Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156 results about "Fossil fuel combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion of Fossil Fuels. Introduction. In this lesson, you will investigate what happens to fossil fuels, such as hydrocarbons, when they burn. This process of burning is called combustion. To better understand the combustion of fossil fuels, you will access two online resources.

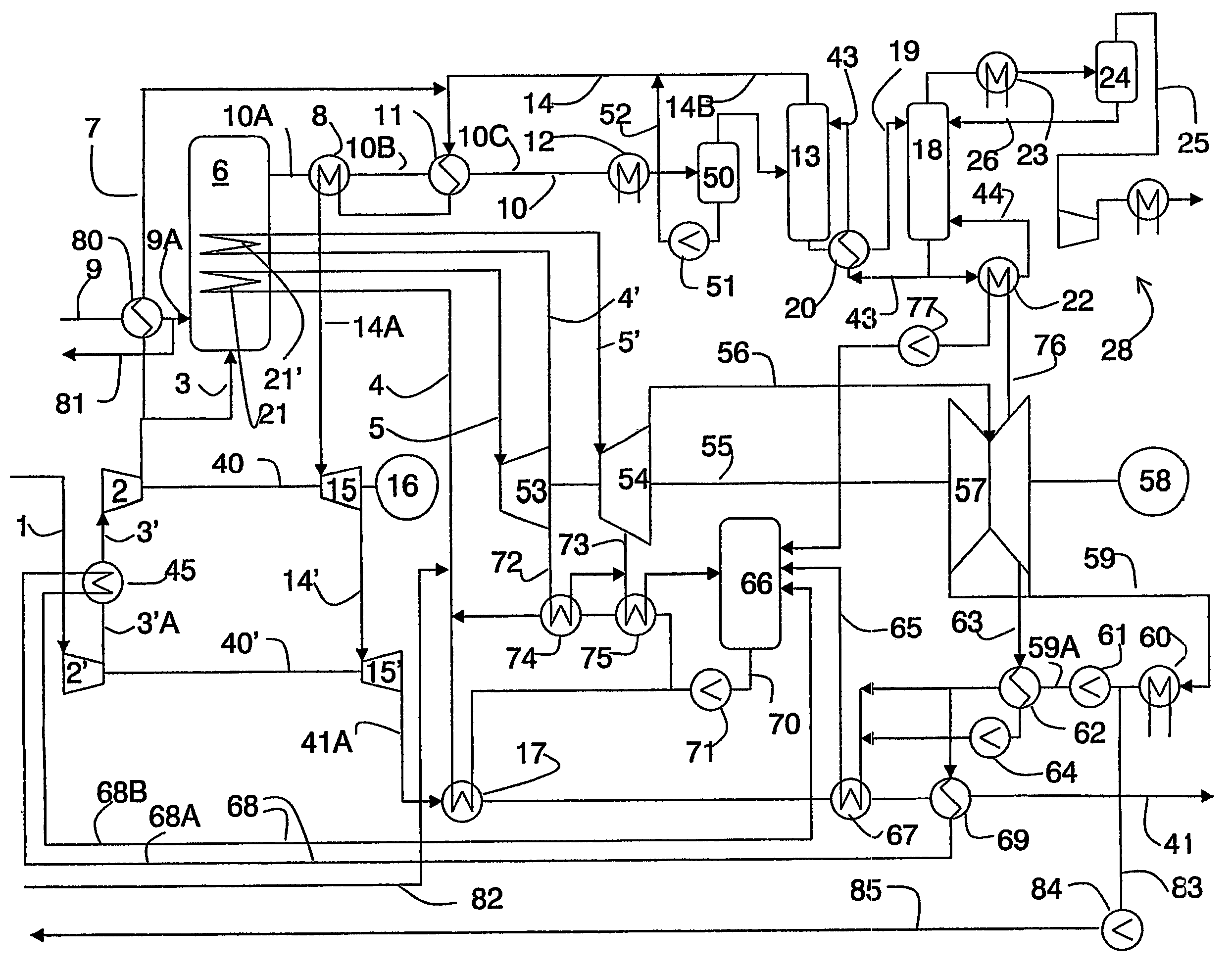

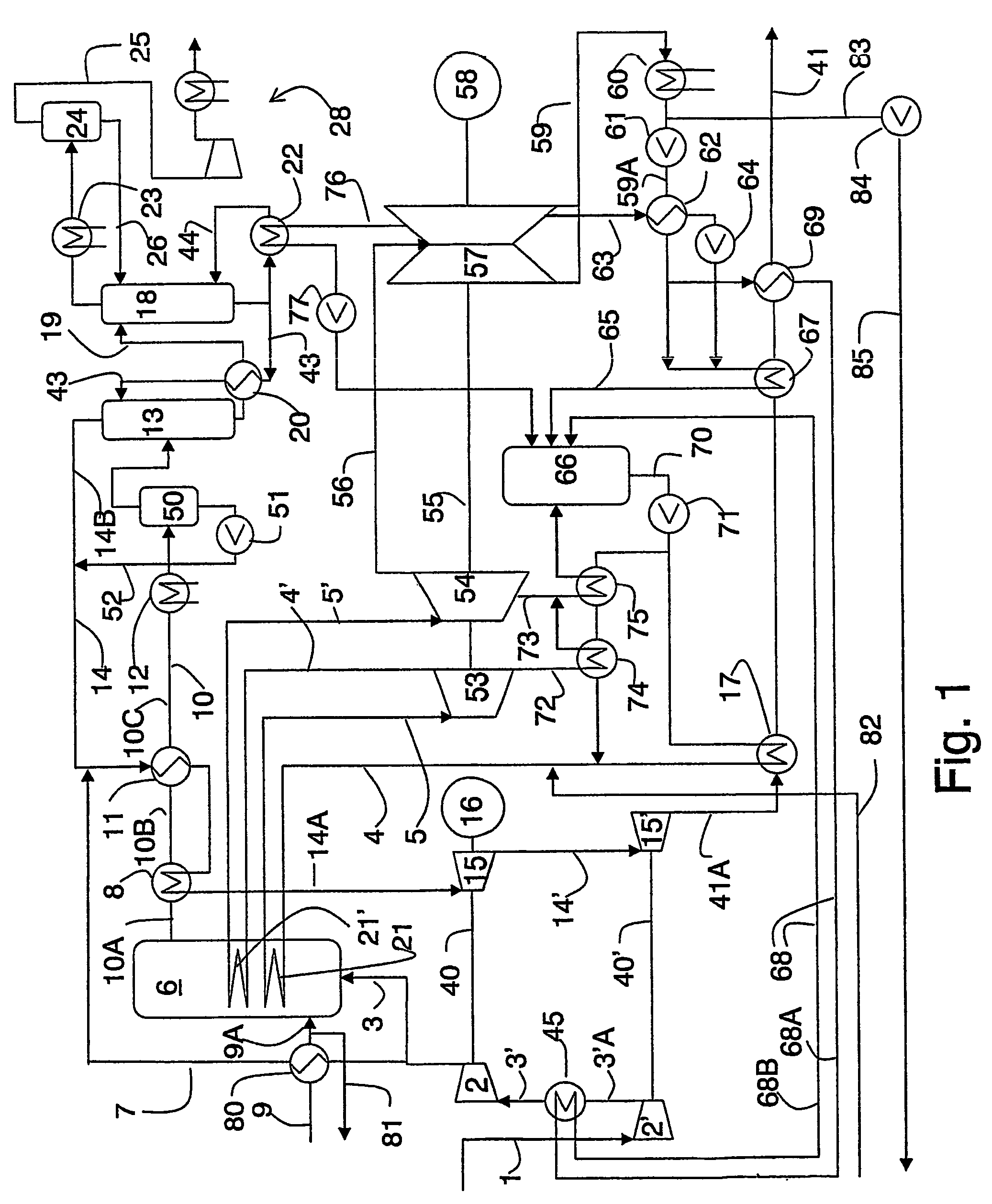

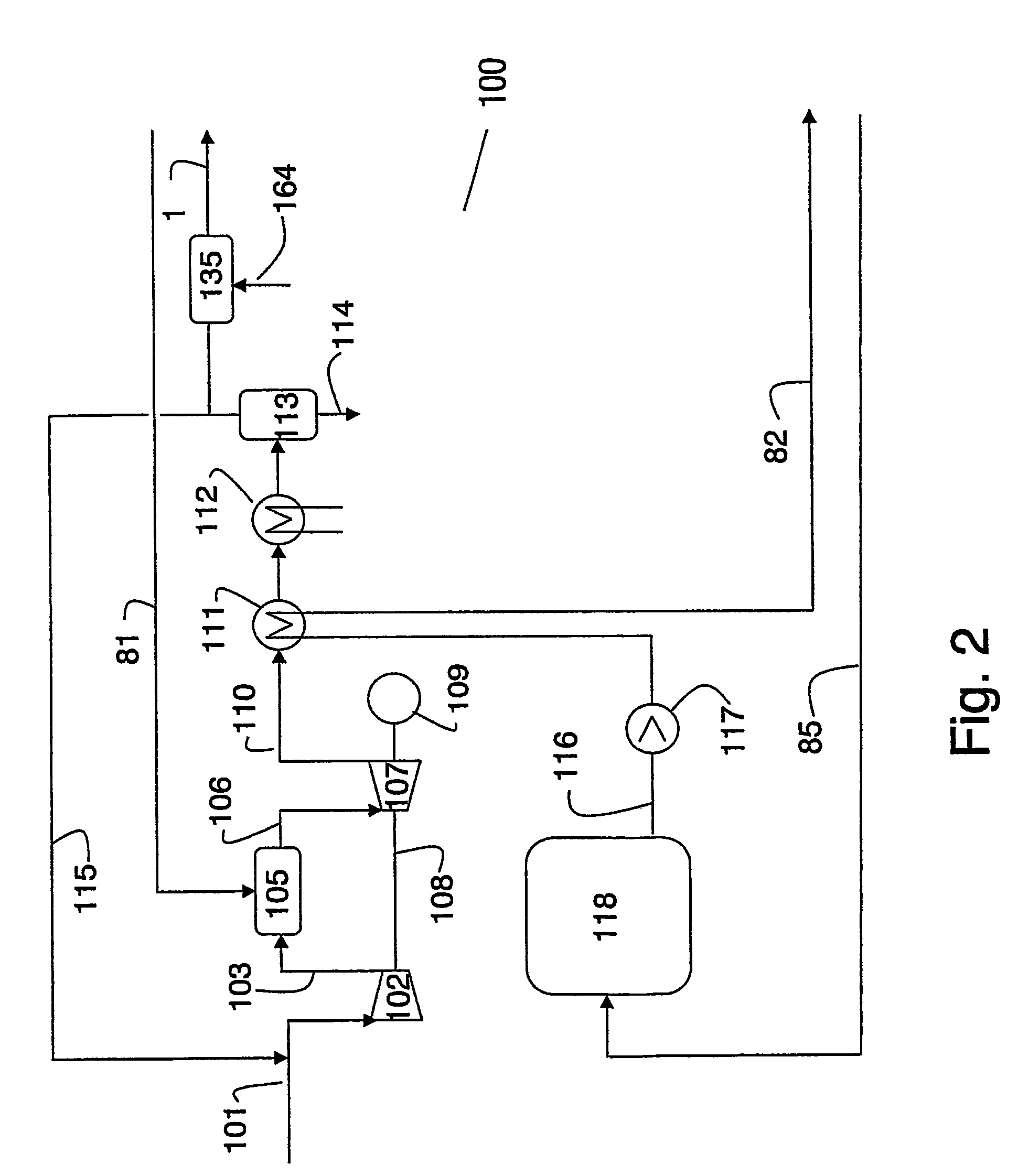

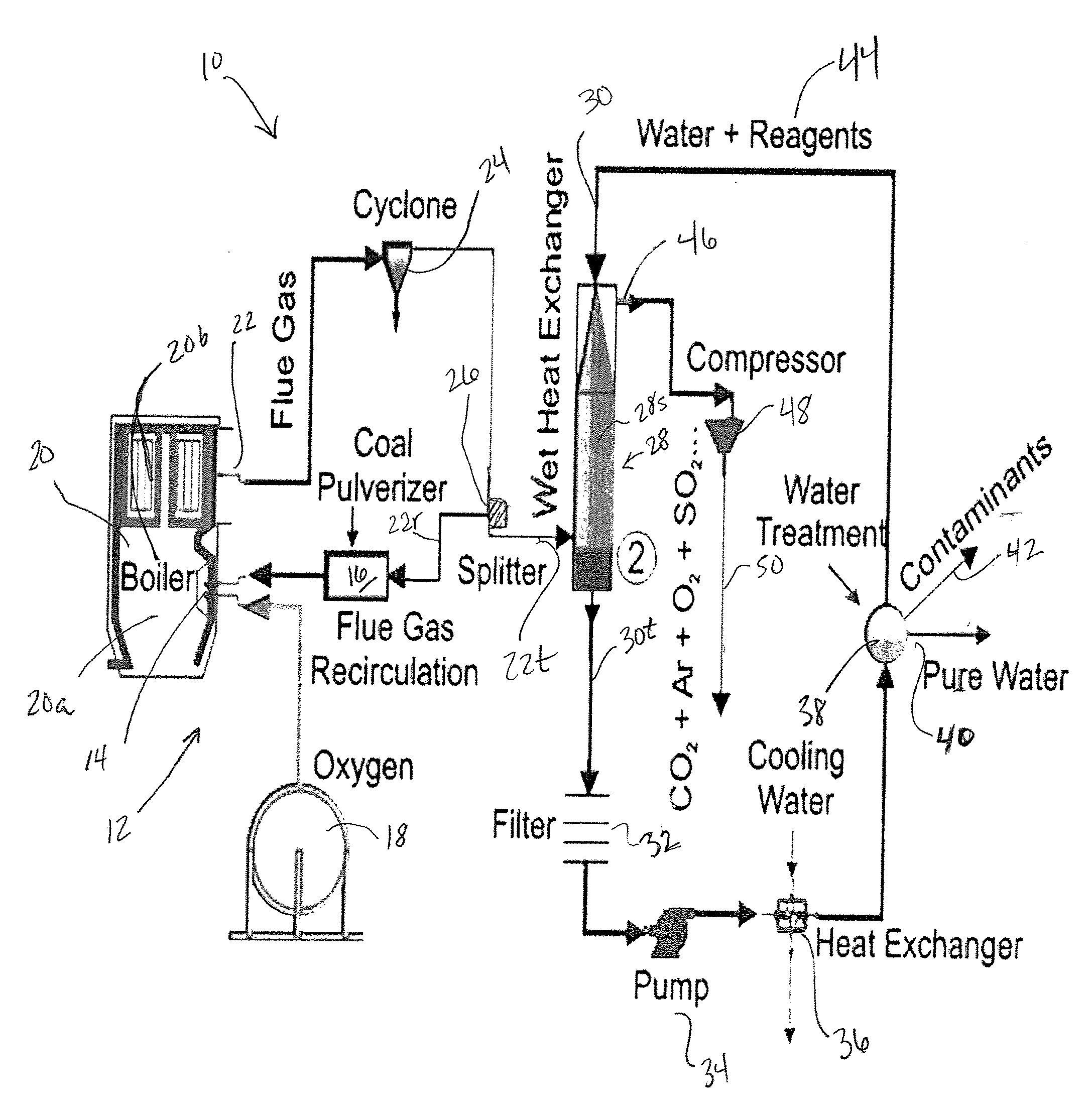

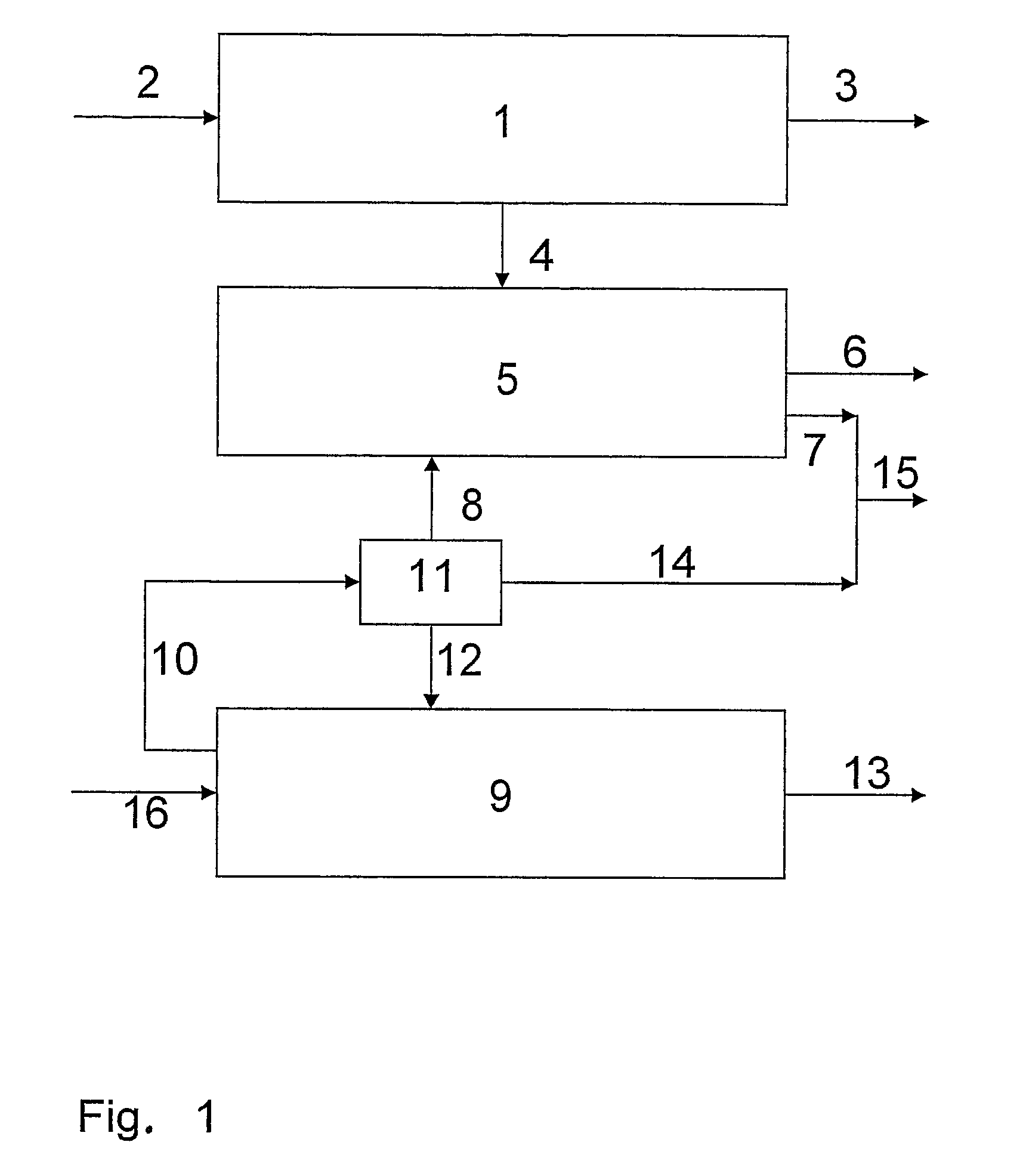

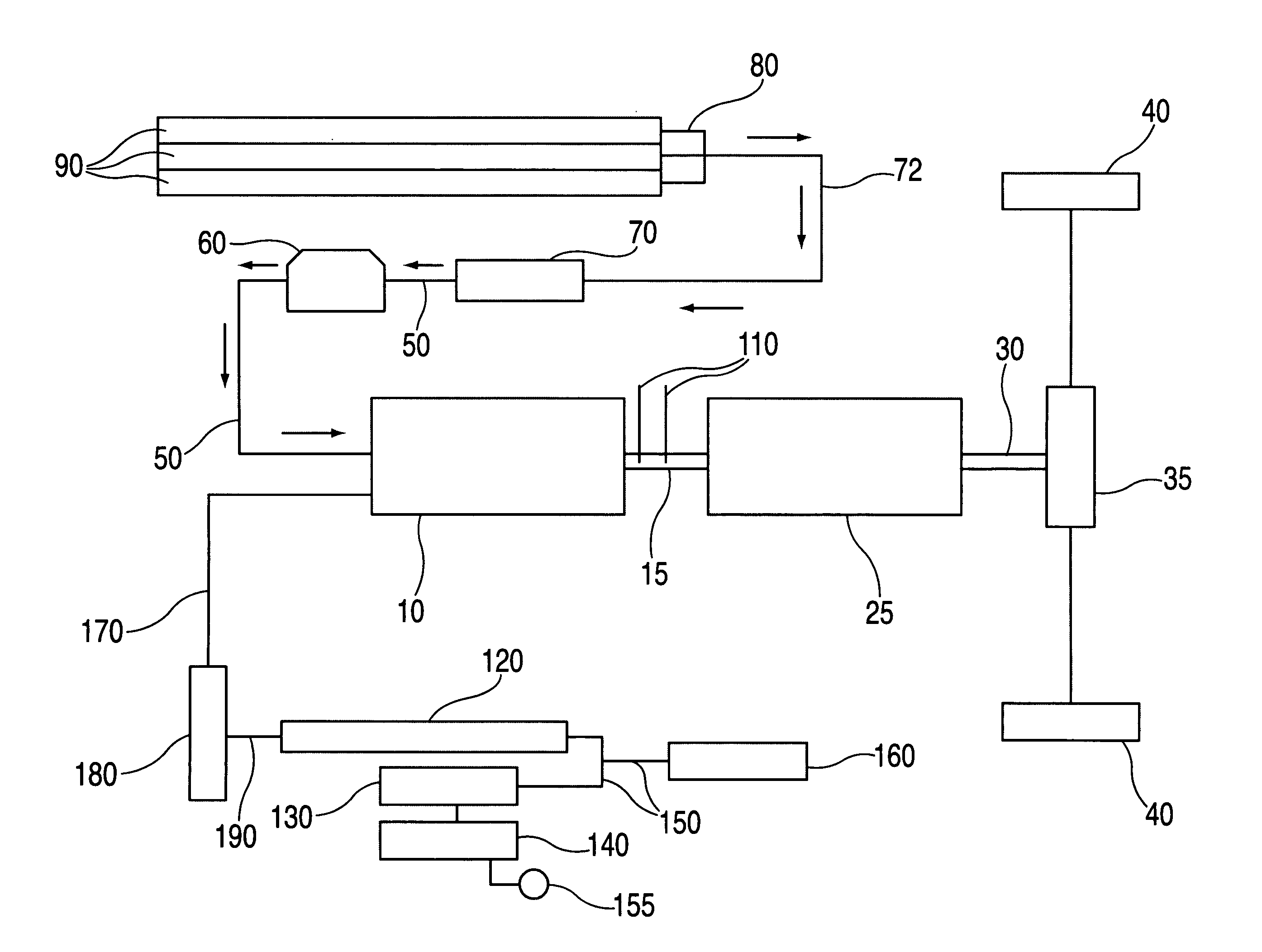

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

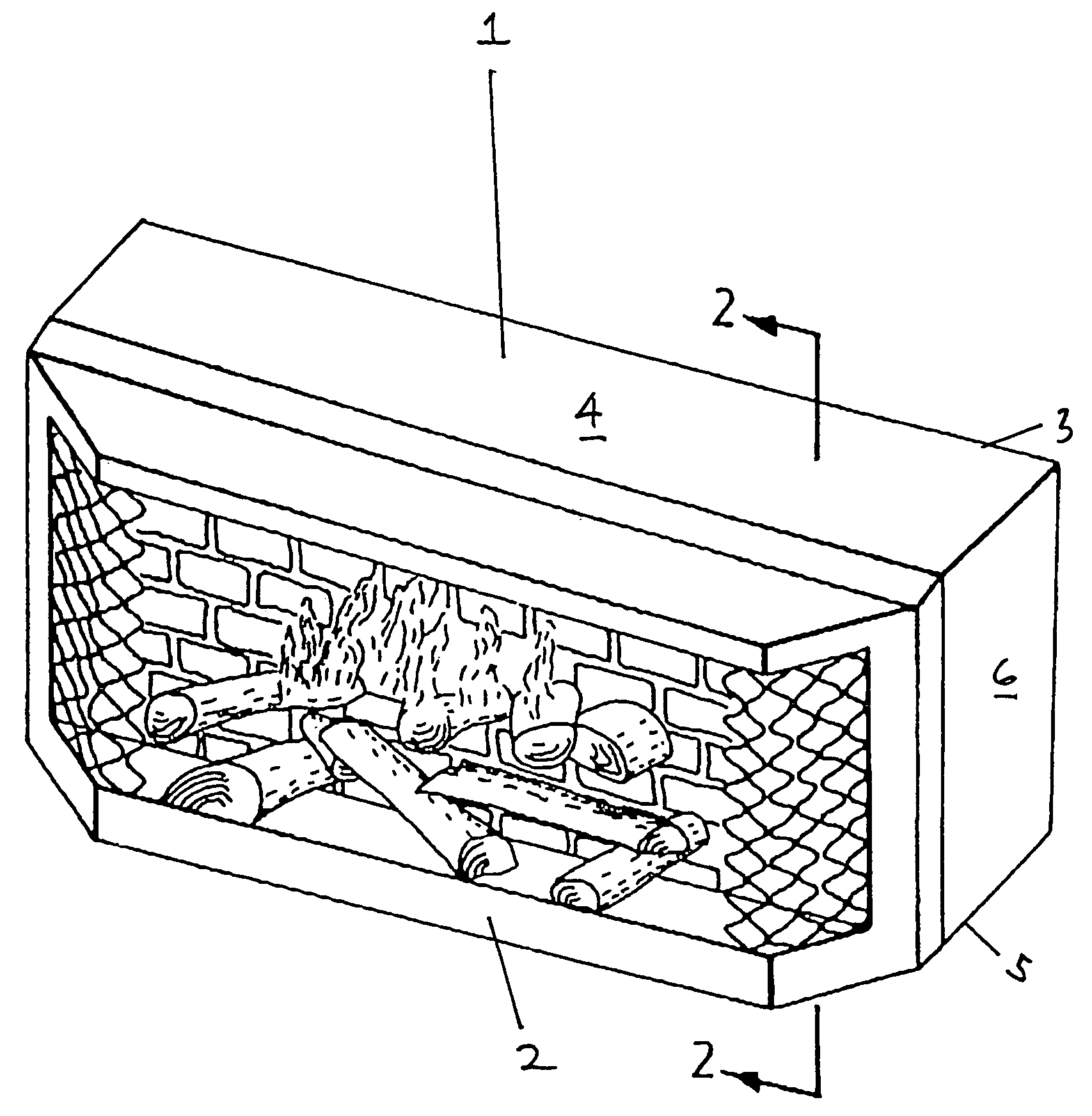

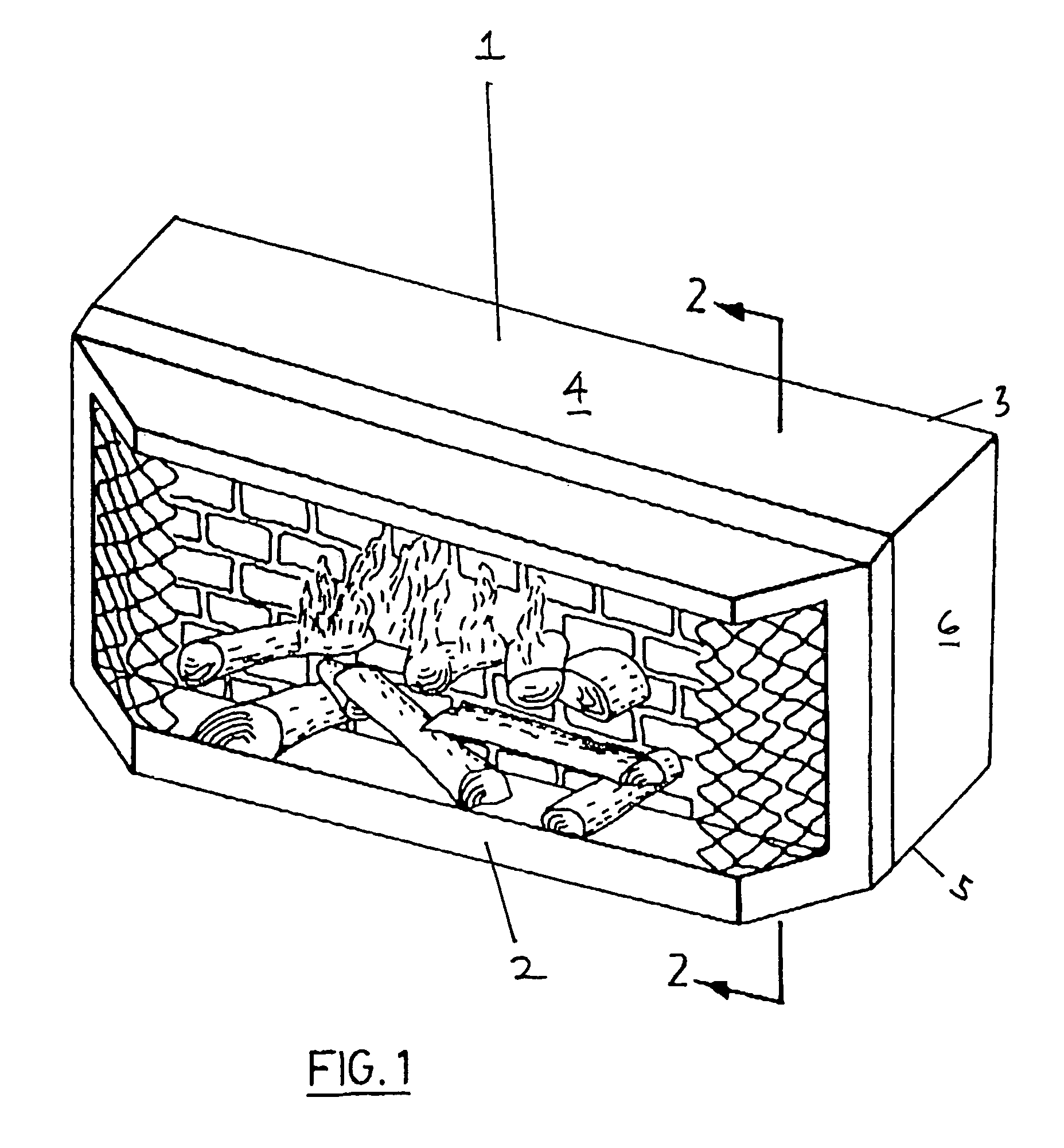

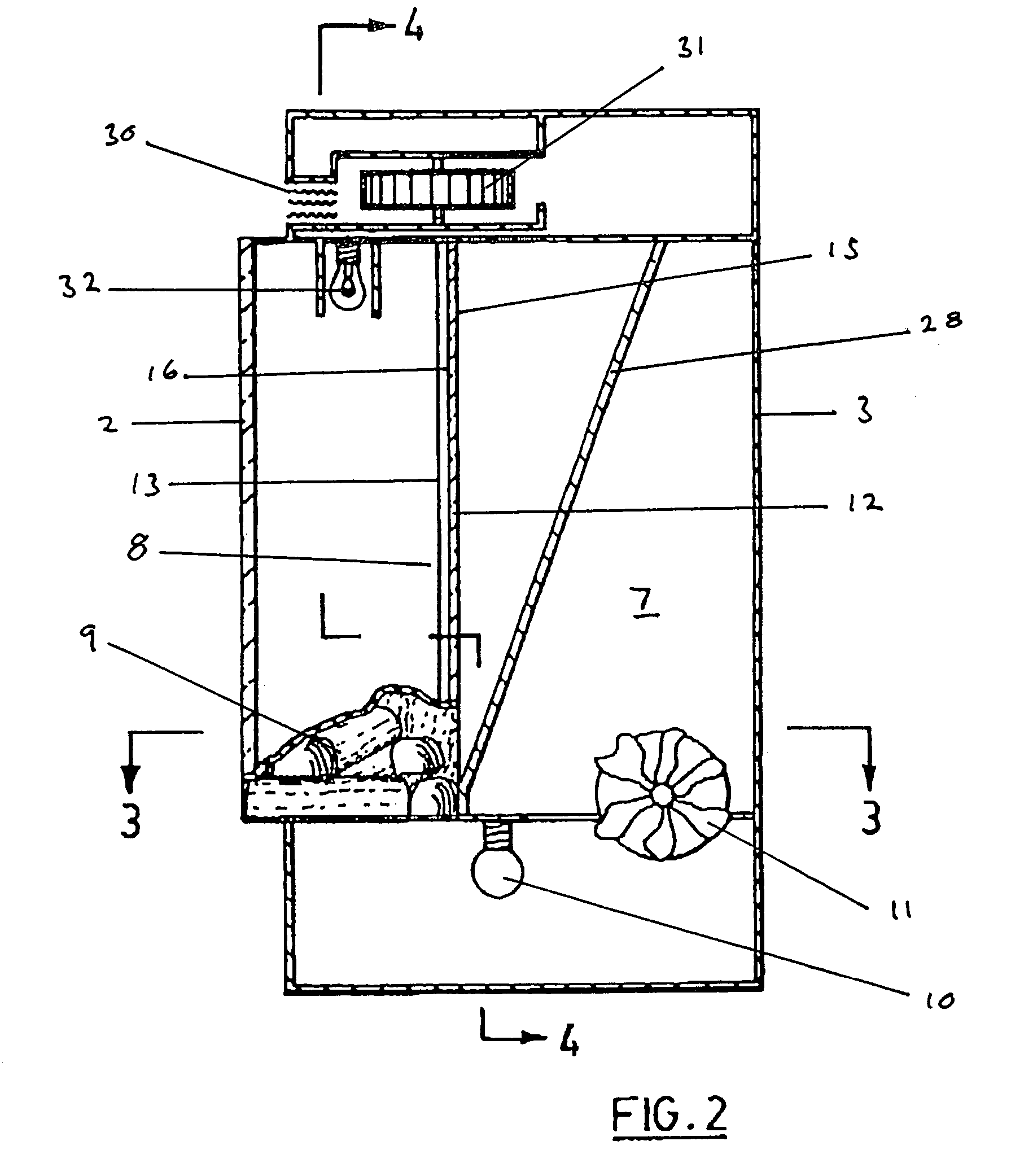

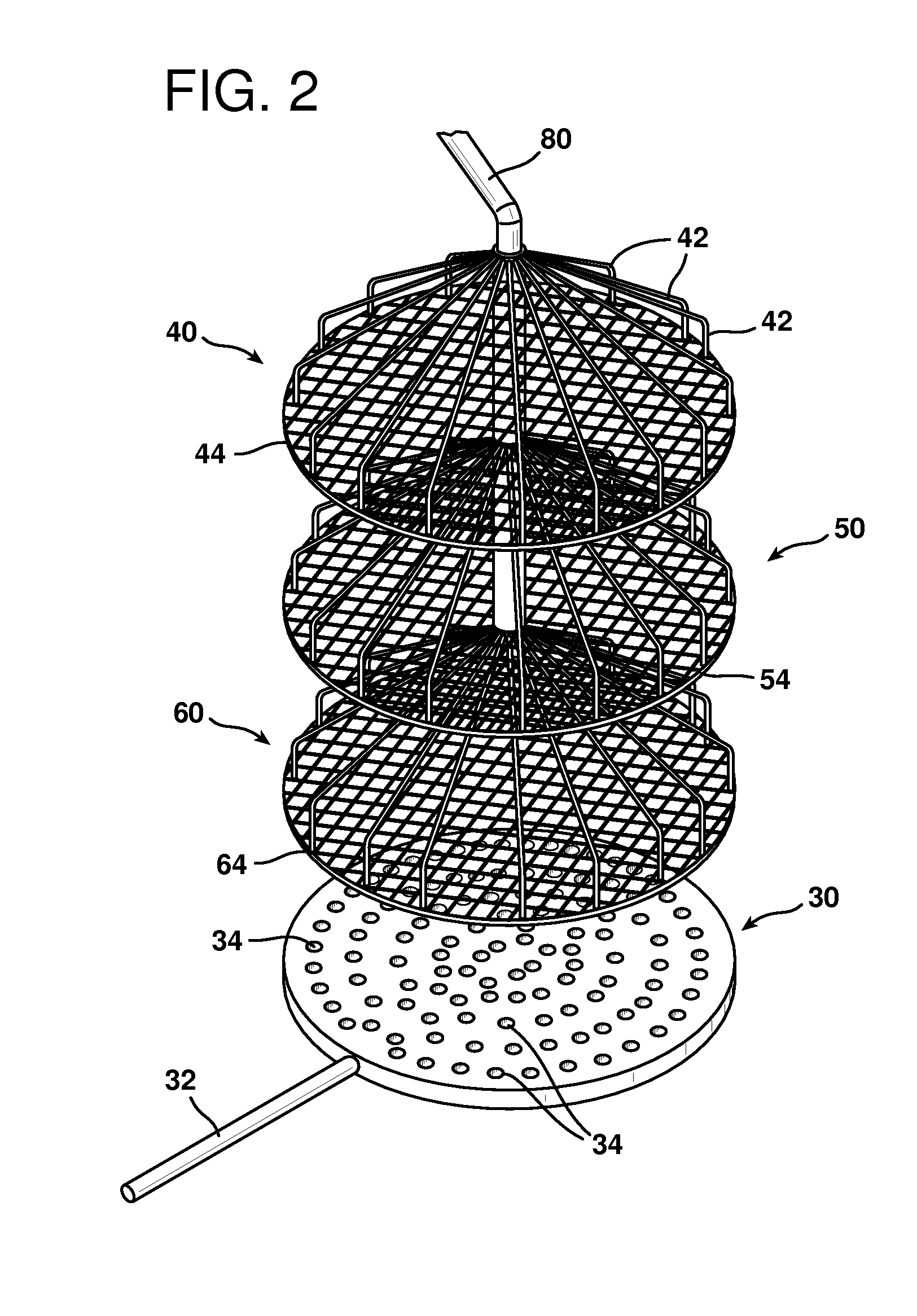

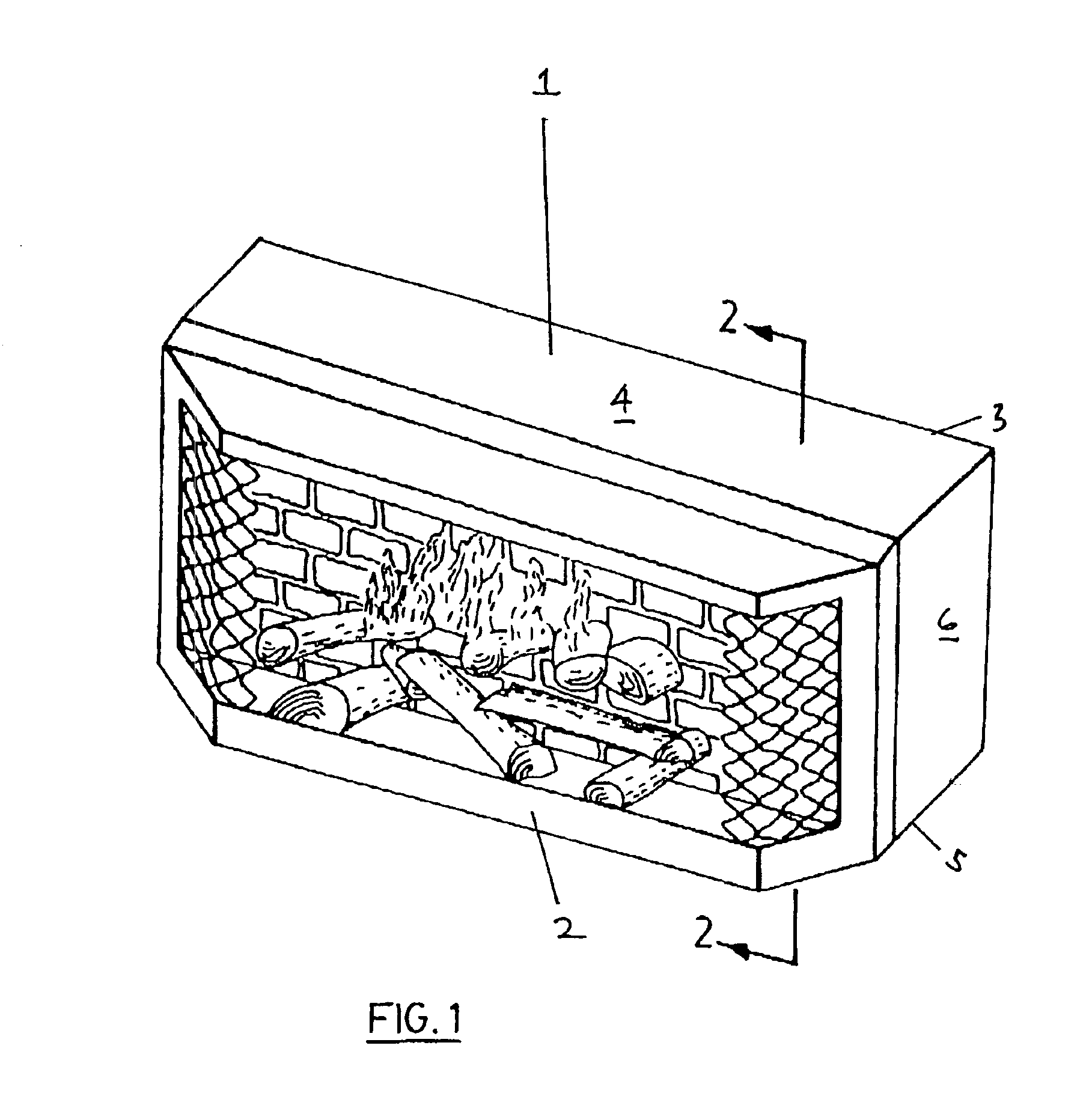

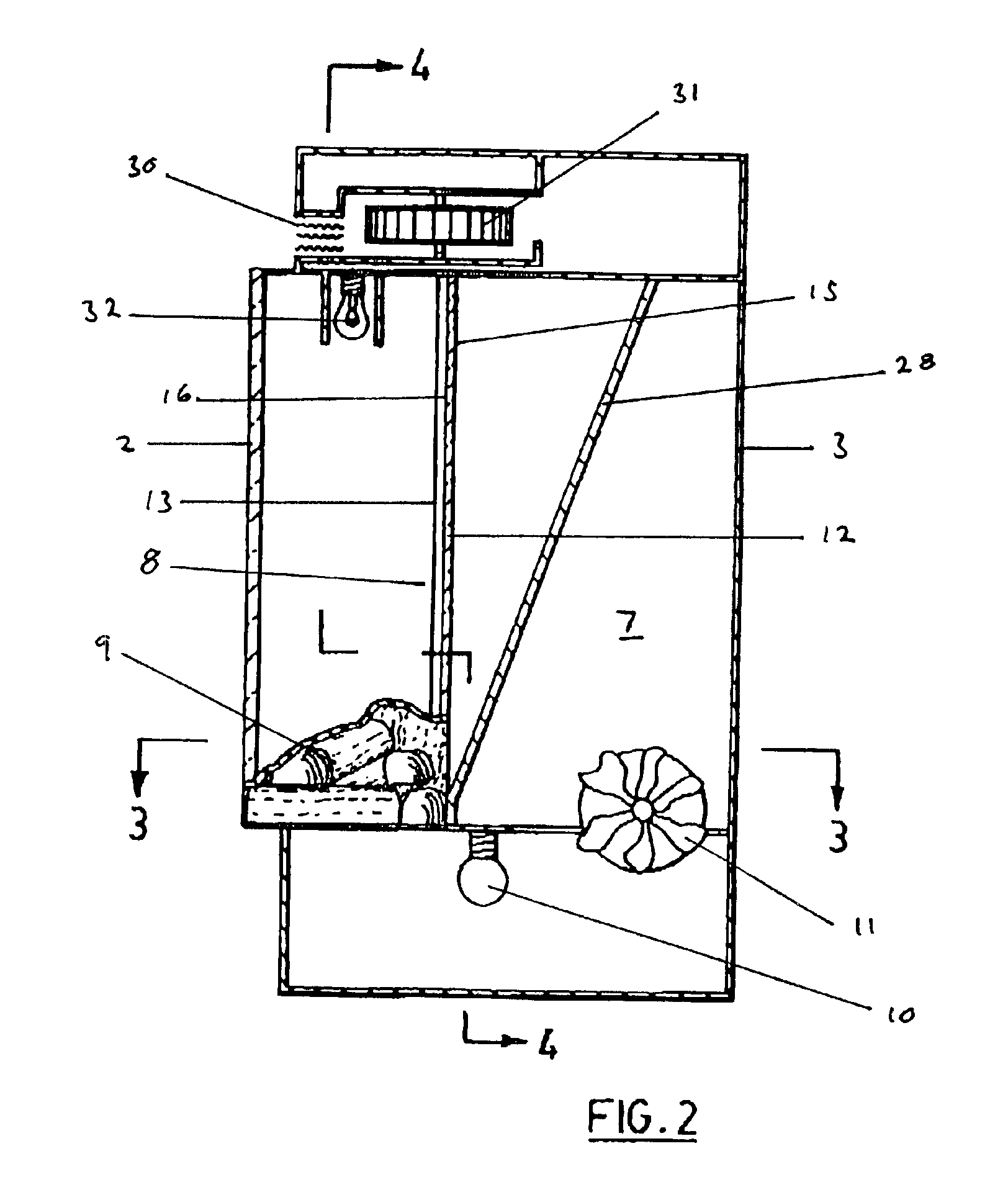

Flame simulating apparatus

A flame simulating apparatus to simulate flames emanating from a wood or fossil fuel burning fire. The flame simulating apparatus includes a light source, a light reflecting element, and a fire simulation screen. The light reflecting element produces a moving and generally random pattern of reflected light when light is cast upon it by the light source. The fire simulation screen has the image of a fire thereon and is positioned so that reflected light from the light reflecting element is cast upon its rear surface. The fire simulation screen includes at least one portion that is at least partially translucent such that light cast upon the partially translucent portion by the light reflecting element is diffused and at least partially passes through the translucent portion to present a moving flame image when viewed from a position in front of the fire simulation screen.

Owner:NAPOLEON SYST & DEV

Purification works for thermal power plant

