Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Linen cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

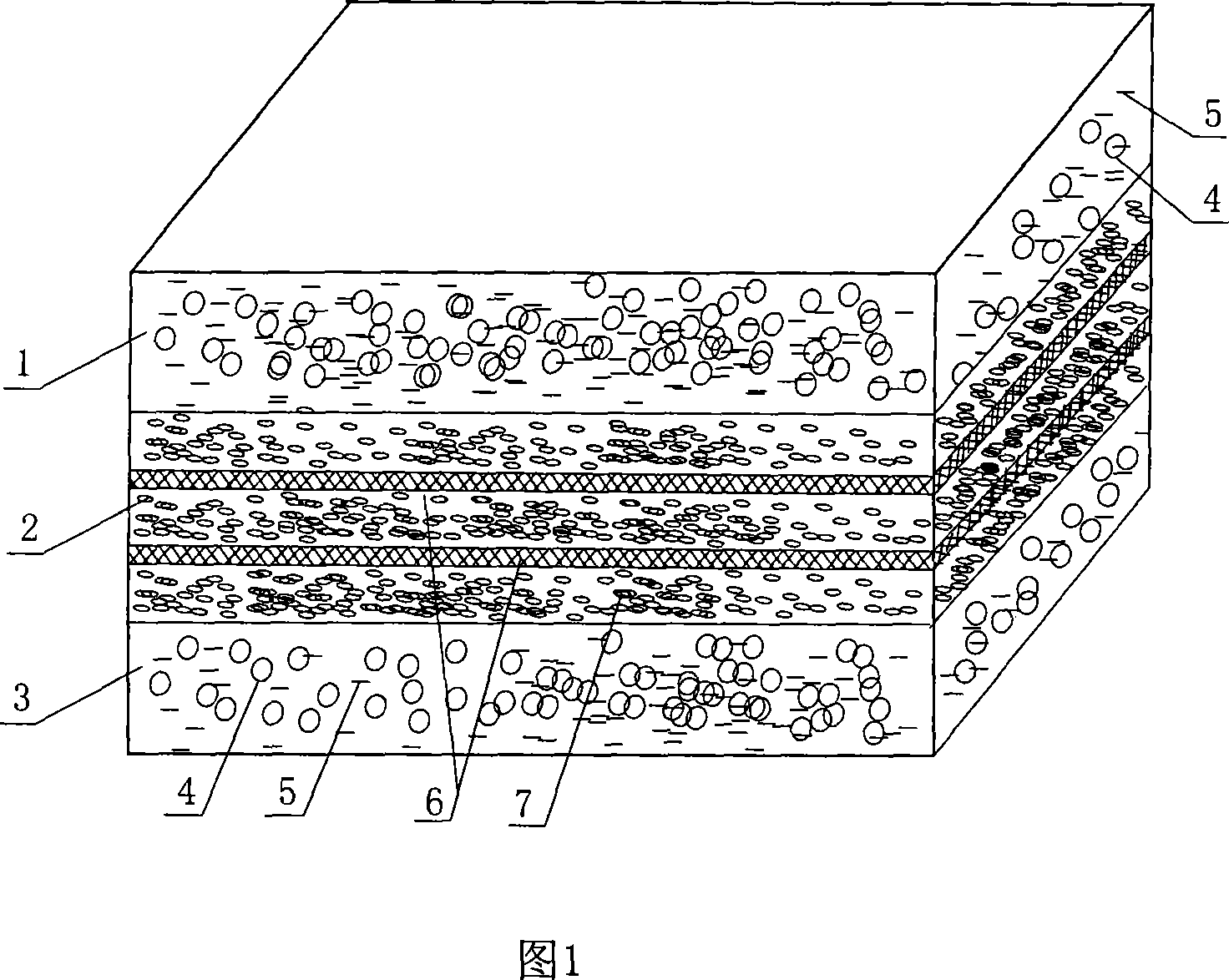

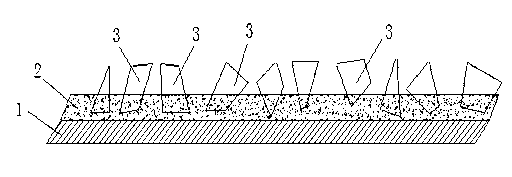

Jute and plastic compound material plank stuff and manufacturing method thereof

InactiveCN101229700AReasonable designSimple structureSynthetic resin layered productsCellulosic plastic layered productsFiberEngineering

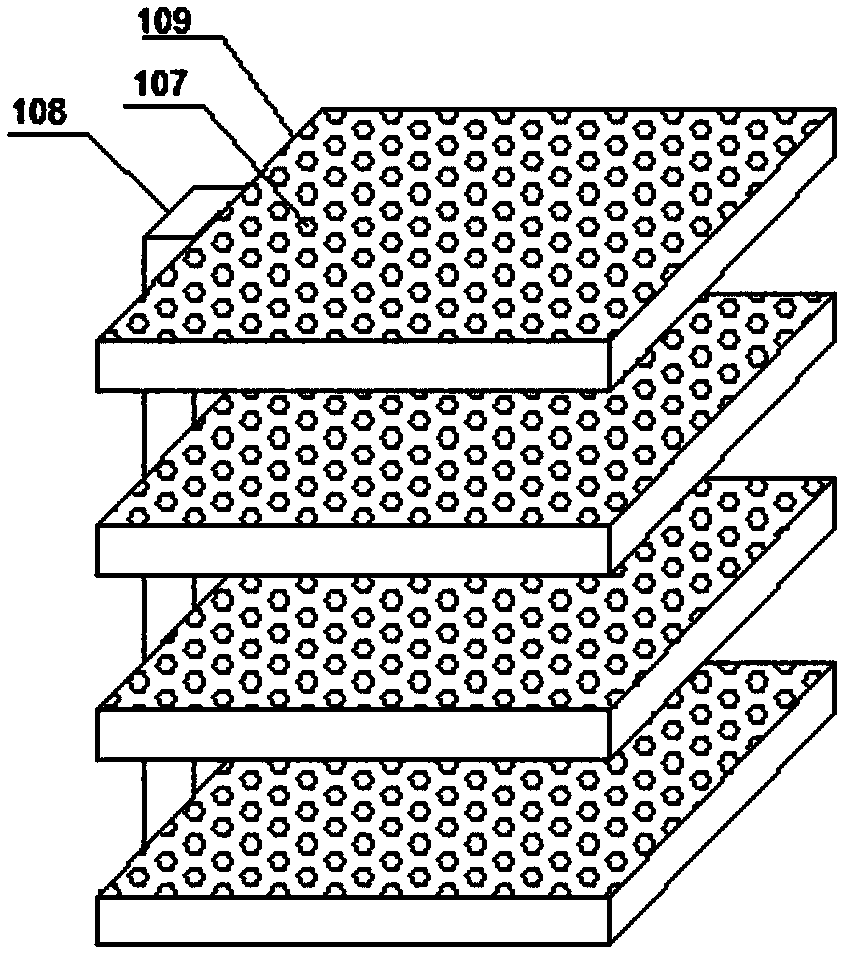

The invention relates to a linen-plastic compound material plate and a preparation method thereof, in particular to a compound material and an environment-friendly material and a preparation method thereof. The material is preferably used for manufacturing goods shelf plates, door panels, etc. of vehicles such as cars, planes, etc. in traffic field, manufacturing decorative boards, palisades, rails, etc. in architecture field as well as manufacturing trays, goods shelves, etc. in packaging field. The linen-plastic compound material plates consist of two layers of linen fiber modification plastic layers and a linen fiber cloth enhancement plastic layer; the linen fiber cloth enhancement plastic layer is molded and pressed between the two layers of linen fiber modification plastic layers; modification plastic particles, linen fiber and interface compatilizer are mixed and calendered to form the linen fiber modification plastic layers; the plastic particle and a plurality of layers of fiber linen cloth processed by silane coupling agent are molded and pressed to form the linen fiber cloth enhancement plastic layer.

Owner:NANJING FORESTRY UNIV

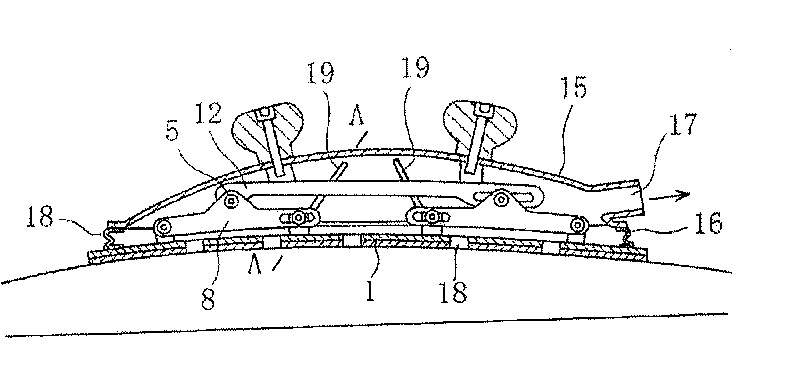

A sander used in particular for sanding of flat, concave, and convex surfaces and the method of its utilisation

InactiveCN101743096APrecisely form the curvatureFlexible constraintsPortable grinding machinesGrinding/polishing hand toolsTextileConcave surface

The sander for sanding particularly of the flat, concave and convex surfaces and the method of its usage is based on the fact, that the sanding tool (paper, linen or other carrier with sanding abrasive layer) is pressed onto the grinded surface by means of a flexible pressure plate able to copy the concave and convex surfaces with the possibility to set accurately the radius of this curve. The principle of the technical solution of the invention of the flexible pressure plate consists in the fact, that the pressure generated during the work onto the body, handle, or handles of the sander with mechanical drive is transferred onto this pressure plate at least at two points simultaneously or over at least one balance beam.

