Preparation method of anion exchange membrane through crosslinking by using 4,4'-trimethylenedipiperidine (TMDP)

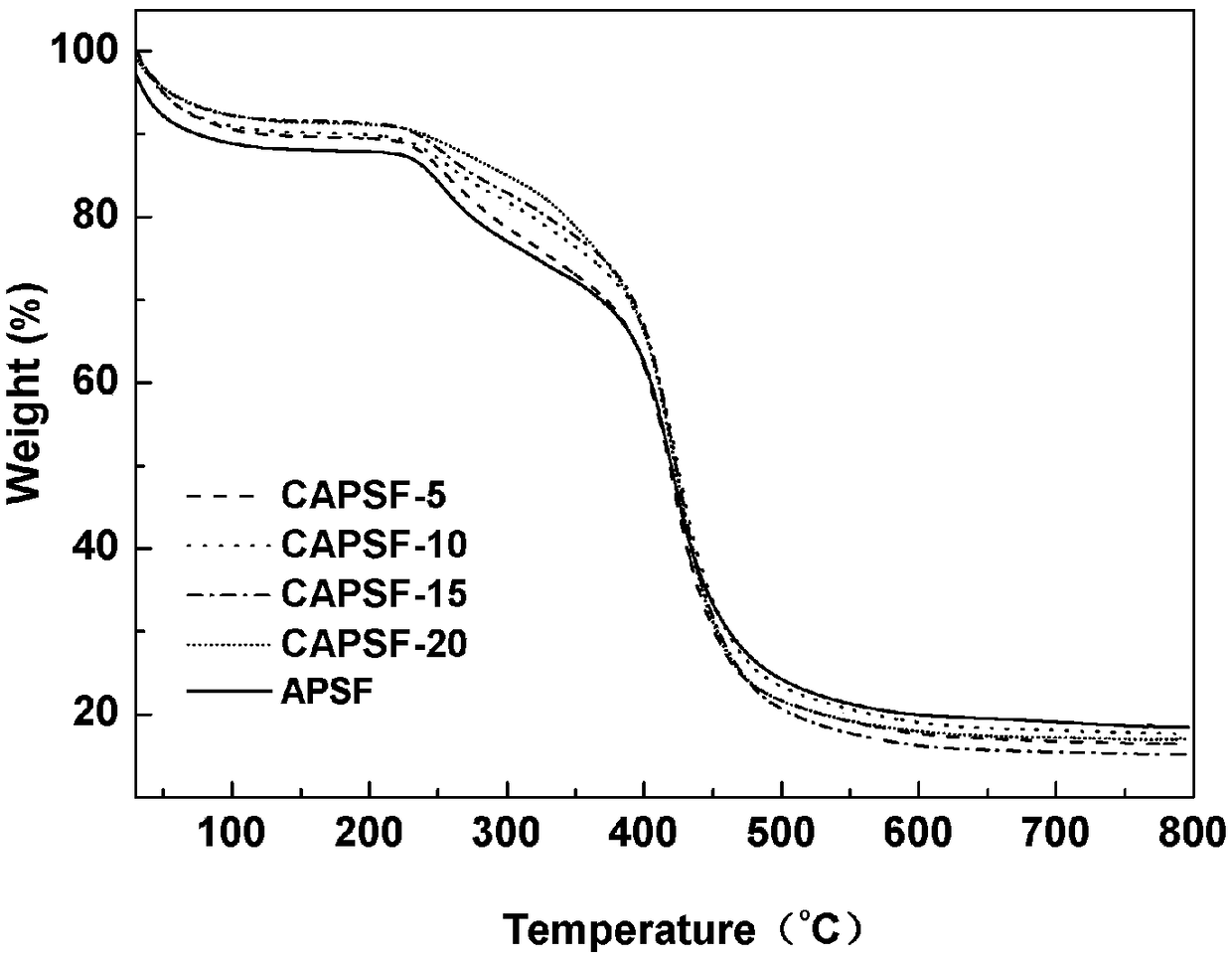

A technology of anion exchange membrane and cross-linking agent, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the limitation of practical application, reduce the swelling degree and water absorption rate of anion exchange membrane, and the deterioration of mechanical properties and dimensional stability and other problems, to achieve the effect of improving anti-swelling performance, good physical and chemical stability, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

