Lamellar mordenite preparation method

A mordenite and lamella technology is applied in the field of preparation of lamellar mordenite, which can solve the problems of side reactions, shorten the life of molecular sieve, increase diffusion resistance and the like, and achieve the effect of a simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] (1) Preparation of structure directing agent

[0036]Add 30g (0.35mol) of N-methyltetrahydropyrrolidine into the three-necked flask, dropwise add 33g (0.18mol) of 1,2-dibromoethane, slowly rise to reflux, the solution is white and slightly turbid, reflux for 12h and then cool down. Water and ethyl acetate were added for extraction, the oil phase and the water phase were separated, and then the water phase was distilled and dehydrated under reduced pressure to obtain 52.5 g of a yellow oil, which was 1,2-bis(N-methylpyrrolidine)ethane bromide. That 1 H-NMR spectrum chemical shift (300MHz, internal standard TMS, solvent CDCl 3 ) δ (ppm) is: 2.11 (8H, m), 2.92 (6H, s), 3.09 (8H, m), 3.65 (4H, s).

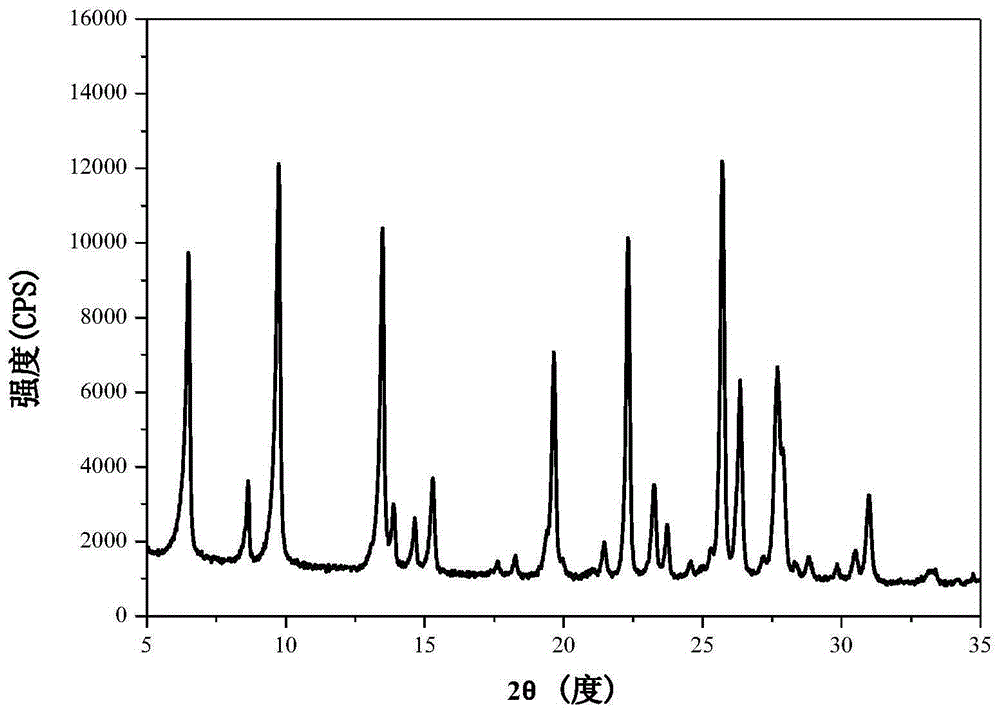

[0037] (2) Preparation of lamellar mordenite

[0038] Take 0.134g of sodium metaaluminate and add it to a 45mL polytetrafluoroethylene (Teflon) container, add 23.28g of deionized water, 0.7947g of sodium hydroxide, and 1.74g of 1,2-bis(N-methylpyrrolidine) ethyl Alkyl bromid...