Owner:彼得·弗罗涅克

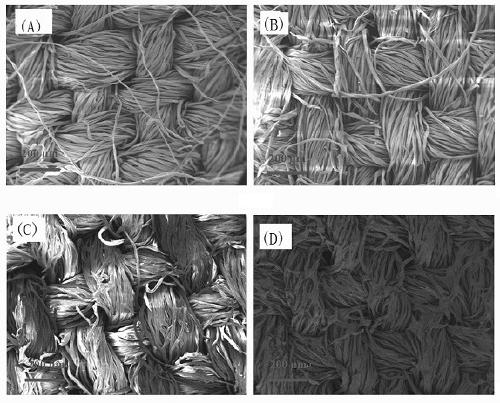

Cellulose-based multifunctional absorbing material and preparation and application methods thereof

PendingCN109569527AGuaranteed mechanical propertiesLow alcoholOther chemical processesWater contaminantsCelluloseAlcohol

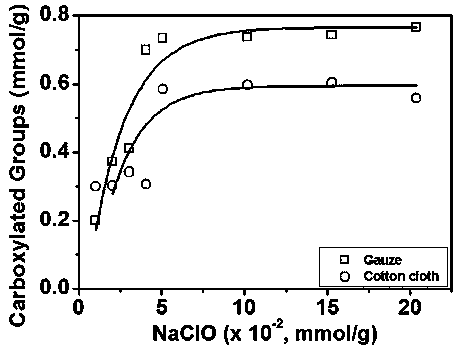

The invention relates to a cellulose-based multifunctional absorbing material and preparation and application methods thereof. The preparation method comprises performing TEMPO (tetramethylpiperidine-1-oxyl) oxidation / NaIO4 oxidation or NaIO4 oxidation / TEMPO oxidation sequentially on cellulose-based materials such as cotton cloth, gauze linen, and then performing further surface grafting modification to obtain a multifunctional absorbing fabric in a submicrometer and nanometer structure. The multifunctional absorbing fabric contains special functional groups such as carboxyl, aldehyde, amido,sulfydryl, sulfon, cyan and acylamino and can be applied to the fields of absorbing heavy metal ions such as lead ions and dichromic ions in polluted water, dyes such as methylene blue and acid yellow, ethyl alcohol in yellow rice wine to reduce alcoholic strength and the like.

Owner:BEIJING UNIV OF CHEM TECH

A smart bed sheet that can measure body temperature

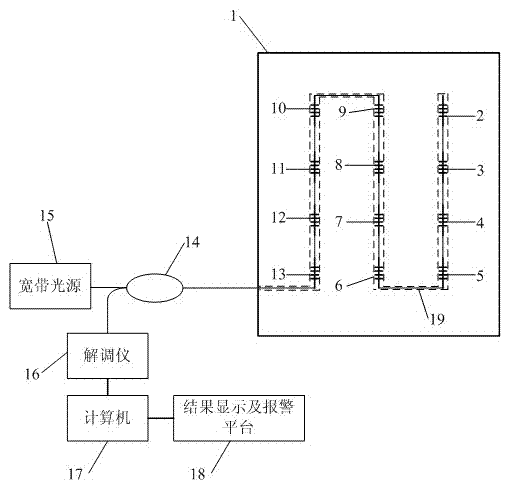

InactiveCN102283538ADetermine abnormal body temperature alarm signalMonitor temperature in real timeBlanketBed linenFiberGrating

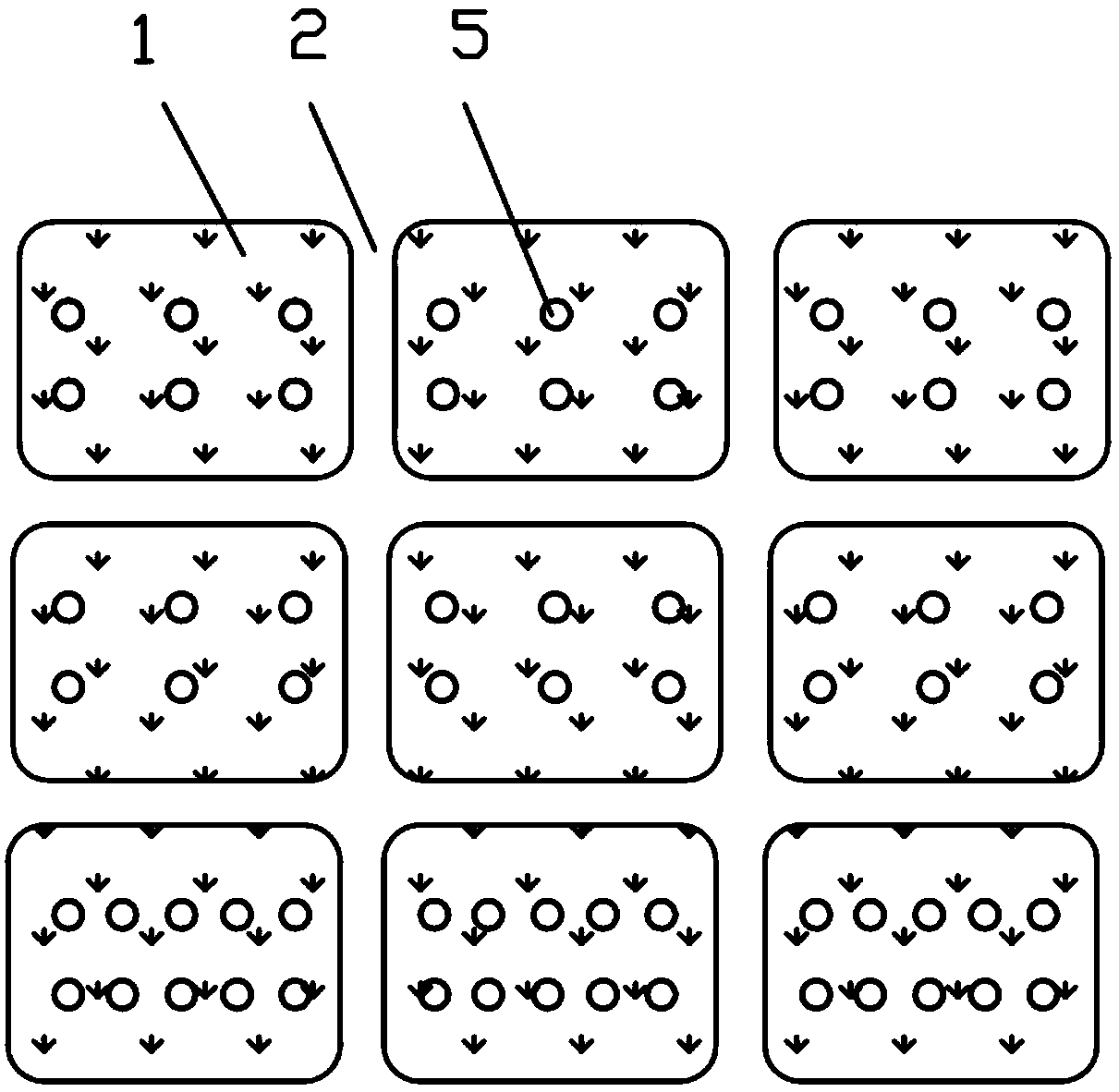

The invention relates to an intelligent bed sheet that can be used for measuring the temperature of a human body. The intelligent bed sheet is made of two pieces of cloth with the same area by stitching corresponding sides, and an array composed of a plurality of fiber grating temperature sensors is built in the bed sheet, and all fiber grating The temperature sensor is connected in series through an optical fiber. One end of the optical fiber is led out from the edge of the bed sheet, and the led out optical fiber is connected to an optical coupler. One of the optical couplers is connected to a broadband light source, and the other is connected to a demodulator. The demodulator is connected to a computer. The computer is connected to the result display and alarm platform. The intelligent bed sheet of the present invention can conduct non-interventional real-time monitoring of the health status of the human body, and can automatically decide whether to send an abnormal body temperature alarm signal according to the monitored data.

Owner:BANDWEAVER TECH CO LTD

Linen shell fabric and production method

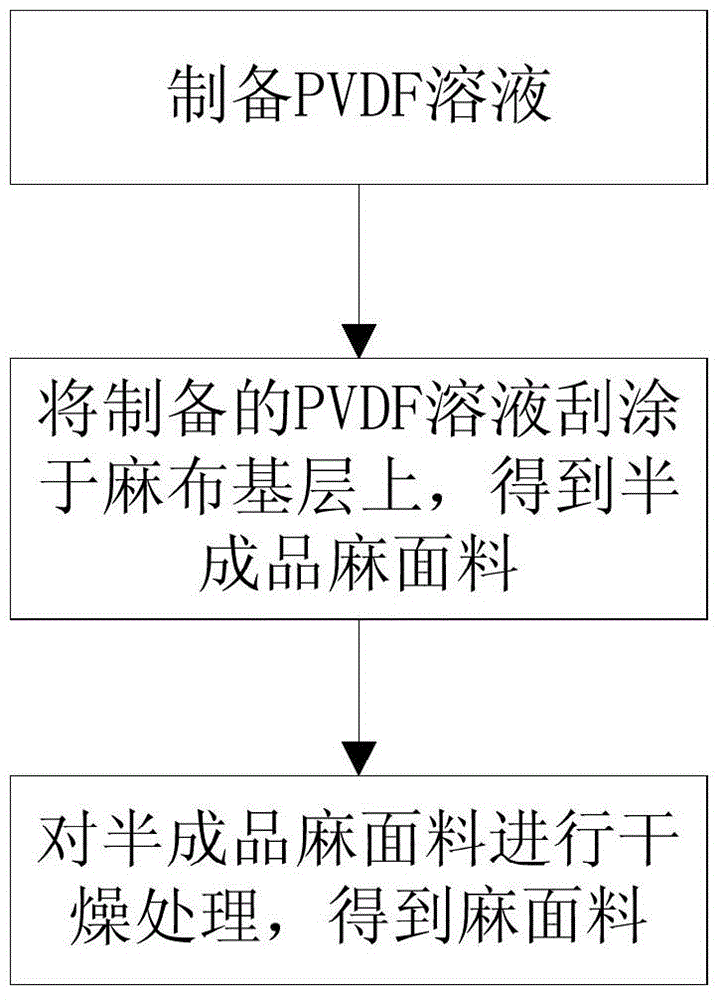

ActiveCN103556467ADoes not destroy antibacterial propertiesNon-destructive moisture wickingVegetal fibresEngineeringMoisture absorption

