Shearing machine for substrate strip for manufacturing nickel-hydride battery cathode

A nickel-metal hydride battery and shearing equipment technology, which is applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., can solve the problem that the shearing accuracy cannot reach ultra-thin precision steel strips, and achieve simple structure and simplified The effect of shearing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

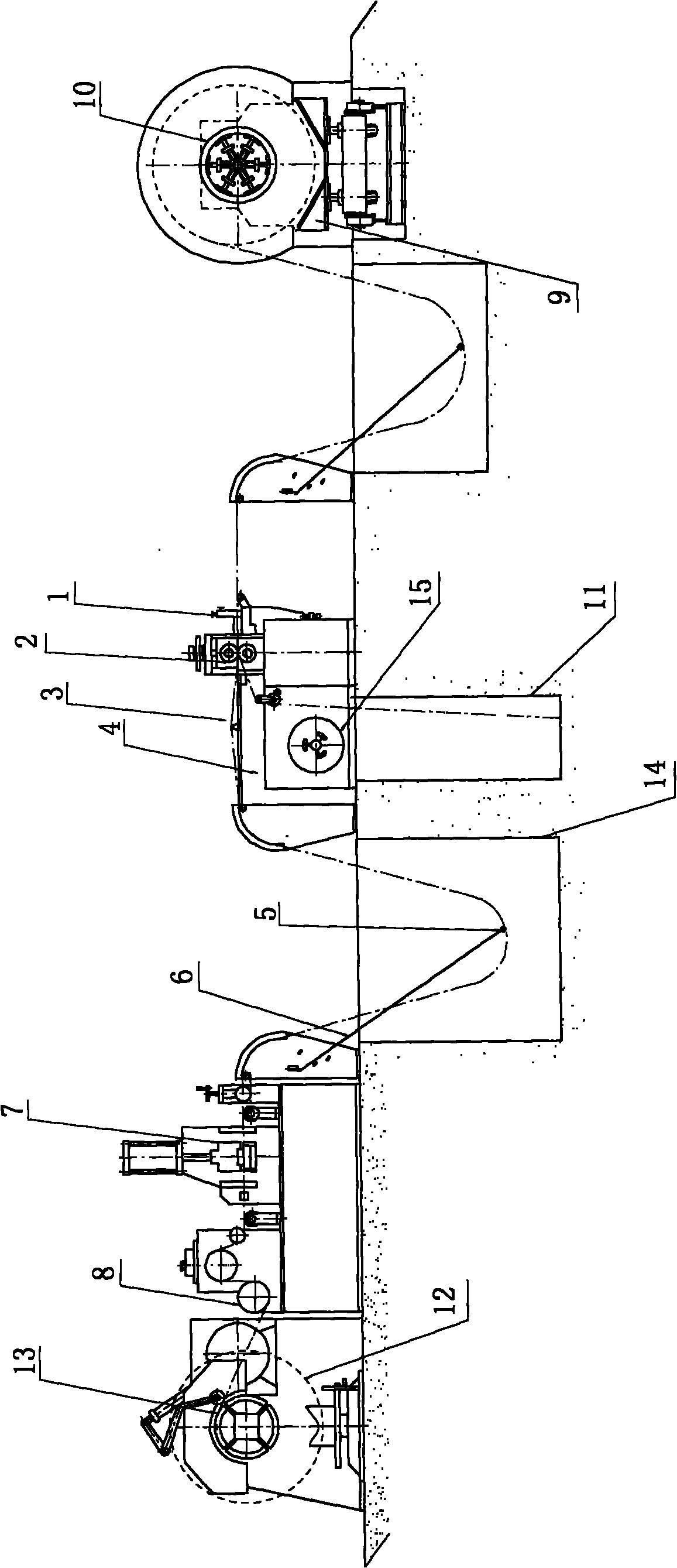

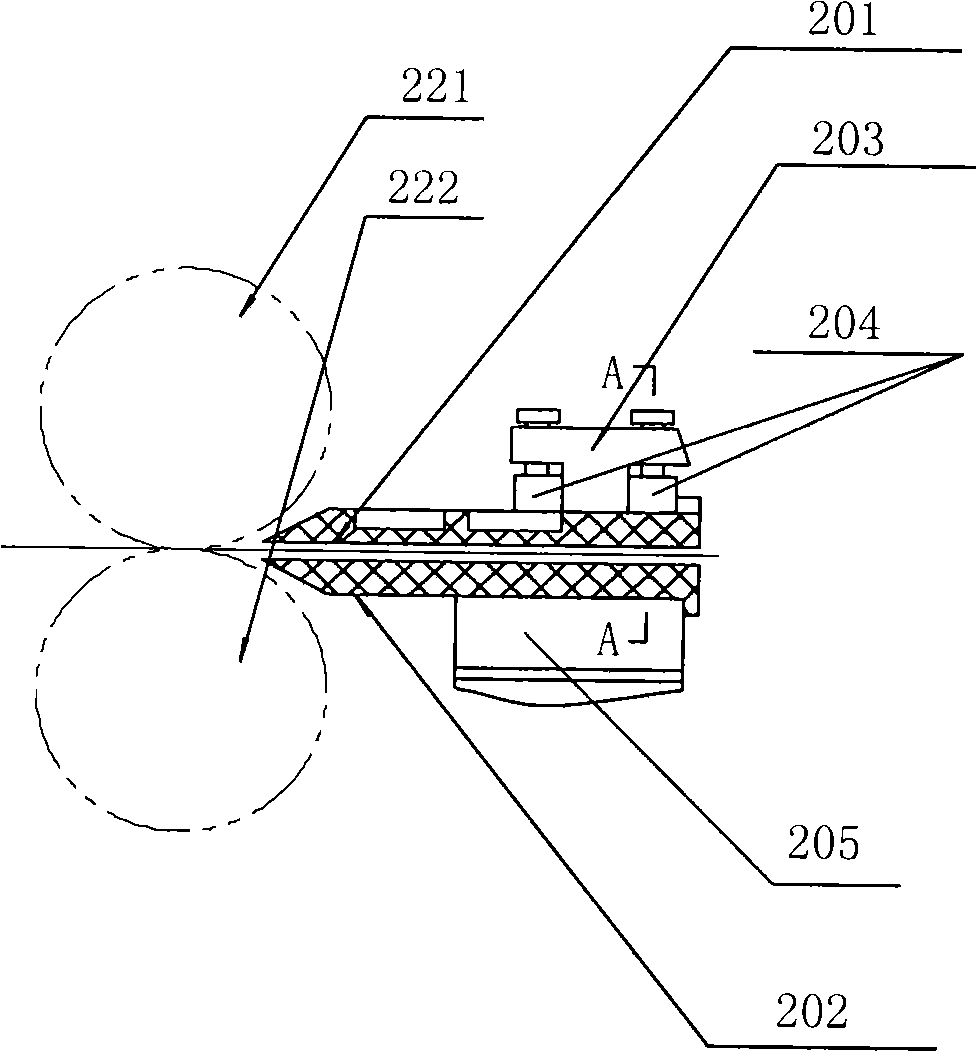

