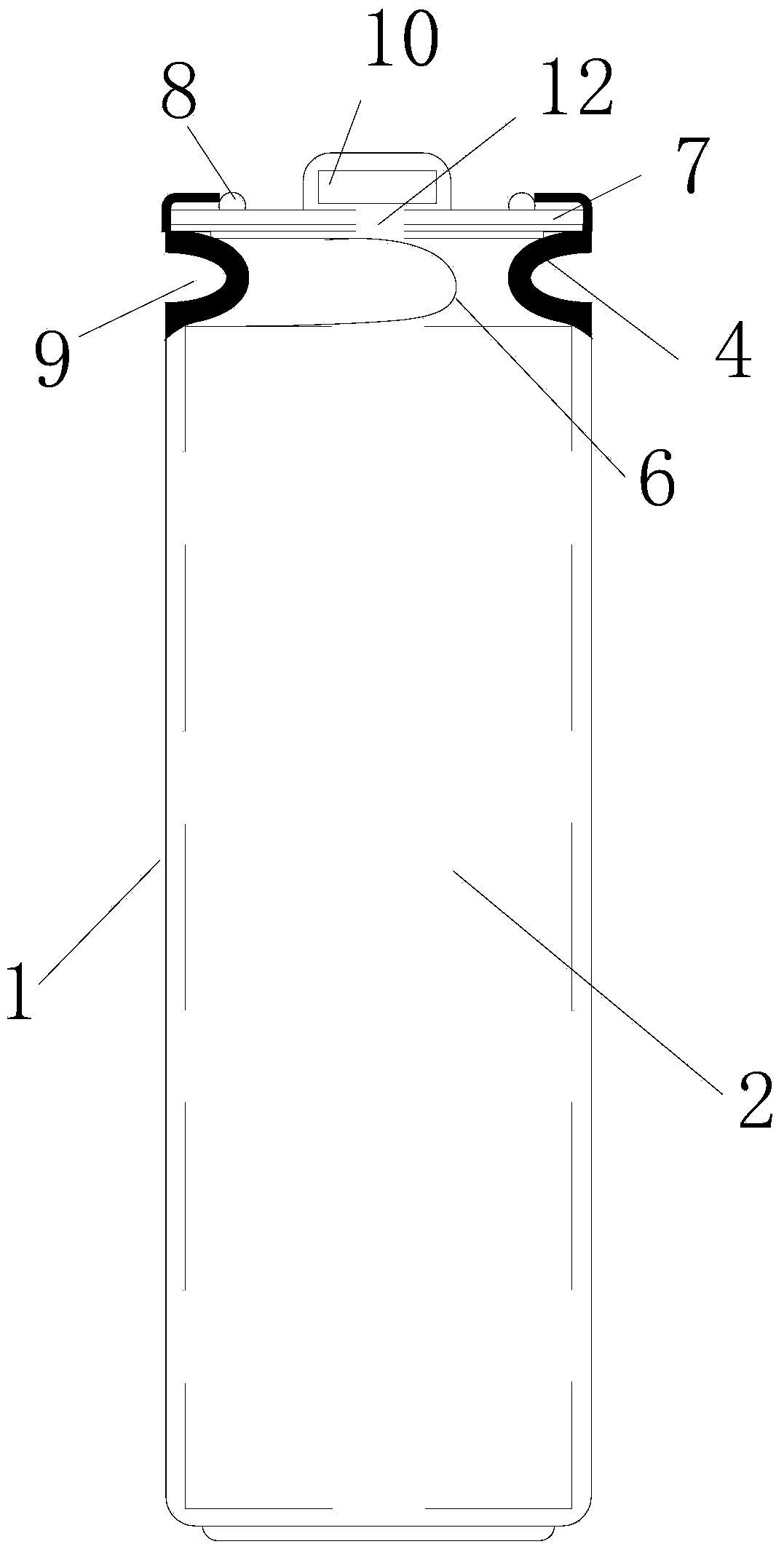

Nickel-hydride battery life determining method and life determining apparatus

InactiveUS20080125987A1Accurately determineBatteries circuit arrangementsMaterial analysis by electric/magnetic meansEngineeringLife time

Owner:PANASONIC CORP

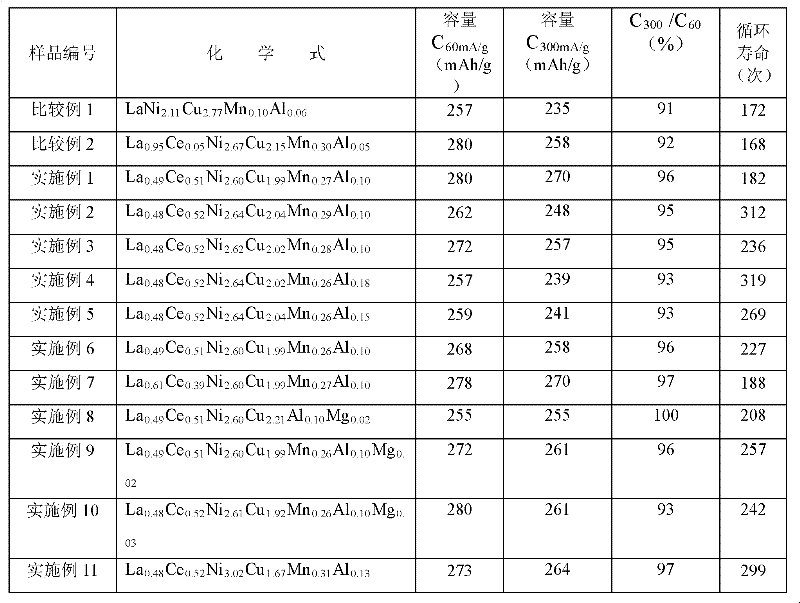

Non-cobalt low-nickel hydrogen storage alloy

The invention discloses a non-cobalt low-nickel hydrogen storage alloy, relating to a hydrogen storage alloy. The invention provides a non-cobalt low-nickel hydrogen storage alloy which has the characteristics of moderate volume, good comprehensive electrochemical property, high cost performance and the like and can satisfy the requirements of parts of medium and low-volume nickel hydride batteries. The non-cobalt low-nickel hydrogen storage alloy belongs to an AB5 type and has the general formula of La(1-x)CexNiaCubMncAldMge, wherein x is more than or equal to 0.1 and less than or equal to 0.7, a is more than or equal to 2.0 and less than or equal to 3.3, b is more than or equal to 1.3 and less than or equal to 2.6, c is more than or equal to 0 and less than or equal to 0.4, d is more than or equal to 0 and less than or equal to 0.2, e is more than or equal to 0 and less than or equal to 0.1, and the sum of a, b, c, d and e is more than or equal to 4.7 and less than or equal to 5.2. An x value is more than or equal to 0.3 and less than or equal to 0.7; c can be more than or equal to 0.25 and less than or equal to 0.35; d can be more than or equal to 0.05 and less than or equal to 0.2; e can be more than or equal to 0.01 and less than or equal to 0.05; and the sum of a, b, c, d and e can be more than or equal to 4.8 and less than or equal to 5.1. The non-cobalt low-nickel hydrogen storage alloy has a CaCu 5 type single-phase structure.

Owner:XIAMEN TUNGSTEN

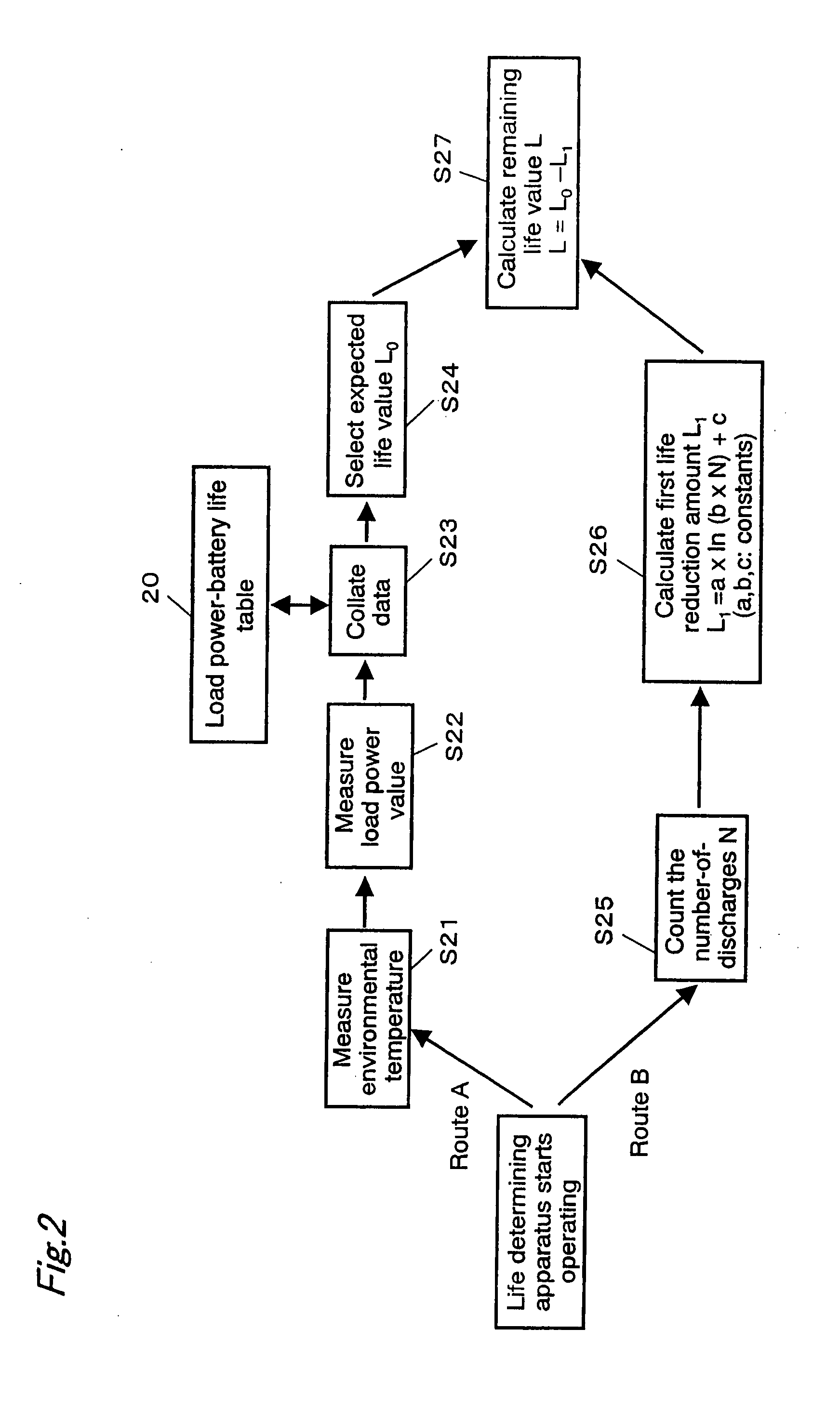

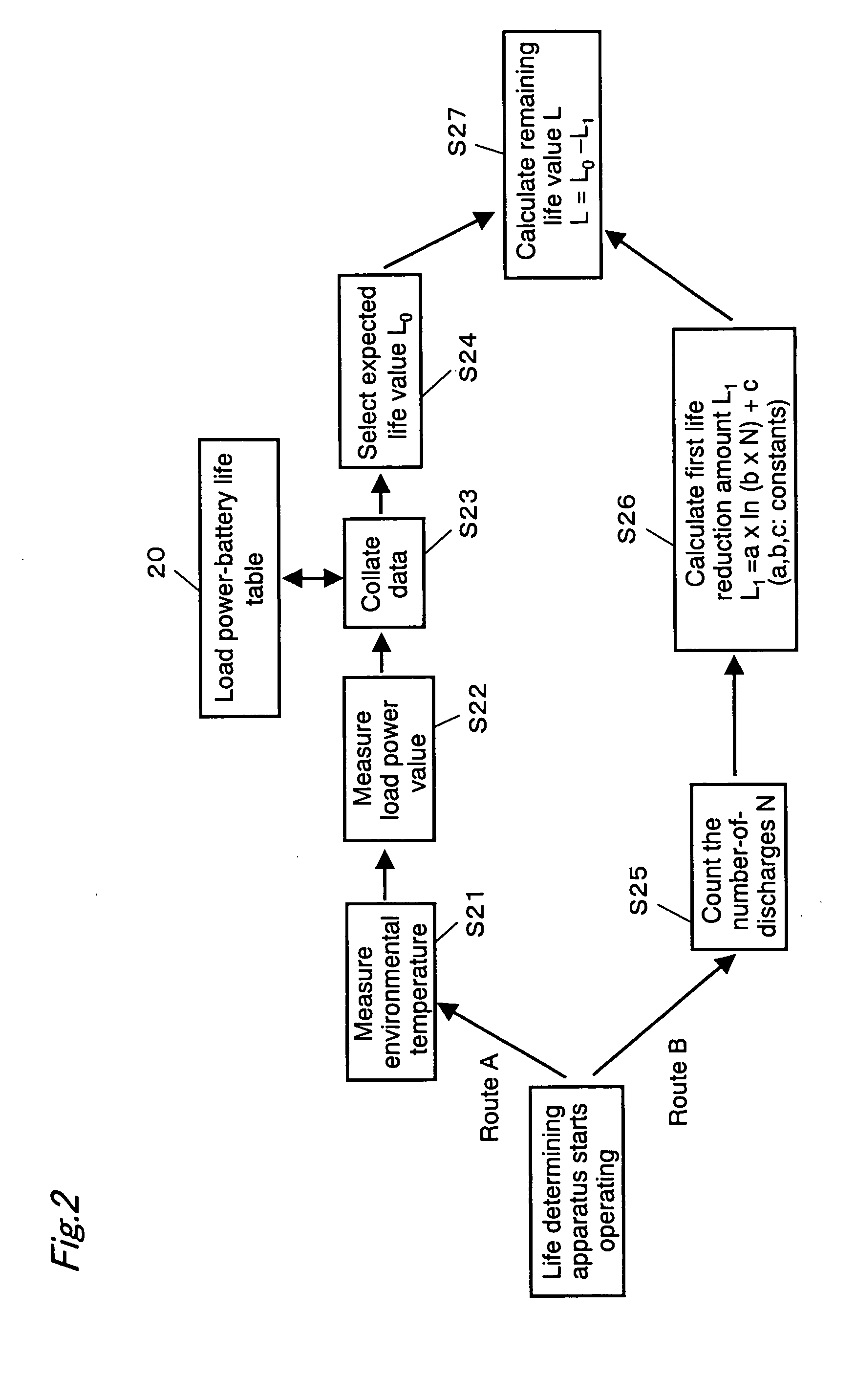

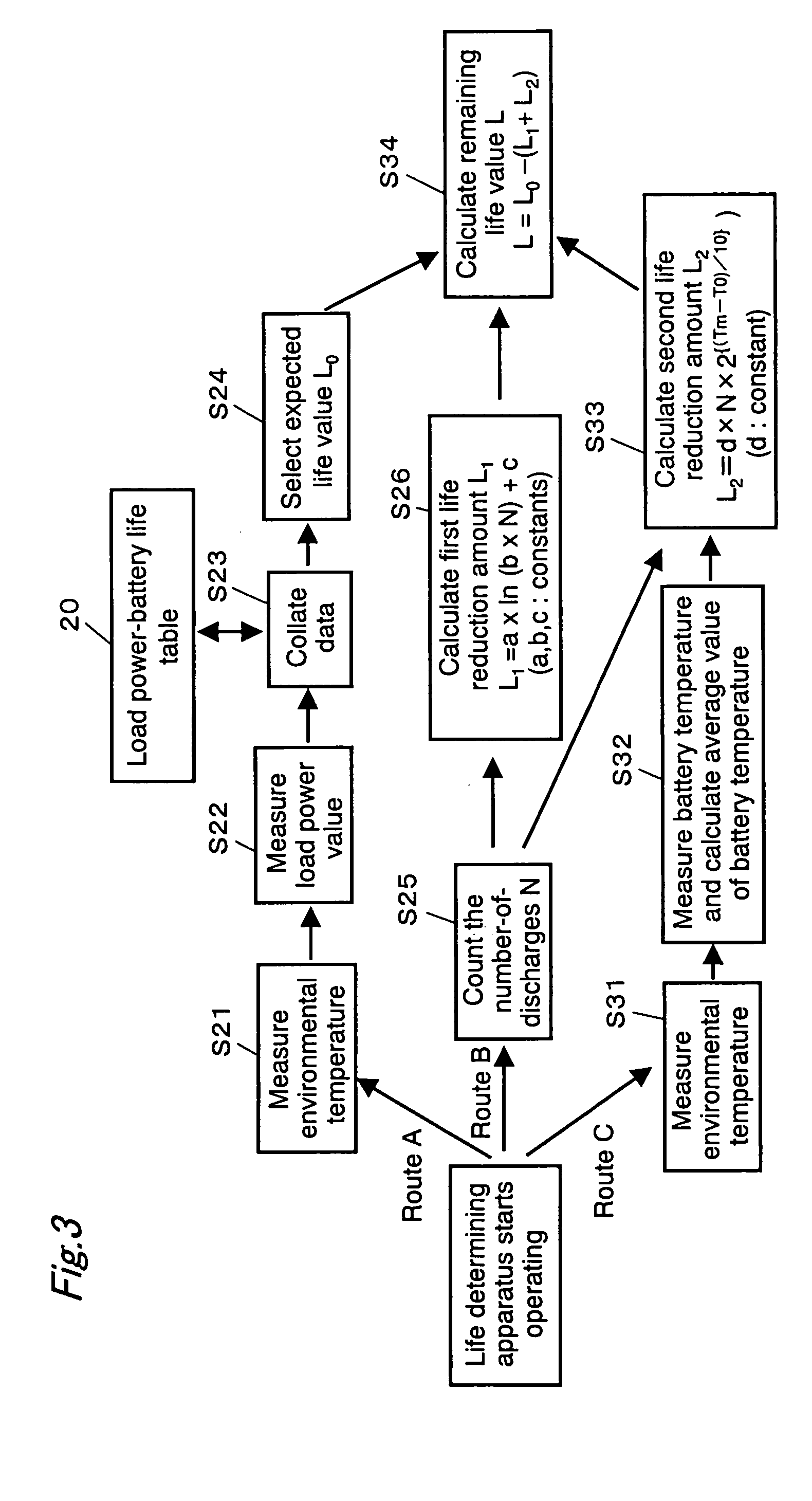

Nickel-hydride battery life determining method and life determining apparatus

InactiveUS20070164707A1Accurately determineBatteries circuit arrangementsMaterial analysis by electric/magnetic meansElectrical batteryEngineering

Data indicating a relationship of life of a battery to a value of load power applied to the battery in discharge and environmental temperature of a place where the battery is installed are prepared beforehand. Next, the load power and the environmental temperature when the battery is discharged are measured, and then a life value corresponding to these measured values is selected from the data so as to be set as an expected life value. Next, a first life reduction amount is calculated from a natural logarithmic function with the number-of-discharges as a variable, and the difference between the expected life value and the first life reduction amount is set to a remaining life value, on the basis of which the life of the nickel-hydride battery is determined. By this method, the life of the nickel-hydride battery as a backup power source can be accurately determined, while correction based on phenomena unique to the nickel-hydride battery is performed.