The invention discloses a piece of linen shell fabric and a production method and aims at solving the problems that an existing waterproof and sun-proof shell fabric is not ventilated, does not absorb sweat, has poor comfort and the like. The linen shell fabric comprises a linen cloth base layer and at least one coating arranged on the linen cloth base layer; the at least one coating is made of PVDF (Polyvinylidene Fluoride). The linen cloth base layer is a pure linen fabric, a linnet fabric, a ramie cotton fabric or a silk linen fabric. Meanwhile, the invention provides the production method of the linen shell fabric. The linen shell fabric keeps antibacterial, moisture-absorption, sweat-releasing, cool and comfortable functions and the like of the linen fabric, also has good chemical corrosion resistance, high temperature resistance, oxidization resistance, wear resistance, flexibility and anti-impact performance and can effectively resist ultraviolet rays.

Owner:北京麻世纪麻业科技发展有限公司

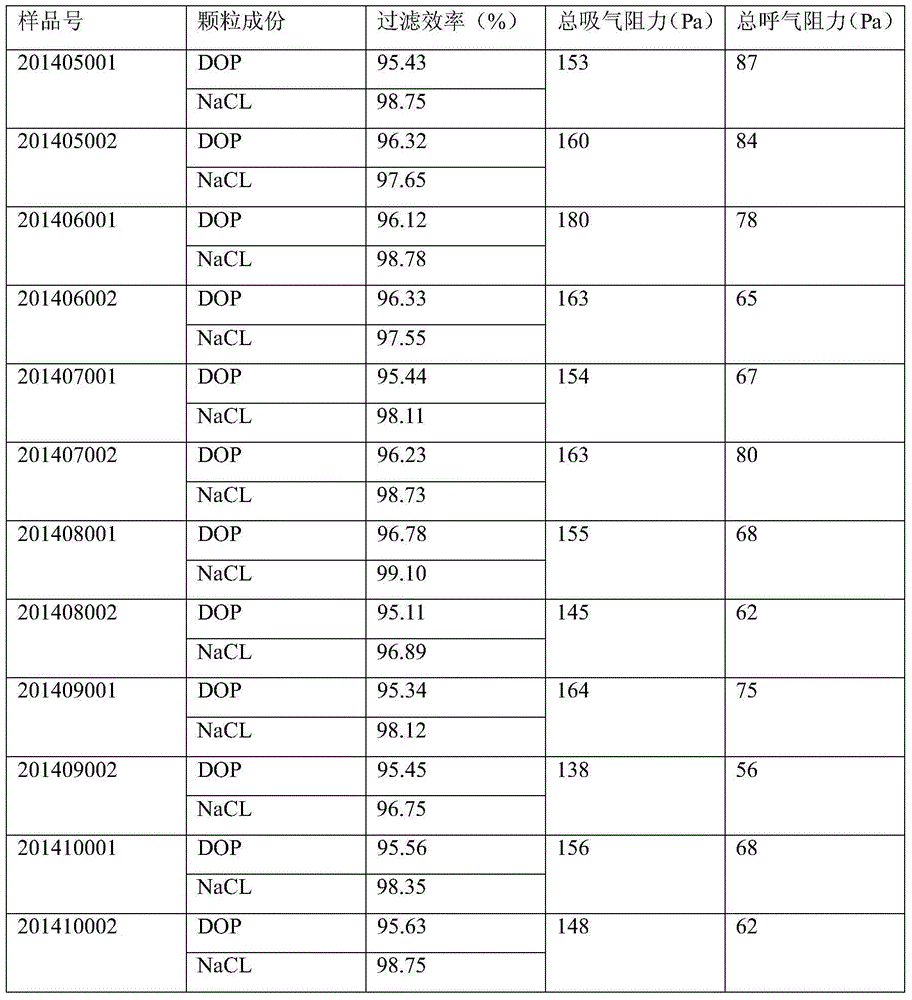

Antibiosis and haze prevention mask

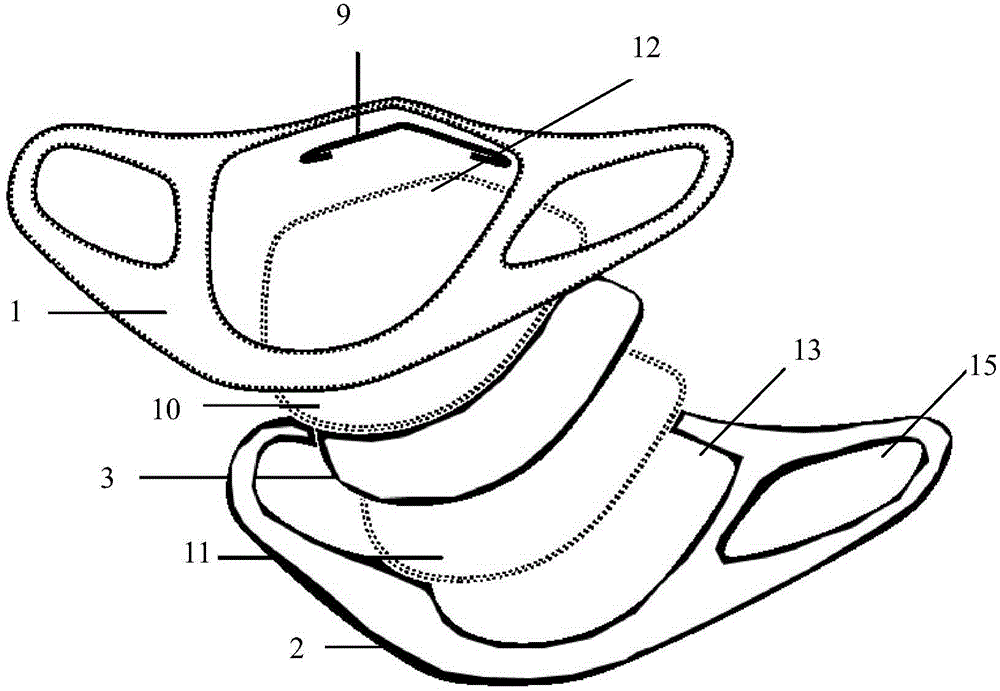

The invention discloses an antibiosis and haze prevention mask which comprises a surface layer and a lining, and an antibiosis and haze prevention functional layer is arranged between the surface layer and the lining. The functional layer is composed of a first fiber layer, a silver-loaded short fiber non-woven fabric layer, a silver-loaded filament filter layer, an efficient filter layer and a second fiber layer from outside to inside; the first fiber layer and the second fiber layer are each composed of linen cloth or cotton and linen cloth or all cotton cloth or blended cloth; the silver-loaded short fiber non-woven fabric layer is composed of polypropylene fiber or terylene non-woven fabric, and a layer of nano-silver is arranged on the surface of the non-woven fabric; the silver-loaded filament filter layer is composed of multiple filaments, the filaments are hollow polyester filaments, the line diameter of the filaments is 20-30 micrometers, and nano-silver is impregnated in a hollow inner cavity of each filament; the efficient filter layer is composed of polypropylene ultra-thin fiber, and the surface of the polypropylene ultra-thin fiber is coated with teflon. The antibiosis and haze prevention mask has the advantages of being resistant to bacteria, and capable of preventing haze and being used repeatedly.

