Mesoporous IM-5 molecular sieve preparation method

A technology of IM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of diffusion product molecular sieve diffusion, decrease in reactivity and stability, unfavorable reactant molecules, etc., to achieve The effect of improving the anti-coking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] (1) Preparation of IM-5 molecular sieve

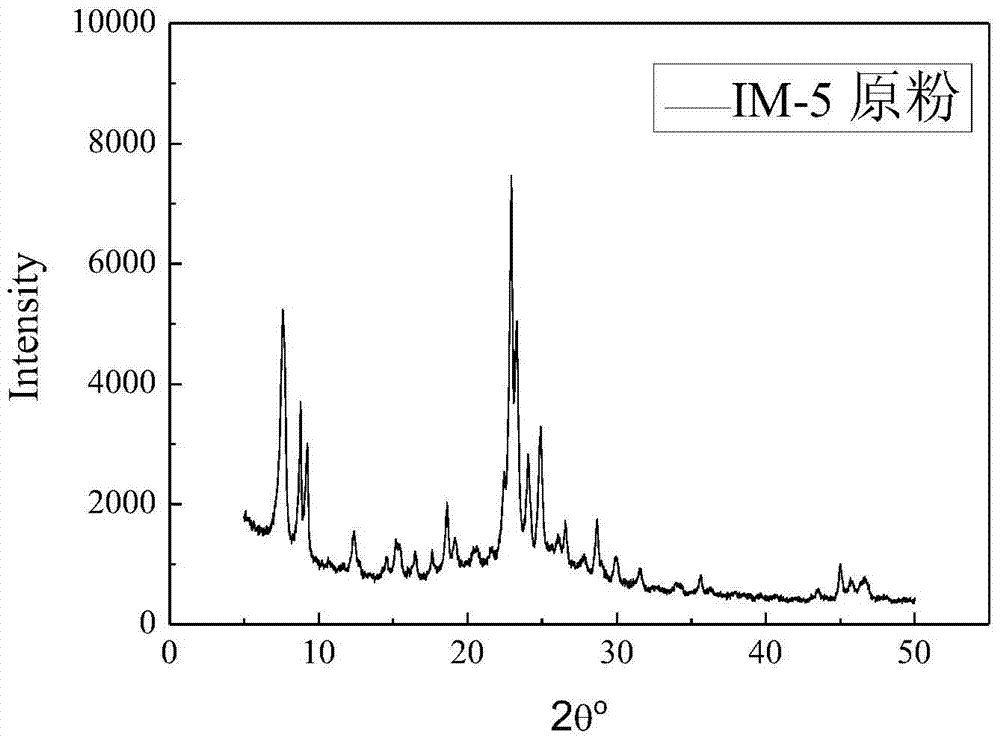

[0057] IM-5 molecular sieves were synthesized by the method disclosed in the literature Synthesis, characterization, and catalytic properties of zeolites IM-5 and NU-88 (Journal of Catalysis 2003: 215151-170).

[0058] 3.00g (0.0075mol) of 1,5-bis(N-methylpyrrolidine) pentylene dibromide and 2.92g concentration of 50% NaOH aqueous solution, 0.427g Al(NO 3 ) 3 9H 2 O (98%, Junsei), 3.00g of white carbon black (Aerosil 200, Degussa) and 45.4g of deionized water were mixed to make a colloid, and the molar composition of the reaction mixture was SiO 2 :Al 2 o 3 : Na 2 O: SDA: H 2 O=1:0.0167:0.365:0.15:40, wherein SDA is 1,5-bis(N-methylpyrrolidine)pentylene dibromide.

[0059] The above mixture was stirred at 25°C for 30 minutes, then transferred to a closed crystallization kettle lined with polytetrafluoroethylene, and rotated and crystallized at 100 rpm and 160°C for 14 days. The crystallization reaction product was washed...

example 2

[0063] (1) Synthesize IM-5 molecular sieve according to the method of CN102452666A.

[0064] Dissolve 2.88g NaOH and 2.06g NaBr in 42.42g deionized water, add 0.17g NaAlO 2 Mix well with 16.02g of 1,5-bis(N-methylpyrrolidine)pentylene dibromide, and slowly add 40g of alkaline silica sol (SiO 2 The content is 30wt%, produced by Beijing Feilongma Science and Trade Co., Ltd., the pH value is 11.0), made into a colloid, and continued to stir for 2 hours. The molar composition of the reaction mixture is SiO 2 :Al 2 o 3 : Na 2 O: NaBr: R: H 2 O=60:0.5:12:6:12:1200.

[0065] The prepared colloid was transferred to a crystallization kettle lined with polytetrafluoroethylene, and rotated and crystallized at 160°C for 6 days. The crystallized reaction product was washed, filtered, and dried at 80°C for 12 hours to obtain IM-5 molecular sieve C. Its XRD spectrum shows that it is IM-5 molecular sieve with a crystallinity of 88.5%.

