Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "N-methylpyrrolidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance flat plate type cellulose acetate/nano-titanium dioxide blended forward osmosis membrane

ActiveCN104474920AControl performancePollution resistantSemi-permeable membranesCellulose acetateN-Methyl-2-pyrrolidone

The invention discloses a high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane, which is prepared by comprising the following steps: adding the following raw materials in percentage by weight: 7.0%-26.0% of cellulose acetate, 2.0%-16.0% of additives, 0.1%-5.0% of nano-titanium dioxide, 0.05%-0.1% of graphene, and a dimethylformamide or dimethylacetamide, N-methylpyrrolidine and acetone mixed solvent into a dissolving tank according to certain sequence, stirring and dissolving for 3-15h to be full and even at 25-90DEG C, thus obtaining blended forward osmosis membrane casting liquid; and preparing the high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane on a supporting material by using a phase conversion method. According to the prepared forward osmosis membrane, 1M NaCl and deionized water are respectively taken as driving liquid and feed solution, the flux of pure water can reach more than 17.5L / m<2>.h during testing time of1h and the backward salt flux is less than 3.0g / m<2>.h.

Owner:UNIV OF JINAN

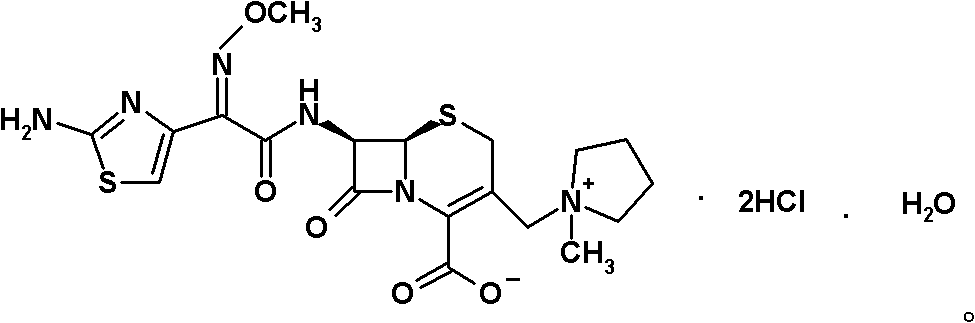

Method for synthesizing cefepime hydrochloride

InactiveCN101735251AHigh densityHigh reactivityAntibacterial agentsOrganic chemistryCefepime hydrochlorideVolumetric Mass Density

The invention relates to a method for synthesizing cefepime hydrochloride. The method comprises the following steps: taking 7-aminoce-phalosporanic acid (7-ACA) and N-methylpyrrolidine as raw materials, firstly, carrying out carboxylic and amino protection on the 7-ACA by HMDS, then preparing the N-methylpyrrolidine and iodotrimethylsilane into a quaternary ammonium salt intermediate, finally, adding the intermediate into the protected 7-ACA solution and reacting to prepare 7-MPCA; taking the 7-MPCA and AE-active ester, adding a phase transfer catalyst into an organic phase for carrying out an N-acidylating reaction, salifying and reacting to obtain the cefepime hydrochloride. The invention has the main characteristics that the quaternary ammonium salt intermediate is prepared in the step (1), the defects of high electron cloud density, strong reactivity and many side reactions of the N atom of N-methyl pyrrole are overcome, the yield is enhanced by 7%, and the product purity is enhanced. During the N-acidylating reaction in the organic phase in the step (2), the phase transfer catalyst is added, so that the conversion rate of the reaction is enhanced by 5%, and the product yield is enhanced.

Owner:YIYUAN XINQUAN CHEM

Preparation method of cefepime hydrochloride

ActiveCN101935325ASimple processAvoid the phenomenon of inhomogeneous crystal form and poor fluidityOrganic chemistryCefepime hydrochlorideBetaine

The invention discloses a preparation method of cefepime hydrochloride, comprising the following steps of: reacting oxalyl chloride with 2-methoxyimino-2-(2-aminothiazole-4-yl) acetic acid hydrochloride to obtain a midbody I, i.e. 2-methoxyimino-2-(2-aminothiazole-4-yl) acetyl chloride hydrochloride; mixing silanized 7-aminoce-phalosporanic acid and silanized N-methylpyrrolidine, and reacting to obtain a midbody II, i.e. hydriodic acidification (6R, 7R)-7-amino-3-[(1-methyl-1-tetrahydro pyrrolidine) methyl]-3-cephem-4-formic betaine, in the presence of trimethyl idodine silicon hydride, isopropanol and an aqueous solution of hydrogen iodide; dissolving the midbody II into dichloromethane, sequentially adding trimethylchlorosilane and hexamethyldisilazane for reaction, and then adding the midbody I and triethylamine to react to prepare the cefepime hydrochloride. The cefepime hydrochloride prepared by the method has the advantages of uniform crystal form, good flowability and simple process and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

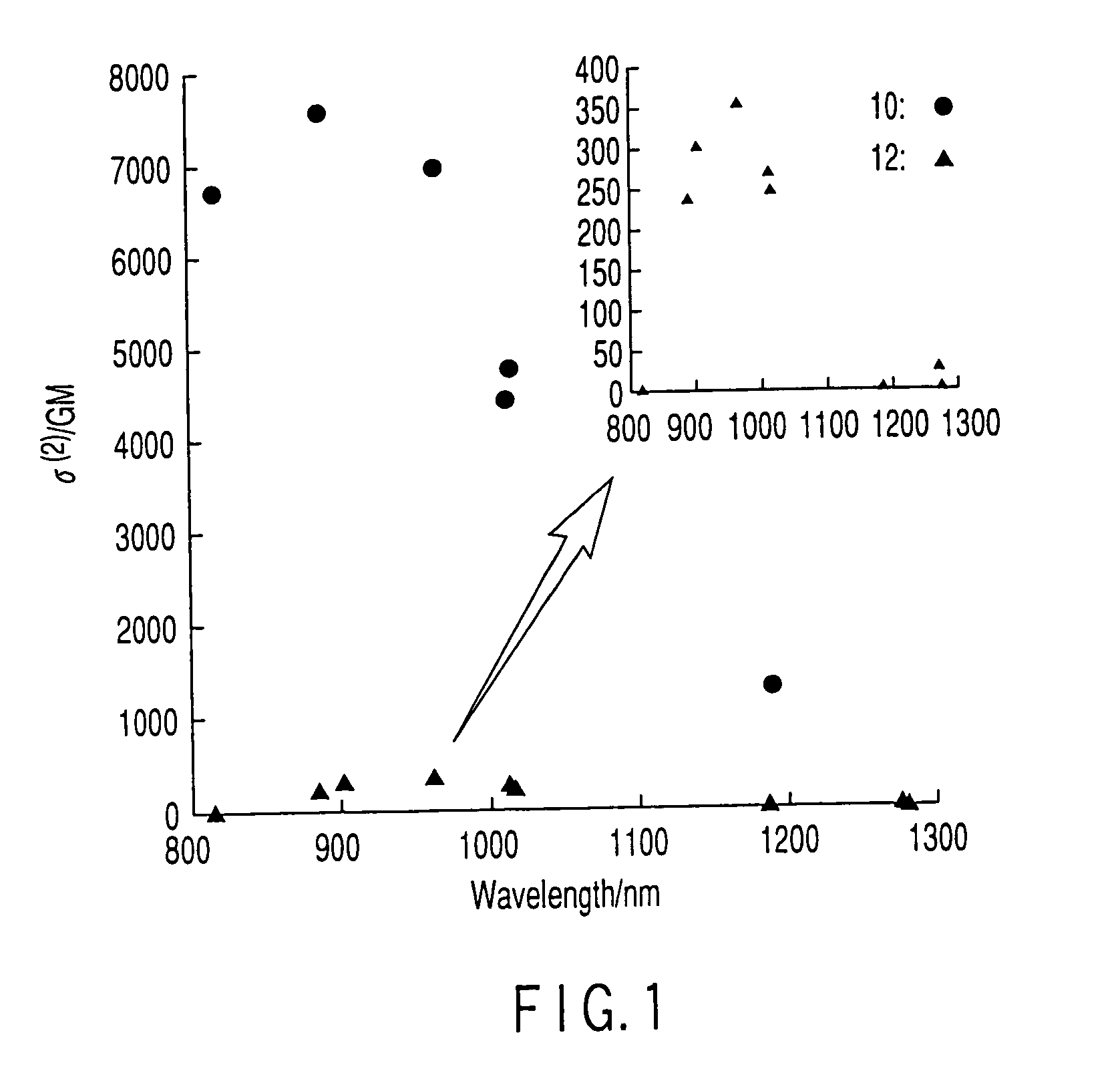

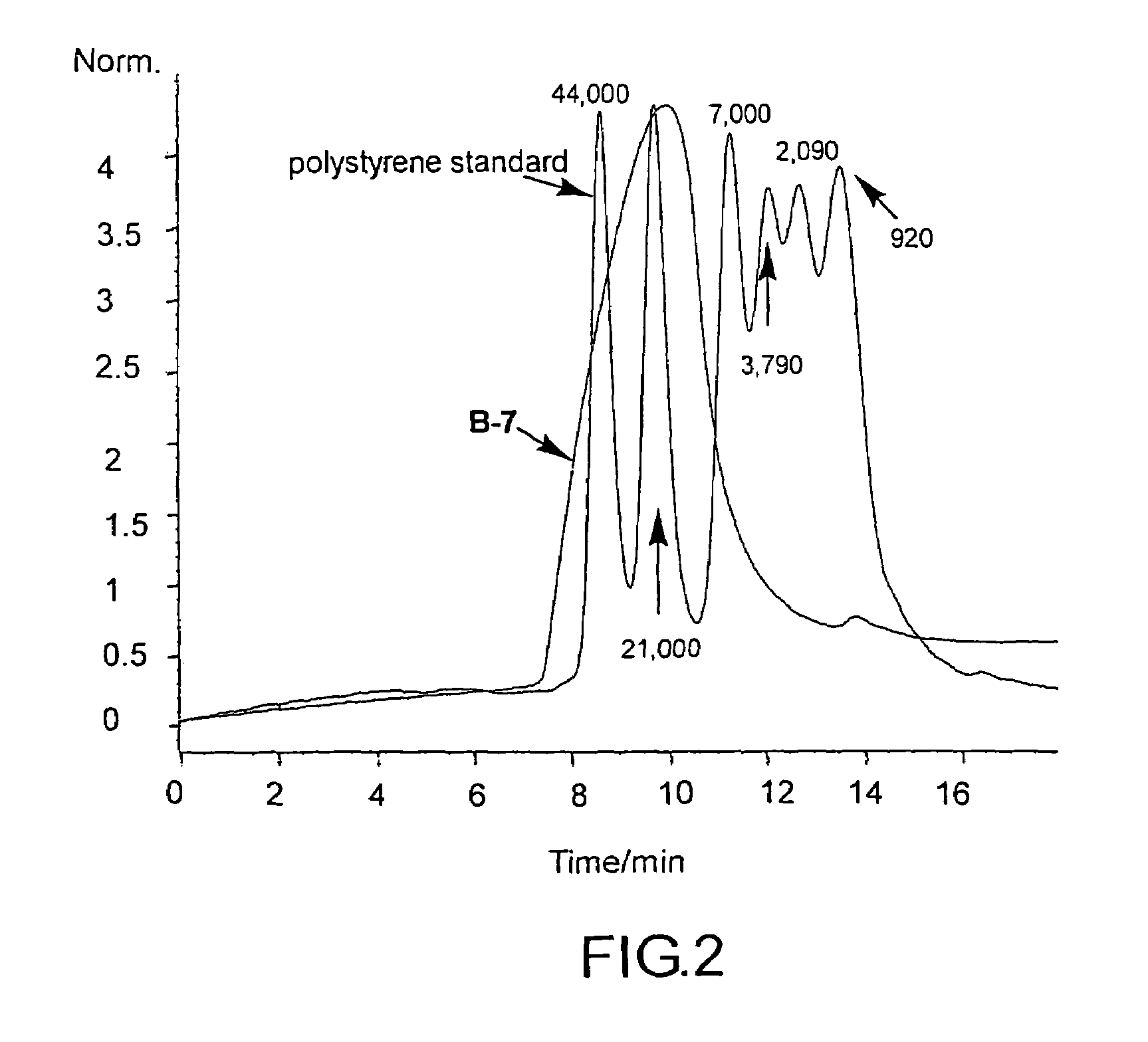

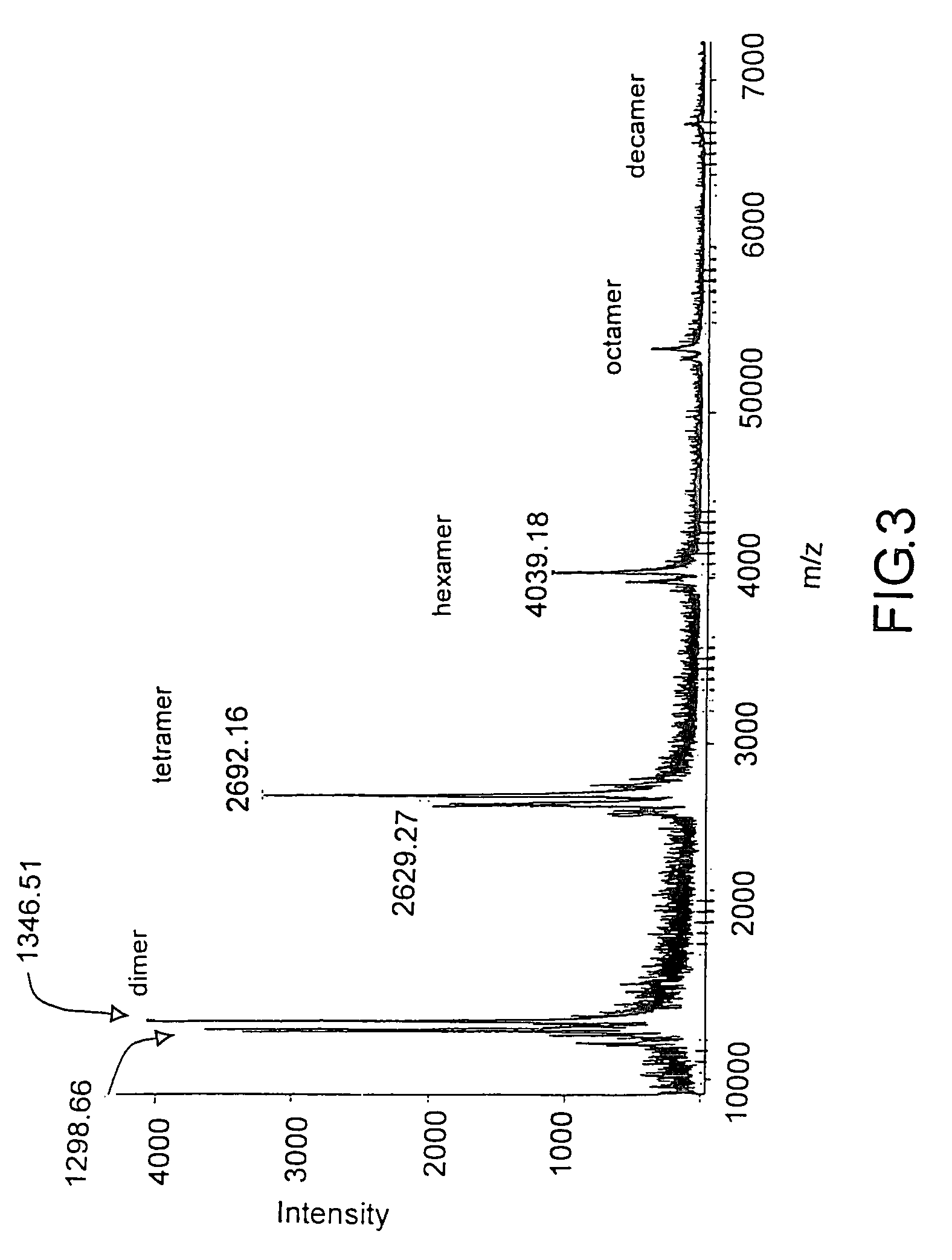

Porphyrin array exhibiting large two photon absorption property and including, as structural unit, bis (imidazolylporphyrin metal complex) linked with acetylenic bond and the derivative thereof, and method of producing the same

InactiveUS7022840B2Big absorptionUltrasonic/sonic/infrasonic diagnosticsBiocidePorphyrinMethyl group

A porphyrin array exhibiting a large two-photon absorption property, and being linked with an acetylenic bond(s), represented by the following formulas: wherein R1 represents an alkyl or aryl group, M1 represents a metal ion capable of serving as a core metal and forming a coordinate bond with Im, M2 represents two protons or a metal ion incapable of forming a coordinate bond with Im, R2 and R3 represent a group selected from a porphyrin residue or porphyrin metal complex residue, a cyclic diimide residue, a dialkylviologen residue, a benzoquinone residue, an N-methylpyrrolidine-fullerene derivative residue and a ferrocene residue, Im is represented by Im1 or Im2: (R8 represents methyl or H), L1 represents —(—C≡C—)m— (m=1 to 3); n represents an integer of 1 or more; R9 represents one of R1, R2, R3 and Im.

