Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Flame polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire polishing, also known as flame polishing, is a method of polishing a material, usually glass or thermoplastics, by exposing it to a flame or heat. When the surface of the material briefly melts, surface tension smooths the surface. Operator skill is critical with this method. When done properly, flame plastic polishing produces the clearest finish, especially when polishing acrylic. This method is most applicable to flat external surfaces. Flame polishing is frequently used in acrylic plastic fabrication because of its high speed compared to abrasive methods. In this application, an oxyhydrogen torch is typically used, one reason being that the flame chemistry is unlikely to contaminate the plastic.

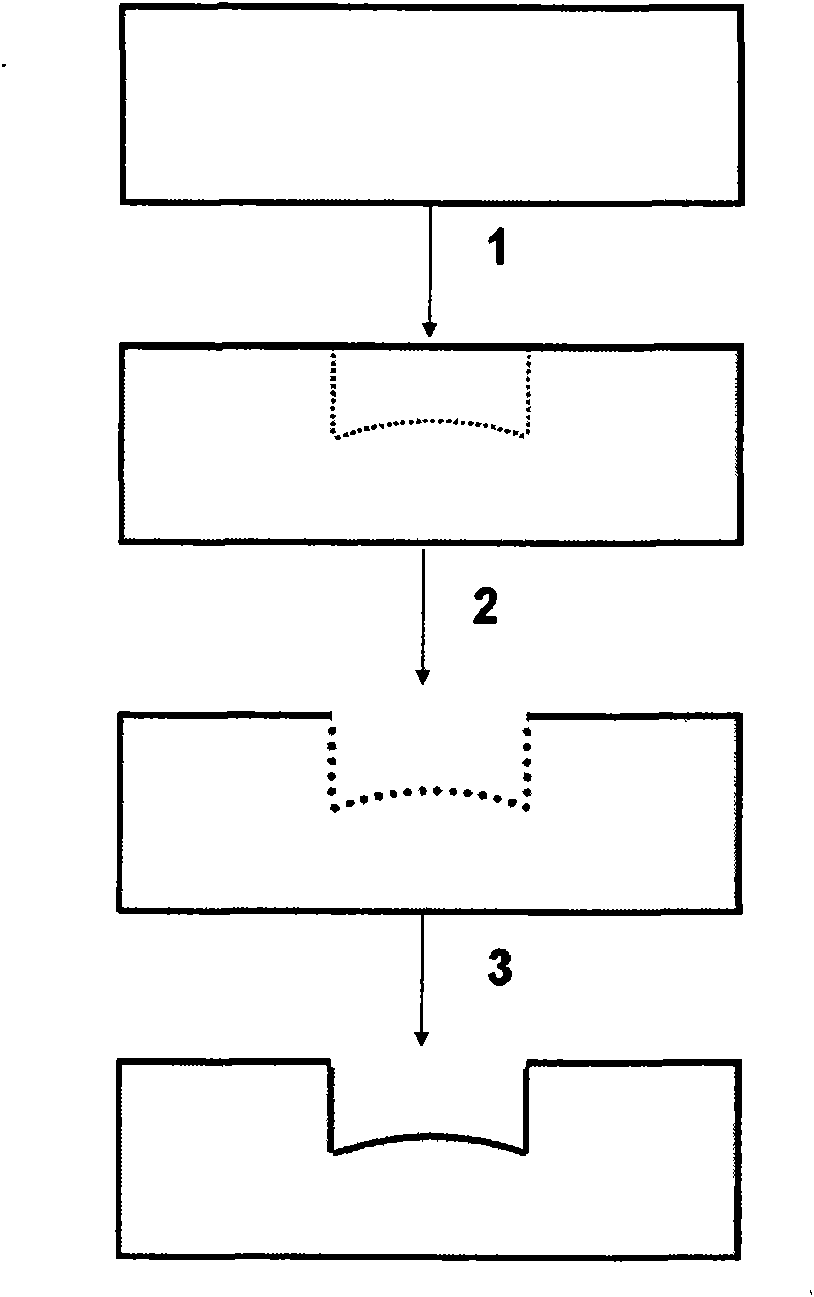

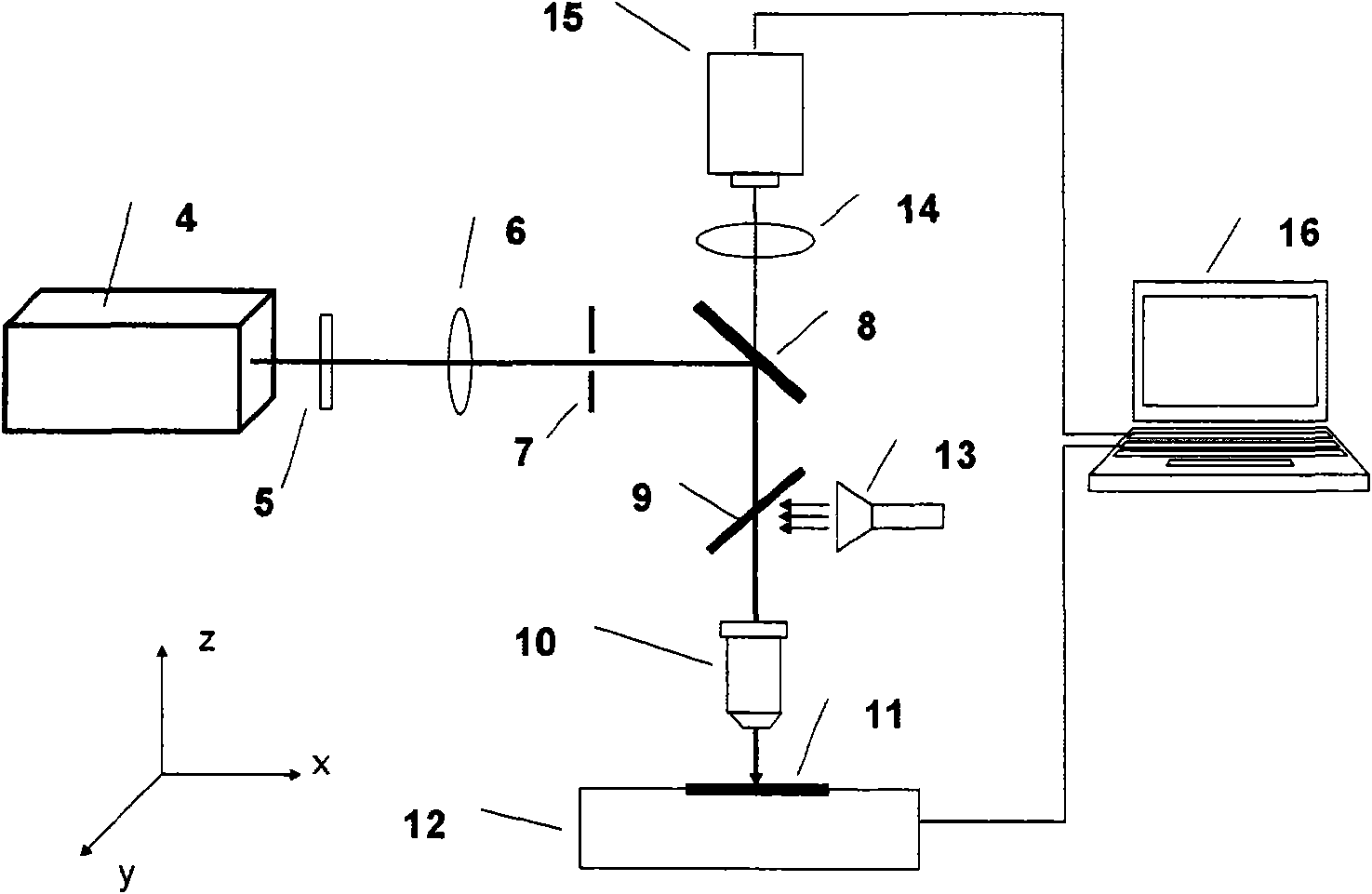

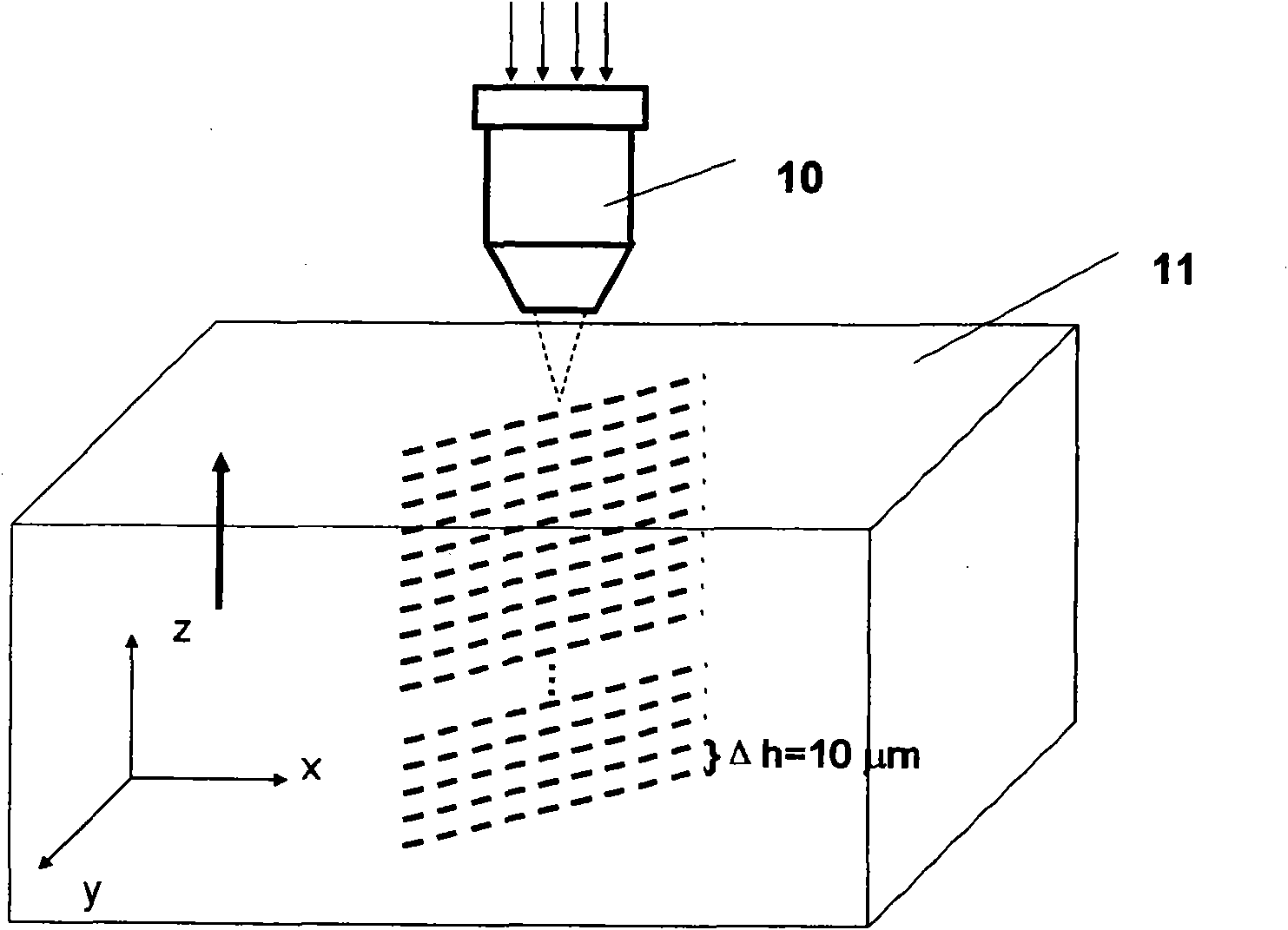

Method for preparing micro optical element on quartz glass substrate by applying femto-second laser

InactiveCN101571603AReduce thermal effectsAchieve high precision machiningPhotomechanical apparatusCleaning using liquidsChemical reactionEtching

The invention relates to a method for preparing a micro optical element on a quartz glass substrate by applying femto-second laser, which is characterized by comprising three steps of femto-second laser irradiation, chemical etching and hydrogen-oxygen flame polishing. The method can achieve processing of any surface types including a plane, a standard spherical surface, a non-spherical surface and the like; and the step of the hydrogen-oxygen flame polishing only has a generated product of water, thus the method is environment-friendly, has quick polishing, avoids physical contacts and chemical reactions at the same time, and solves the difficulty which cannot be solved by a common polishing wheel because the high temperature of the flame can repair lattice damages caused by micro-machining.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