InactiveUS7559977B2Reduce heat lossIncrease energy yieldUsing liquid separation agentCombustion enginesCombustion chamberExhaust fumes

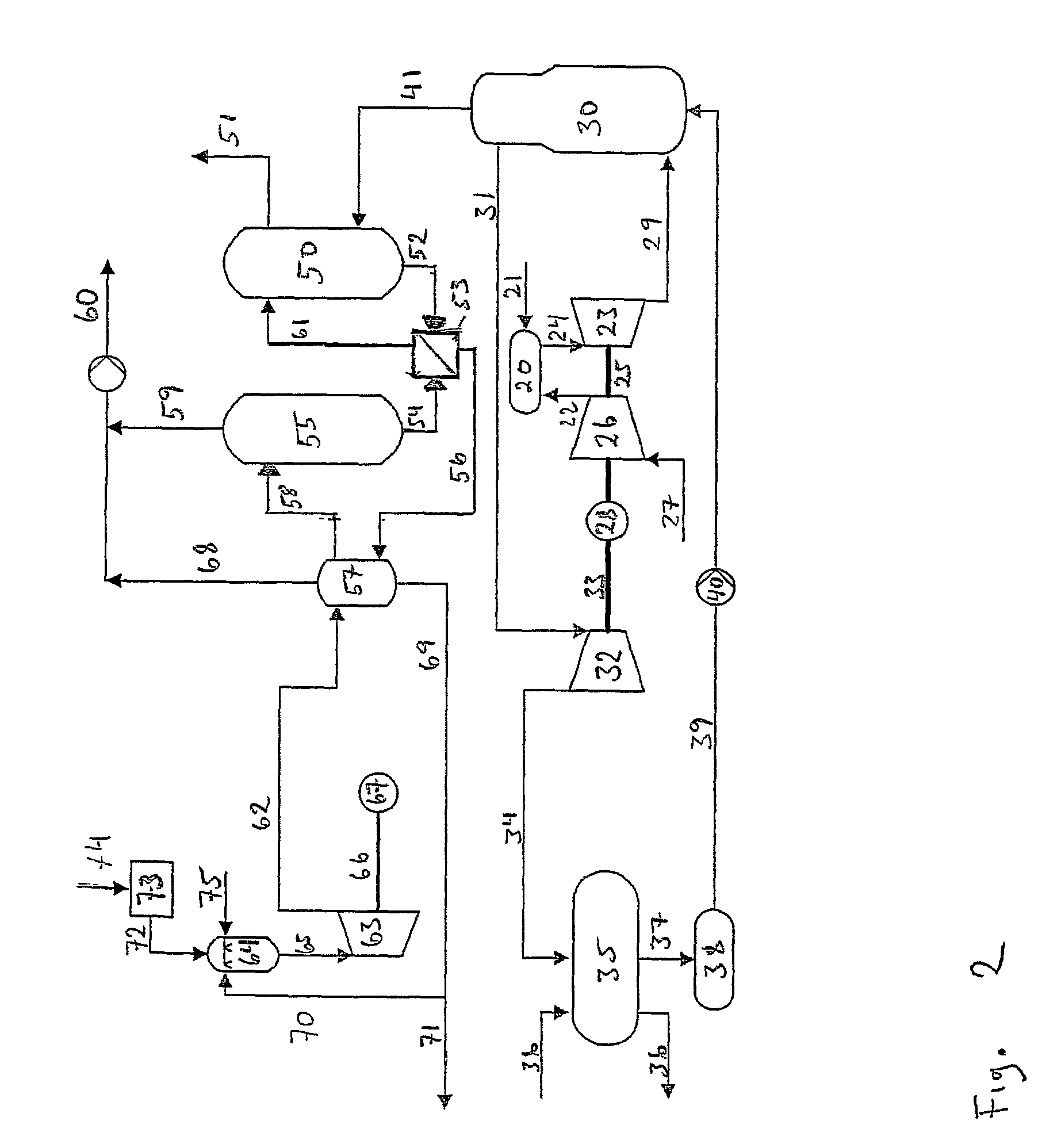

A method for separation of CO2 from the combustion gas from a thermal power plant fired with fossil fuel, wherein the combustion gas from the thermal power plant is used as cooled, compressed and reheated by combustion of natural gas in a combustion chamber to form an exhaust gas, where the exhaust gas is cooled an brought in contact with an absorbent absorbing CO2 from the exhaust gas to form a low CO2 stream and an absorbent with absorbed CO2, and where the low CO2 stream is heated by means of heat exchanges against the hot exhaust gas leaving the combustion chamber before it is expanded in turbines, is described. A plant for performing the method and a combined plant is also described.

Owner:CO2 CAPSOL

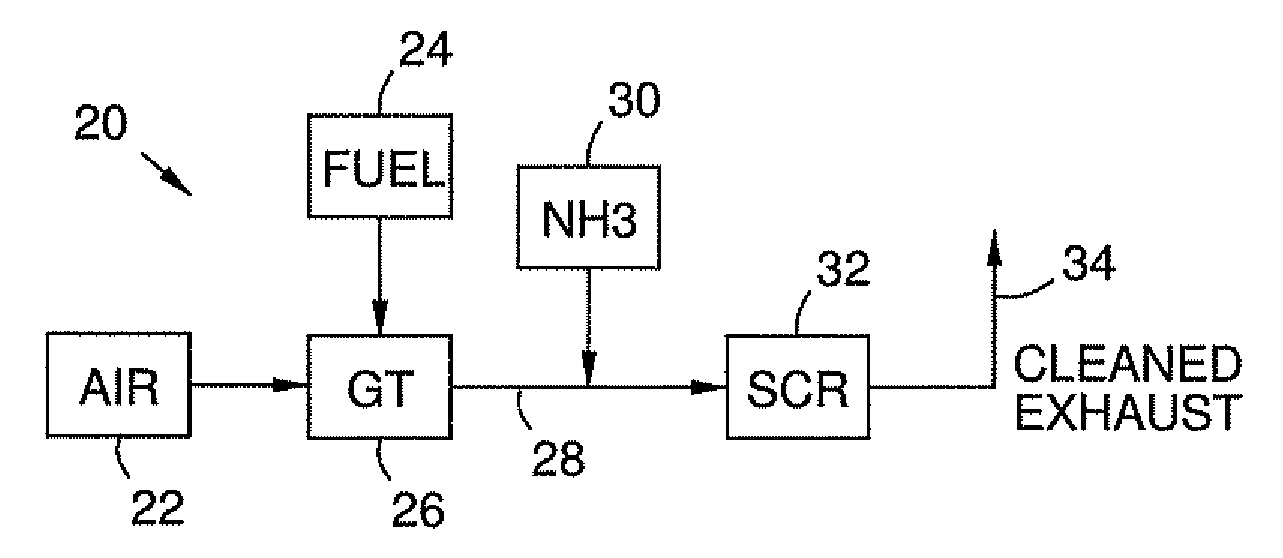

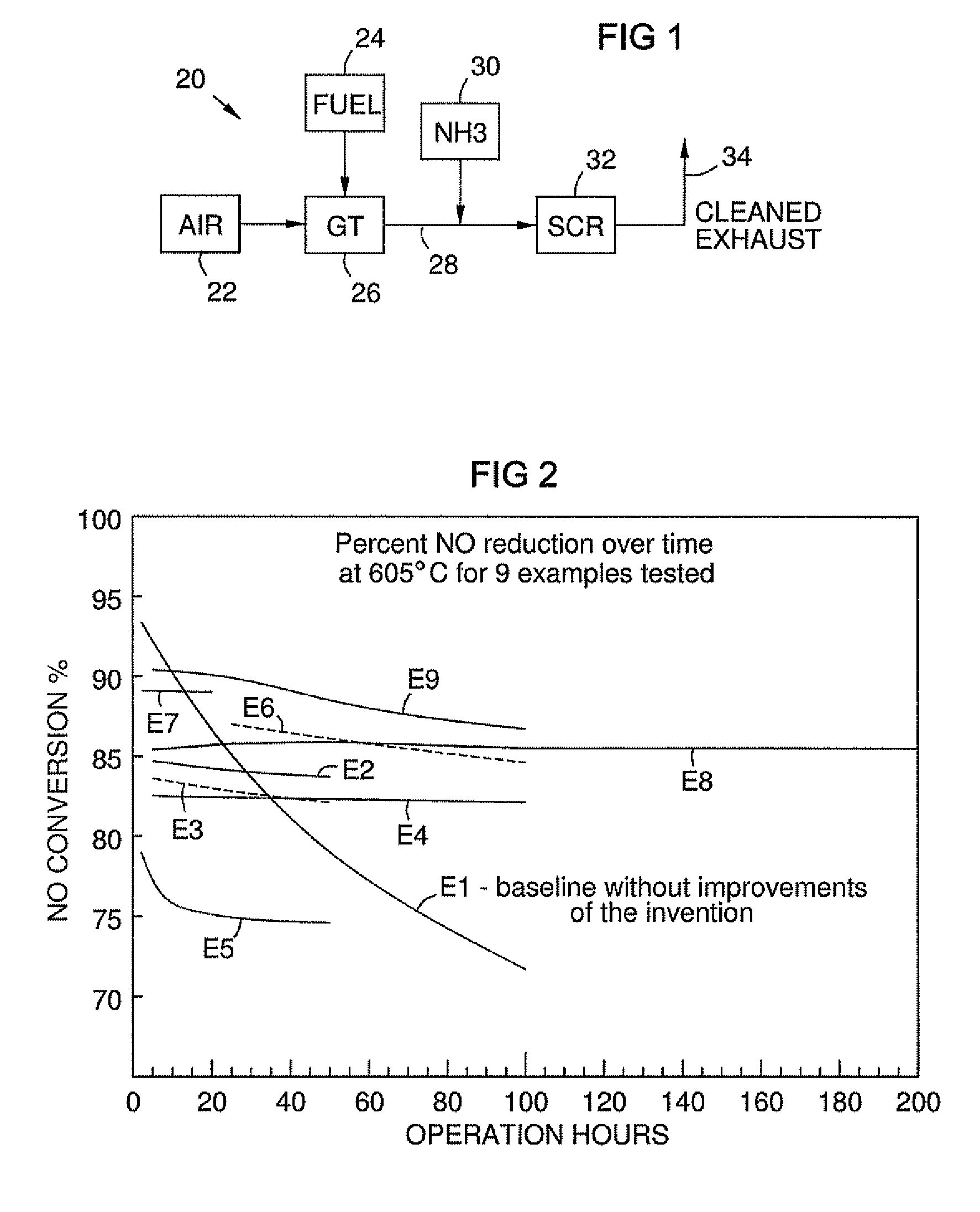

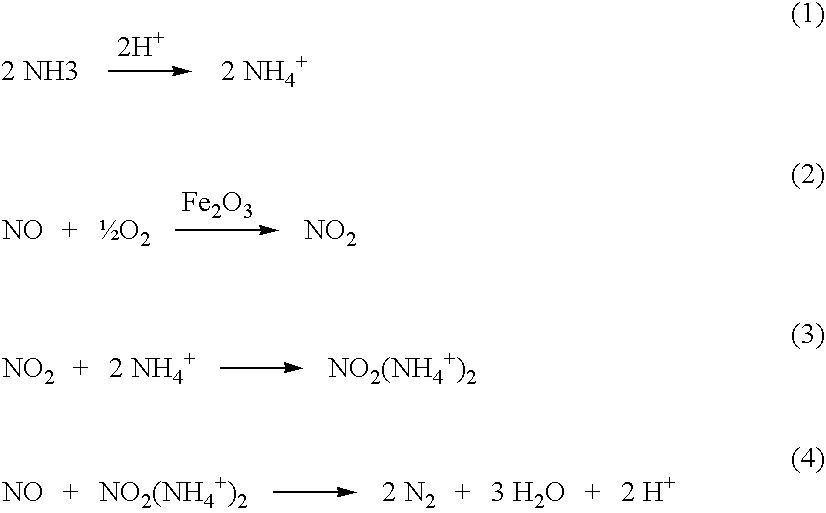

High temperature catalyst and process for selective catalytic reduction of NOx in exhaust gases of fossil fuel combustion

A process for producing a stable high-temperature catalyst for reduction of nitrogen oxides in combustion exhaust gases at operating temperatures from 300° C. to over 700° C. without the need for exhaust dilution. A zeolite material is steam-treated at a temperature and duration sufficient to partially de-aluminize the zeolite to approximately a steady state, but not sufficient to fully collapse its chemical structure. Iron is added to the zeolite material. The zeolite material is calcined at a temperature, humidity, and duration sufficient to stabilize the zeolite material. Examples and specifications for ranges, order, and durations of steaming, calcining, and other steps are provided.

Owner:SIEMENS ENERGY INC

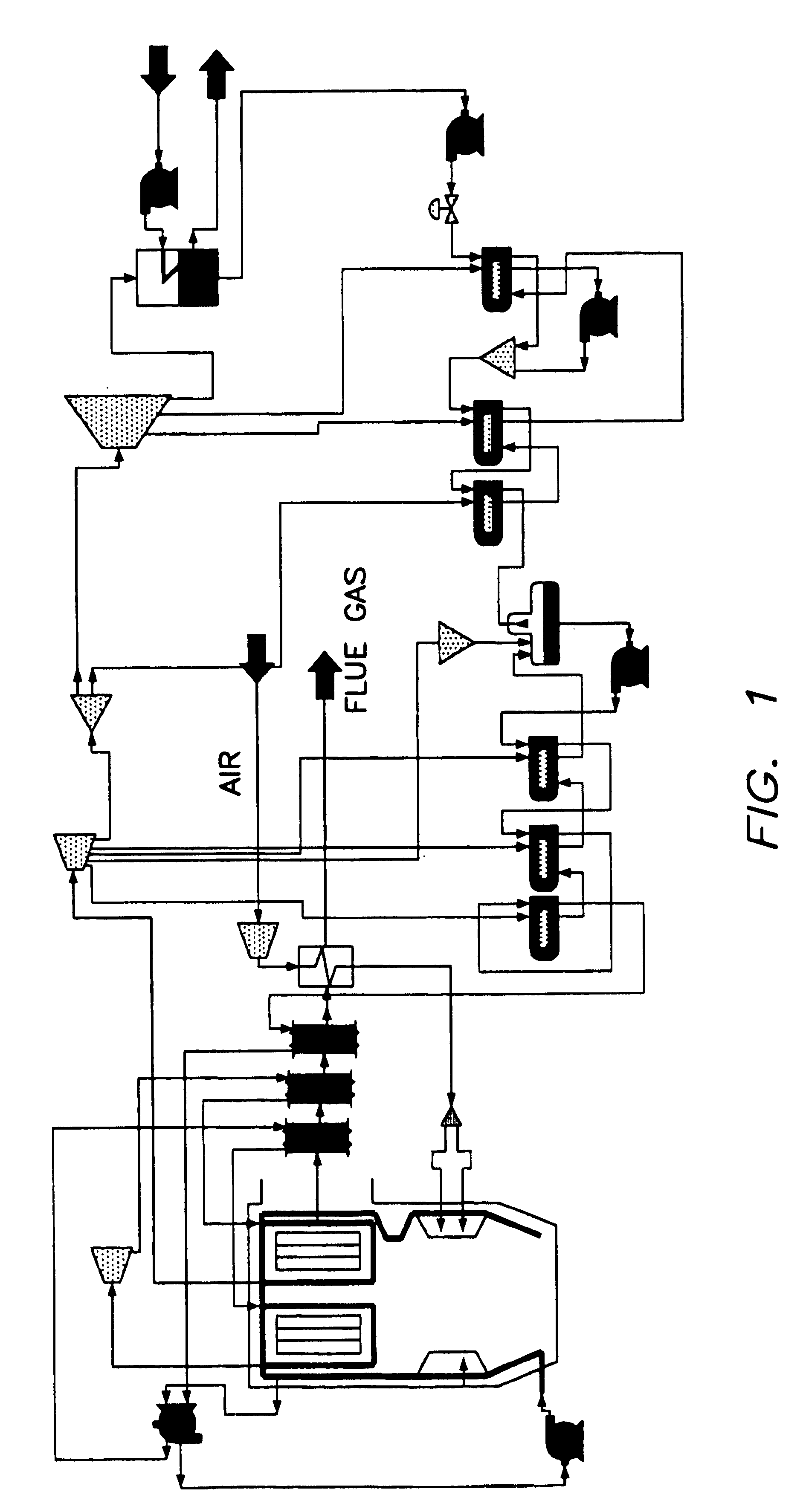

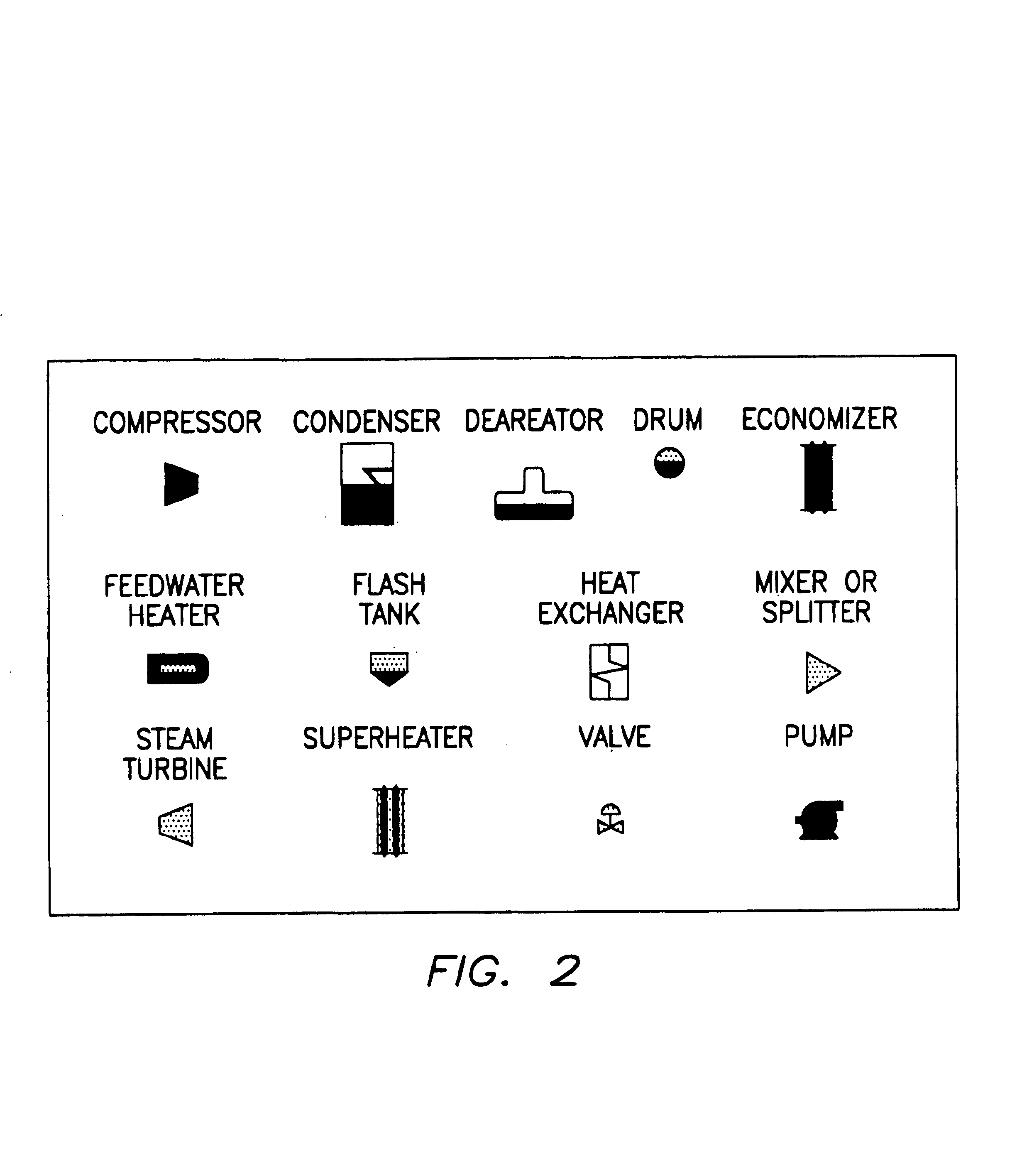

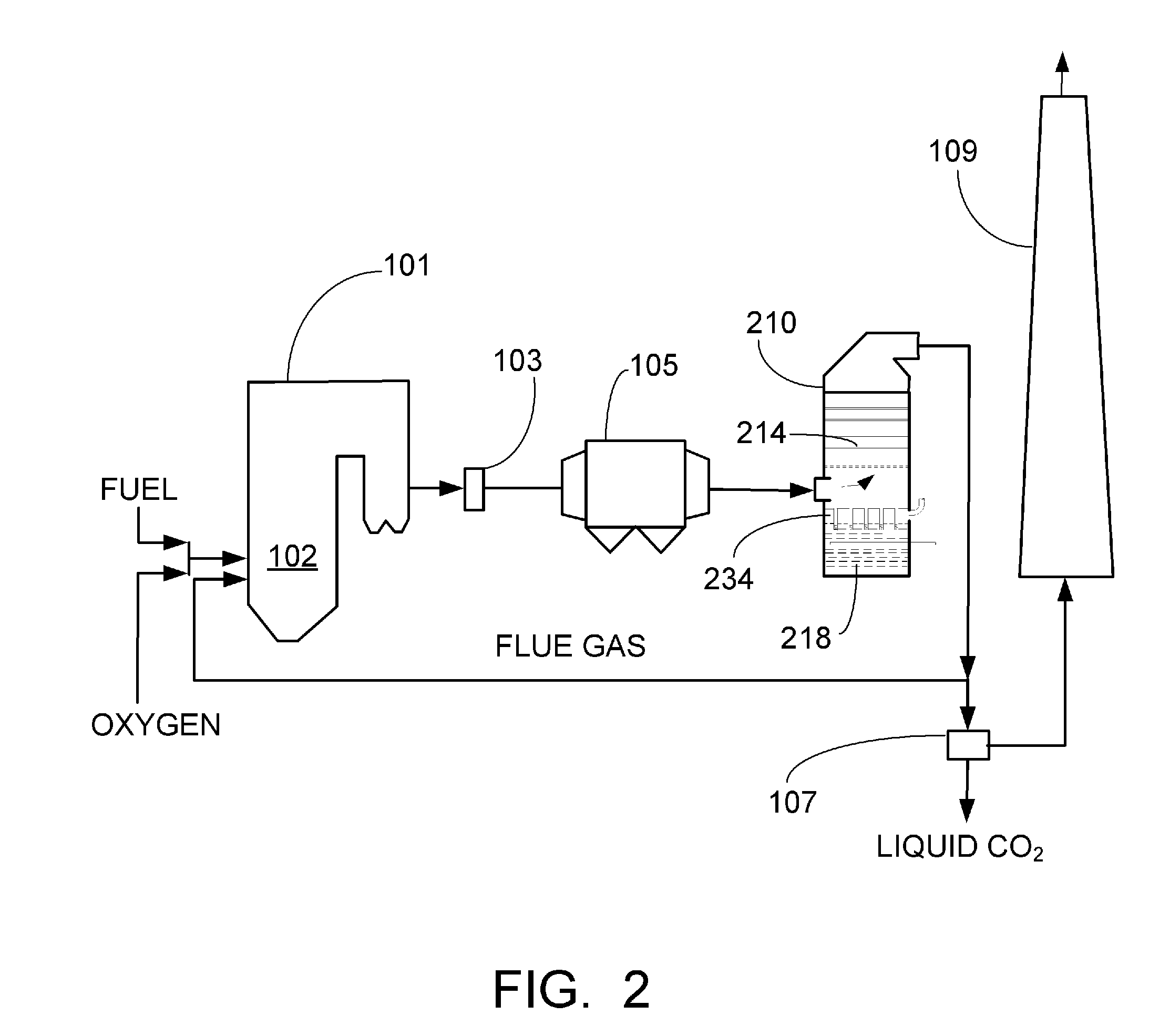

Integrated capture of fossil fuel gas pollutants including co2 with energy recovery