Owner:SHANGHAI HAISHE TECH DEV CO LTD

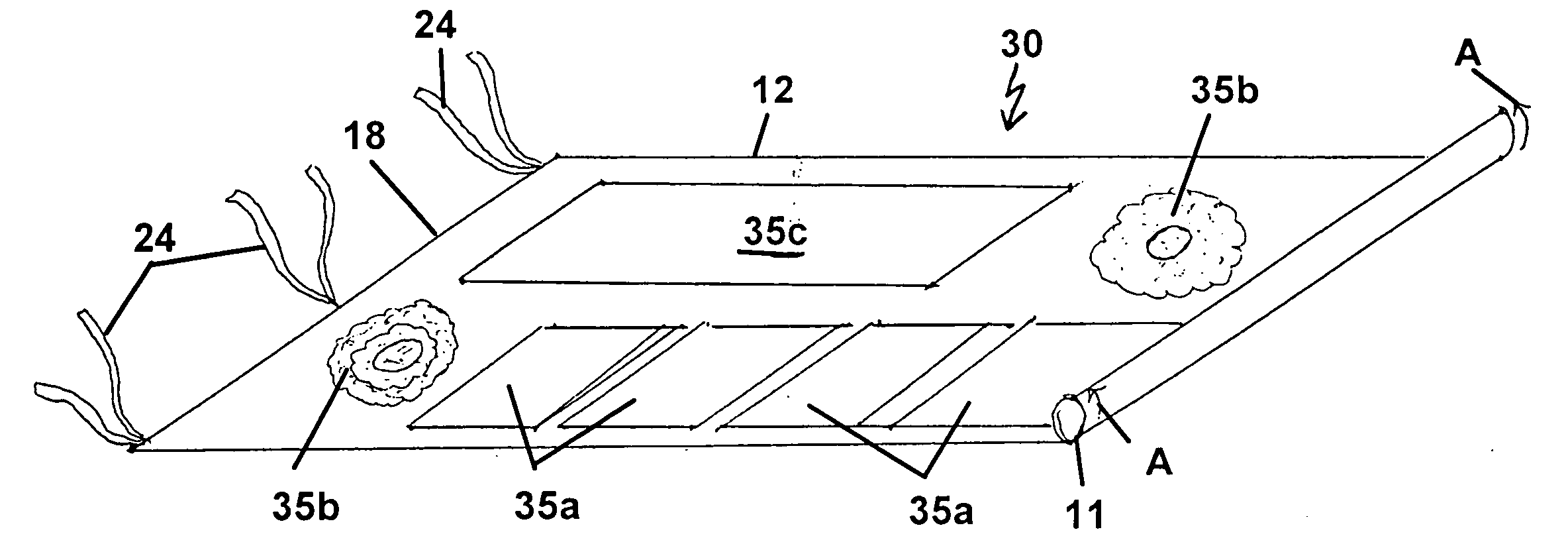

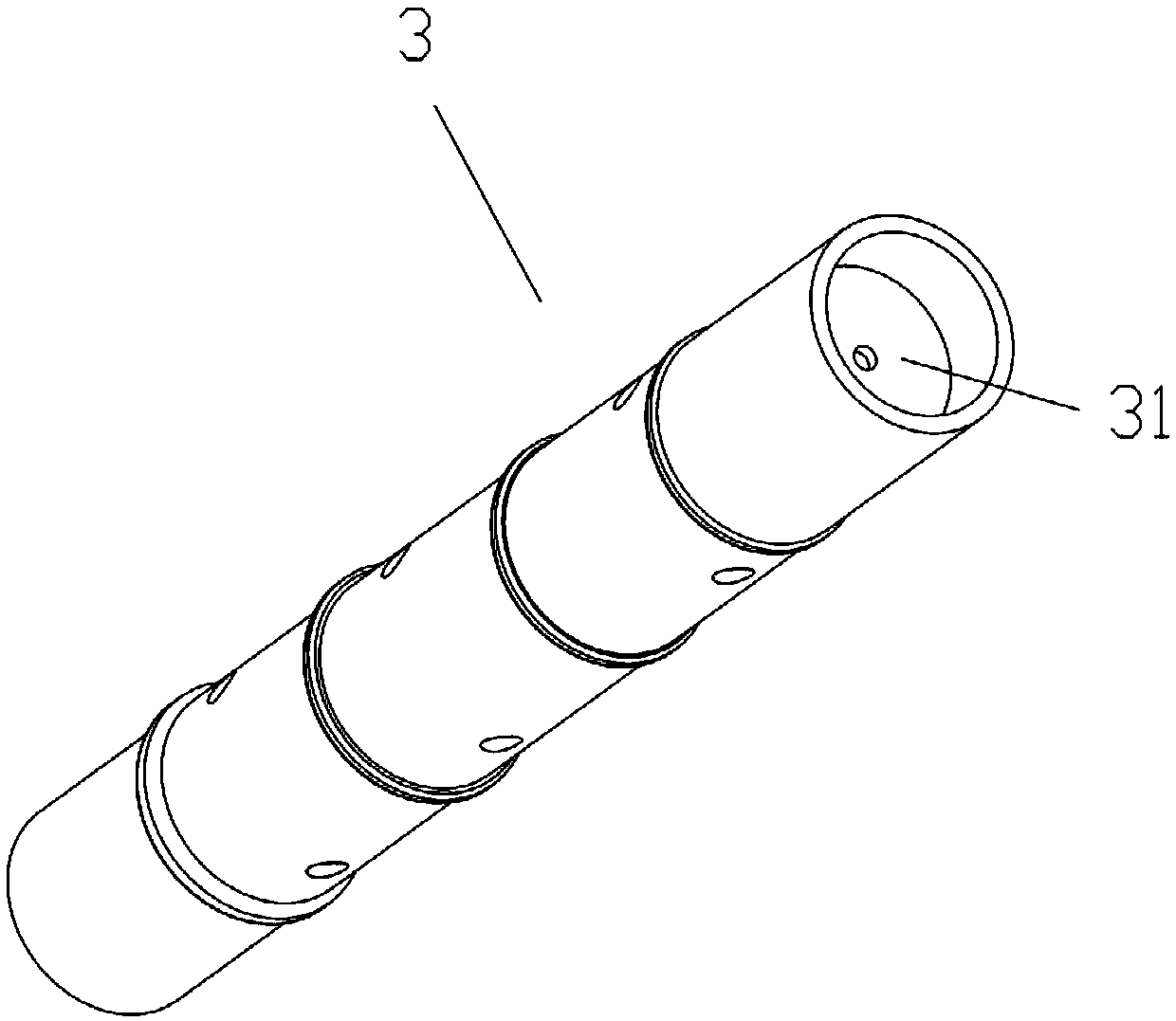

Storage device and method for storing linens and other household goods

A storage device for storing table linens and other foldable household goods virtually dust and wrinkle-free includes: (a) a generally cylindrical core tube; and (b) a flexible wrap guide extending from the core tube along a longitudinal axis of the core tube; wherein the storage device is interchangeable between an unrolled position in which the wrap guide is not wrapped around the core tube, and a rolled-up position in which the wrap guide and at least one of the table linens or other household goods are wrapped around the core tube. Also included herein is a method of storing at least one linen or other household good.

Owner:MITCHELL MARCI ELIZABETH

Synthetic method of flax fabric finishing agent

InactiveCN101328683AMild reaction conditionsSimple and fast operationVegetal fibresSynthesis methodsFiltration

The invention discloses a method for synthesizing a linen cloth finishing agent. The method takes citric anhydride as a modified compound for degraded chitosan and comprises the following steps: firstly, the degraded chitosan is added into a medium according to a certain proportion and then stirred and swelled for 0.5 hour; secondly, the citric anhydride is added into the mixture according to the mass ratio of the degraded chitosan to the citric anhydride is 1 to 2-5; thirdly, a catalyst of 1 to 2 percent against the total mass is added into the mixture and reacted for 16 to 24 hours at a normal temperature; and fourthly, after the reaction is stopped, the pH value is adjusted to neutrality and the mixture undergoes pump filtration and decompression concentration, is added with 60 milliliters of ethanol, stands overnight, and then undergoes pump filtration and vacuum drying. The method has the advantages that: the synthesis method has mild reaction condition and simple and convenient operation; and the synthesized citric acylated degraded chitosan is an environment-friendly product, not only contains chitosan molecules with the antibacterial performance but also contains polybasic carboxylic acid radicals with wrinkle resistance, can simultaneously give play to the dual function of antibacterium and wrinkle resistance when used for linen cloth finishing, and is a multifunctional environment-friendly linen cloth finishing agent.