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY

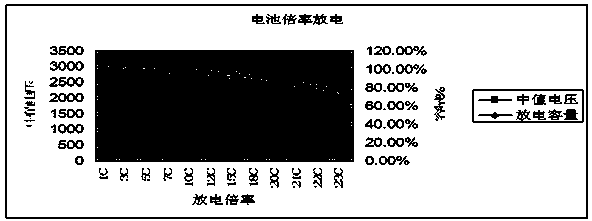

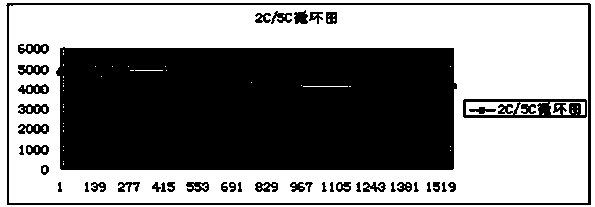

Positive pole piece of large multiplying power lithium iron phosphate battery and preparation method thereof

InactiveCN103972471AIncrease volume capacityImprove qualityCell electrodesSecondary cellsHexafluoropropylenePole piece

The invention provides a positive pole piece of a large multiplying power lithium iron phosphate battery, which comprises a current collector and an active material layer coated on the positive pole piece, wherein the active material comprises spherical lithium iron phosphate, a binding agent, a conductive agent; the current collector comprises aluminium foil and a conducting layer printed on the current collector; the conducting layer comprises carbon black, polyvinylidene fluoride or polyvinylidene fluoride-hexafluoropropylene copolymer. The preparation method comprises the following steps: the binding agent, the conductive agent and the spherical lithium iron phosphate are sequentially added into N-methylpyrrolidine ketone to obtain uniform positive pole slurry; then the current collector is coated with the positive pole slurry to obtain a coating pole piece; finally, the coating pole piece is rolled to obtain a positive pole piece. According to the design of the positive pole piece, the positive pole piece with high quality is prepared, the service life of the battery can be prolonged on the basis that the requirement for the high-current discharging performance of the applied lithium ion battery is guaranteed, the favorable contact of the current collector and the slurry can be guaranteed and the favorable adhesive property is expressed and the working efficiency is relatively high.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for synthesizing antibiotic cefepime hydrochloride

ActiveCN101337971ASimple process conditionsEasy to operateAntibacterial agentsOrganic chemistryCefepime hydrochlorideHexamethyldisilane

The invention relates to a synthesis method of cefepime dihydrochloride that is a bacteriophage. 7-amin cethalosporanic acid (7-ACA) is used as starting material and reacts with hexamethyldisilane amine (HMDS) and iodotrimethylsilane (TMSI) first to obtain 7-ACA for protecting amino and carboxyl; then 7-ACA, amino and carboxyl of which are protected, reacts with iodotrimethylsilane and N-methylpyrrolidine to synthesize (6R, 7R)-7-amino-3-((1-methyl-1-pyrrolidine) methyl) cephalosporin-3-alkene-4-carboxylic acid hydrochloride (7-MPCA) through a one-pot method; 7-MPCA reacts with AE active ester to obtain a product of cefepime dihydrochloride through acidylation reaction and salifying reaction. Compared with the existing technical route, the synthesis method has the advantages that the process conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, the method is suitable for the large-scale industrialized production, etc.

Owner:国药集团致君(苏州)制药有限公司

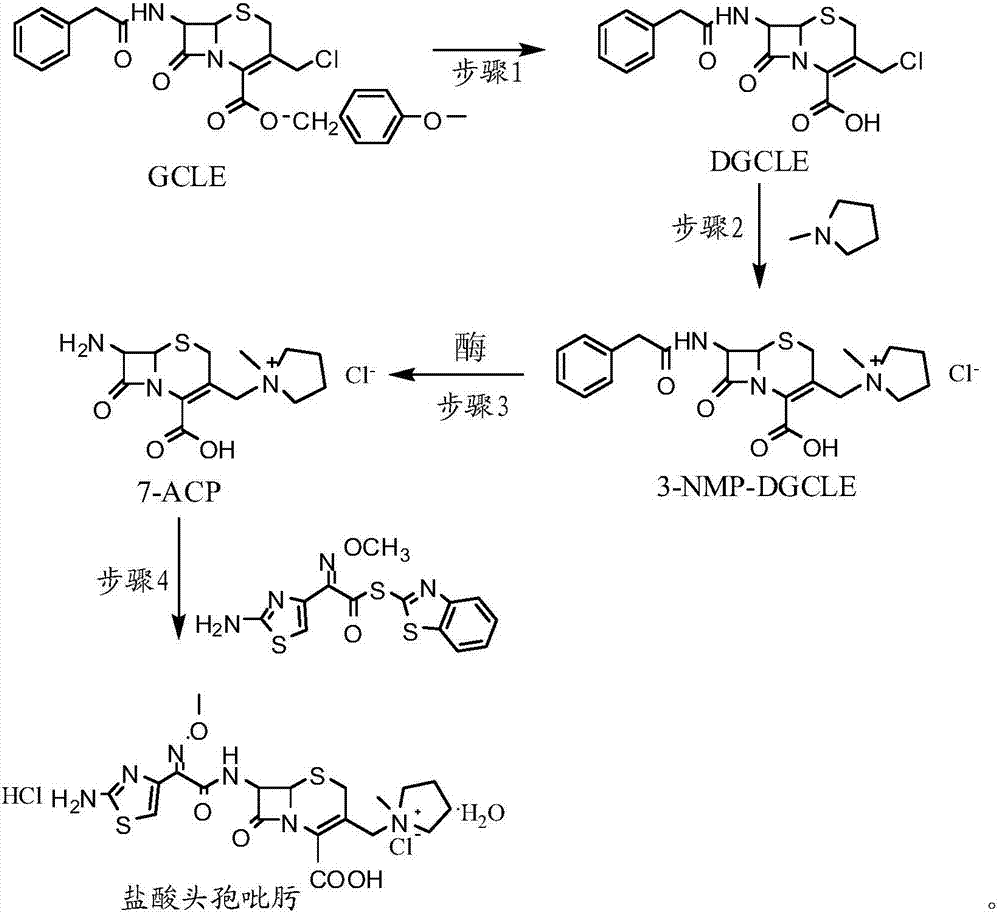

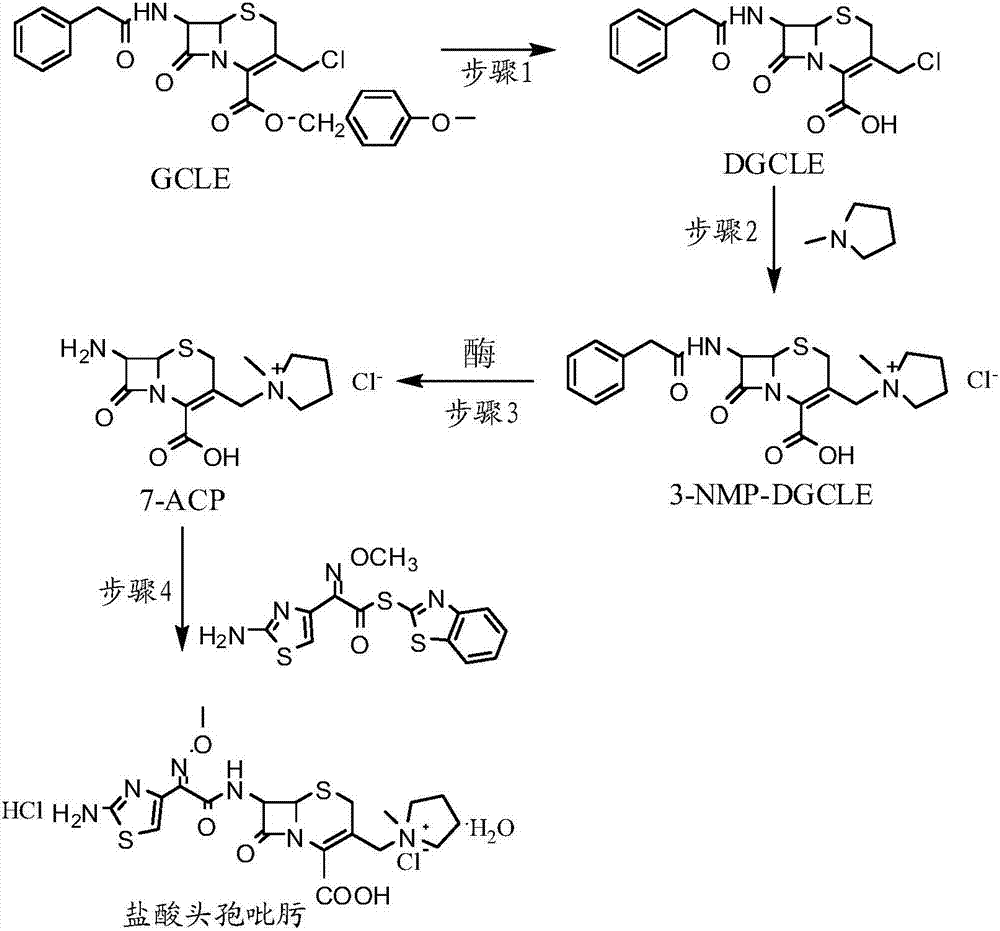

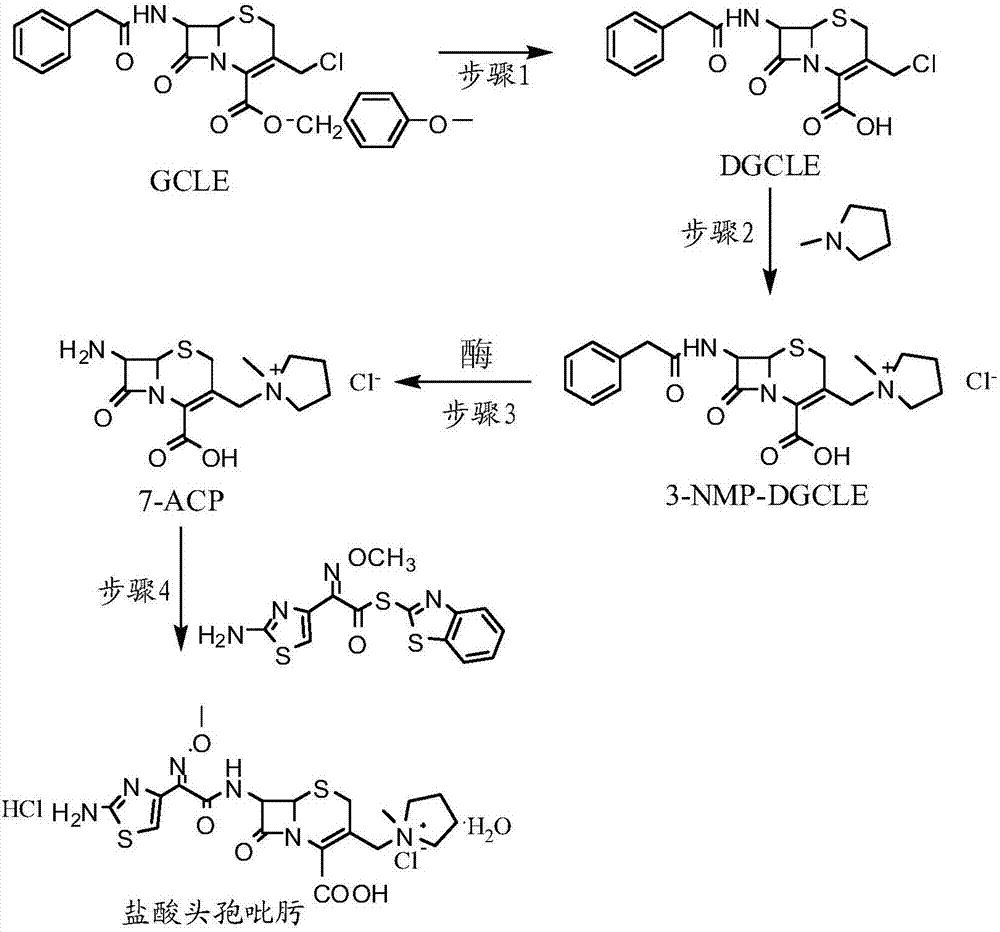

Synthesis method of cefepime hydrochloride

ActiveCN107201391AReduce usageLow costOrganic chemistryFermentationCefepime hydrochlorideSynthesis methods

The invention provides a synthesis method of cefepime hydrochloride. The synthesis method comprises the following steps: taking GCLE (7-phenylacetamide-3-chloromethyl-3-cepham-4-carboxylic acid p-methyl-oxybenzyl ester) as a raw material; cutting a 4-site protecting group (p-methoxybenzyl) and enabling the 4-site protecting group to react with N-methylpyrrolidine (NMP); then cutting a 7-site protecting group through an enzyme method to obtain an immediate 7-amino-3-(1-methylpyrrolidine)methyl)-3-cepham-4-carboxylic acid hydrochloride (7-ACP); taking cheap and available methoxyiminoacetic acid mercaptobenzothiazole active ester (AE-active ester) and the 7-ACP to be subjected to 7-site acylation reaction, so as to finally prepare the cefepime hydrochloride. A route provided by the invention can be used for obtaining the high-yield and high-quality cefepime hydrochloride without a delta2 isomer. The synthesis method provided by the invention has the advantages of simple process, no harsh reaction conditions and the like and is very suitable for industrial production.