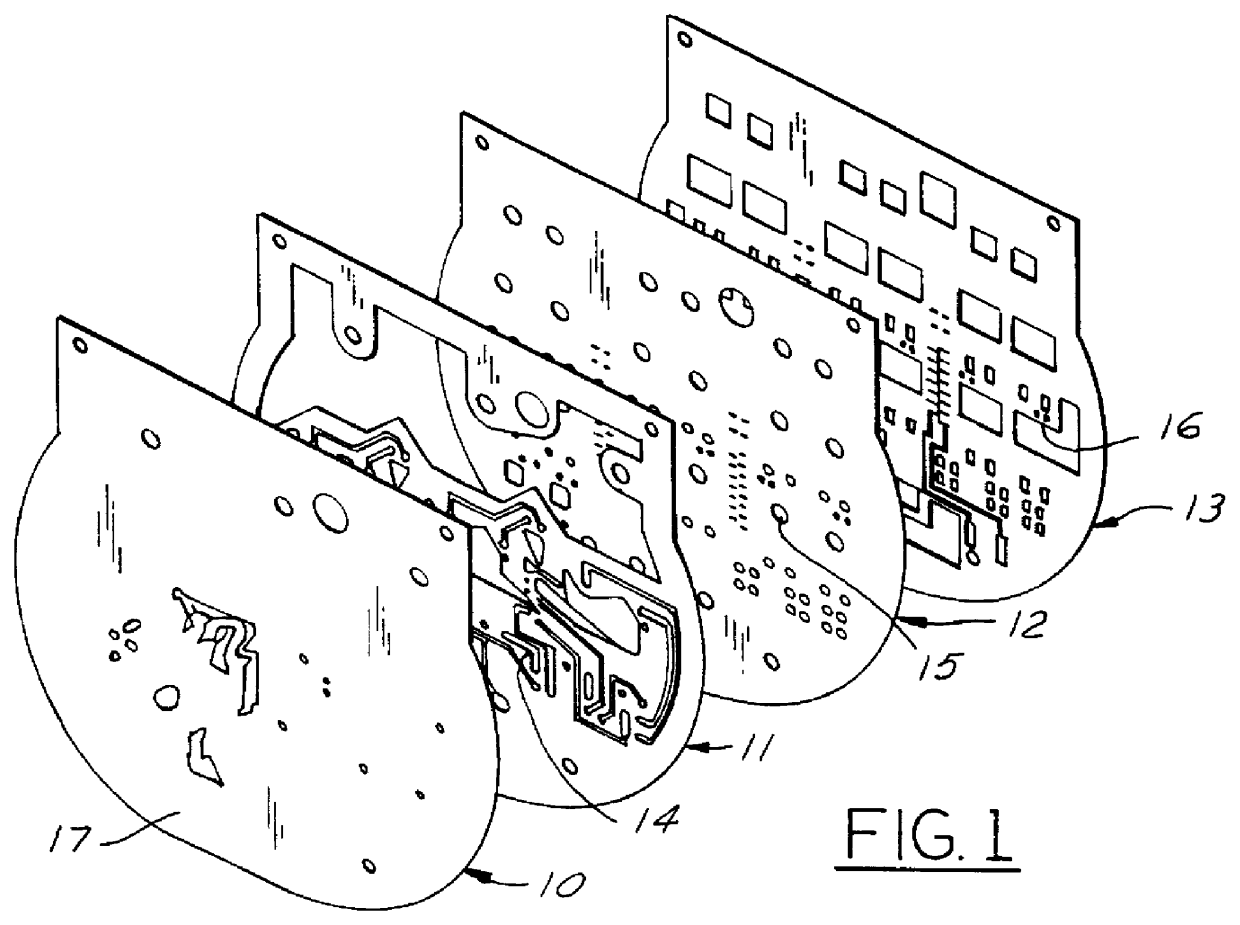

Making and using thermal spray masks carrying thermoset epoxy coating

Method of making a mask assembly by providing a heat resistance mask substrate having an exposed surface with a surface smoothness less than 2000 micro inches, uniformly spraying a thermoset epoxy organic coating onto such exposed surface in one or more layers to provide a coating having (e.g., a thickness equal to or less than about 0.005 inches), a smoothness characterized by an average profilometer reading (Ra) of no greater than 1.5 micrometers, said coating being devoid of pores that exceed about 0003 inch in size, and flame polishing all or a portion of such coating to effect a surface finish of about 1.0 micrometers. A mask assembly which is useful in masking areas from thermal spray particles, comprising a heat resistance substrate presenting an exposed grit blasted surface having a smoothness of less than 2000, and a thin thermoset epoxy coating bonded to said exposed surface and having a surface smoothness characterized by an average profilometer reading (Ra) no greater than 1.5.

Owner:FORD GLOBAL TECH LLC

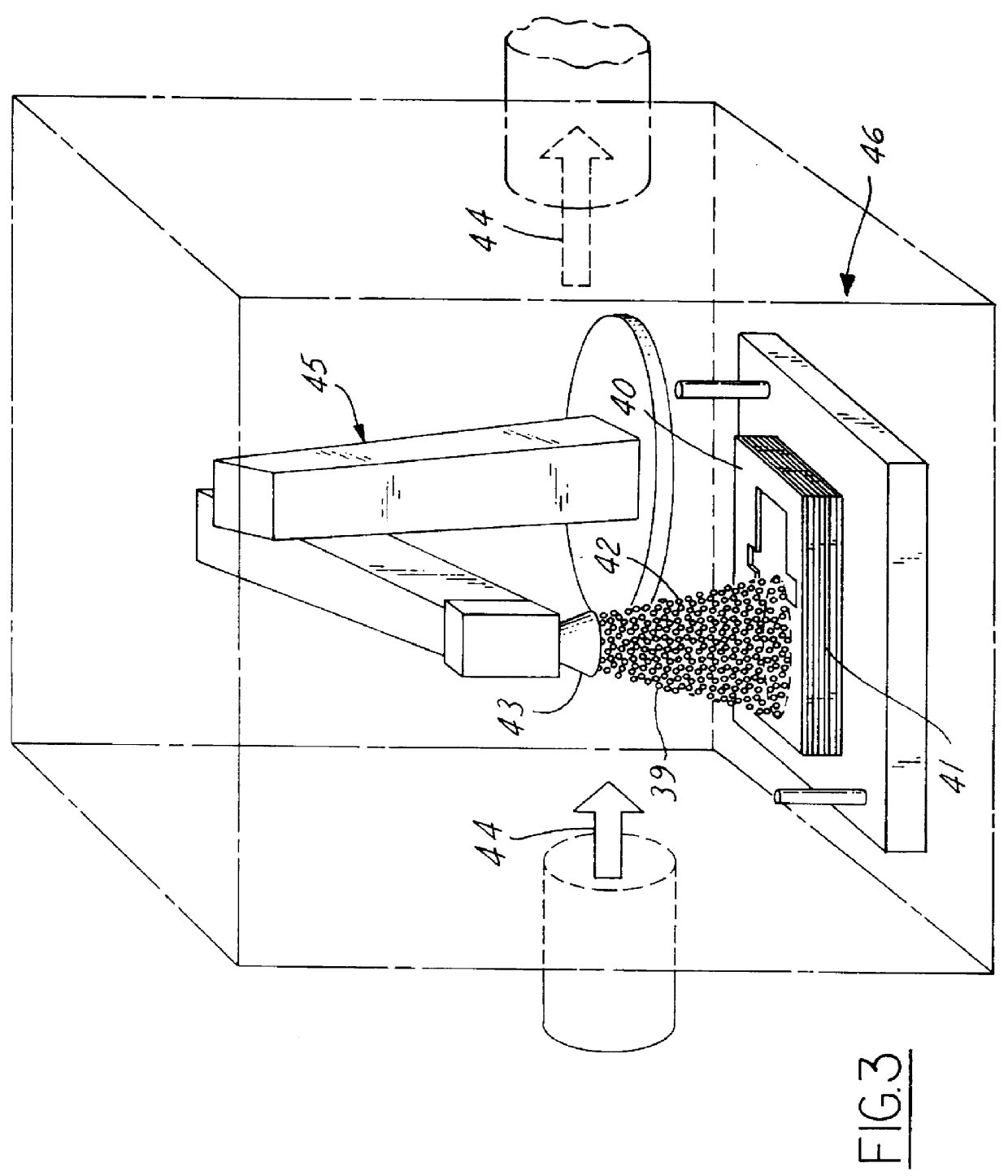

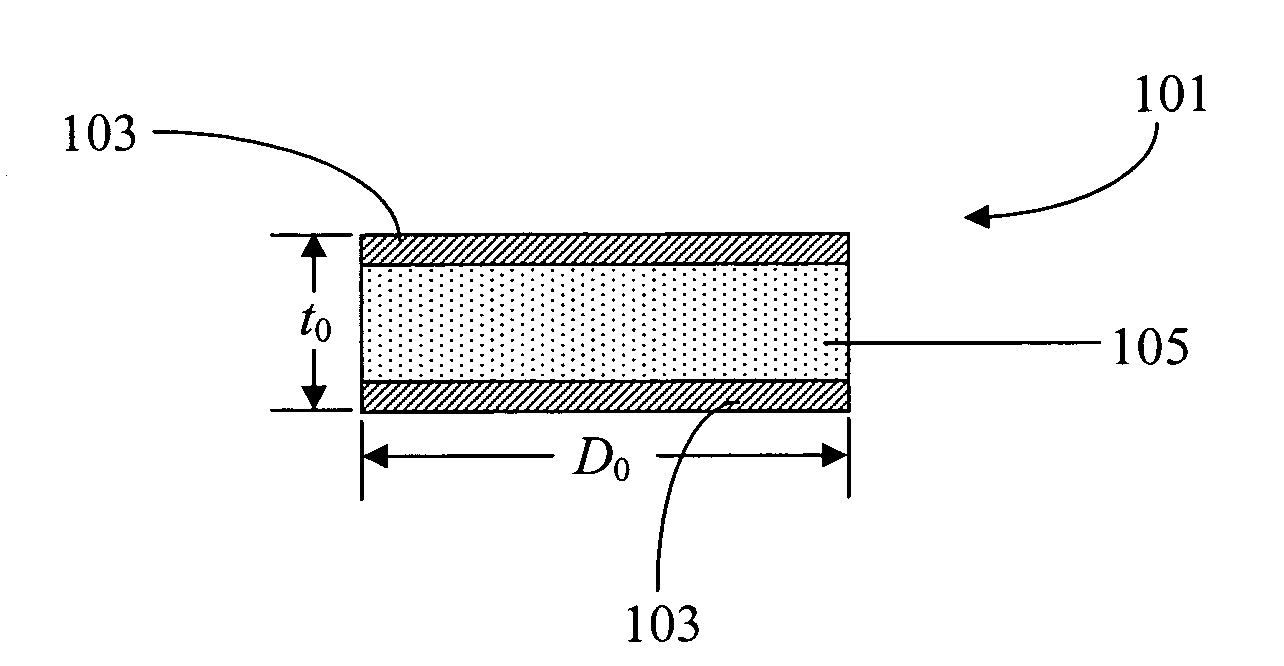

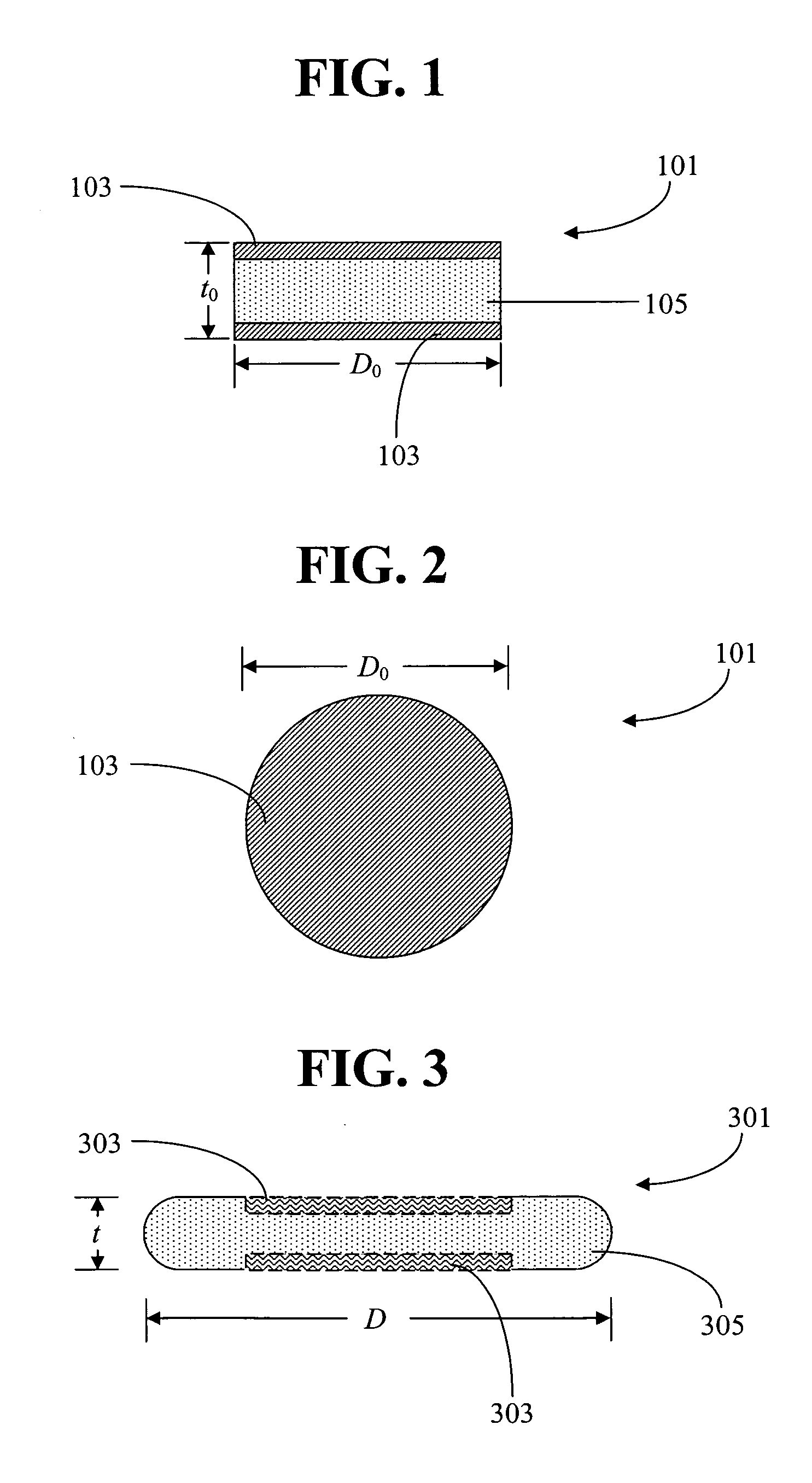

Process for making low-OH glass articles and low-OH optical resonator

InactiveUS20050044893A1Lower levelReduce defectsLaser detailsGlass shaping apparatusProduct gasHelical resonator

Disclosed are optical resonators having low OH content in at least the near-surface region and a process for making low OH glass article by chlorine treatment of consolidated glass of the article. Cl2 gas was used to remove OH from depth as deep as 350 μm from the surface of the consolidated glass. The process can be used for treating flame-polished preformed optical resonator disks. A new process involving hot pressing or thermal reflowing for making planar optical resonator disks without the use of flame polishing is also disclosed.