ActiveUS20080016868A1Increase costMaximum recoveryUsing liquid separation agentEmission preventionParticulatesEnergy recovery

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

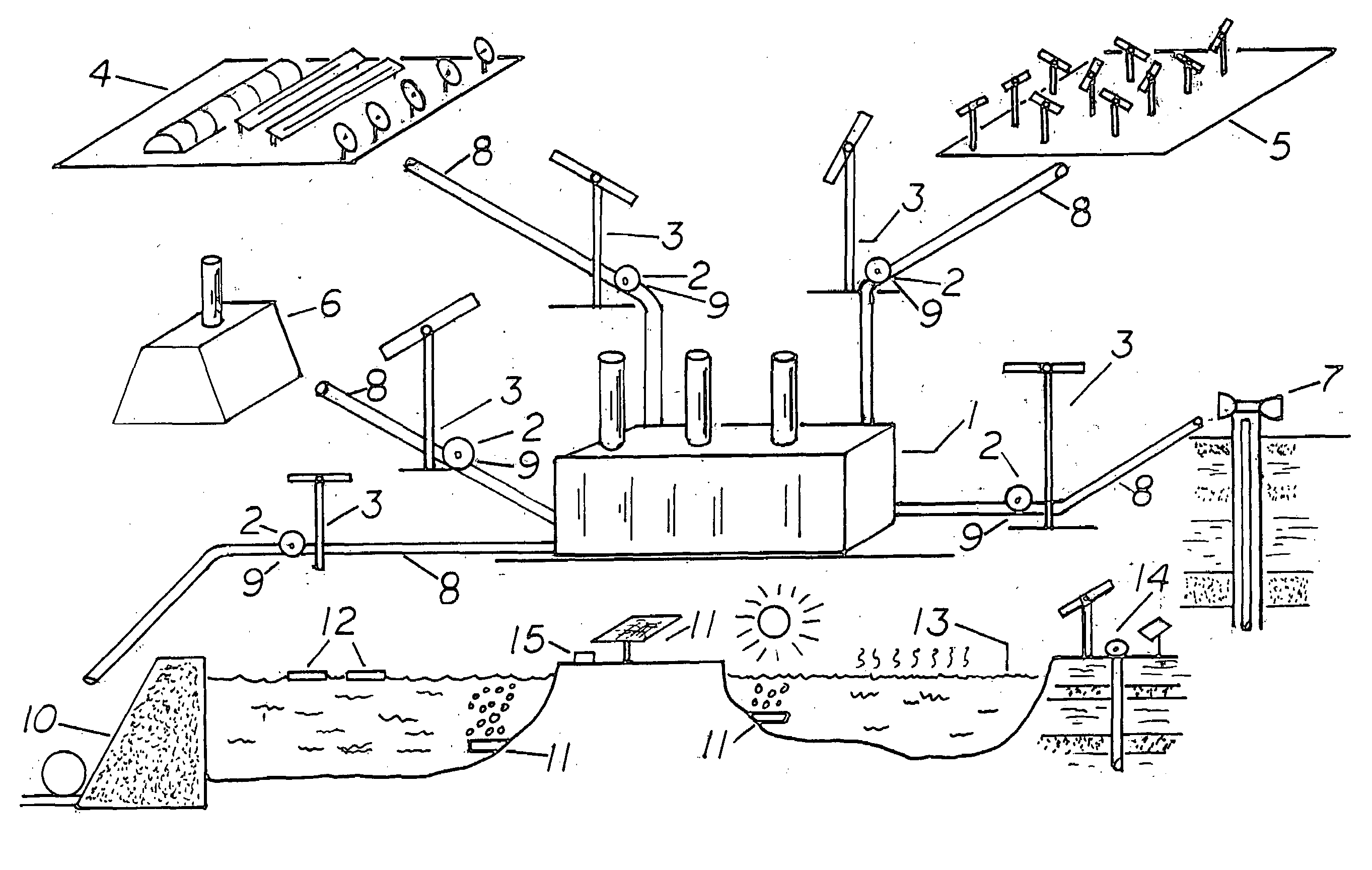

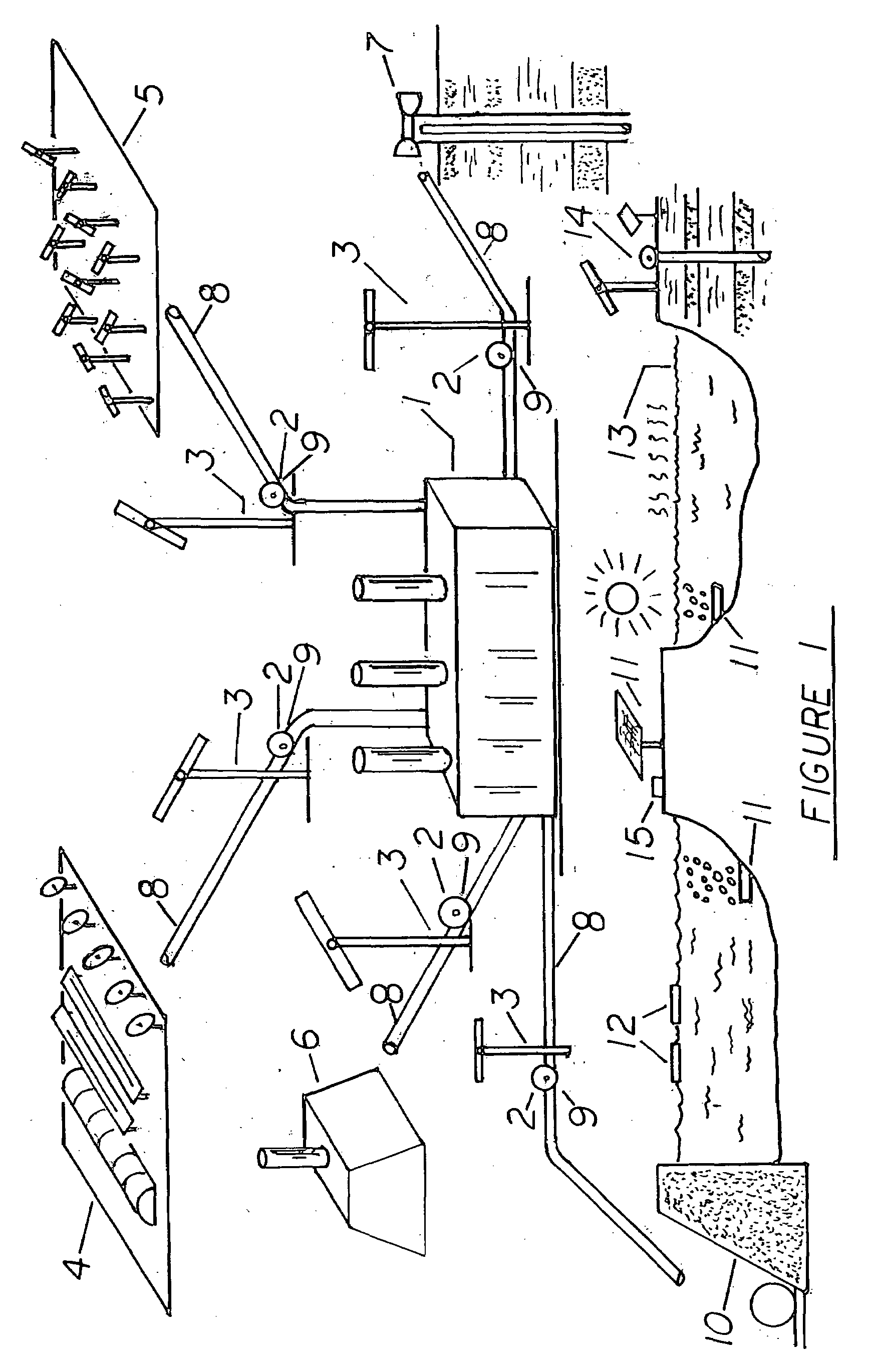

Use of renewable energy like solar, wind, geothermal, biomass, and hydropower for manufacturing combustion air for a fossil fuel burner and firebox

InactiveUS20080131830A1Reduce the amount requiredCarbon reductionSolar heating energyFuel heating with wind energyCombustion chamberEvaporation

Invented is a method of making combustion air for a fossil fuel burner, as a coal burning power plant, oil refinery or gas fired household appliance. Combustion air is made from solar, wind, biomass, hydropower or geothermal. A staged progression using lower cost greenhouses, or flatplates, or solarponds, feed warm air to higher cost concentrator solar collectors. Wind energy, biomass, geothermal energy heat and compress combustion air. Hydropower also heats and compresses combustion air. Solar evaporation from salt or impure water creates water or local rain for the hydropower system. Combustion air thus is made economically hot, compressed and high velocity, and placed into a heavily insulated pipes for long distance transmission to a distant power plant.

Owner:NIX MARTIN E

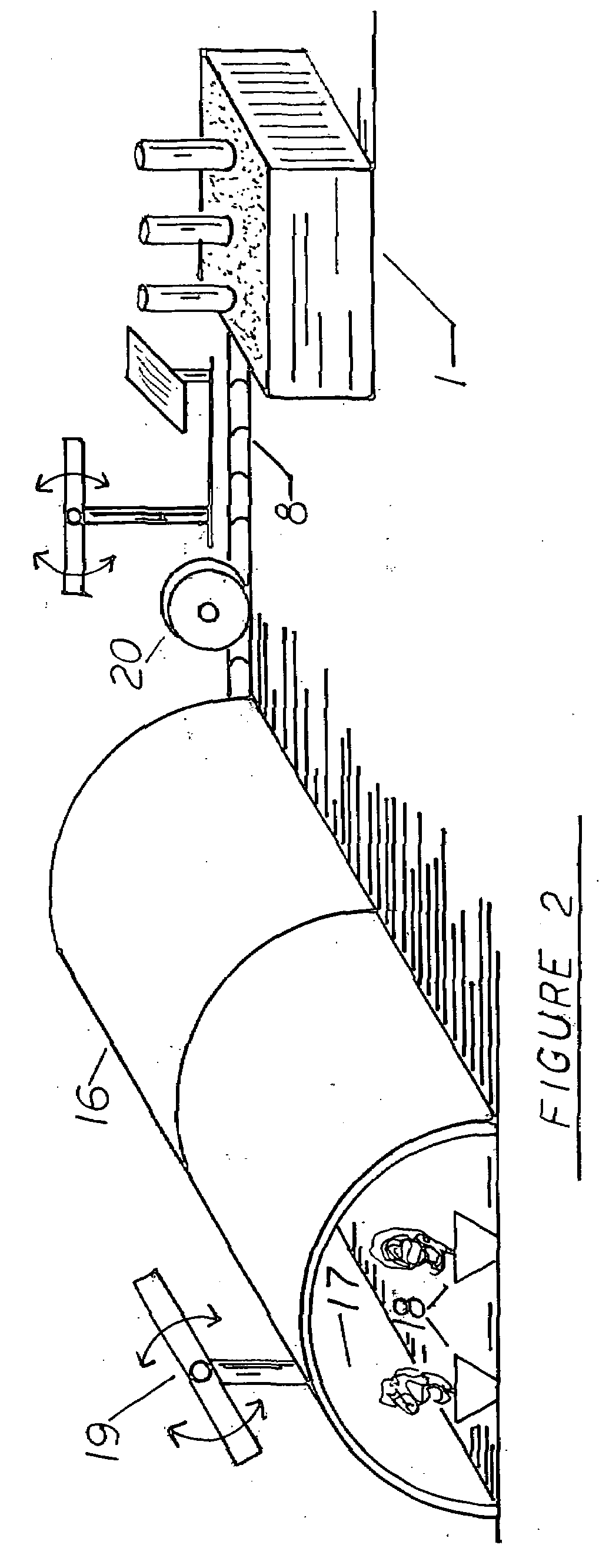

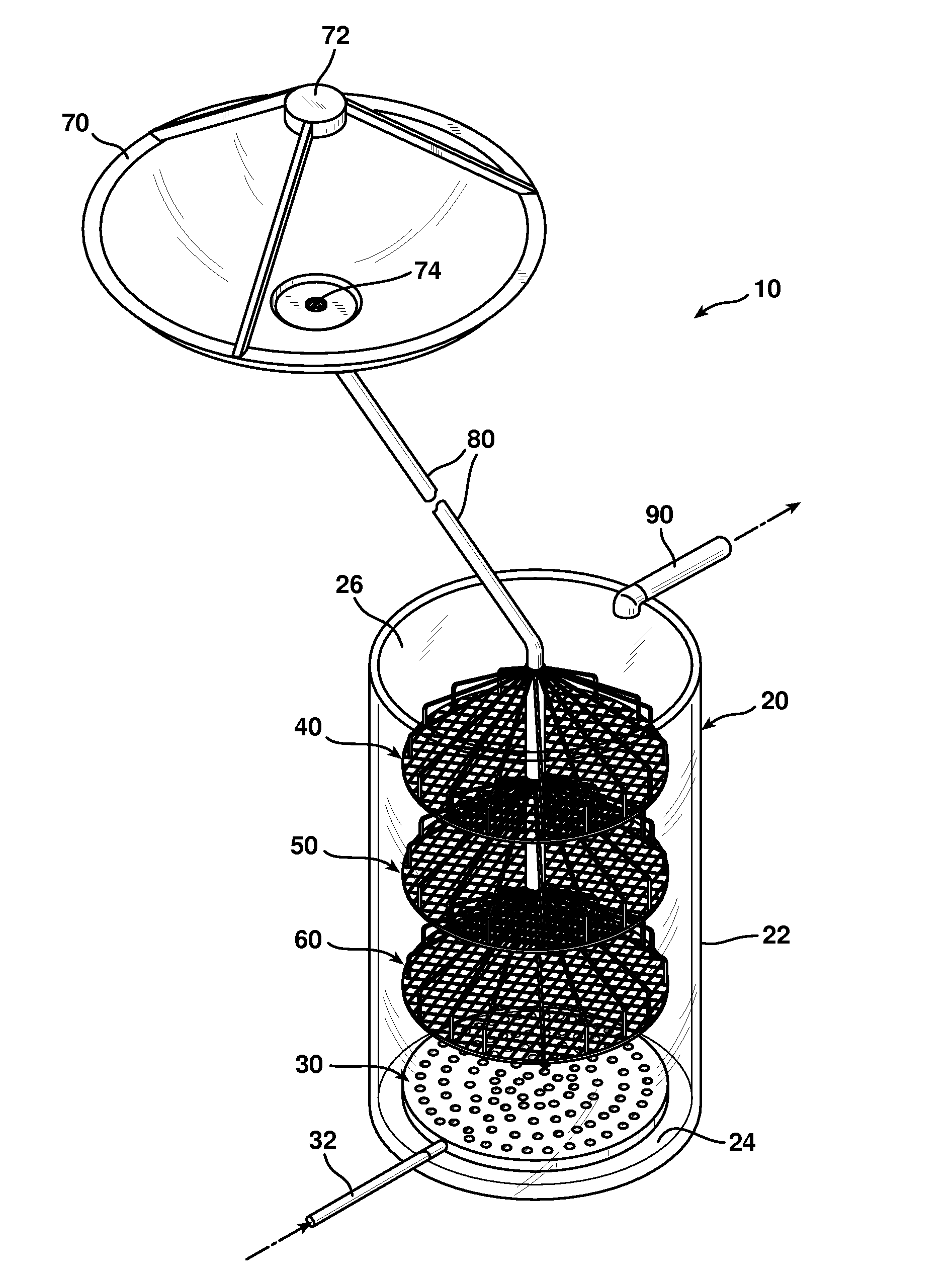

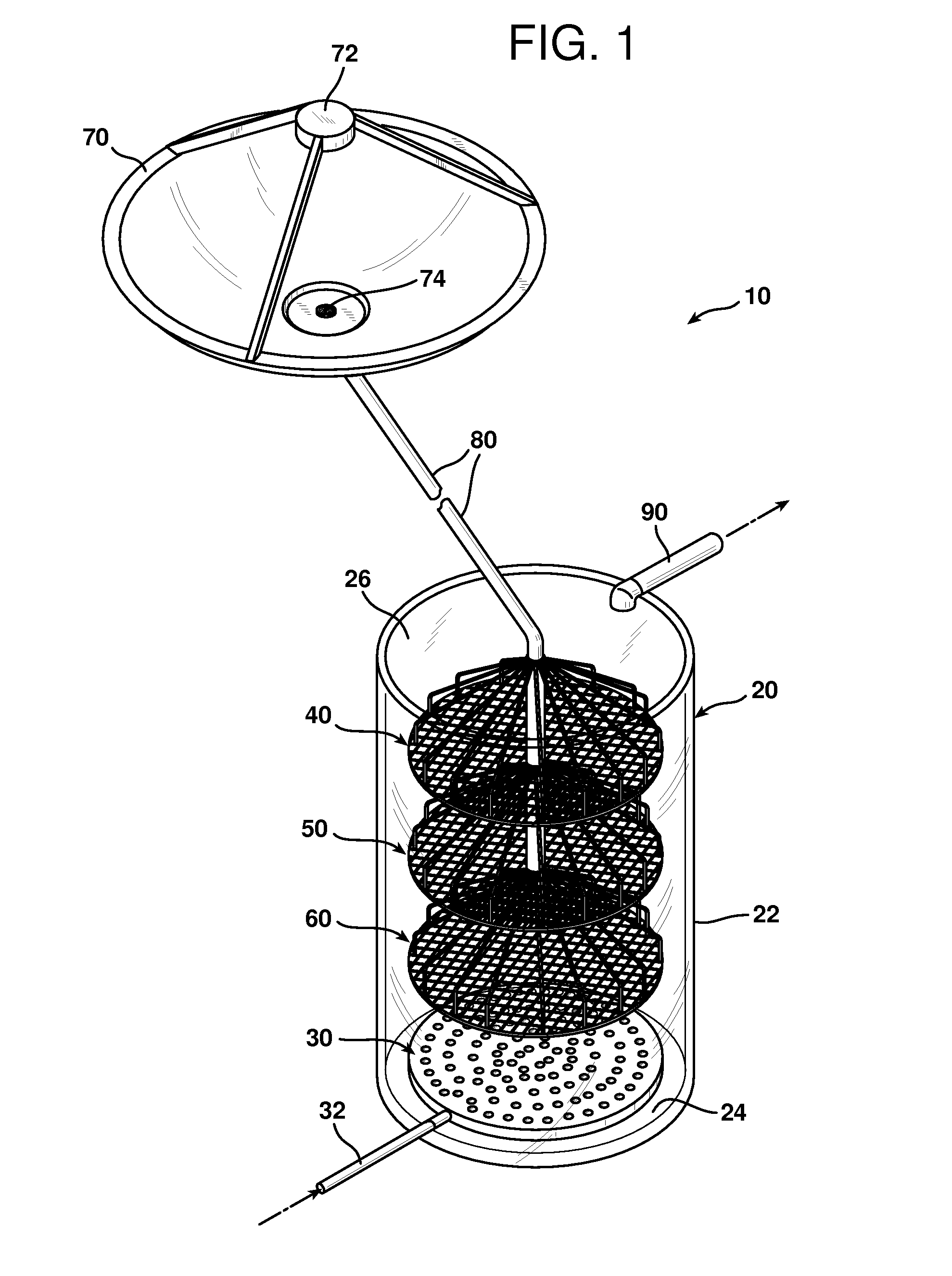

Apparatus and Method for Growing Biological Organisms for Fuel and Other Purposes

ActiveUS20070264708A1Reduce space consumptionImprove productivityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSlurry

A bioreactor apparatus in which a container has sidewalls, a floor and a ceiling defining a chamber that contains a slurry of water, nutrients and photosynthetic microorganisms. A plurality of optical fibers, each of which has a first end disposed outside the chamber and a second end in the mixture. A light collector spaced from the container has light incident on it and focuses the light onto the first ends of the plurality of optical fibers, thereby permitting the light to be conveyed into the mixture to promote photosynthesis. At least one nozzle is in fluid communication with a source of gas, such as exhaust gas from a fossil-fuel burning power plant containing carbon dioxide. The nozzle is disposed in the mixture beneath the second ends of the optical fibers for injecting the gas into the mixture.

Owner:OHIO UNIV

Flame simulating apparatus

A flame simulating apparatus to simulate flames emanating from a wood or fossil fuel burning fire. The flame simulating apparatus includes a light source, a light reflecting element, and a fire simulation screen. The light reflecting element produces a moving and generally random pattern of reflected light when light is cast upon it by the light source. The fire simulation screen has the image of a fire thereon and is positioned so that reflected light from the light reflecting element is cast upon its rear surface. The fire simulation screen includes at least one portion that is at least partially translucent such that light cast upon the partially translucent portion by the light reflecting element is diffused and at least partially passes through the translucent portion to present a moving flame image when viewed from a position in front of the fire simulation screen.