Owner:吉林省爱诺德生物工程有限公司

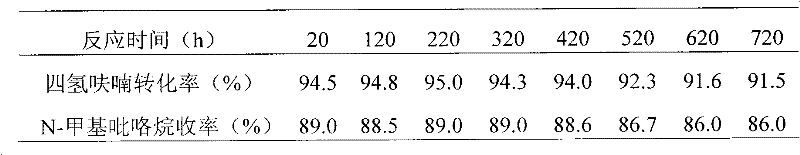

Catalyst for catalytic synthesis of N-methylpyrrolidine and application thereof

InactiveCN101912779AEasy to makeReaction raw materials are cheap and easy to obtainOrganic chemistryMolecular sieve catalystsMolecular sieveChemical industry

The invention relates to technology for synthesizing an intermediate in the medicinal and chemical industry, in particular to a catalyst for catalytic synthesis of N-methylpyrrolidine and a synthesis method thereof. The catalyst consists of a carrier and a catalytic activity component, wherein the carrier is a gamma-Al2O3 or HZSM series molecular sieve; the catalytic activity component is a simple substance of metal M or an oxide thereof; the catalytic activity component accounts for 0.5 to 20 percent of the total weight of the catalyst; and the granular size of the catalyst is 4 to 20 meshes. The catalyst is prepared by a kneading and extruding method or a dipping method. The catalyst has the advantages of simple preparation, low price of raw materials and easy purchase; and when used the catalytic synthesis of N-methylpyrrolidine, the catalyst has the advantages of mild catalytic reaction condition, low three-wastes and no pollution, wherein the conversion rate of tetrahydrofuran is substantially kept over 80 percent and the yield of the N-methylpyrrolidine is substantially kept over 60 percent.

Owner:HEBEI UNIV OF TECH

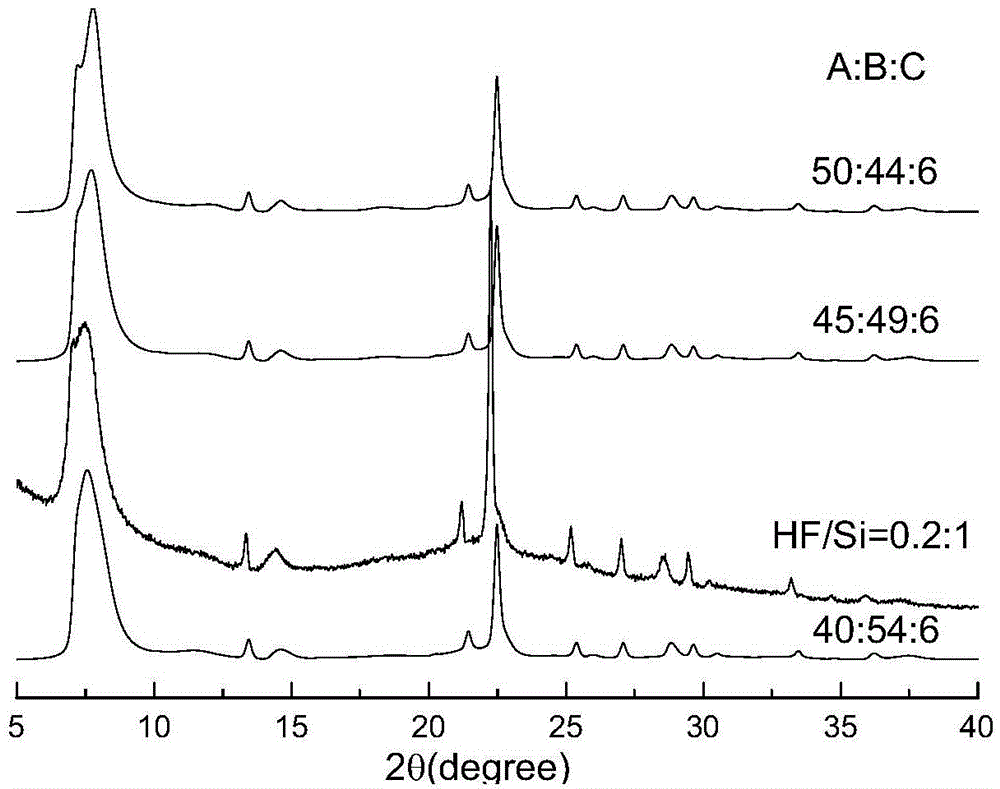

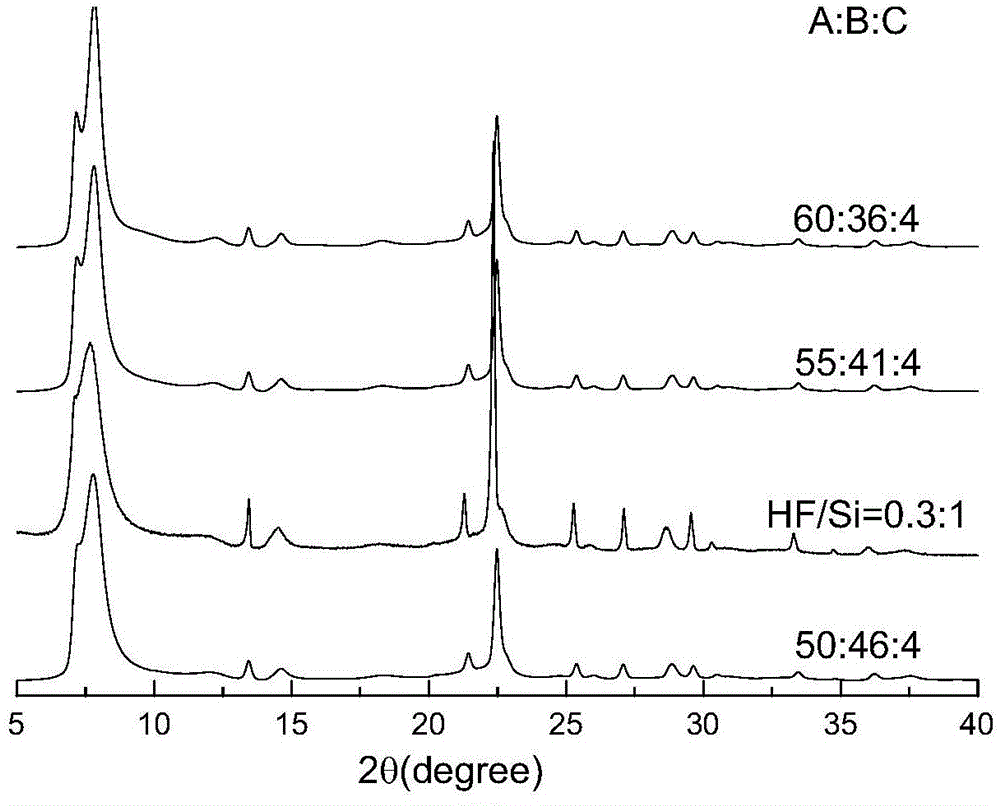

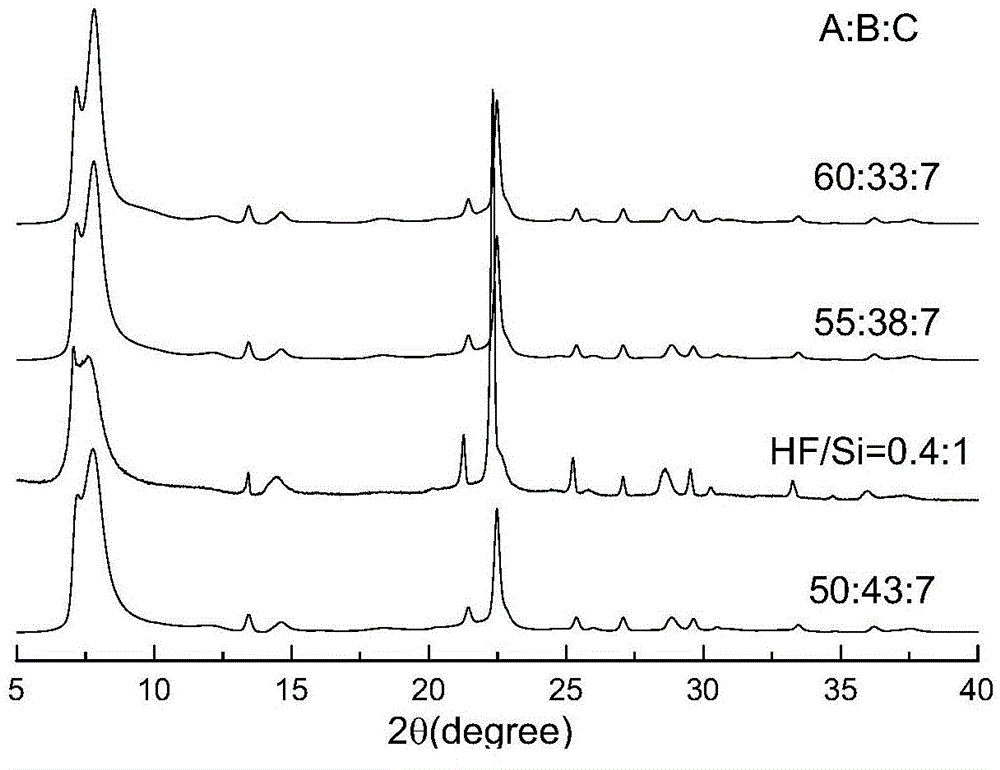

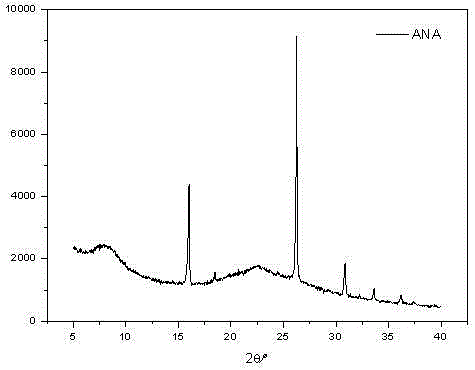

Beta molecular sieve with adjustable relative content of polymorphs and synthetic method thereof

The invention relates to a Beta molecular sieve with adjustable relative content of polymorphs and a preparation method thereof. In comparison with a traditional Beta molecular sieve, the Beta molecular sieve of the invention is characterized in that relative content of three polymorphs A, B and C is adjustable. The invention specifically relates to a pure silicon or transition metal (such as titanium, zirconium, etc) heteroatom-doped Beta molecular sieve synthesized under specific reaction conditions by the use of an organic template. The template of the invention is N-isobutyl-N-methylpyrrolidine hydroxide; a fluorine source is hydrofluoric acid; a silicon source is tetraethyl orthosilicate; a titanium source is tetraethyl titanate or tetrabutyl titanate; and a zirconium source is zirconium n-butoxide. By modulating the ratio of fluorine to template in the synthetic system, relative content of the three polymorphs A, B and C can be modulated.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lamellar mordenite preparation method

ActiveCN106542538AHigh silica/alumina molar ratioThe synthesis method is simpleCrystalline aluminosilicate zeolitesSynthesis methodsAlkali metal oxide

The invention relates to a lamellar mordenite preparation method, which comprises: (1) dissolving an inorganic alkali, an aluminum source and a structure-directing agent (R) in water and uniformly mixing to prepare a solution, wherein the structure-directing agent is a 1,n-bis(N-methylpyrrolidine)alkylene bromine salt having the structure formula represented by a formula (I), and n is 2-5; (2) adding a silicon source to the solution prepared in the step (1), and uniformly mixing to prepare a colloid or solid-liquid mixture, wherein the molar ratios of the added reactants comprise that the SiO2 / Al2O3 is 10-50, the H2O / SiO2 is 5-50, the R / SiO2 is 0.05-0.5, and the M2O / SiO2 is 0.05-1.0, and the M2O is an alkali metal oxide; and (3) carrying out hydrothermal crystallization for 1-5 days at a temperature of 80-140 DEG C under autogenous pressure, heating to a temperature of 150-250 DEG C, carrying out hydrothermal crystallization for 6-14 days under autogenous pressure, collecting the solid product after the crystallization, washing, and drying, wherein the obtained product has characteristics of high crystallinity, small grain thickness, and simple synthesis method. The formula (I) is defined in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