Owner:CORNING INC

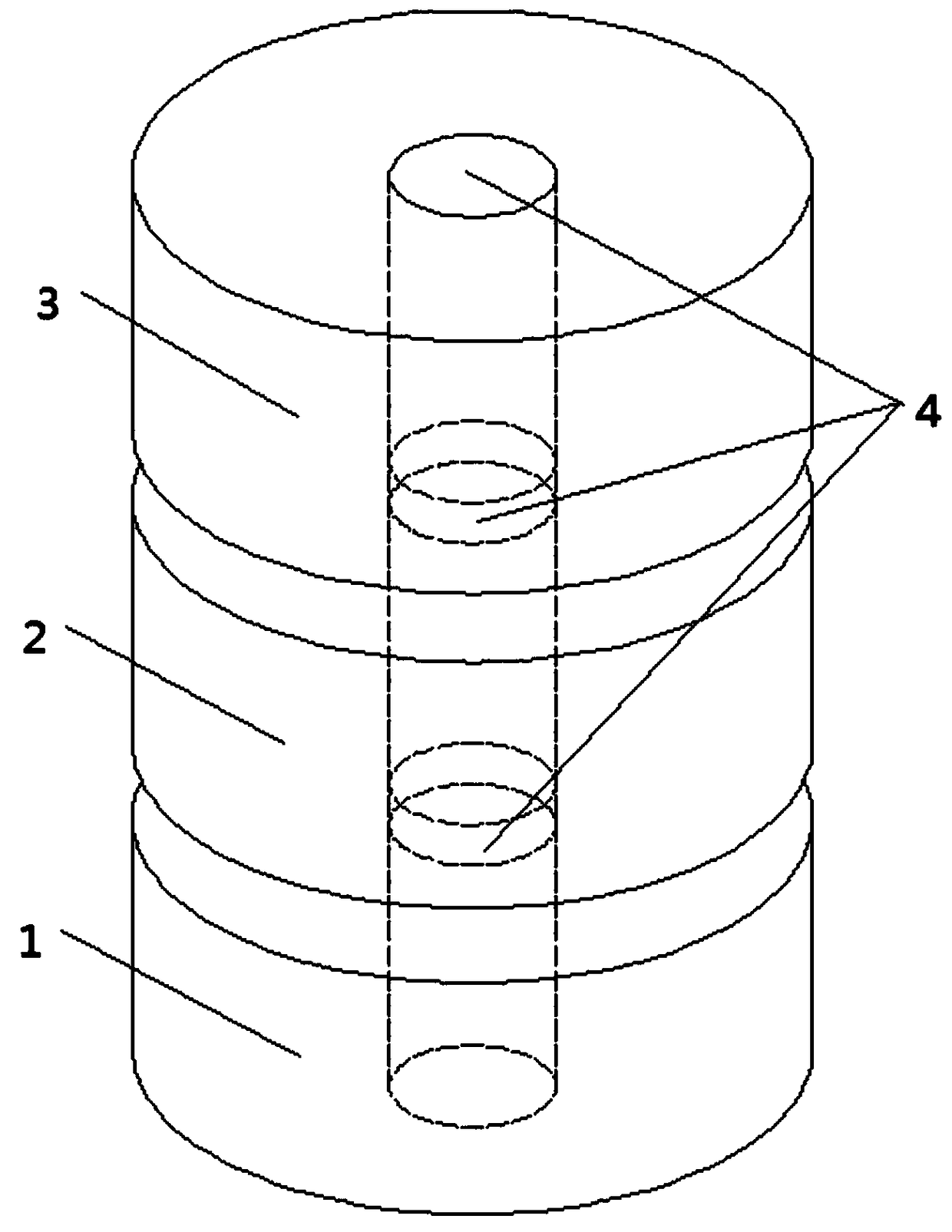

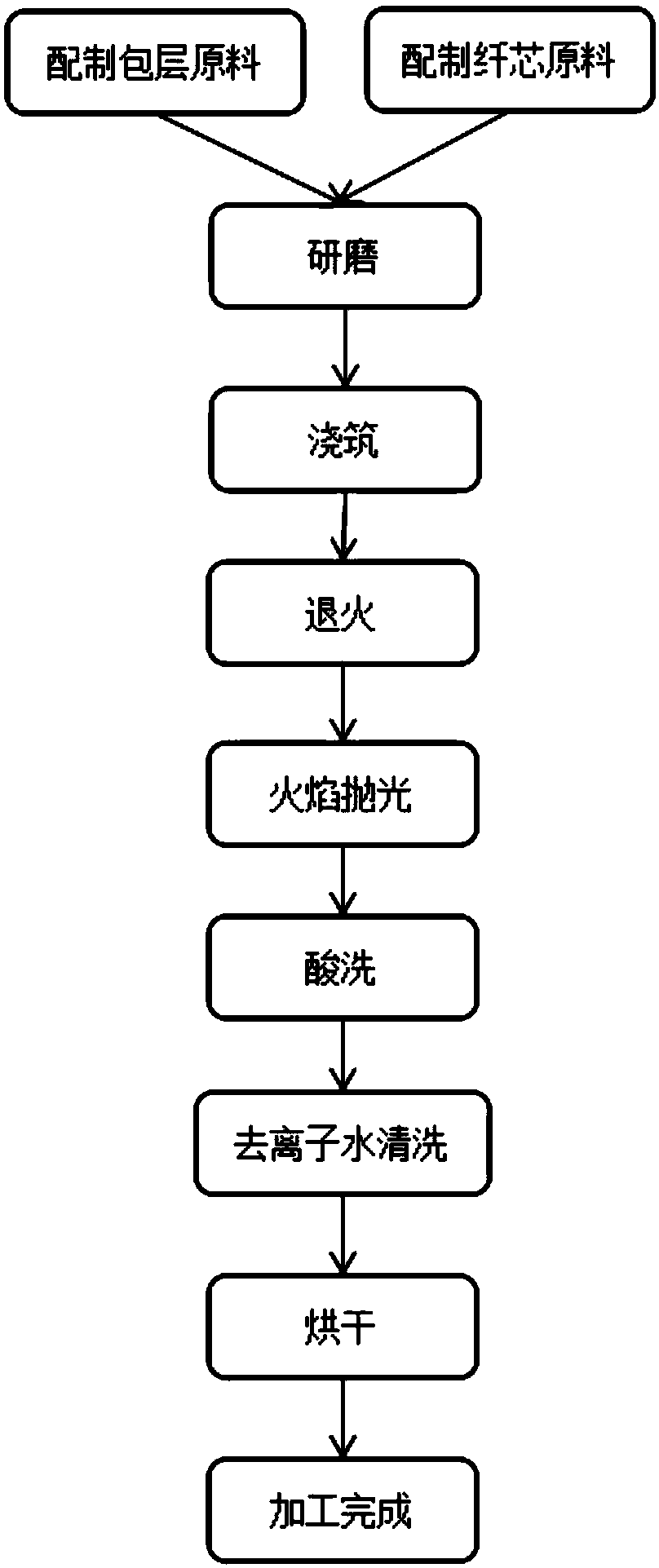

Preparation method for optical fiber preform

InactiveCN109320063AGood chemical stabilityImprove thermal stabilityGlass making apparatusFiberMaterials science

The invention provides a preparation method for an optical fiber preform. The preparation method is characterized by comprising the steps of preparing a cladding and a fiber core, and specifically comprises the steps that (1) raw materials of the cladding and raw materials of the fiber core are prepared; (2) the raw materials of the cladding and the fiber core are ground in an agate mortar and areeach put into a corundum crucible with a cover, after melting is carried out in an electric furnace, cladding molten glass is poured into a preheated copper film, and protective gas is introduced into a hollow glass tube; (3) fiber core molten glass is poured into the glass tube of the cladding, and pouring is carried out so as to form an optical fiber preform body; (4) the poured optical fiber preform together with a mold is clamped and drawn into the electric furnace for annealing treatment, and after annealing treatment is finished, natural cooling is carried out to reach room temperature;and (5) the optical fiber preform body is taken out for flame polishing, then mixed hydrofluoric acid and nitric acid are added for acid pickling, washing is repeatedly carried out with deionized water, and drying is carried out so as to obtain the processed optical fiber preform. According to the preparation method, fiber breaking is not liable to occur for an optical fiber drawing tower wire after the wire drawing process, and the fiber breaking rate in the disc dividing process is relatively low.