example 2

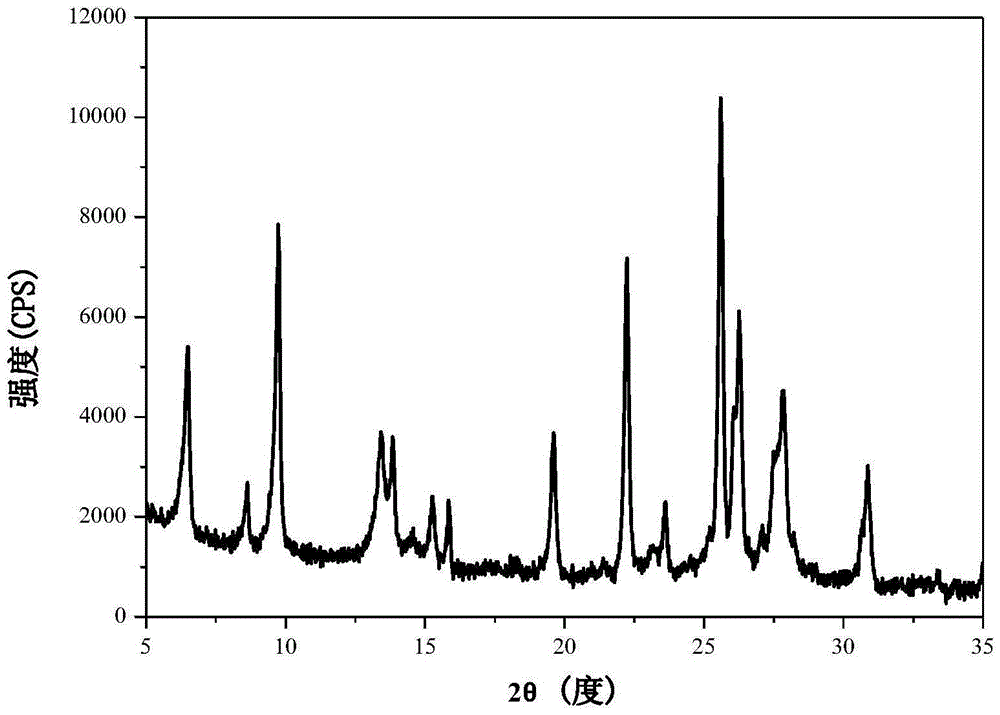

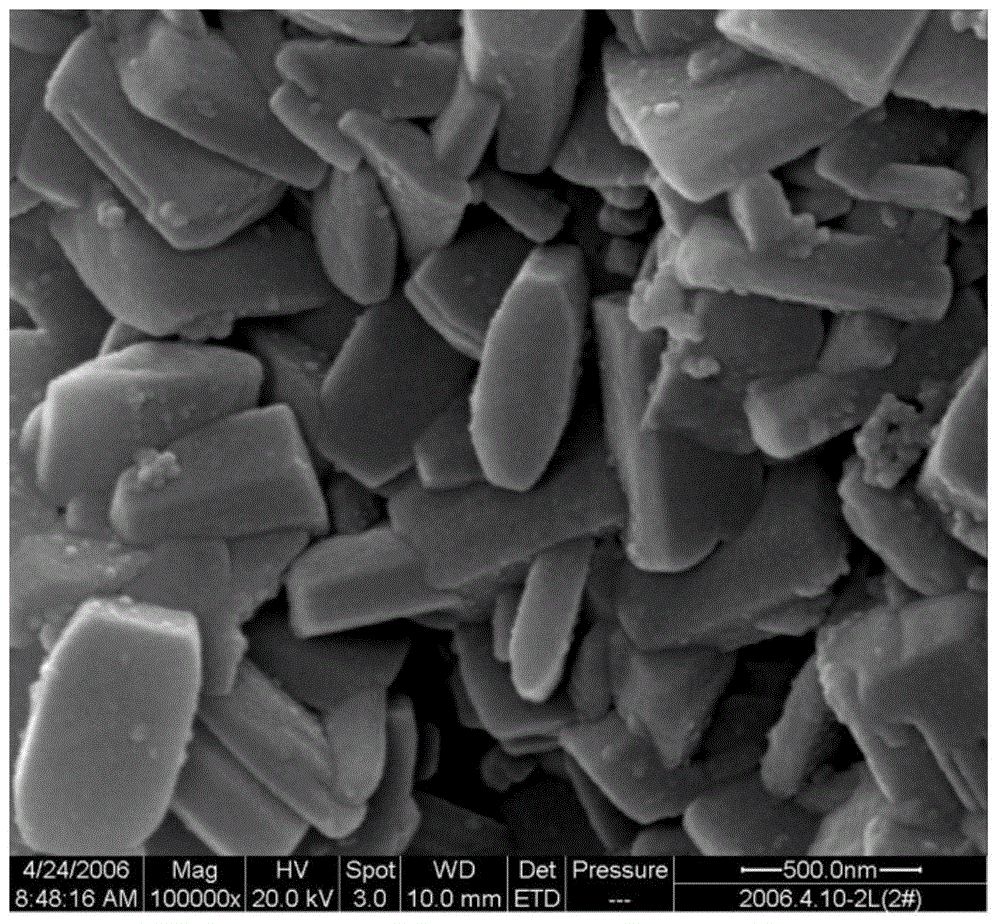

[0043] Take 0.134g of sodium metaaluminate and add it to a 45mL Teflon container, add 11.64g of deionized water, 0.56g of sodium hydroxide, and 1.16g of 1,2-bis(N-methylpyrrolidine)ethane bromide as structure-guided Agent R, stirred for 30 minutes until uniform, then added 2g of white carbon black, mixed thoroughly for 15 minutes, and the molar ratio of each component was: SiO 2 / Al 2 o 3 =40,Na 2 O / SiO 2 =0.56,H 2 O / SiO 2 =20, R / SiO 2 = 0.10.

[0044] Put the above mixture into a 45mL steel autoclave with Teflon lining and seal it, place the autoclave in a rotary convection oven at 120°C, set the rotation speed at 20rpm, react for 2 days, and raise the temperature to 175°C °C, react for 6 days. Take out the autoclave and let it cool down rapidly to room temperature, separate the mixture on a high-speed centrifuge at 5000rpm, collect the solid, wash with deionized water until the washing liquid is free of bromide ions, and dry at 100°C for 5 hours to obtain sheet-layer...

example 3

[0046] Prepare the structure-directing agent by the method of example 1 (1) step, the difference is to replace 1,2-dibromoethane with 0.18mol of 1,4-dibromobutane to obtain 1,4-bis(N-methyl Pyrrolidine) butane bromide salt.

[0047] Take 0.134g of sodium metaaluminate and add it to a 45mL Teflon container, add 11.64g of deionized water, 0.56g of sodium hydroxide, and 1.25g of 1,4-bis(N-methylpyrrolidine)butane bromide respectively as the structure Directing agent R, stir for 30 minutes until uniform, then add 2g of white carbon black, mix thoroughly for 15 minutes, and the molar ratio of each component is: SiO 2 / Al 2 o 3 =40,Na 2 O / SiO 2 =0.56,H 2 O / SiO 2 =20, R / SiO 2 = 0.10.

[0048] Put the above mixture into a 45mL steel autoclave with Teflon lining and seal it, place the autoclave in a rotary convection oven at 120°C, set the rotation speed at 20rpm, react for 2 days, and raise the temperature to 175°C °C, react for 6 days. Take out the autoclave and let it cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com