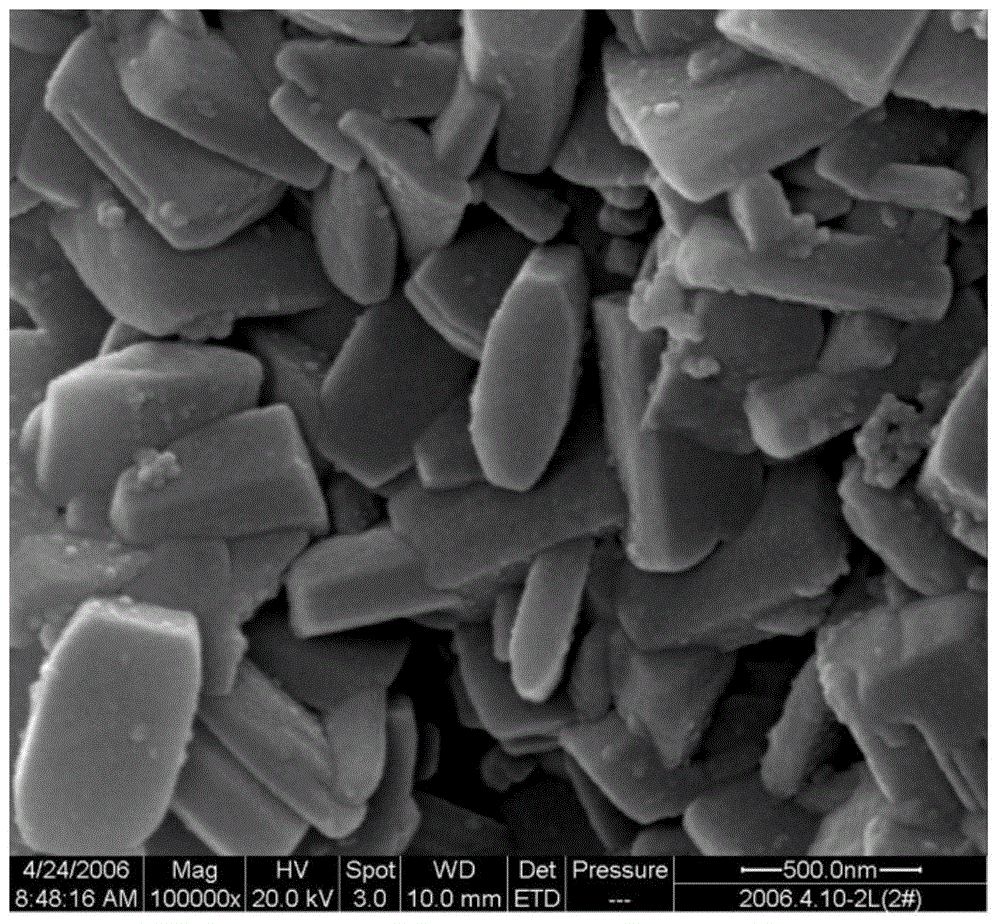

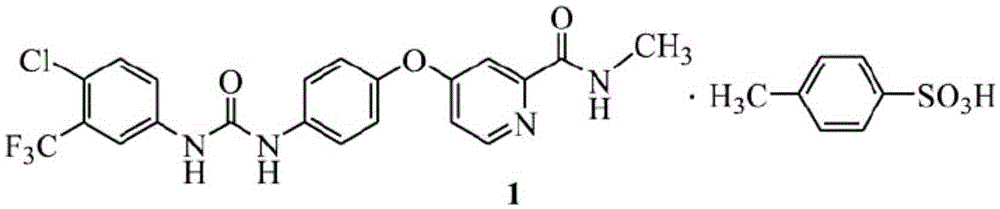

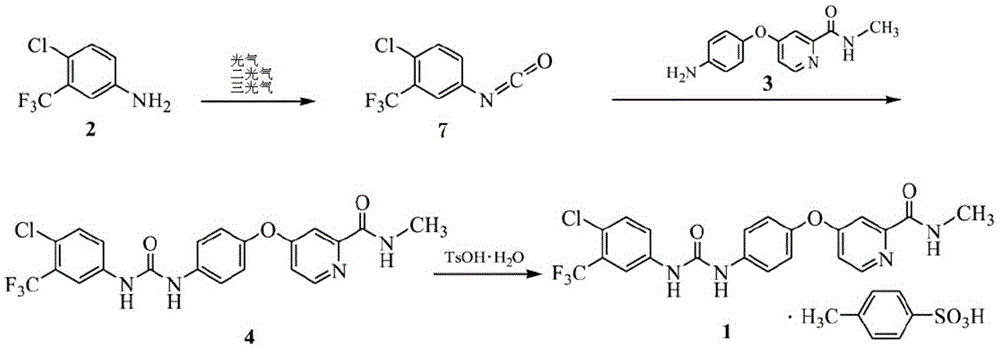

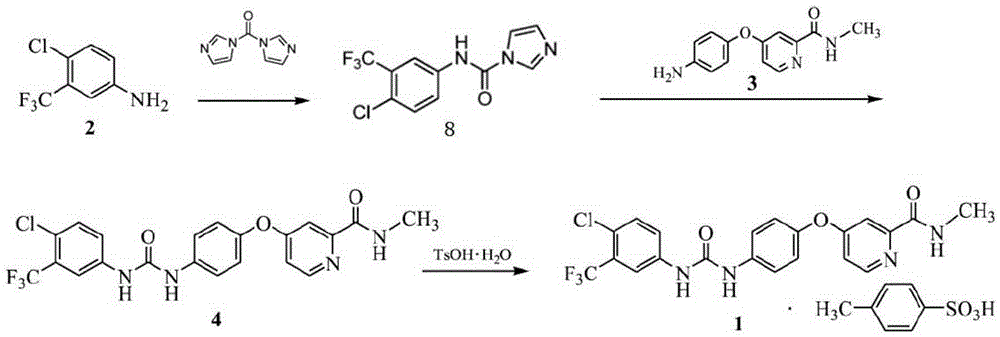

Preparation method of sorafenib tosylate

The invention relates to a preparation method of sorafenib tosylate. The preparation method comprises the steps of reacting propylene chloroformate (5) with low cost and 4-chloro-3-trifluoromethyl phenylamine (2) with low cost to generate activated ester (6); reacting activated ester and 4-(4-aminophenoxy)-N-methyl-2-pyridine carboxamide (3) under the catalysis of N-methylpyrrolidine to obtain sorafenib with high yield; carrying out simple aftertreatment on the reaction to obtain sorafenib with relatively high purity; and then, reacting sorafenib and p-toluene sulphonic acid to generate the target product. The method is low in cost, simple in operation, few in reaction step, short in period, low in energy consumption, safe in process, free of high-toxicity reagents and suitable for industrial production, and the obtained product is high in yield and purity and free of potential safety problems.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD

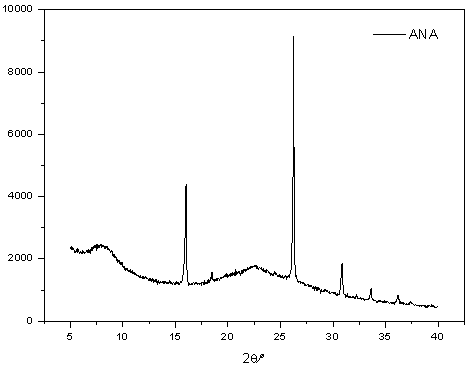

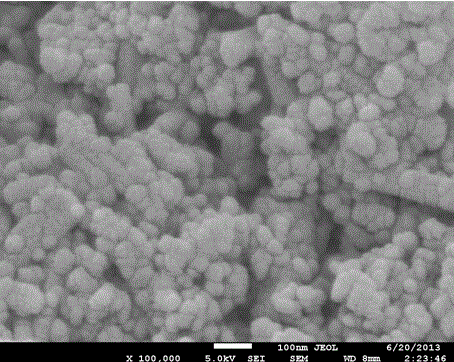

Nano-scale ultra-fine analcime preparation method

ActiveCN106672991APrevent crystallizationReduce dosageMaterial nanotechnologyCrystalline aluminosilicate zeolitesUltra fineCrystallinity

The present invention discloses a nano-scale ultra-fine analcime preparation method, wherein an alkali source, a silicon source, an aluminum source, water and N-methylpyrrolidine are adopted as reaction raw materials and crystallization is performed for 5-200 h under autogenous pressure and 140-200 DEG C hydrothermal condition to obtain the small grain nanometer analcime. According to the present invention, the obtained nano-scale ultra-fine analcime has characteristics of simple process, pure crystal phase, high crystallinity, large specific surface, low cost and the like, and has wide application prospects in ion adsorption and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

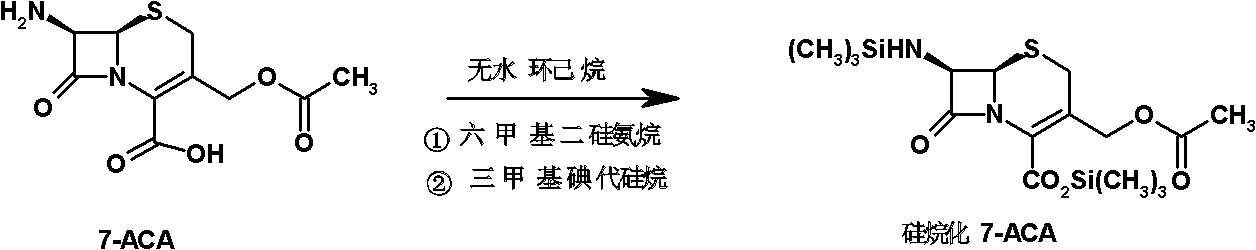

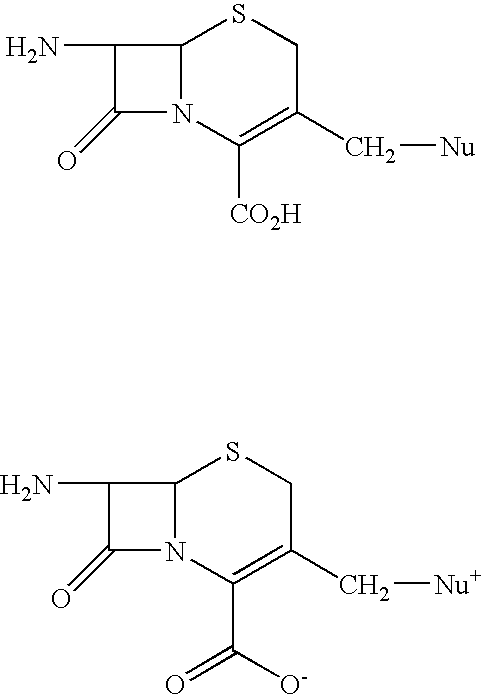

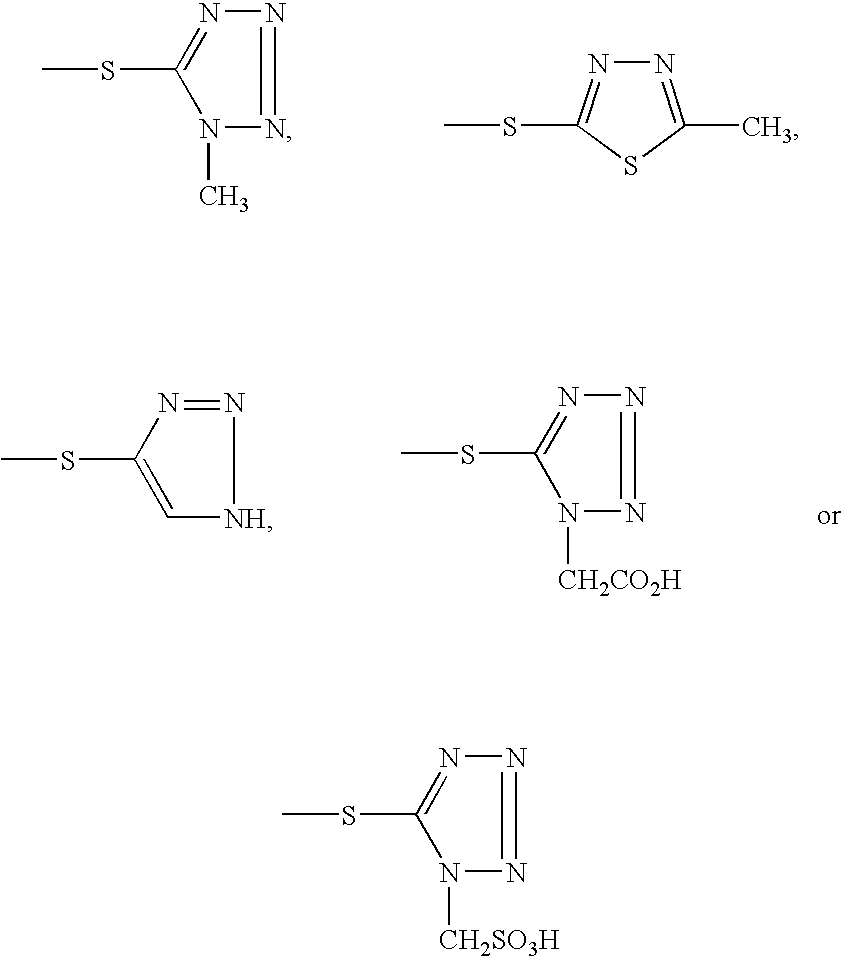

Process for preparing pure cephalosporine intermediates

The present invention relates to a process for preparing key intermediates for cephalosporin antibiotics substantially free of undesired Δ2 isomer. Thus, 7-aminocephalosporanic acid (7-ACA) is silylated with hexamethyldisilazane in cyclohexane at reflux temperature. (6R,7R)-3-[(Acetyloxy)methyl]-7-(trimethylsilyl)aminoceph-3-em-4-oic acid obtained is reacted with the mixture of N-methylpyrrolidine and trimethylsilyl iodide in cyclohexane, desilylated with isopropyl alcohol and treated with hydrochloric acid to obtain [6R-(6α,7β)]-1-[[7-Amino-2-carboxy-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-en-3-yl]methyl]-1-methylpyrrolidinium inner salt hydrochloride. [6R-(6α,7β)]-1-[[7-Amino-2-carboxy-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-en-3-yl]methyl]-1-methylpyrrolidinium inner salt hydrochloride is N-acylated with syn-2-(2-aminothiazol-4-yl)-2-methoxyimino acetic acid 2-benzothiazolyl thioester (MAEM) followed by treatment with hydrochloric acid to give cefepime dihydrochloride monohydrate.