Owner:JIANGSU STERLITE TONGGUANG FIBER

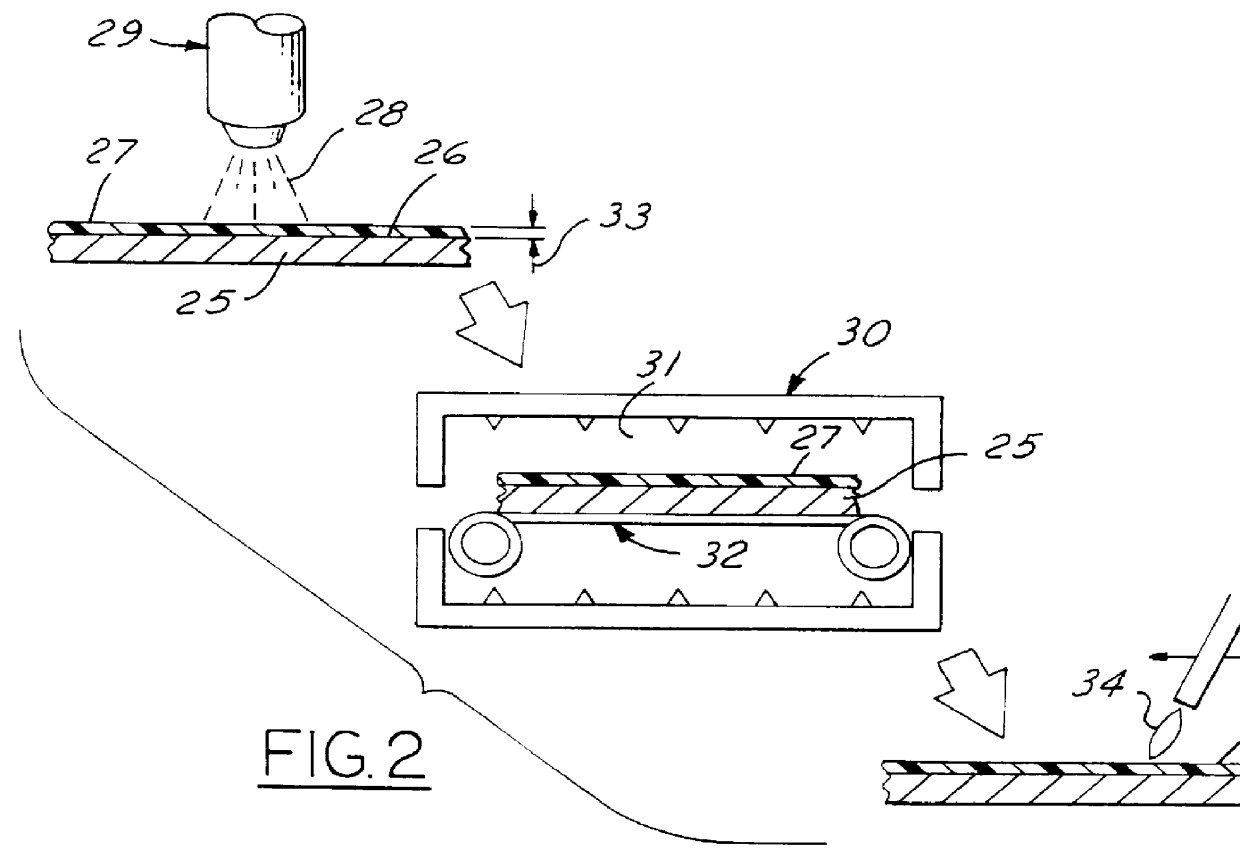

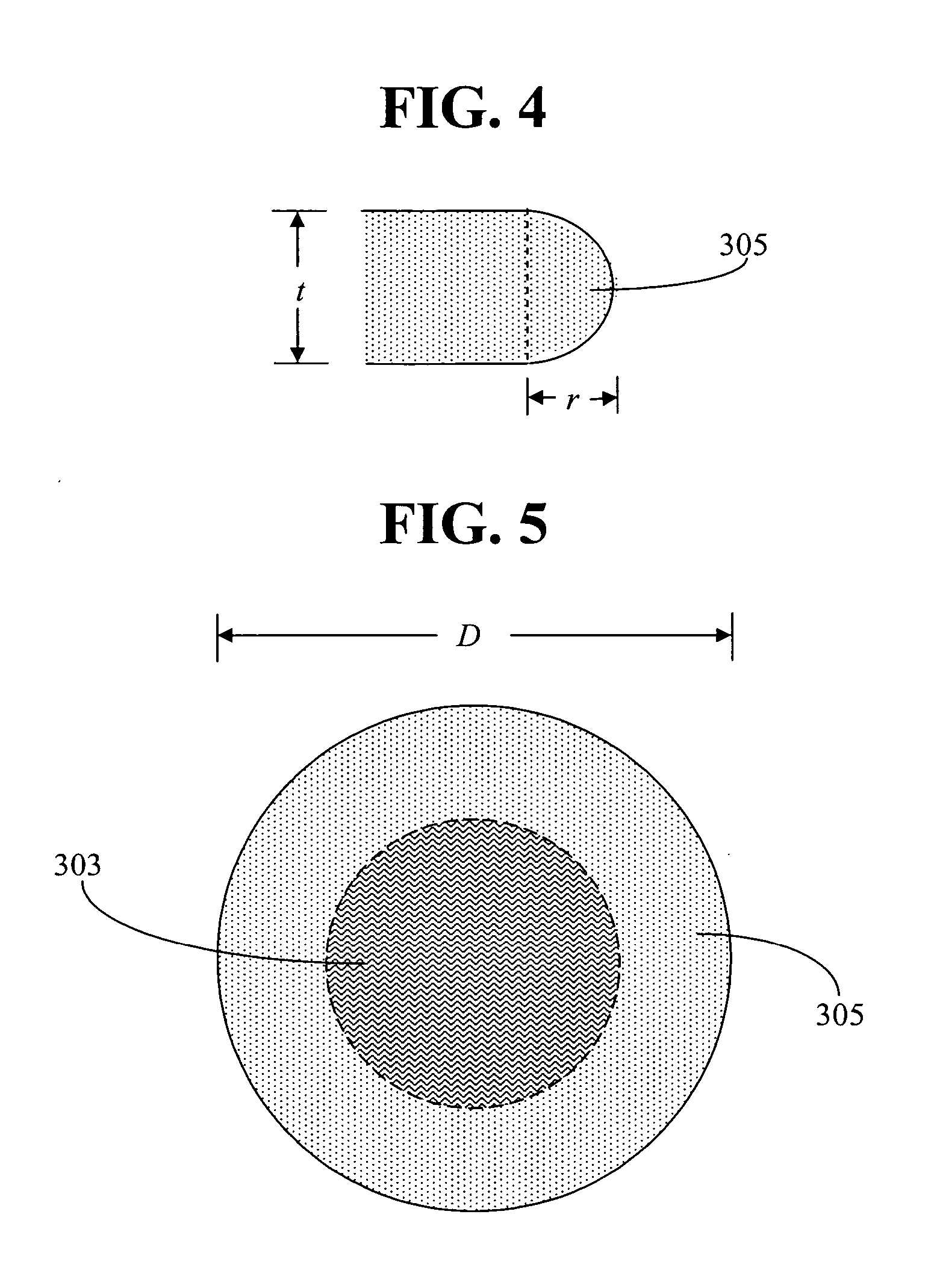

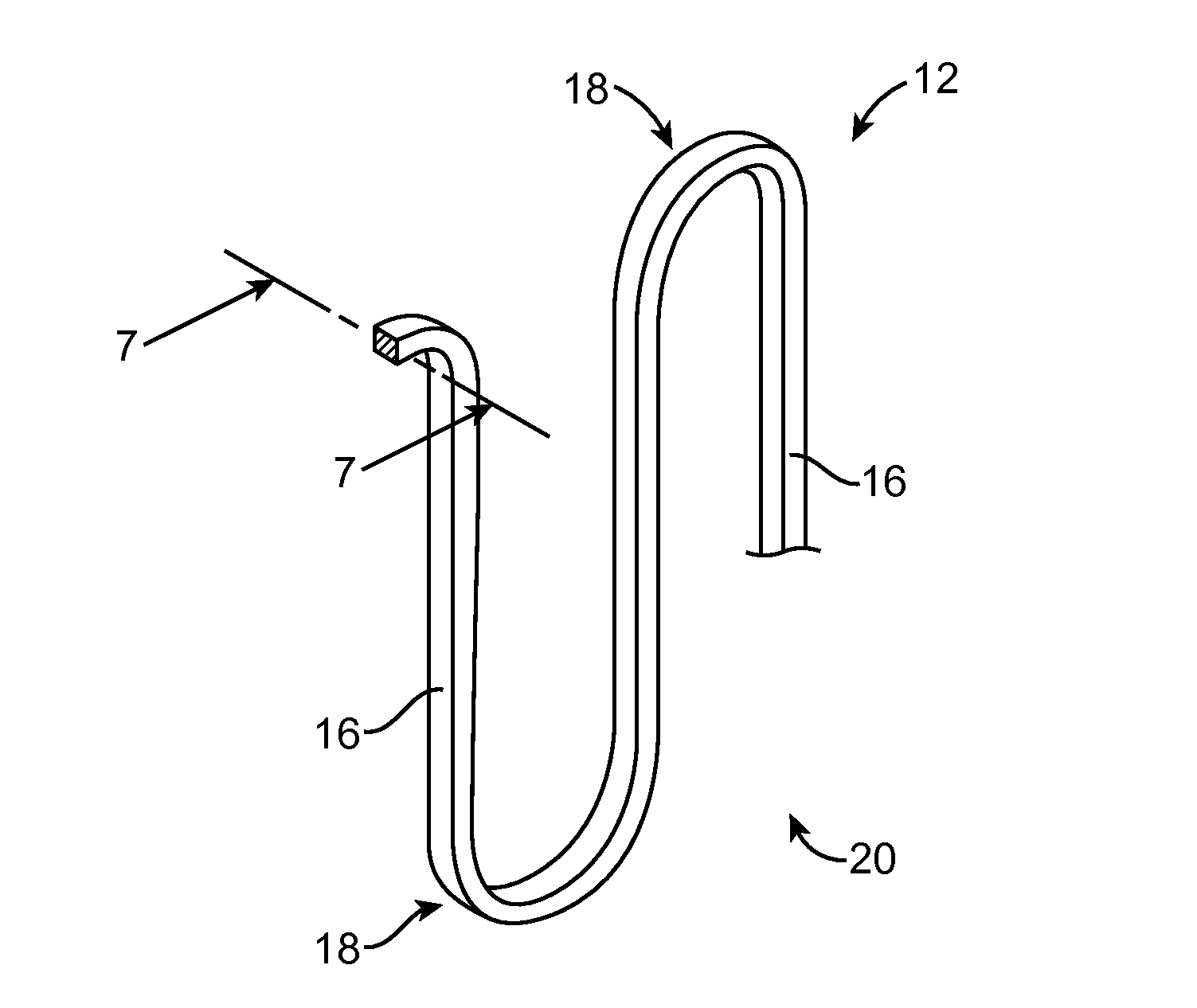

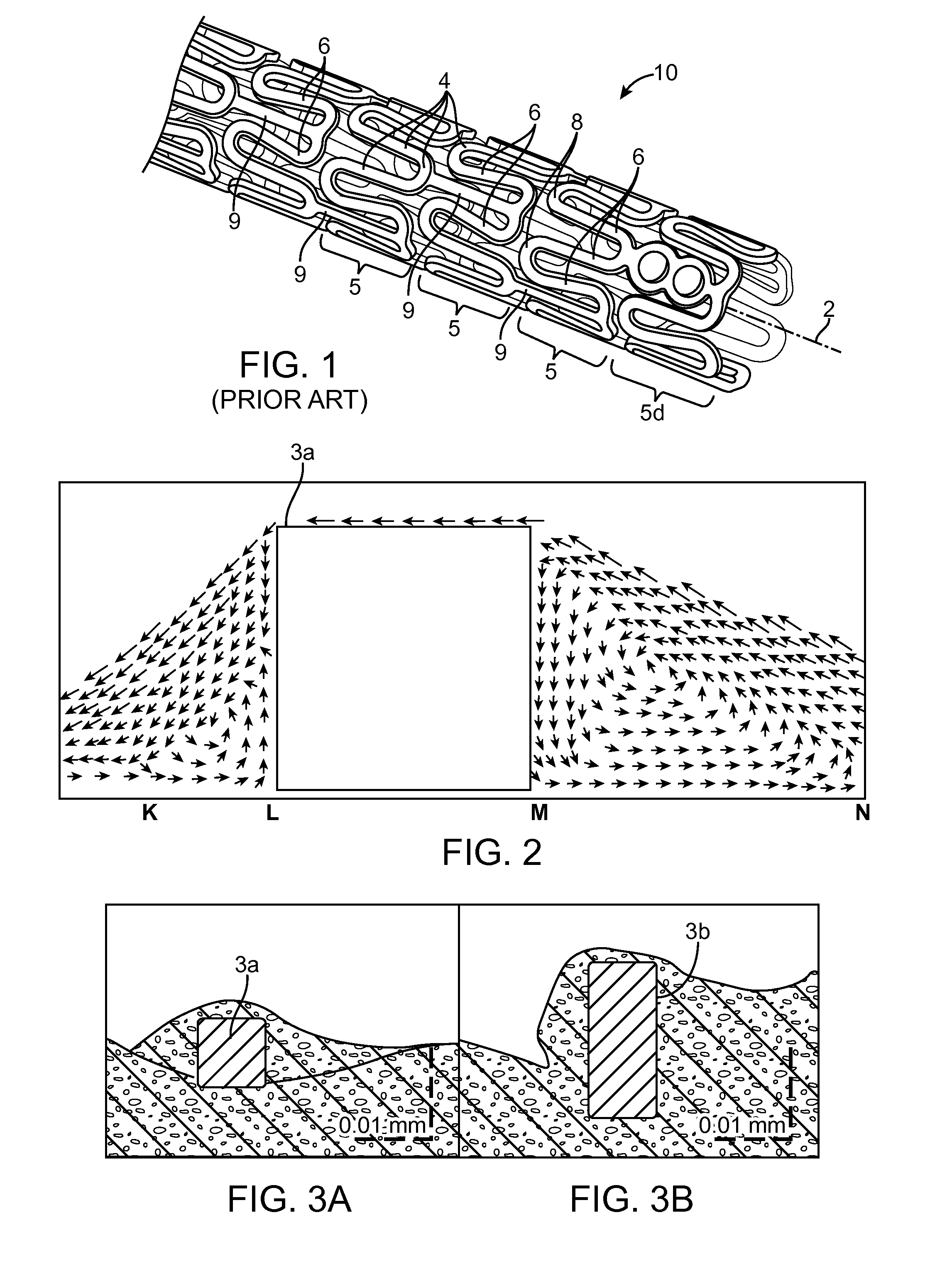

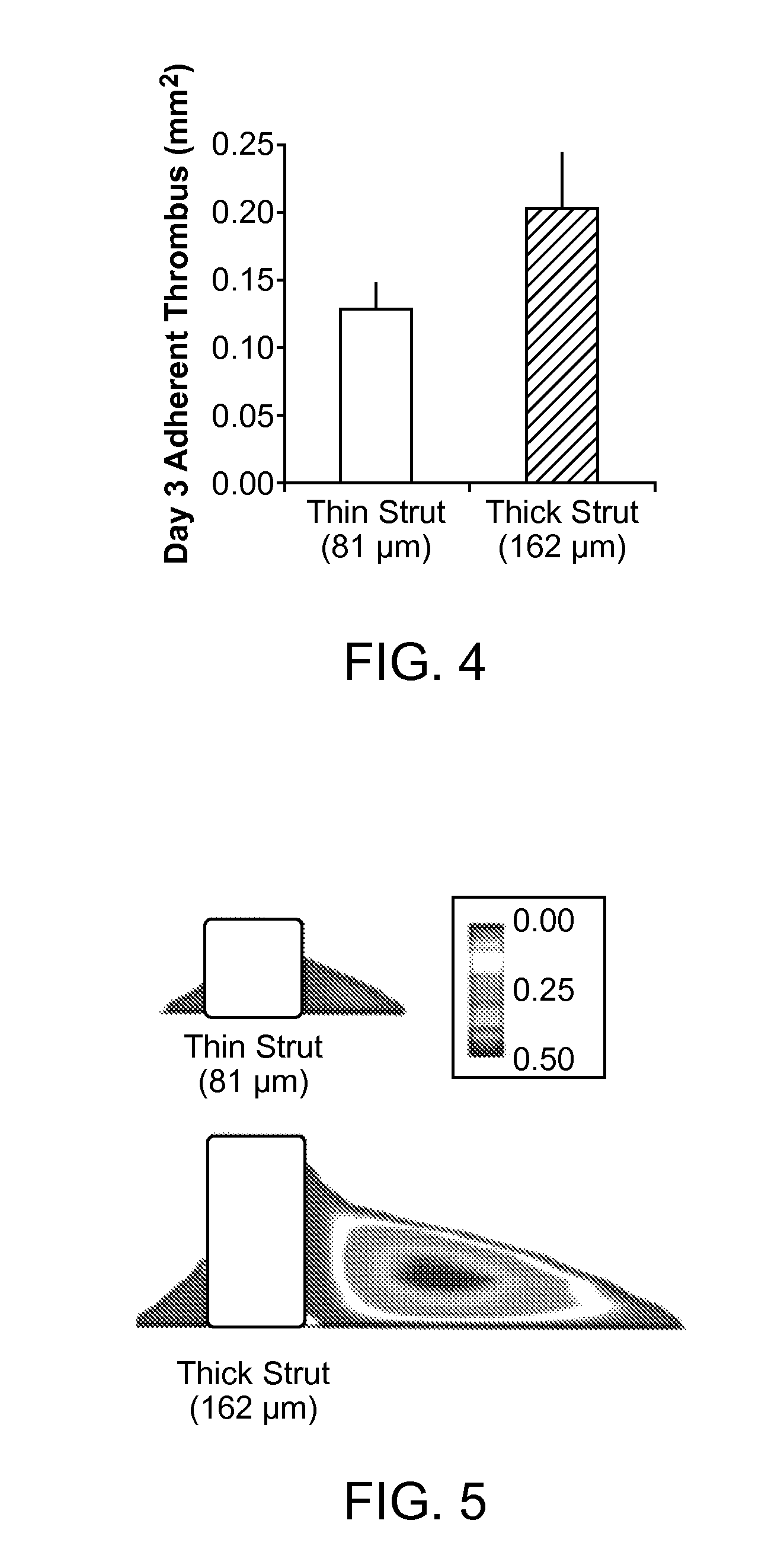

Scaffold having a shaped strut and methods for shaping scaffold struts

A scaffold strut is shaped to improve hemocompatibility. After laser cutting, the scaffold is placed on a work piece and its struts are shaped by flame polishing or brushing. The abluminal surfaces and luminal surfaces can have corners rounded. The strut can have a sloped surface on its luminal side without reducing strut thickness needed for strength.