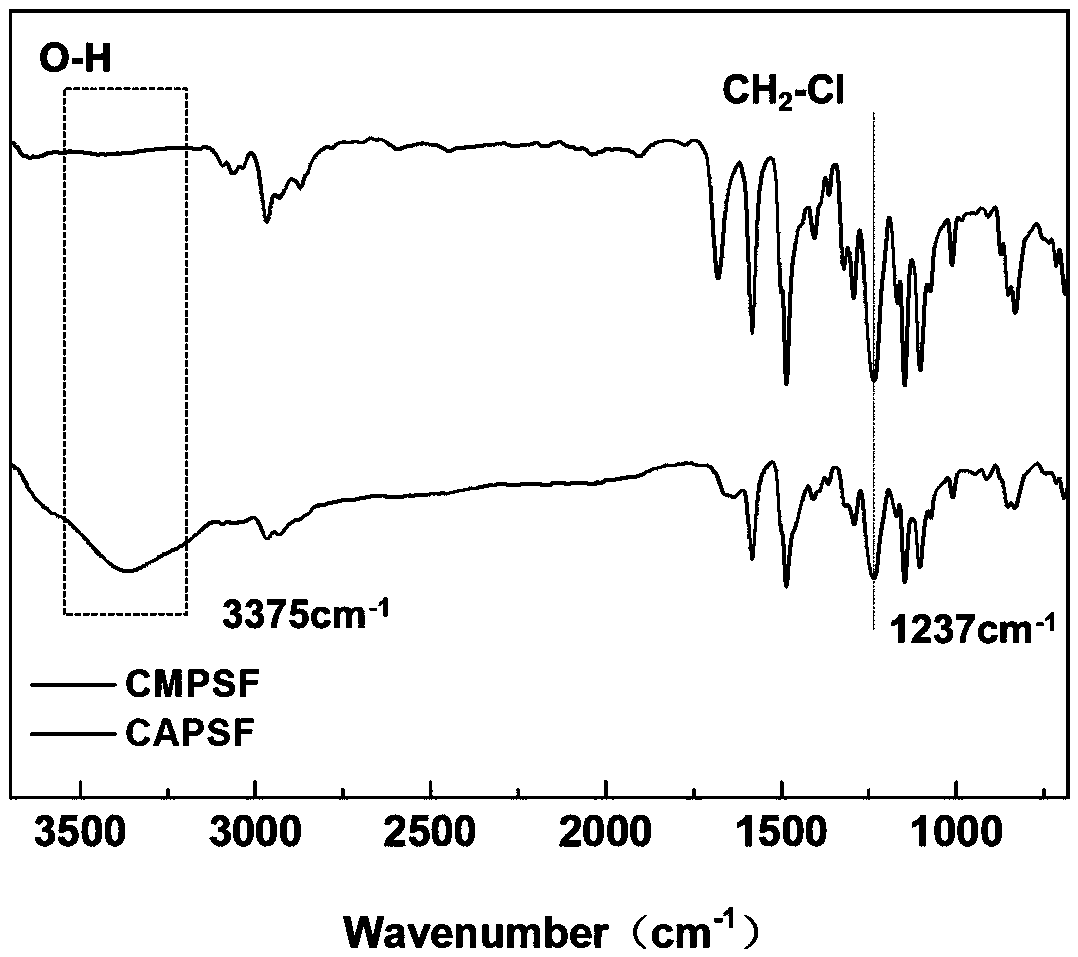

[0024] Preparation of chloromethylated polysulfone (CMPSF):

[0025] Pour 10g of polysulfone (PSF) into a three-necked flask, then add 500mL of chloroform, stir for 12h to completely dissolve, then add 13.56g of paraformaldehyde, 57.36mL of trimethylchlorosilane and 0.53mL of tetra Tin chloride was sequentially added to the above solution, heated and stirred for 60 h, and the temperature was set at 50°C. Finally, the solution was precipitated in an ethanol solution to precipitate the product, and then the product was suction-filtered and dried to obtain chloromethylated polysulfone (CMPSF).