Owner:HETERO DRUGS LTD

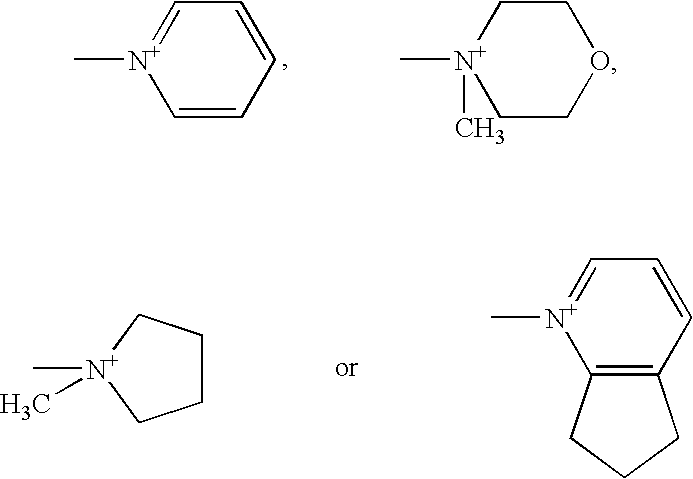

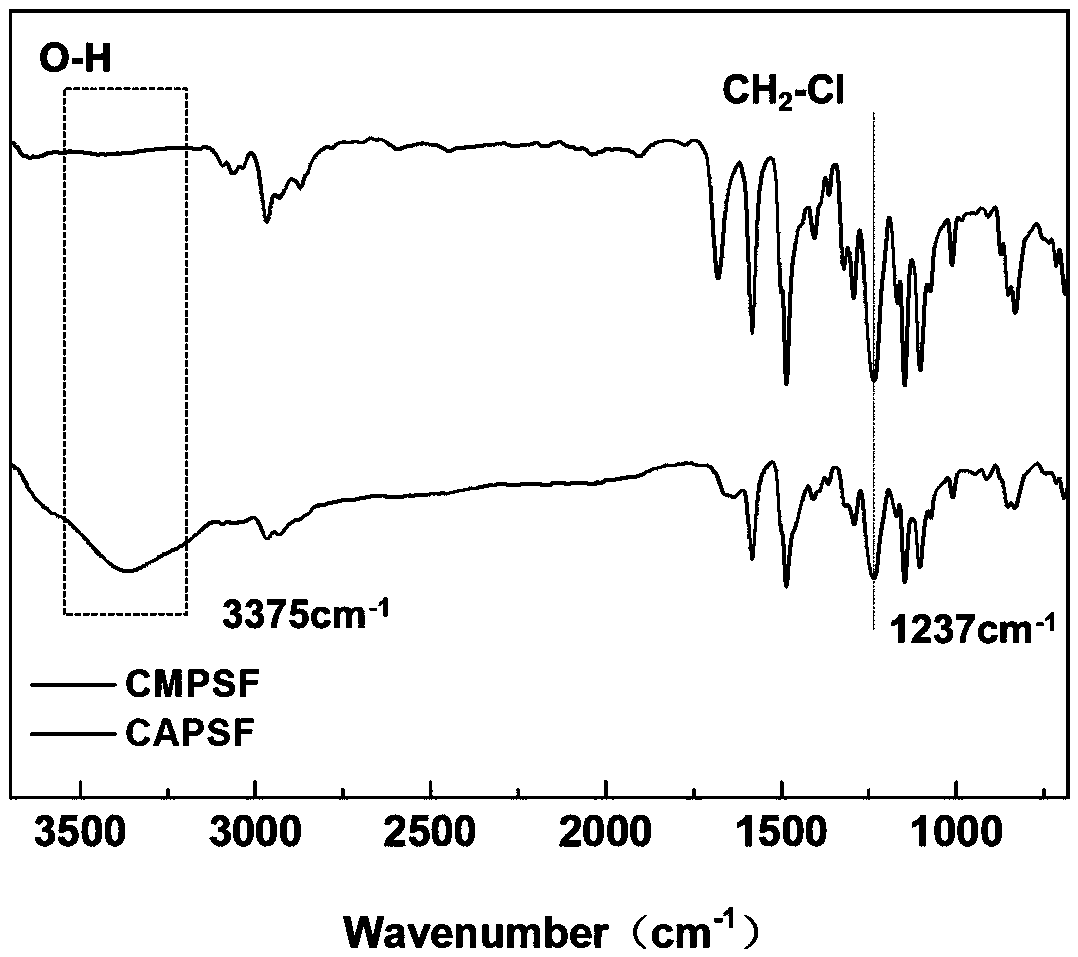

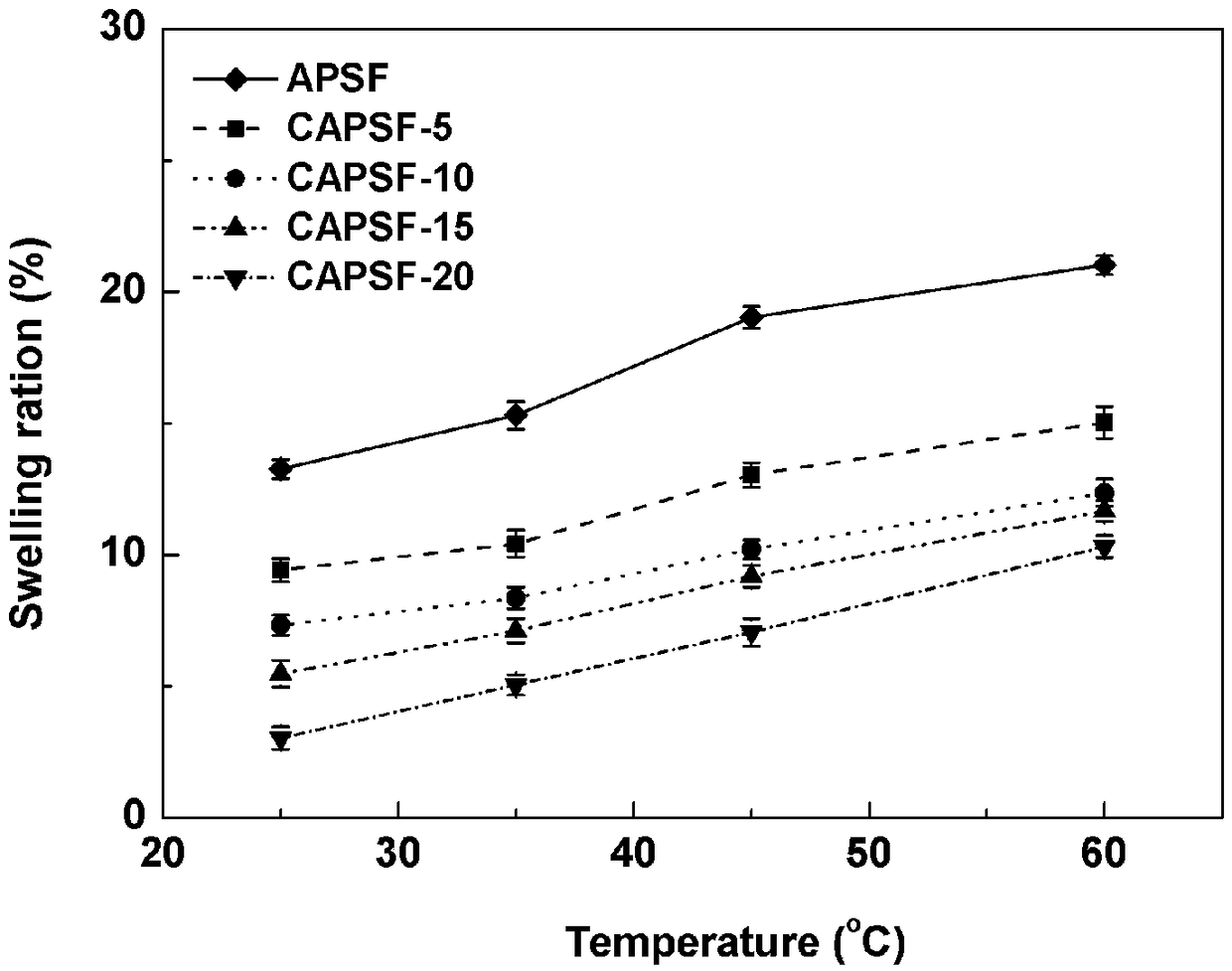

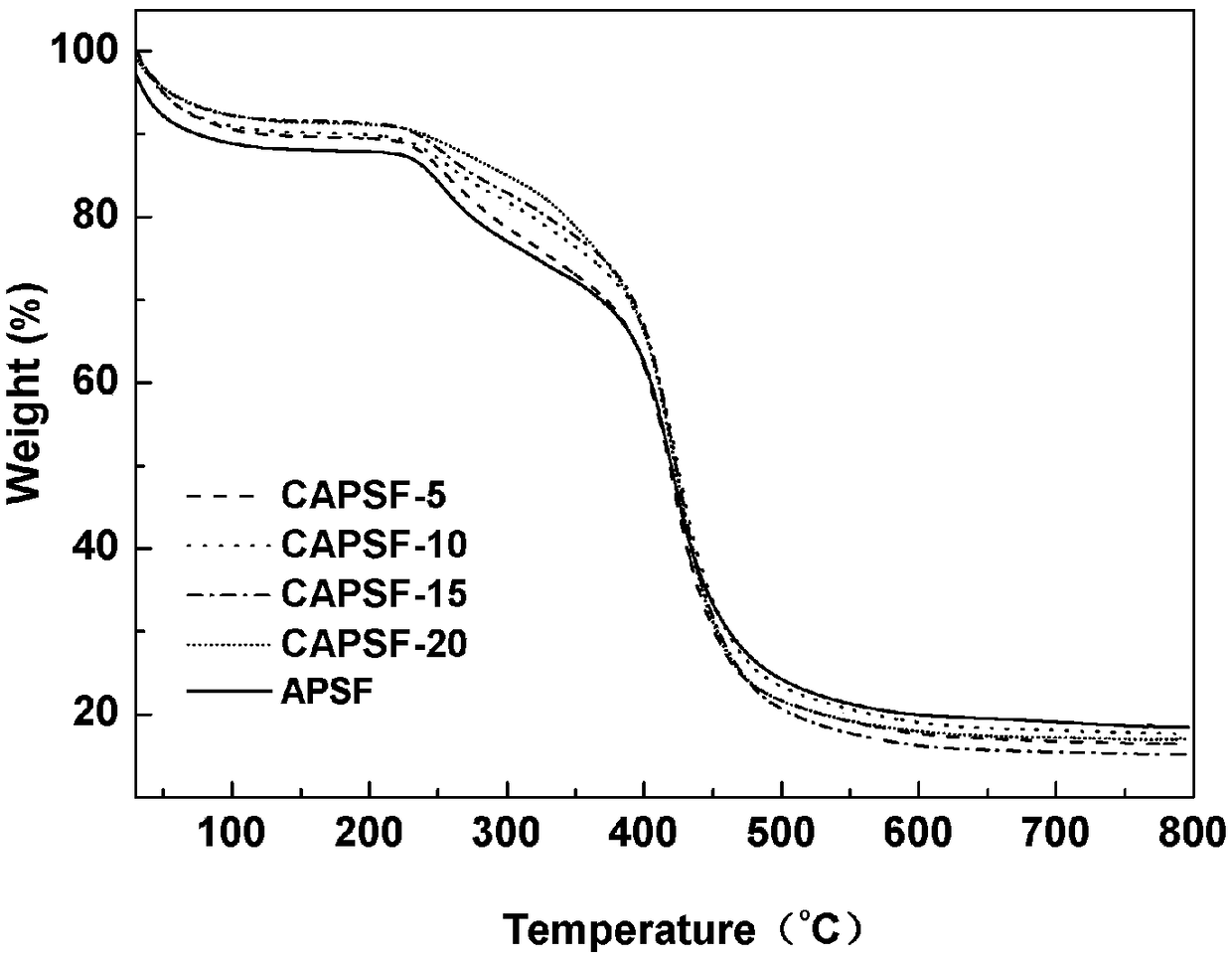

Preparation method of anion exchange membrane through crosslinking by using 4,4'-trimethylenedipiperidine (TMDP)

ActiveCN109289556AImprove mechanical propertiesImprove thermal stabilityMembranesSemi-permeable membranesCross-linkPhysical chemistry

The invention disclose a preparation method of an anion exchange membrane by using 4,4'-trimethylenedipiperidine (TMDP) as a cross-linking agent. The preparation method is implemented according to thefollowing steps: (1) dissolving chloromethylated polysulfone in 1-methyl-2-pyrrolidinone (NMP) at room temperature to obtain a colorless transparent chloromethylated polysulfone solution A; (2) adding a certain amount of 4,4'-trimethylenedipiperidine into the chloromethylated polysulfone solution A at room temperature, and carrying out stirring for 0.5-2 hours to carry out a cross-linking reaction on the 4,4'-trimethylenedipiperidine with the chloromethylated polysulfone to obtain a chloromethylated polysulfone solution B; (3) adding N-methylpyrrolidine into the chloromethylated polysulfone solution B at room temperature, carrying out stirring for 0.5-4 hours to carry out a quaternization reaction until the reaction is completed to obtain a membrane casting solution; and (4) completely deforming the membrane casting solution, pouring the membrane casting solution on a clean glass plate, carrying out film scraping by using a scraper, then carrying out vacuum drying, soaking the glass plate in deionized water so that a membrane naturally falls off from the glass plate, and carrying out washing with deionized water to obtain the anion exchange membrane. The anion exchange membrane has good alkali resistant stability and swelling resistance.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing N-methylpyrrolidine through catalysis

ActiveCN108299336AGreen and efficient synthesisEasy to makeOrganic chemistryMolecular sieve catalystsActive componentReaction temperature

The invention discloses a method for preparing N-methylpyrrolidine through catalysis. According to the method, 1,4-butanediol and a methylamine water solution which are used as raw materials react inan H2 reduction atmosphere at the reaction temperature of 230-330 DEG C and under the pressure of 4-10 Mpa for 1-8 h with a supported bimetal oxide as a catalyst to produce N-methylpyrrolidine. A supporter of the catalyst is an Al2O3, SiO2 or ZSM-5 molecular sieve, and active components are CuO and NiO. The method has the advantages that the reaction time is short, the catalyst is low in cost andreusable, the product yield is high and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

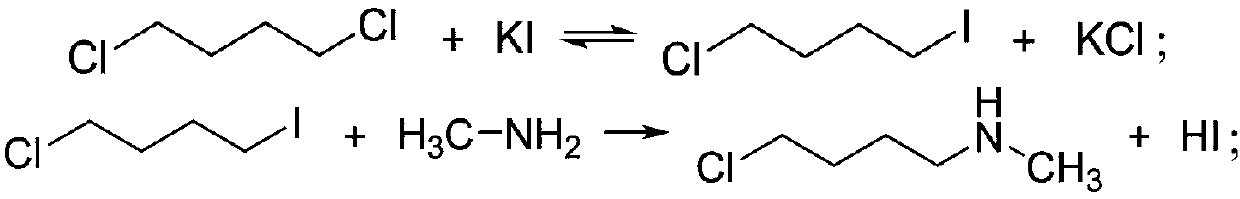

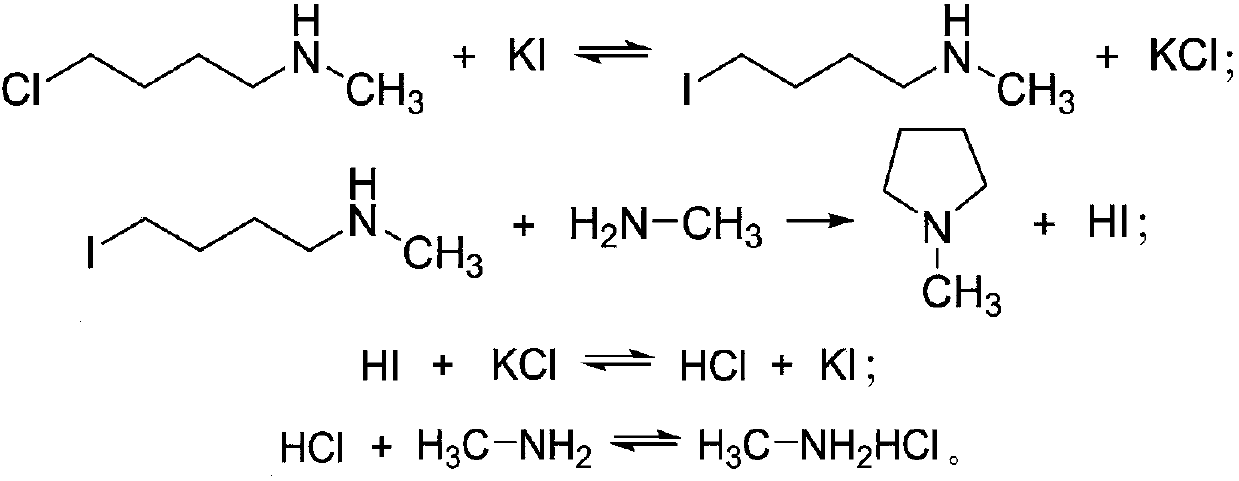

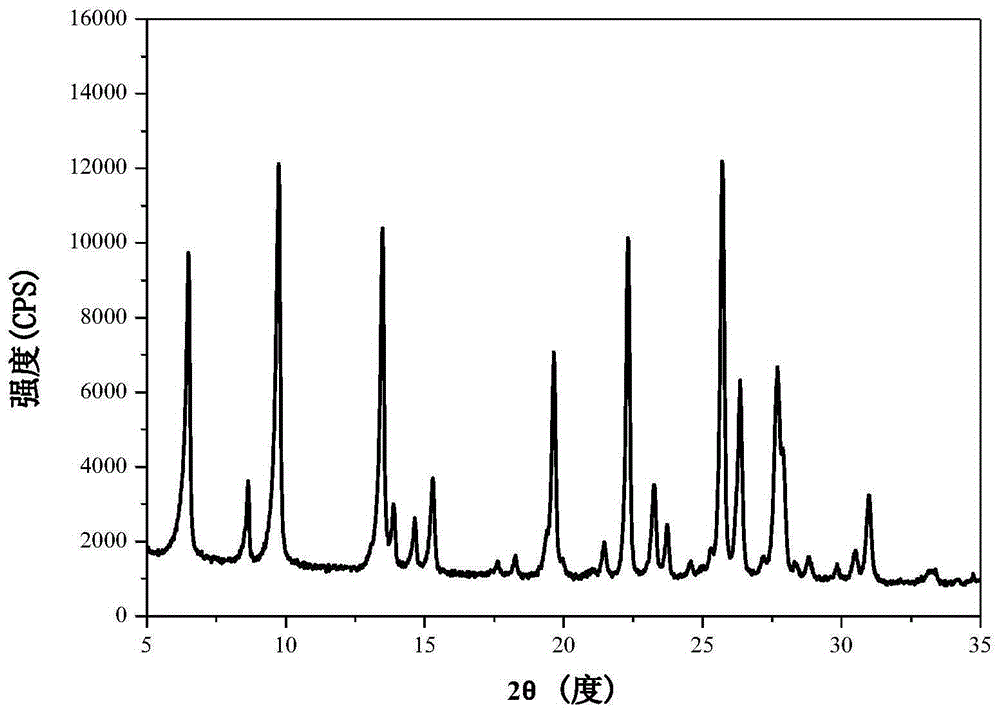

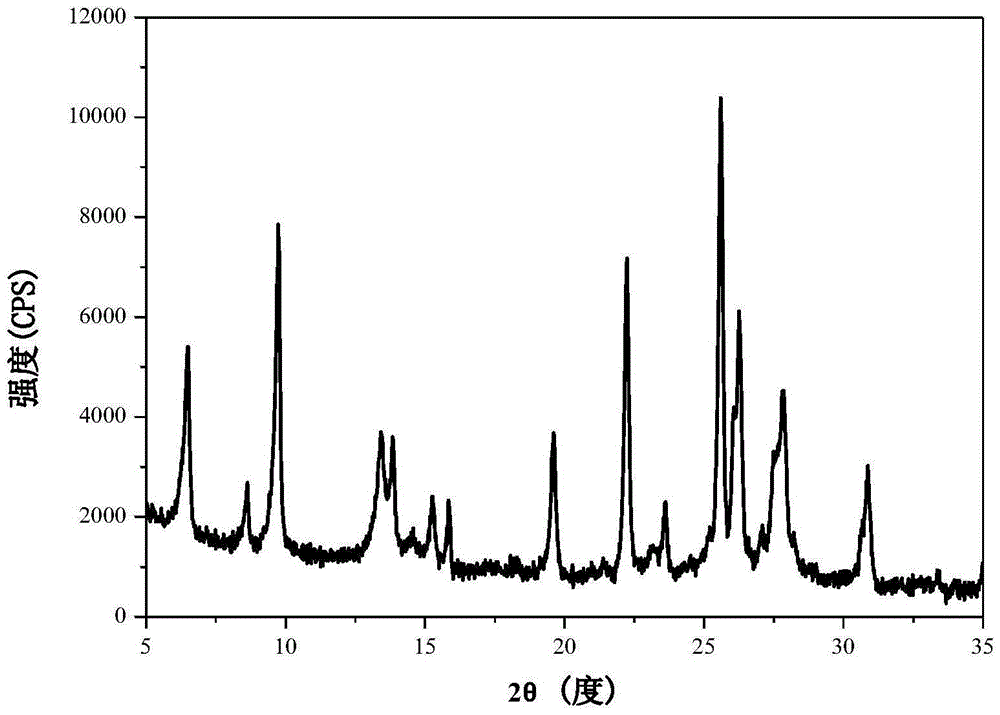

Process for producing 7-amino-3-[(1-methyl pyrrolidine) methyl]-3- cephalosporin-4-carboxylic dihydrochloride