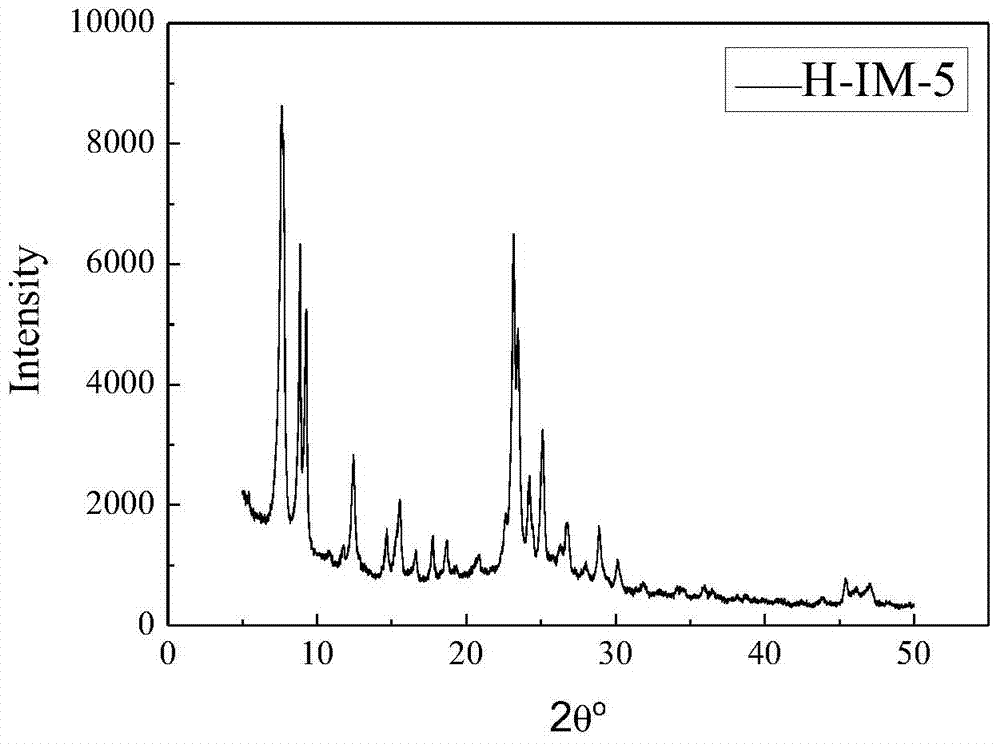

[0066] (2) Preparation of hydrogen-form IM-5 mol...

example 3

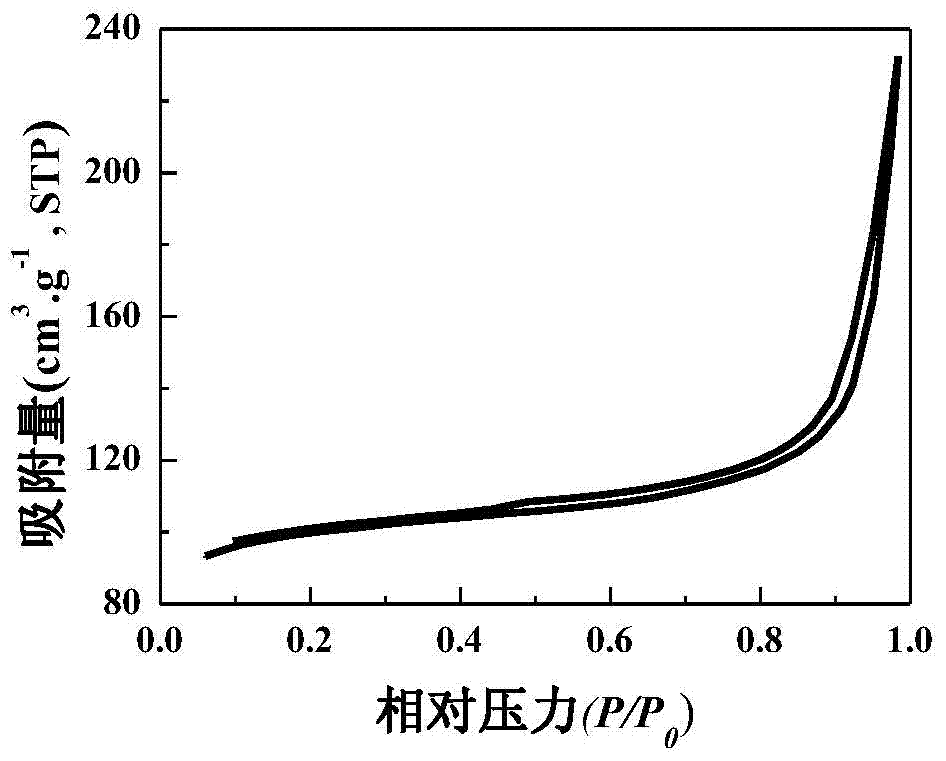

[0069] The following example prepares the mesoporous IM-5 molecular sieve of the present invention.

[0070] Dissolve 0.20g NaOH, 4.80g template agent 1,5-bis(N-methylpyrrolidine) pentylene dibromide in 16.20g deionized water, stir evenly, add 6g of IM prepared by the method of Example 1 and roasted -5 molecular sieves, mixed well, the molar composition of the reaction mixture is Z:B:R:H 2 O=1:0.05:0.12:9, wherein Z is the calcined IM-5 molecular sieve, B is the added alkali NaOH, and R is the template.

[0071] The above reactants were transferred to a 50ml autoclave lined with polytetrafluoroethylene, and subjected to dynamic crystallization treatment at 175°C for 3 hours. The processed product was washed with water, filtered, and dried at 80°C for 12 hours to obtain mesoporous IM-5 molecular sieves. Its crystallinity was 92.0%.

[0072] Mesoporous IM-5 molecular sieve is converted into hydrogen type by the method of example 1 (2) step, obtains hydrogen type mesoporous IM-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com