Owner:PANASONIC CORP

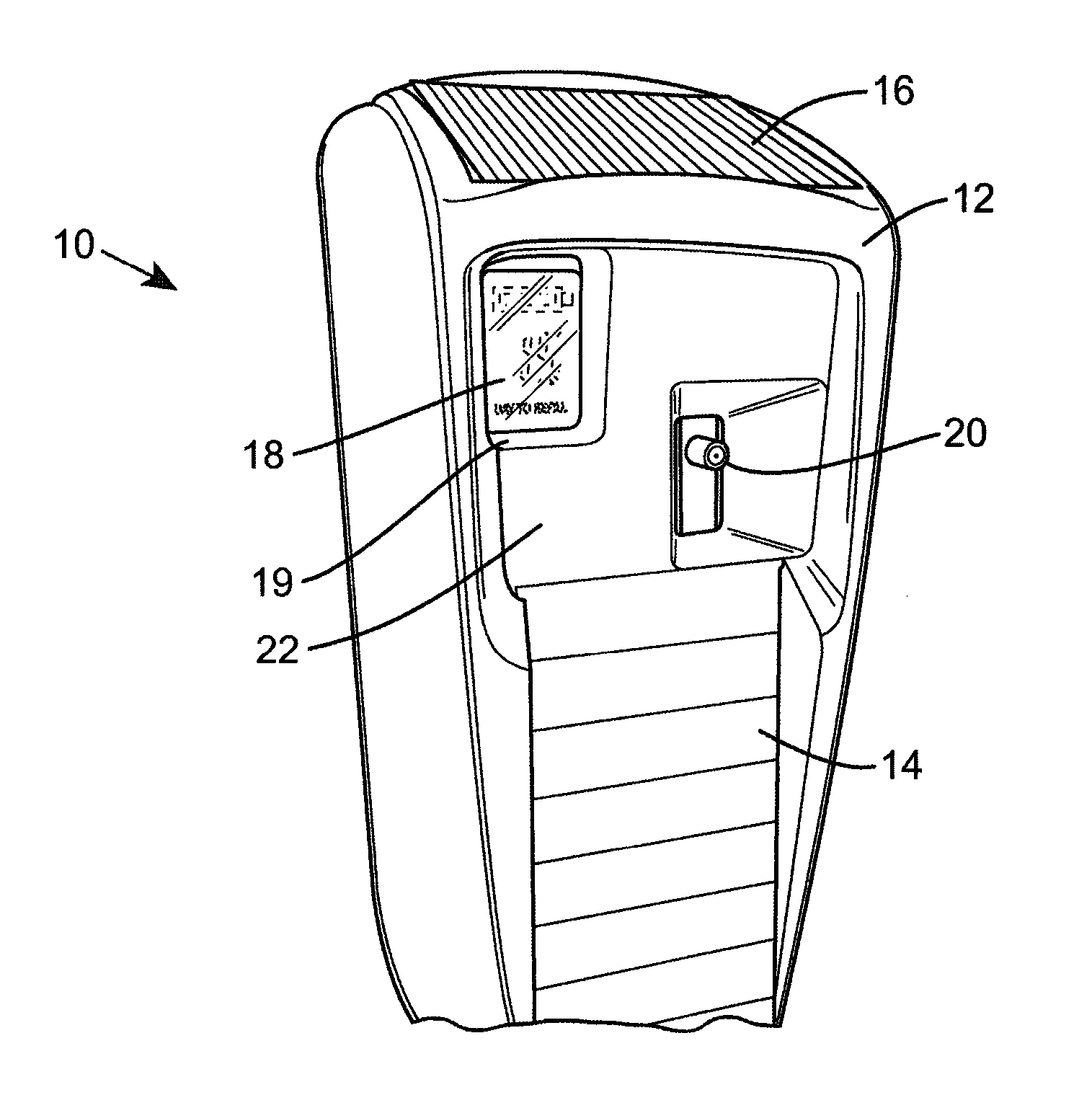

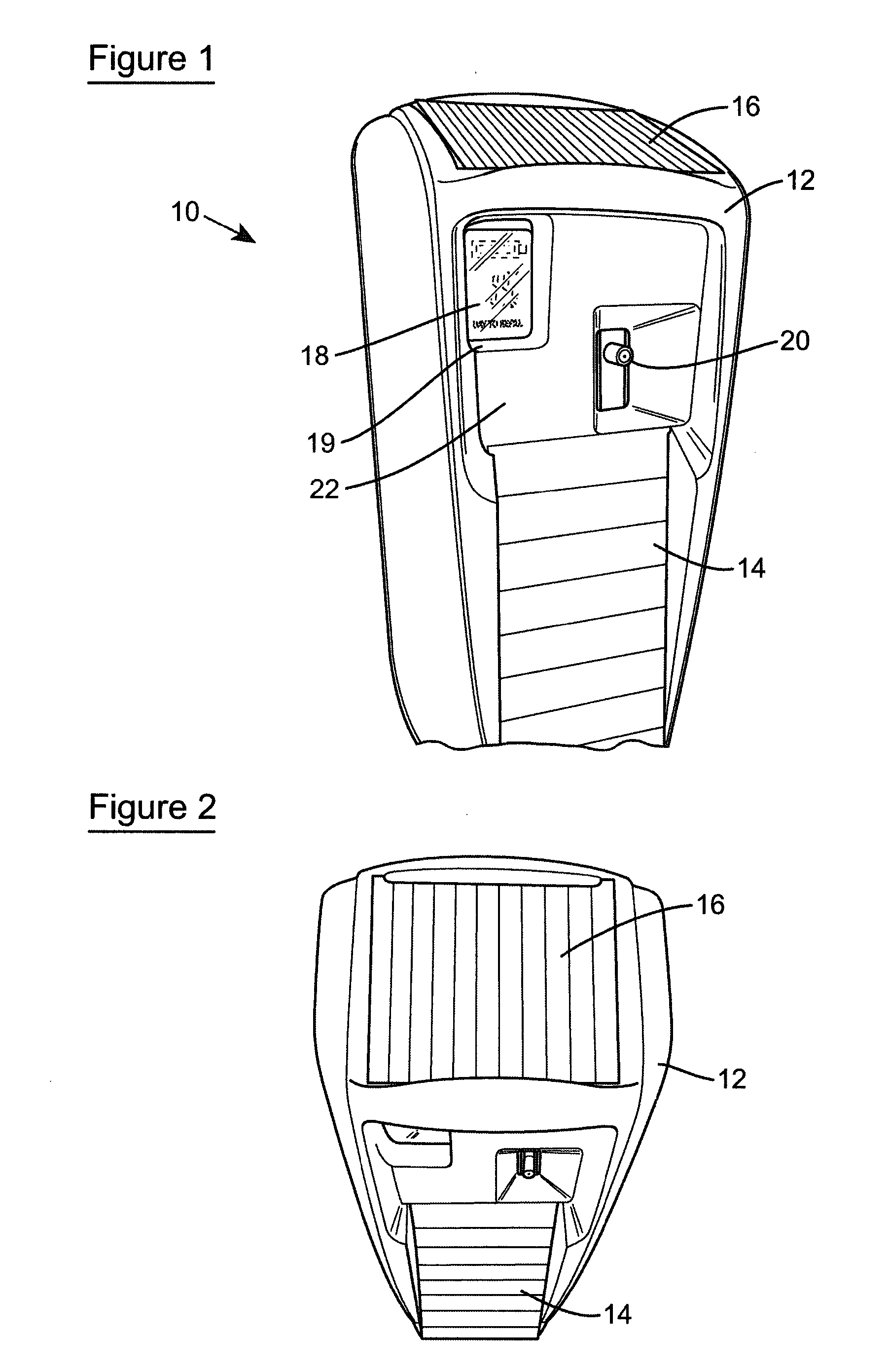

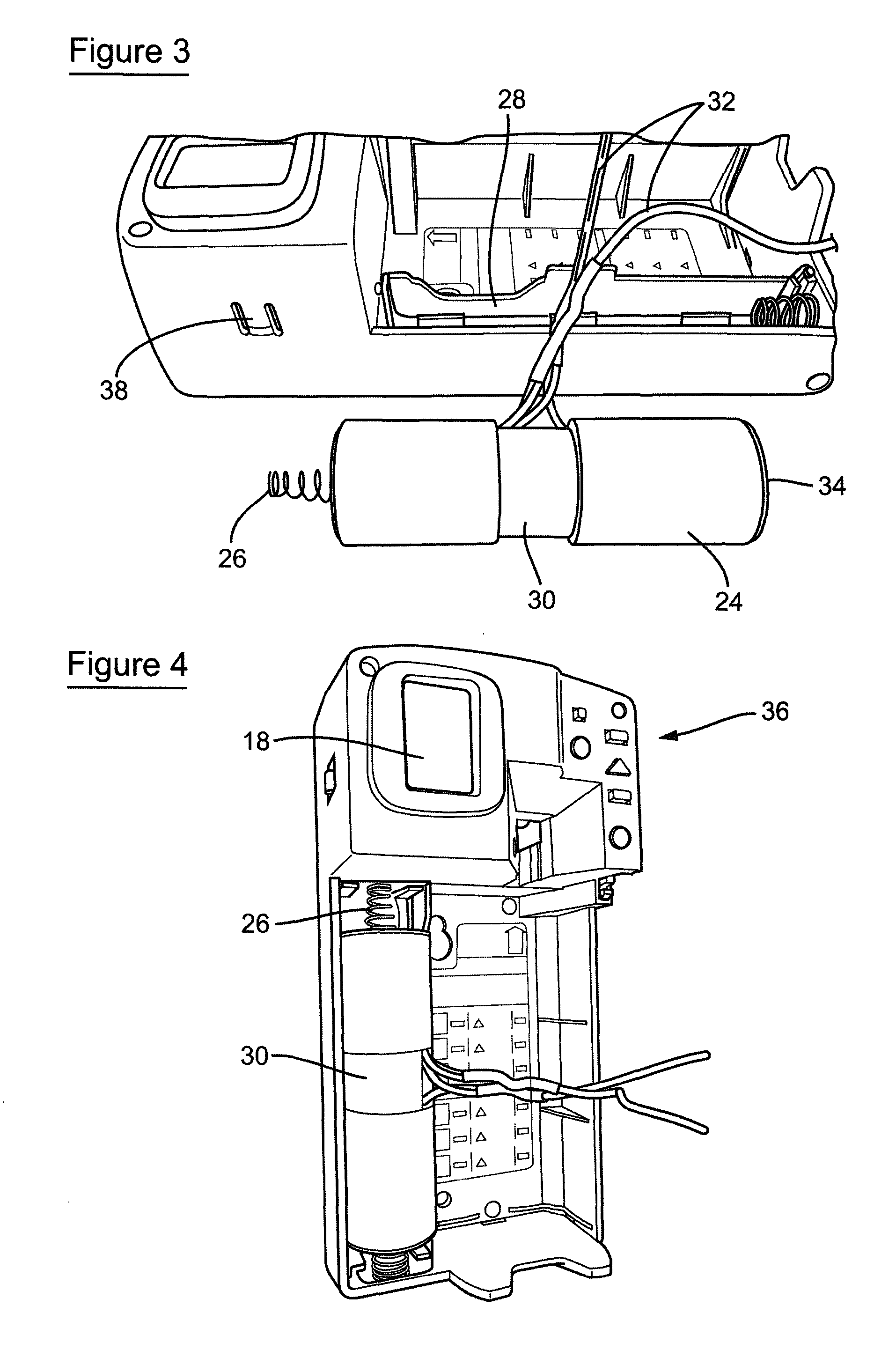

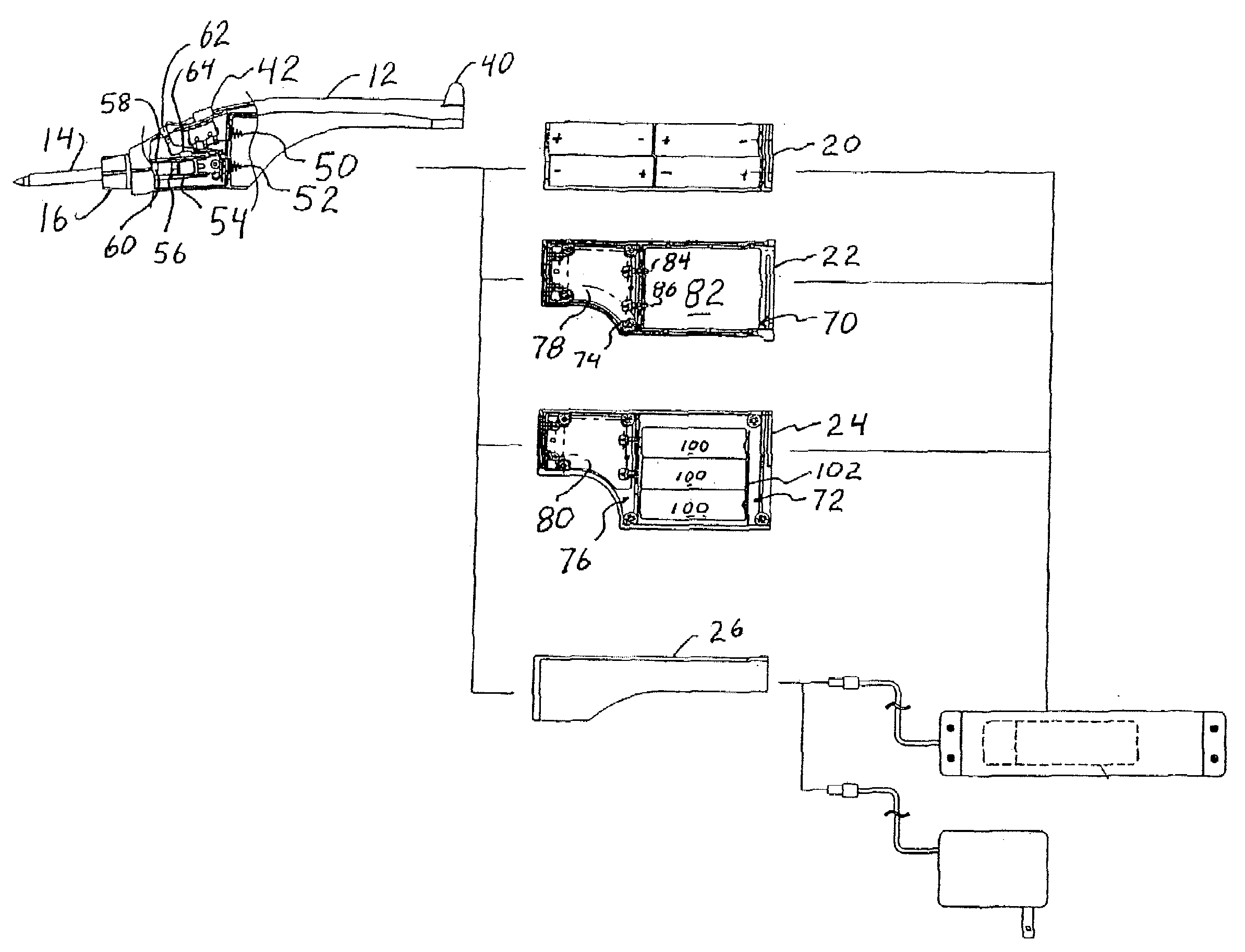

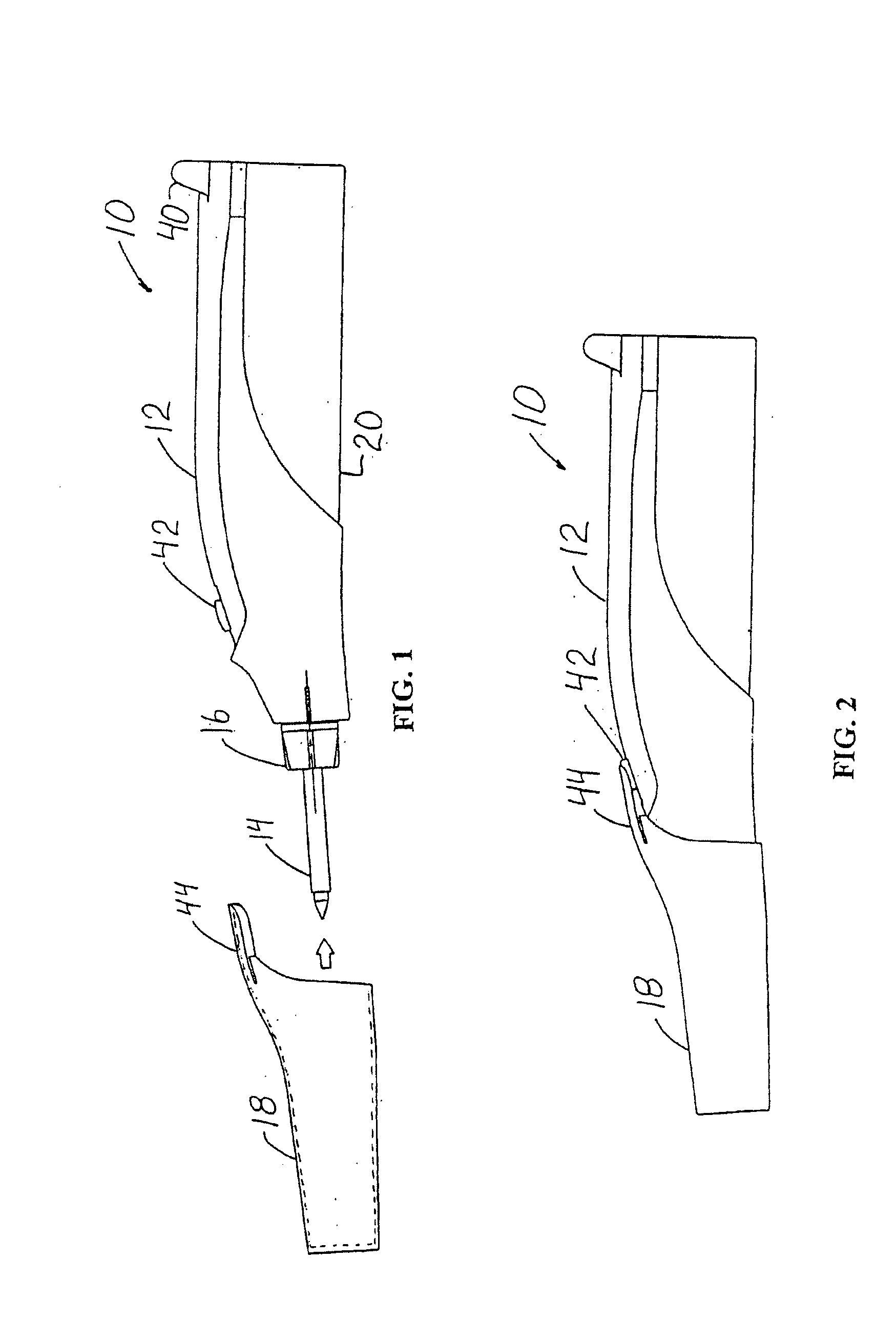

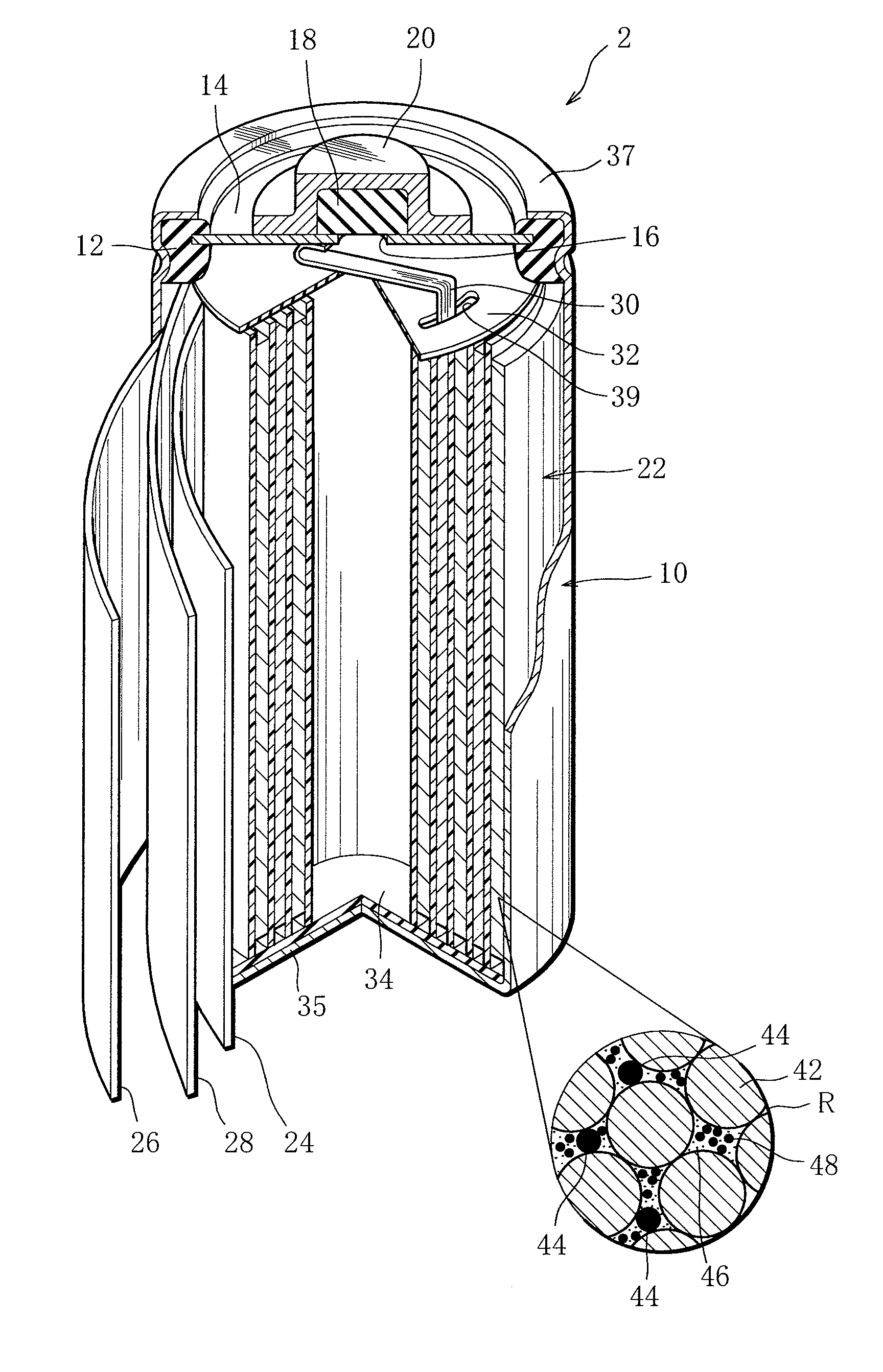

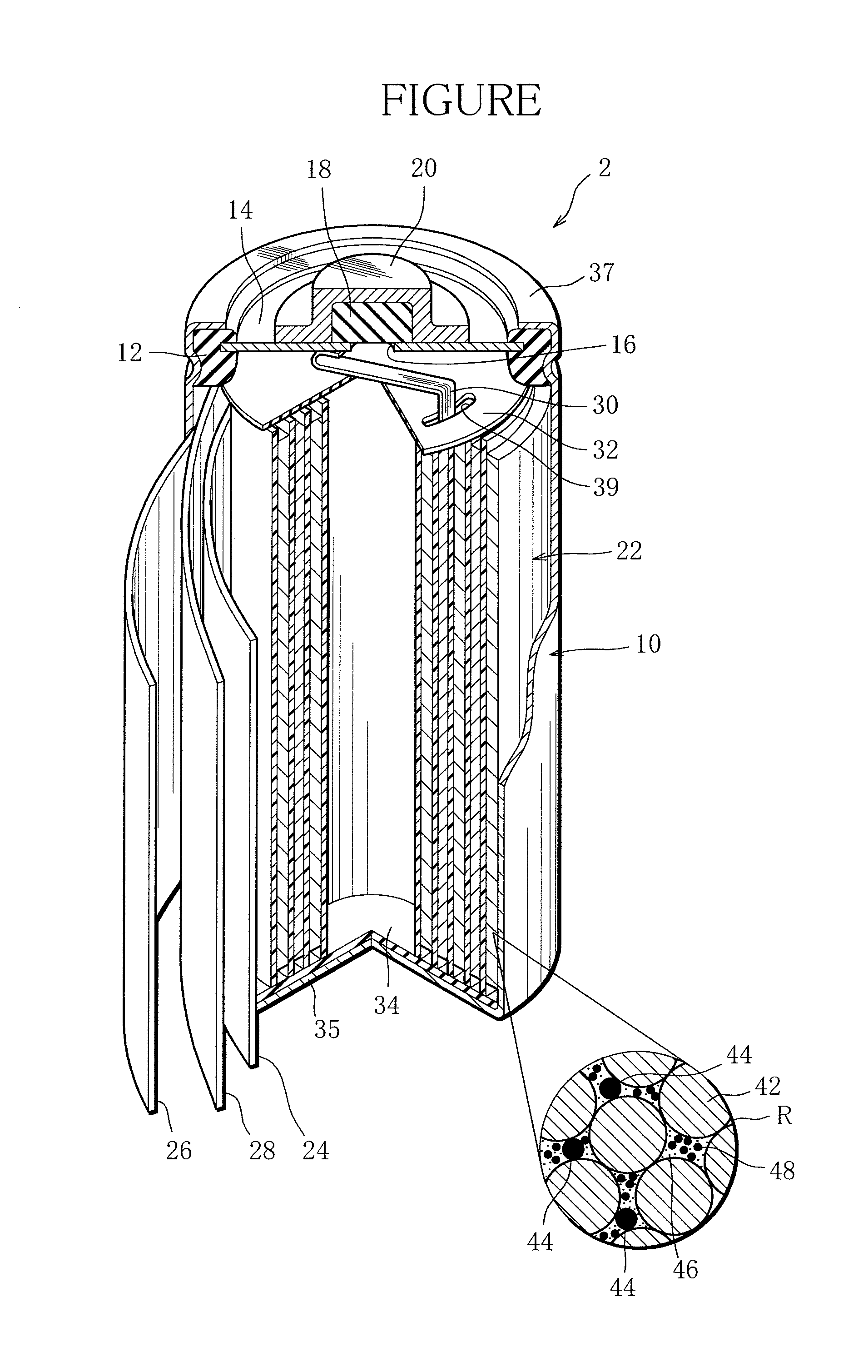

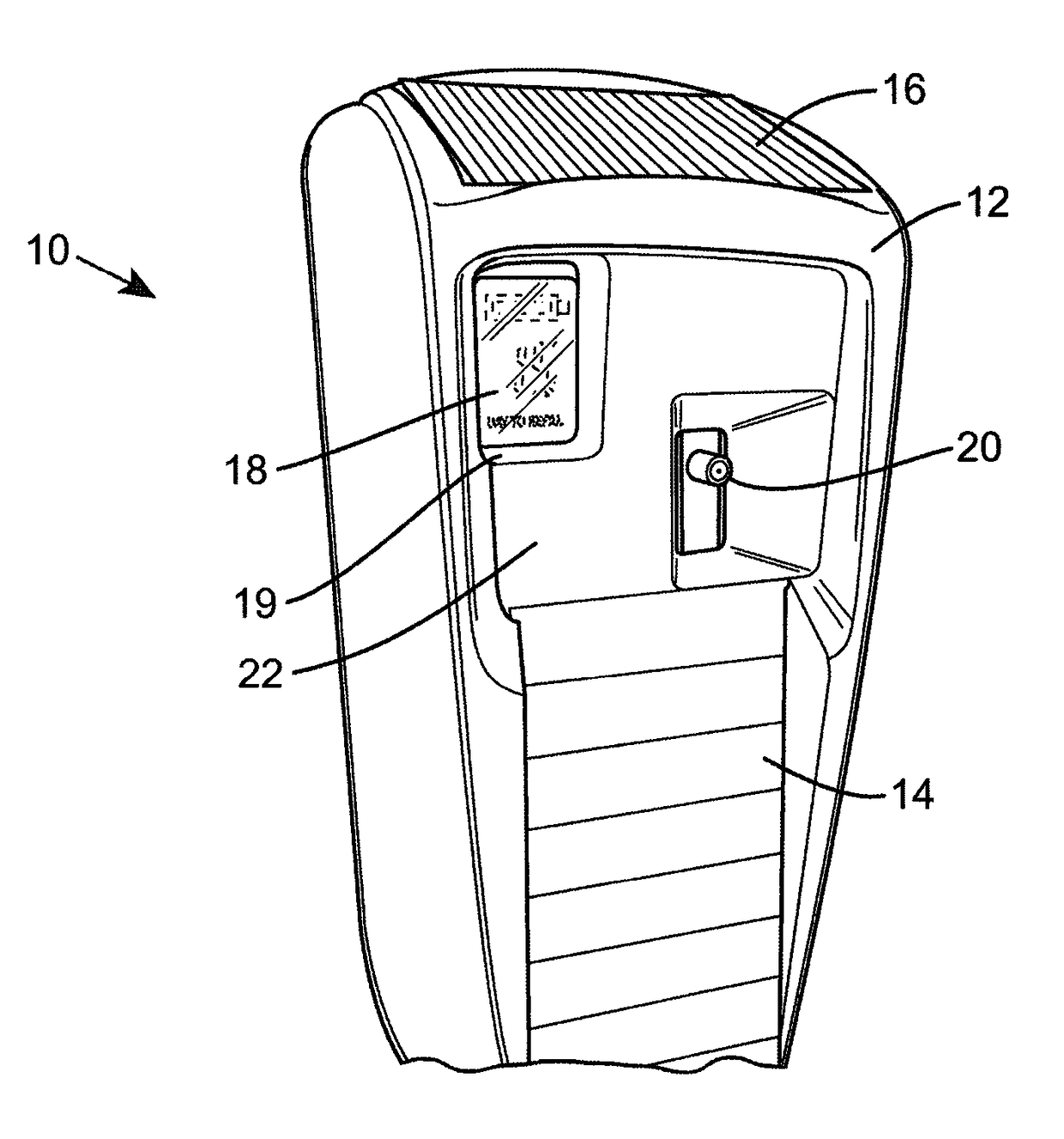

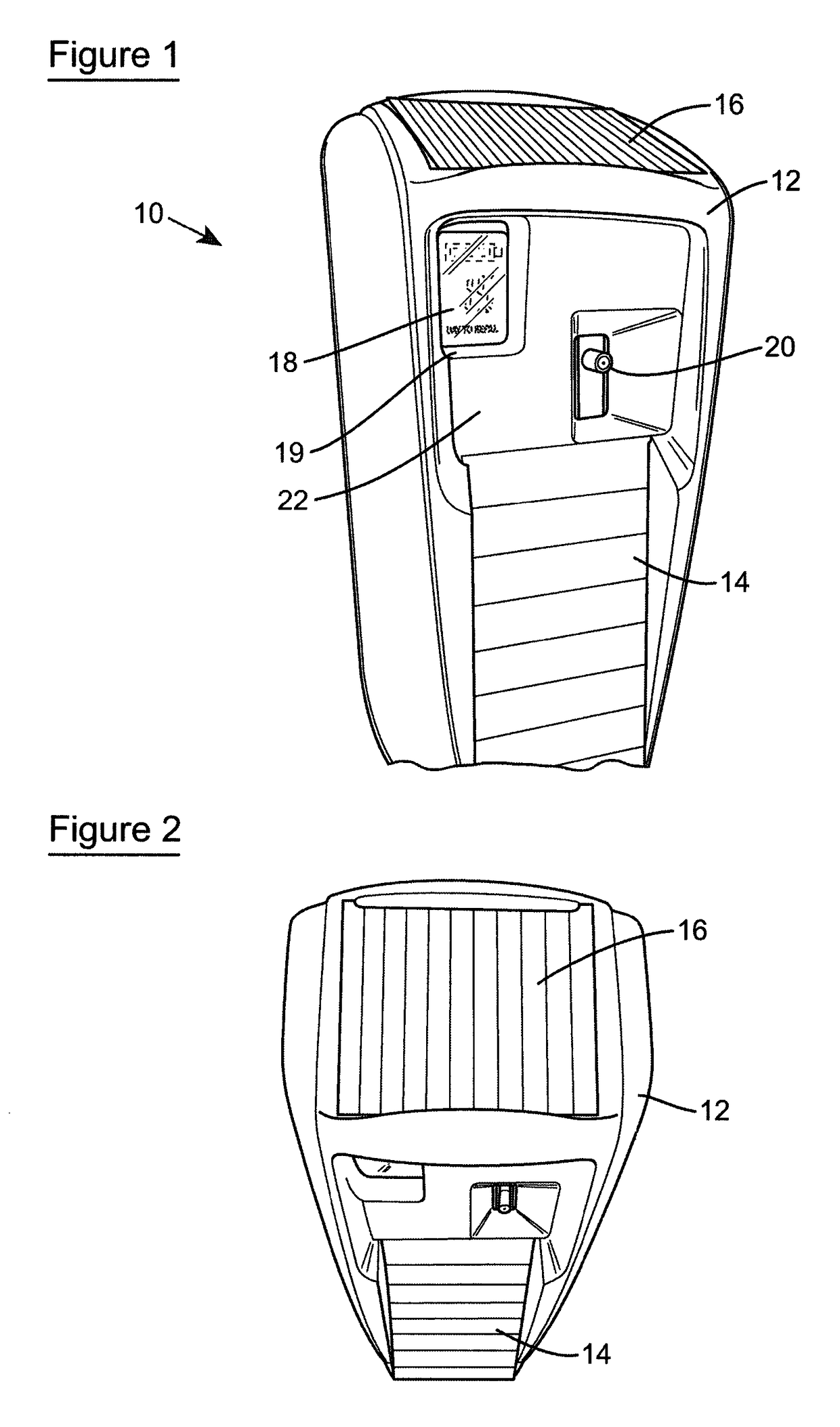

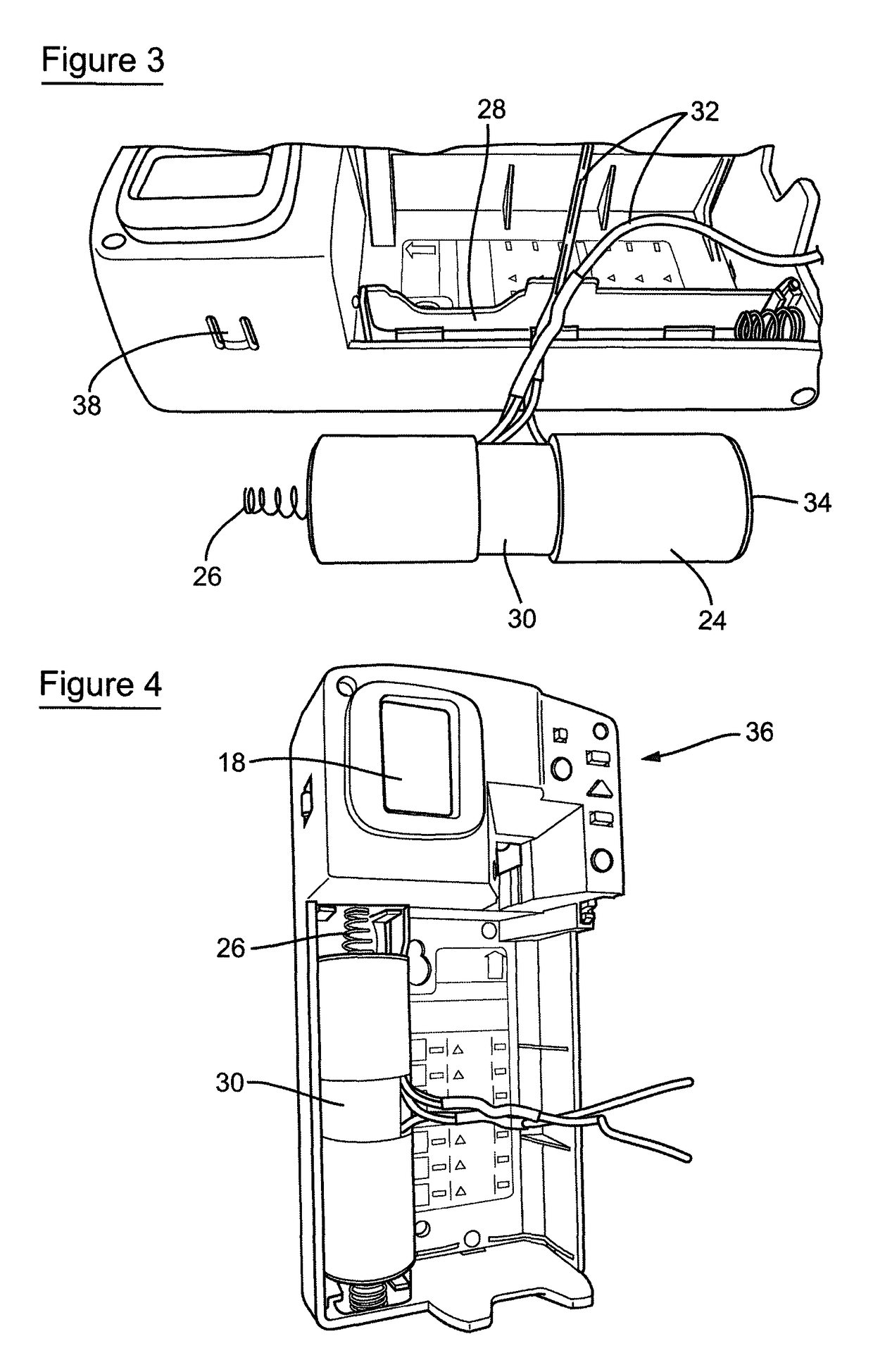

A Kit for Converting a Battery-Powered Automatic Fragrance Sprayer to Solar Power

ActiveUS20160211799A1Quickly and easily upgradedBattery efficiencyDc network circuit arrangementsPhotovoltaicsAmorphous silicon solar cellSprayer

A kit for converting a battery-powered fragrance sprayer of the type described into a solar powered automatic fragrance sprayer for use in an indoor lit area, comprising: a battery pack (24) for fitting into a battery compartment (28) of the fragrance sprayer, the battery pack (24) including a rechargeable nickel-hydride (Ni—Mh) low self-discharge (LSD) battery (30) mounted within a battery casing having positive and negative connection areas (26, 34) at the respective ends for connection with connectors in the battery compartment (28); a replacement outer casing (12) for the fragrance sprayer; at least one tuned amorphous silicon solar panel (14, 16) or at least one dye sensitised solar cell panel (14,16) disposed on the replacement outer casing (12); and cable connection means (32) electrically connecting the at least one tuned amorphous silicon solar panel (14,16) or the at least one dye sensitised solar cell panel (14,16) to the Ni-Mh LSD battery (30) in the battery pack (24).