InactiveCN101429207AReduce decompositionIncreased weight yieldOrganic chemistryHydrolysateCarboxylic acid

The invention discloses a method for preparing 7-amino-3-[(1-methylpyrro-lidinio)methyl]-3-cephem-4-carboxylic acid dihydrochloride, which comprises the following steps: imidazole, trimethylchlorosilane and 7-ACA react in a methylene dichloride solvent at a temperature of between 10 and 30 DEG C, and then are filtered; the temperature is reduced, and TMSI is dripped to react; THF is added into the mixture after methylene dichloride is distilled from a reaction feed liquid, and a N-methylpyrrolidine solution is dripped and stirred at a temperature of between 30 DEG C below zero and 25 DEG C below zero to react; methanol is dripped after the reaction, and then concentrated hydrochloric acid or hydriodic acid is dripped to hydrolyze; a hydrolysate is added with the methylene dichloride, and an aqueous phase is obtained through the separation; a yellow aqueous solution is obtained after the aqueous phase is decolored; and then acetone is added into the mixture to be filtered, washed and dried to obtain a 7-MPCA product. The methylene dichloride is distilled, so as to effectively improve the utilization rate of equipment, and the method can improve 30 percent of the utilization rate of the equipment compared with a process that the methylene dichloride is not distilled; and imidazole hydrochloride generated by the reaction which affects the subsequent layering and crystallization is filtered, which is favorable for the reaction, and ensures that the yield can reach 100 percent and the purity of a liquid phase is more than 99 percent.

Owner:河北九派制药股份有限公司

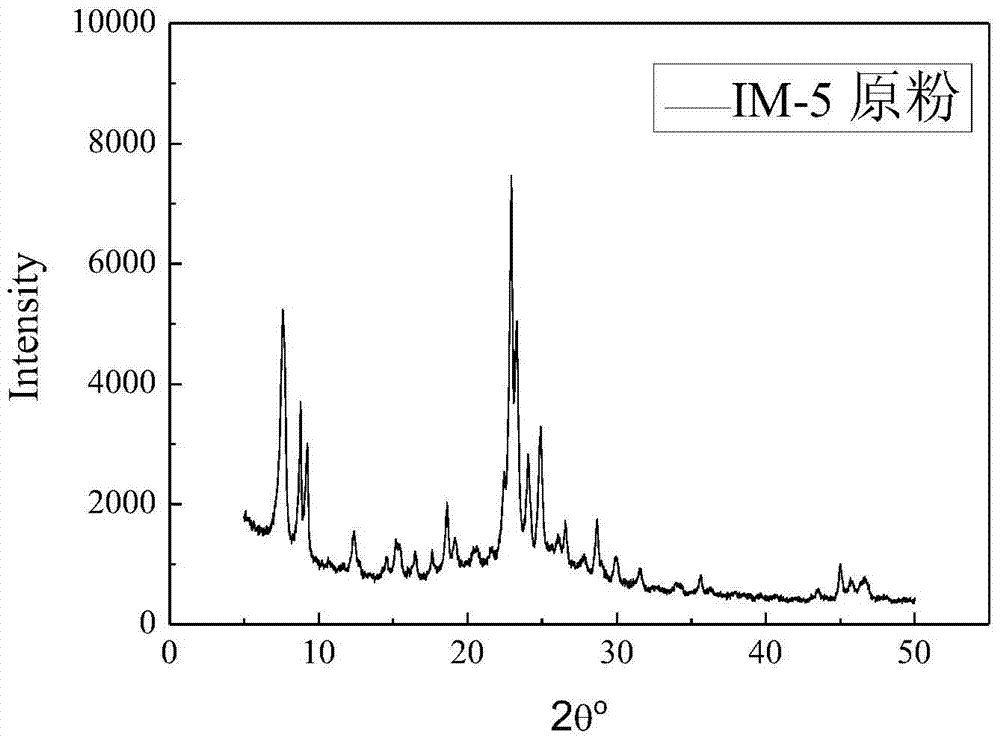

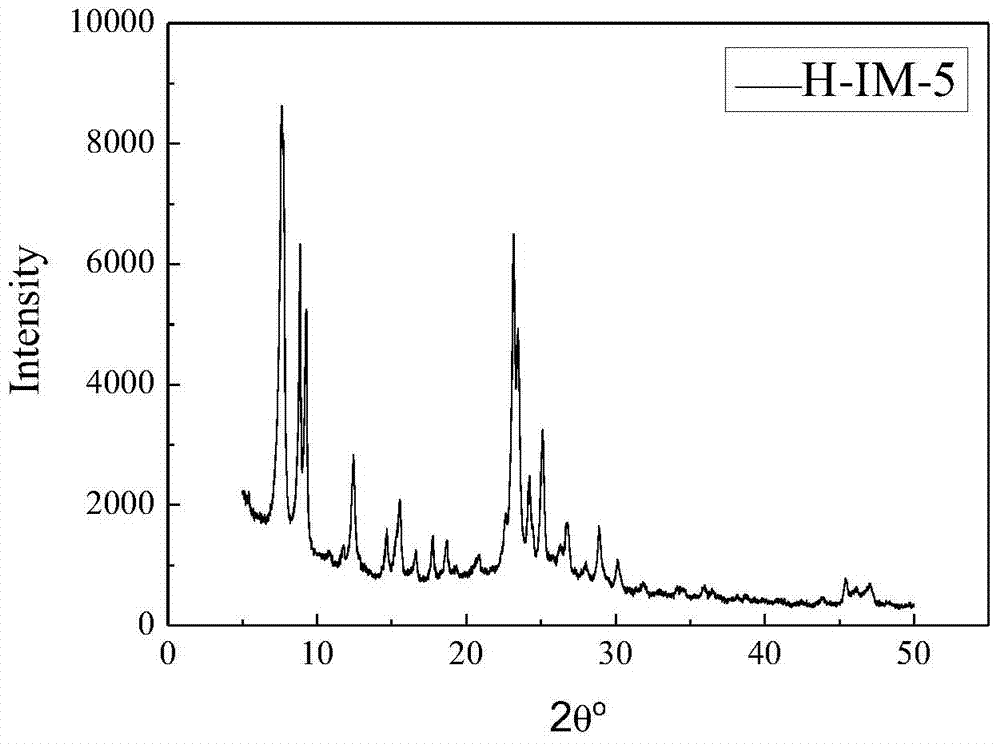

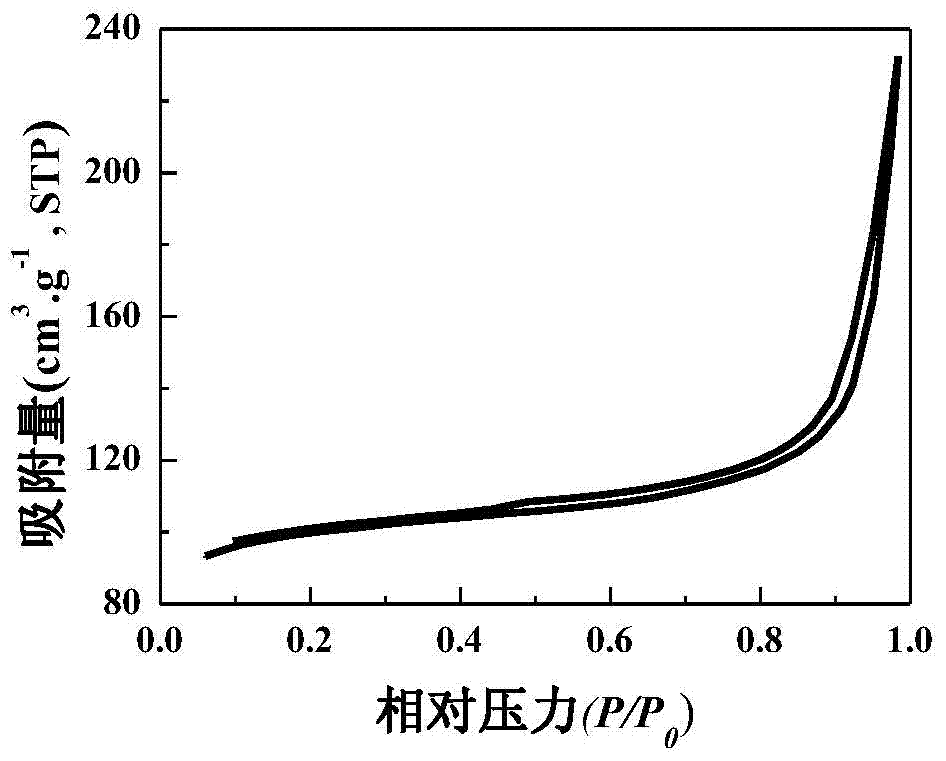

Mesoporous IM-5 molecular sieve preparation method

ActiveCN107021504AImprove anti-coking performanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveAlkyl transfer

The invention relates to a mesoporous IM-5 molecular sieve preparation method, which comprises: (1) dissolving an inorganic alkali or an organic alkali and a templating agent in water to prepare a mixed solution, and adding a microporous IM-5 molecular sieve to obtain a solid-liquid mixture, wherein a molar ratio of Z to B to R to H2O is 1:(0.01-0.03):(0.01-0.20):(5-40), Z is a microporous IM-5 molecular sieve (calculated as SiO2), the silicon oxide / alumina molar ratio of the microporous IM-5 molecular sieve is 40-200, B is an inorganic alkali or an organic alkali, R is a templating agent, the organic alkali is a quaternary ammonium alkali having a general formula NR14OH, and R1 is a C1-C2 alkyl or a 1,5-bis(N-methylpyrrolidine)pentane diquaternary ammonium alkali; and (2) carrying out hydrothermal crystallization treatment on the solid-liquid mixture obtained in the step (1) at a temperature of 120-200 DEG C, drying the solid obtained after the treatment, and calcining. According to the present invention, the prepared mesoporous IM-5 molecular sieve has intracrystal mesopores, and can provide high activity stability when the mesoporous IM-5 molecular sieve is used in toluene-methanol alkylation reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