Owner:NAPOLEON SYST & DEV

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:SOLAR REACTOR TECH

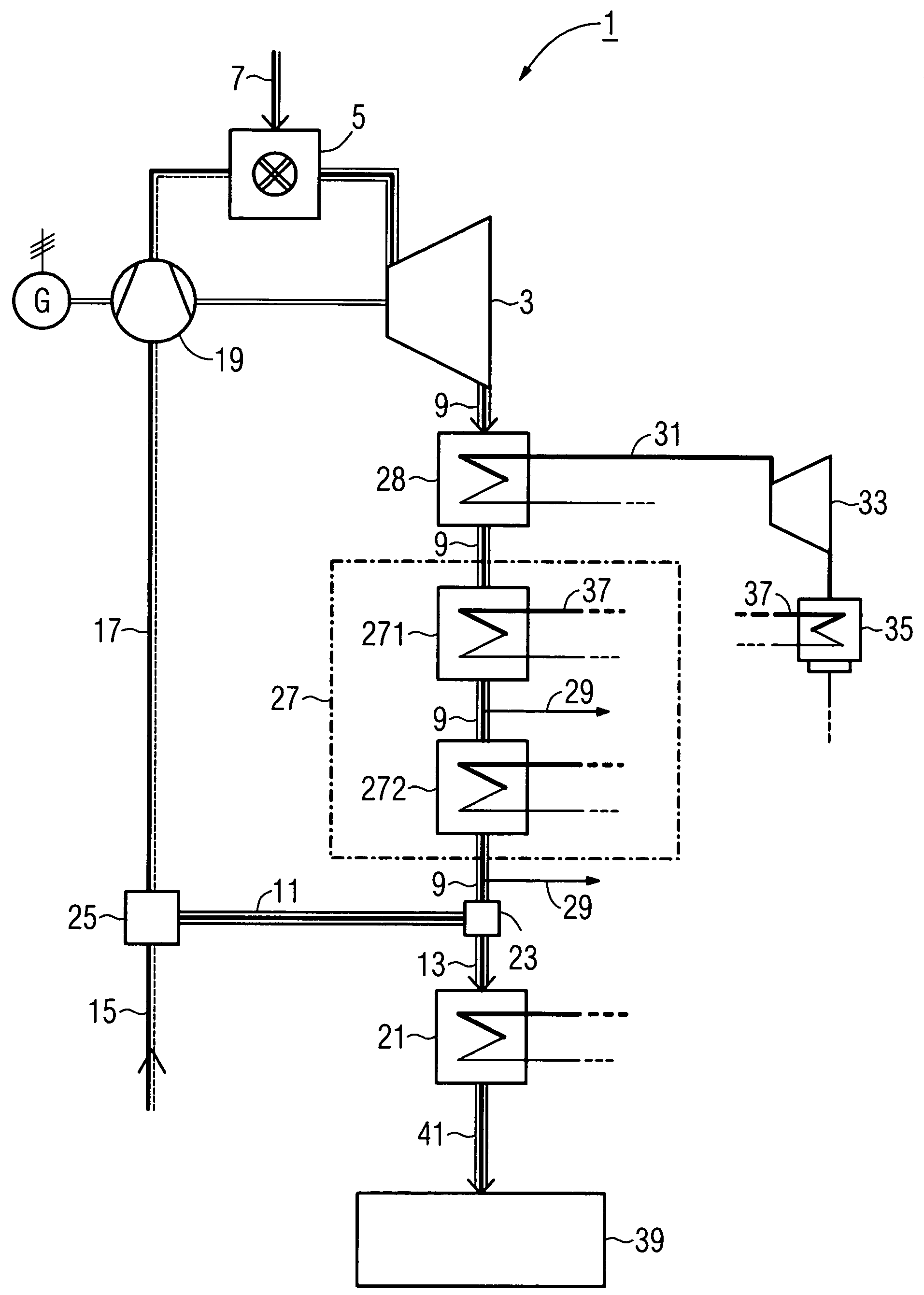

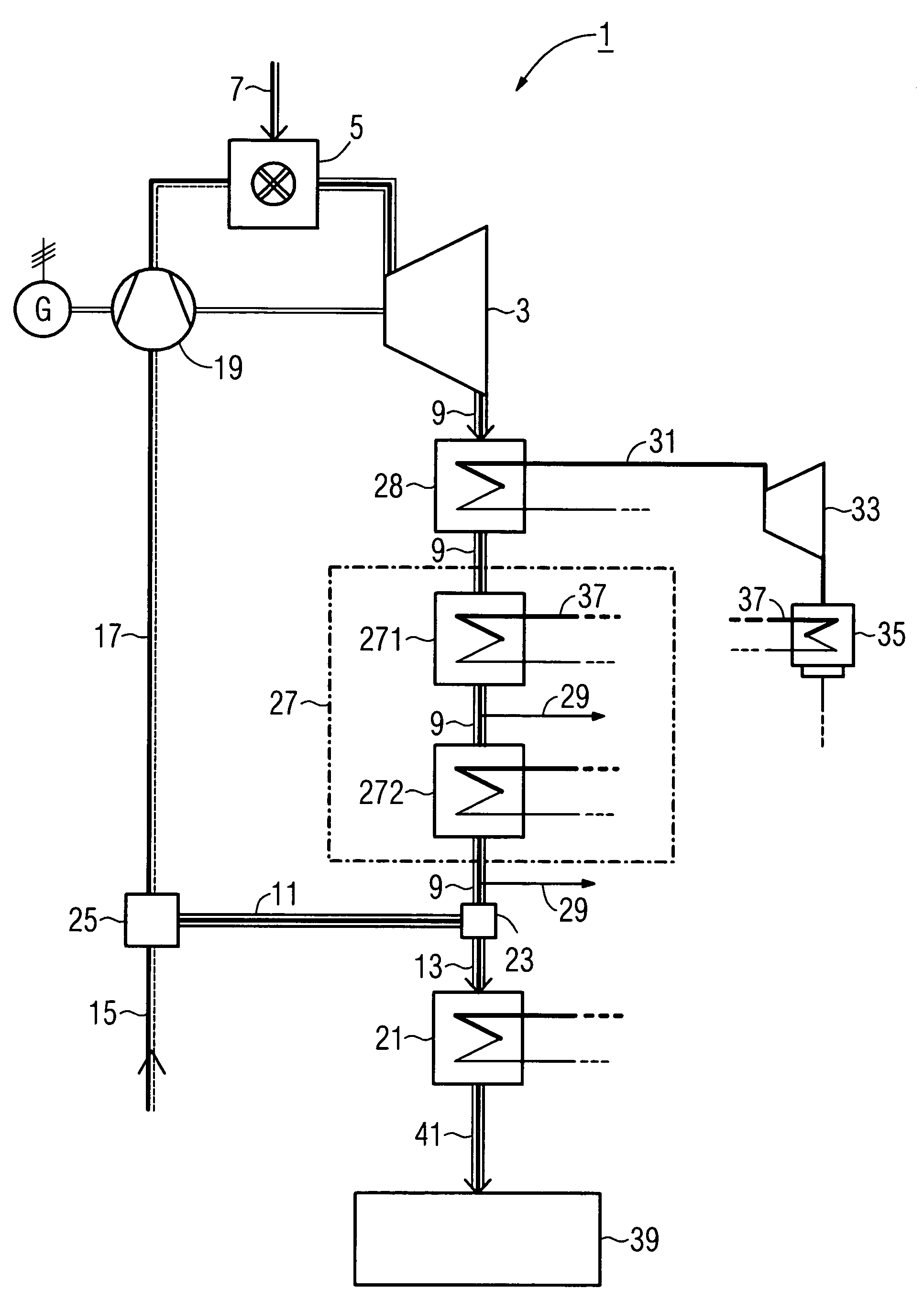

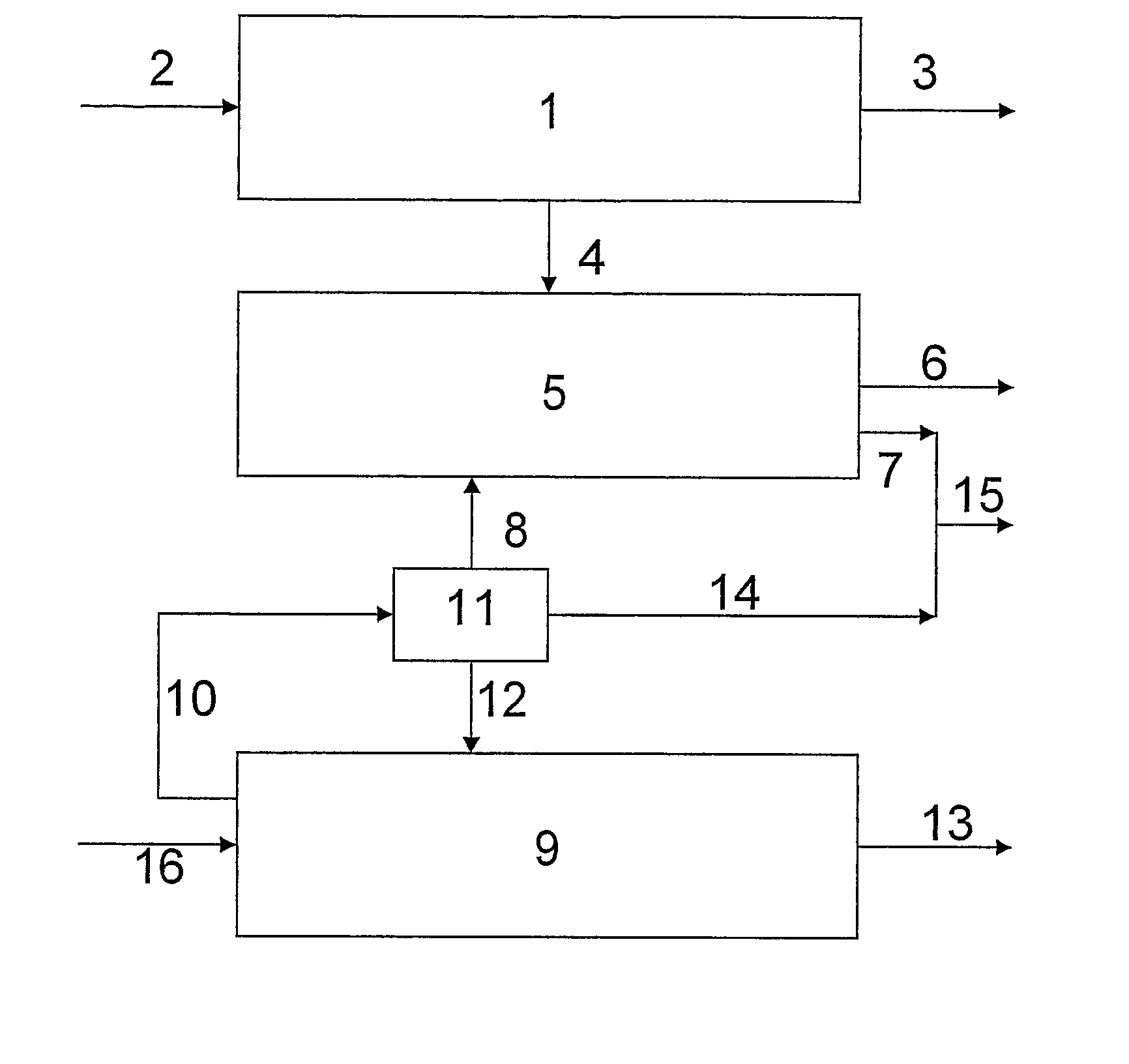

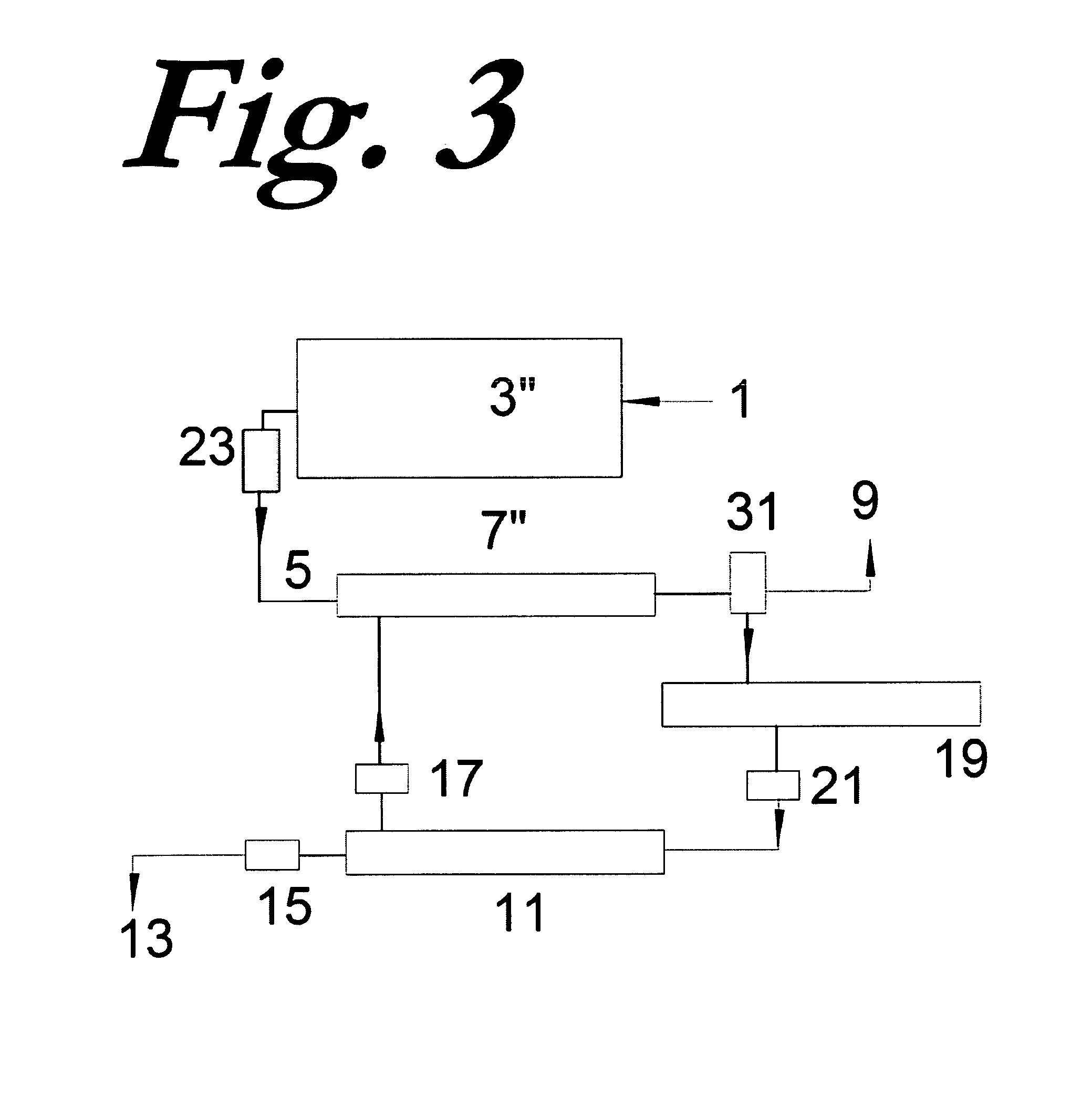

Method and device for operating a gas turbine with a fossil-fuel fired combustion chamber

InactiveUS7299637B2Reduce nitrogen oxide contentRisk minimizationGas turbine plantsDirect carbon-dioxide mitigationSteam-electric power stationCombustion chamber

A method according to the invention or a corresponding device (1) provides for dividing exhaust gas (9) exiting the gas turbine into a first (11) and a second partial stream (13), for mixing the first partial stream (11) with combustion air (15), and for channeling the resulting mixture (17) to the combustion chamber (5) and the second partial stream (13) to a carbon dioxide precipitation plant (21).In an advantageous embodiment the exhaust gas (9) exiting the gas turbine (3) is previously used to generate process steam (31) for a steam turbine (33) (gas and steam power station) then cooled before the exhaust gas (9) is divided into said partial streams (11,13). Water (29) precipitating during cooling is removed.

Owner:SIEMENS AG

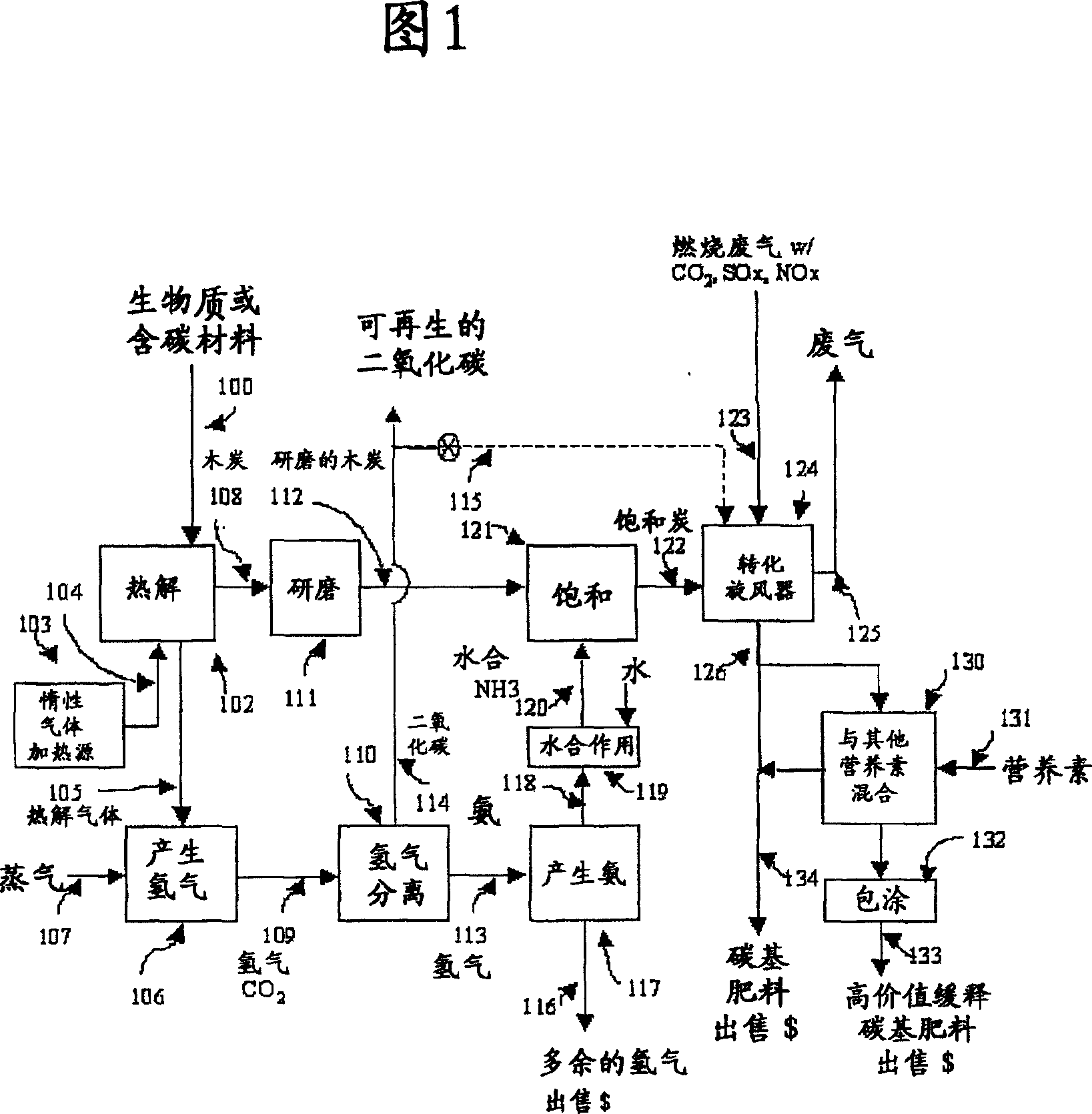

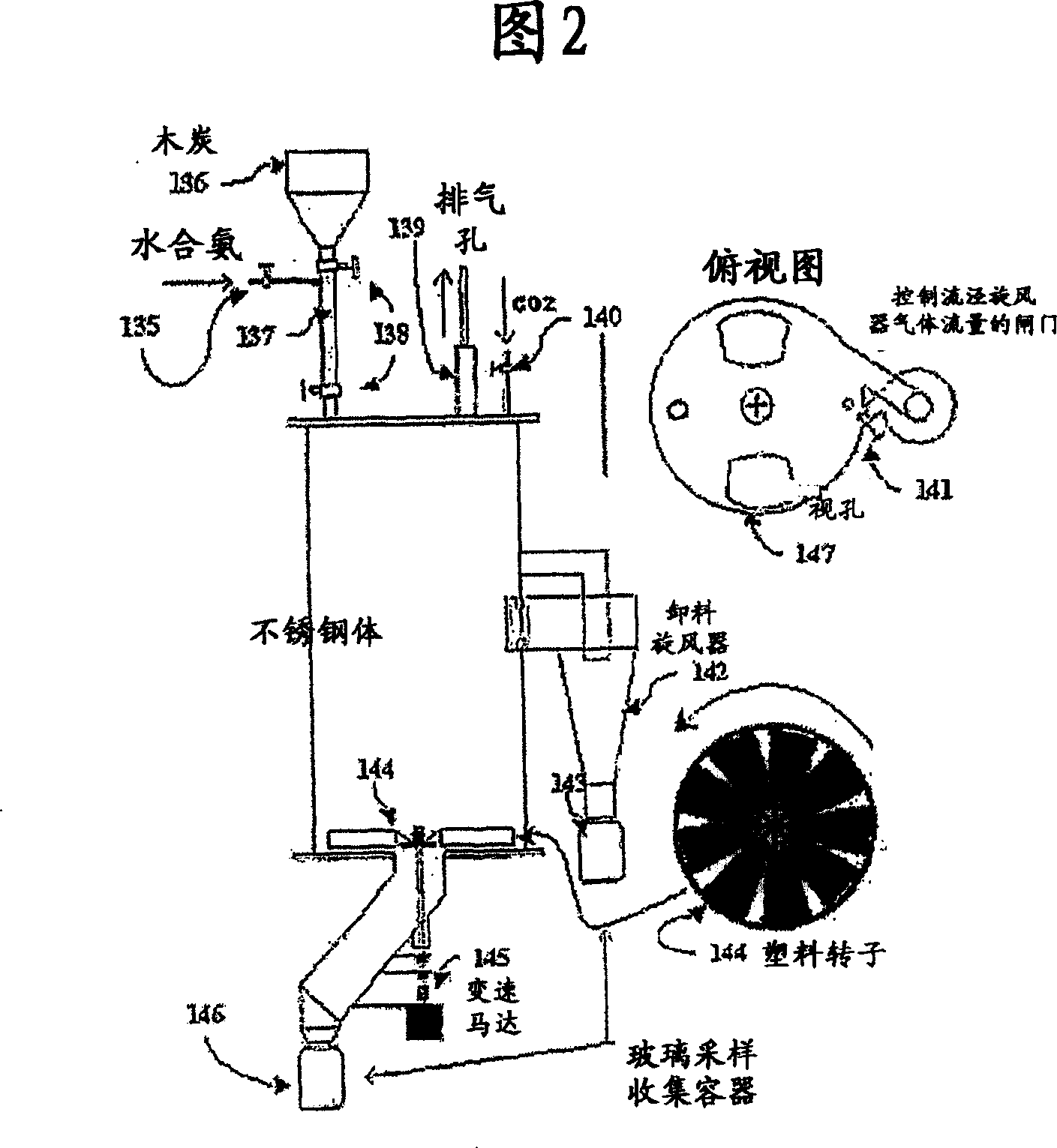

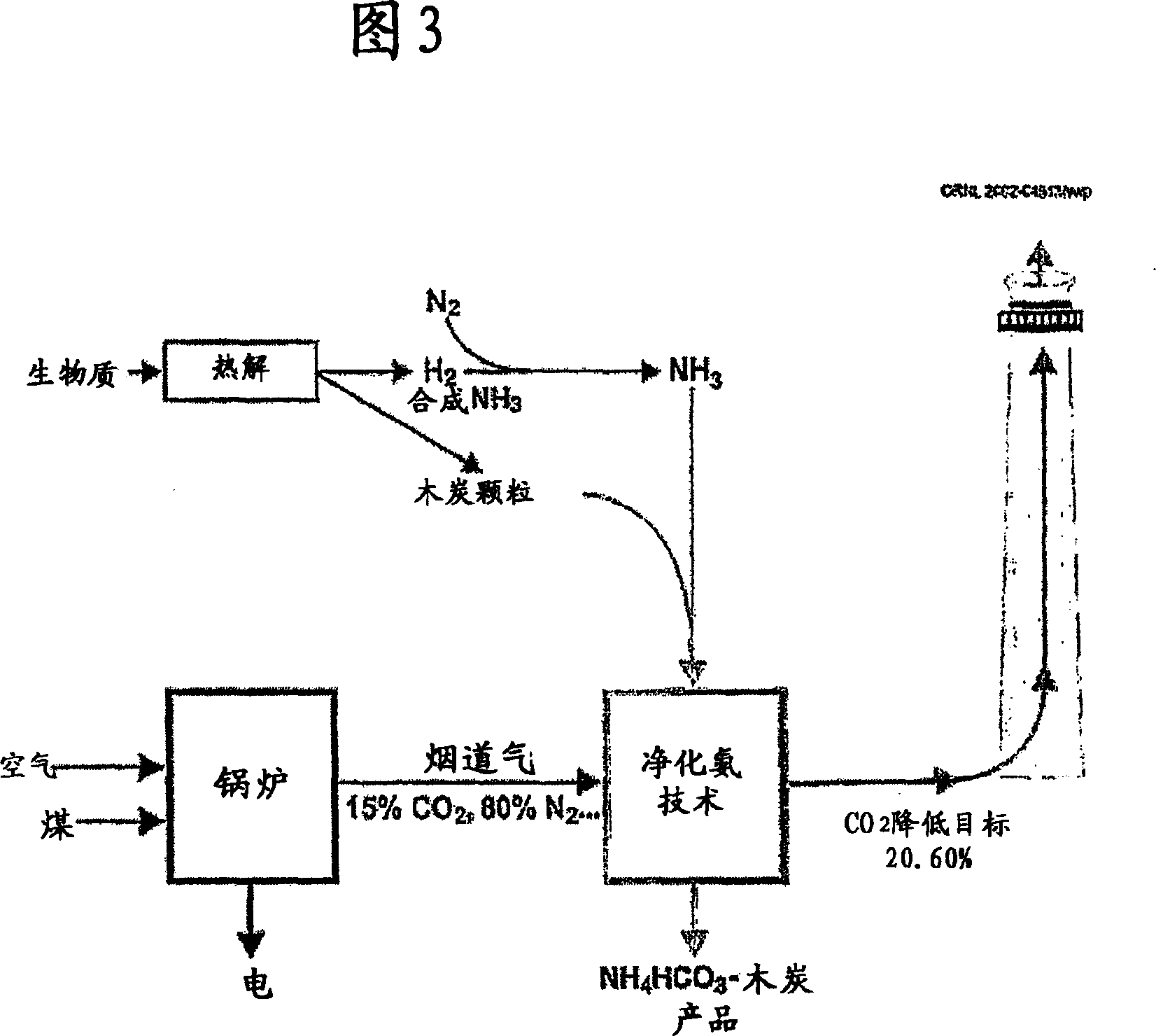

Production and use of a soil amendment made by the combined production of hydrogen, sequestered carbon and utilizing off gases containing carbon dioxide

InactiveCN1997590AHigh carbon contentReduce churn rateNitrous oxide captureMethane captureBiofuelCo product

This invention relates a series of steps to provide an economical production of a carbon based fertilizer and soil amendment made during the capture of greenhouse gases from the combustion of fossil and non fossil fuels. The invention uses biomass and other carbonaceous sources through pyrolytic conversion to gases and charcoal, to allow for the further production of co-products, such as hydrogen and ammonia. The invention also relates to the combination of hydrated ammonia, combustion flue gas exhaust, and charcoal, provide for the conversion of the charcoal into a valued added soil amendment to return essential trace minerals and plant nutrients to the soil. The ability to produce a large volume carbon co-product while removing mandated emissions and producing renewable based hydrogen provides an economic gain to a large number small and large businesses and increase the chance of achieving significant reductions in greenhouse gas emissions.

