Preparation method of boron modified phenolic resin

A technology of phenolic resin and boron modification, applied in the field of phenolic resin preparation, can solve the problems of difficult production control and large-scale industrial production, achieve excellent thermal oxidation resistance, facilitate large-scale industrial production, and have mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of boron modified phenolic resin, comprising the following steps:

[0022] (1), add phenol and aldehyde that molar ratio is 1.0:0.1~1.0 in the reactor, stir reflux reaction in acidic environment for 5 hours~6 hours;

[0023] (2), the reaction product of step (1) carries out normal pressure distillation dehydration, to water content less than 10% by weight;

[0024] (3) Add a boron-containing hydroxy compound to the dehydrated product in step (2) for esterification; the amount of the boron-containing hydroxy compound is at most 20% by weight of the phenol.

[0025] The preparation method of above-mentioned boron-modified phenolic resin, at first adopts traditional synthetic method to prepare phenolic resin, just limits the condition of reaction under acidic environment, promptly adds acidic solution in reactor, thereby makes the phenolic resin that synthetically obtains be Linear structure, that is, thermoplastic phenolic resin. The thermoplastic p...

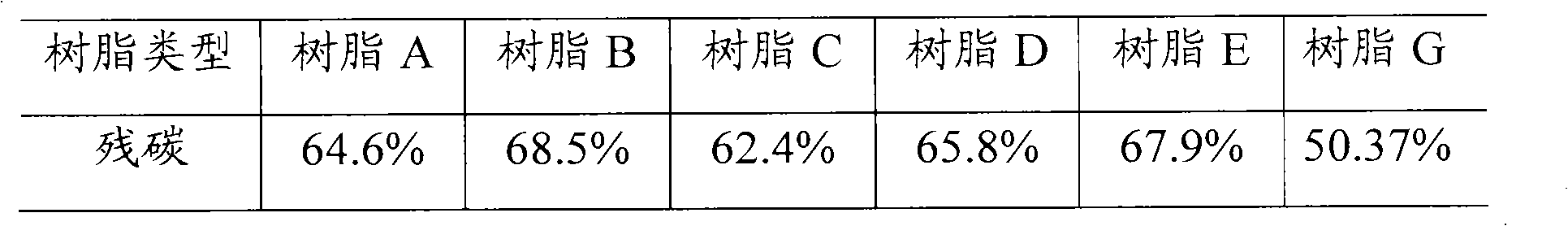

Embodiment 1

[0029] Put 500g of phenol, 301g of 37% formaldehyde solution, and 5g of oxalic acid into a 1000ml reaction vessel equipped with a thermometer, a stirring device, and a reflux condenser, heat up to 80°C to 85°C for 1 hour, and then heat up to 90°C to 95°C, keep the temperature for 1 hour, finally raise the temperature to 100°C, reflux for 3 hours, end the reaction and carry out atmospheric distillation dehydration, atmospheric distillation dehydration to 150°C ~ 160°C, when the moisture content in the resin is detected to be 2.3%, stop the atmospheric pressure Distillation, adding 50g of boric acid, esterification reaction for 30 minutes, then under the conditions of 150℃~160℃, pressure 8000Pa, vacuum distillation dehydration, dephenolization, when the detected moisture content is 4.3%, stop vacuum distillation, release the material to cool , to obtain 530g of boron-modified phenolic resin A.

Embodiment 2

[0031] Put 445g of phenol and 4.45g of sulfuric acid with a content of 20% into a 1000ml reaction vessel equipped with a thermometer, a stirring device, and a reflux condenser, heat up to 80°C to 90°C, start adding formaldehyde dropwise, finish adding in 90 minutes, and then Heat up to 100°C, reflux for 3 hours, add barium hydroxide to neutralize, end the reaction and carry out atmospheric distillation dehydration, atmospheric distillation dehydration to 160°C ~ 170°C, when the moisture content is 1.2%, stop atmospheric distillation, add Boric acid 66g, esterification reaction for 40 minutes, then dehydration and dephenolization by vacuum distillation under the conditions of 160°C-170°C and pressure 5000Pa, when the detected moisture content is 3.7%, stop the vacuum distillation, release the material to cool, and obtain 408g boron Modified phenolic resin B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com