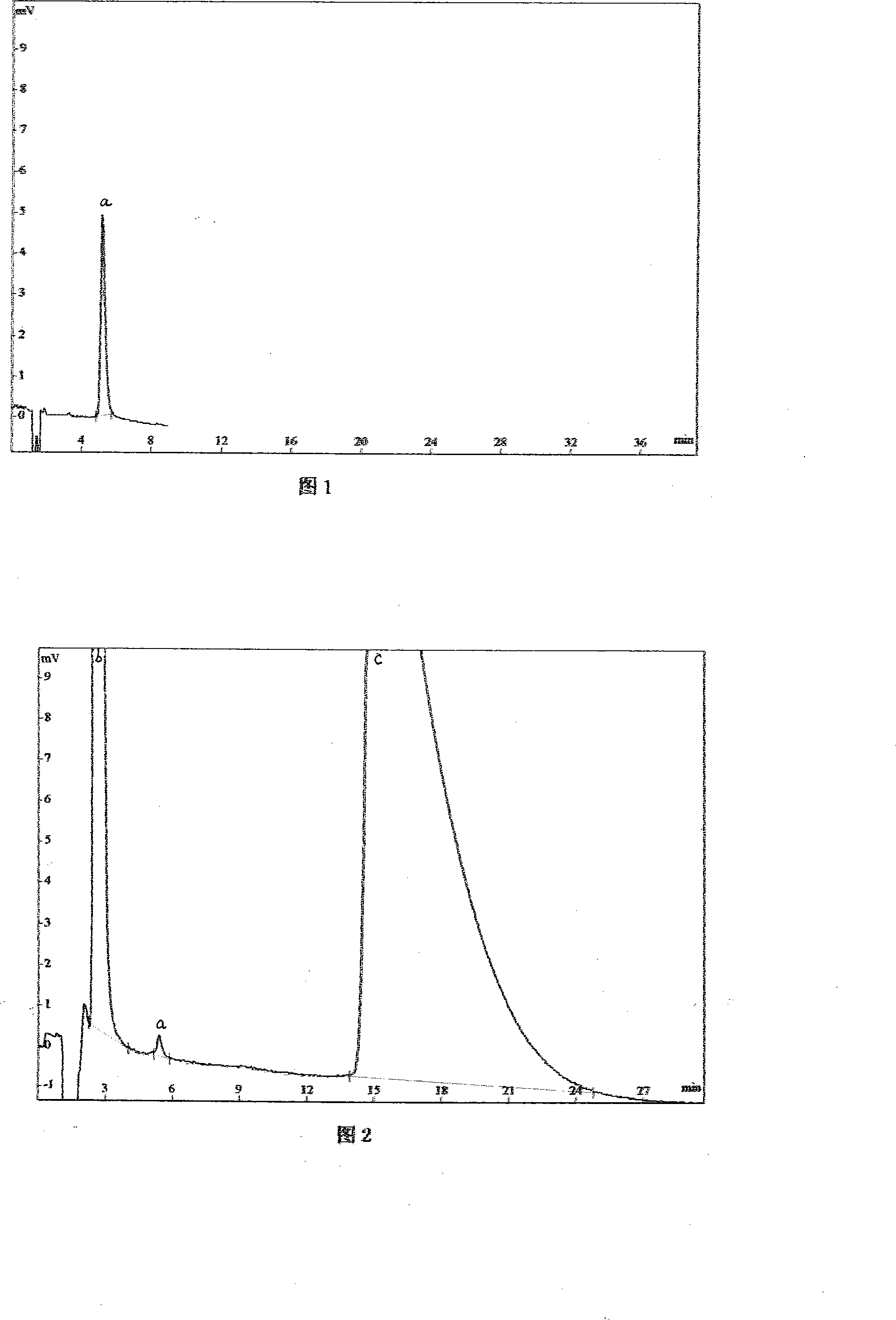

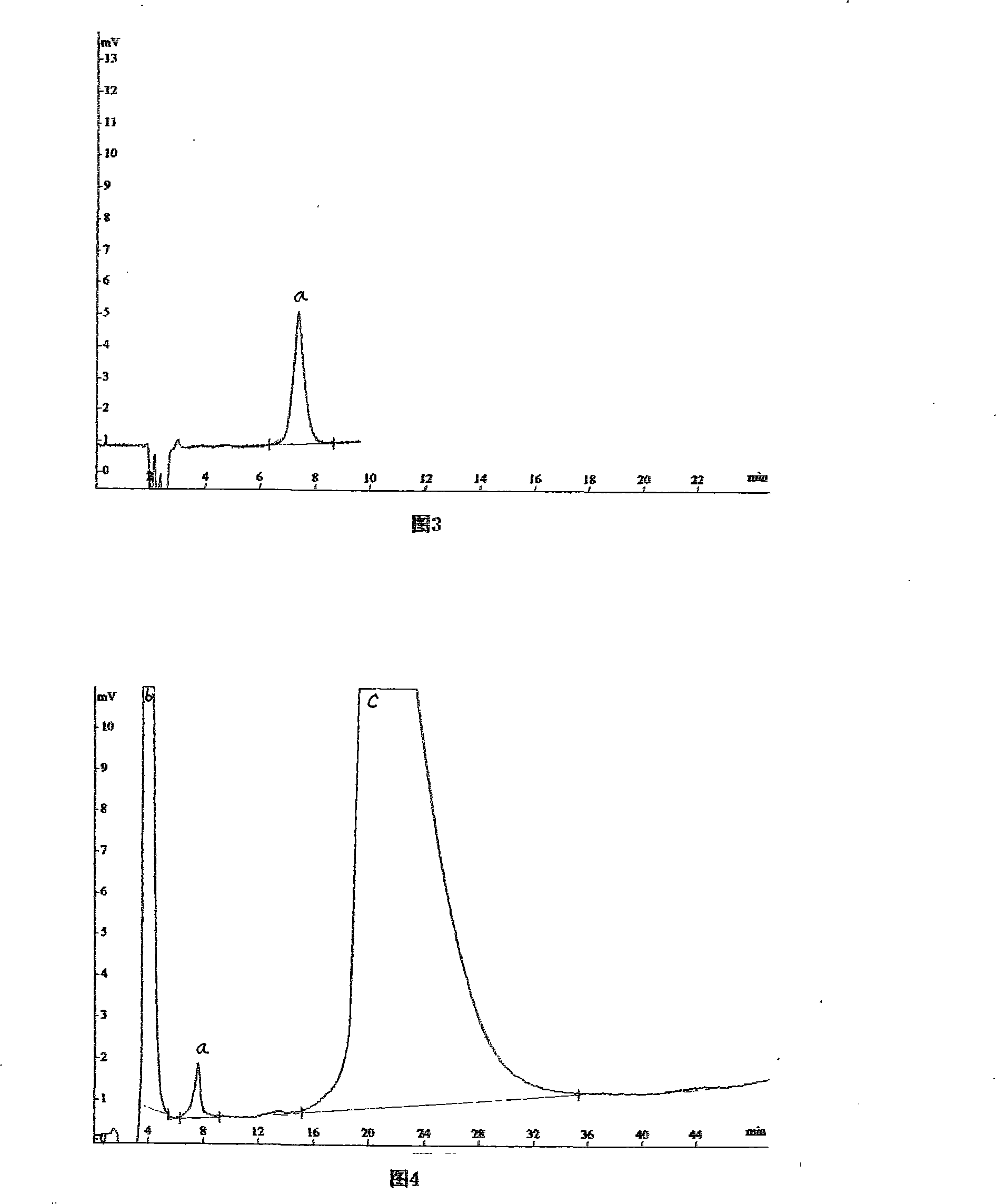

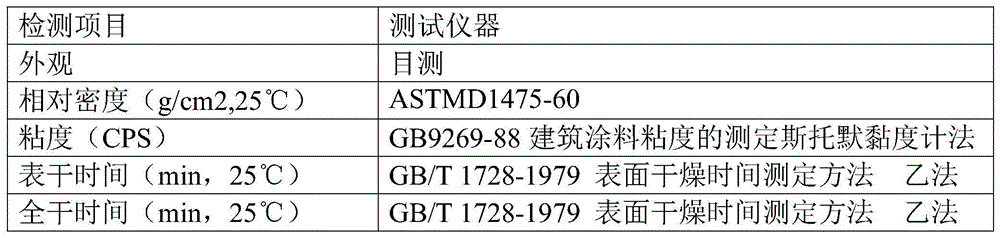

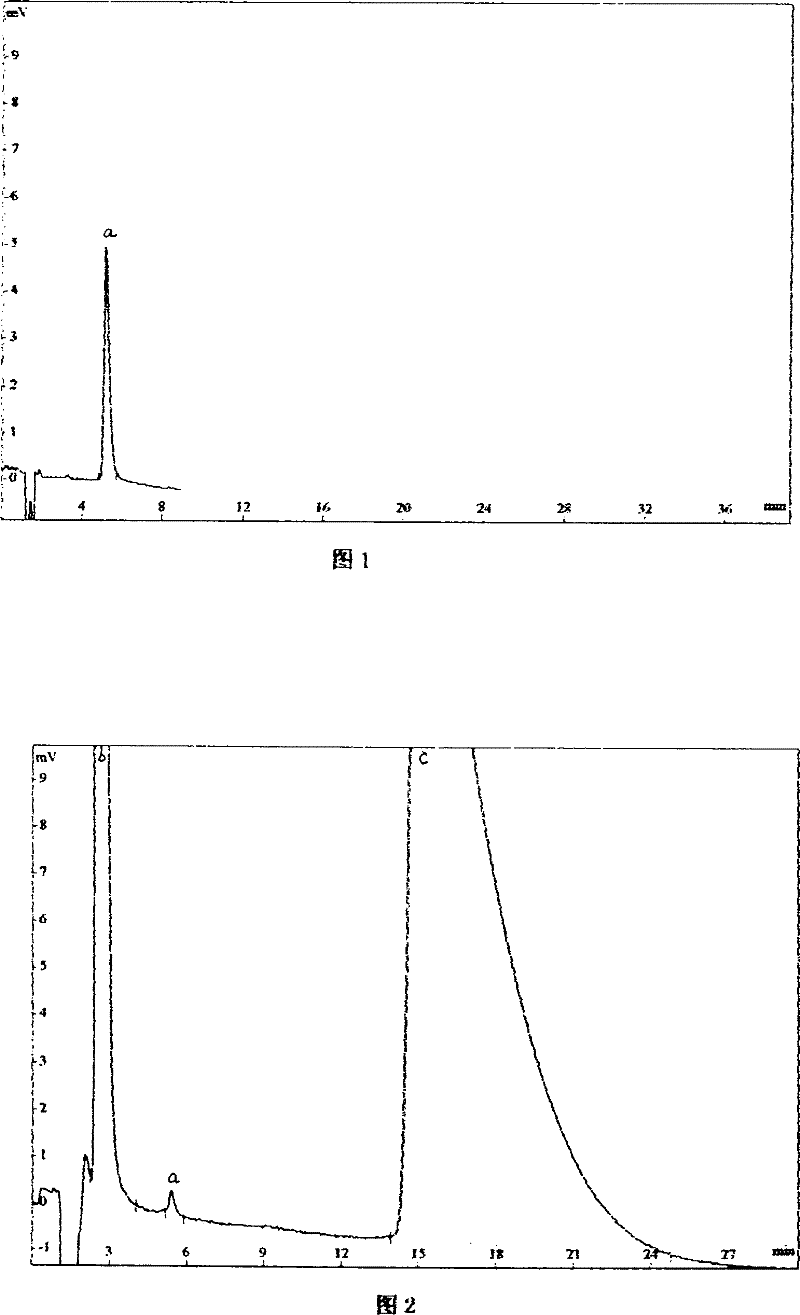

Hydrochloric acid cefepime raw material and method for measuring content of N-methyl pyrrolidine in preparation thereof

ActiveCN101226174AImprove balanceShort measurement timeComponent separationCefepime hydrochlorideRetention time

The invention relates to a measurement method of N-methylpyrrolidine content of cefepime dihydrochloride material and relative agent, for evaluating the quality of cefepime dihydrochloride material and relative agent. The invention discloses a liquid chromatograph which comprises using carboxylic cationic column as analysis column, uses a conductive detector to check, preparing flow phase, preparing sample solution and reference substance solution, using test method to respectively inject the sample solution and reference substance solution into a liquid chromatograph, recording high pressure liquid chromatographs, and calculating the N-methylpyrrolidine content of the sample. The inventive chromatograph system has easy balance, short sample test time, better repeatability in preserved time, stable baseline, durable column, high quality of chromatograph peak of N-methylpyrrolidine, better repeatability, accurate, simple and reliable process.

Owner:GUANGZHOU BAIYUSN TIANXIN PHARMA

Bacteriostatic environment-friendly film and preparation method thereof

The invention discloses a bacteriostatic environment-friendly film and a preparation method thereof. The environment-friendly film is prepared from the following raw materials by weight: 1-2 parts ofsilane coupling agent kh560, 49-50 parts of tetrabutyl titanate, 30-40 parts of methanol, 1-2 parts of bis[tetrakis(hydroxymethyl)phosphonium]sulfate solution, 8-11 parts of isocyanuric acid, 1-2 parts of ethylene bisstearamide, 110-140 parts of high density polypropylene, 2-3 parts of diisocyanate, and 10-12 parts of N-methylpyrrolidine. According to the bacteriostatic environment-friendly film and the preparation method thereof, quaternization reaction is carried out by blending a phosphate-modified sol solution and a silane-polypropylene alcohol solution, thereby effectively improving the bacteriostatic performance and flexibility of the finished film, and the film provided by the invention has high mechanical stability, good uniformity and high quality.

Owner:合肥拖油瓶信息科技有限公司

Paint cleaning agent and preparation method thereof

InactiveCN102807781AEasy to cleanQuick Dissolving PeelChemical paints/ink removersKetoneEthyl acetate

The invention relates to a cleaning agent, in particular to a paint cleaning agent which is strong, powerful, economical, high-efficient, energy-saving, environment-friendly, novel and concentrated and a preparation method thereof. The paint cleaning agent is prepared by the following raw materials by weight percent: 15 to 25 percent of dimethoxy dipropylene glycol, 25 to 40 percent of N-methylpyrrolidine, 5 to 8 percent of ethanolamine, 20 to 30 percent of ethyl acetate, 5 to 10 percent of fatty acid ester, 15 to 25 percent of dimethyl ketone and 0.2 percent of fruity essence.

Owner:刘杰

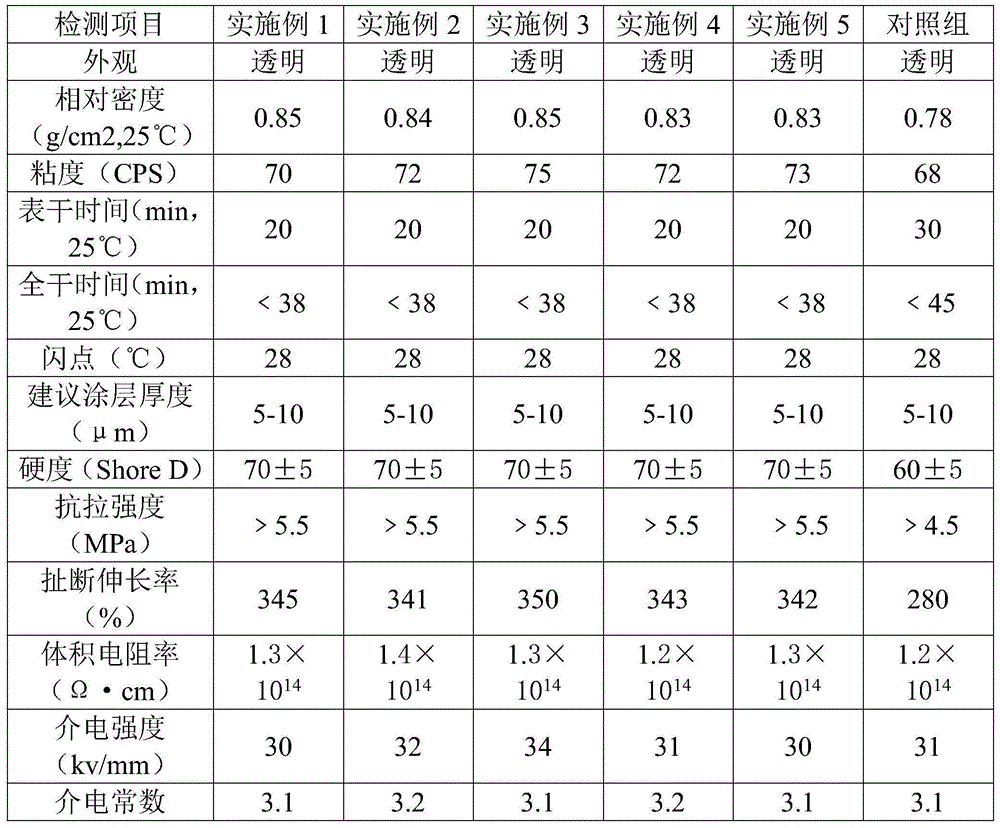

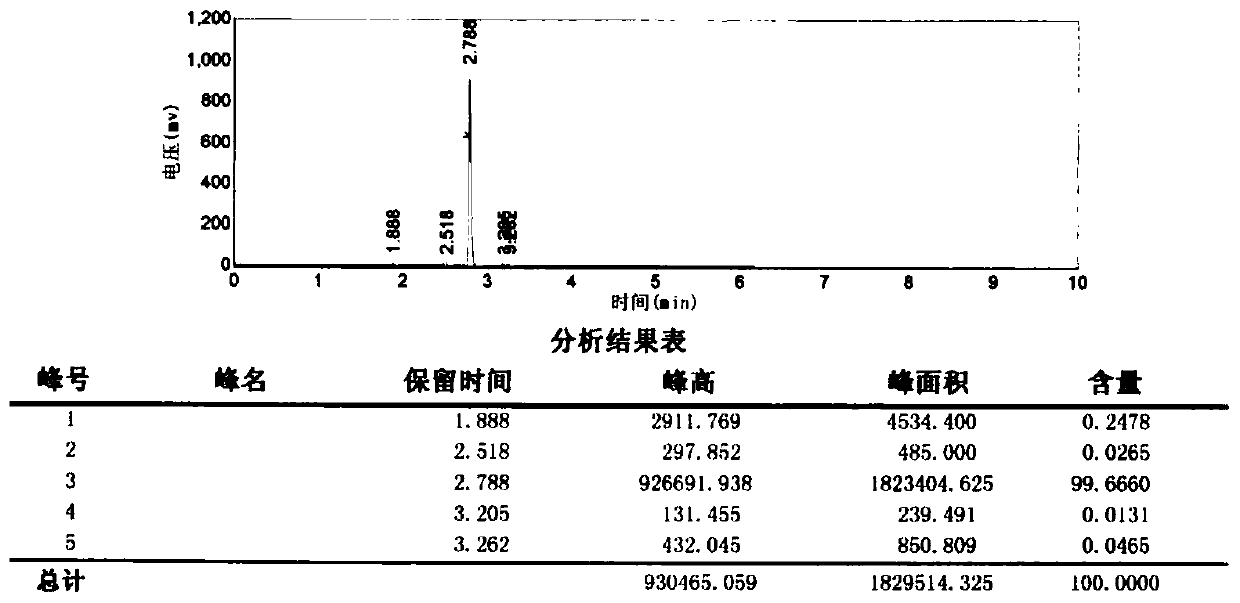

Three-proofing lacquer for circuit board preventing electromagnetic interference

The invention relates to the field of coating technology, in particular to three-proofing lacquer for circuit board preventing electromagnetic interference. The three-proofing lacquer comprises the following components in parts by mass: 20-40 parts of polysiloxane, 6-12 parts of rosin modified alkyd resin, 12-16 parts of ethyl acetate, 10-15 parts of trioctyl phosphate, 0.6-1.2 parts of nano-graphite, 0.8-1.8 parts of titanium phosphide powder, 6-10 parts of mineral oil, 6-8 parts of N-Methylpyrrolidine, 2-6 parts of antioxygen, and 2-8 parts of defoamer. The polysiloxane, the rosin modified alkyd resin, the trioctyl phosphate, the nano-graphite, the titanium phosphide powder, the mineral oil and the N-Methylpyrrolidine are compounded to use, so that the three-proofing lacquer is easy to spray during the actual use process, is quick in paint film curing, has both hardness and toughness, is transparent in a paint film, is firm to attach, is waterproof and dampproof, is good in heat stability, has a certain shielding effect on electromagnetic wave, and is beneficial to improving the safety reliability of the circuit board and reducing the failure occurrence probability.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

N-methylpyrrolidine preparation method

ActiveCN110590706AImprove solubilityLower gas phase partial pressureOrganic chemistryPotassium iodineHigh pressure

The invention relates to preparation of organic alkalis of medical and chemical raw materials, particularly to a N-methylpyrrolidine preparation method, which comprises: a) under the catalysis of potassium iodide, carrying out a mixed reaction on 1,4-dichlorobutane and methylamine aqueous solution in an ether solvent to obtain N-methylpyrrolidine, wherein the ether solvent can form a hydrogen bondwith methylamine, and the boiling point of the ether solvent is greater than the azeotropic point of methylamine and water in the mixed system. According to the invention, the preparation method hasadvantages of abundant raw material sources and simple synthesis process route, and does not require high-pressure reaction conditions so as to achieve advantages of equipment investment reducing, production management simplifying, comprehensive cost reducing, excellent economical efficiency and wide popularization prospect compared with the high-pressure method; and the experimental results showthat with the application of the method to prepare N-methylpyrrolidine, the preparation yield is larger than 88%, and the product purity is larger than 99%.