Owner:丹尼·马歇尔·戴 +1

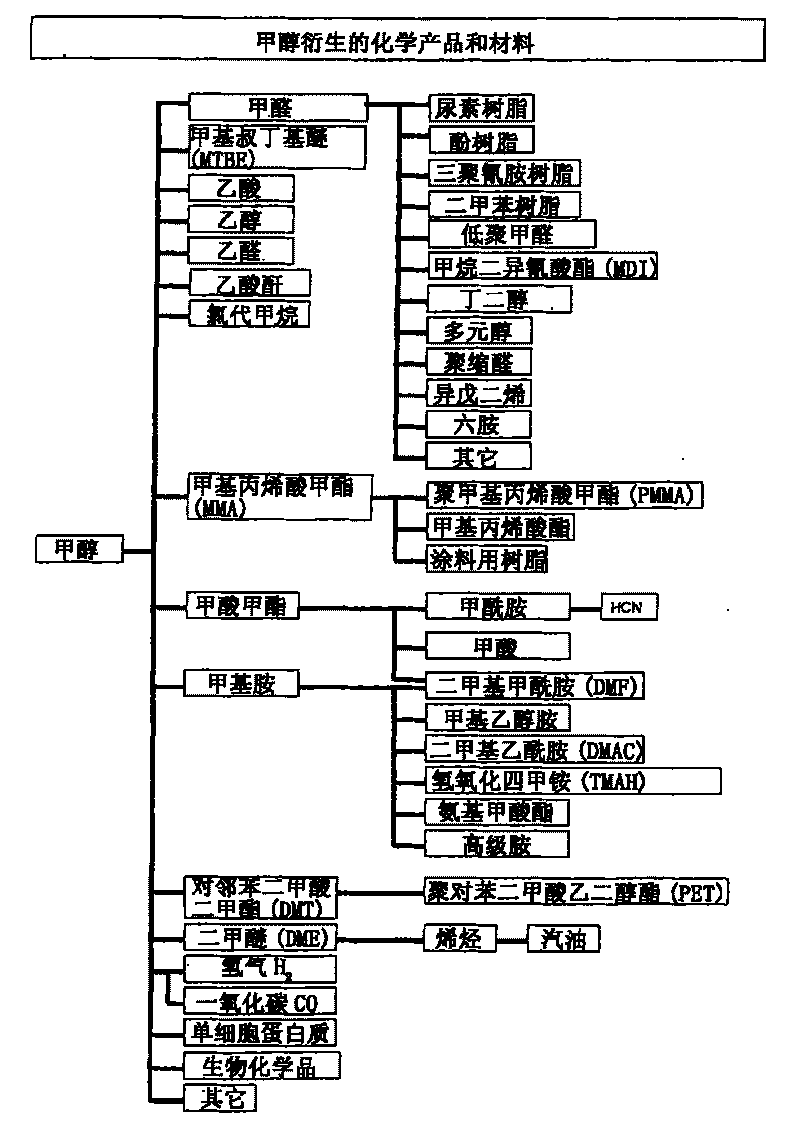

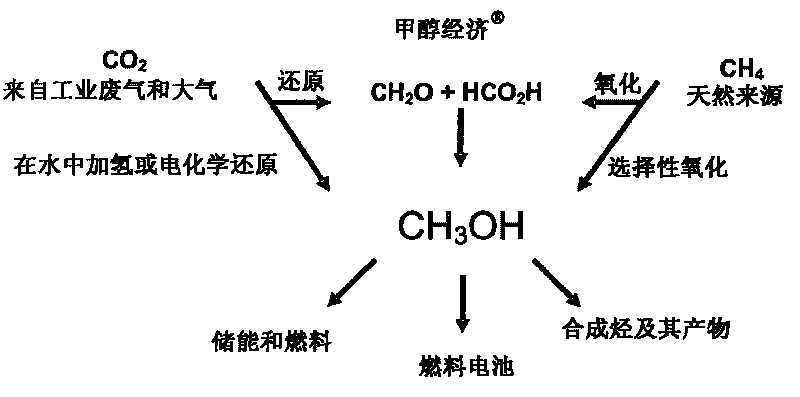

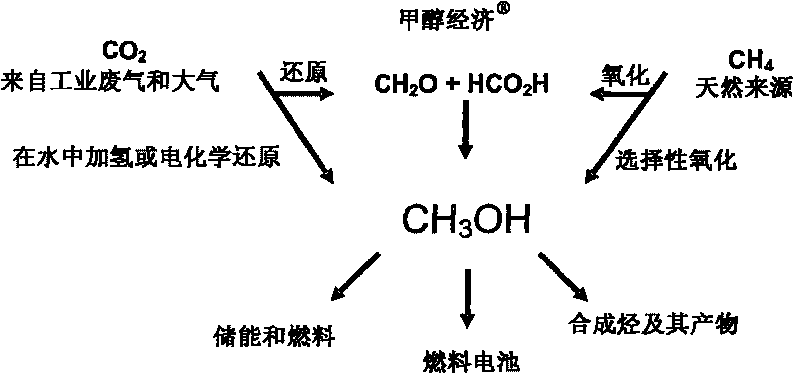

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

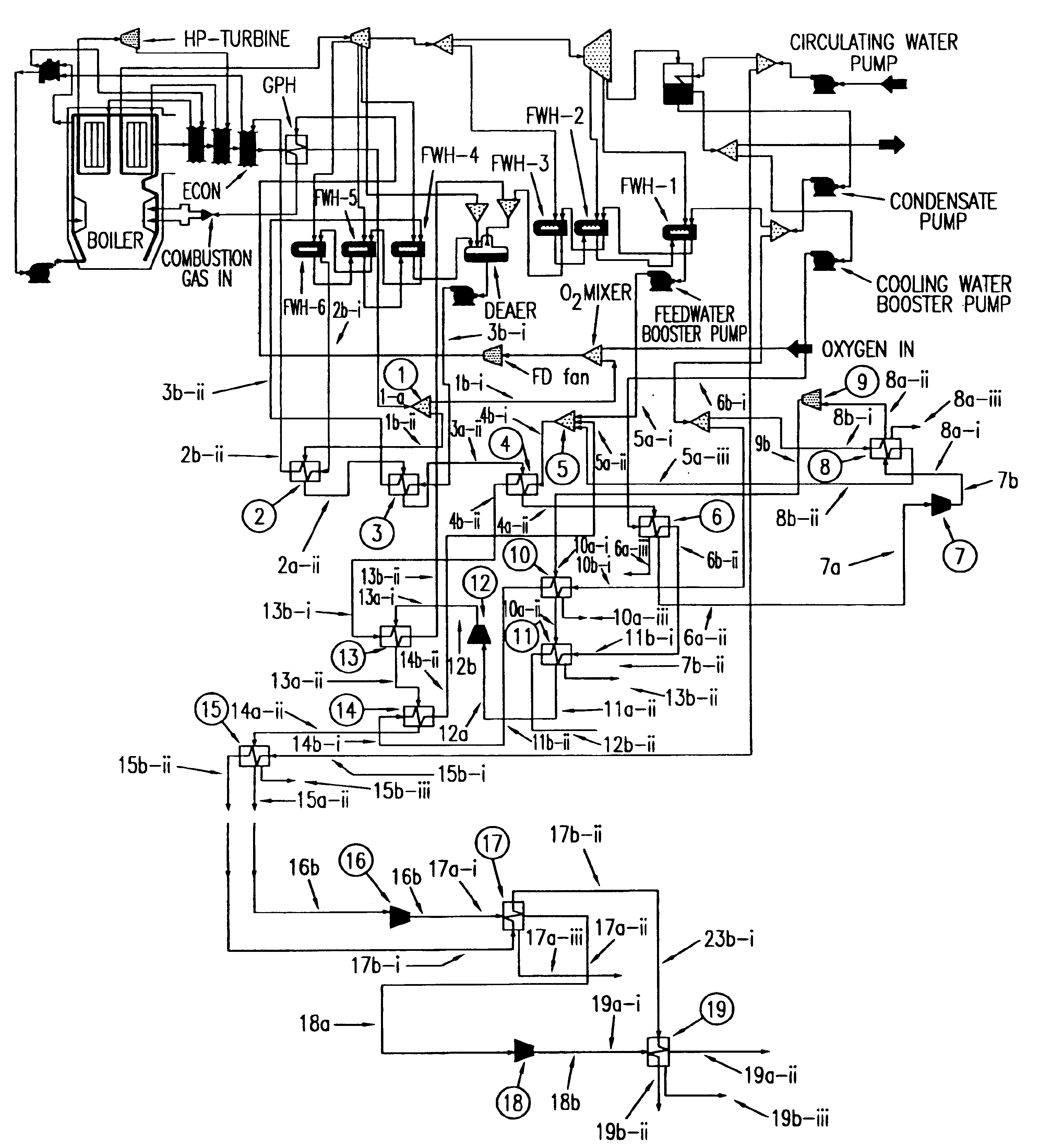

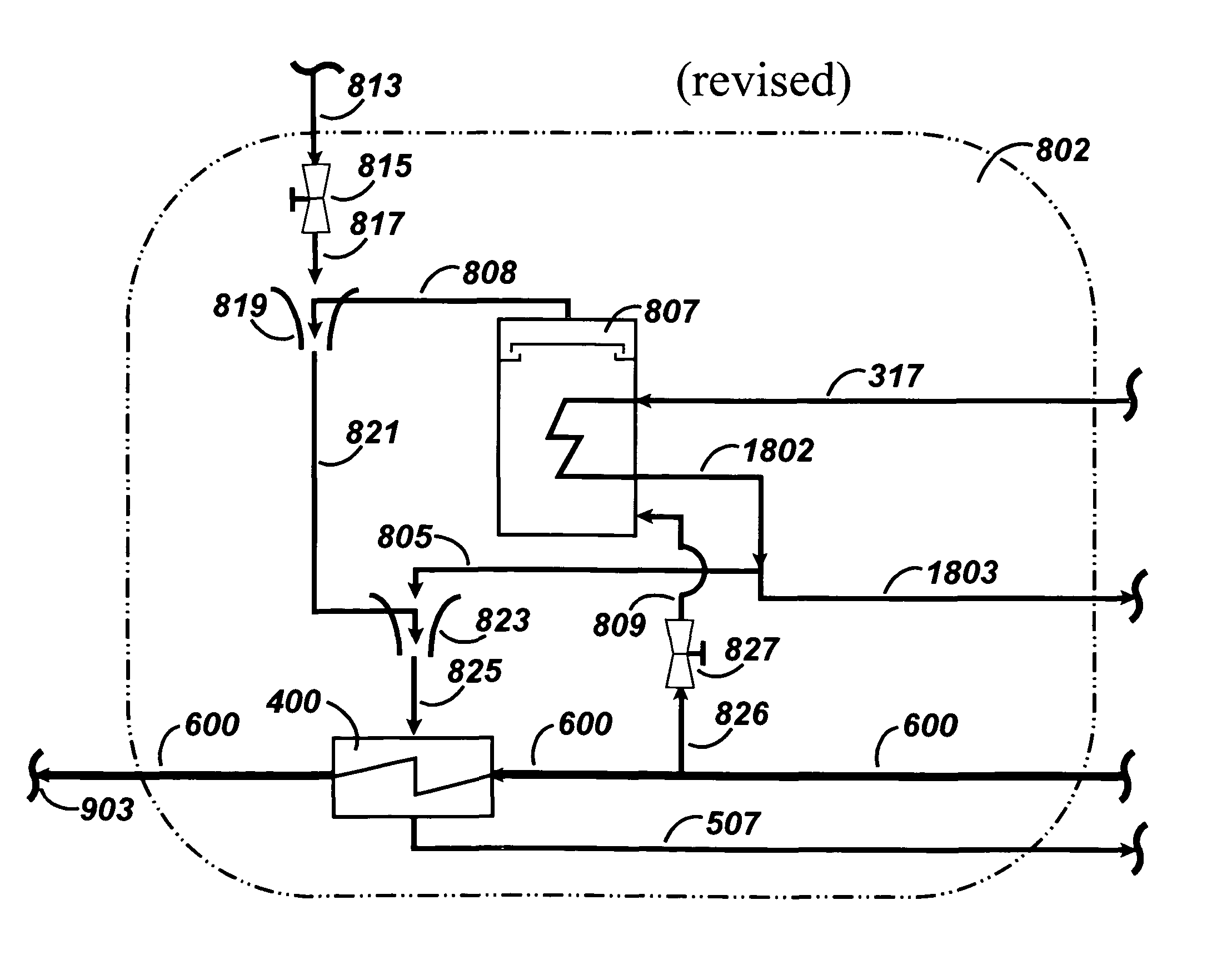

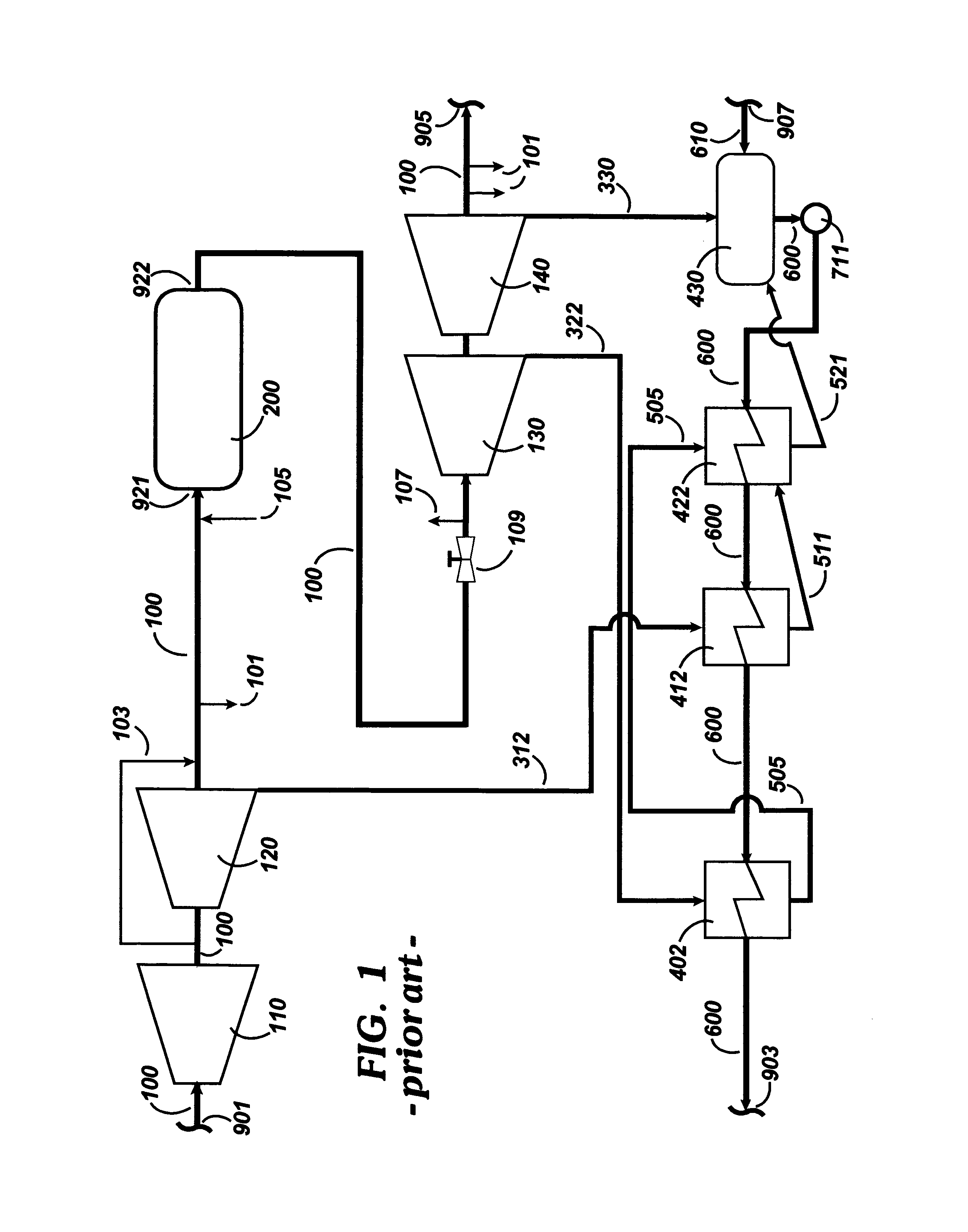

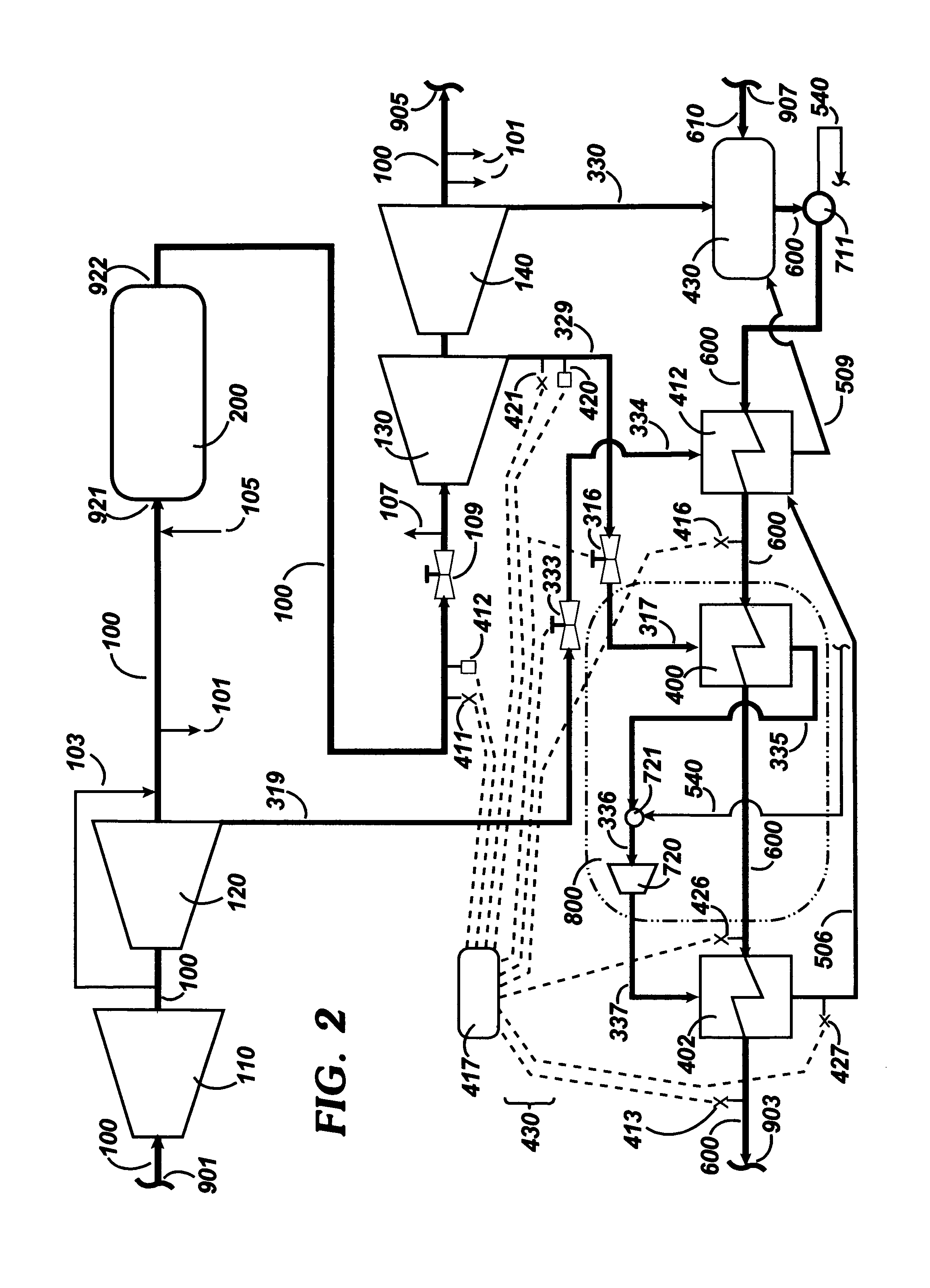

Method and apparatus for controlling the final feedwater temperature of a regenerative Rankine cycle using an exergetic heater system

ActiveUS8091361B1Power Loss MinimizationImprove system reliabilitySteam regenerationSteam useWorking fluidPower station

This invention relates to a method and apparatus for increasing the final feedwater temperature associated with a regenerative Rankine cycle, said cycle commonly used in thermal systems such as conventional power plants, whose steam generators are fired with a fossil fuel and whose regenerative Rankine cycle employs a reheating of the working fluid. This invention involves the placement of an Exergetic Heater System in the feedwater path of the regenerative Rankine cycle. The Exergetic Heater System conditions and heats feedwater such that the temperature of the cycle's final feedwater as it enters the steam generator has reached a desired value. The Exergetic Heater System receives its driving steam from an Intermediate Pressure turbine extraction.

Owner:EXERGETIC SYST

Method and plant for removing carbon dioxide from flue gas

InactiveUS8043588B2Reduce energy costsEasy to modifyCombination devicesLiquid degasificationThermal energyDesorption

Owner:CO2 NORWAY +1

Flue gas conversion apparatus and method

InactiveUS7252806B1Energy penalty of operating the apparatus will be minimizedCombination devicesGas treatmentAtmospheric airEngineering

An apparatus and method of converting flue gases produced by a fossil fuel burning furnace boiler is disclosed. The flue gas is separated into its constituent parts by cooling and filtering. Carbon dioxide, the main constituent, is then converted to carbon monoxide in a laser powered gas converter in which carbon is a catalyst. The laser powered converter also produces hydrogen from steam, and the two newly produced gases are chemically combined to produce a hydrocarbon fuel product which can then be burned in the furnace boiler. In this manner no harmful greenhouse gases are permitted to escape to the atmosphere.

Owner:PET PROJECTS

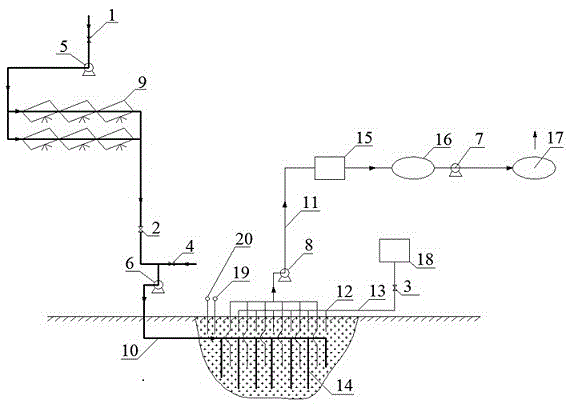

Solar hot air system enhanced in-situ bio-ventilation soil restoration system

InactiveCN105478468AAdjustable temperaturePromote degradationContaminated soil reclamationVacuum extractionCollection system

The invention relates to a solar hot air system enhanced in-situ bio-ventilation soil restoration system. The system comprises a solar air heat collection system, a ventilation system, a contaminant vacuum extraction system and a gas purification system. The ventilation system is a ventilation pipeline, and the solar air heat collection system is connected with the ventilation pipeline and used for heating air in the ventilation pipeline. The contaminant vacuum extraction system comprises a gas phase extraction pipe and a vacuum pump, the gas phase extraction pipe is directly buried in the heated contaminated soil area, and the upper portion of the gas phase extraction pipe is connected with the gas purification device. The solar hot air system enhanced in-situ bio-ventilation soil restoration system further comprises a nutrient solution injection system, and a nutrient solution is evenly pumped into organic matter contaminated soil through the nutrient solution injection system. According to the system, solar energy serves as a heat source, heated air is injected into a soil embedded radiating pipe, soil temperature is adjusted, soil microbial flora and the nutrition environment are optimized, degradation of microorganisms for organic matter in the contaminated soil is promoted, and then following vacuum extraction is facilitated. By means of the system, energy is saved, the emission of greenhouse gas is reduced, and secondary pollution generated by combustion of fossil fuel is avoided.

Owner:中钢集团天澄环保科技股份有限公司

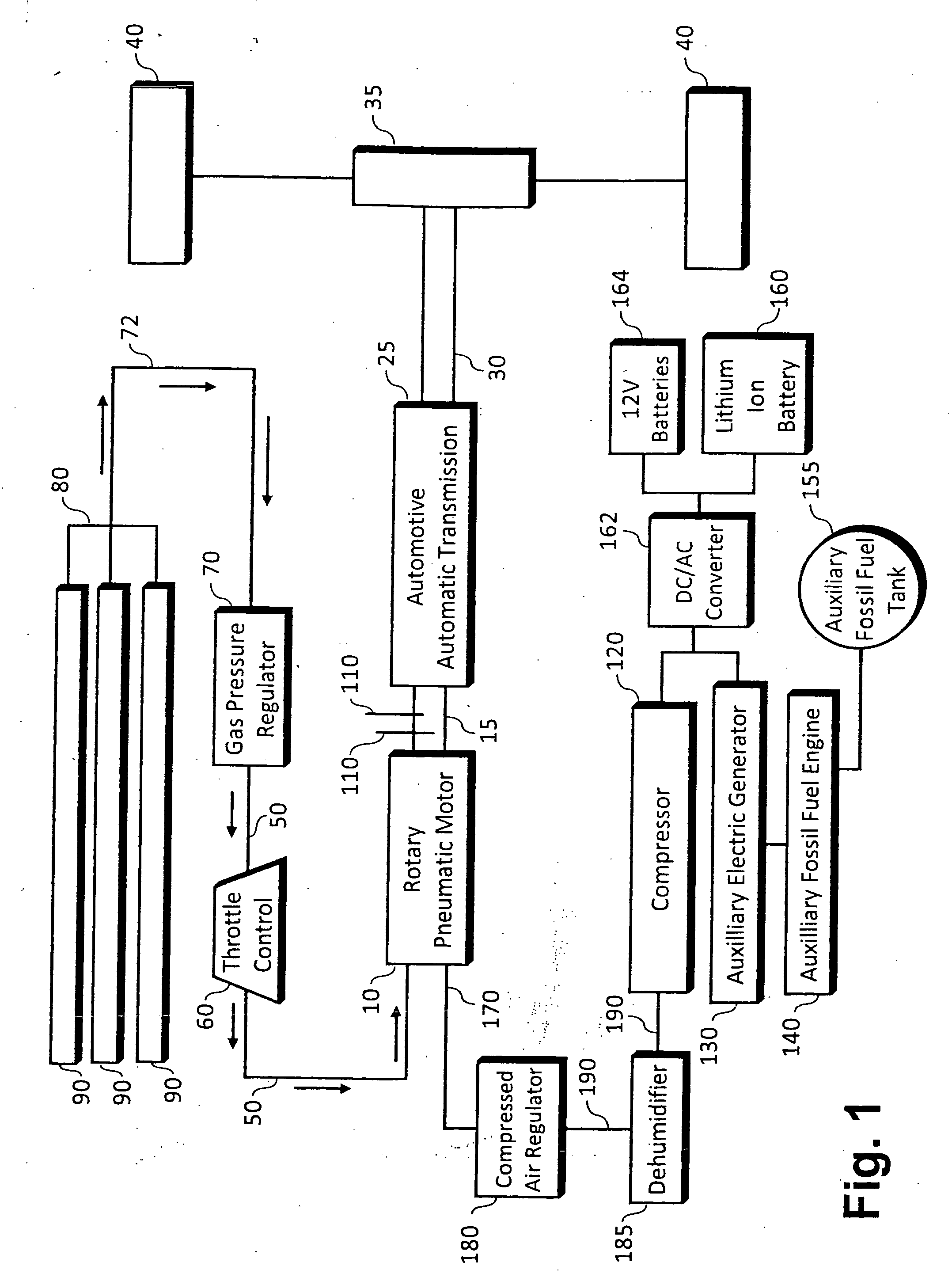

Pneumatic mechanical power source

ActiveUS20090266069A1Eliminate consumptionEliminate the problemAuxillary drivesRailway vehiclesAviationNitrogen

An mechanical power system is provided for providing torque without using a heat engine in virtually any non-aviation application where fossil-fuel engines have conventionally been used, by simply replacing the fossil-fuel burning engine with a rotary pneumatic motor of appropriate size for the application and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used virtually anywhere, and requires merely a supply of compressed gas to run it, preferably compressed nitrogen. Automotive, marine and electrical generating applications are easily adaptable, and auxiliary fossil-fuel engines can be added for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. Tanks of compressed gas are to be conveniently user replaceable.

Owner:DOMES TIMOTHY J

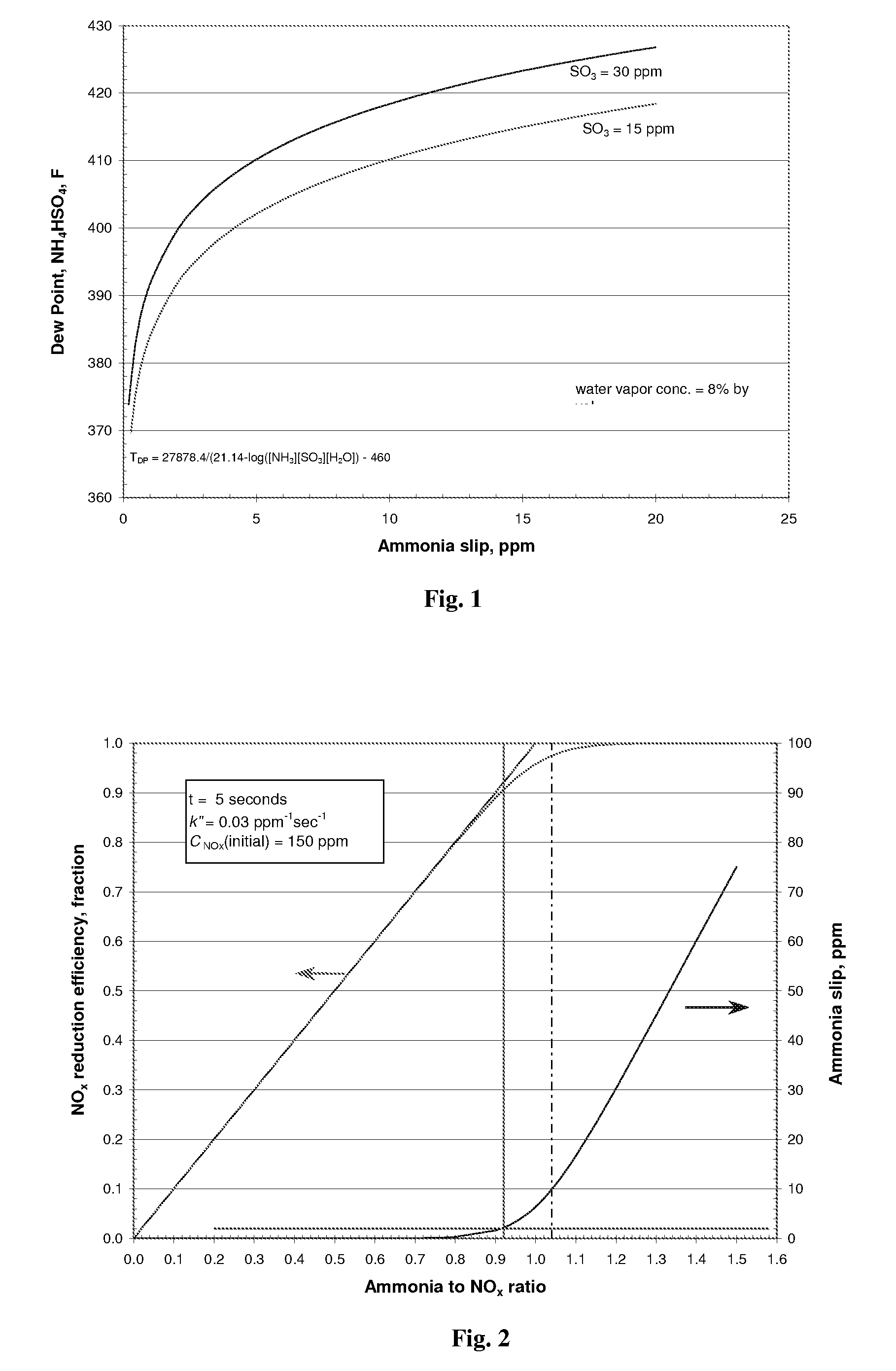

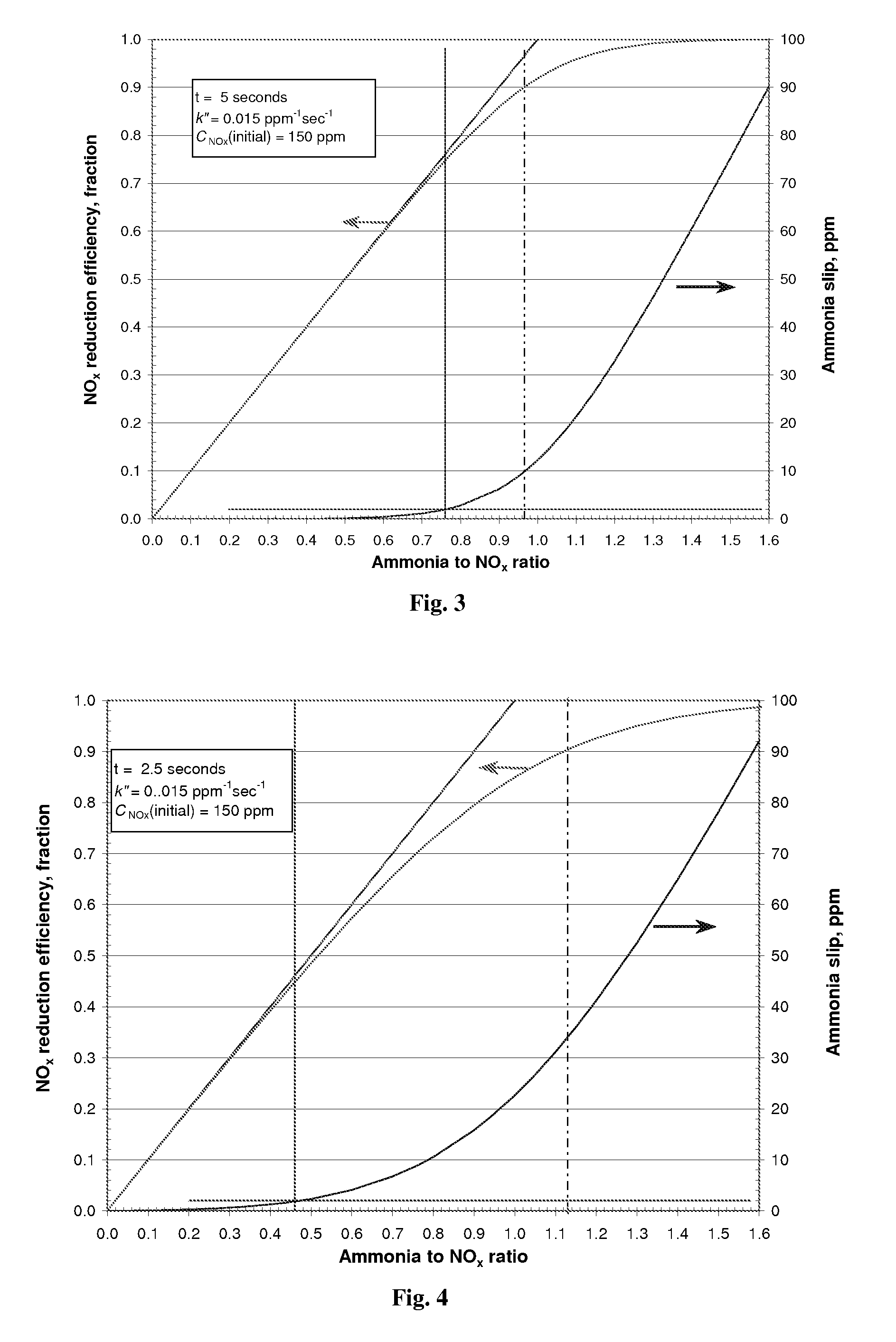

Enhancement of conventional scr and sncr processes with ammonia destruction catalyst

InactiveUS20090252665A1Increasing ammonia slipIncrease the supply rateNitrous oxide captureGas treatmentInjection pointEnvironmental engineering

An apparatus and method for achieving increased NOx removal efficiency from an emissions control portion of a fossil fuel fired boiler while controlling ammonia slip provides excess levels of ammonia above those levels conventionally employed in SCR and / or SNCR applications. The apparatus and methods comprise, in part, use of a NOx reduction system comprising at least one selective catalytic reduction system which receives ammonia in higher amounts than conventional practice from an upstream ammonia injection point, and an ammonia reduction system positioned downstream of one or more ammonia injection points and the NOx reduction system. The excess ammonia achieves increased NOx removal, while the ammonia reduction system contains at least one ammonia destruction catalyst which permits the NOx reduction system to be operated at an increased NOx removal efficiency without a corresponding increase in ammonia slip.

Owner:THE BABCOCK & WILCOX CO

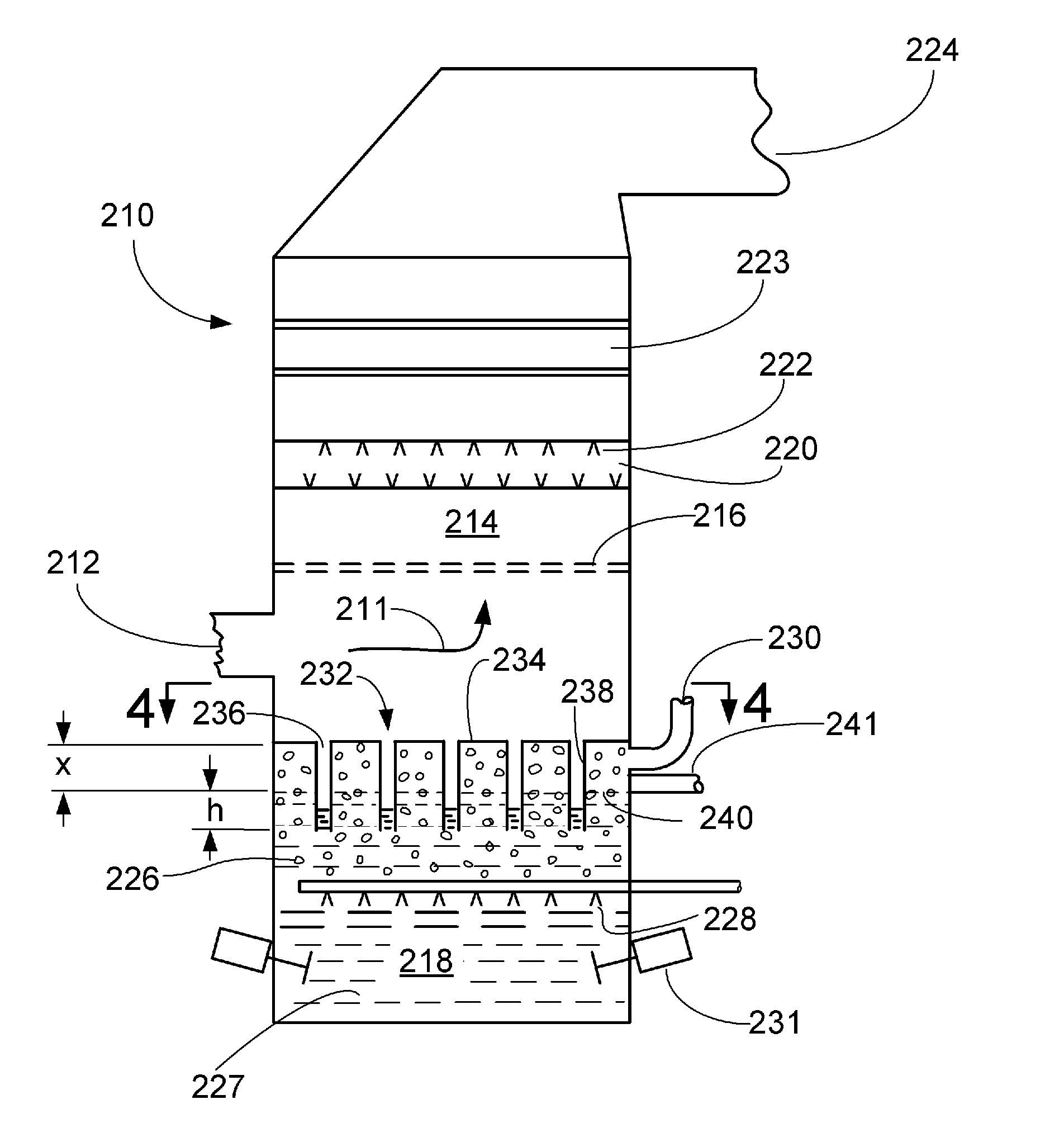

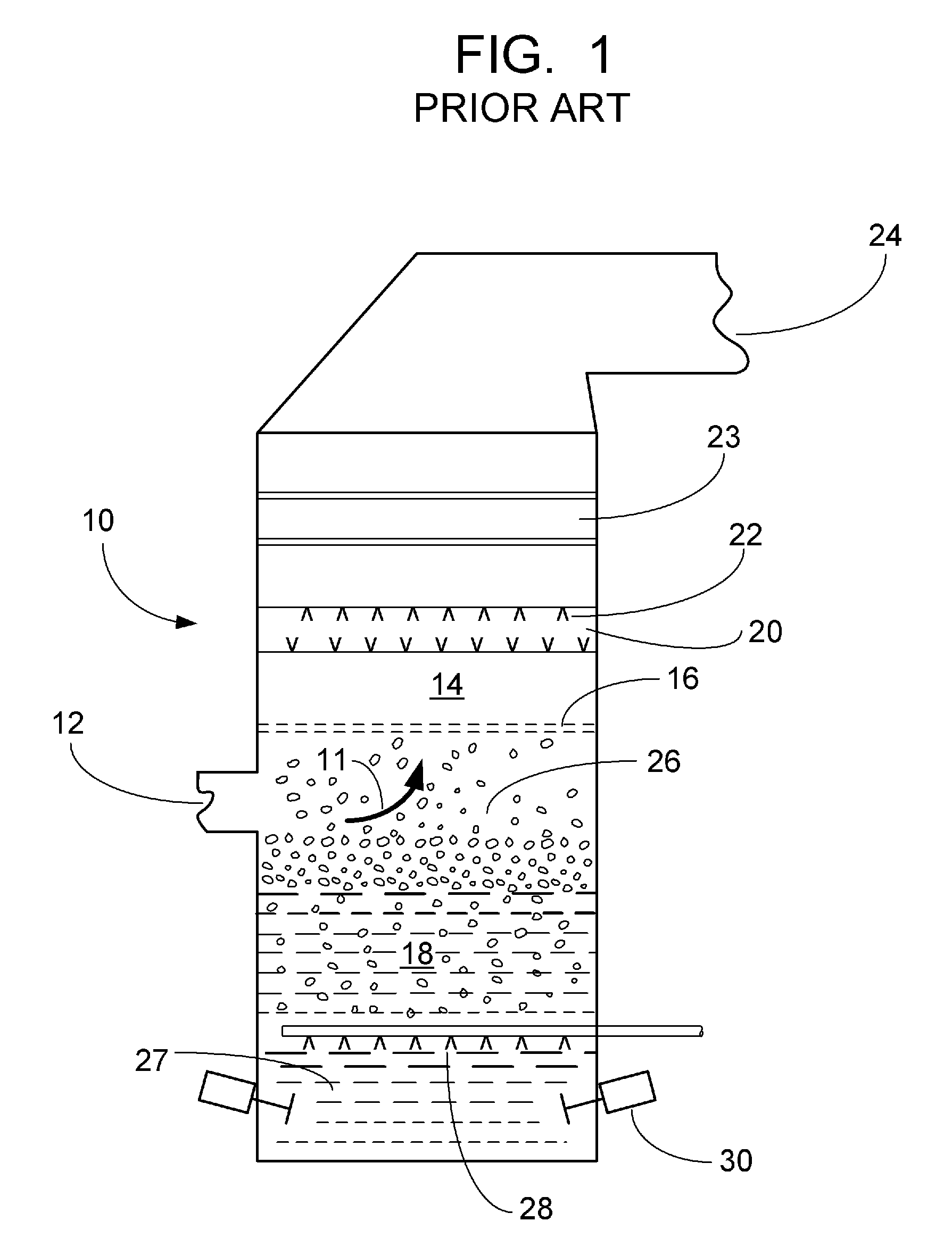

Segregated in-situ forced oxidation wet flue gas desulfurization for oxygen-fired fossil fuel combustion

ActiveUS20110083592A1Avoid mixingAvoid introducingUsing liquid separation agentEmission preventionSlurryOxygen

An in-situ forced oxidation wet flue gas desulfurization apparatus, method and arrangement for utilization with oxy-fuel combustion power plants. The apparatus is a tower-like structure having a flue gas scrubbing zone and a reaction zone located subjacent to the gas scrubbing zone. A sulfur oxide absorbing liquid slurry is supplied to the gas scrubbing zone to react with and scrub the sulfur oxides from the flue gas. The partially reacted liquid slurry reagent and the scrubbed products drain into the reaction zone, rising to a set level. Oxidation air is introduced into the liquid slurry in the reaction zone to force the in-situ oxidation of sulfur compounds collected in the reaction zone. A wall separates and communicates the gas scrubbing zone and the reaction zone, the wall prevents the oxidation air from entering the gas scrubbing zone and extends into the liquid slurry below a nominal depth required to establish and maintain a liquid slurry seal thereby substantially precluding the leakage of flue gas into the reaction zone while allowing the partially reacted liquid slurry reagent and scrubbed products to drain into the reaction zone.