Owner:HARBIN INST OF TECH +1

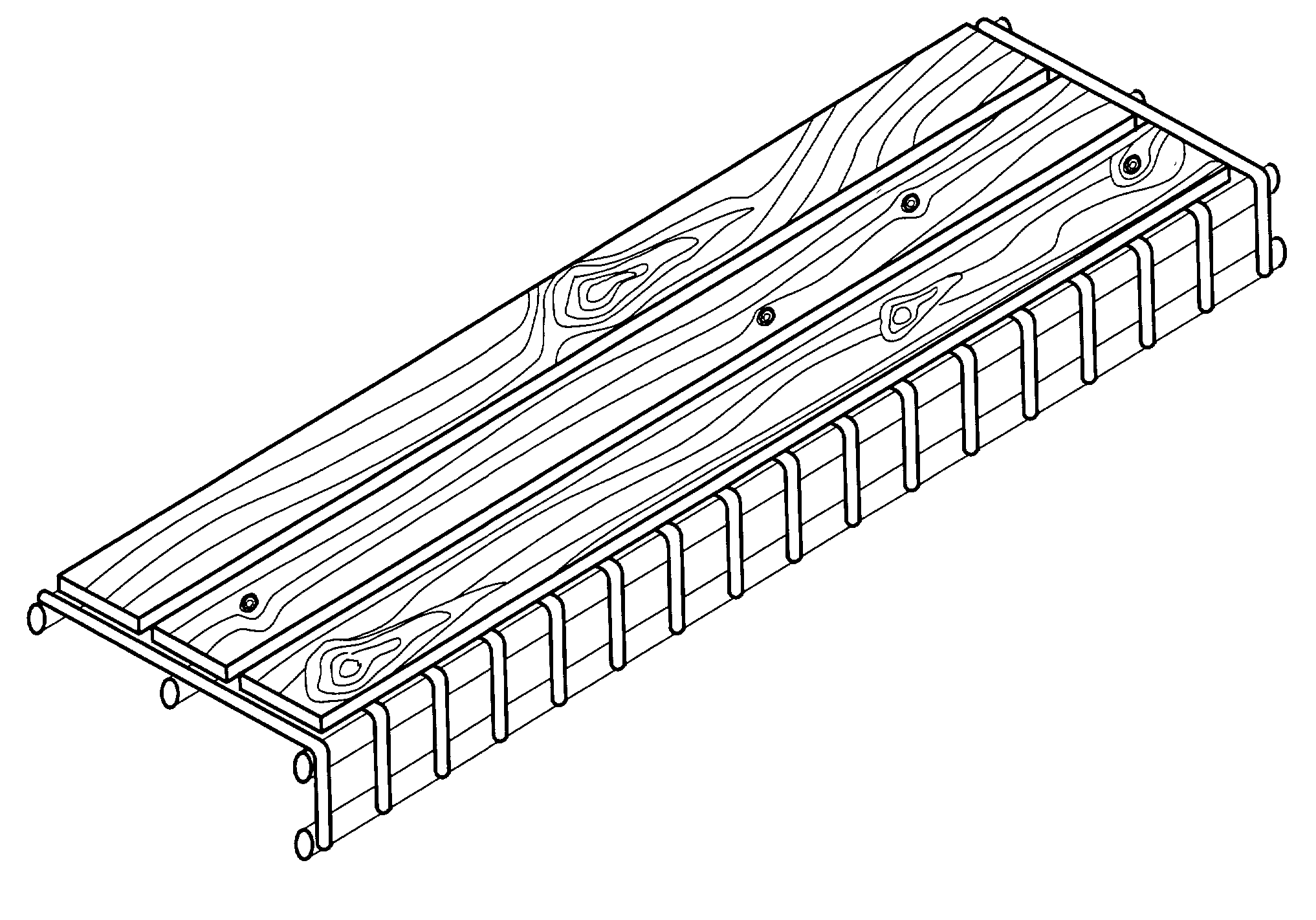

Shelving unit

A shelving unit for a wire rack is formed from an essentially flat elongated shelf member with at least one cleat attached transverse to the underside of the shelf member and extending downward between a pair of adjacent support wires of the wire rack, preferably in a frictional fit to prevent movement of the shelf in a sideways, forward and back, or twisting manner. Additional cleats, spaced apart from each other and extending downward between other pairs of support wires are typically used. The shelf unit member may be formed from slats that are spaced apart from each other or in contact with each other in a butt, lap, tongue and grove or other joint arrangement. Each cleat may be formed as two or more spaced apart cleat sections that, when properly sized and positioned, accept differently positioned cental support rods from major wire-rack manufacturers which serve as a stop to prevent the shelf unit from falling from the wire rack. Preferably, the cleats and shelf member are made from aromatic cedar to give an air, linen and clothing freshening aroma and insect repelling qualities.

Owner:GAWEL THEODORE E

Dyeing and drying machine for cotton and linen cloths

ActiveCN108708110AGuaranteed liquidityLiquidityLiquid/gas/vapor removalTextile treatment machine arrangementsPolymer scienceEngineering

The invention provides a dyeing and drying machine for cotton and linen cloths, comprising a baking chamber and a dyeing chamber below the same. A plurality of transmission rollers are arranged in thedyeing chamber; an air pipe is arranged in an area enclosed by the transmission rollers; a partition is arranged on the inner right of the baking chamber and divides the baking chamber into a dryingchamber and a flattening chamber; the bottom of the flattening chamber is provided with an opening that is communicated with the top of the dyeing chamber; the right side of the flattening chamber ismovably penetrated by a flat plate; a plurality of flattening strips are arrayed on the right of the partition; a plurality of guide rollers are staggered in the drying chamber from top to bottom; theinner rear wall of the drying chamber is provided with an intake pipe; the inside of the drying chamber is provided with an air guide chamber corresponding to each guide roller; the rear ends of theair guide chambers are communicated with the intake pip. The dyeing and drying machine for cotton and linen clothes has good uniform dyeing effect of cloths; a dyeing liquid has good mobility; the dyeing and drying machine for cotton and linen cloths also has excellent flattening effect and tensioning effect and high drying efficiency, front and back of cloth are uniformly heated and dried, multiple flatten-compressing can be performed during drying, and cloths have good comprehensive quality.

Owner:安徽职业技术学院

Greening method for garden slope

ActiveCN109042103AWide variety of sourcesAvoid pollutionHops/wine cultivationGrowth substratesDry seasonGreening

The invention provides a greening method for a garden slope. In the process of repairing the garden slope, biodegradable bamboo tubes are utilized, the bamboo tubes are filled with a water retention material, and then cotton and linen cloth strips wrap and cover biomass chippings; the bamboo tubes and the water retention material are placed in a groove pre-dug in the slope, and then after soil covers the groove, climbing plants with root hairs are planted; grass is planted on the surface of a soil block divided on the slope, half of bamboo tubes are laid on the positions reserved on the two sides of the groove to drain excess rainwater, and an environment-friendly material is utilized for reducing investment; the water retention material is utilized for absorbing the excess water, and in the dry seasons, water can be supplied.

Owner:GUANGDONG BAILIN GARDEN CONSTR CO LTD

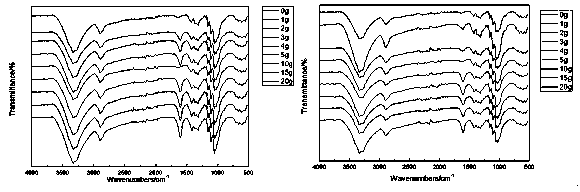

Linen printing and dyeing method with high dye-uptake rate, as well as linen product printed and dyed by method

InactiveCN105507035AImprove friction resistanceHigh color fastness to washingDyeing processPulp and paper industryLinen cloth

The invention a linen printing and dyeing method with high dye-uptake rate, as well as a linen product printed and dyed by the method. The method comprises the following steps: conducting destarching treatment, boiling-off treatment and bleaching treatment on a linen raw material in sequence, and conducting printing and dyeing treatment to obtain the linen product, wherein the printing and dyeing auxiliary is one or more of 2,3-epoxypropyltrimethyl ammonium chloride, tartaric acid and benzalkonium chloride, and the mass ratio of the printing and dyeing auxiliary to a dye mordant is 1:(10-50). According to the provided linen printing and dyeing method with high dye-uptake rate, linen can be dyed with very high tint amount, and the printed and dyed linen has very high friction resistance and very high water washing resistant color fastness. Besides, the provided linen printing and dyeing method is low in raw material cost, simple to operate, good in operability and very suitable for industrial printing and dyeing.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

Laundry Process Temperature Indicators / Markers and Fabrics Incorporating Same

The invention is a fabric-based article, or linen, including a temperature-sensing indicator to report whether the article has been subjected to laundering / processing temperatures in excess of a threshold recommended temperature. The temperature-sensing indicator visually reports whether the fabric-based article has exceeded the threshold temperature by changing color upon application of heat in excess of the threshold temperature. The temperature-sensing indicator may be incorporated into the body of the linen itself as part of the fabric or may be affixed to a linen as a tag or label.

Owner:WESTPOINT HOME

Cotton and linen cloth drying equipment

ActiveCN109506442AHeating fastImprove drying efficiencyDrying machines with progressive movementsDrying solid materialsWater vaporPulp and paper industry

The invention discloses cotton and linen cloth drying equipment. The cotton and linen cloth drying equipment comprises a frame, a box body covering the frame, a drying roller structure for contactingwith wet cotton and linen cloth and stretching the cotton and linen cloth to open holes in the cotton and linen cloth during drying the cloth, a heating structure for increasing the temperature of thedrying roller structure, and a dehumidifying structure for absorbing water vapor in an oven and heating the inner wall of the box body by the absorbed water vapor. As the drying roller structure is directly contacted with the cloth, when the cloth is dried, the temperature of the cloth can be quickly transferred to the cloth, the cloth is fast in heating, and the drying efficiency is high.

Owner:SHAOXING UNIVERSITY

Ancient mural holographic imitating and copying manufacturing method and holographic imitating and copying ancient mural obtained therethrough

ActiveCN110802980ATo achieve a high degree of simulation effectIncreased durabilitySpecial artistic techniquesEngineeringImage segmentation

The invention provides an ancient mural holographic imitating and copying manufacturing method and a holographic imitating and copying ancient mural obtained therethrough. The method comprises the following steps that data analysis and arrangement are performed according to cultural relic experimental investigation data so as to obtain a high-definition scanning image and a picture with the size ratio of 1:1 to an original mural as well as materials and structures used in an ancient mural original base layer and pigment used in the original wall painting; the high-definition scanning image isdivided into a plurality of parts, the size of each part is determined, image line drawing and copying are carried out, and bottom frame split manufacturing is carried out according to the size of each part; after a bottom frame is manufactured, single surface laying of a bottom lining plate is carried out, and then pure linen cloth is stretched and bound on the frame; according to the materials and the structures used in the ancient mural original base layer, a base layer and a surface layer are manufactured on the stretched linen cloth; pigment is selected according to the pigment used in the original wall painting, and a pigment blending liquid is prepared; the traditional drawing performance technique is applied to carry out ancient mural image information coping; and manufactured mural imitating and coping works are subjected to combined installation and gap filling.

Owner:宋志旭

A three-dimensional printing curtain releasing negative ions and its printing slurry preparation technology

The invention prepares a three-dimensional printed curtain releasing negative ions and describes the printing slurry and the preparation process of the printed curtain. With EPVC as the carrier, thin cotton cloth, nylon silk, velvet cloth, cotton linen cloth and polyester cloth as the base material, the seagull stone negative ion additive is fixed on the curtain through the process of resin three-dimensional printing, so that the curtain has the effect of releasing negative ions. The method is convenient and quick, the flower shape is full of three-dimensional effect, and the effect of releasing negative ions is remarkable.

