Automatic welding machine for anode cap of nickel hydride/nickel cadmium AA cylindrical battery

A cylindrical battery and automatic welding machine technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of low product qualification rate, high cost, human injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

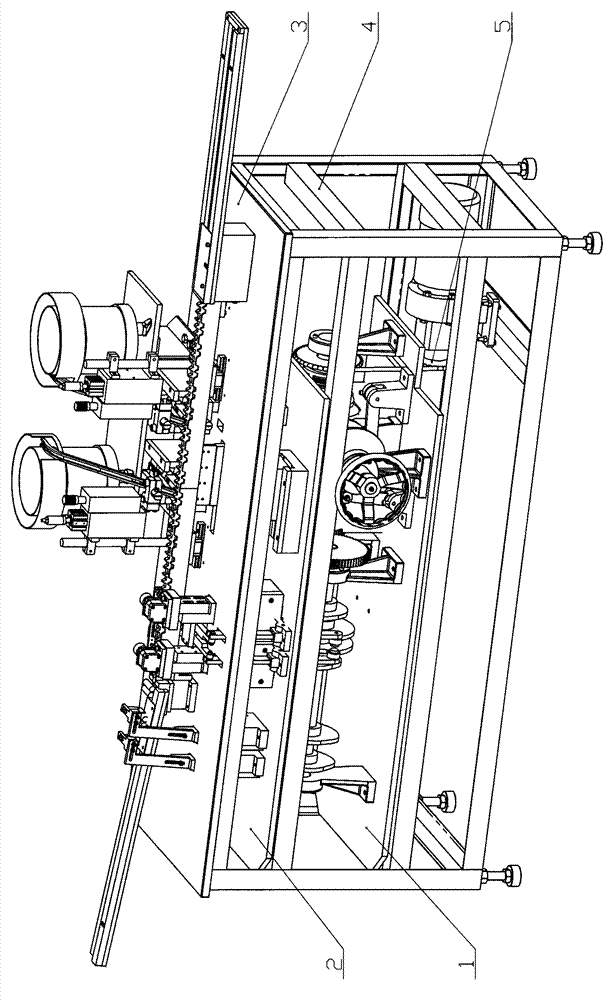

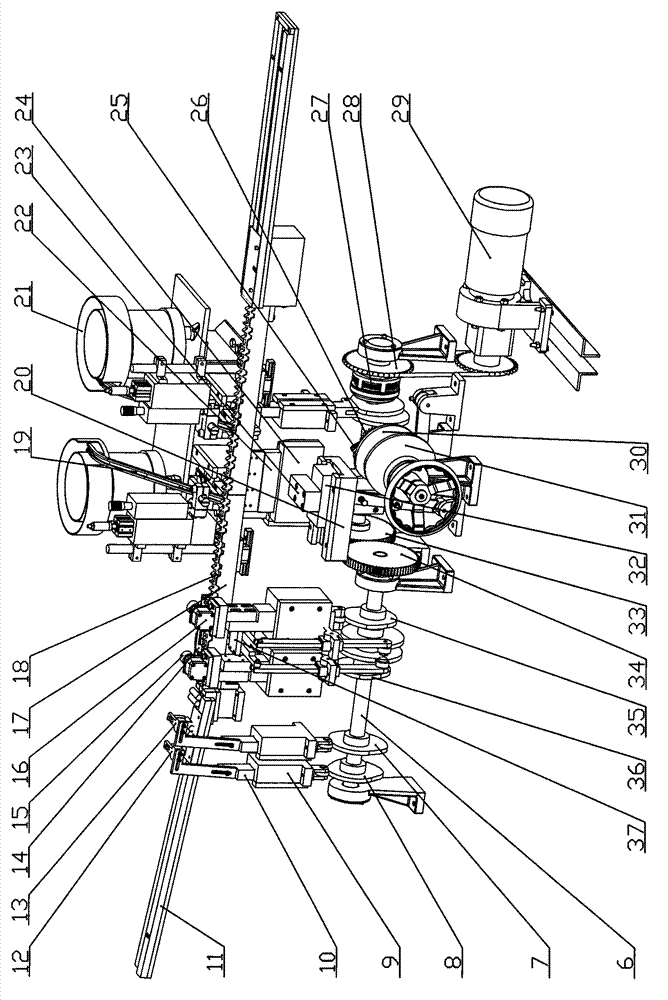

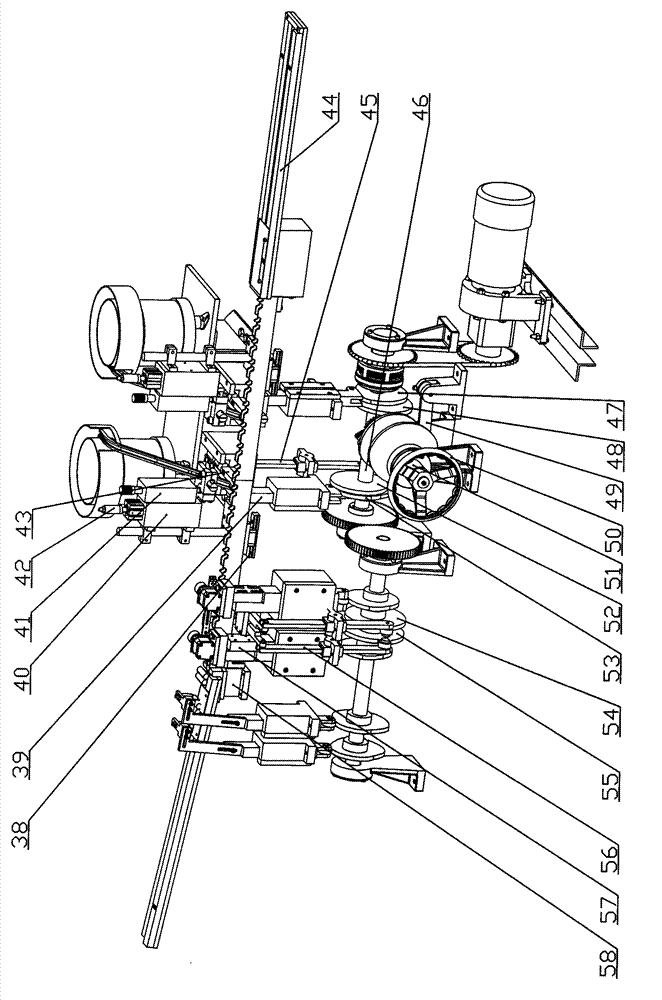

[0010] Referring to the accompanying drawings, the Ni-MH / Ni-Cd AA cylindrical battery positive electrode cap automatic welding machine of the present invention includes a workbench frame (4), a frame panel, a power mechanism and a transmission mechanism, and is characterized in that it also includes a frame and a machine The battery feeding mechanism, the battery cap conveying mechanism, the battery direction adjustment mechanism, the energy storage welding mechanism, and the finished product receiving mechanism on the rack panel.

[0011] Power mechanism and transmission mechanism comprise the cycloidal needle deceleration motor (29) that is installed on the bottom of the frame (4), the roller sprocket (5) that is installed on the cycloidal needle deceleration motor (29) axle head, through chain and roller The main shaft sprocket (28) that sub-sprocket (5) connects is installed on the clutch (27) on the left side of the main shaft sprocket (28), and the main shaft (46) driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com