Owner:THE BABCOCK & WILCOX CO

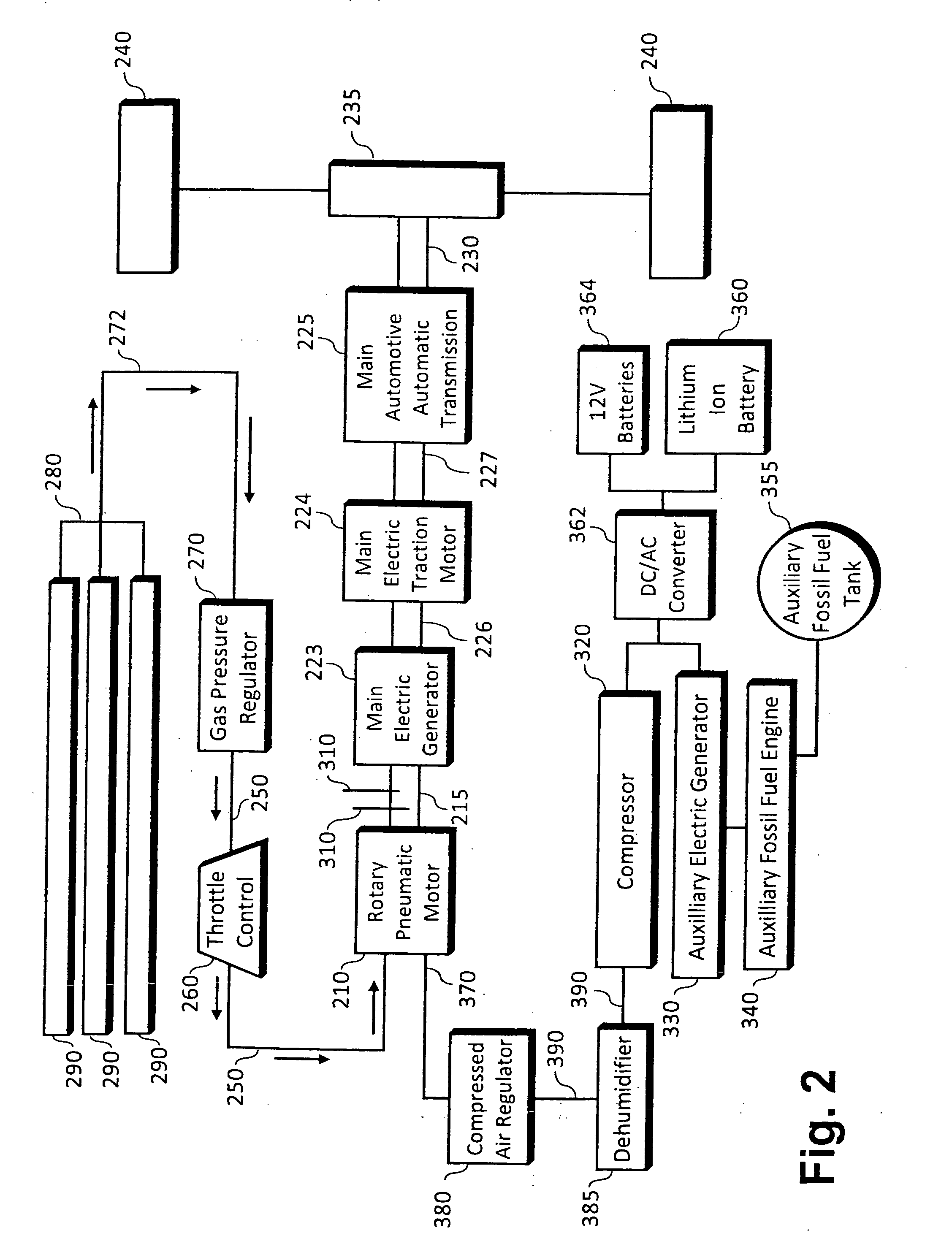

Pneumatic mechanical power source

ActiveUS20110049909A1Eliminate consumptionEliminate the problemServomotor componentsPlural diverse prime-mover propulsion mountingPower stationLiquid state

An mechanical power system provides torque without using a heat engine where fossil-fuel engines have conventionally been used, by replacing the fossil-fuel burning engine with a rotary pneumatic motor and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used anywhere, and requires preferably compressed nitrogen in a non-liquid state. Automotive, marine and electrical generating applications are adaptable, and auxiliary power is available for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. An electrical generating power plant includes an array of solar panels for generating direct current (DC) and a DC / AC converter for converting the DC to alternating current (AC) and outputting a portion of the AC via a power plant output port to supply an AC load.

Owner:DOMES TIMOTHY

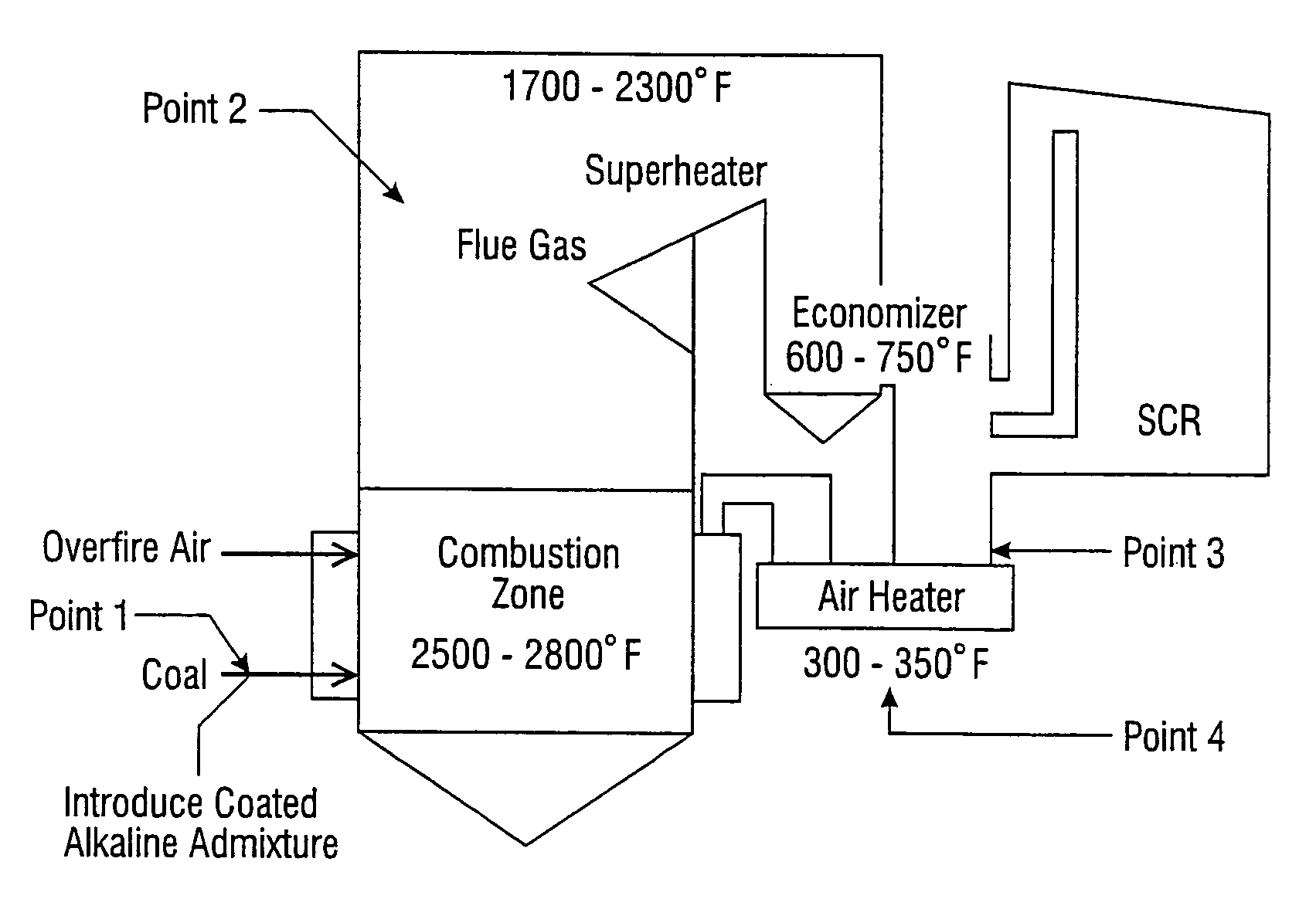

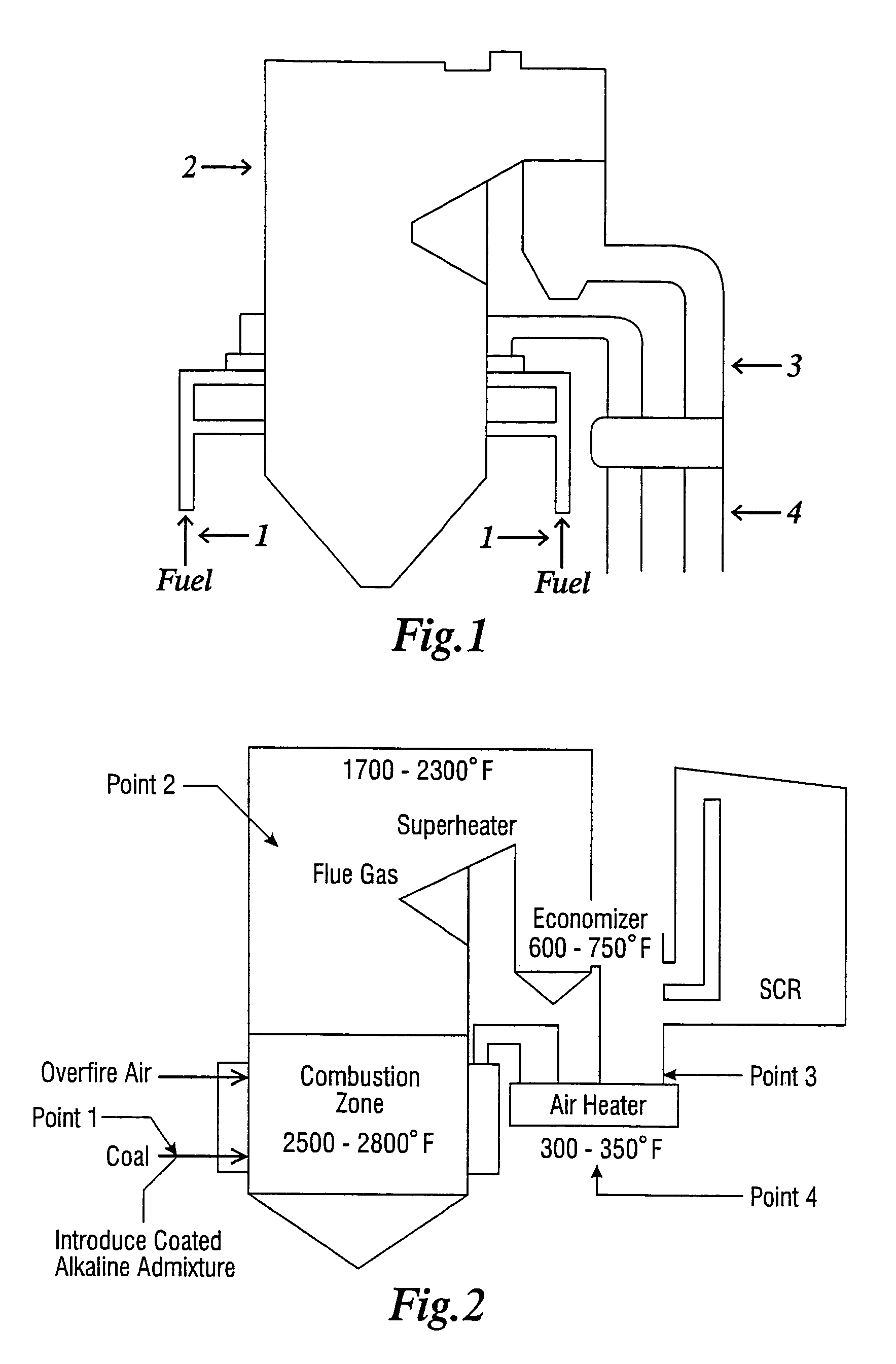

Method for reducing the amount of a pollutant in a flue gas resulting from the combustion of a fossil fuel

ActiveUS7013817B2Reduce the amount requiredGood dispersionGas treatmentEmission preventionCombustionFlue gas

Owner:OMNI MATERIALS

Physical separation and sequestration of carbon dioxide from the exhaust gases of fossil fuel combustion

InactiveUS20120058042A1Maximizes carbon dioxideEasy to separateCalcium/strontium/barium carbonatesOrganic chemistryCalcium bicarbonateNitrogen gas

Methods are provided for physically removing all the carbon dioxide from the combustion products of solid, liquid, and gaseous fossil fuels. The combustors operate without excess air to maximize the carbon dioxide at the exhaust, which is compressed with the nitrogen and mixed with pressurized water to dissolve the carbon dioxide in a chamber from which the nitrogen gas is removed. The solution is drained into a second lower pressure chamber from which the carbon dioxide re-evolves as a gas, which is then pressurized for sequestration in limestone formations as calcium bicarbonate. The water is recycled to repeat the separation process, and depressurization of the two gases recovers most of the compression energy.

Owner:ZAUDERER BERT

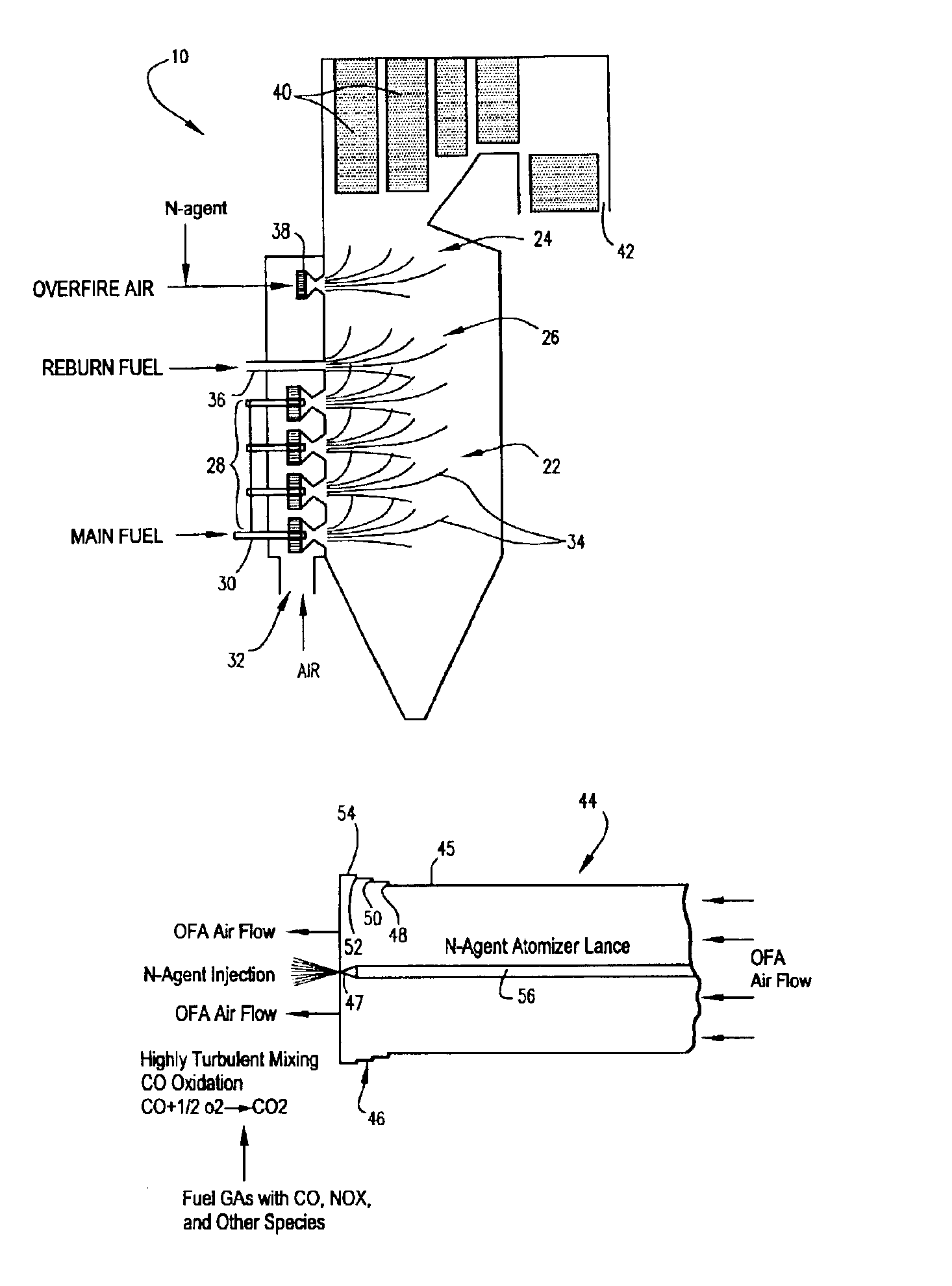

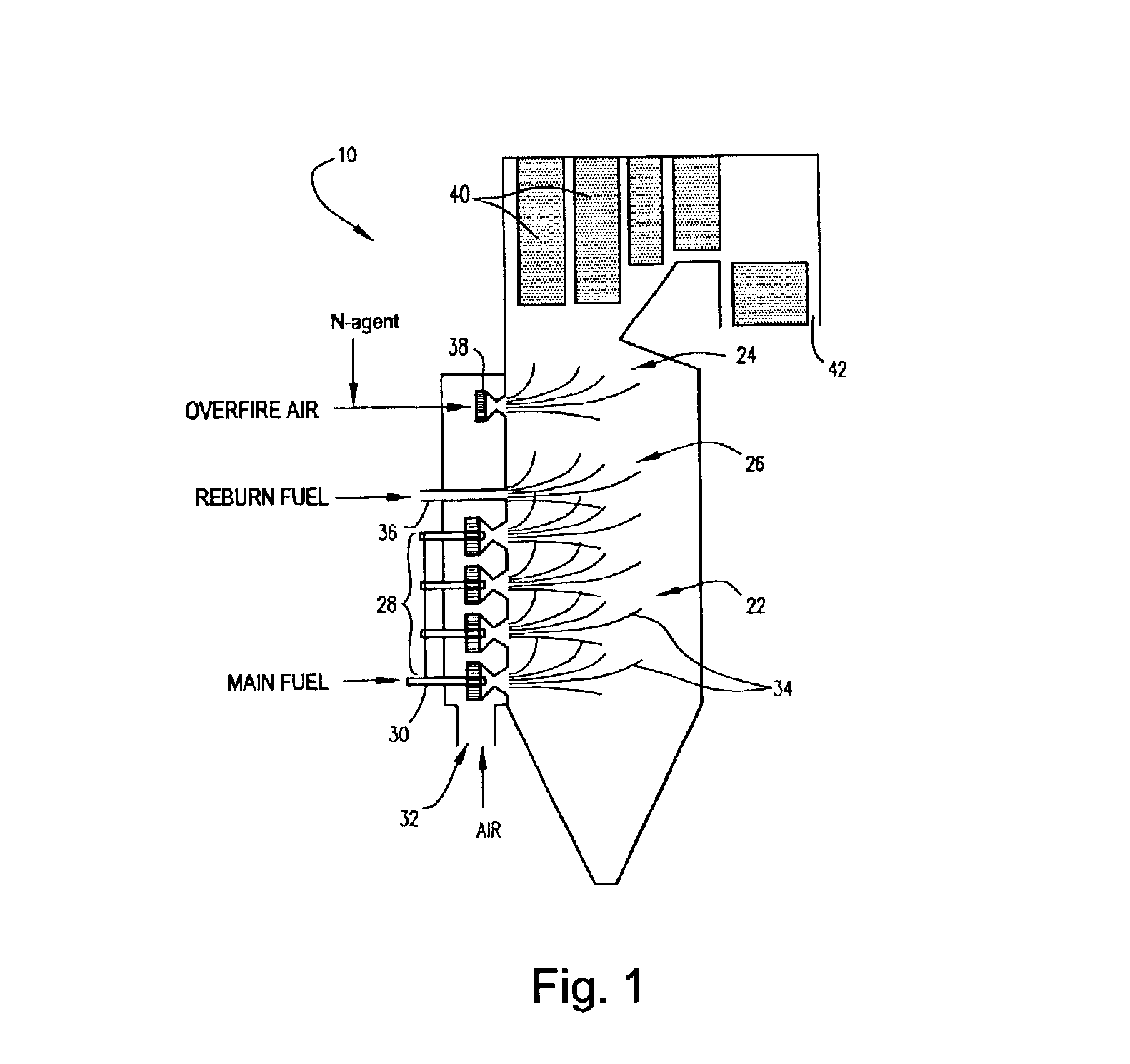

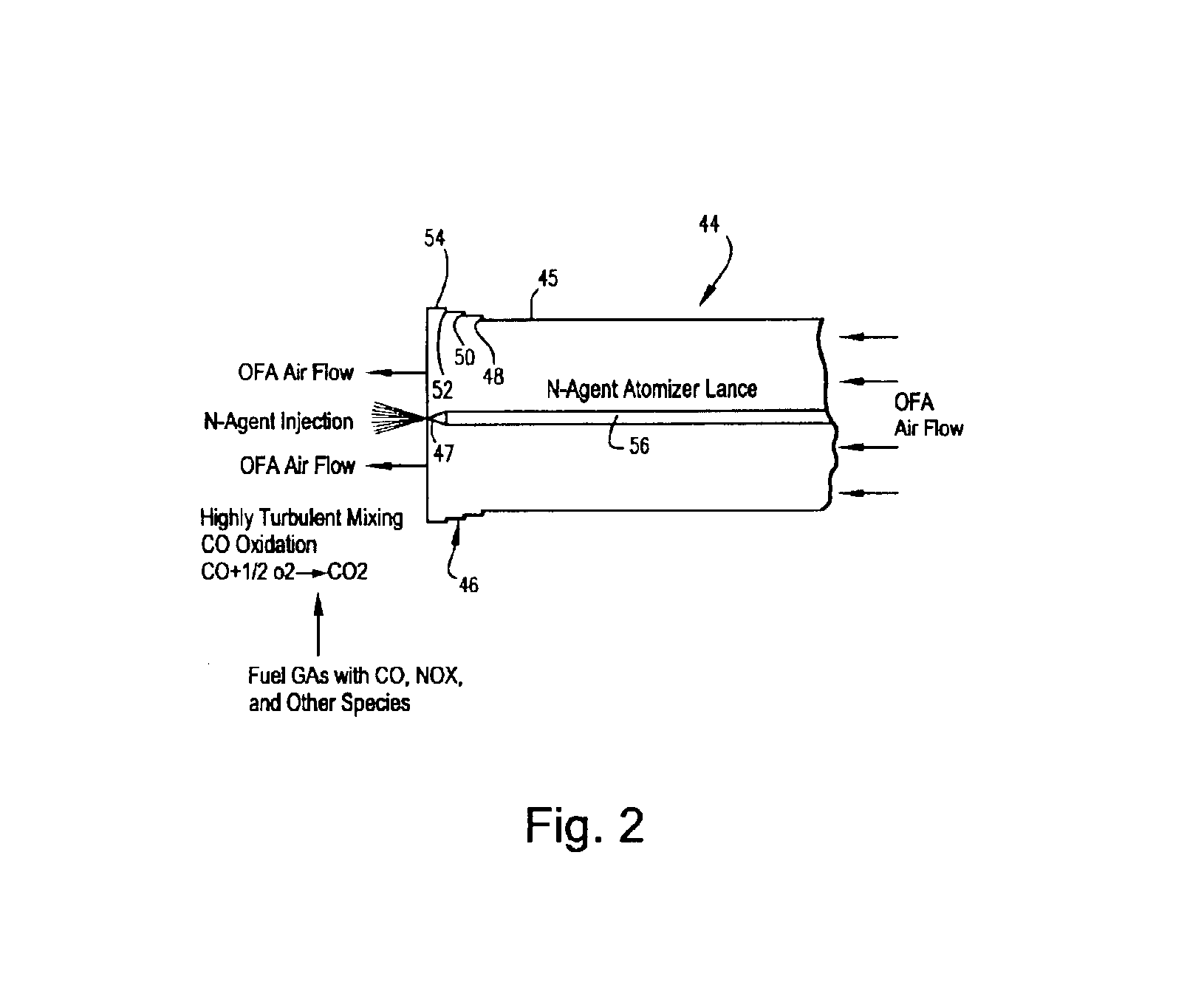

Step-diffuser for overfire air and overfire air/N-agent injector systems

InactiveUS6865994B2Enhance small-scale mixingPromote oxidationNitrous oxide captureSolid fuel combustionCombustionFossil fuel

An overfire air injector for use in a fossil fuel-fired combustion device includes a cylindrical nozzle having an outlet end formed with a step diffuser comprising one or more radial steps that enlarge the outlet end of the nozzle. An atomizer lance may be mounted within the nozzle, having a discharge orifice at the outlet end of the nozzle, for supplying a reducing agent to the overfire air to reduce NOx emissions.

Owner:GENERAL ELECTRIC CO

Pneumatic mechanical power source

An mechanical power system is provided for providing torque without using a heat engine in virtually any non-aviation application where fossil-fuel engines have conventionally been used, by simply replacing the fossil-fuel burning engine with a rotary pneumatic motor of appropriate size for the application and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used virtually anywhere, and requires merely a supply of compressed gas to run it, preferably compressed nitrogen. Automotive, marine and electrical generating applications are easily adaptable, and auxiliary fossil-fuel engines can be added for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. Tanks of compressed gas are to be conveniently user replaceable.