Owner:RUBBERMAID COMMERCIAL PRODUCTS

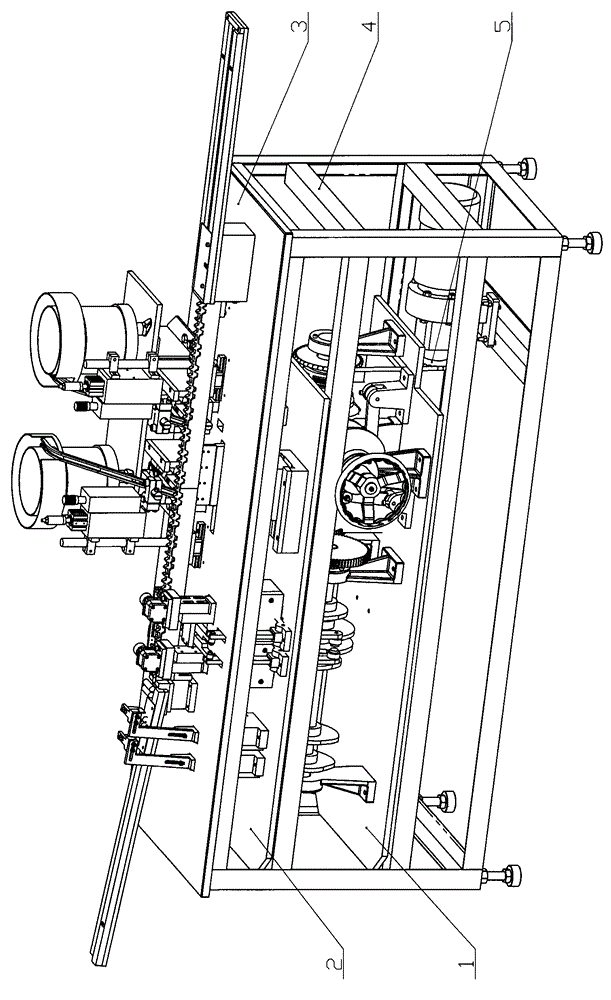

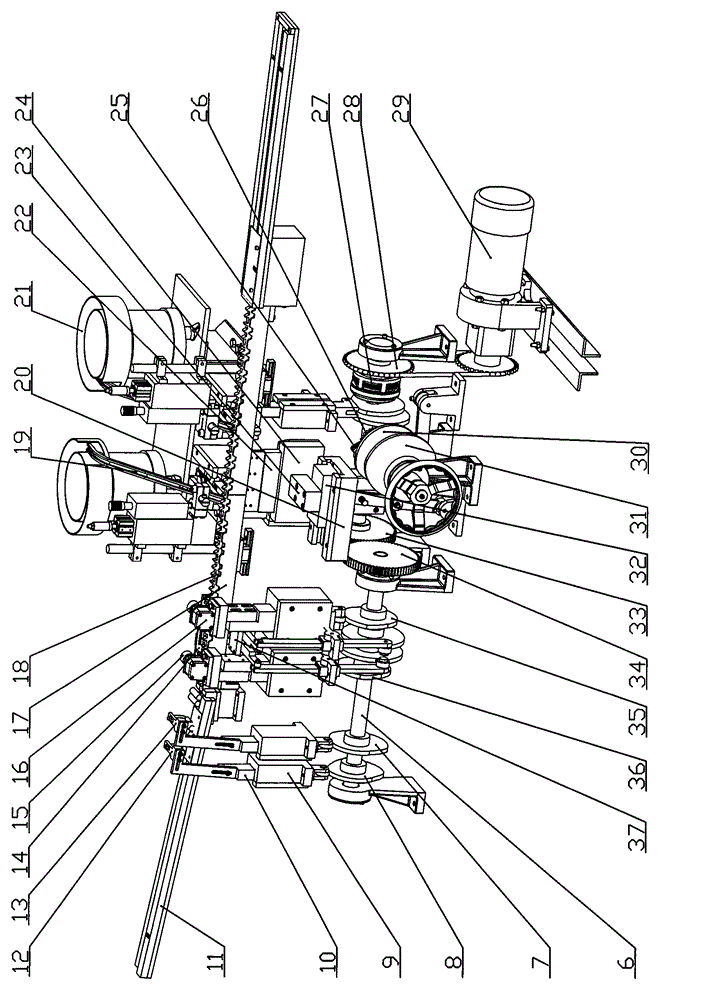

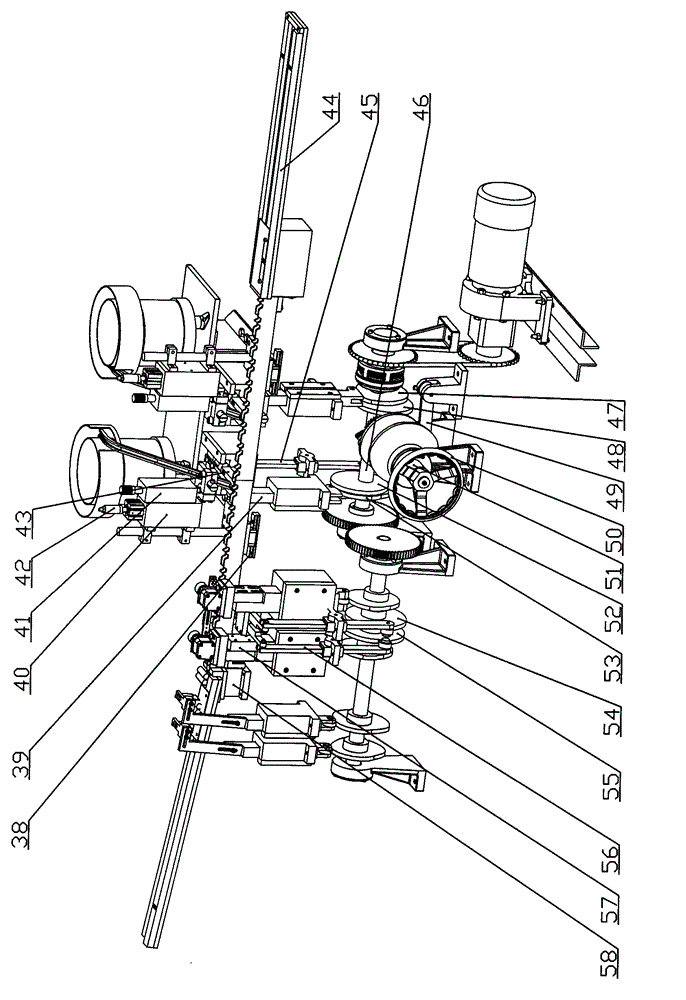

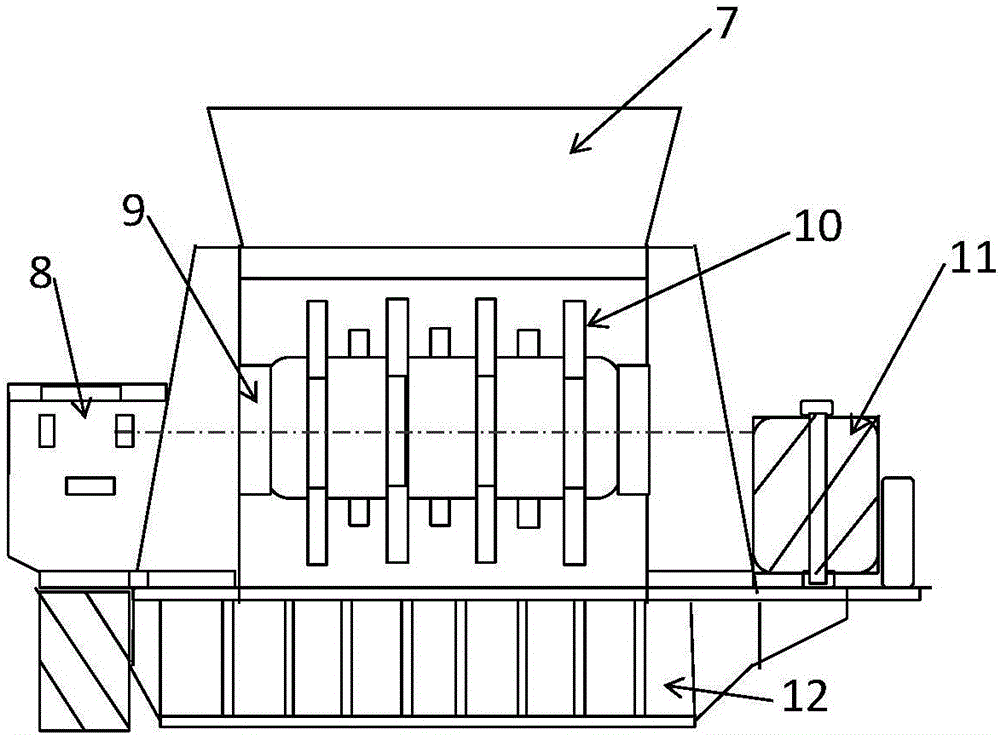

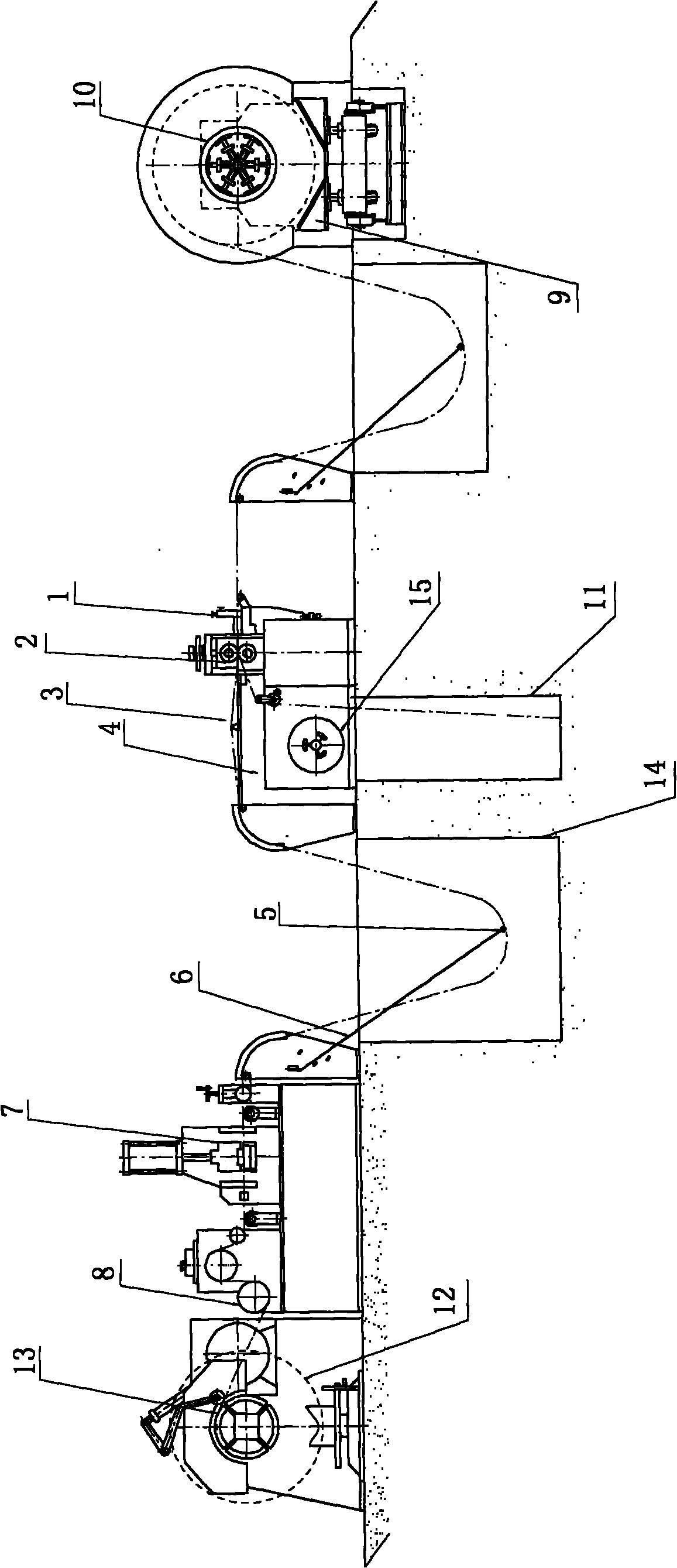

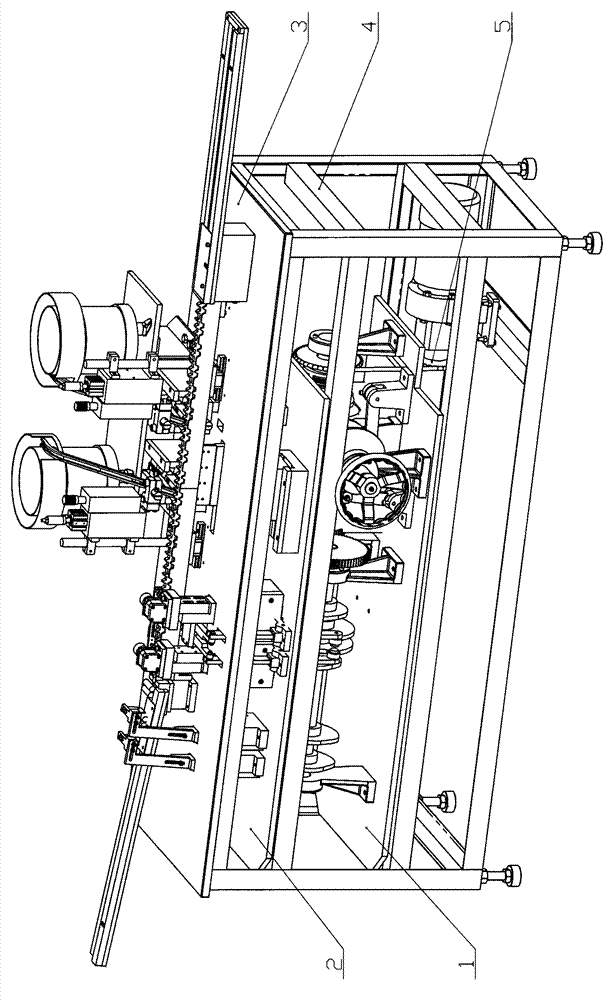

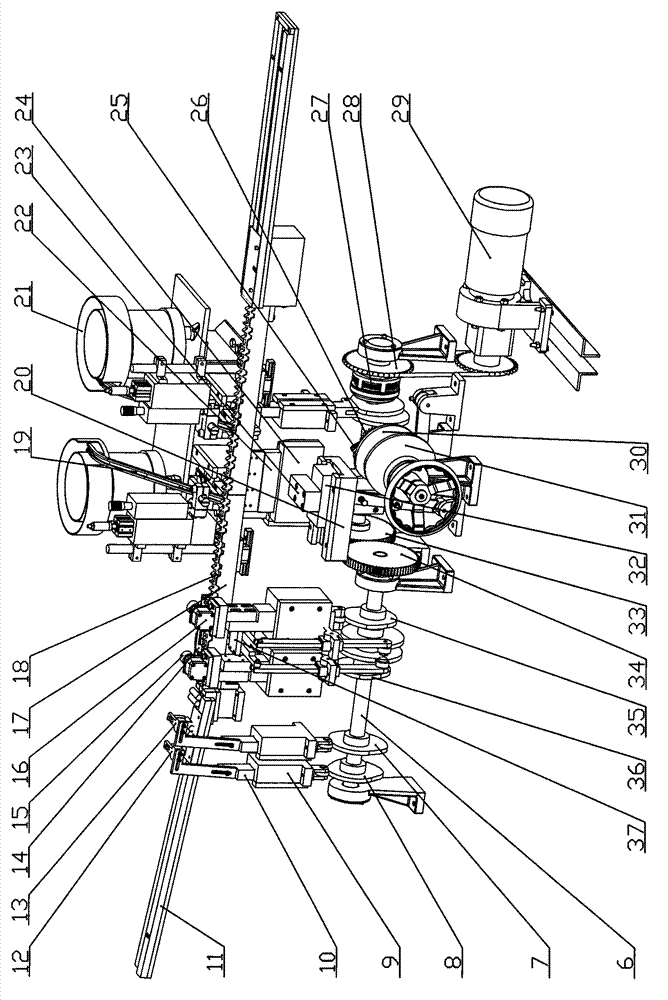

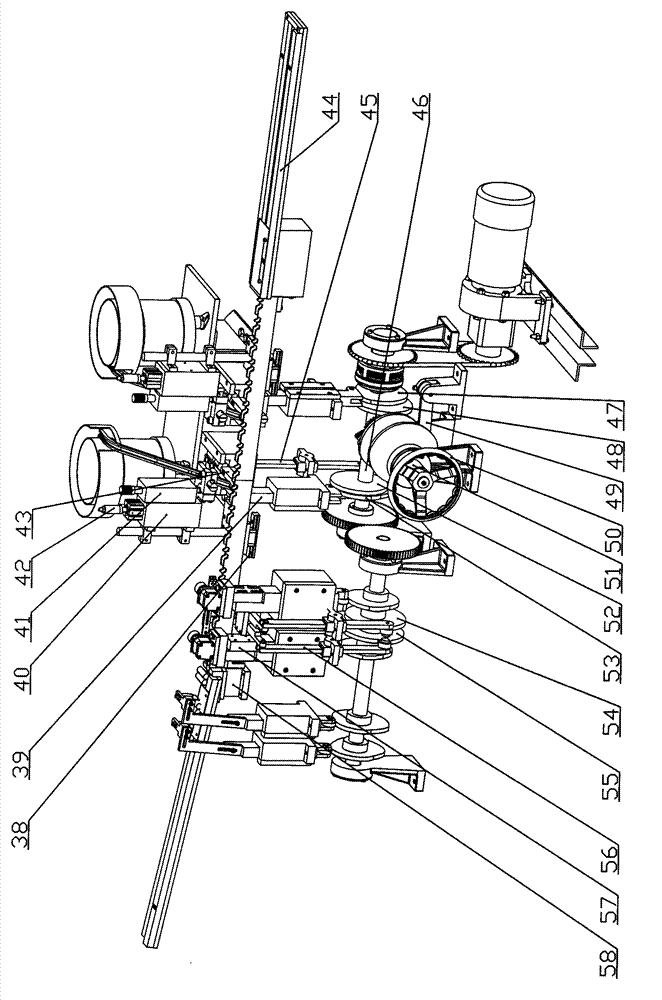

Automatic welding machine for anode cap of nickel hydride/nickel cadmium AA cylindrical battery

InactiveCN102941406ANo harmRealize automatic weldingResistance welding apparatusElectrical batteryNickel cadmium

The invention relates to an automatic welding machine for an anode cap of a nickel hydride / nickel cadmium AA cylindrical battery, which comprises a working table rack, a power mechanism arranged on the rack, a transmission mechanism, a battery feeding mechanism, a battery cap conveying mechanism, a battery direction regulating mechanism, an energy storage welding mechanism and a finished product receiving mechanism. The machine can implement the automatic welding of an anode plate and a battery cap of the nickel hydride / nickel cadmium AA cylindrical battery; the axis contact ratio of the anode plate and the cap is plus and minus 0.05 mm; the automatic welding speed of 80 pieces per minute can be achieved; the yield of one piece of equipment can replace that of 10 operators; particularly, the operator does not need to directly contact heavy metals such as nickel and cadmium; the automatic welding machine has no damage to human bodies, is safe, has no pollution and is efficient, energy-saving and environmental-friendly.

Owner:梧州市奥西力工业自动化有限公司

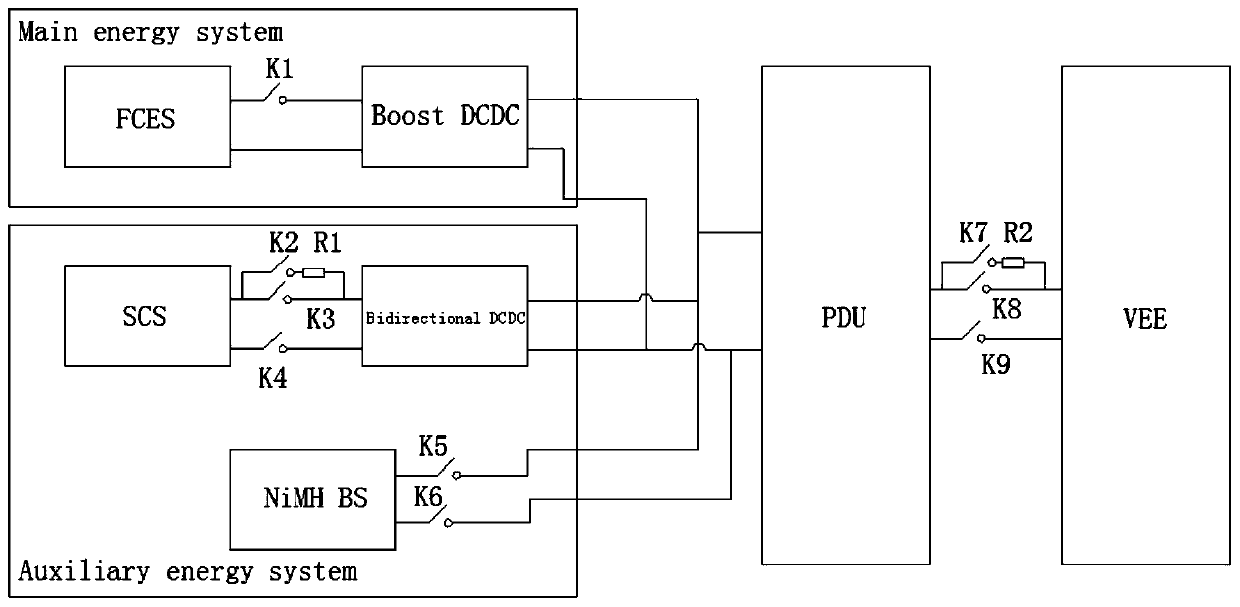

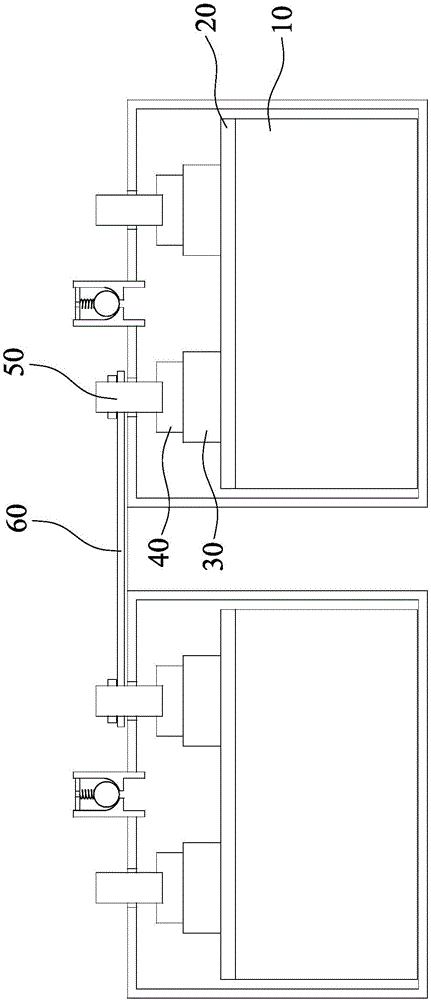

Auxiliary energy system of hydrogen fuel cell vehicle

InactiveCN110103733AOptimize auxiliary energy architectureNot to break downPropulsion by capacitorsPropulsion by batteries/cellsCapacitanceElectrical battery

The invention discloses an auxiliary energy system of a hydrogen fuel cell vehicle, and relates to the technical field of auxiliary energy systems of hydrogen fuel cell vehicles. The auxiliary energysystem specifically comprises a main energy system, an auxiliary energy system body, a power distribution unit (PDU) and vehicle electric equipment (VEE); the main energy system comprises a fuel cellengine system (FCES) and a boost DCDC; and the auxiliary energy system body comprises a super-capacitor system (SCS), a bidirectional DCDC and a nickel hydride battery system (NiMH BS). According to the auxiliary energy system of the hydrogen fuel cell vehicle, an auxiliary energy framework is optimized, the system structure is a multi-structure, the super-capacitor energy system and the nickel hydride battery energy system are included and make good for deficiency, and thus the whole auxiliary energy system can meet normal work of the vehicle under any operating condition.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

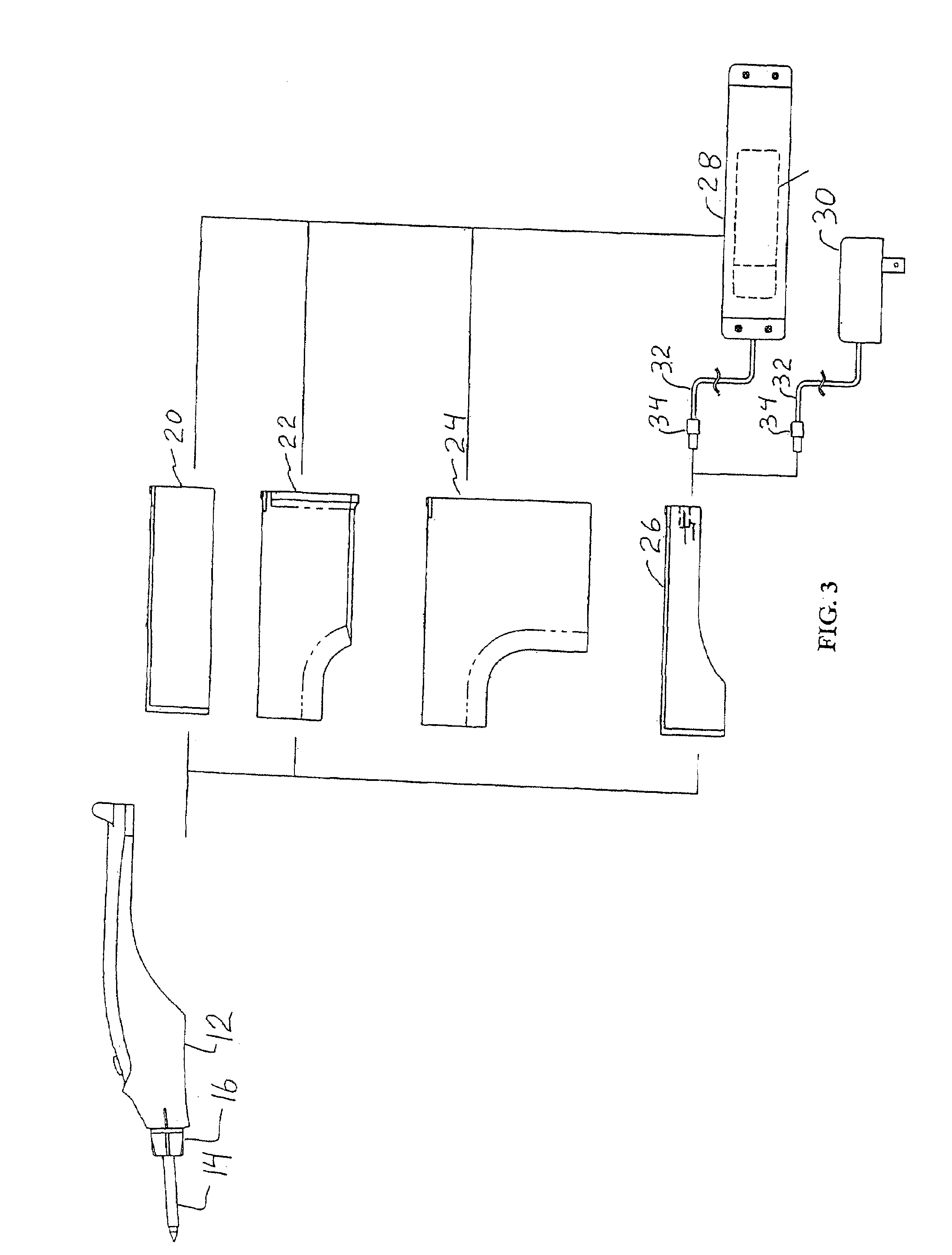

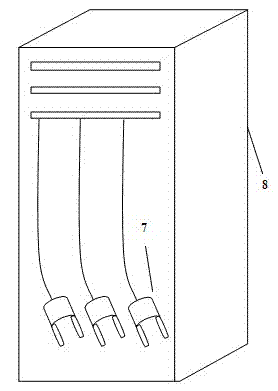

Soldering Device with Cartridge Type Battery Pac

A method of configuring a soldering device includes the steps of purchasing (or offering for sale) a soldering device package including a handle, a power cartridge containing an AA battery, a power cartridge containing a lithium ion battery, and a power cartridge containing a nickel-hydride battery; selecting (or instructing a user to select) one of the three power cartridges from the purchased soldering device package for use with the handle to form a soldering device; and inserting the selected power cartridge in the handle to form a soldering device. The selecting step includes selecting one of the three power cartridges based on a specific use of the soldering device and based on soldering performance requirements of the specific use and based on operating times and relative costs of the power cartridges.