Owner:ABBOTT CARDIOVASCULAR

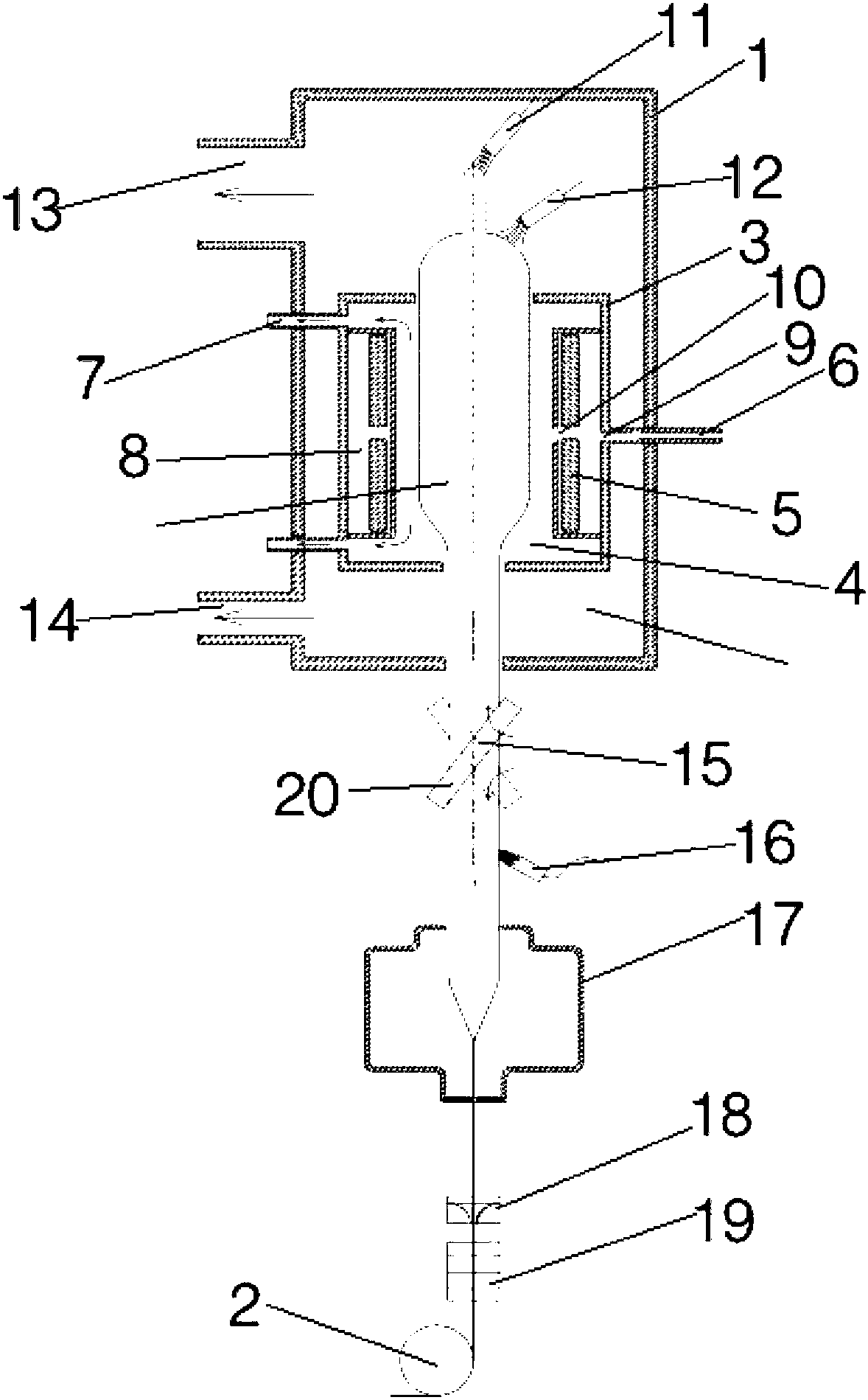

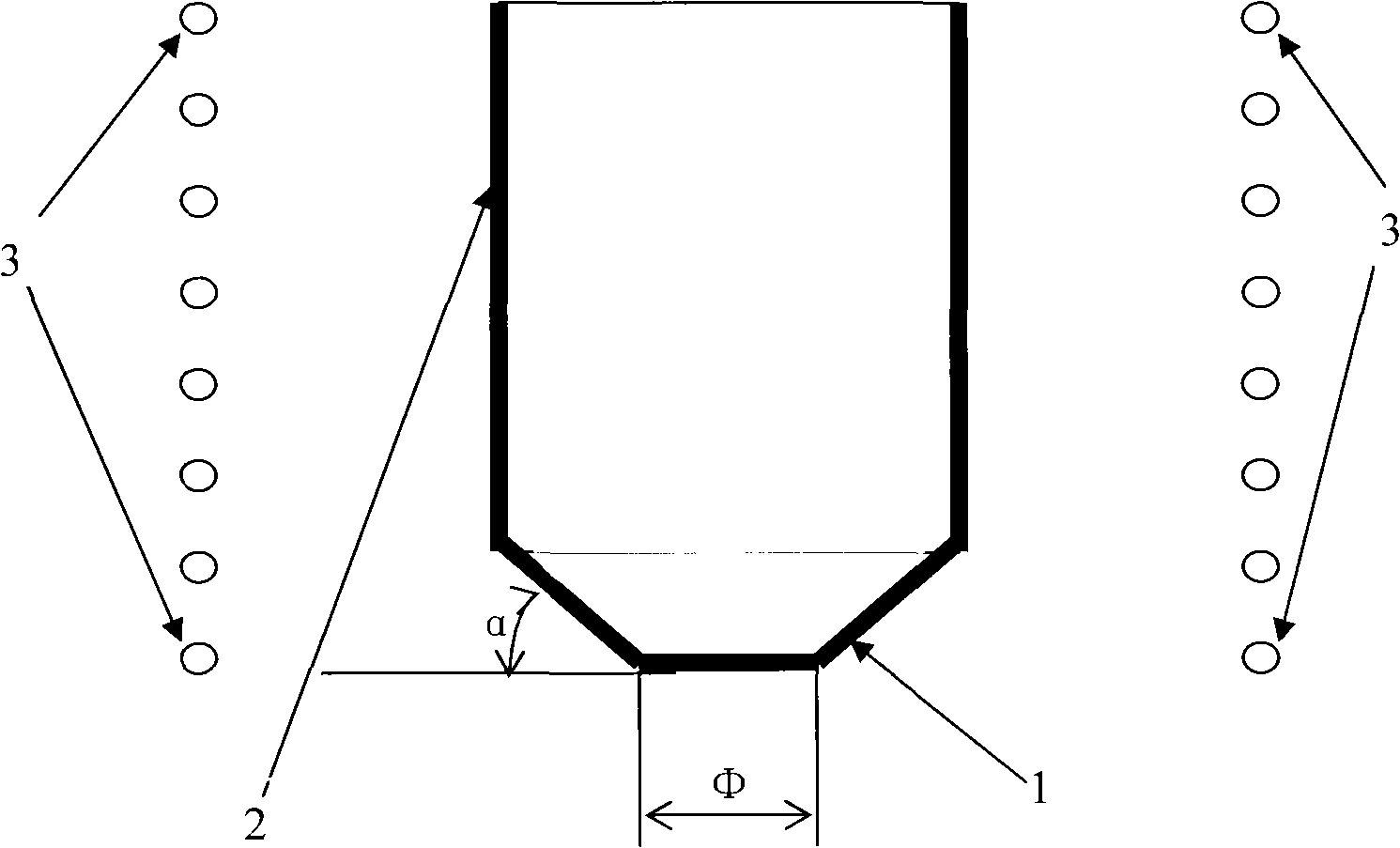

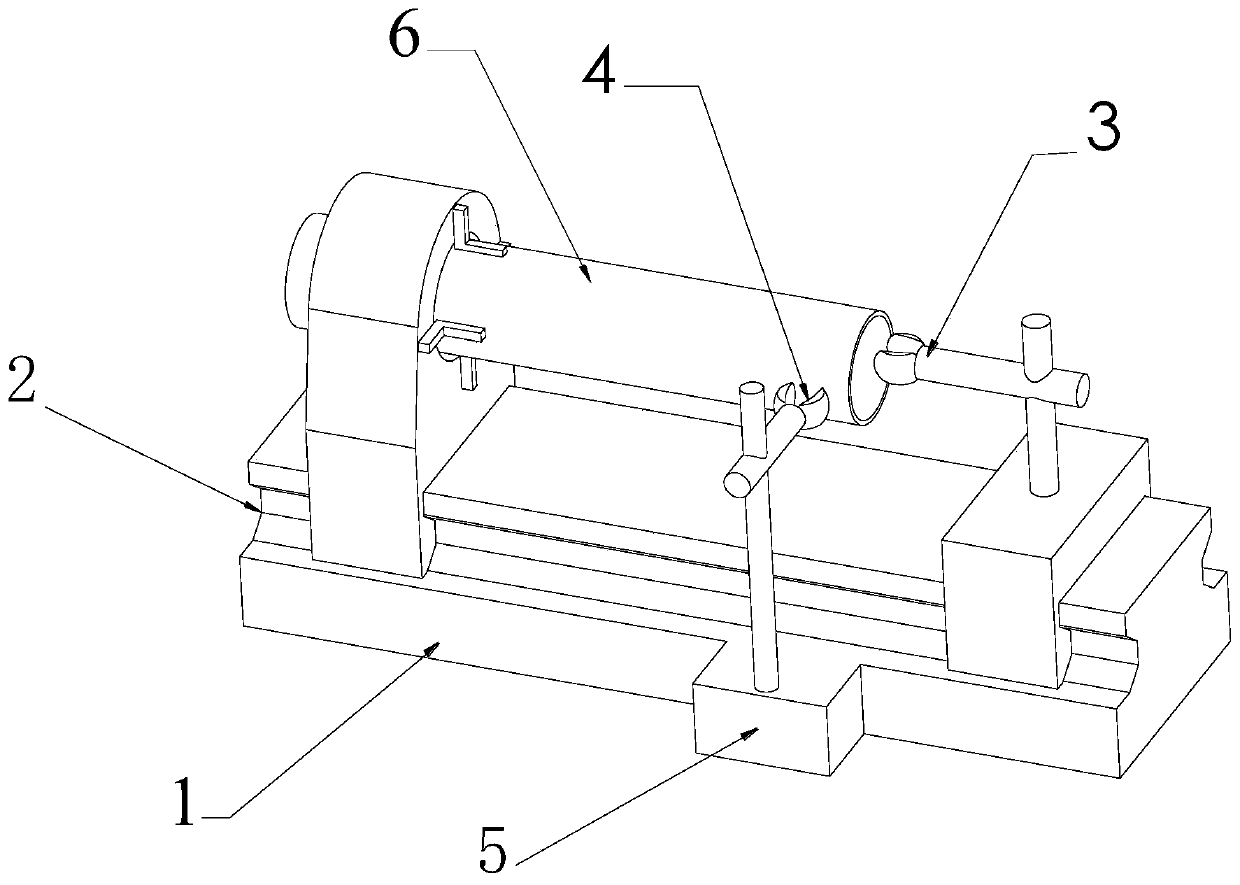

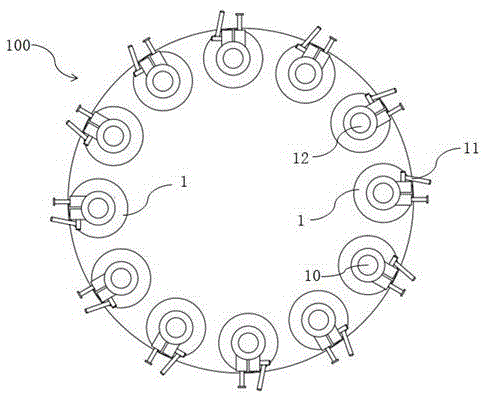

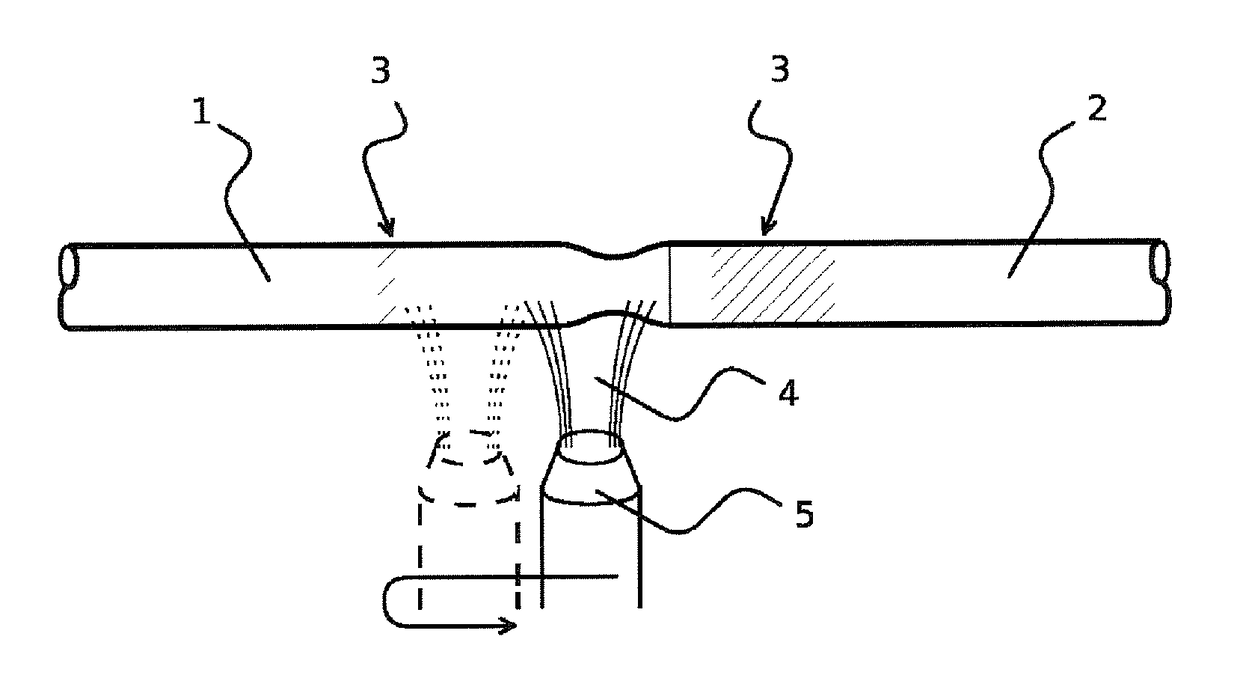

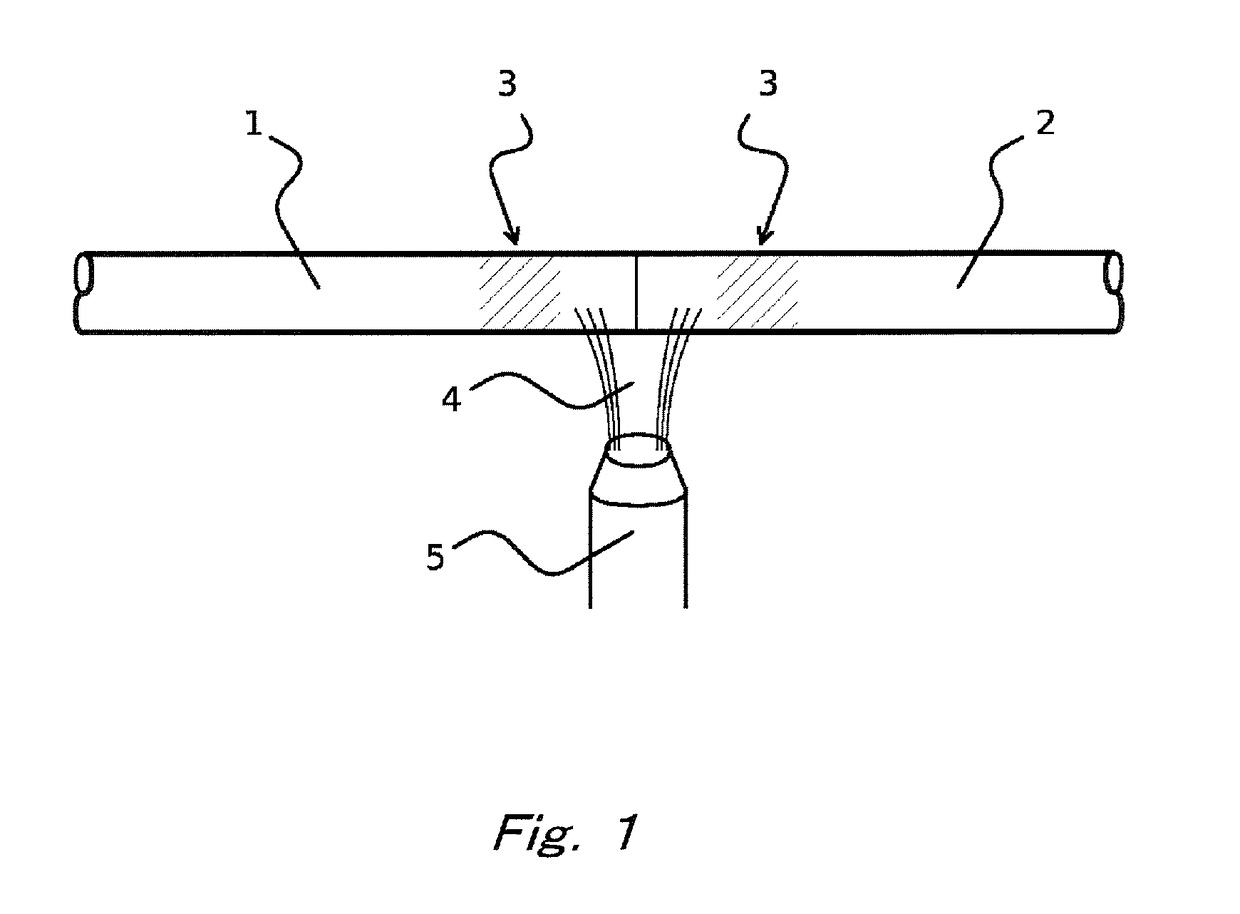

Device and method for continuously preparing optical fiber preform rods and achieving drawing

PendingCN108046582AReduce usageIncrease profitGlass fibre drawing apparatusGlass deposition burnersContinuous/uninterruptedBlow torch

The invention provides a device for continuously preparing optical fiber preform rods and achieving drawing. The device comprises a preform rod preparation unit and a drawing furnace, the preform rodpreparation unit is internally provided with a degassing sintering unit, and the degassing sintering unit comprises heating devices arranged in a degassing sintering cavity of the degassing sinteringunit; a core-layer blow torch and a covering-layer blow torch are arranged above the degassing sintering unit; the preform rod preparation unit is provided with an upper tail gas exhaust pipe, and thelower portion of a deposition chamber is correspondingly provided with a lower exhaust pipe; a driving mechanism, a flame polishing device, the drawing furnace, a coating device, a curing device anda traction wheel are sequentially arranged below the preform rod preparation unit. According to the device, by specially designing a blow torch system, a preform rod motion system and the like of theoptical fiber preform rods, the optical fiber preform rods can be continuously prepared, and meanwhile the prepared optical fiber preform rods are drawn into optical fibers online.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

Production method of profiled silex glass holding bar and apparatus

InactiveCN101289272AEliminates the annealing stepSimple processGlass forming apparatusElectric furnaceProduction rateMedium frequency

The invention discloses a method for producing a special quartz glass holding stick and a device thereof. The raw material of quartz glass is first pulled to be a special stick blank with different diameters at the two ends; the special stick blank is then processed to be a special stick which is then done with flame polishing and precise annealing. The lower part of a melting furnace used for pulling the special stick blank is provided with a tapered feeding port the side wall of which has an induced angle of 30 degrees to 40 degrees with a horizontal plane and the diameter of which is 85 mm to 90 mm. The winding density at the lower part of a medium-frequency induction heating coil of the melting furnace is higher than that of the upper part thereof and the melting furnace adopts (medium-frequency induction) graphite for heating. The method of the invention leaves out the steps of welding of the special stick and annealing after the welding, which results in simple technology and improved production efficiency; additionally, products produced by the method has uniform inner texture and high bearing strength but no joints.