Owner:四平市精细化学品有限公司

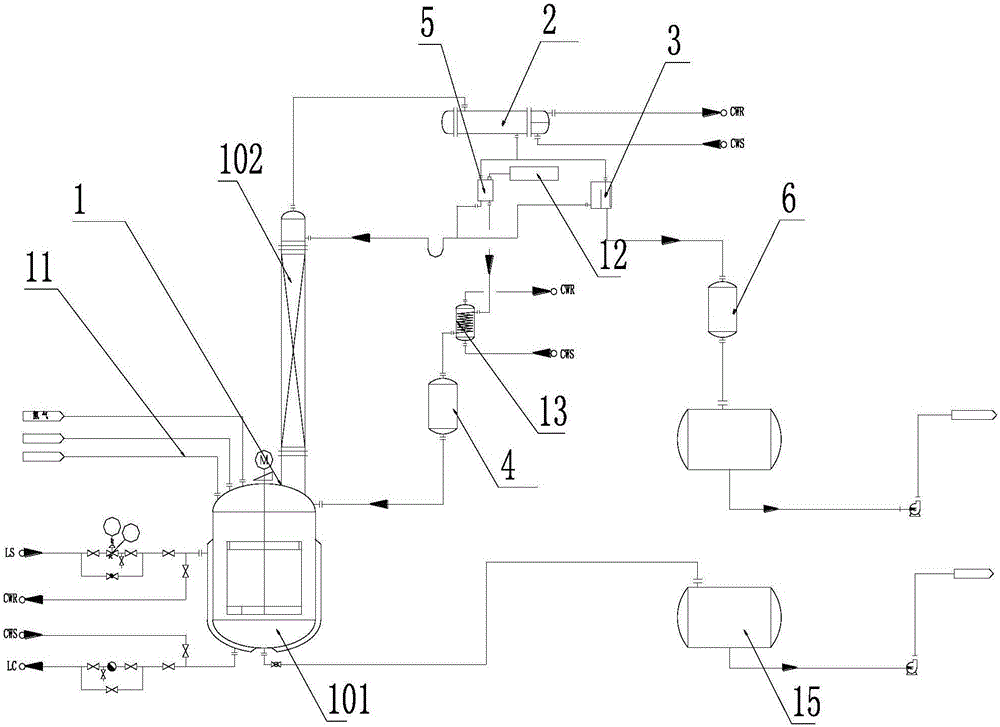

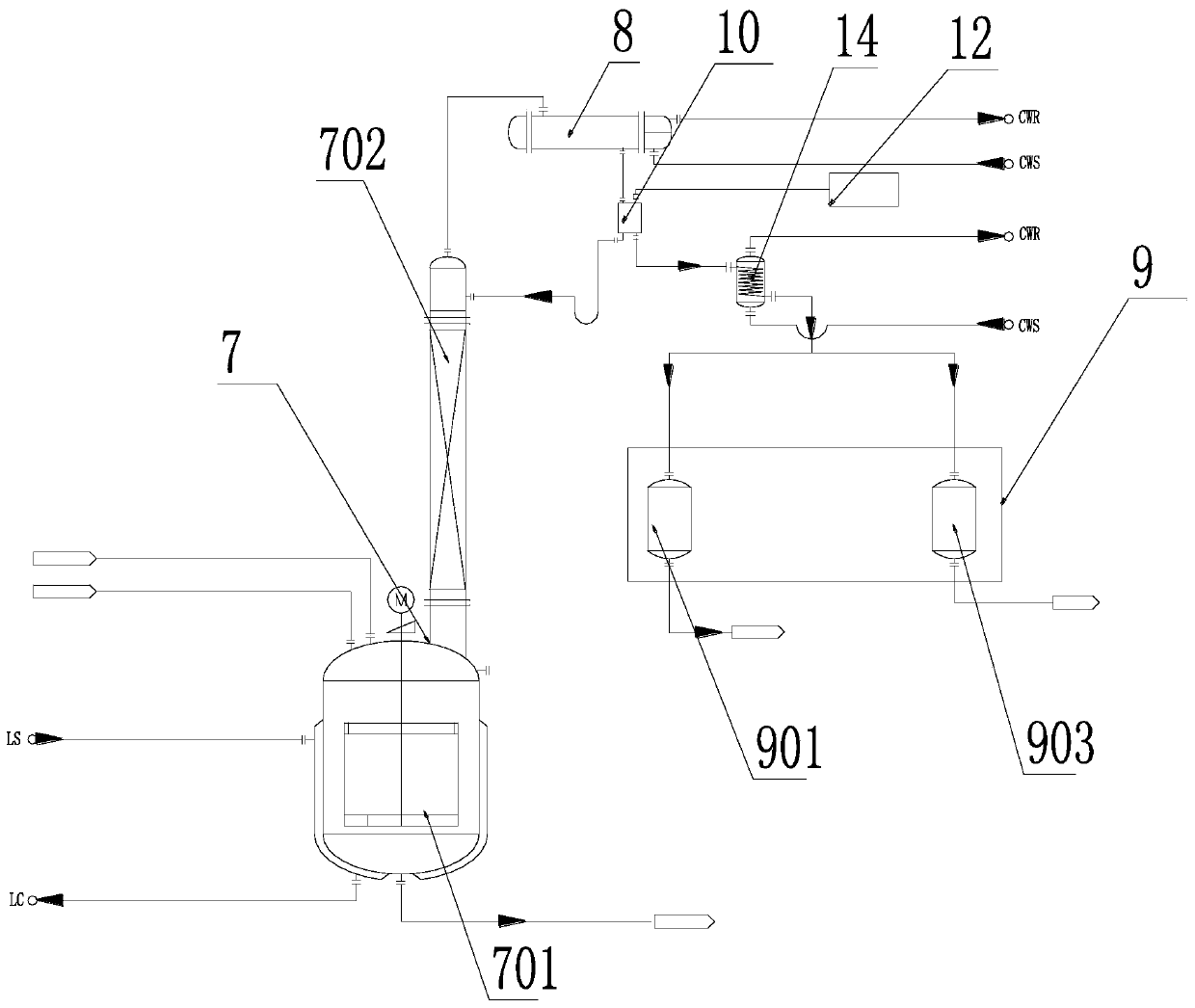

Device and method for separating N-methylpyrrolidine, water and tetrahydrofuran

ActiveCN105061363ASolve the problem of energy consumptionSettlement yieldOrganic chemistryPhase splittingProcess engineering

Provided are a device and method for separating N-methylpyrrolidine, water and tetrahydrofuran. The device comprises a crude product dehydration working section and a product refining working section. The crude product dehydration working section comprises a crude product intermittent column, a first condenser, a phase splitting tank, a backflow head and the like. The crude product intermittent column comprises a crude steaming column reactor and a crude steaming column. The product refining working section comprises a refining intermittent column, a second condenser, a transition cut fraction receiving tan and a product receiving tank. The refining intermittent column comprises a rectifying column reactor and a rectifying column located at the top of the rectifying column reactor. The crude product dehydration working section is communicated with the rectifying column reactor of the product refining working section through a crude product storage tank communicated with the crude steaming column reactor. A two-column intermittent rectifying process is adopted in the method, water and tetrahydrofuran are taken out through the crude product intermittent column, left raw materials are purified through the product refining working section, and high-purity N-methylpyrrolidine is obtained. The problems that a traditional device and technique are large in energy consumption, low in yield, high in production cost and troublesome in aftertreatment are solved.

Owner:烟台国邦化工机械科技有限公司

Hydrochloric acid cefepime raw material and method for measuring content of N-methyl pyrrolidine in preparation thereof

ActiveCN101226174BImprove balanceShort measurement timeComponent separationCefepime hydrochlorideTested time

The invention relates to a measurement method of N-methylpyrrolidine content of cefepime dihydrochloride material and relative agent, for evaluating the quality of cefepime dihydrochloride material and relative agent. The invention discloses a liquid chromatograph which comprises using carboxylic cationic column as analysis column, uses a conductive detector to check, preparing flow phase, preparing sample solution and reference substance solution, using test method to respectively inject the sample solution and reference substance solution into a liquid chromatograph, recording high pressureliquid chromatographs, and calculating the N-methylpyrrolidine content of the sample. The inventive chromatograph system has easy balance, short sample test time, better repeatability in preserved time, stable baseline, durable column, high quality of chromatograph peak of N-methylpyrrolidine, better repeatability, accurate, simple and reliable process.

Owner:GUANGZHOU BAIYUSN TIANXIN PHARMA

Catalyst for catalytic synthesis of N-methylpyrrolidine and application thereof

InactiveCN101912779BEasy to makeReaction raw materials are cheap and easy to obtainOrganic chemistryMolecular sieve catalystsMolecular sieveChemical industry

Owner:HEBEI UNIV OF TECH

A Flat Type Cellulose Acetate/Nano Titanium Dioxide Blended Forward Osmosis Membrane

ActiveCN104474920BControl performancePollution resistantSemi-permeable membranesCellulose acetateN-Methyl-2-pyrrolidone

The invention discloses a high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane, which is prepared by comprising the following steps: adding the following raw materials in percentage by weight: 7.0%-26.0% of cellulose acetate, 2.0%-16.0% of additives, 0.1%-5.0% of nano-titanium dioxide, 0.05%-0.1% of graphene, and a dimethylformamide or dimethylacetamide, N-methylpyrrolidine and acetone mixed solvent into a dissolving tank according to certain sequence, stirring and dissolving for 3-15h to be full and even at 25-90DEG C, thus obtaining blended forward osmosis membrane casting liquid; and preparing the high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane on a supporting material by using a phase conversion method. According to the prepared forward osmosis membrane, 1M NaCl and deionized water are respectively taken as driving liquid and feed solution, the flux of pure water can reach more than 17.5L / m<2>.h during testing time of1h and the backward salt flux is less than 3.0g / m<2>.h.

Owner:UNIV OF JINAN

Device and method for separating n-methylpyrrolidine, water and tetrahydrofuran

ActiveCN105061363BHigh yieldApplication rate increasedOrganic chemistryPhase splittingProcess engineering

Provided are a device and method for separating N-methylpyrrolidine, water and tetrahydrofuran. The device comprises a crude product dehydration working section and a product refining working section. The crude product dehydration working section comprises a crude product intermittent column, a first condenser, a phase splitting tank, a backflow head and the like. The crude product intermittent column comprises a crude steaming column reactor and a crude steaming column. The product refining working section comprises a refining intermittent column, a second condenser, a transition cut fraction receiving tan and a product receiving tank. The refining intermittent column comprises a rectifying column reactor and a rectifying column located at the top of the rectifying column reactor. The crude product dehydration working section is communicated with the rectifying column reactor of the product refining working section through a crude product storage tank communicated with the crude steaming column reactor. A two-column intermittent rectifying process is adopted in the method, water and tetrahydrofuran are taken out through the crude product intermittent column, left raw materials are purified through the product refining working section, and high-purity N-methylpyrrolidine is obtained. The problems that a traditional device and technique are large in energy consumption, low in yield, high in production cost and troublesome in aftertreatment are solved.

Owner:烟台国邦化工机械科技有限公司

A kind of preparation method of nanoscale ultrafine analcime

ActiveCN106672991BMaterial nanotechnologyCrystalline aluminosilicate zeolitesUltra fineCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiling type iron plate-glass synthetic resin adhesive

InactiveCN107177317ALow viscosityHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAlcohol

The invention discloses a boiling type iron plate-glass synthetic resin adhesive. The adhesive is prepared from components in parts by weight as follows: 8-15 parts of poly (adipic acid)-5-hexanediol, 5-10 parts of alcohol chain extenders, 20-35 parts of epoxy resin, 1.5-5 parts of a curing agent, 1-6 parts of N-methylpyrrolidine, 3-5 parts of diallyl ester, 3-8 parts of dibutyltin and 20-30 parts of plasma water. Accordingly, the boiling type iron plate-glass synthetic resin adhesive is low in viscosity and good in adhesion strength after curing, can be removed in boiling water automatically, can be cured at a low temperature or room temperature, is solidified moderately and post-cured quickly, applies to an iron plate base and glass and can be removed automatically in boiling water after cutting.

Owner:SUZHOU RUNDE NEW MATERIAL

Preparation method of paint cleaning agent

InactiveCN102807781BEasy to cleanQuick Dissolving PeelChemical paints/ink removersKetoneCleansing Agents

The invention relates to a cleaning agent, in particular to a paint cleaning agent which is strong, powerful, economical, high-efficient, energy-saving, environment-friendly, novel and concentrated and a preparation method thereof. The paint cleaning agent is prepared by the following raw materials by weight percent: 15 to 25 percent of dimethoxy dipropylene glycol, 25 to 40 percent of N-methylpyrrolidine, 5 to 8 percent of ethanolamine, 20 to 30 percent of ethyl acetate, 5 to 10 percent of fatty acid ester, 15 to 25 percent of dimethyl ketone and 0.2 percent of fruity essence.

Owner:刘杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for producing 7-amino-3-[(1-methyl pyrrolidine) methyl]-3- cephalosporin-4-carboxylic dihydrochloride Process for producing 7-amino-3-[(1-methyl pyrrolidine) methyl]-3- cephalosporin-4-carboxylic dihydrochloride](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8efa9ad5-0c87-4130-9b0a-da146deb41a4/a200810080086d00041.PNG)

![Process for producing 7-amino-3-[(1-methyl pyrrolidine) methyl]-3- cephalosporin-4-carboxylic dihydrochloride Process for producing 7-amino-3-[(1-methyl pyrrolidine) methyl]-3- cephalosporin-4-carboxylic dihydrochloride](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8efa9ad5-0c87-4130-9b0a-da146deb41a4/a200810080086d00061.PNG)