Positive pole piece of large multiplying power lithium iron phosphate battery and preparation method thereof

A technology of lithium iron phosphate battery and positive pole piece, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of not being able to meet the high current discharge of lithium ion batteries at the same time, and achieve excellent fluidity, high packing density, and volume. The effect of larger capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

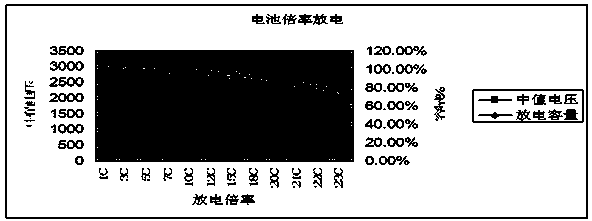

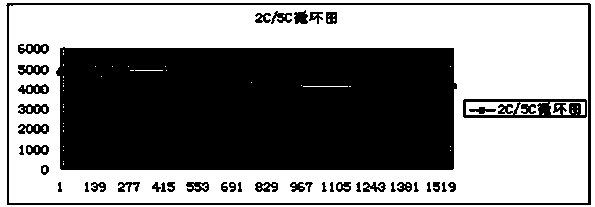

Image

Examples

Embodiment 1

[0054] A positive electrode sheet of a large-rate lithium iron phosphate battery, the positive electrode sheet includes a current collector and an active material layer coated thereon, the composition of the active material layer and its mass part ratio are: spherical lithium iron phosphate 88 , binder 8, conductive agent 6 (flaky graphite 2, carbon black 2.5, carbon nanotube 1.5); the microscopic morphology of the spherical lithium iron phosphate is a spherical structure, and its material tap density is 1.2g / cm 3 , D50 is ≤ 50nm, the conductive agent is a mixture of carbon black, flake graphite, and carbon nanotubes, and the binder is polyvinylidene fluoride or polyvinylidene fluoride-hexafluoropropylene copolymer;

[0055] The current collector includes aluminum foil and a conductive layer printed on it, the conductive layer includes carbon black, polyvinylidene fluoride or carbon black, polyvinylidene fluoride-hexafluoropropylene copolymer, and the thickness of the conductiv...

Embodiment 2

[0061] The basic content is the same as in Example 1, except that the composition of the active material layer and its mass part ratio are: spherical lithium iron phosphate 92, binder 5, conductive agent 3 (flaky graphite 1, carbon black 1, carbon nanometer Tube 1). The surface internal resistance of the positive pole piece is 500-1000Ω.

Embodiment 3

[0063] The basic content is the same as in Example 1, except that the composition of the active material layer and its mass part ratio are: spherical lithium iron phosphate 95, binder 3, conductive agent 1 (flaky graphite 0.4, carbon black 0.4, carbon nano tube 0.2). The surface internal resistance of the positive pole piece is 1200-2000Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com