Owner:DOMES TIMOTHY J

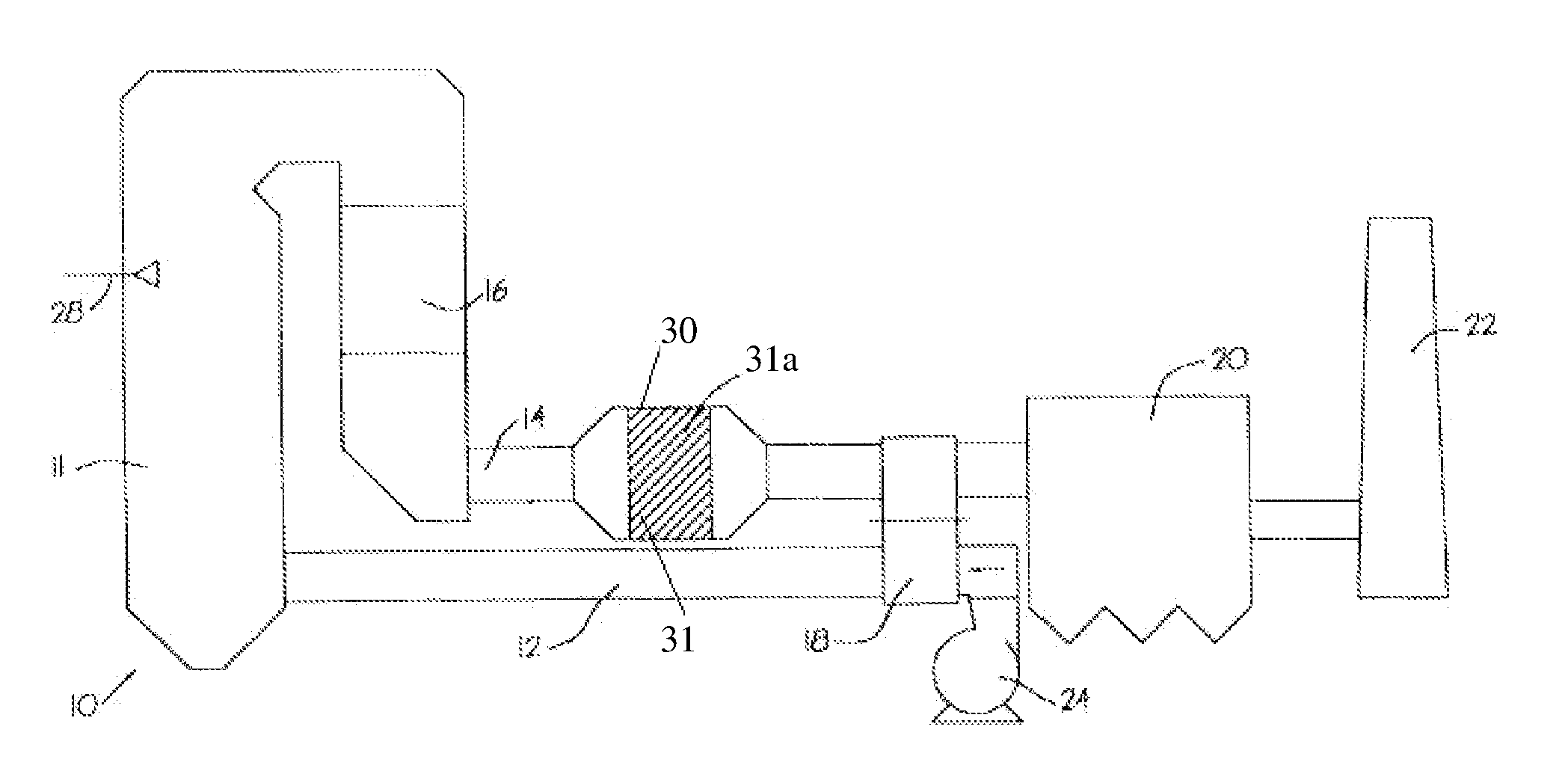

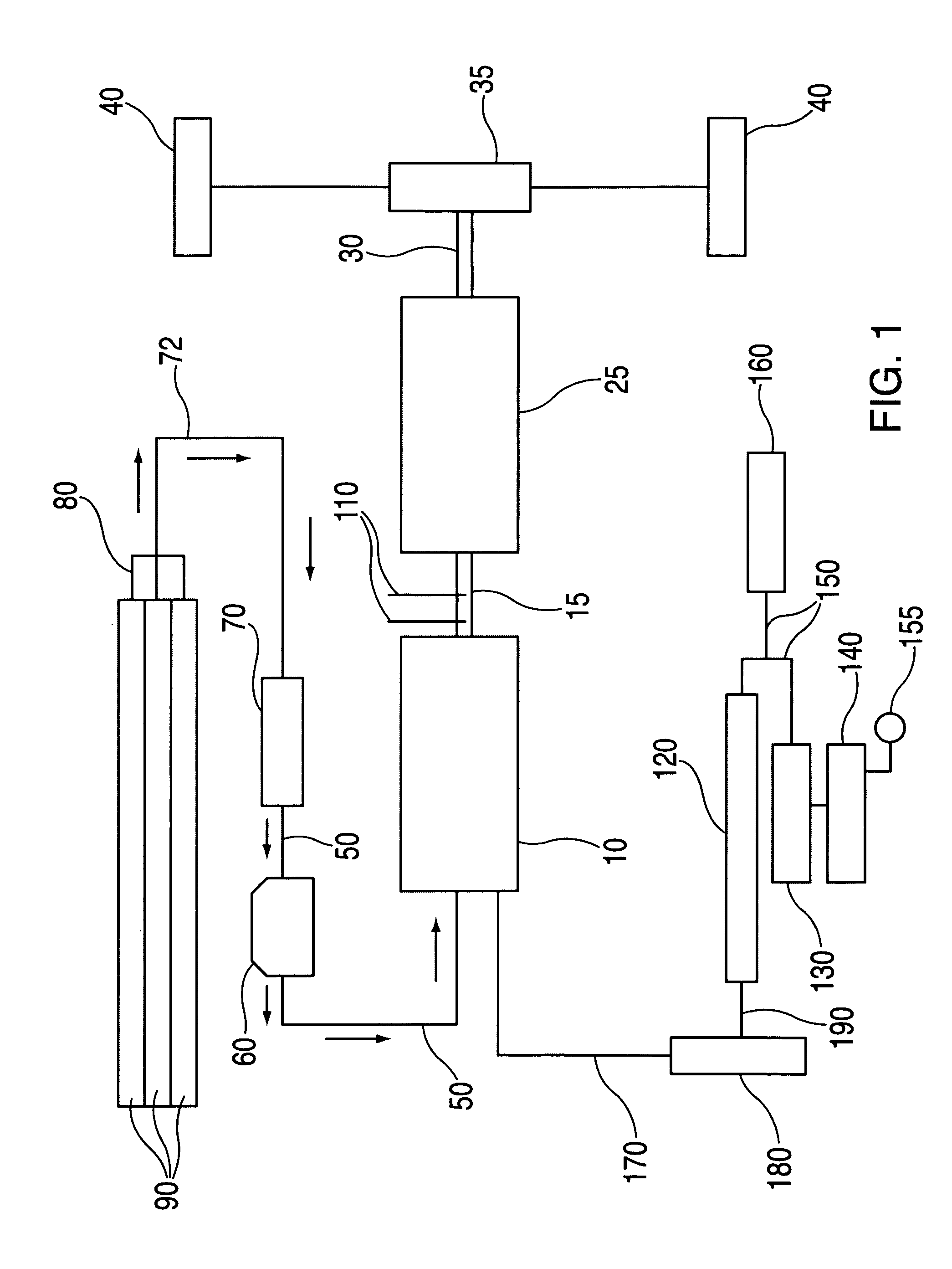

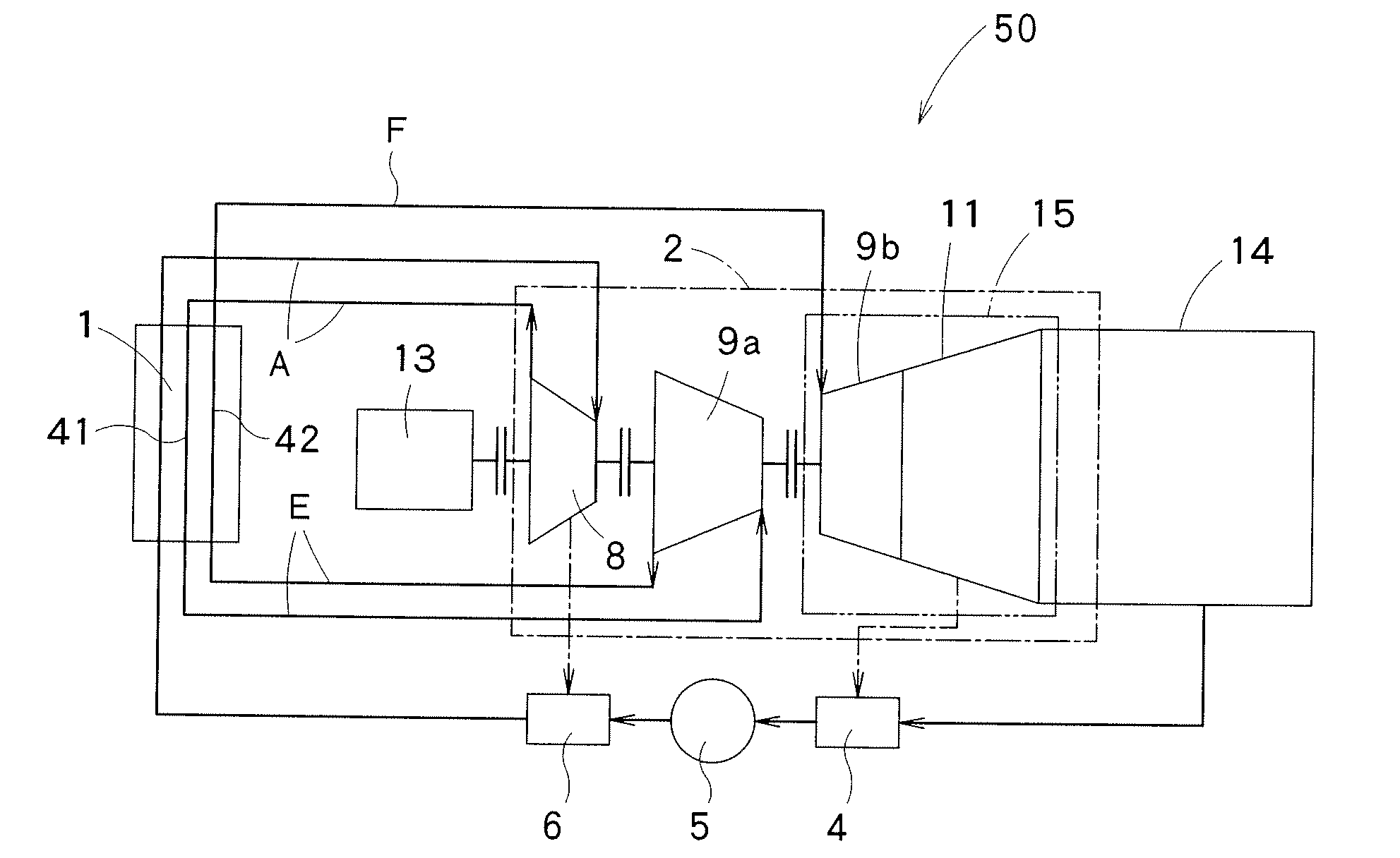

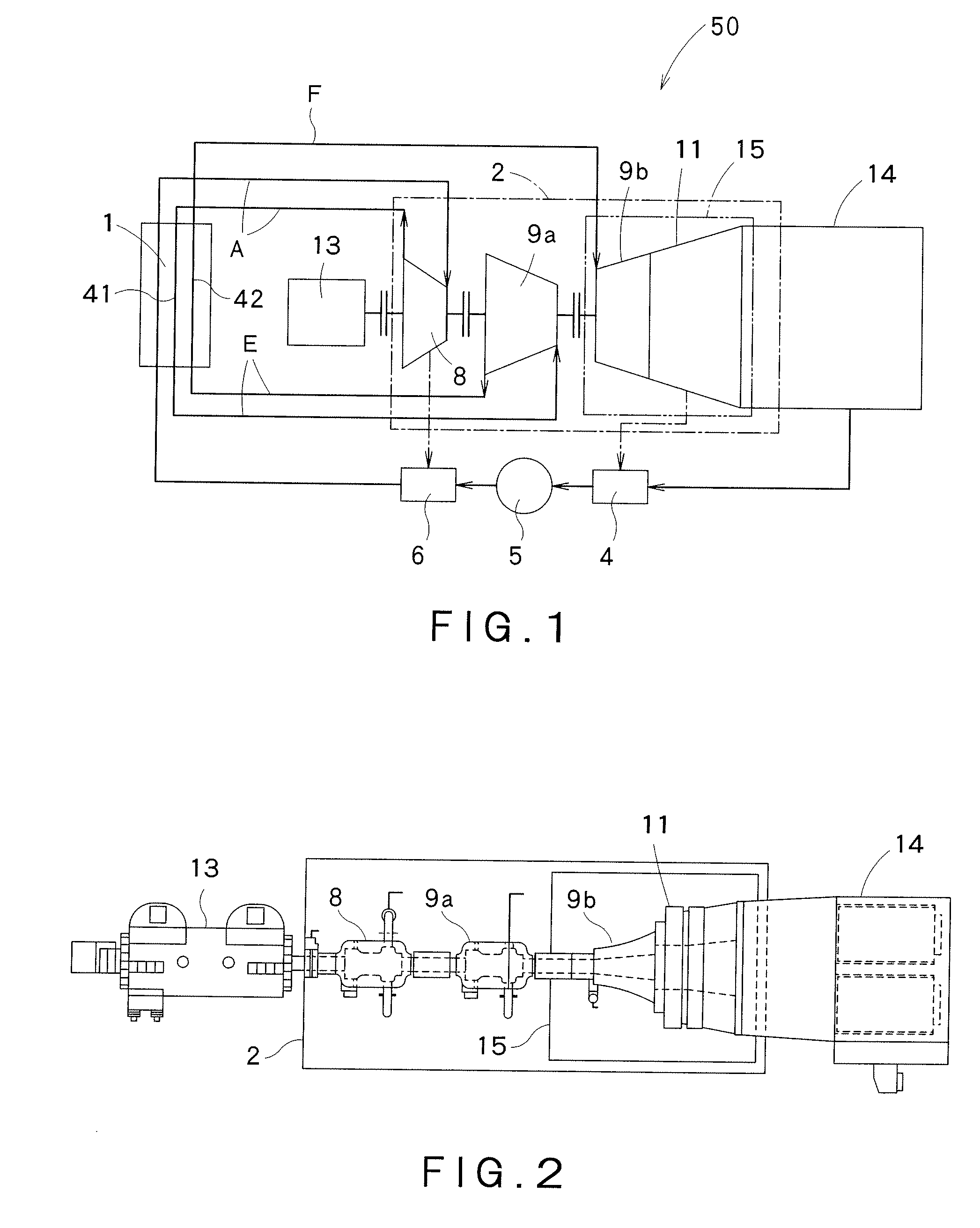

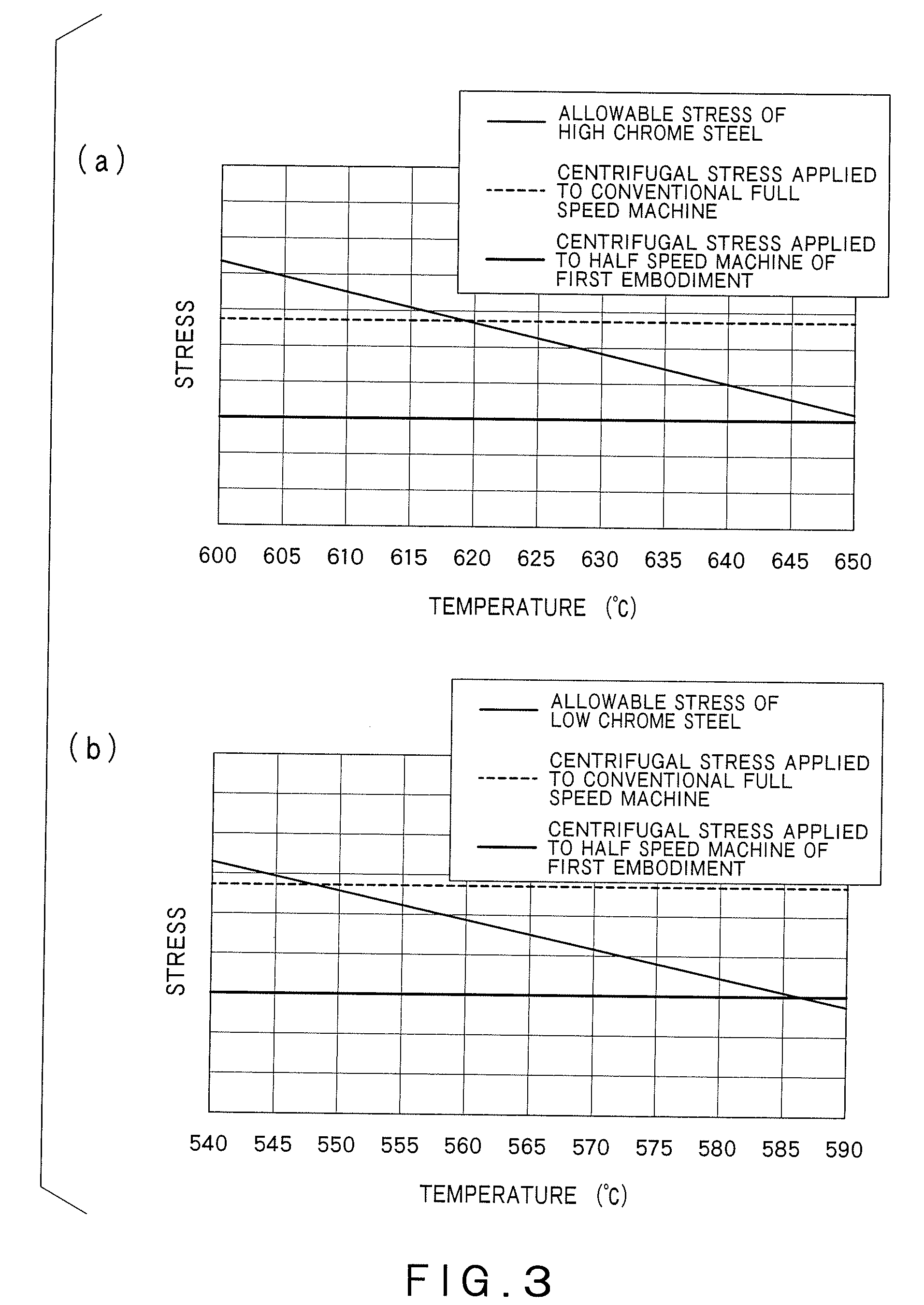

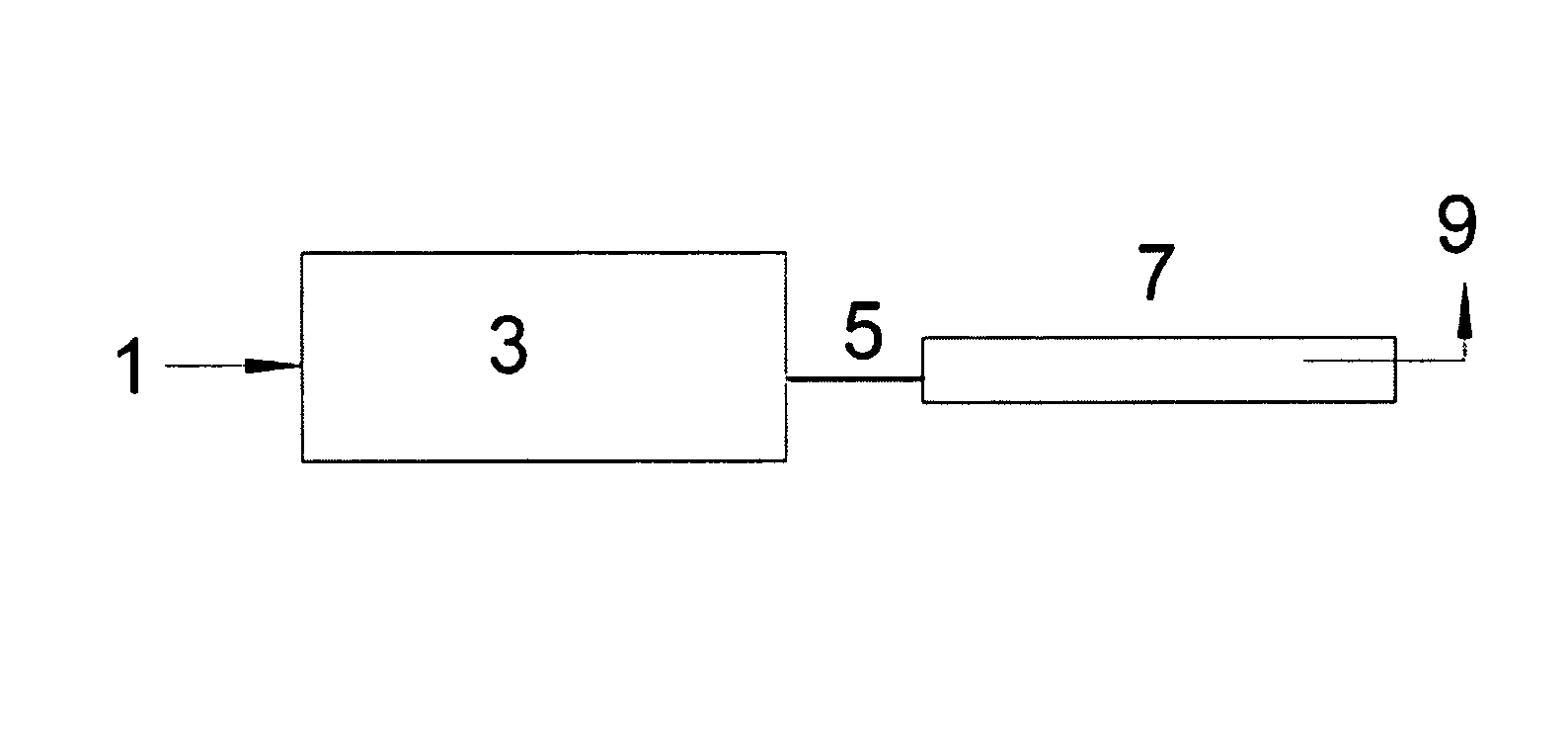

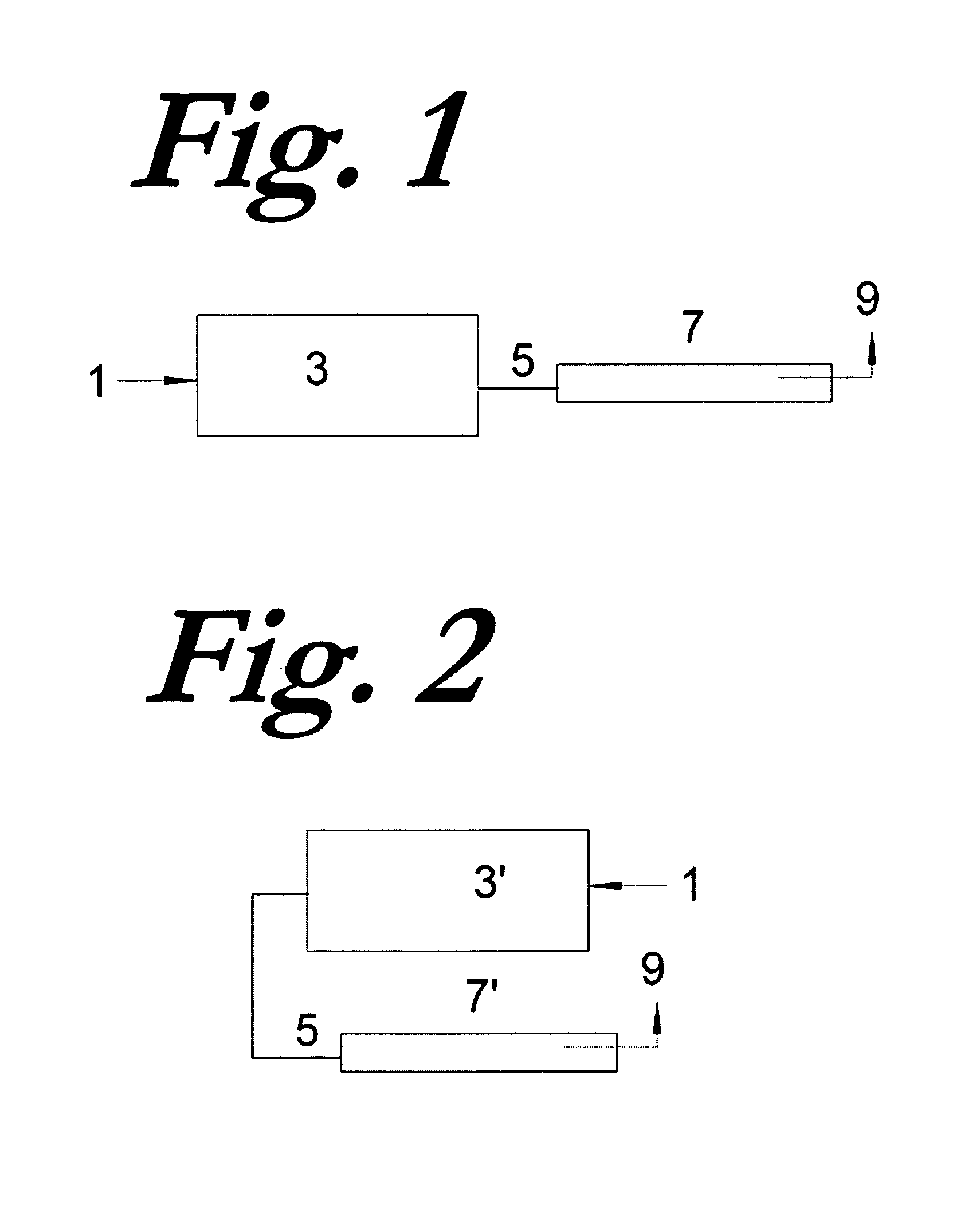

Thermal power plant

InactiveUS20080245071A1Improve power generation efficiencyImprove turbine efficiencyExhaust apparatusSilencing apparatusCombustionTurbine

By improving a turbine efficiency, a power generation efficiency can be easily improved. The thermal power plant of the present invention comprises, for example: a boiler 1 that heats a feed water by utilizing a heat caused by combustion of a fossil fuel so as to generate a main steam A; reheaters 41 and 42 installed in the boiler 1; a turbine 2; and a generator 13 connected to the turbine 2. The turbine 2 includes: a high pressure turbine into which the main steam A from the boiler 1 is introduced; an intermediate pressure turbine 9 into which the reheated steams E and F generated by the reheaters 41 and 42 are introduced, the intermediate pressure turbine 9 being uniaxially connected to the high pressure turbine 8; and a low pressure turbine 11 into which the reheated steams E and F discharged from the intermediate pressure turbine 9 is introduced, the low pressure turbine 11 being coupled with the high pressure turbine 8 and the intermediate pressure turbine 9. The generator 7 has more than two poles, and is coupled with the high pressure turbine 8, the intermediate pressure turbine 9, and the low pressure turbine 11.

Owner:KK TOSHIBA

Apparatus and methods for carbon dioxide capture and conversion

ActiveUS8413420B1Reduce electricity costsIncrease in atmospheric CO burdenCombination devicesPhotography auxillary processesWind drivenElectrolysis

To alleviate and possibly even reverse global warming while providing a liquid fuel to replace petroleum, apparatus and methods are disclosed for capturing CO2 from an air mixture and converting it to a useful substance, especially a methanol-containing fuel, utilizing preferably an MgO-loaded cartridge, which is converted partly into MgCO3 as it captures CO2 by a carbonation reaction and is reconverted into MgO by a calcination reaction while emitting a stream of substantially pure CO2. The emitted CO2 stream is reacted with hydrogen or water to yield a methanol-containing fuel or other useful chemical agent. The hydrogen is preferably derived from water electrolysis using inexpensive solar or wind driven electricity thereby also reducing the cost of such electricity by providing an economical energy storage means. Said air mixture may be the effluent from an internal combustion engine of a motor vehicle or from other fossil fuel burning sources or from the ambient atmosphere. The catalytic combination of hydrogen with CO2 to form methanol can provide a new global environmentally beneficial fuel whose burning will not contribute to any net increase in the atmospheric CO2 burden.

Owner:ZAROMB SOLOMON

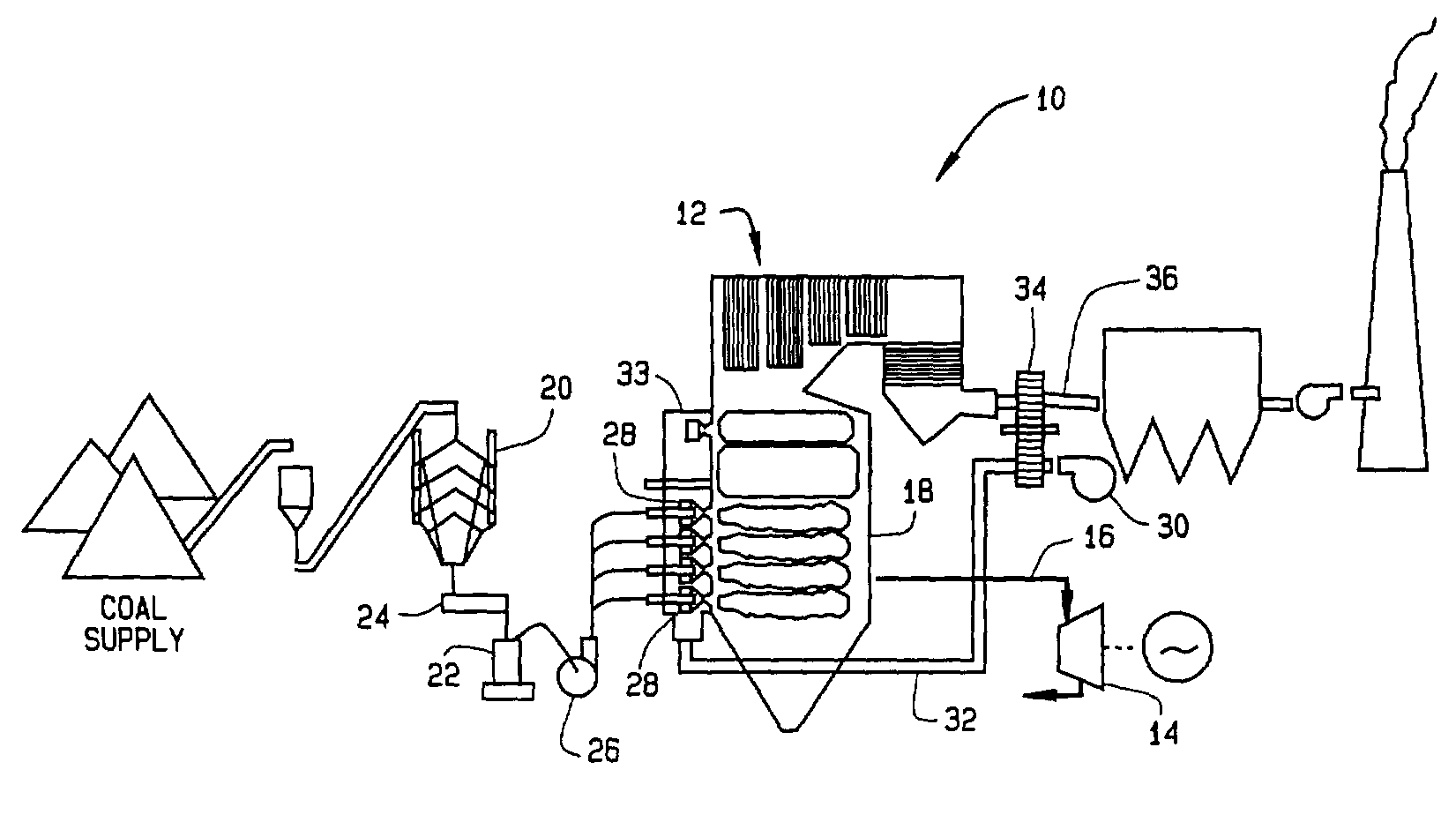

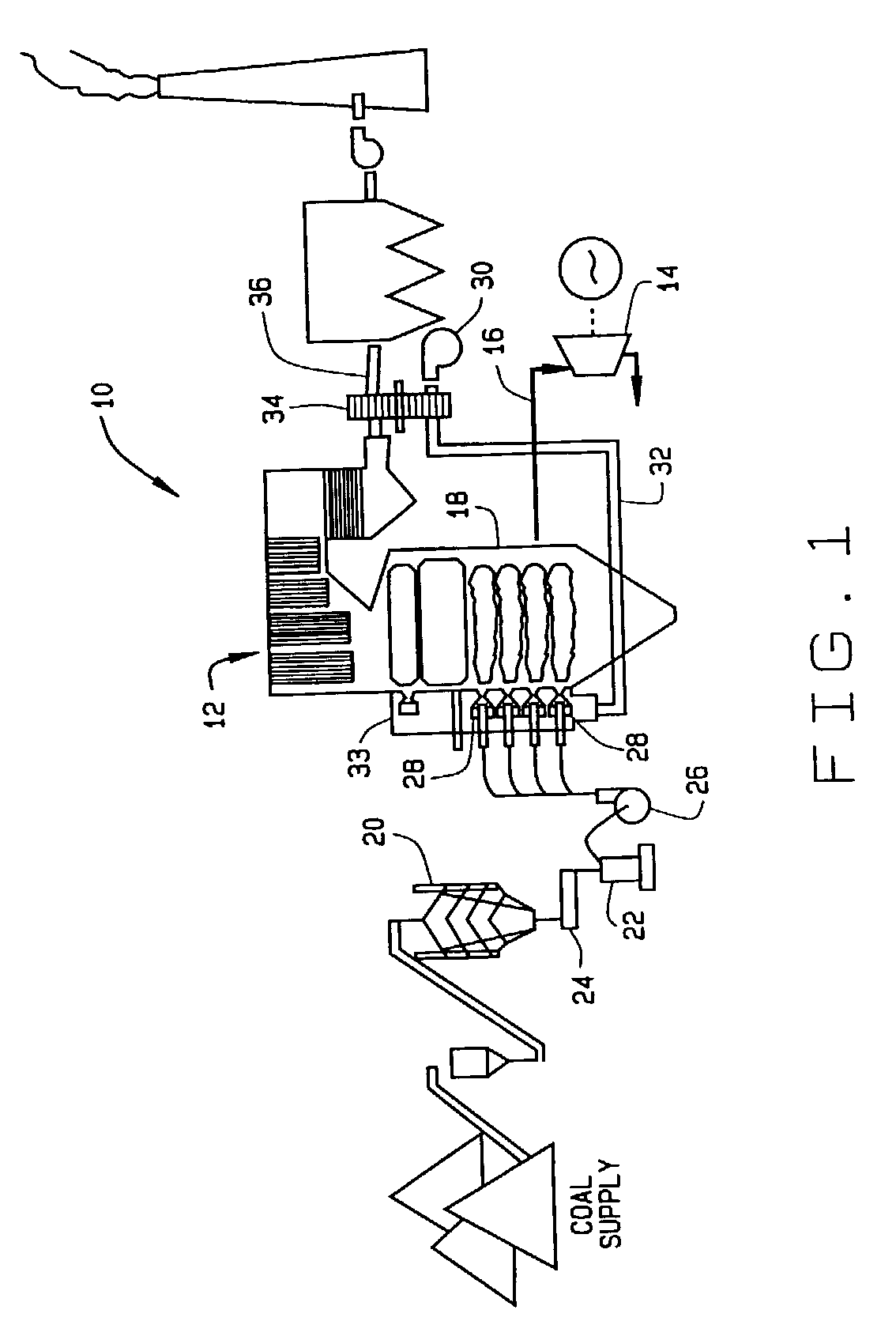

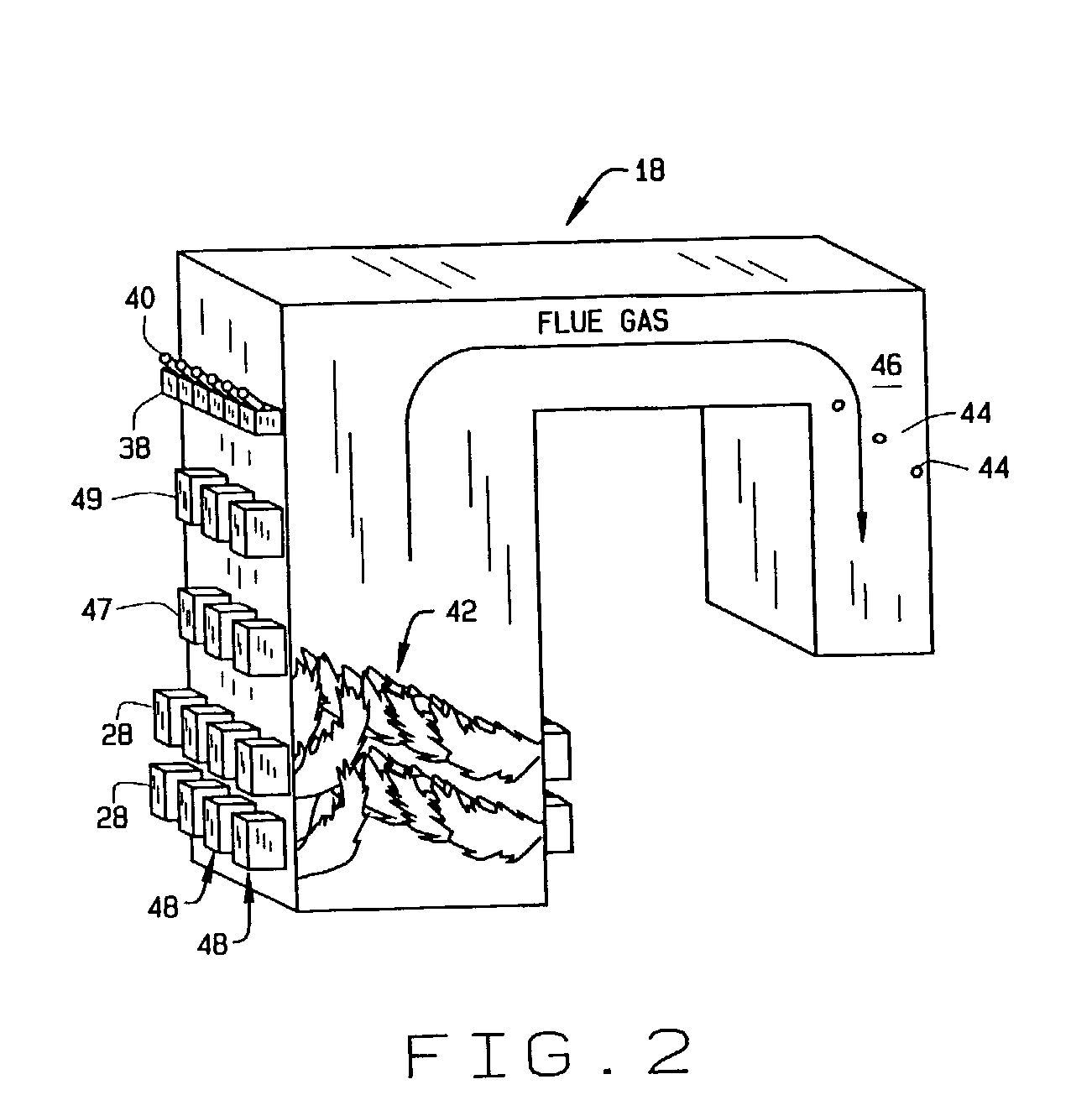

Combustion optimization for fossil fuel fired boilers

ActiveUS7838297B2Alleviate spatial combustion anomalyEasy to operateFuel supply regulationAir supply regulationCombustorFossil fuel

A method of optimizing operation of a fossil fuel fired boiler includes, in an exemplary embodiment, providing a plurality of sensors positioned in different spatial positions within the fossil fuel fired boiler. The method also includes recording sensor outputs, identifying spatial combustion anomalies indicated by sensor outputs, identifying burners responsible for the spatial combustion anomalies, and adjusting air flow of responsible burners to alleviate the spatial combustion anomalies.