Embodiment 1

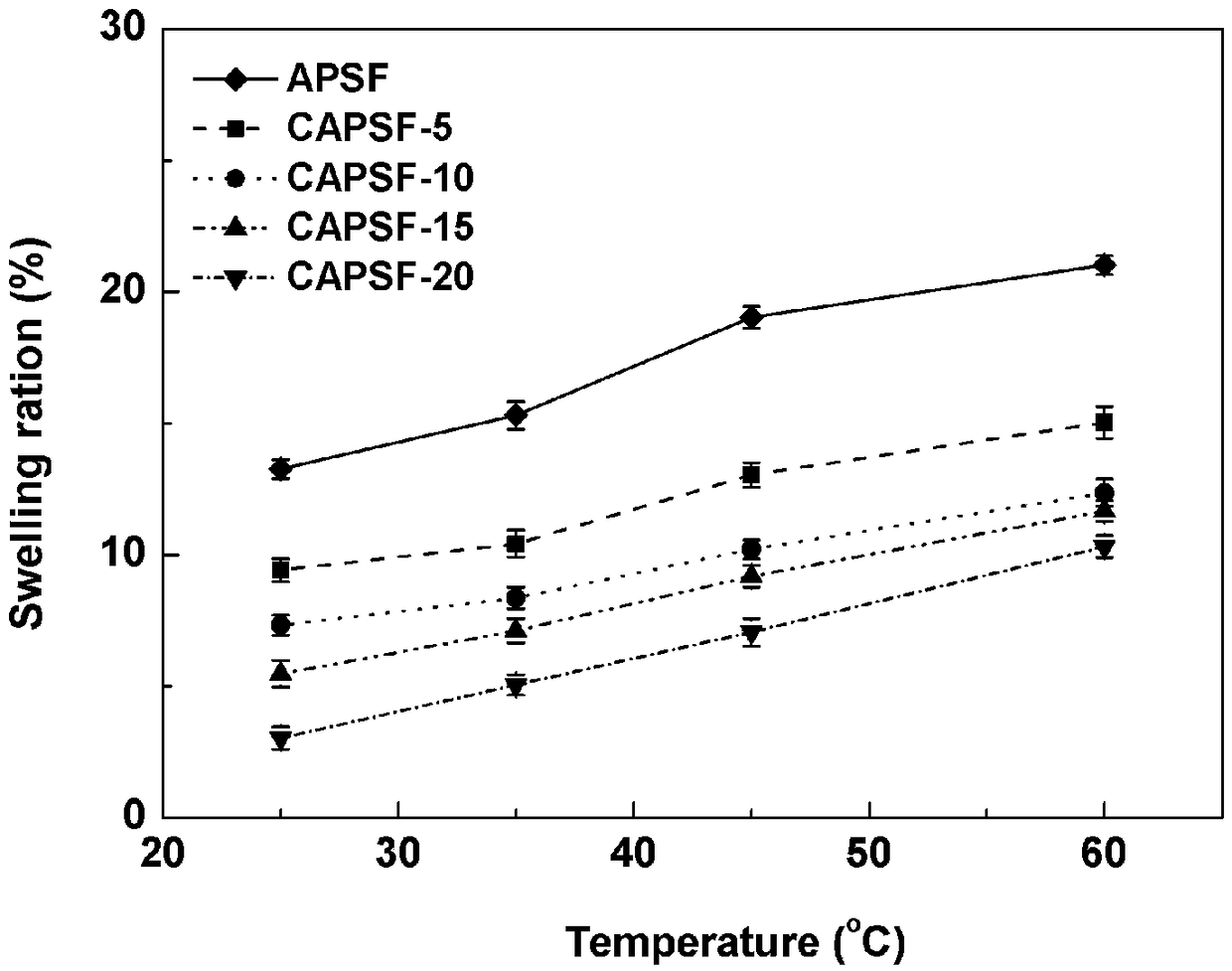

[0027] Accurately weigh 0.5 g of chloromethylated polysulfone into 7 mL of 1-methyl-2-pyrrolidone (NMP), stir and dissolve at room temperature for 5 h to obtain a colorless transparent solution. Add 0.023g of 4,4'-trimethylenedipiperidine (TMDP) to the resulting solution, and then stir the reaction at room temperature for 2h to cause a cross-linking reaction to obtain a light yellow liquid, then add 0.112g of N- Methylpyrrolidine (MPY) was added to the above solution, stirred for 4 hours, and then the obtained casting solution was defoamed in a vacuum drying oven. Then pour it on a clean glass plate and scrape the film with a spatula, and dry it under vacuum for 24 hours at 80°C. Take out the dried membrane, soak it in deionized water, let it fall off freely, and use it for future use (denoted as CAPSF-5 membrane).

Embodiment 2

[0029] Accurately weigh 0.5 g of chloromethylated polysulfone (CMPSF) into 7 mL of 1-methyl-2-pyrrolidone (NMP), stir and dissolve at room temperature for 5 h to obtain a colorless transparent solution. Add 0.039g of 4,4'-trimethylenedipiperidine (TMDP) to the resulting solution, and then stir the reaction at room temperature for 1.5h to cause a cross-linking reaction to obtain a light yellow liquid, then add 0.099g of N - Methylpyrrolidine (MPY) was added to the above solution, stirred for 4 hours, and then the casting solution was defoamed in a vacuum drying oven. Then pour it on a clean glass plate and scrape the film with a spatula, and dry it under vacuum for 24 hours at 80°C. Take out the dried membrane, soak it in deionized water, let it fall off freely, and use it for future use (denoted as CAPSF-10 membrane).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com