Owner:沈莉萍

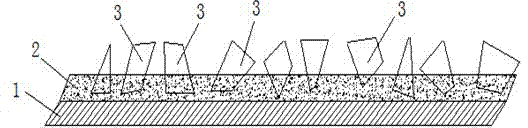

Sackcloth-based industrial abrasive band

The invention discloses a sackcloth-based industrial abrasive band and aims to solve the technical problem that a base material of the conventional abrasive band does not have a grinding function. The sackcloth-based industrial abrasive band comprises sackcloth, wherein the sackcloth is soaked by glue or subjected to scraping and soaking treatment; a primer is coated on the surface of the sackcloth, and a grinding material layer is formed on the surface, which is coated with the primer, of the sackcloth by planting sand; grinding materials or chopped fibers corresponding to the sackcloth are added into the glue for soaking or scraping and soaking; and the sackcloth is one of sisal cloth, hessian, linen, blue linen, ramie cloth and meyer linen or blended cloth of a plurality of hemps and blended cloth of cotton. Abrasive cloth takes the sackcloth as a base material, and messy structures of the chopped fibers of the sackcloth are utilized, so that the shock resistance of a glue layer is improved; the chopper fibers can be synchronously consumed and have certain polishing and grinding performance, so that the performance is improved, and the using cost is reduced.

Owner:谢泽

Anti-radiation cotton and linen plain weave

The invention relates to a radiation-proof hemp spun plain weave cloth, which is manufactured by using cotton fiber, hemp fiber and metal fiber as raw materials. The ratio of metal fiber is 20%-30%, that of hemp fiber is 50-60%, and that of silk fiber is 10%. -30%. Among them, the metal fiber is 3-5um, 1-5cm copper fiber. The weave of the fabric is plain weave, the density of the warp is 350 / cm, the density of the weft is 295 / cm, the surface density of the plain weave is 190g / m2, the tightness is 80%, and the thickness is 0.28mm. The warp yarn is cotton and linen blended yarn mixed with copper fiber, and the weft yarn is pure hemp fiber / spandex core-spun fabric. The invention fully kneads hemp fiber with metal fiber as weft yarn, pure hemp fiber as warp yarn, and the prepared plain cloth has moisture absorption, breathability, comfort and elasticity, and the shielding rate reaches 99%.

Owner:WUJIANG RUIFENG WEAVING

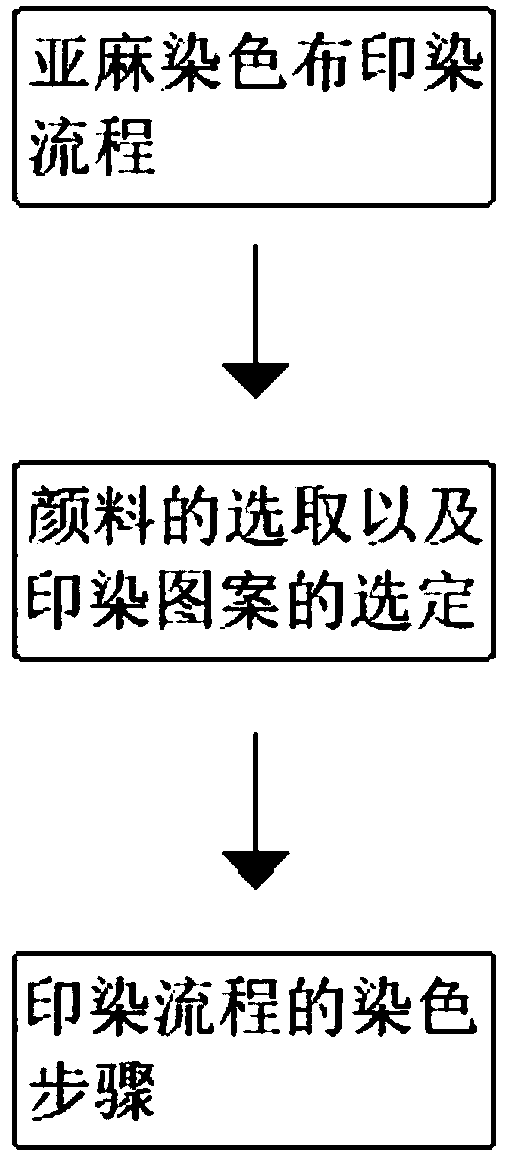

Linen dyed cloth printing and dyeing process

InactiveCN109295771AImprove printing and dyeing efficiencySingeingDry-cleaning apparatus for textilesEngineeringLinen cloth

The invention provides a linen dyed cloth printing and dyeing process. The method comprises the following seven steps: step 1: introduction of a printing and dyeing process; step 2: preparation of a printing and dyeing device; step 3: selection and inspection of linen cloth; step 4: singeing of the linen cloth; step 5: desizing of the linen cloth; step 6: selection of a printing and dyeing pigmentand selection of printing and dyeing patterns; and step 7: dyeing during a printing and dyeing process. Through a series of steps, the different workers can work according to the workflow of the printing and dyeing process, the printing and dyeing efficiency of the linen dyed cloth is improved, and the printing and dyeing process facilitates the widespread use in the society.

Owner:佛山市三水南方天泽印染有限公司

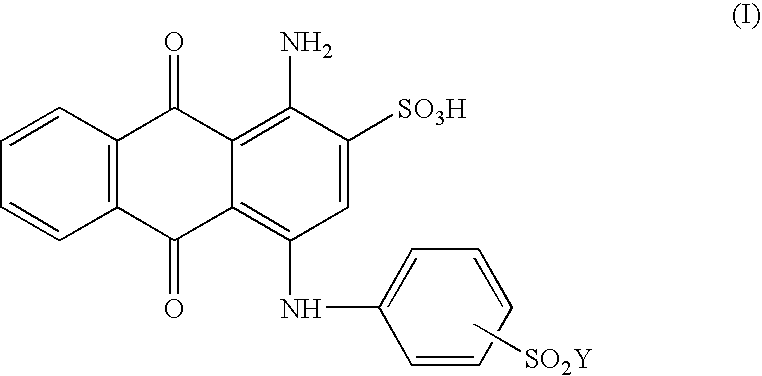

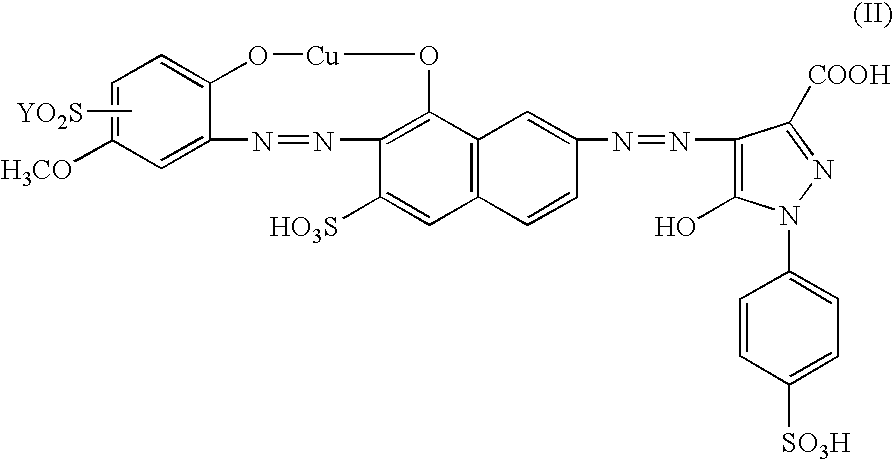

Dye composition and the use thereof

InactiveUS6955693B2Excellent light fastness and perspiration-lightVarious fastness propertyReactive dyesDyeing processAnthraquinonesPerspiration

A dye composition is disclosed, which comprises a blue anthraquinone dye of the following formula (I) wherein Y is —CH═CH2, —CH2CH2Cl or —CH2CH2OSO3H; and a gray-black azo dye of the following formula (II) wherein Y is defined as the above. The dye compositions of the present invention have good stability and build-up property. The dye compositions are suitable for dyeing and printing materials that contain either cellulose fibers, such as cotton, artificial cotton, linen, and artificial linen, or synthetic polyamide, such as wool, silk, and nylon. The materials obtained through treatment with the dye compositions aforementioned show excellent properties, especially in wash-off, level-dyeing, build-up, light fastness and perspiration-light fastness.

Owner:EVERLIGHT USA INC

Massage health cap

The invention discloses a massage health cap which comprises a cap outer layer and a cap inner layer. A massage bag is fixedly and additionally arranged between the cap outer layer and the cap inner layer. A massage magnet is fixedly arranged inside the massage bag, the massage bag is made of antibacterial linen cloth, and the antibacterial linen cloth is fumigated by tee tree fruits. The massage health cap is simple in structure and capable of massaging and protecting health, the magnet has the health functions of improving immunity, being anti-aging, removing fatigue and enhancing memory, after the massage bag cloth is fumigated by the tea tree fruits, the massage health cap has the antibacterial health functions of insect prevention and deodorization, and overcomes the defects of a traditional cap in function, and enriches the functions of the cap.

Owner:NANTONG WULIAN BRAND PLANNING

Detergent for linen clothes

ActiveCN103666828AAntibacterial and antifungal propertiesSimple ingredientsOrganic detergent compounding agentsSurface-active detergent compositionsBenzeneLinear alkylbenzene

A detergent for linen clothes comprises the components in parts by mass as follows: 15-25 parts of linear alkyl benzene sulphonic acid, 15-25 parts of fatty alcohol polyoxyethylene ether, 3-8 parts of sodium sulfate sodium citrate, 1-5 parts of triethanolamine and 20-35 parts of water. Preferably, the detergent comprises the components as follows: 20 parts of the linear alkyl benzene sulphonic acid, 20 parts of the fatty alcohol polyoxyethylene ether, 5 parts of the sodium sulfate sodium citrate, 3 parts of the triethanolamine and 28 parts of the water. The mass ratio of the linear alkyl benzene sulphonic acid to the fatty alcohol polyoxyethylene ether is 1:1. According to the detergent for the linen clothes, the fact that linen cloth has antibacterial and mould-proof characteristics is considered, antibacterial and mould-proof components are not added in the detergent, the components are simple, in order to realize higher dirt-removing power, the linear alkyl benzene sulphonic acid and the fatty alcohol polyoxyethylene ether are selected as main dirt-removing components and matched with each other to further increase the dirt-removing power, and compared with currently common clothes detergents, the detergent is more economic and practical.