Owner:GENERAL ELECTRIC CO

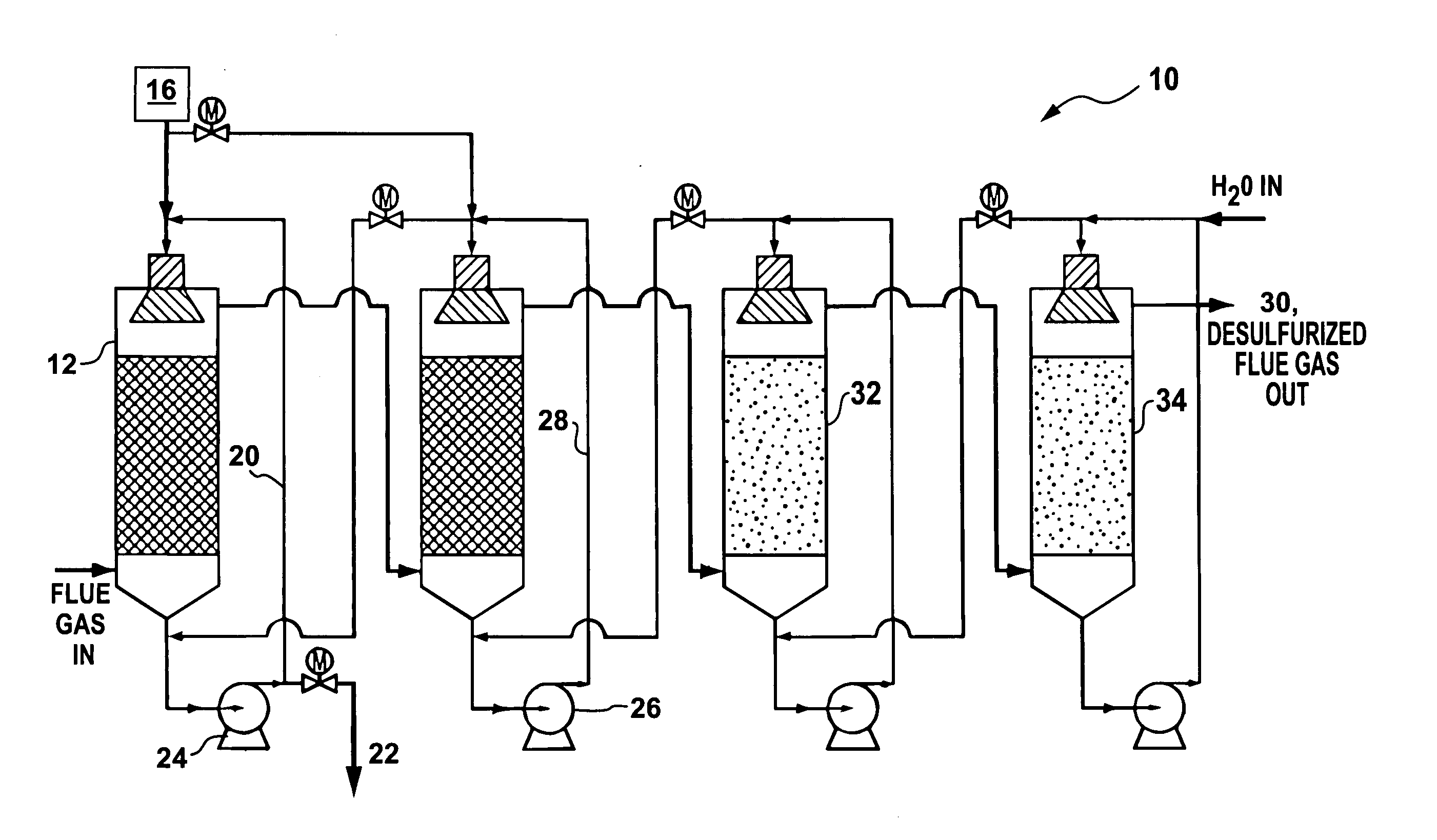

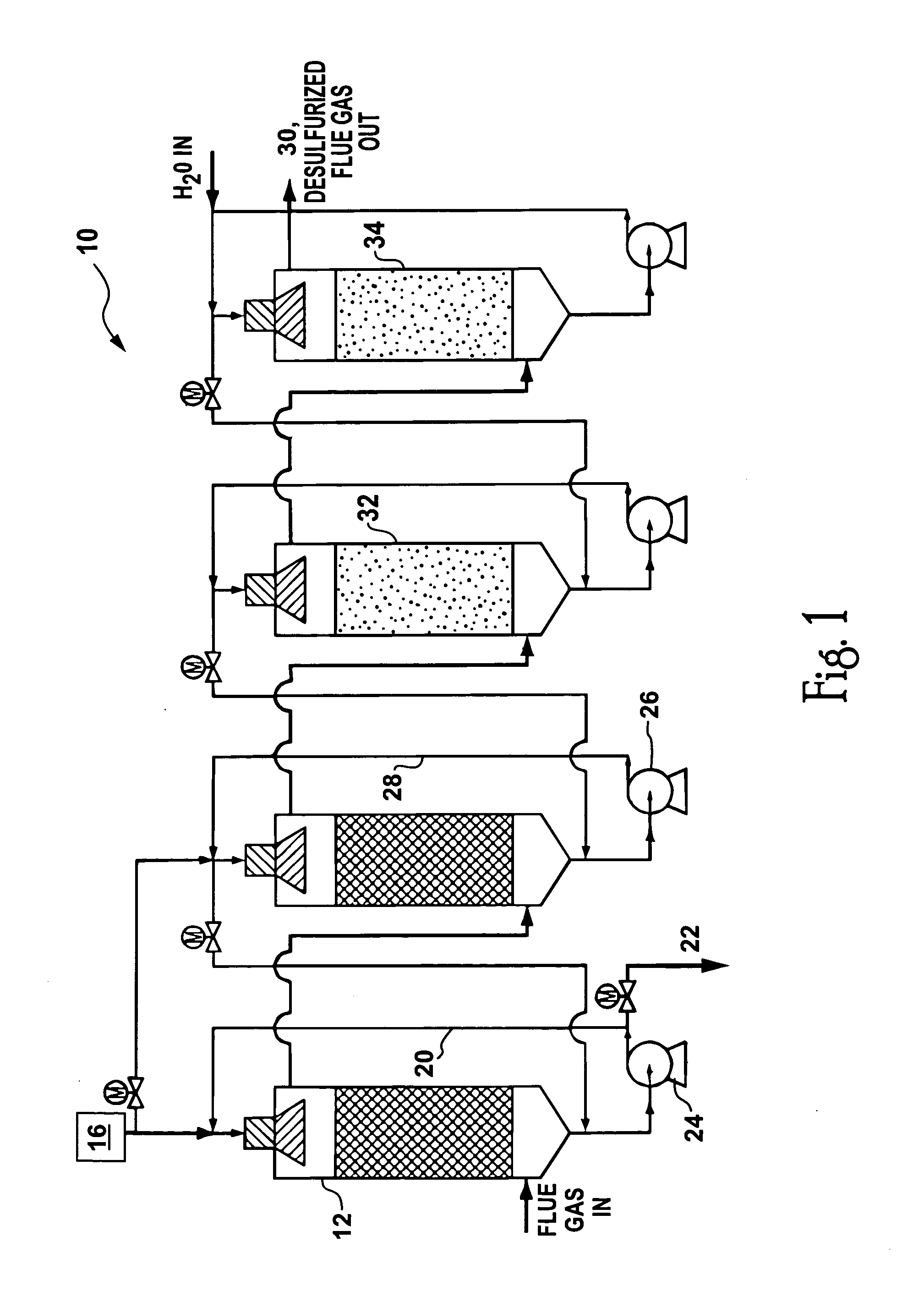

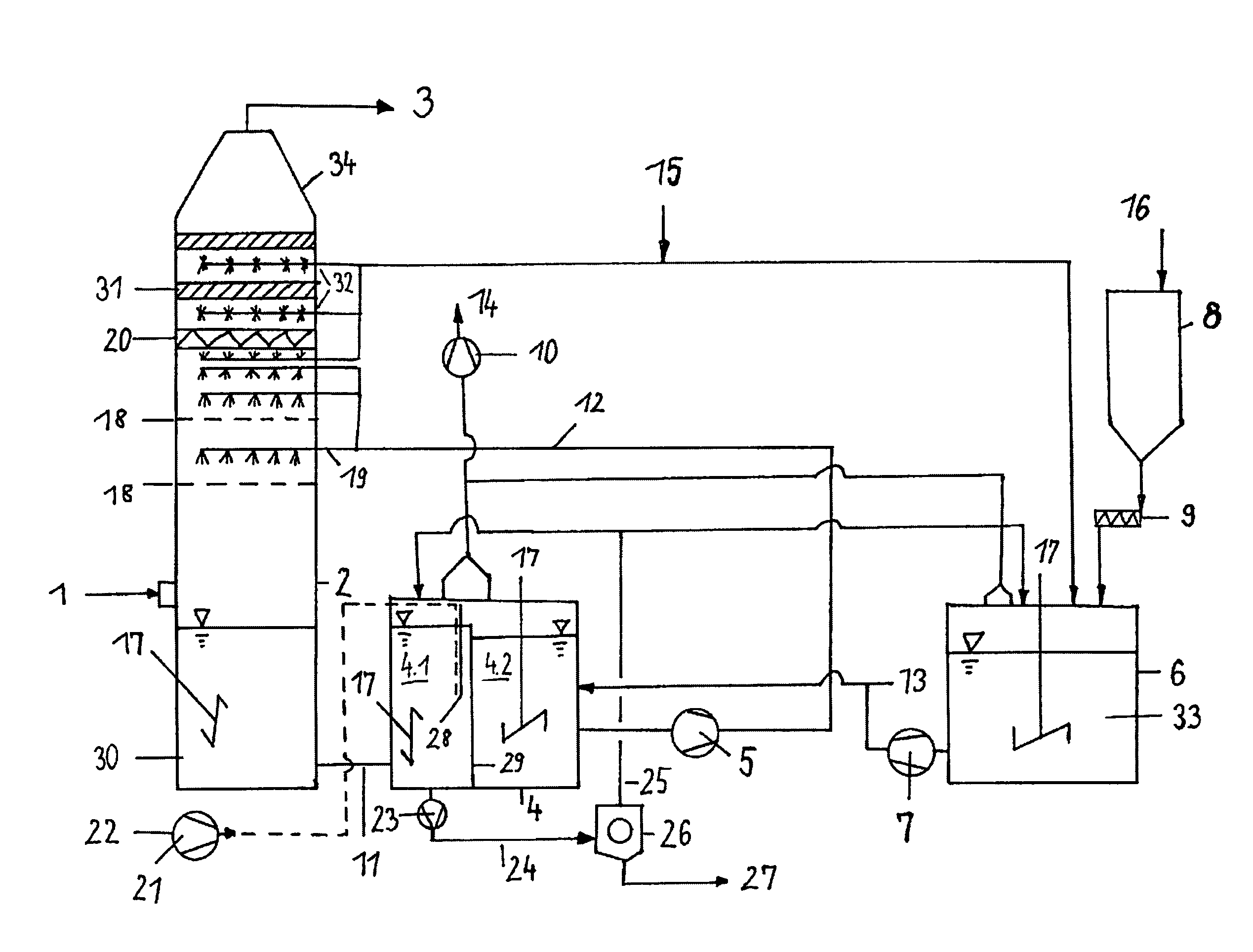

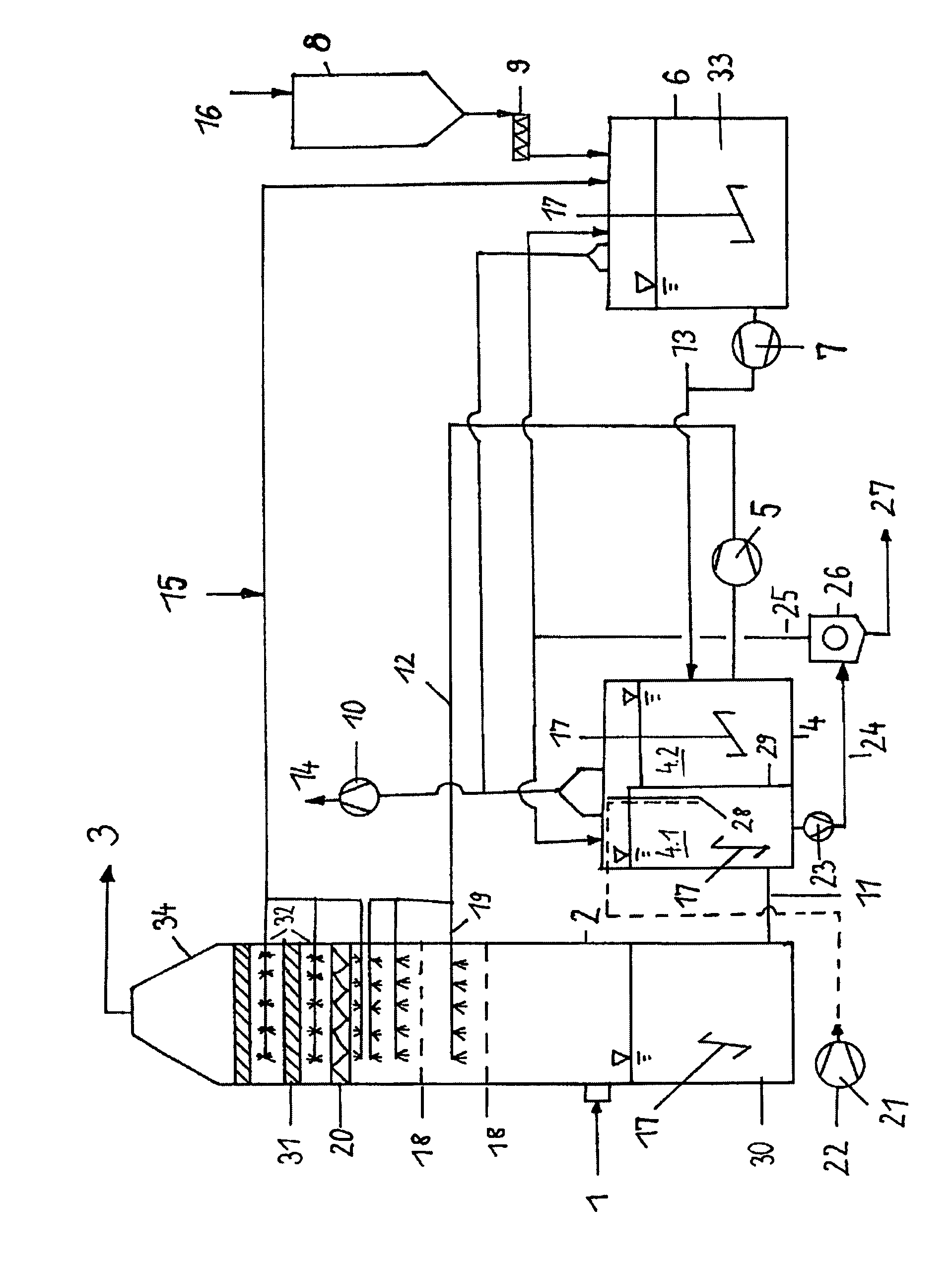

System and method for purification of flue gases

ActiveUS8337790B2Cost advantageAccelerated precipitationCombination devicesGas treatmentPower stationFlue gas

A method and system for purifying flue gases from power plants fired with fossil fuels has an absorber with at least one contact installation level arranged in an upper region, impinged with a suspension, and flowed through by untreated gas. The lower region has an absorption suspension sump, above which the inflow for the untreated gas is disposed. A separate reaction container includes two chambers separated by a partition wall with an overflow. The first chamber is connected with the sump, receives oxidation air, and has in a lower region an opening for discharging suspension. The second chamber is connected with a lime / limestone suspension container. A gas exhaust hood above the reaction container draws exhaust vapors into an exhaust vapor hood. A line for absorption suspension extends between at least one spraying level of the absorber and the reaction container, and a process water feed lies above the spraying level.

Owner:BABCOCK NOELL GMBH

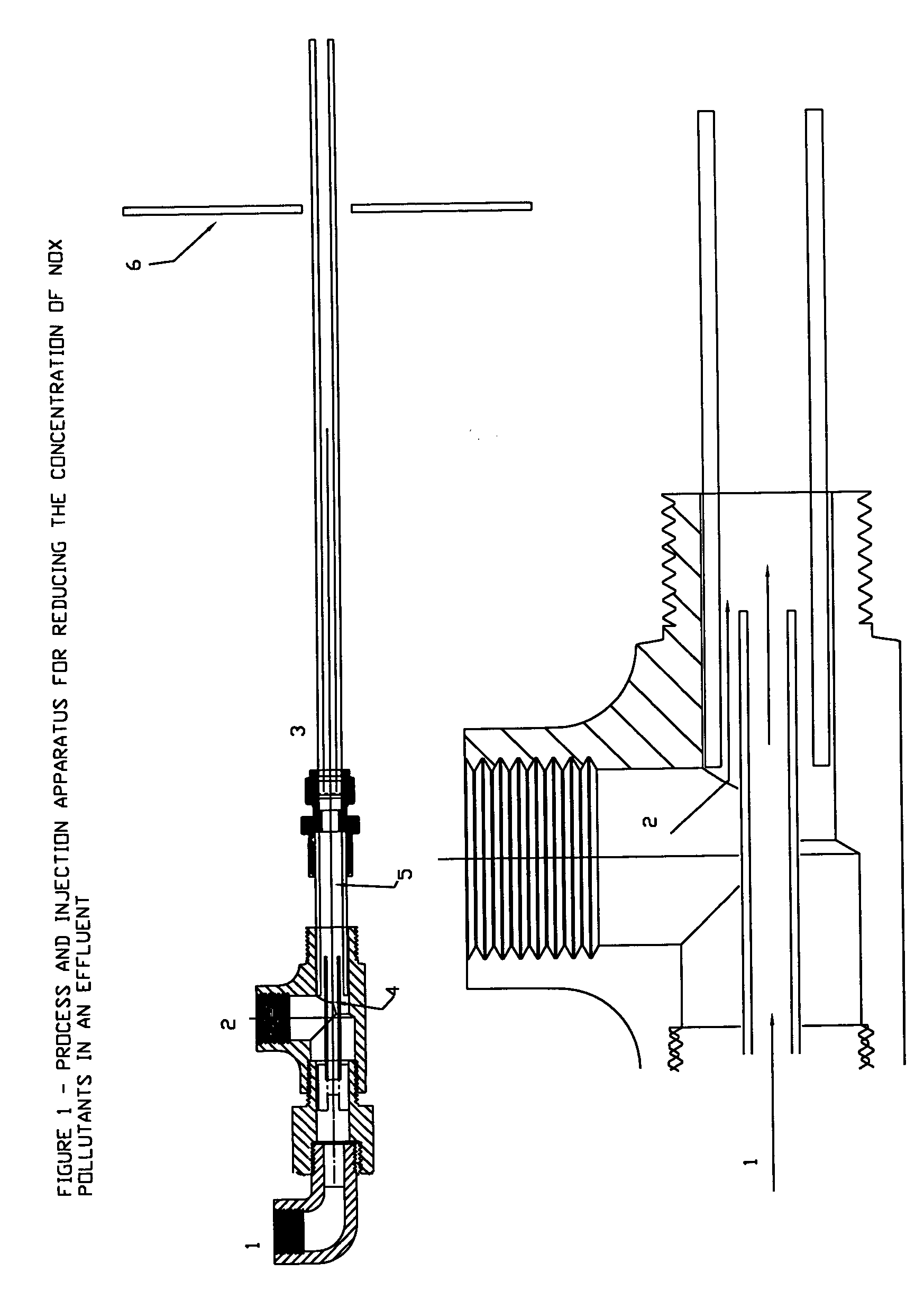

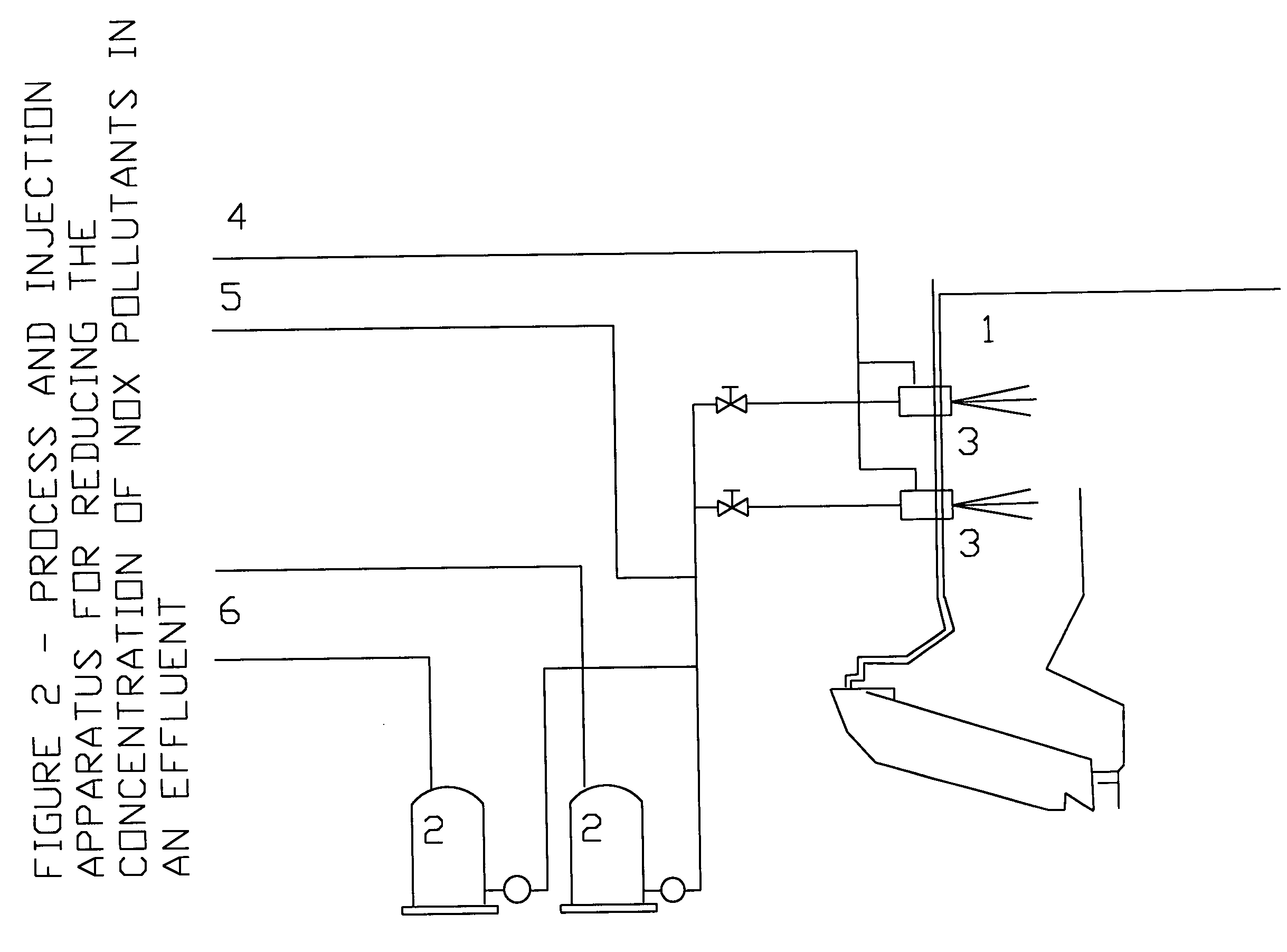

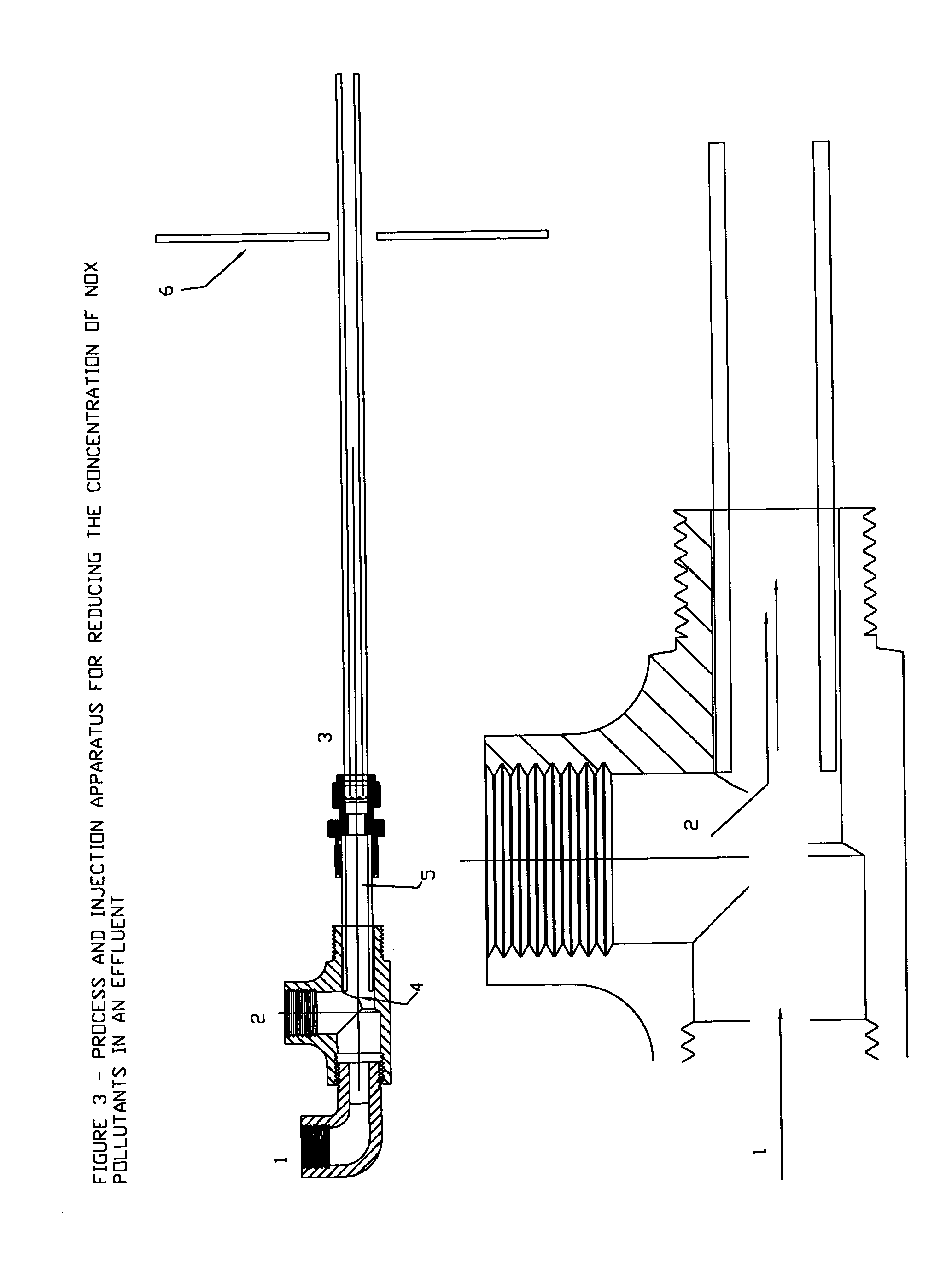

Process and injection apparatus for reducing the concentration of NOX pollutants in an effluent

InactiveUS20050074383A1Improve performanceSimple processNitrogen compoundsEmission preventionCombustionPower station

This invention relates to pollution control requirements for fossil fuel burning facilities, such as power plants, incinerators and cement kilns, and more particularity, to improved methods of atomizing an SNCR reagent into the combustion effluent therof.

Owner:WOJICHOWSKI DAVID LEE

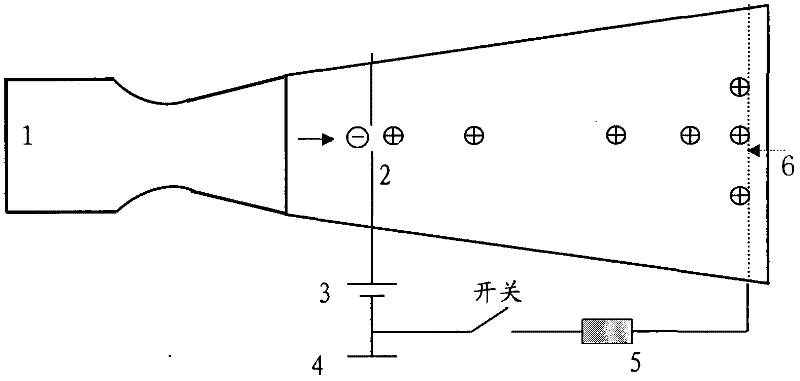

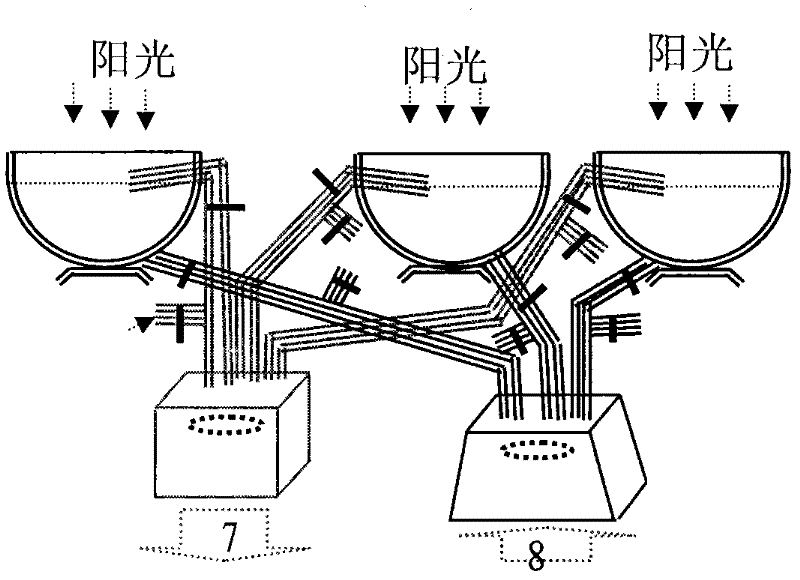

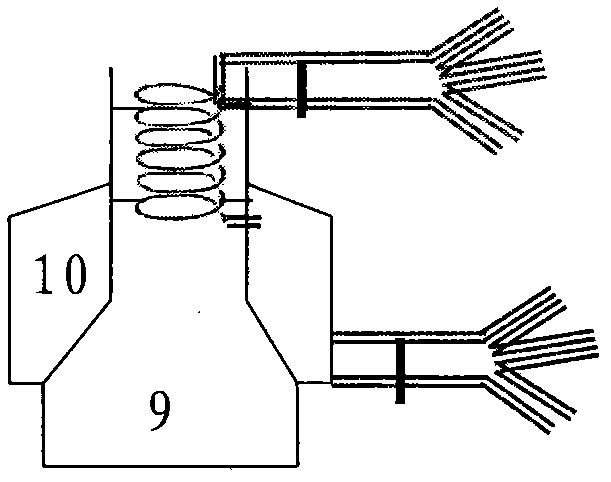

Magnetic fluid power generation device

The invention relates to a magnetic fluid power generation device, which is composed of a solar reflector, an air inlet pipe, an air injection chamber, an ionization chamber, a power generation channel, a recovery chamber, an exhaust pipe, a permanent magnet, a power transmission system and a storage battery pack, wherein a fossil fuel combustion chamber is added additionally. The ionization chamber is provided with two pairs of positive and negative reverse high-voltage discharging rods, the power generation channel is provided with a collection baffle, the reflector is composed of a hemispheric concave mirror and a small cylinder and provided with an automatic steering device for tracking light, the air injection chamber is provided with an air inlet pump and a tourmaline net, and the recovery chamber is provided with an exhaust pump. Working medium xenon absorbs heat in the reflector to rise to a high temperature to be input in the air inlet pipe, is accelerated through the air injection chamber, rubs with the tourmaline net to be ionized, and is sprayed in the ionization chamber to encounter a cross strong electric field to generate electric corona, all of the gas is almost ionized, generated plasma gas enters the power generation channel and is affected by Lorentz force to have deflection, positive and negative charged particles are respectively concentrated on the collection baffle and a negative plate to form a positive pole and a negative pole of a generator, electric power is led out, and rated alternating current is output after voltage stabilization and inversion. Two poles of the generator are in parallel connection with the storage battery pack to be charged or discharged mutually. The magnetic fluid power generation device has the advantages of utilizing light energy and heat energy, converting the light energy and the heat energy into electric energy, and obtaining high power generation efficiency.

Owner:曾令伦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com