Owner:BEIJING KINGLASS QUARTZ

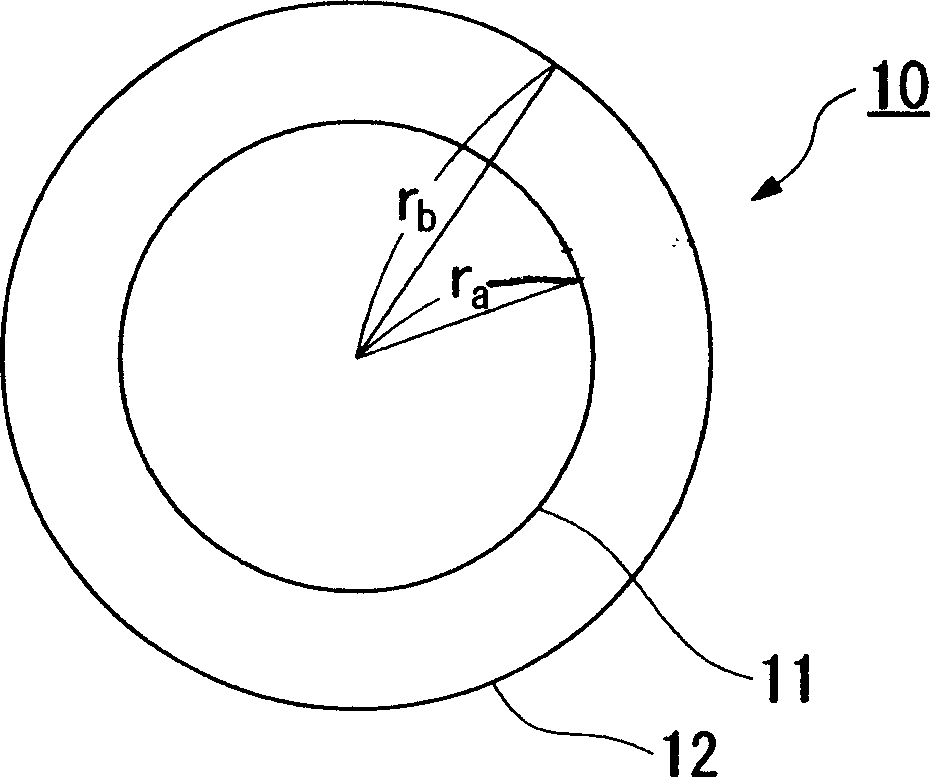

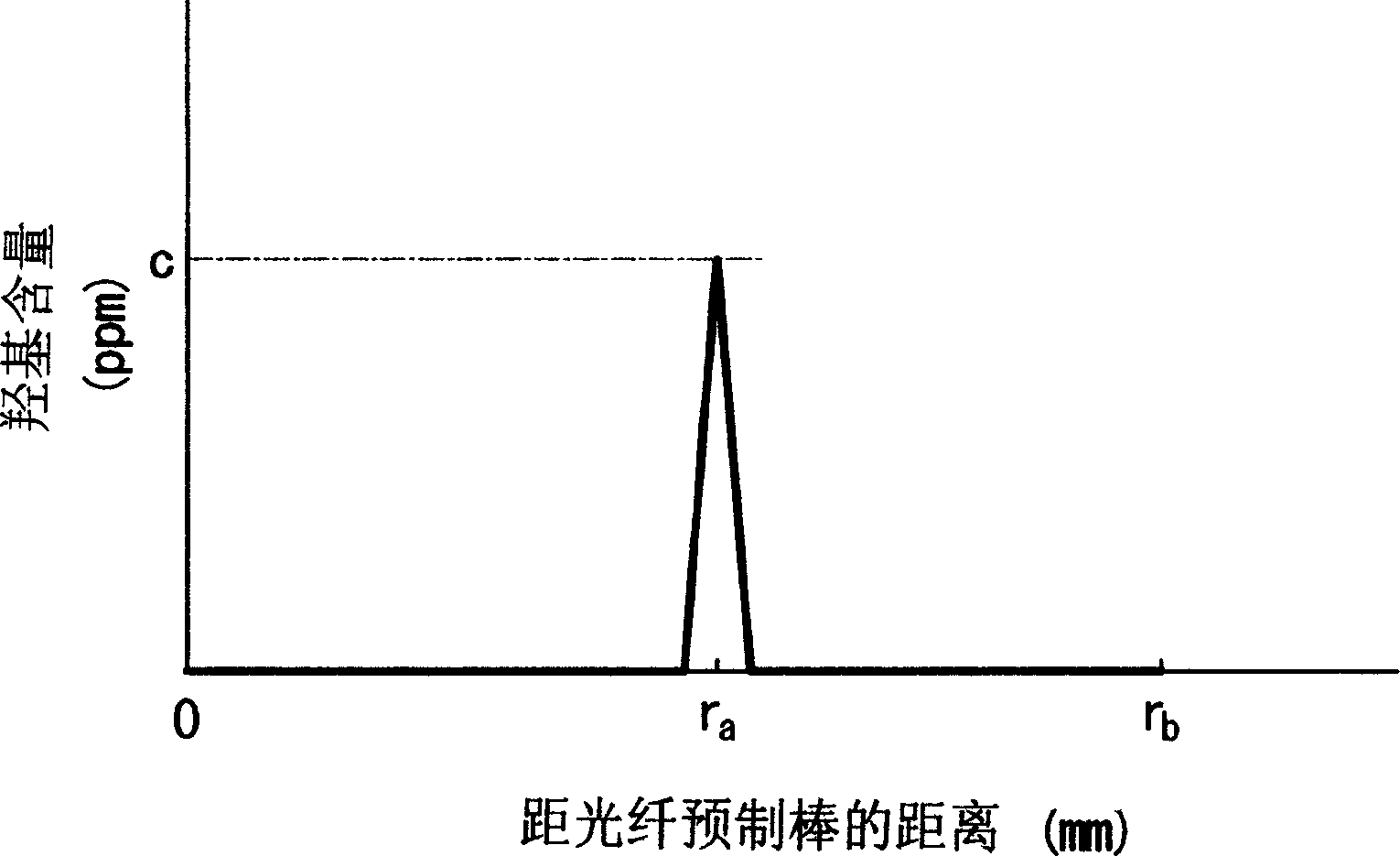

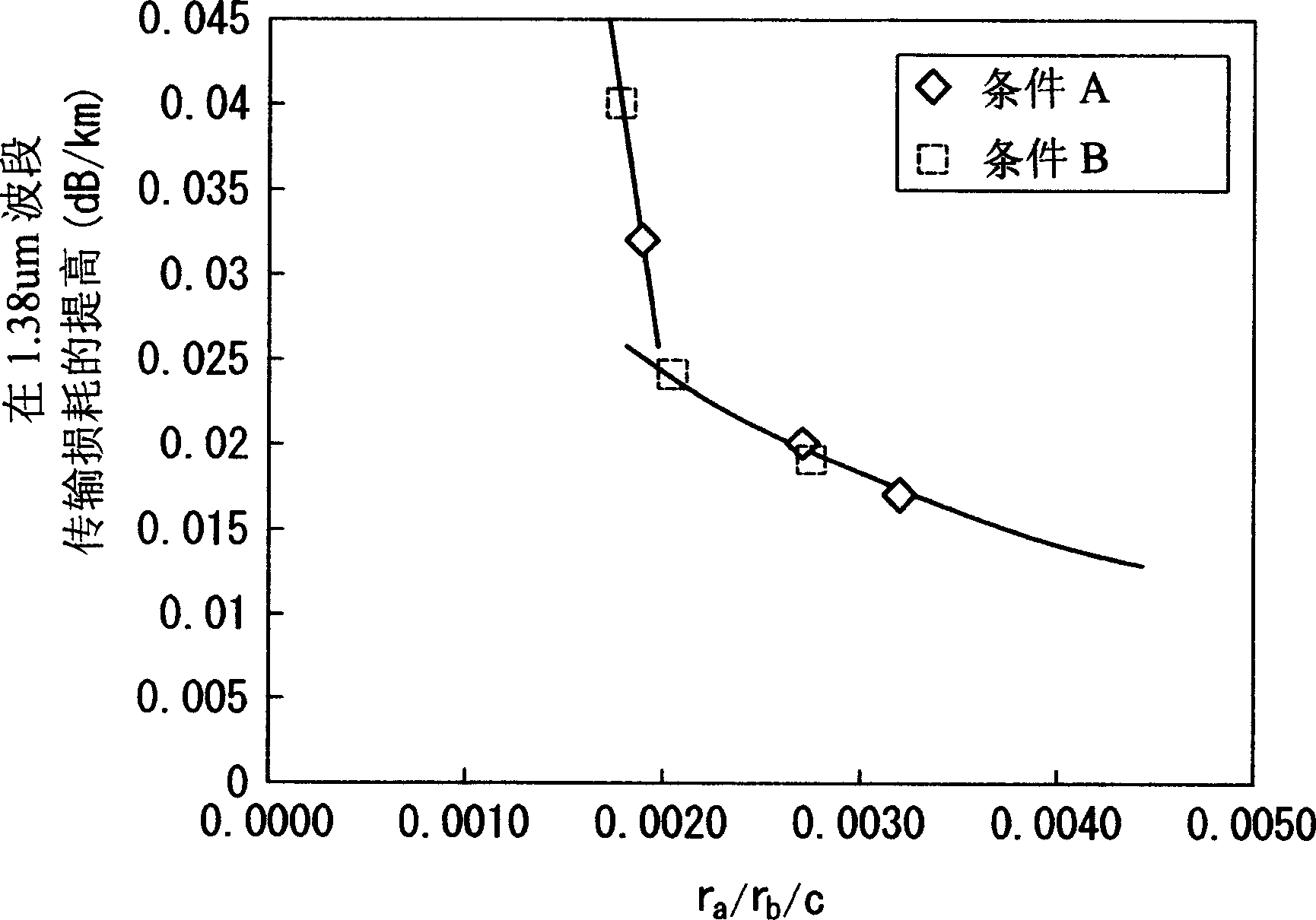

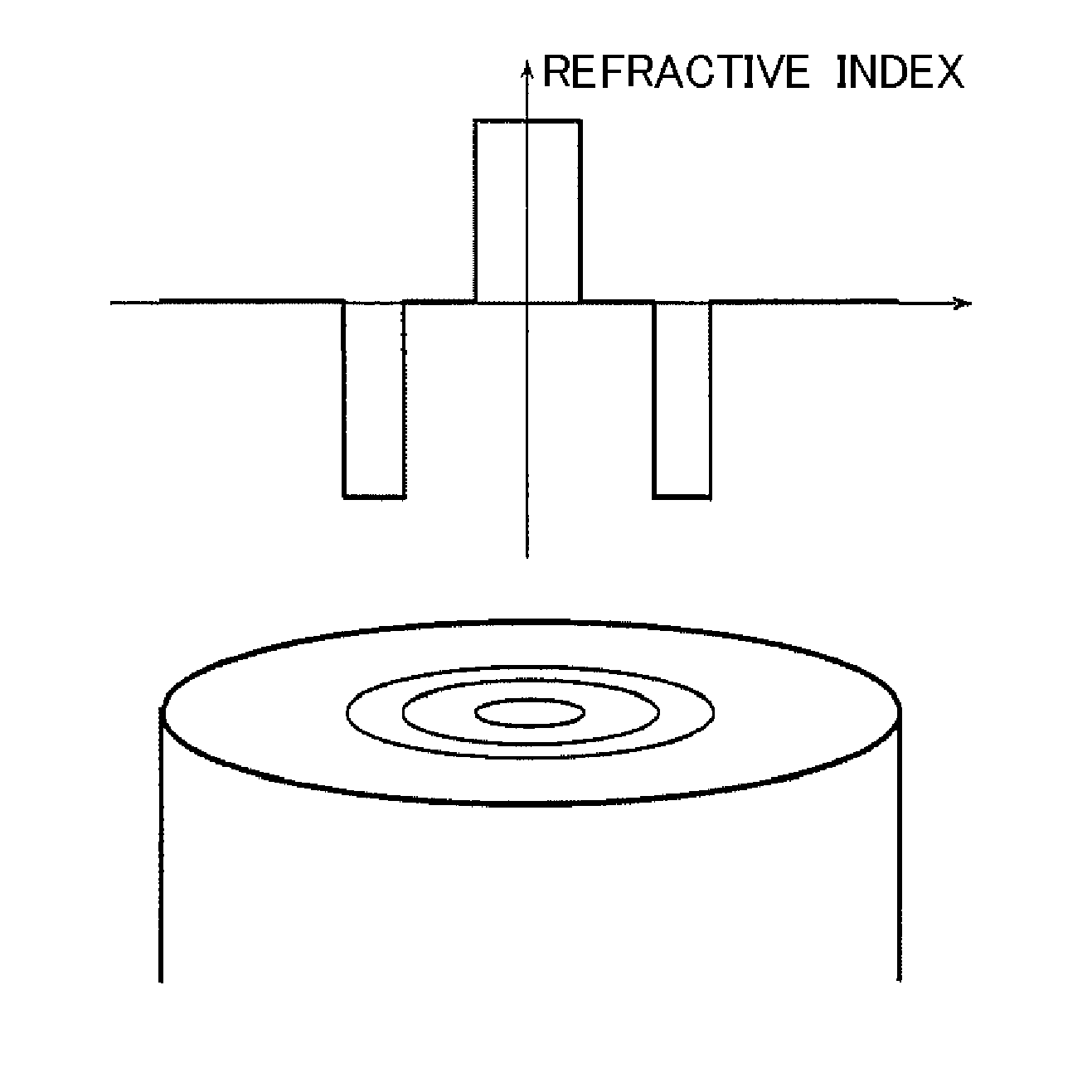

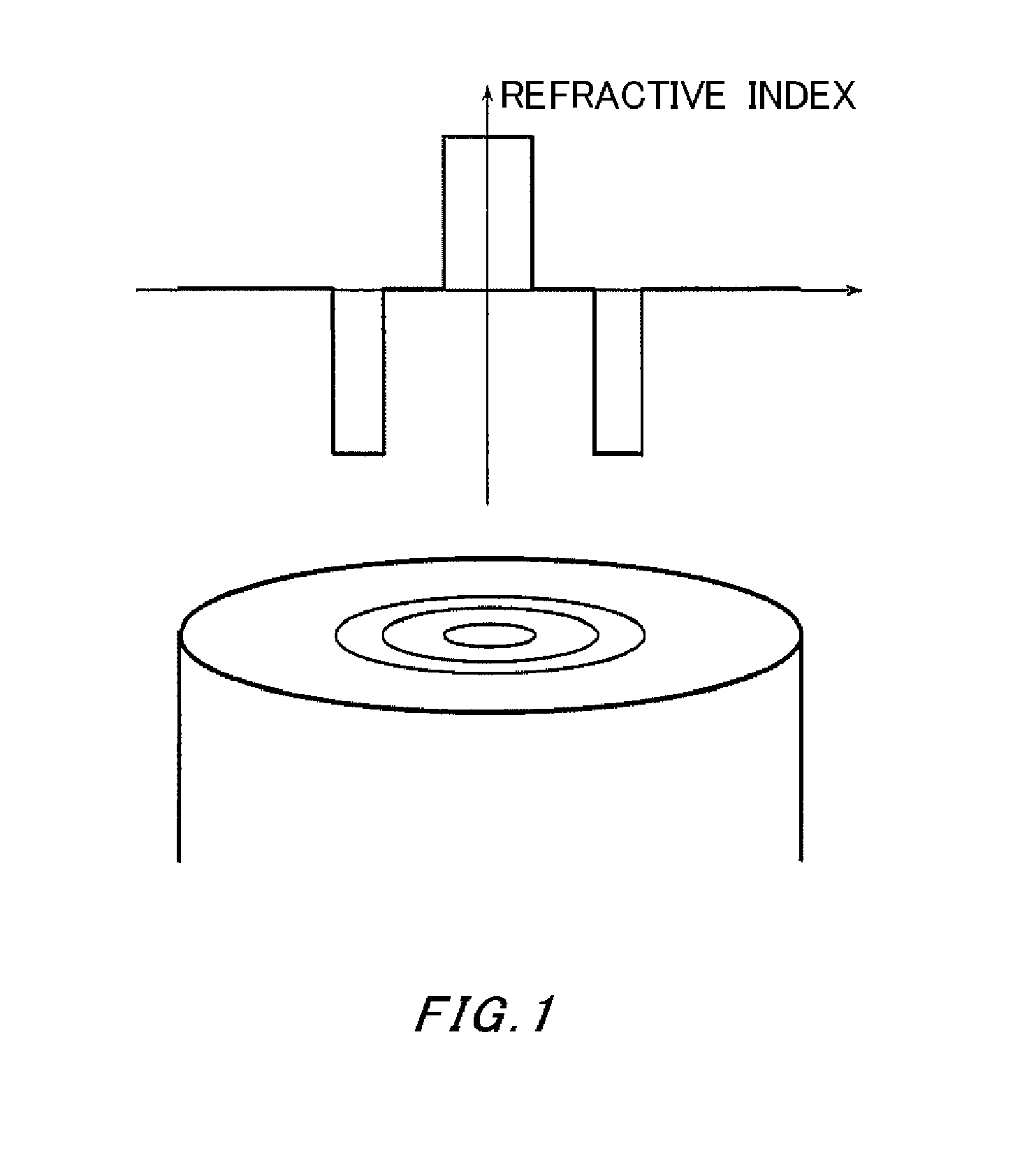

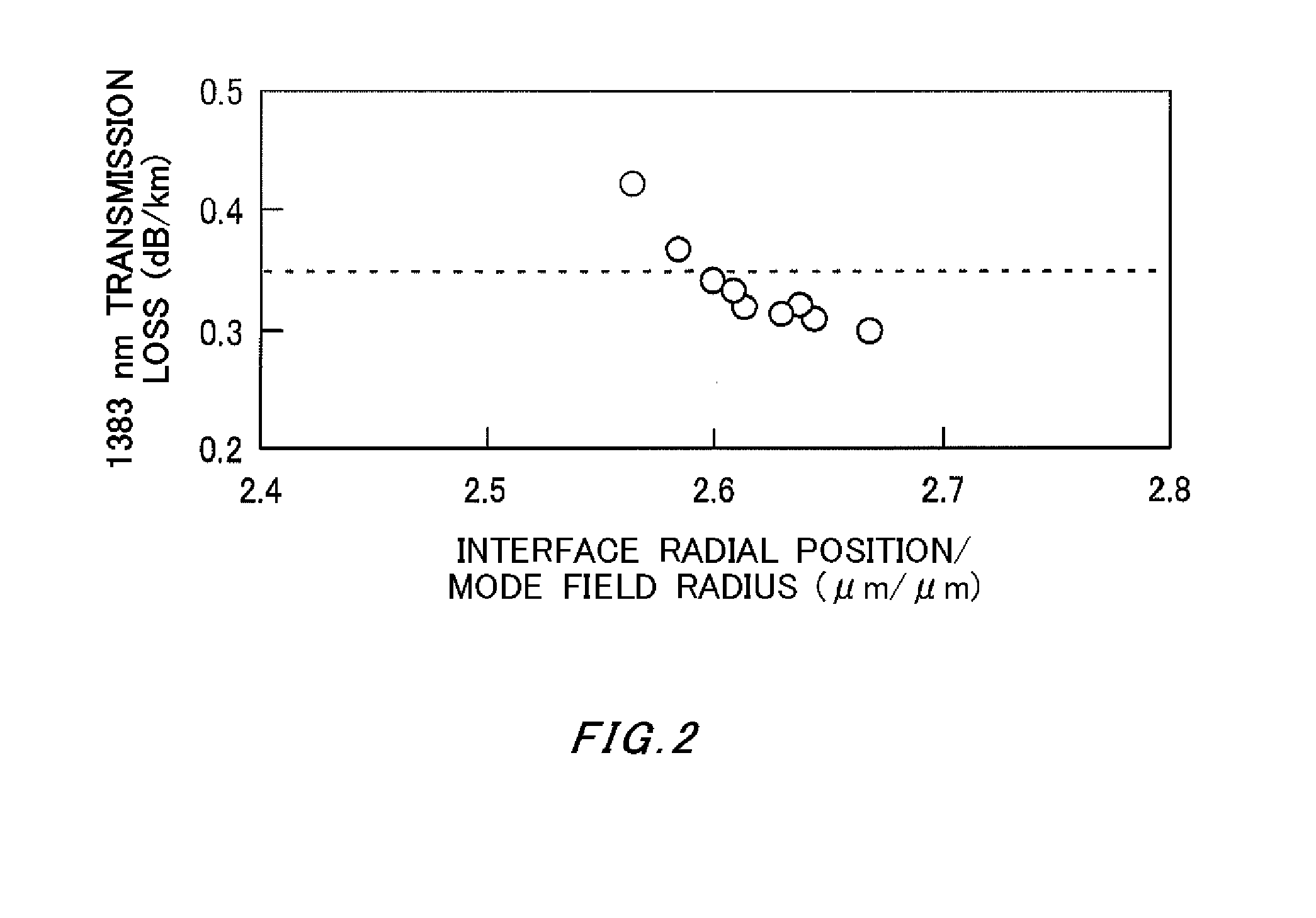

Optical fiber preform and manufacturing method therefor

ActiveCN1550467AReduce transmission lossLow costGlass making apparatusGlass productionVitrificationFlame polishing

A method for manufacturing an optical fiber preform includes a process A of applying flame polishing to a center glass rod, a process B of determining a ratio ra / rb, which is a ratio of a radius ra of the center glass rod expressed in millimeters with respect to a radius rb of a target optical fiber preform expressed in millimeters, based on a refractive index profile of a target optical fiber preform, and a process C of determining an amount of fine glass particles to be deposited on the center glass rod so that a ratio ra / rb / c falls within a range from 0.002 to 0.01, where 'c' is a maximum value of hydroxyl group concentration expressed in ppm in the vicinity of a boundary between the center glass rod and an outer layer, which is formed by depositing fine glass particles on the center rod and by being vitrified.

Owner:FUJIKURA LTD