Owner:MIYAZAKI MITSUHIKO +3

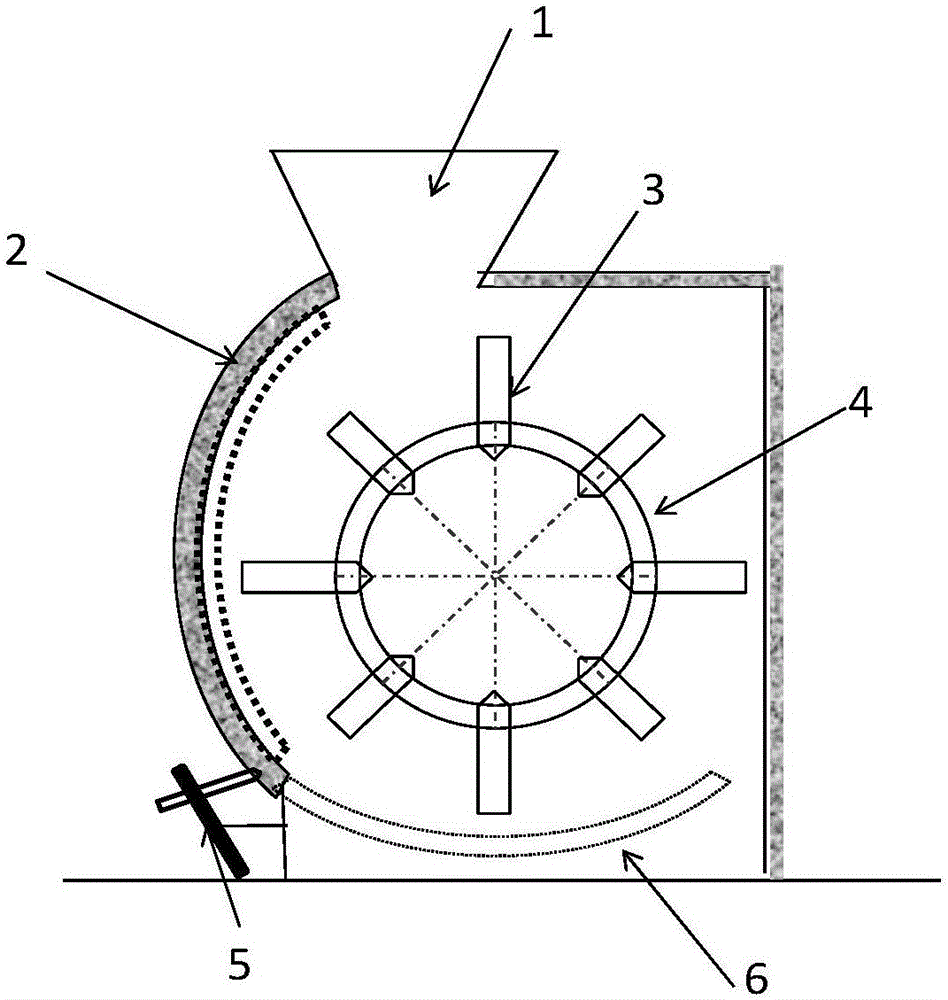

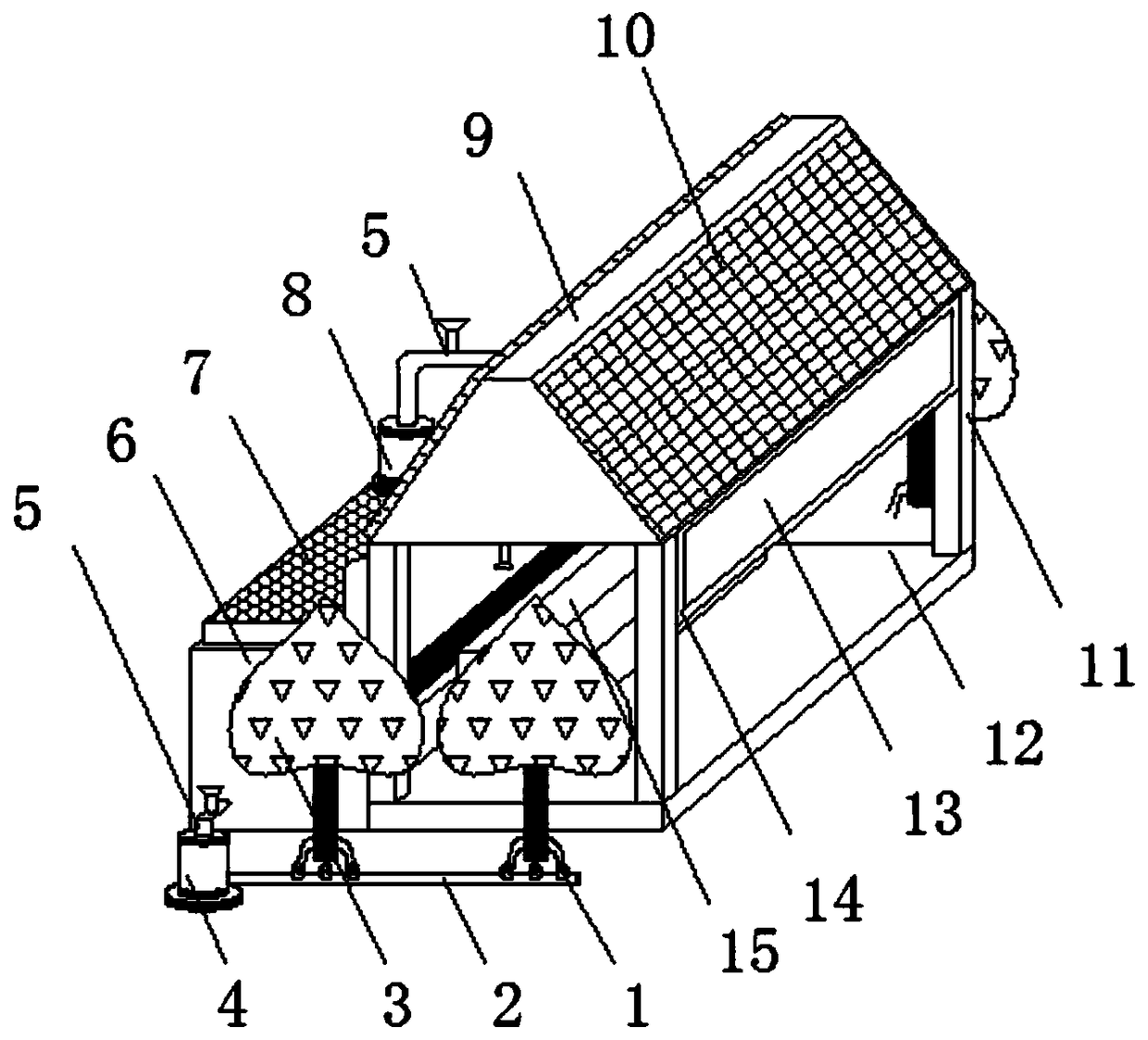

Smashing device of waste nickel-hydride power battery

InactiveCN106252775ASolve the problem of mechanized rapid crushingImprove crushing efficiencyWaste accumulators reclaimingBattery recyclingPower batteryEngineering

The invention discloses a smashing device of a waste nickel-hydride power battery. The smashing device comprises a feeding port, a cutter, a rolling shaft, a discharge port switch, a sieve screen, a control room, an electric motor and a crushed aggregate bin, wherein the waste nickel-hydride power battery of which a shell is disassembled enters the interior of the smashing device through the feeding port, the cutter is arranged in the smashing device, the transmitted waste nickel-hydride power battery is cut and smashed by means of high-speed rotation of the cutter, the cutter is fixed on the rolling shaft, the rolling shaft is connected with the control room and the electric motor, the rotational speed of the rolling shaft is controlled by the control chamber and the electric motor so as to control the cutting speed of the cutter, crushed aggregate smashed by the cutter enters the aggregate bin through a discharge port. By the device, the problem mechanical and rapid smashing of the waste nickel-hydride power battery can be solved, the smashing efficiency is improved, and the working benefit is enhanced.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

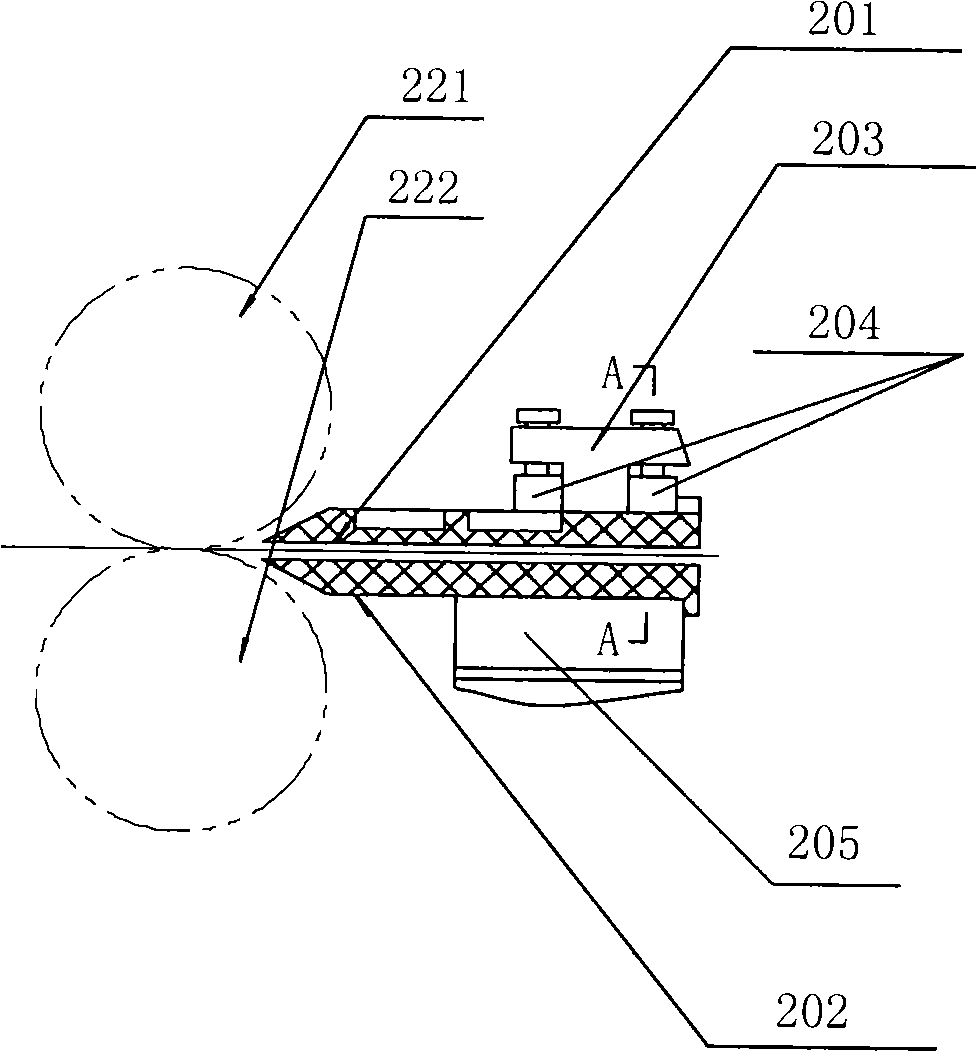

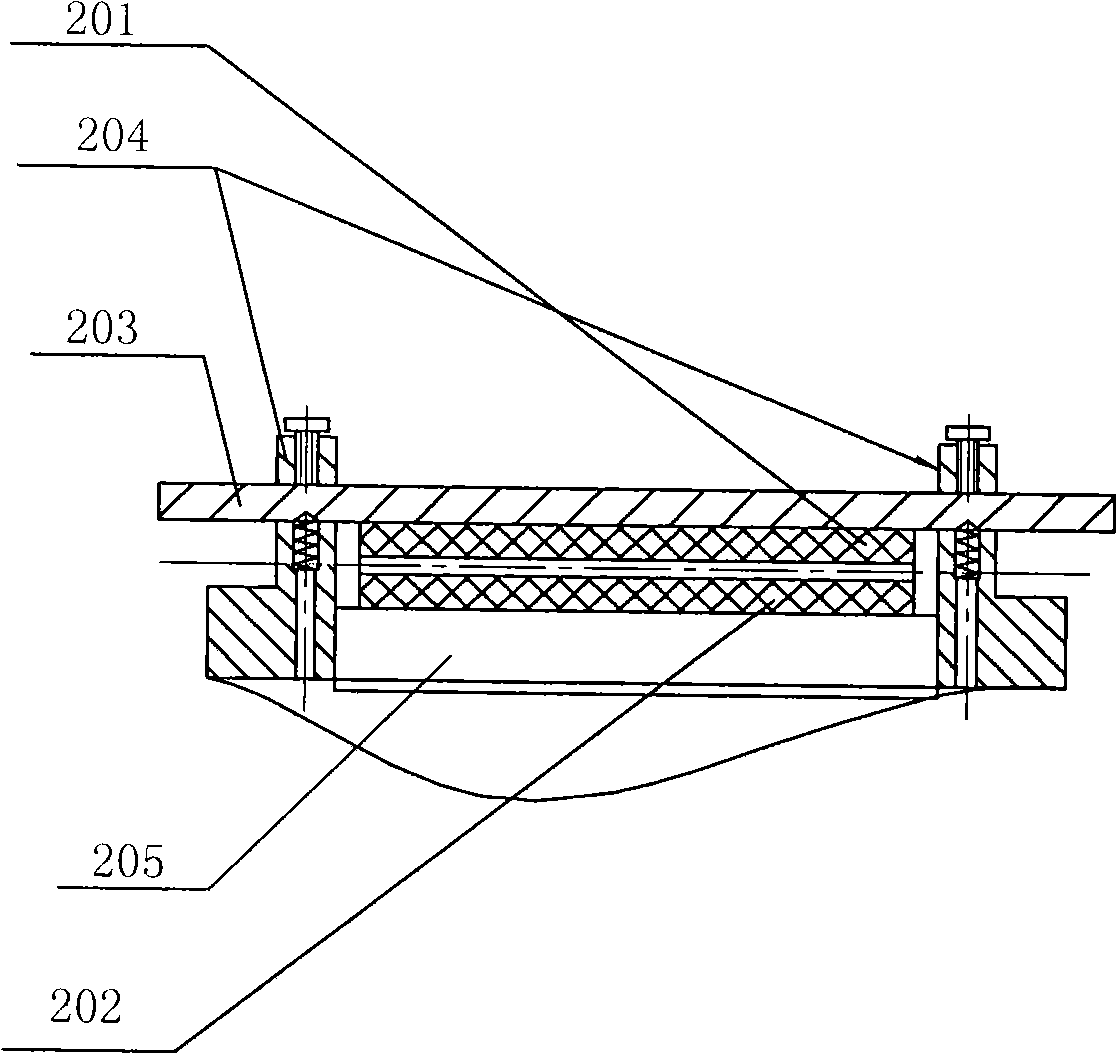

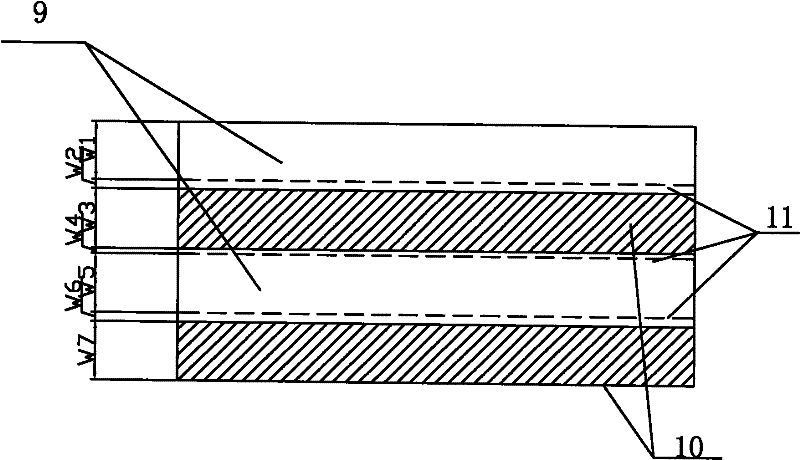

Shearing machine for substrate strip for manufacturing nickel-hydride battery cathode

ActiveCN102009222ASimple structureSimplified shearing processShearing machinesShearing machine accessoriesElectric controlMaterial transfer

The invention discloses a shearing machine for a substrate strip for manufacturing a nickel-hydride battery cathode, comprising: an uncoiler, a material transfer plate, a slitting mill, a side material coiling machine, a tension table, a crimping machine, a hydraulic station, a hydraulic oil cylinder, an electrical box and an electric control cabinet; a material guide device on the slitting mill is formed by matching of an upper guide plate and a lower guide plate, which are made of special materials and have special shape; a rolling shear on the slitting mill is composed of an upper hob and a lower hob, which are both cylindrical, the lower hob is provided with a ring-shaped opening groove matched with the upper hob, and depth of cut formed by matching of the upper hob and the lower hop is not less than 0.2mm. By cooperation of the uncoiler and the material guide device of a shearing device with the specially structured rolling shear, the side material coiling machine and the crimping machine, the shearing machine can shear an ultra-thin steel strip for manufacturing the nickel-hydride battery cathode, wherein thickness of the ultra-thin steel strip is not more than 0.035mm, so that shearing precisions of camber, width error, burr, flatness and the like all meet requirements, and the shearing machine has simple structure and simplified shearing technology.

Owner:赵新岩 +1

Accumulator system

InactiveUS20150280285A1Improve functionalityIncreased durabilityPrimary cell to battery groupingLead-acid accumulatorsElectrical batteryEngineering

In the storage battery system, from the same temperature and the same voltage as both batteries a decrease per day of an open-circuit voltage of the lead-acid storage battery by a self-discharge is ΔV1(V / day) and a decrease per day of an open-circuit voltage of the sub-battery by a self-discharge is ΔV2(V / day), and a relation of ΔV1≧ΔV2 is satisfied. The sub-battery is a nickel hydride storage battery.