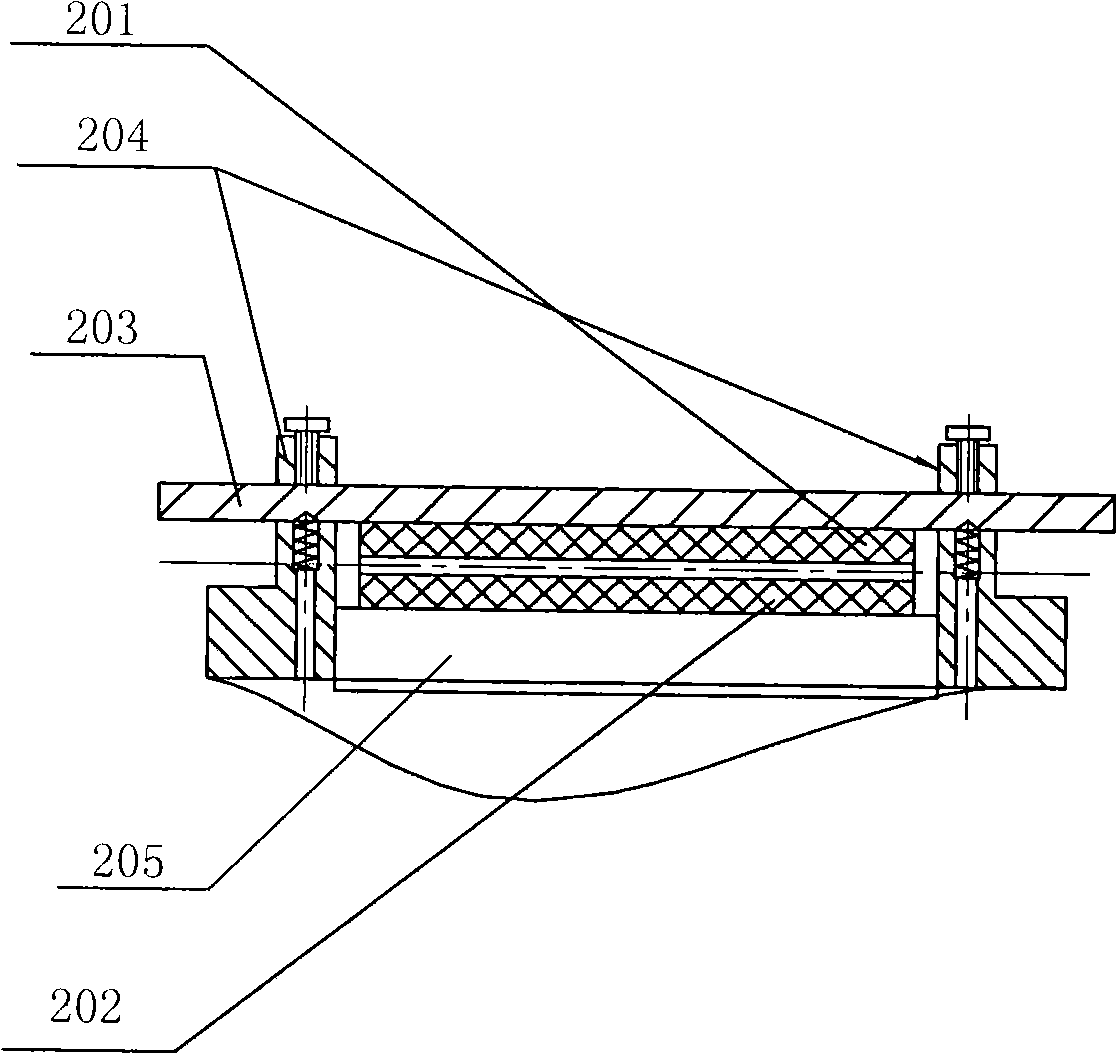

[0017] This embodiment provides a kind of shearing equipment for making the substrate strip for the negative electrode of the nickel-hydrogen battery, which is used for cutting the ultra-thin steel strip with a thickness greater than 0.035mm for making the substrate for the negative electrode of the nickel-hydrogen battery, so as to achieve this The accuracy requirements of the strip, such as figure 1 As shown, the equipment includes: uncoiler, feeding plate, rolling shearing machine, edge material rewinding machine, tension table, coiling machine, hydraulic station, hydraulic cylinder, electrical box and electrical control cabinet; among them, the combination of each equipment forms a A rolling shear unit, the hydraulic station is used to control the expansion and contraction of the uncoiler reel, the tension table, the coiler and the pusher; the electrical box and the electrical control cabinet are used to control the AC asynchronous motor and the DC motor that provide power;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com