Owner:广州盛欣化妆品有限公司

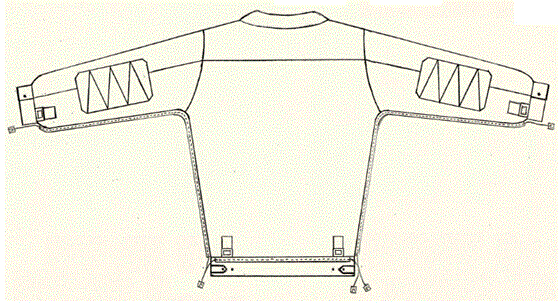

Induction electric protection suit

PendingCN106174788AAvoid wastingImprove comfortProtective garmentSpecial outerwear garmentsProduction lineConductive shoe

The invention relates to an induction electric protection suit. The induction electric protection suit is composed of an upper garment and a lower garment which are made of pure cotton or pure linen cloth, wherein lead grooves are reserved in the protection suit, and the extending directions of leads are as follows: for the upper garment, a lead is arranged at each of two cuffs of the upper garment, extends to the lower hem of the upper garment, and is connected with the other lead arranged at the lower hem of the upper garment, at the joint of the leads, the two leads are connected with each other and are stranded into one lead, and two wiring connectors are separated out; one wiring connector is connected with a waist lead end opening of the lower garment, the other wiring connector is connected with a grounding wire; lead end openings capable of being connected with conductive gloves are reserved in the two cuffs of the upper garment; for the lower garment, a lead is arranged from each of the left and right waist parts to the corresponding trouser leg of the lower garment, and waist lead end openings capable of being connected with the connectors are reserved in the waist parts; and lead end openings capable of being connected with conductive shoes are reserved in the trouser legs. The induction electric protection suit is suitable for the construction, production, as well as maintenance and testing of power enterprises, and also suitable for wearing use of employees of the first production line of industrial and mining enterprises including metallurgy and chemical engineering.

Owner:上海熙凌电器有限公司

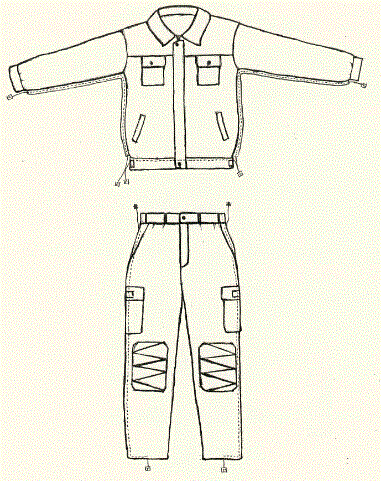

Composite material, preparation method and application thereof

PendingCN109532158AAvoid enteringKeep healthyChemical protectionHeat protectionCellulosePhysical well being

The invention discloses a composite material and a preparation method thereof. The composite material is formed by laminating, successively from top to bottom, a barrier layer, a nano-selenium composite material layer, a water-absorbing layer, and a contact layer; wherein the barrier layer is a rubber-plastic waterproof material; the nano-selenium composite material layer is a nano-composite and includes, by mass, 70-90% of nano-active carbon, 5-10% of nano-selenium and 5-20% of a hot melt adhesive; the water-absorbing layer is made from a cellulose water-absorbing material; and the contact layer is made of any one of cotton cloth, nonwoven fabric and linen cloth. The composite material has excellent water-absorbing function, permeability and barrier performance, has strong capture effecton mercury, effectively prevents direct contact between liquid mercury and mercury vapor and skin of workers in mercury industry or avoids re-volatilization of the liquid mercury on clothes. The composite material can guarantee body health of workers in high-mercury industry and has great social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

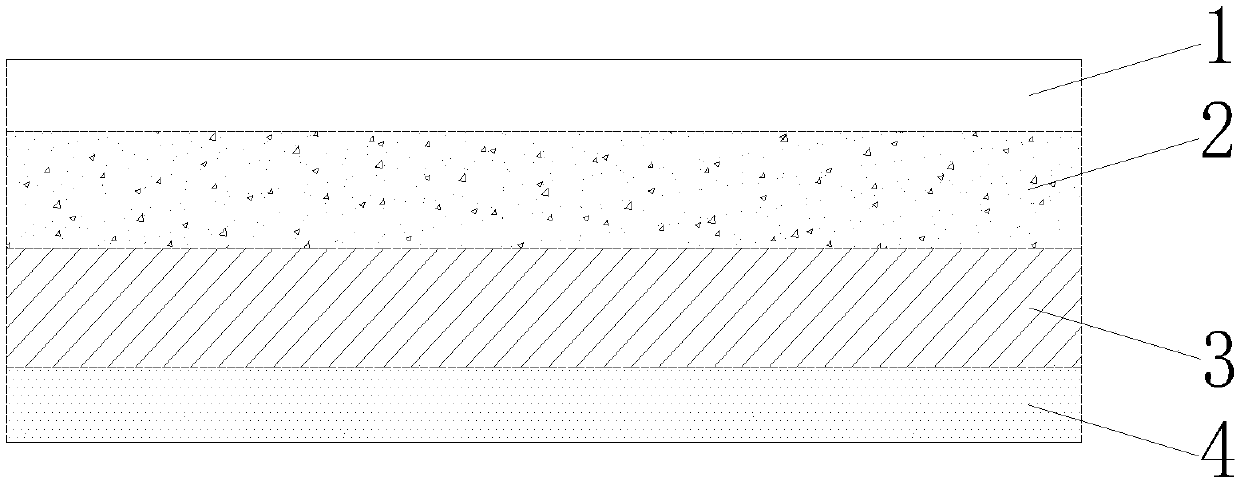

Device for filtering and turning impurities in cotton and linen cloth material washing water

PendingCN109173402AEfficient filtering and pouring processMoving filtering element filtersFiltrationLap joint

The invention discloses a device for filtering and turning impurities in cotton and linen cloth material washing water. The device comprises an inclined plate, two ends of the inclined plate are respectively provided with two rotation rods, a belt is arranged round the rotation rods and the inclined plate, a filtering mechanism comprises side blocks in two sides of the belt, the surfaces of the two side blocks are provided with pin holes, a filter net is arranged between the two side blocks, the side of the filter net is provided with a pin shaft, the pin shaft is located at the upper part ofthe side of the filter net, and the distance between the pin shaft and the edge of the filter net is small than the distance between the pin hole and the belt. Through circulating rotation of the belt, the filter net on the belt can form lap joint with the belt so that washing water from the upstream of the belt flows through the filter net and is filtered so that the impurities are aggregated onthe filter net, and after the filter net is turned to the lower surface along with the belt, the filter net is turned down under the gravity and the inner impurities are dumped. The automatic filtration and pouring process is more efficient.

Owner:YI HE STOCK

Preparation method of high-strength protective fabric with quantitative tension

PendingCN112210999AImprove breathabilityImprove wear resistanceLaminationElectro-spinningFlax fiberLinen cloth

The invention discloses a preparation method of a high-strength protective fabric with quantitative tension. The preparation method comprises the following steps of 1, taking bamboo pulp fiber and flax fiber, putting the bamboo pulp fiber and the flax fiber into a 10 g / L sodium periodate solution, and oxidizing for 1 h in a dark place at 40 DEG C to obtain oxidized bamboo fiber, wherein the mass ratio of the bamboo pulp fiber to the flax fiber to the sodium periodate solution is 1: 1: 4; and 2, putting the oxidized bamboo pulp and flax fiber into a 0.1 mol / L lycerol solution to be soaked for 30 min, then washing the soaked oxidized bamboo pulp and flax fiber with 100 g of deionized water for 3-5 times, and drying to obtain the oxidized bamboo pulp and flax fiber. According to the preparation method, the bamboo pulp fiber has a long fiber mesoporous structure, has many pores, has strong air permeability, hygroscopicity and wear resistance, can rapidly absorb sweat steam discharged by ahuman body and discharge the sweat steam to the outside, adjusts the microclimate between clothes and the human body and improves the comfort; and in addition, the flax fiber is added, the advantage that flax cloth is high fiber strength and not prone to being worn is used for improving the mechanical property of the textile fabric, and meanwhile, the higher tensile property is also ensured.

Owner:FUJIAN CHANGLE CITY CHANGYUAN TEXTILE

Textile fabric production process and production equipment thereof

ActiveCN111979786ASealedWith comfortTextile treatment machine arrangementsTextile treatment with treating outlet contectPulp and paper industryCotton cloth

The invention discloses a textile fabric production process and production equipment thereof, and relates to the textile field. The textile fabric production process comprises the following steps that1, raw material preparation is conducted, and comprises finished cotton cloth, linen and a colloid stock solution; 2, singeing, desizing, boiling off, bleaching, mercerizing and the like are carriedout on the finished cotton cloth and the linen in the raw material preparation; and 3, the finished cotton cloth and the linen are weaved in the raw materials, the two fabrics are weaved together to form a group of fabrics, and whether to dye or not is selected according to needs. According to the textile fabric production process and the production equipment thereof, through arrangement of the step 1 preparing the raw materials comprising the finished cotton cloth, the linen and the colloid stock solution, and step 5 pouring the colloid stock solution into equipment, and allowing cloths to pass through the equipment to make the colloid stock solution adhere to the outer side of the cloths to form a solid in order to realize the fusion of the cotton cloth, the linen cloth and the colloid cloth, and finally, the cloth facing the skin is made of cotton, and the cloth facing the outer side is made of colloid, so that the final cloth has a sealing effect and also has certain comfort.