Owner:SANYO ELECTRIC CO LTD +2

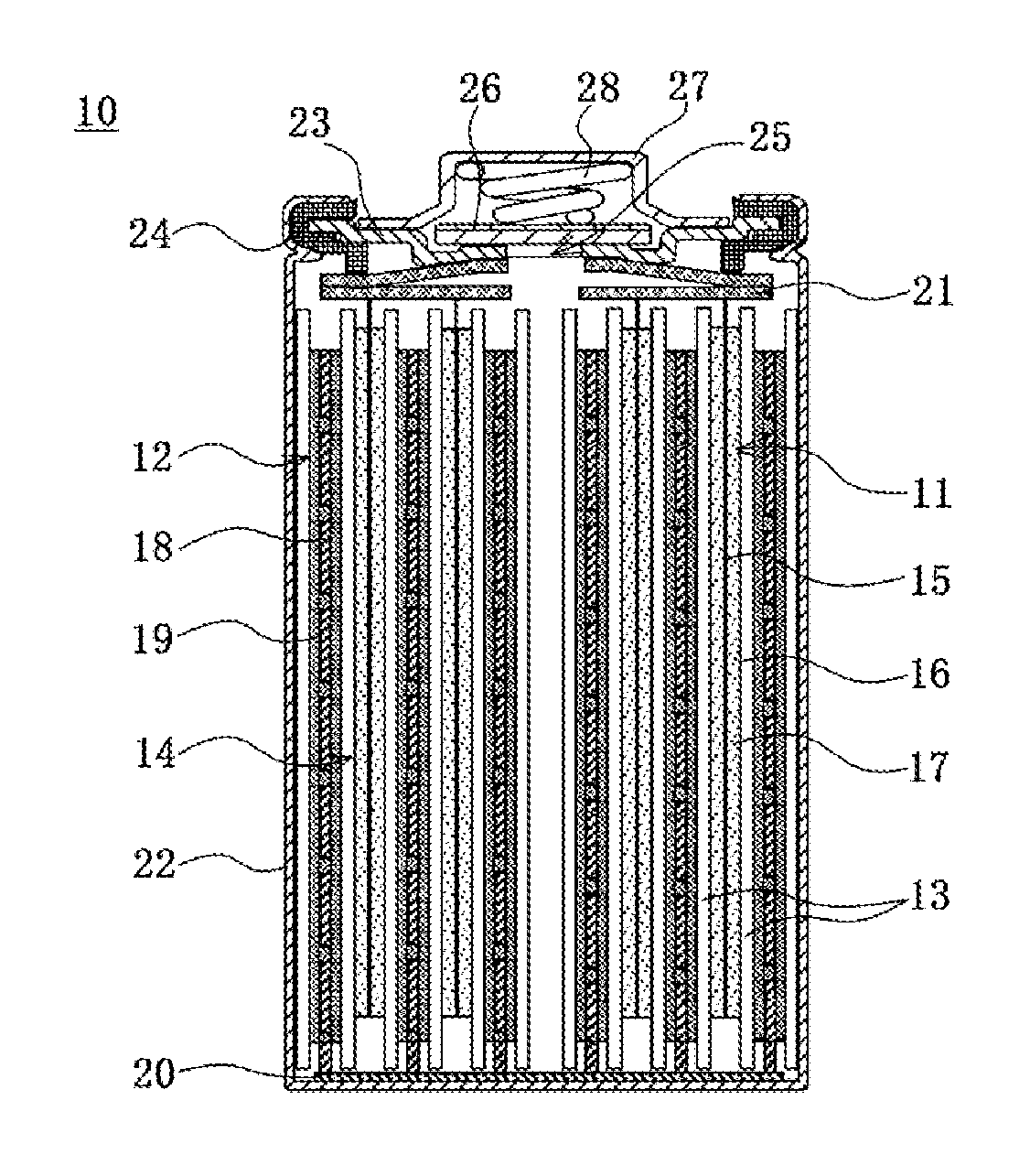

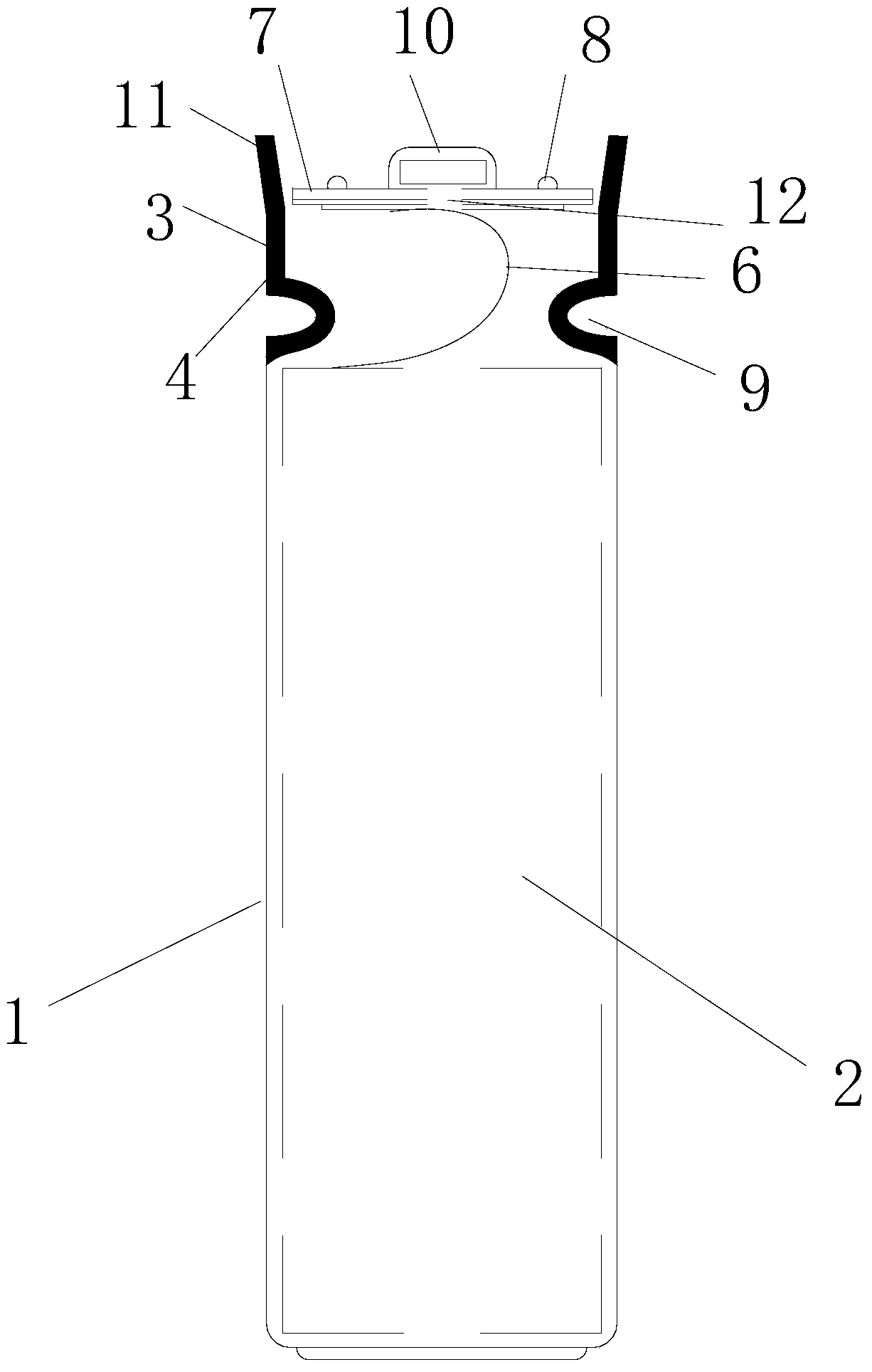

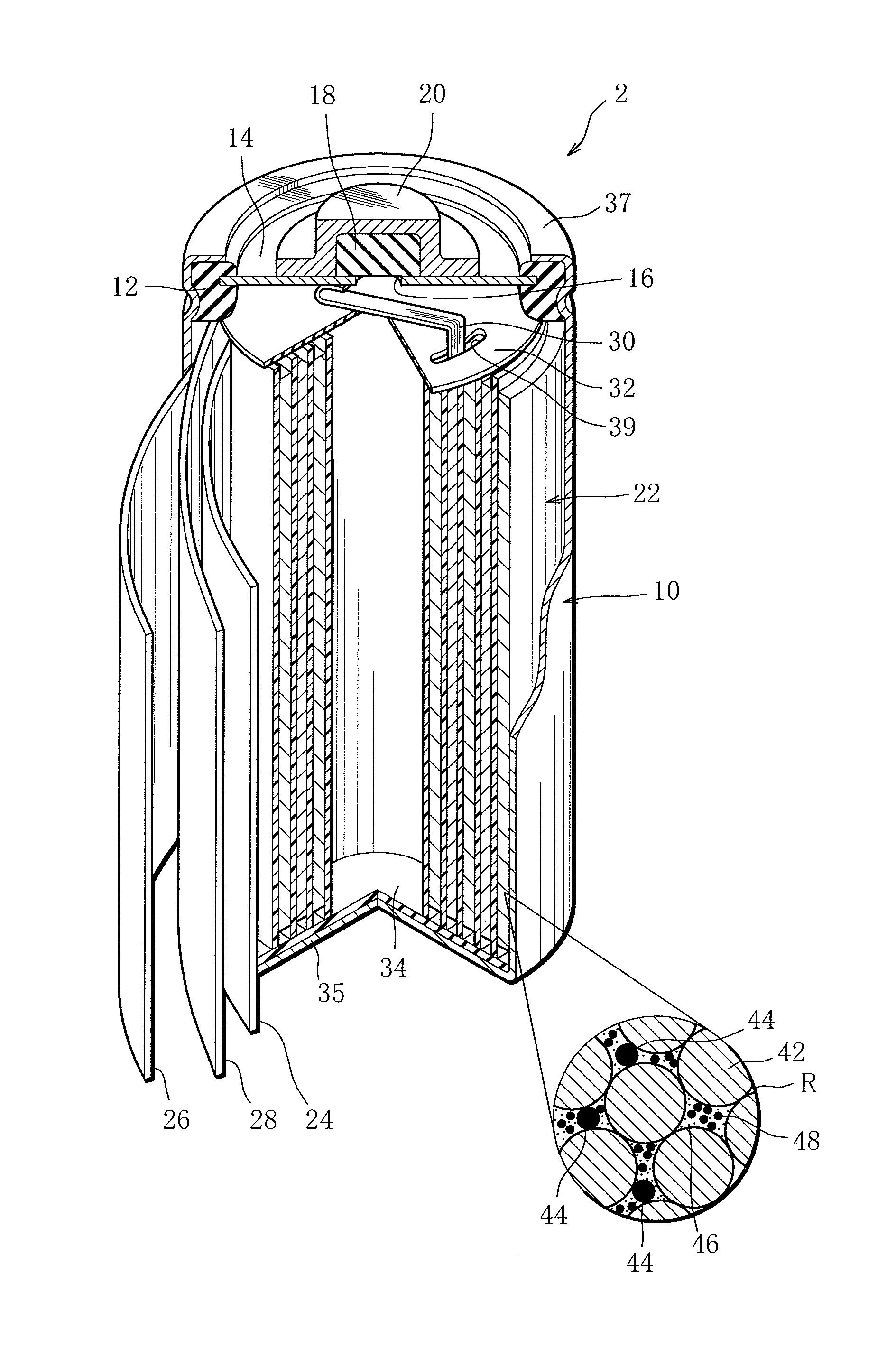

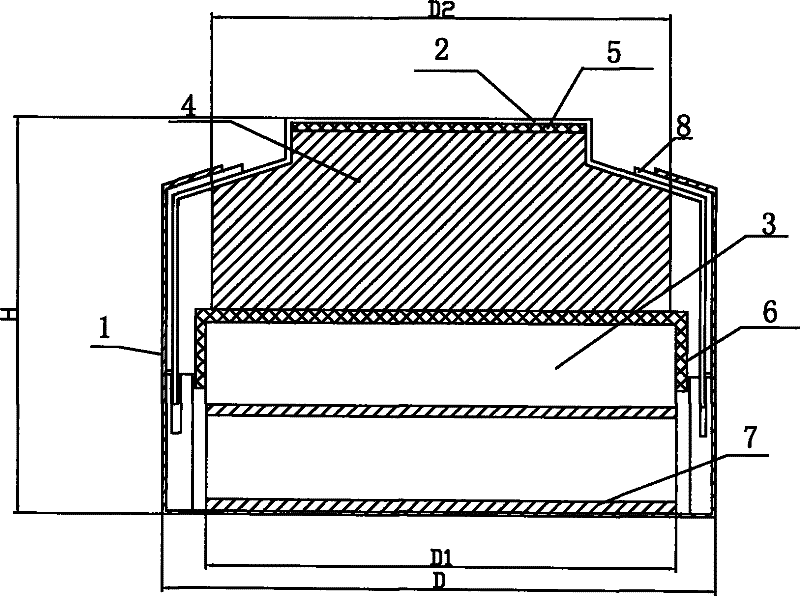

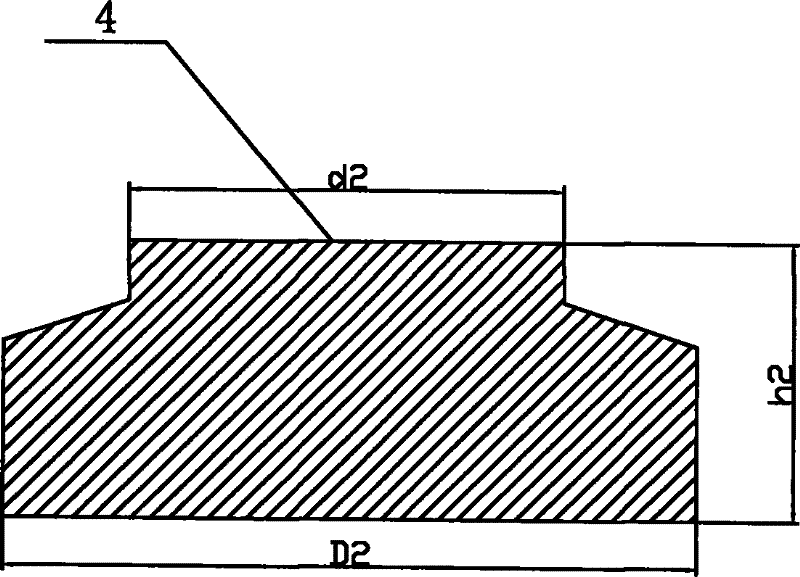

Preparation method of nickel hydride battery and nickel hydride battery product

InactiveCN104362264AReduce production processIncrease productivityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFilm-coated tablet

The invention discloses a preparation method of a nickel hydride battery. The preparation method is characterized by comprising the following steps: (1) preparing a cylindrical shell with an opening at the top end and a battery core; (2) coating the inner wall of the opening of the cylindrical shell with an insulating wet film; (3) installing the battery core into the shell, pitting at the insulating coating by a pitting machine, fixing the battery core, adding electrolyte, uniformly redistributing the insulating wet film coating on the inner wall of the deformed shell at the moment, and further curing to form a dense insulating wet film layer; (4) preparing a battery top cover, fixing the battery top cover to obtain the nickel hydride battery. The invention further provides a nickel hydride battery product prepared by the preparation method. The nickel hydride battery product comprises the cylindrical shell and the battery core; the inner wall of the opening of the cylindrical shell is coated with the insulating coating. An insulating meson is not required to be added additionally, so that preparation processes and components of the battery are reduced, the production efficiency and the product quality of the battery are improved and the production cost of the battery is reduced.

Owner:HUIZHOU SHIDAI BATTERY

Long-service-life high-temperature battery formation method

ActiveCN108808127ASolving activityResolution cycleFinal product manufactureAlkaline accumulators manufactureEngineeringBiological activation

The invention discloses a long-service-life high-temperature battery formation method. The long-service-life high-temperature battery formation method comprises the following steps: I, manufacturing an anode; II, manufacturing a cathode; III, performing assembly; IV, implementing a pre-charging process; V, forming. The long-service-life high-temperature battery formation method has the beneficialeffects that the problems of incomplete activation, long formation period, short cycle life, high liquid-leakage rate, high alkaline electrolyte creepage rate and high rejection rate in a nickel hydride high-temperature battery are solved, and the aims of lowering the production cost, increasing equipment utilization rate and enhancing battery performance are fulfilled.

Owner:HENGYANG BST POWER

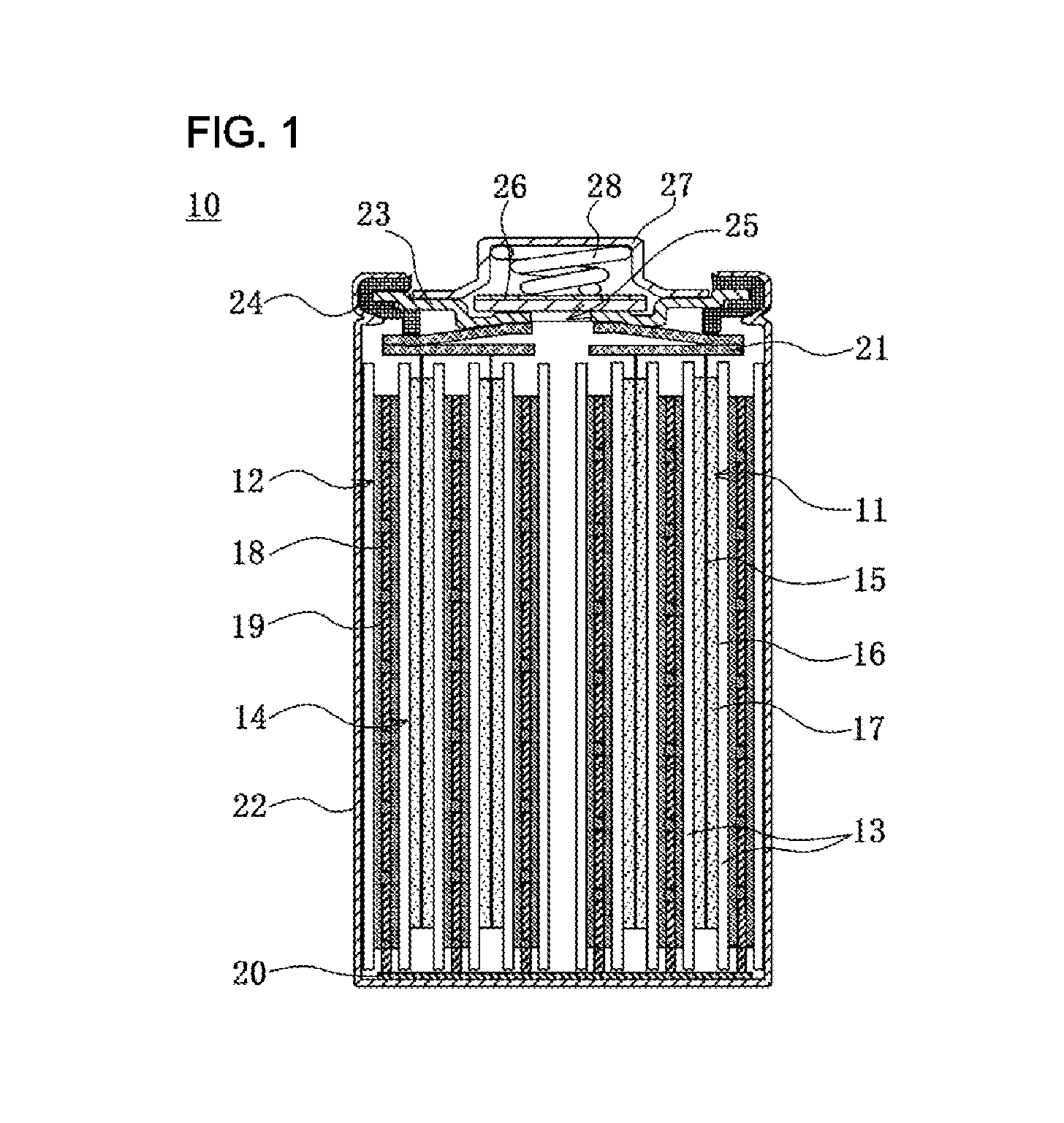

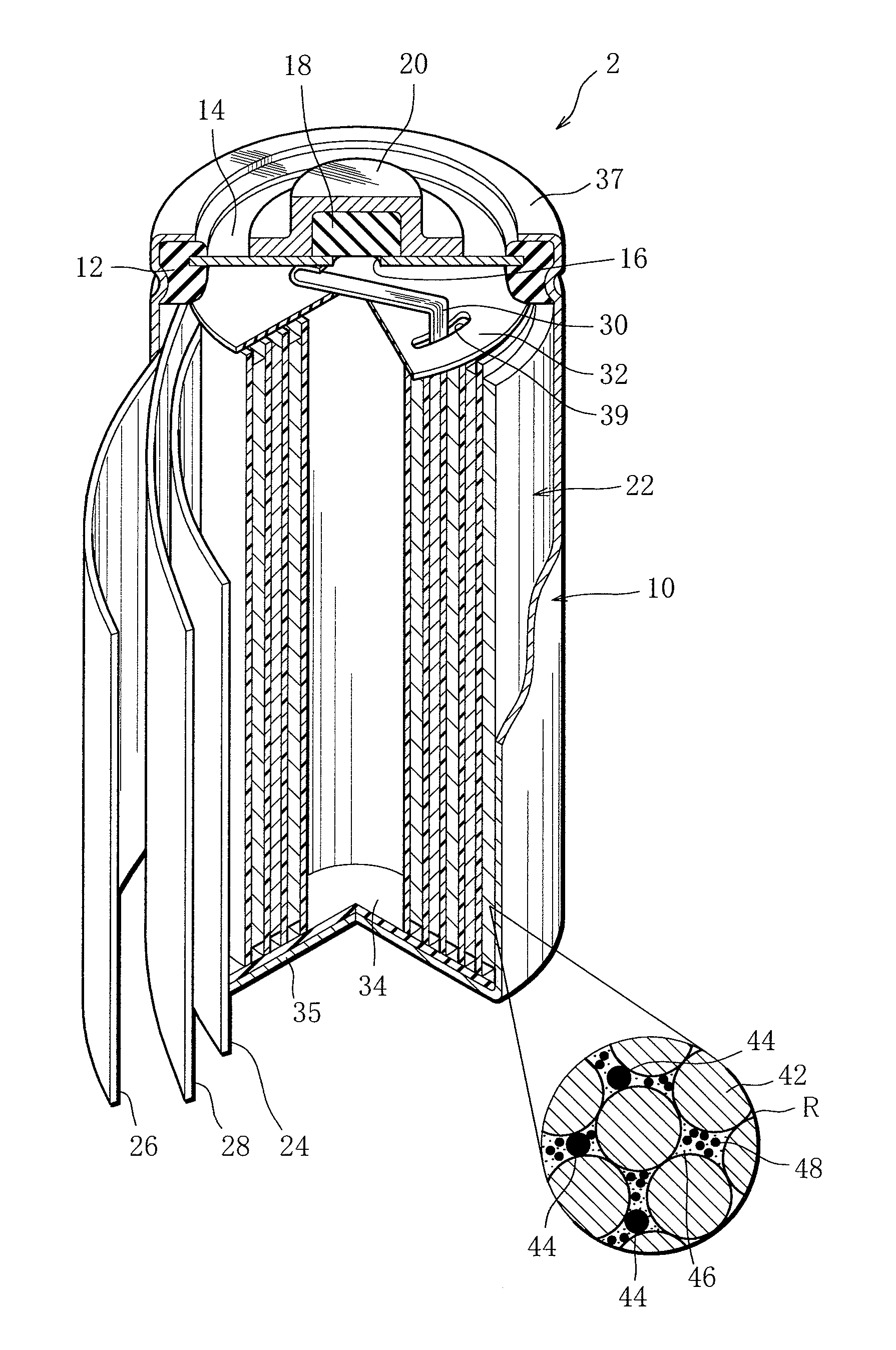

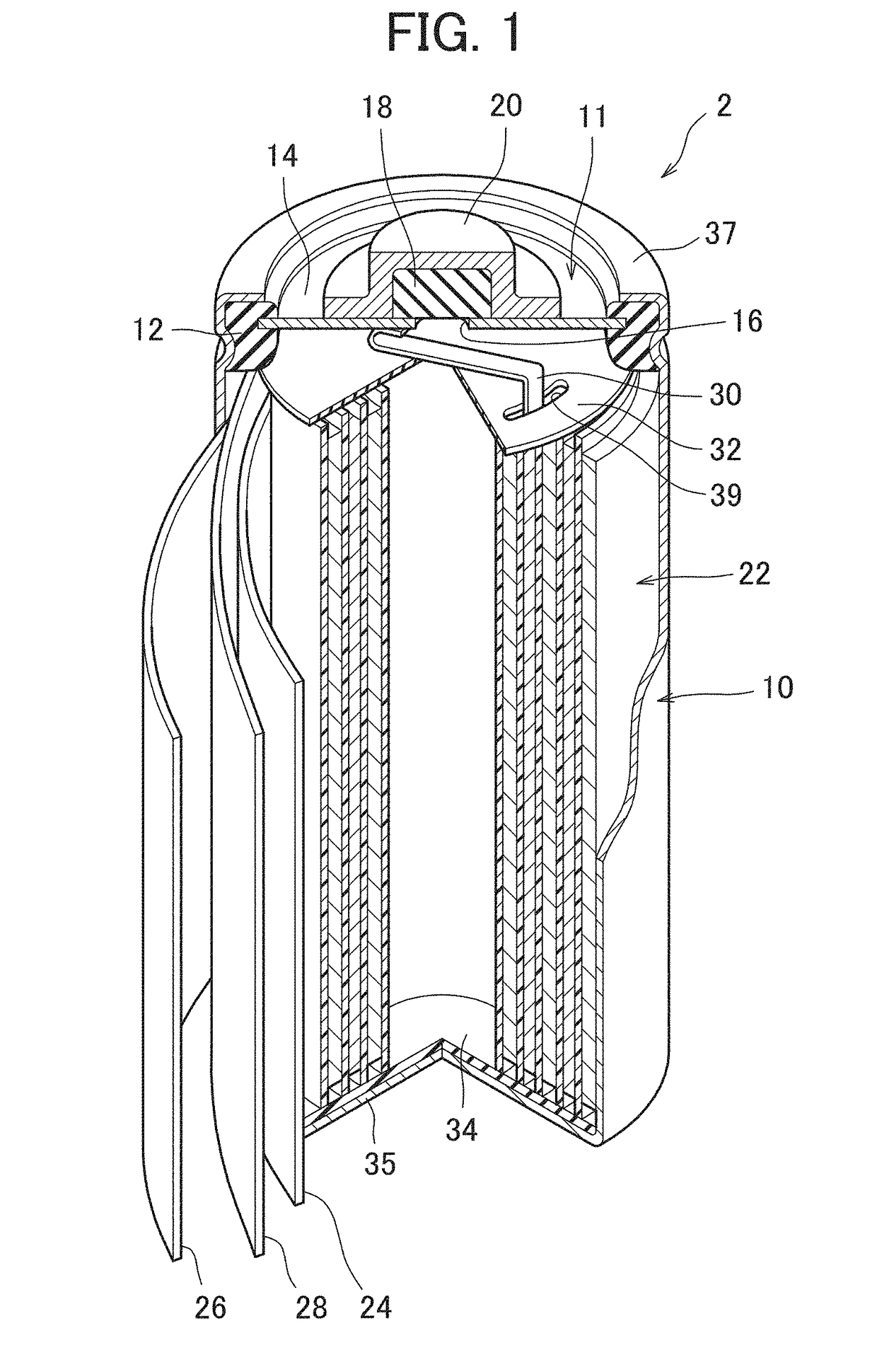

Nickel hydride secondary battery

ActiveUS20140120411A1Optimizing slurry viscosityFunction increaseHydrogenFinal product manufactureCalcium sulfideConductive materials

A nickel hydride secondary battery houses an electrode group including a positive electrode and a negative electrode which are overlapped with each other via a separator with an alkaline electrolyte solution, the negative electrode includes a hydrogen absorbing alloy, a negative-electrode additive agent, a thickening agent, and a conductive material, and the negative-electrode additive agent includes at least one selected from calcium fluoride, calcium sulfide, and calcium chloride.

Owner:FDK CORP

Magnesium base hydride composite system for hydrolysis hydrogen production and preparation method and application thereof

InactiveCN101811667BSimple processEase of industrial mass productionAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen productionCombustionGraphite

The invention discloses a magnesium base hydride composite system for hydrolysis hydrogen production and a preparation method and application thereof. The composite system is prepared by a method comprising the following steps of: taking magnesium powder and nickel powder in a mole ratio of 30:1-49:1; performing hydrogenation combustion synthesis under the action of a catalyst and an organic dispersant which account for 3 to 10 percent of the total weight of the mixture of the magnesium powder and the nickel powder; and performing strong mechanical ball milling. The magnesium hydride in the prepared magnesium base hydride composite system for the hydrolysis hydrogen production accounts for 95 to 98 percent of the weight of hydride, and the magnesium nickel hydride accounts for 2 to 5 percent; the catalyst is one of graphite, B, Al, La, Ca, V, Ce and Nb; the magnesium hydride is MgH2; and the magnesium nickel hydride is a mixture of Mg2NiH4 and Mg2NiH0.3 in any ratio. The theoretical hydrogen production amount of the composite system is up to 1,600 ml / g, and a preparation process of the magnesium base hydride composite system is time-saving, energy-saving and simple and is easy forindustrial production.

