Magnesium base hydride composite system for hydrolysis hydrogen production and preparation method and application thereof

A technology for magnesium-based hydride and hydrogen production by hydrolysis, which is applied in the field of a magnesium-based hydride composite system for hydrolysis and hydrogen production and its preparation, and can solve the problems of poor hydrolysis reaction kinetic performance, harsh hydride production conditions, and low effective hydrogen production. and other problems, to achieve the effect of simple and easy hydrogen production facilities, low hydrogen production environment requirements, and high hydrolysis activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

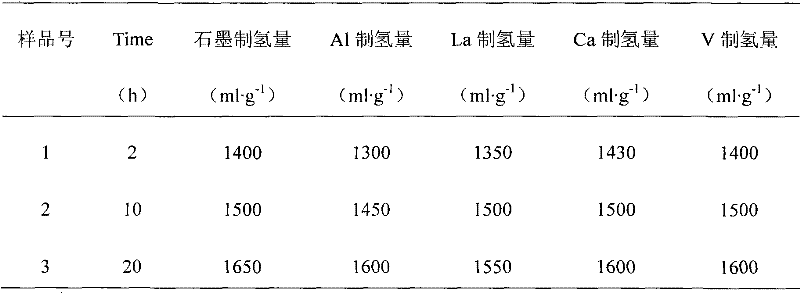

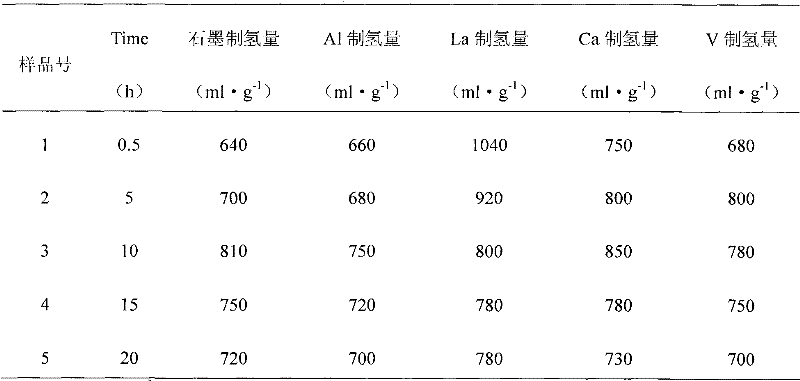

Embodiment 1

[0037] Weigh a total of 10g of magnesium powder and nickel powder at a molar ratio of 40:1, mix with 0.3g of alum powder evenly, add an appropriate amount of acetone (the ratio of the total weight of the mixture of magnesium powder and nickel powder is 1 to 2:1ml / g), and ultrasonically Mix for 1 hour and dry it in an oven at 326K. Put the mixture in a synthesis furnace, vacuumize the furnace chamber to 25Pa, pass in argon to clean, repeat 3 times and then pass in hydrogen with a purity of 99.999%, the initial hydrogen pressure is 2.0MPa, at an average speed of 10K / min Raise the temperature to 823K, and then keep it at this temperature for 1 hour to completely alloy the magnesium-nickel metal powder. Naturally lower the temperature to 623K and keep it warm for 10 hours to completely hydrogenate the metal powder. Then cool down to room temperature naturally.

[0038] Put 1 g of the hydrogenated combustion synthesis product obtained above into a ball mill jar, and then flush it...

Embodiment 2

[0040] Weigh a total of 10g of magnesium powder and nickel powder at a molar ratio of 45:1, mix with 0.3g of aluminum powder evenly, add an appropriate amount of acetone (the ratio of the total weight of the mixture of magnesium powder and nickel powder is 1 to 2:1ml / g), and ultrasonically Mix for 1 hour and dry it in an oven at 326K. Put the mixture in a synthesis furnace, vacuumize the furnace chamber to 25Pa, pass in argon to clean, repeat 3 times and then pass in hydrogen with a purity of 99.999%, the initial hydrogen pressure is 2.0MPa, at an average speed of 10K / min Raise the temperature to 823K, and then keep it at this temperature for 1 hour to completely alloy the magnesium-nickel metal powder. Naturally lower the temperature to 623K and keep it warm for 10 hours to completely hydrogenate the metal powder. Then cool down to room temperature naturally.

[0041] Put 1 g of the hydrogenated combustion synthesis product obtained above into a ball mill jar, and then flus...

Embodiment 3

[0043] Weigh a total of 10g of magnesium powder and nickel powder at a molar ratio of 49:1, mix with 0.5g of lanthanum powder evenly, add an appropriate amount of acetone (the ratio of the total weight of the mixture of magnesium powder and nickel powder is 1 to 2:1ml / g), and ultrasonically Mix for 1 hour and dry it in an oven at 326K. Put the mixture in the synthesis furnace, vacuum the furnace cavity to 25Pa, pass in argon to clean, repeat several times and then pass in hydrogen with a purity of 99.999%, the initial hydrogen pressure is 2.0MPa, and the average speed is 10K / min Raise the temperature to 823K, and then keep it at this temperature for 1 hour to completely alloy the magnesium-nickel metal powder. Naturally lower the temperature to 623K and keep it warm for 2 hours to completely hydrogenate the metal powder. Then cool down to room temperature naturally.

[0044] Put 1 g of the hydrogenated combustion synthesis product obtained above into a ball mill jar, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com