Owner:CHANGXING SANJIN SPECIAL TEXTILE

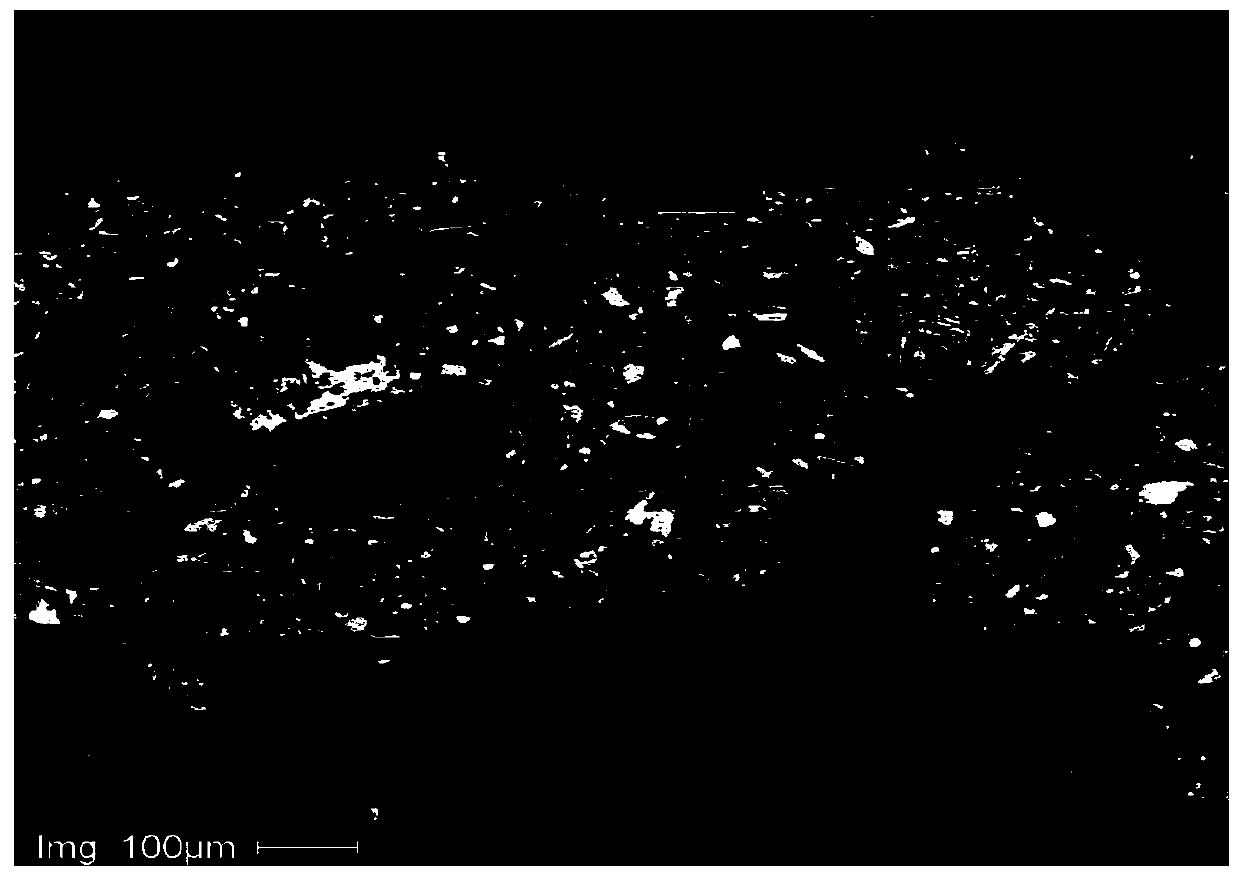

Industrial abrasive belt production method based on flax fabrics

ActiveCN103111951AIncrease profitImprove grinding performanceAbrasion apparatusAdhesive glueFlax fiber

The invention relates to an industrial abrasive belt production method based on flax fabrics. The industrial abrasive belt production method based on the flax fabrics aims to solve the technical problem that any of existing abrasive belts do not have the function of grinding. Firstly the flax fabrics are processed, glue is used for steep or scratching soak the flax fabrics, and sand or flax fabrics chopped fibers can be added or not added in the process of steep or scratching soak; then bottom glue is deposited on one face of the flax fabrics; and then an abrasive material layer is formed through sand implanting. The flax fabrics can be one kind of sisal hemp fabrics, jute fabrics, linen fabrics or ramie fabrics, blended fabrics of flax fabrics or blended fabrics of flax and cotton. The industrial abrasive belt production method based on the flax fabrics uses the flax fabrics as base materials, flax fibers have a grinding property due to certain rigidity and fragility of the flax fibers and is low in cost, the tear resistance of the flax fabrics are improved significantly after the flax fabrics are processed, and thus all performances of a product are ensured.

Owner:四川省三台县固锐实业有限责任公司

Formula design for a solid laundry fabric softener

ActiveUS11015144B2Premium softness without causing yellowing or other fabric discolorationCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceAmmonium compounds

Solid laundry fabric softening compositions for laundry applications of use are disclosed. In particular, solid laundry fabric softening compositions combining quaternary dialkyl actives with low iodine values and silicone provide softness without causing any significant yellowing or loss of water absorption or wicking to the treated linen. The solid laundry fabric softening compositions can be provided as a multi-use block having uniform dispensing rates and without block sloughing. Beneficially, the combination of processing aids for solidification comprising one or more of (A) polyethylene glycol and an acidulant, (B) a surfactant and an acidulant, or (C) polyethylene glycol, a surfactant and an acidulant, are combined with the quaternary ammonium compounds and silicone to provide the stable solid composition.

Owner:ECOLAB USA INC

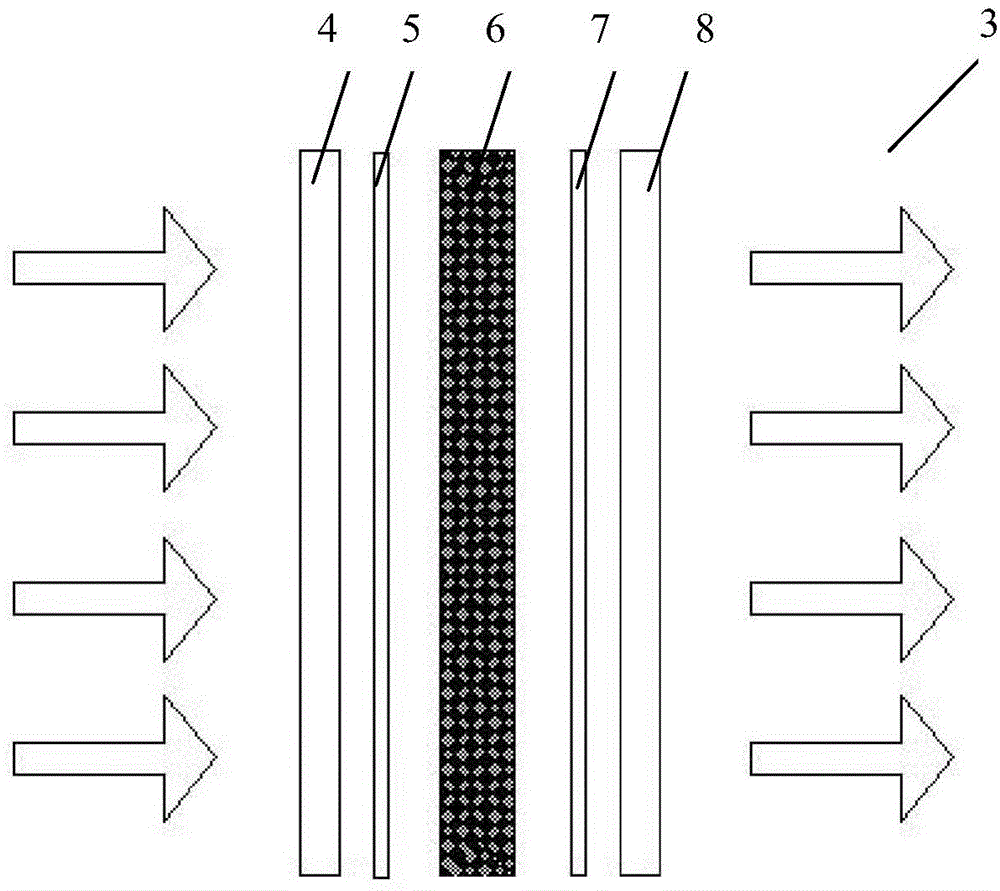

Method for polaroids debubbling in LCD (liquid crystal display) production

InactiveCN106547125AWill not cause accumulationGuaranteed pressureNon-linear opticsInternal pressureLiquid-crystal display

A method for polaroids debubbling in LCD (liquid crystal display) production includes steps: 1) putting an LCD with the polaroids between pressure bearing plates, and tightening the pressure bearing plates by the aid of bolts, wherein the pressure bearing plates are steel plates wrapped with linen cloth; 2) putting the LCD at the step 1) along with the pressure bearing plates into a debubbling machine; 3) heating the interior of the debubbling machine to 60-70 DEG C, and keeping for 10-20min; 4) feeding compressed air into the debubbling machine to adjust the internal pressure of the debubbling machine to 0.5-0.8MPa, and keeping for 8-15min. By adoption of the method for polaroids debubbling in LCD production, bubbles generated in surface mounting of the polaroids can be eliminated effectively.

Owner:曾周

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com