Owner:NANJING TECH UNIV

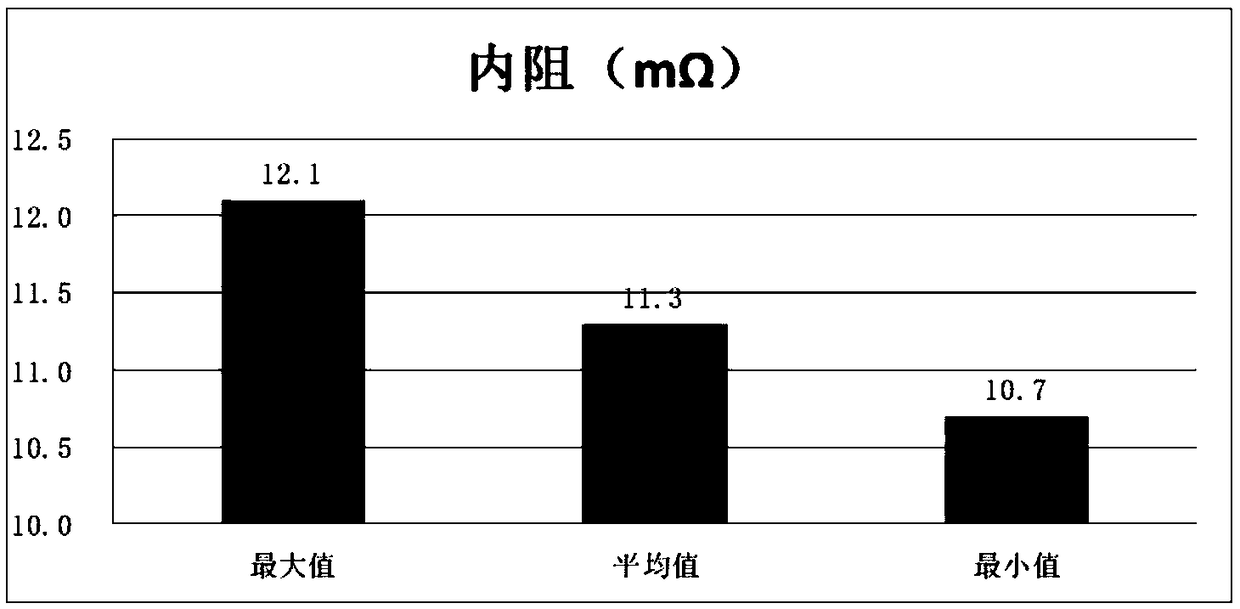

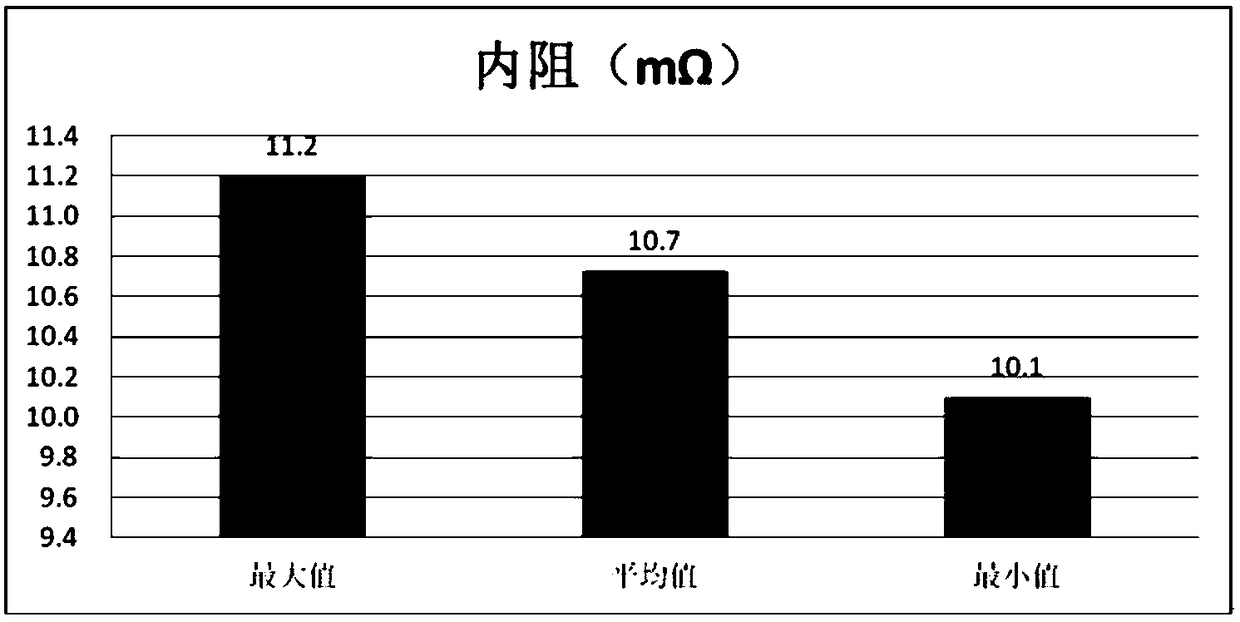

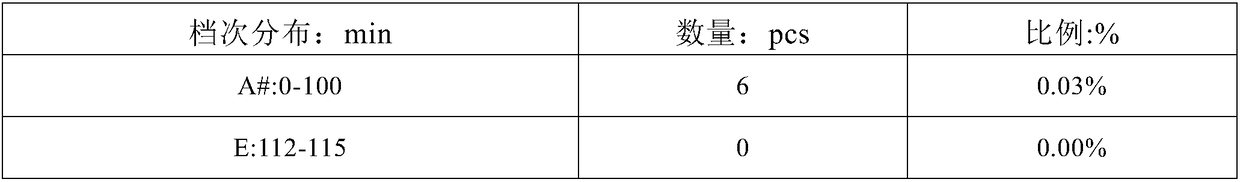

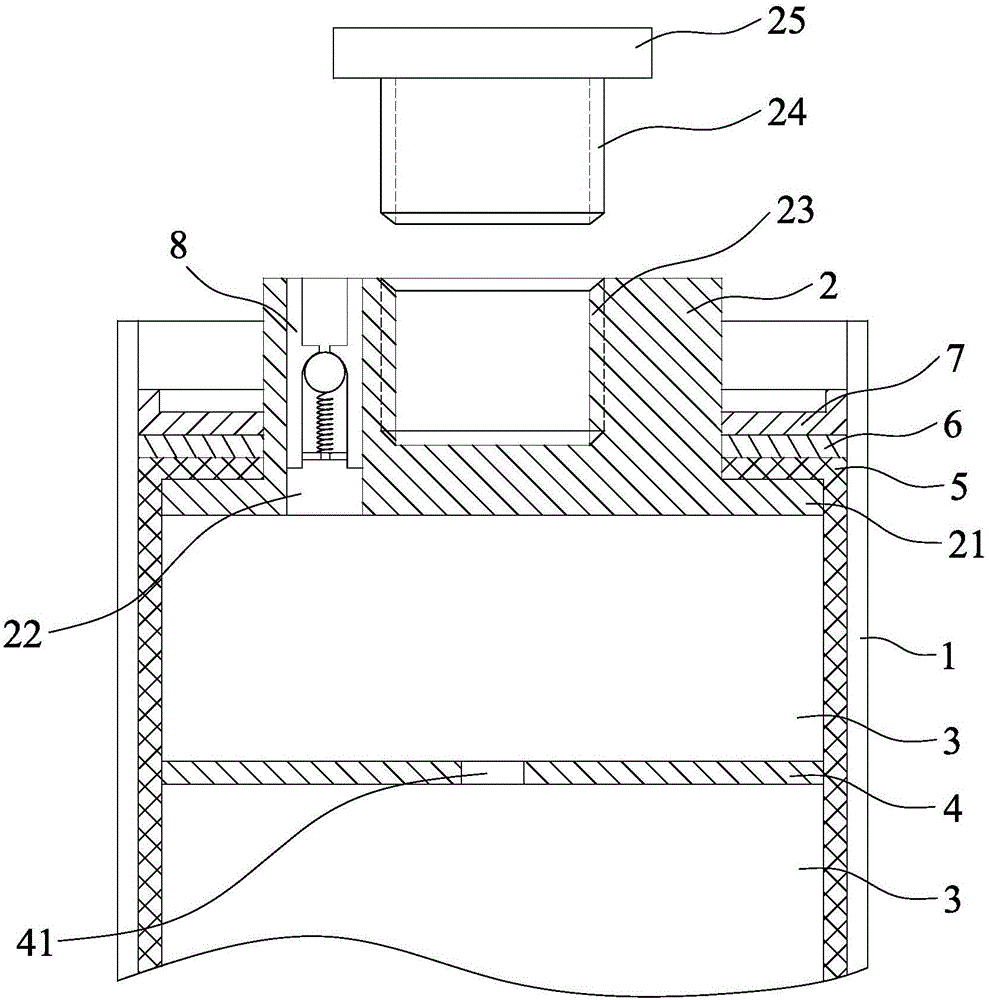

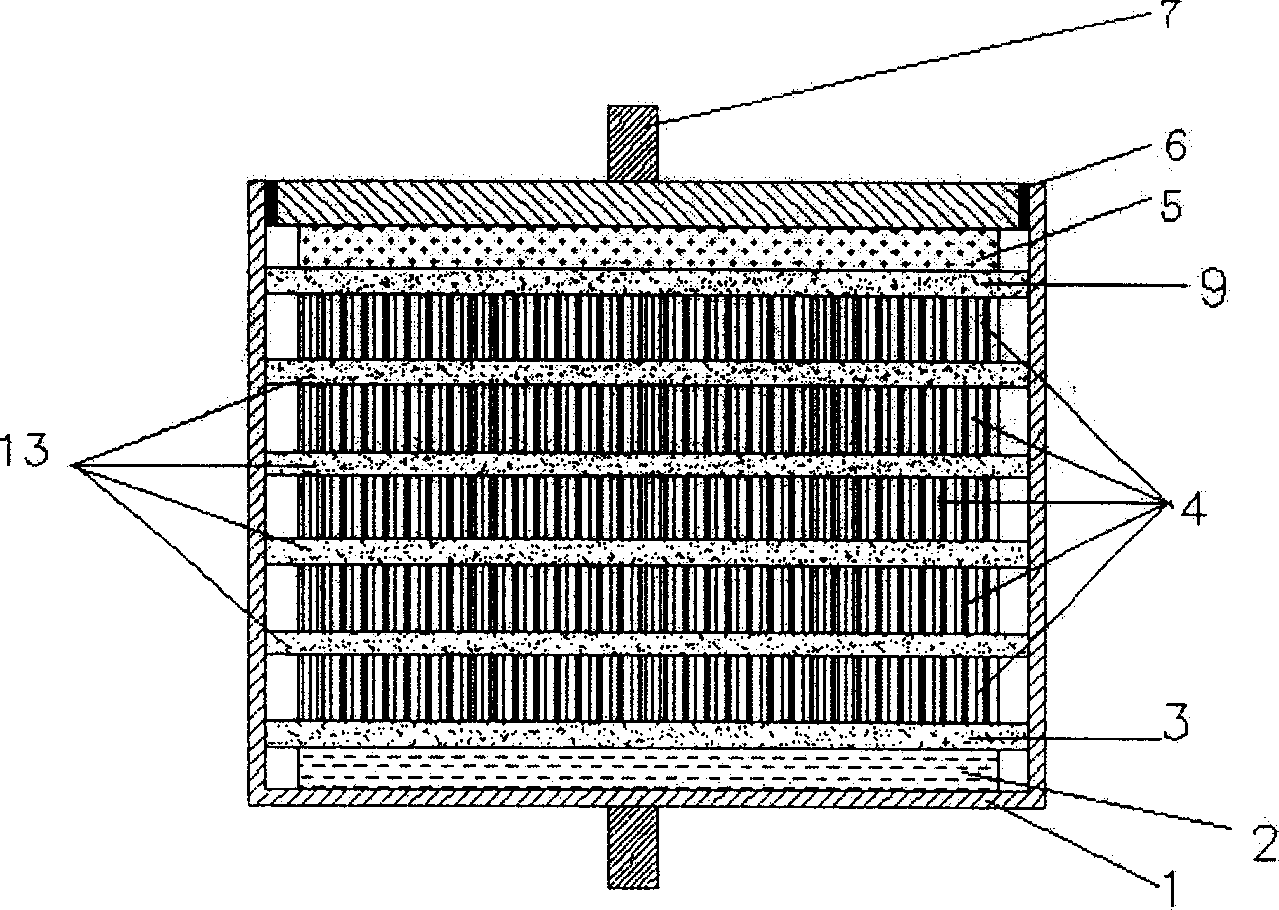

Square nickel hydride battery

InactiveCN106025392ALower internal resistanceClose electrical contactCell component detailsNickel accumulatorsInternal resistanceBusbar

The invention discloses a square nickel hydride battery. The square nickel hydride battery comprises a square shell, electrode busbars, conductive plates and more than two single power cores, wherein the more than two single power cores are successively placed in the square shell; each two adjacent single power cores are isolated from each other by the corresponding conductive plate; a communicating hole is formed in each conductive plate, so that the single power cores are communicated with one another and share electrolyte; each single power core comprises a plurality of positive plates, a plurality of negative plates and a continuous folded diaphragm; the positive plates and the negative plates of each single power core are respectively placed on two sides of the corresponding continuous folded diaphragm and are isolated from each other completely; the positive plates of each single power core are isolated from one another by wrinkles of the corresponding continuous folded diaphragm; the negative plates of each single power core are also isolated from one another by the wrinkles of the corresponding continuous folded diaphragm; after partially extending out of the corresponding continuous folded diaphragm, the positive plates and the negative plates of each single power core are in close contact with the corresponding conductive plate, so that the single power cores are serially connected with one another; the electrode busbars are respectively mounted at two ends of the square shell. The composition structure of the conventional battery is changed to greatly reduce internal resistance of the battery.

Owner:卞超英

Nickel hydride secondary battery

ActiveUS9343742B2Reduce the valueImprove featuresHydrogenFinal product manufactureCalcium sulfideConductive materials

Owner:FDK CORP

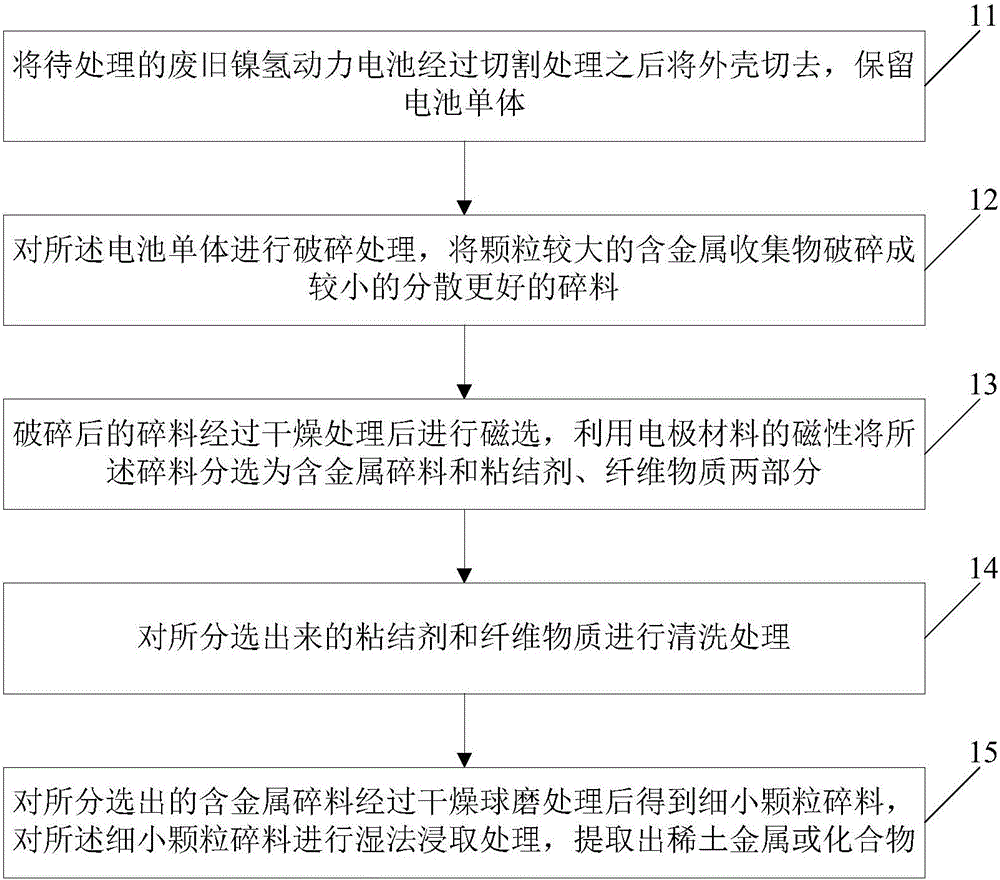

Recycle processing method of waste nickel-hydride power battery

InactiveCN106252774AHarm reductionImprove recycling ratesWaste accumulators reclaimingBattery recyclingFiberRare-earth element

The invention discloses a recycle processing method of a waste nickel-hydride power battery. The recycle processing method comprises the following steps of cutting a shell after the waste nickel-hydride power battery to be processed is cut, and reserving a single battery; smashing the single battery, and smashing a metal-containing collection substance with relatively large particles to relatively small and highly-dispersed crushed aggregates; performing magnetic separation after drying the smashed crushed aggregates, separating the crushed aggregates to two parts of metal-containing crushed aggregates and a binding agent / fiber substance by means of magnetism of an electrode material; cleaning the separated binding agent and the fiber substance; and drying and ball-grinding the separated metal-containing crushed aggregates to obtain fine particle crushed aggregates, performing wet immersion on the fine particle crushed aggregates, and extracting a rare-earth element or a compound. By the method, the harm of the waste nickel-hydride power battery to an ecological environment can be reduced, and the recycle rate of resources is effectively improved.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

Kit for converting a battery-powered automatic fragrance sprayer to solar power

ActiveUS9819305B2Quickly and easily upgradedBattery efficiencyPhotovoltaicsEnergy storageAmorphous silicon solar cellSprayer

A kit for converting a battery-powered fragrance sprayer of the type described into a solar powered automatic fragrance sprayer for use in an indoor lit area, comprising: a battery pack (24) for fitting into a battery compartment (28) of the fragrance sprayer, the battery pack (24) including a rechargeable nickel-hydride (Ni-Mh) low self-discharge (LSD) battery (30) mounted within a battery casing having positive and negative connection areas (26, 34) at the respective ends for connection with connectors in the battery compartment (28); a replacement outer casing (12) for the fragrance sprayer; at least one tuned amorphous silicon solar panel (14, 16) or at least one dye sensitized solar cell panel (14,16) disposed on the replacement outer casing (12); and cable connection means (32) electrically connecting the at least one tuned amorphous silicon solar panel (14,16) or the at least one dye sensitized solar cell panel (14,16) to the Ni-Mh LSD battery (30) in the battery pack (24).

Owner:RUBBERMAID COMMERCIAL PRODUCTS

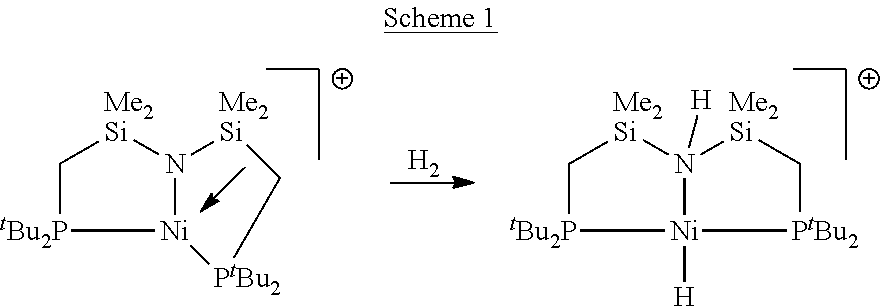

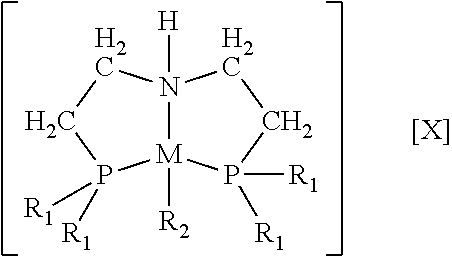

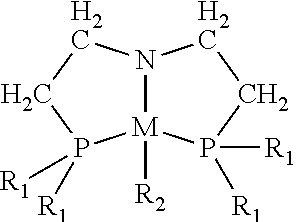

Catalytic hydrogenation using complexes of base metals with tridentate ligands

Owner:TRIAD NAT SECURITY LLC

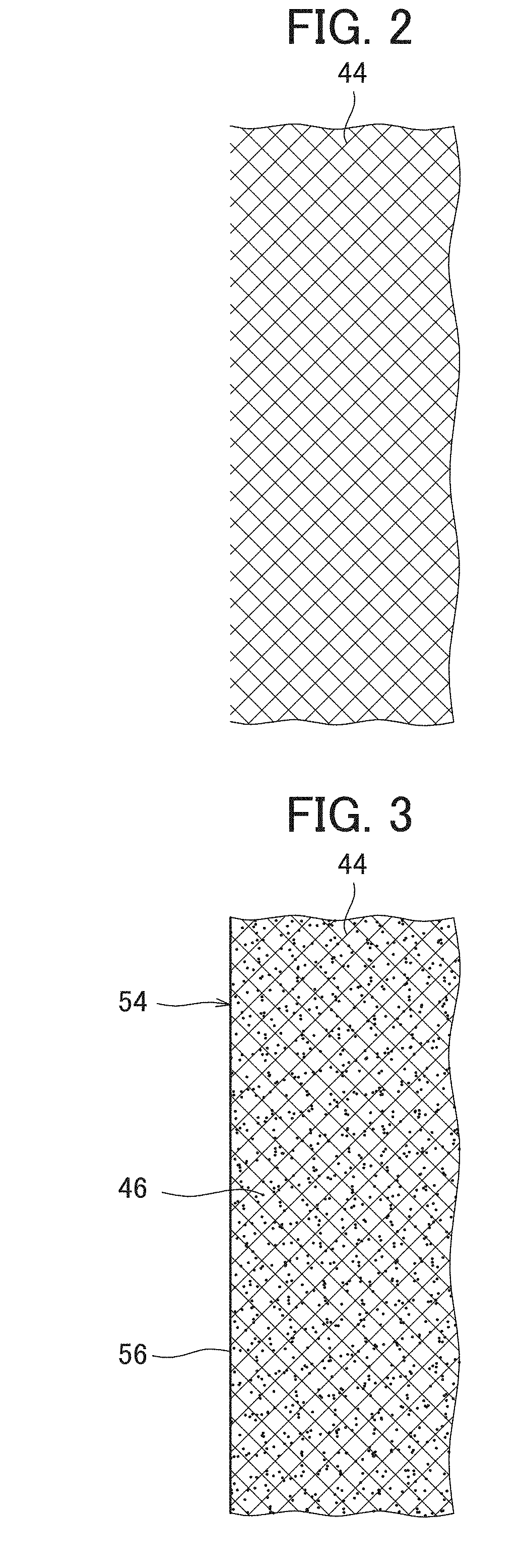

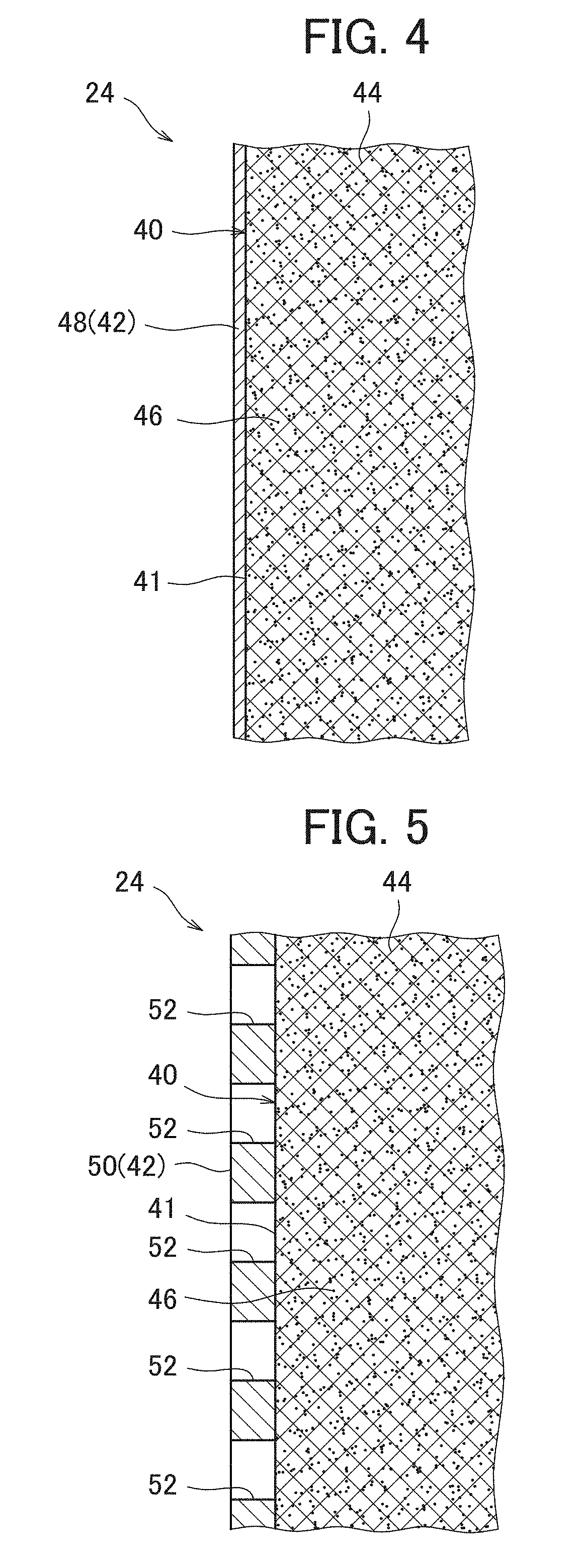

Non-sintered positive electrode for alkaline secondary battery and alkaline secondary battery including non-sintered positive electrode

InactiveUS20180358609A1Charge acceptabilityInhibit swellingElectrode carriers/collectorsPositive electrodesNickel hydrideNickel

A nickel hydride secondary battery includes an electrode group including a separator, a positive electrode and a negative electrode. The positive electrode includes a positive electrode body including a positive electrode core member and a positive electrode mixture that is filled in the positive electrode core member, and a surface layer existing on a surface part of the positive electrode body. The positive electrode mixture contains nickel hydroxide as a positive electrode active material, and the surface layer contains nickel.

Owner:FDK CORP

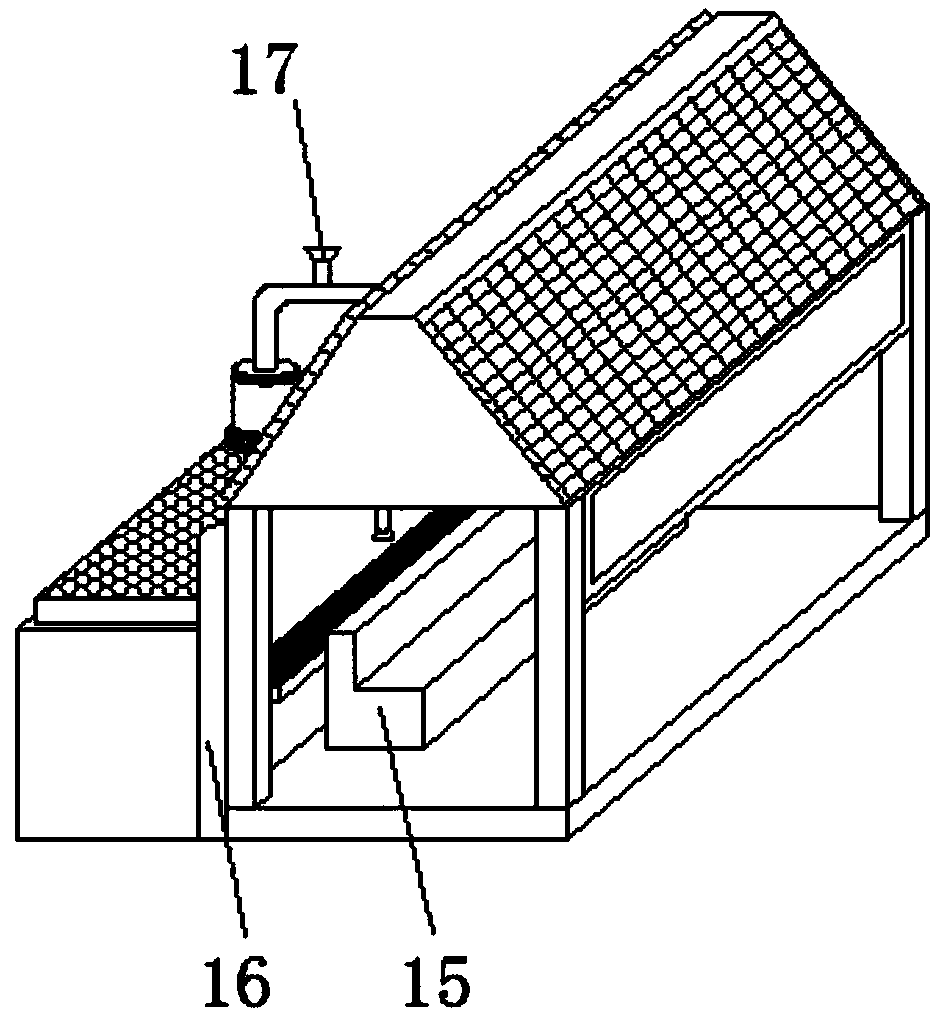

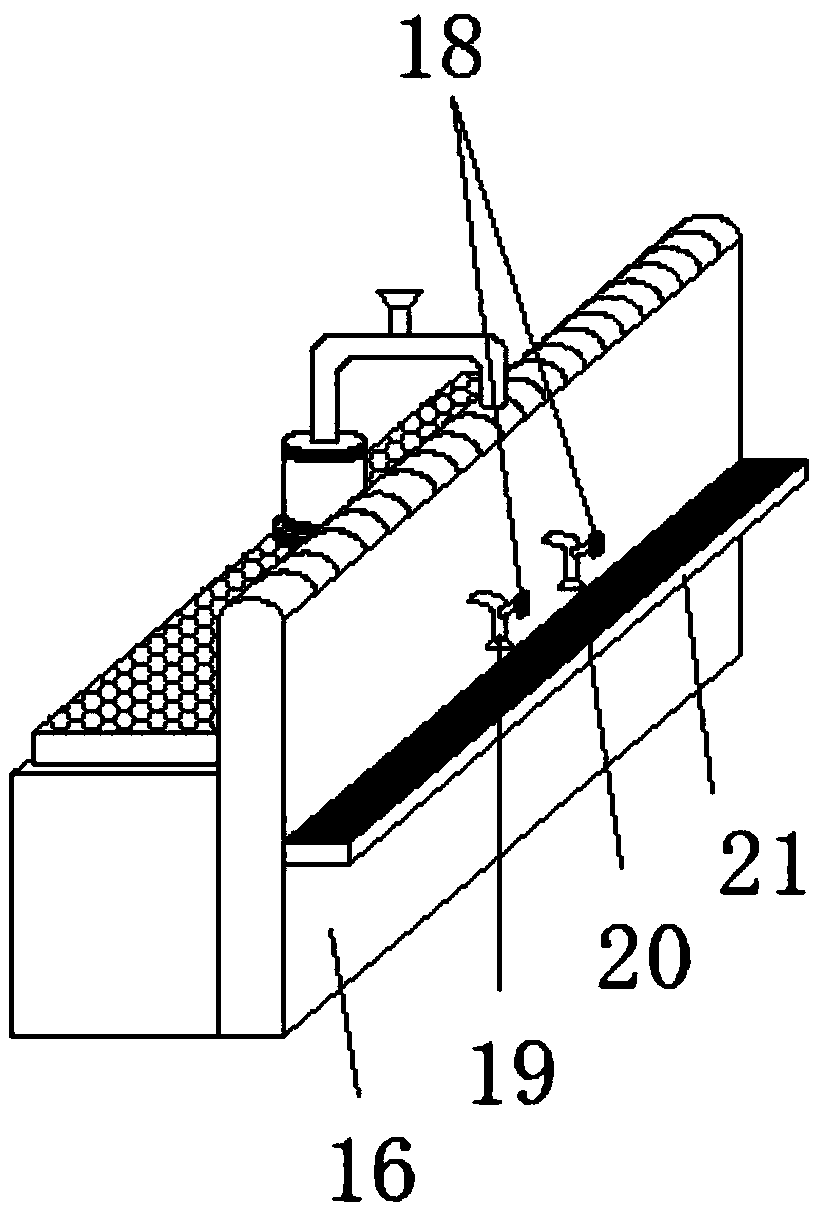

Energy-saving and environment-friendly bus stop board rainshed

InactiveCN108716294ANovel shapeFunctionalRoof covering using slabs/sheetsBatteries circuit arrangementsCeiling fanLight energy

The invention discloses an energy-saving and environment-friendly bus stop board rainshed. The energy-saving and environment-friendly bus stop board rainshed comprises nozzles, spraying pipes, green plants, a first water pump, a water sucking pipe, a water gathering tank, a refined filtering plate, a second water pump, a rainshed body, solar panels, an LED display screen, a chair, a water dispenser, a water collecting switch, a cool water pipe, a hot water pipe, a lap-joint plate, a water purifier, nickel hydride batteries, a single-chip microcomputer, a PLC, a USB interface, ceiling fans, pulling rings, ceiling fan switches and pulling ropes. On the basis of all functions of a traditional bus stop board rainshed, the energy-saving and environment-friendly bus stop board rainshed is combined with the energy-saving and environment-friendly idea. Firstly, through the arrangement of the water gathering tank, rainwater generated on rainy days can be gathered together, and is then guided into the water dispenser to be provided for pedestrians to drink after being filtered and purified; secondly, through the planted green plants, not only can a shady and cool place be provided for the pedestrians who wait for buses on the side, but also a bit of greenery can also be provided for cities, and besides, water for watering the green plants also comes from the rainwater stored in the watergathering tank; finally, power is produced by using the solar panels to absorb the light energy and convert the light energy into electric energy. The bus stop board rainshed saves the energy, and isenvironmentally friendly, high in innovativeness, and worthy of application and popularization.

Owner:熊贵

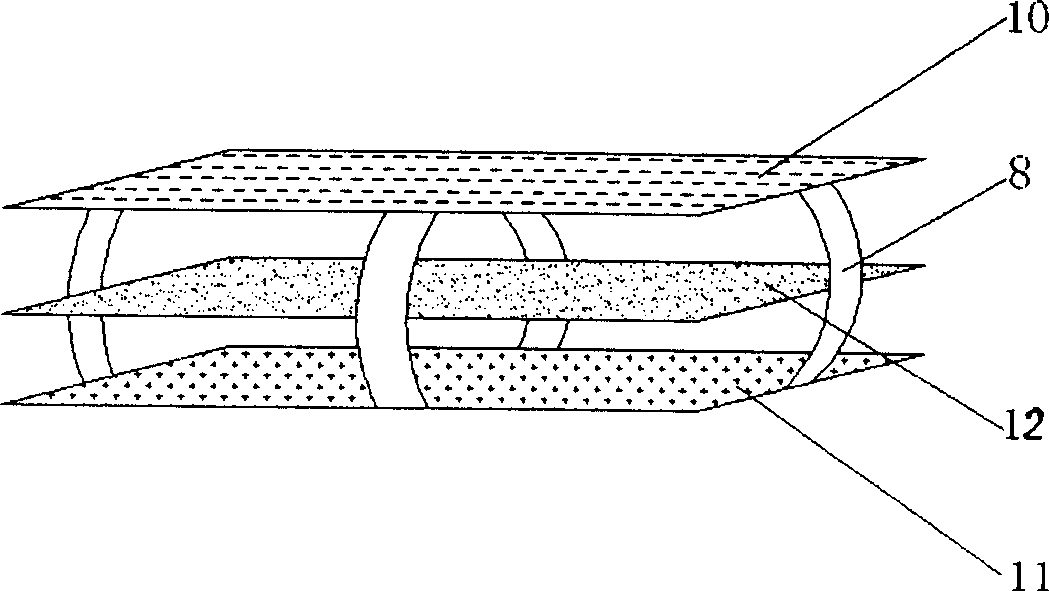

Small-sized sealing nickel hydride charging button cell and preparation method thereof

ActiveCN101615691BExtend your lifeImprove the effect of current collectionFinal product manufactureAlkaline accumulators manufactureButton batteryConductive materials

The invention relates to a small-sized sealing nickel hydride charging button cell for medical devices and a preparation method thereof. The method comprises the following steps: firstly, dividing anode conductive base materials evenly; coating anode active materials on the spaced anode conductive base materials; making a crease between the coating area and non-coating area, wherein the width of the crease is the same as the roll forming thickness of the coating area; stamping the anode conductive materials into a continuously circular shape in an integrally stamping manner after rolling the anode active materials; then folding the anode conductive base materials into anode groups according to the crease; placing the folded anode group into an anode shell; covering a septum on the anode group; dipping electrolyte solution and placing an insulating ring into the anode shell; placing the integrally die-casting cathode group into a cathode shell with cathode conductive base materials, and covering the cathode shell on the anode shell; and finally pressing and sealing. The invention has good security, favorable charging performance, simple manufacturing process, long service life and is suitable for large-scale and quick production.

Owner:LIAONING JIUYI ENERGY TECH

Automatic welding machine for anode cap of nickel hydride/nickel cadmium AA cylindrical battery

InactiveCN102941406BNo harmRealize automatic weldingResistance welding apparatusNickel cadmiumElectrical battery

The invention relates to an automatic welding machine for an anode cap of a nickel hydride / nickel cadmium AA cylindrical battery, which comprises a working table rack, a power mechanism arranged on the rack, a transmission mechanism, a battery feeding mechanism, a battery cap conveying mechanism, a battery direction regulating mechanism, an energy storage welding mechanism and a finished product receiving mechanism. The machine can implement the automatic welding of an anode plate and a battery cap of the nickel hydride / nickel cadmium AA cylindrical battery; the axis contact ratio of the anode plate and the cap is plus and minus 0.05 mm; the automatic welding speed of 80 pieces per minute can be achieved; the yield of one piece of equipment can replace that of 10 operators; particularly, the operator does not need to directly contact heavy metals such as nickel and cadmium; the automatic welding machine has no damage to human bodies, is safe, has no pollution and is efficient, energy-saving and environmental-friendly.

Owner:梧州市奥西力工业自动化有限公司

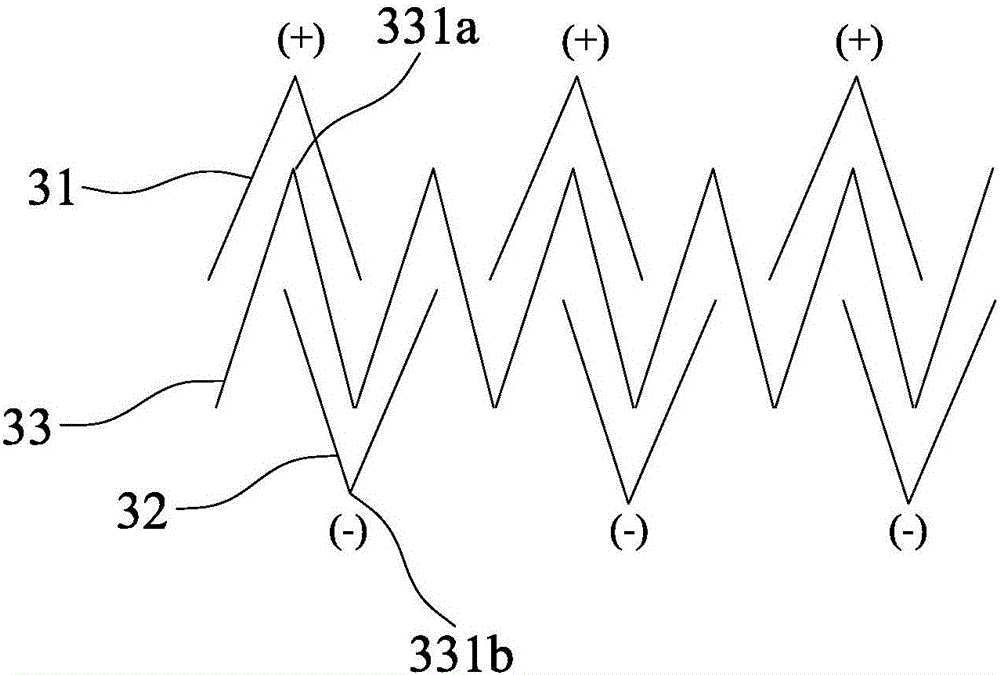

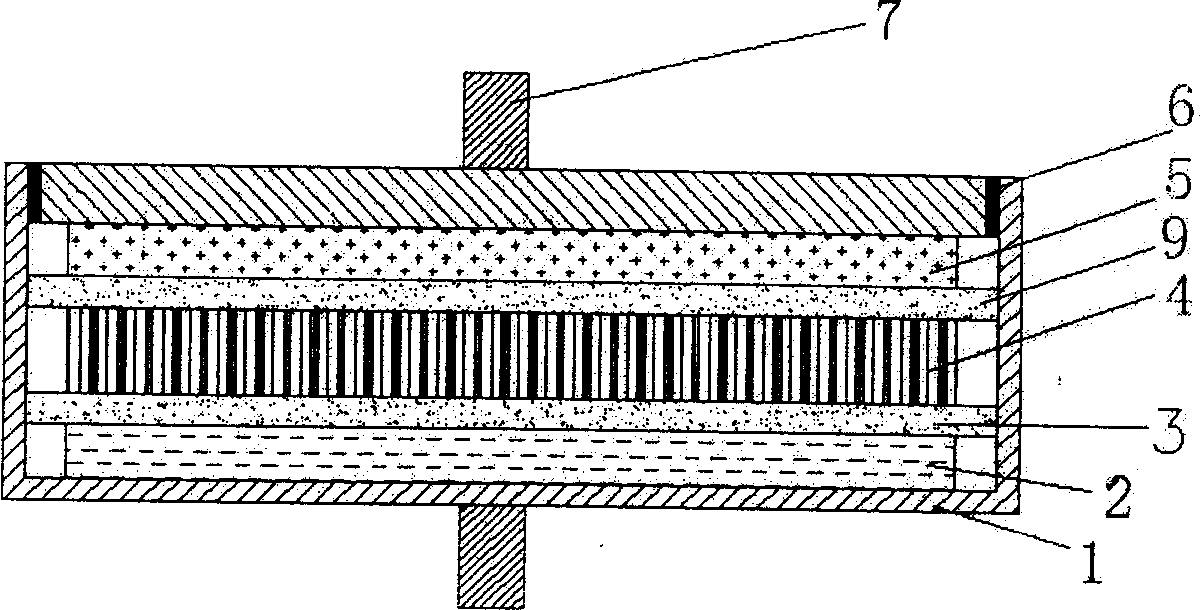

Multipole type metal nickel hydride sealing alkaline secondary battery

InactiveCN1794509AReduce volumeReduce weightAlkaline accumulatorsCell component detailsPower toolNickel hydride

This invention discloses a complex pole metallic hydride Ni sealed alkali secondary battery including a shell with a first negative pole, first membrane paper, a complex pole monomer electrode, second membrane paper and a first positive pole stacked from the bottom to the top, in which, the first negative and the second positive poles are led from leading holes obligated in the shell, the shell is sealed by a seal loop, the complex pole is stacked by a second negative pole, a film and a second positive from the top to the bottom and the second negative pole and the second positive pole are conducted by a welded Ni strip.

Owner:ZHEJIANG UNIV

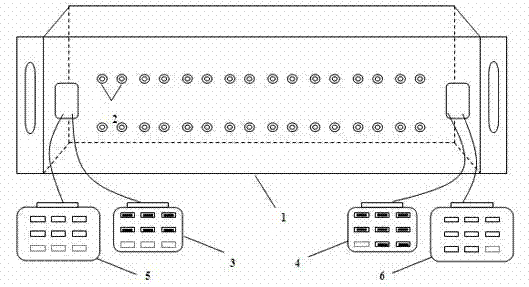

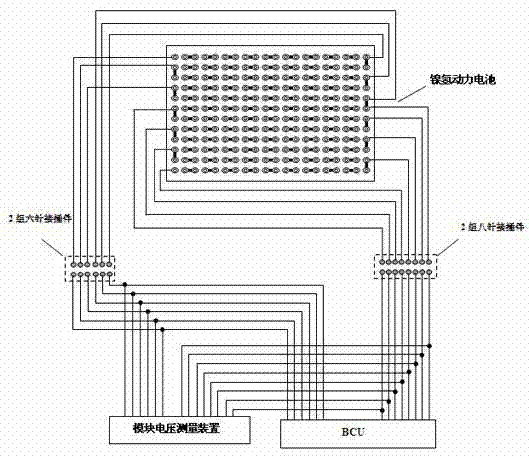

Device for measuring voltage of nickel hydride power battery assembly module

InactiveCN101995508BEasy to measureEasy to operateCurrent/voltage measurementPower batteryElectrical battery

The invention relates to a device for measuring the voltage of a nickel hydride power battery assembly module, comprising a circuit board. The circuit board is provided with module voltage test holes which are in one-to-one correspondence to voltage collecting wirings of a power battery module; four groups of connectors are connected behind the circuit board, wherein the insides of the first group and the third group of connectors are connected in parallel; two groups of connectors are respectively connected with a module voltage connection wiring beam six-pin connector of a battery assembly and a voltage collection six-pin connector of the nickel hydride power battery assembly BCU (Battery Control Unit) module; the insides of the second and the fourth groups of the connectors are connected in parallel; and both groups of connectors are respectively connected with a module voltage connection wiring beam eight-pin connector of the battery assembly and a voltage collection eight-pin connector of the nickel hydride power battery assembly BCU module. The device has the advantages of simple production, simple and convenient measuring method, safety and strong operability.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com