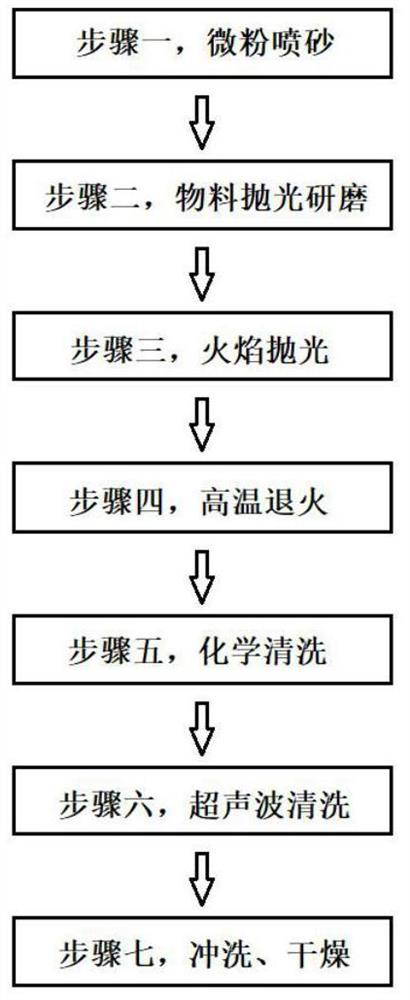

Regeneration cleaning method for quartz part of semiconductor high-order process APC device

ActiveCN111940394AReach the purpose of regenerative cleaningReduce surface roughnessPolishing machinesDrying gas arrangementsSand blastingPhysical chemistry

The invention relates to the technical field of semiconductors. The invention discloses a regeneration cleaning method for a quartz part of a semiconductor high-order process APC device. The regeneration cleaning method comprises the following steps: step 1, micro-powder sand blasting; step 2, physical polishing and grinding; step 3, flame polishing; step 4, high-temperature annealing; step 5, chemical cleaning: firstly, soaking in an ammonia water hydrogen peroxide solution at the temperature of 20-40 DEG C for 10 minutes, then soaking in a nitro-fluoro acid solution for 5-20 minutes, and finally, soaking in a nitro-fluoro acid solution for 5-20 min; step 6, ultrasonic cleaning; and step 7, washing and drying. According to the method, the cost is reduced, and the purpose of avoiding the corrosion problem of chemical film removal is achieved.

Owner:上海富乐德智能科技发展有限公司

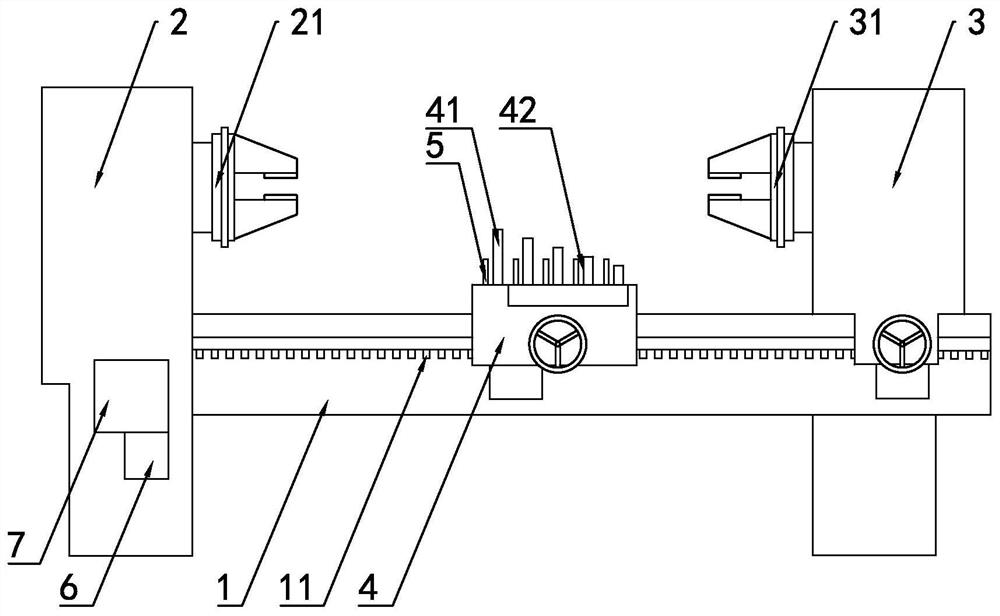

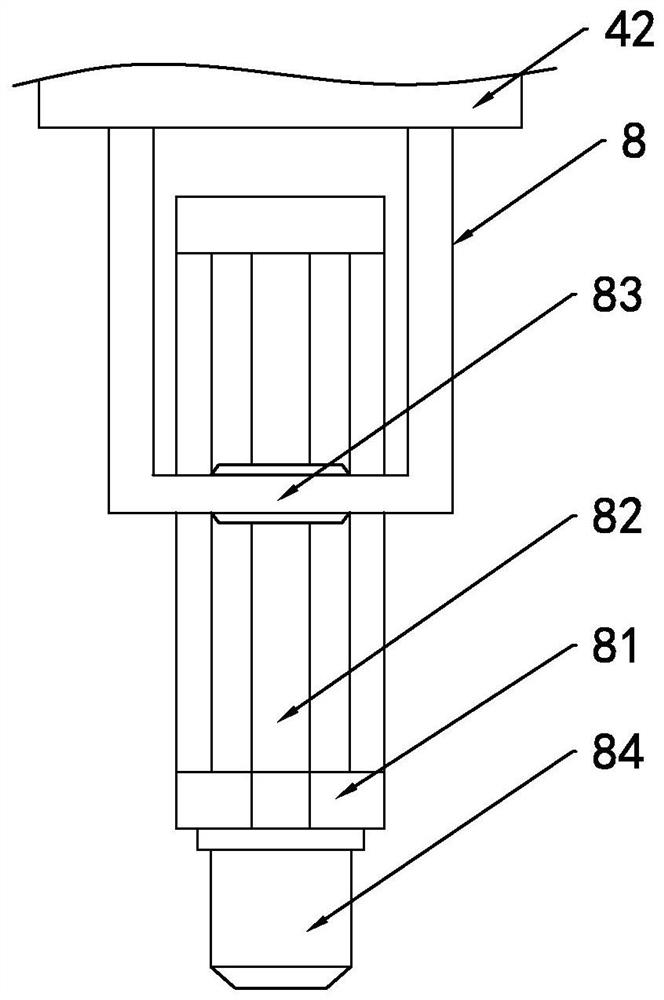

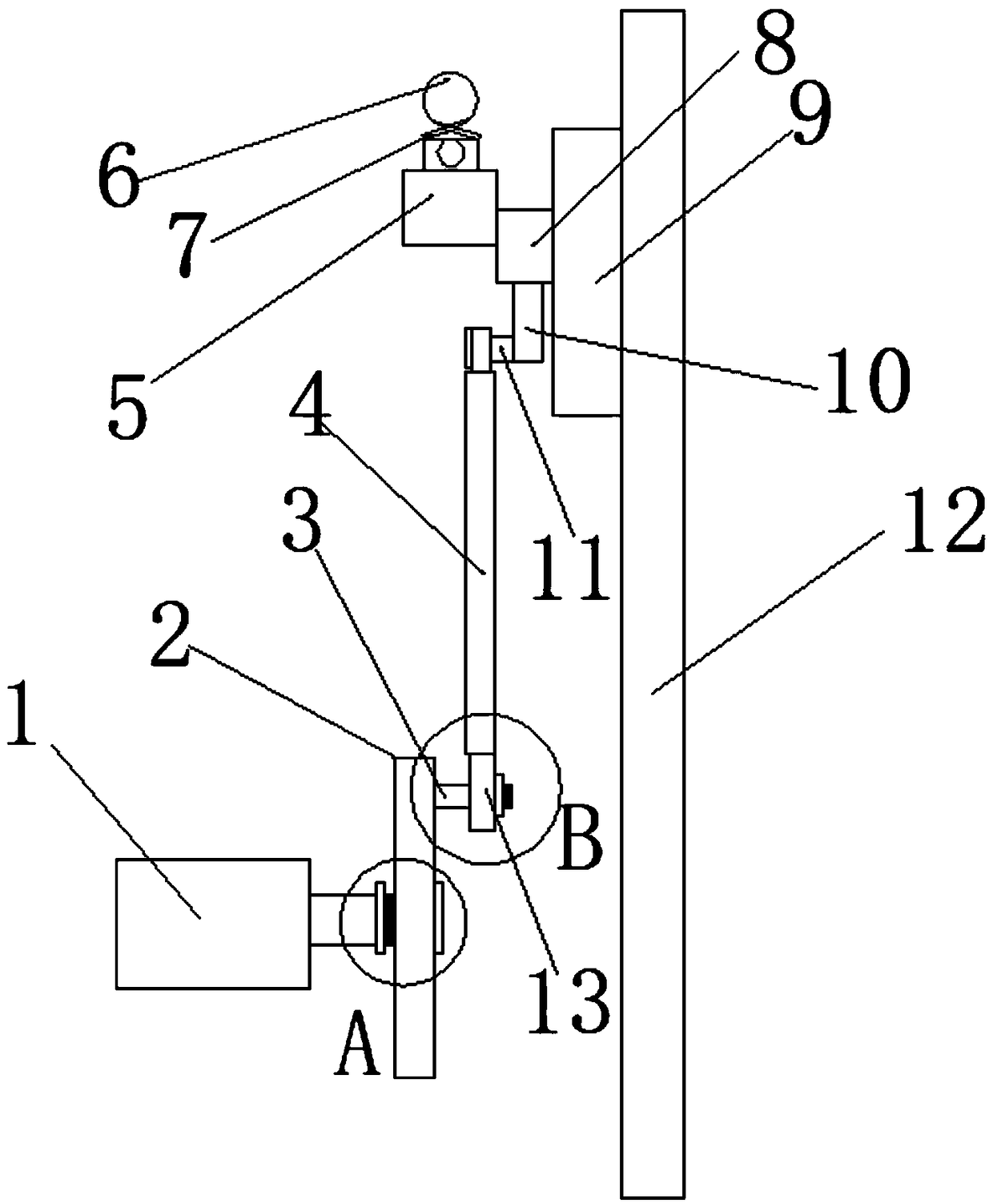

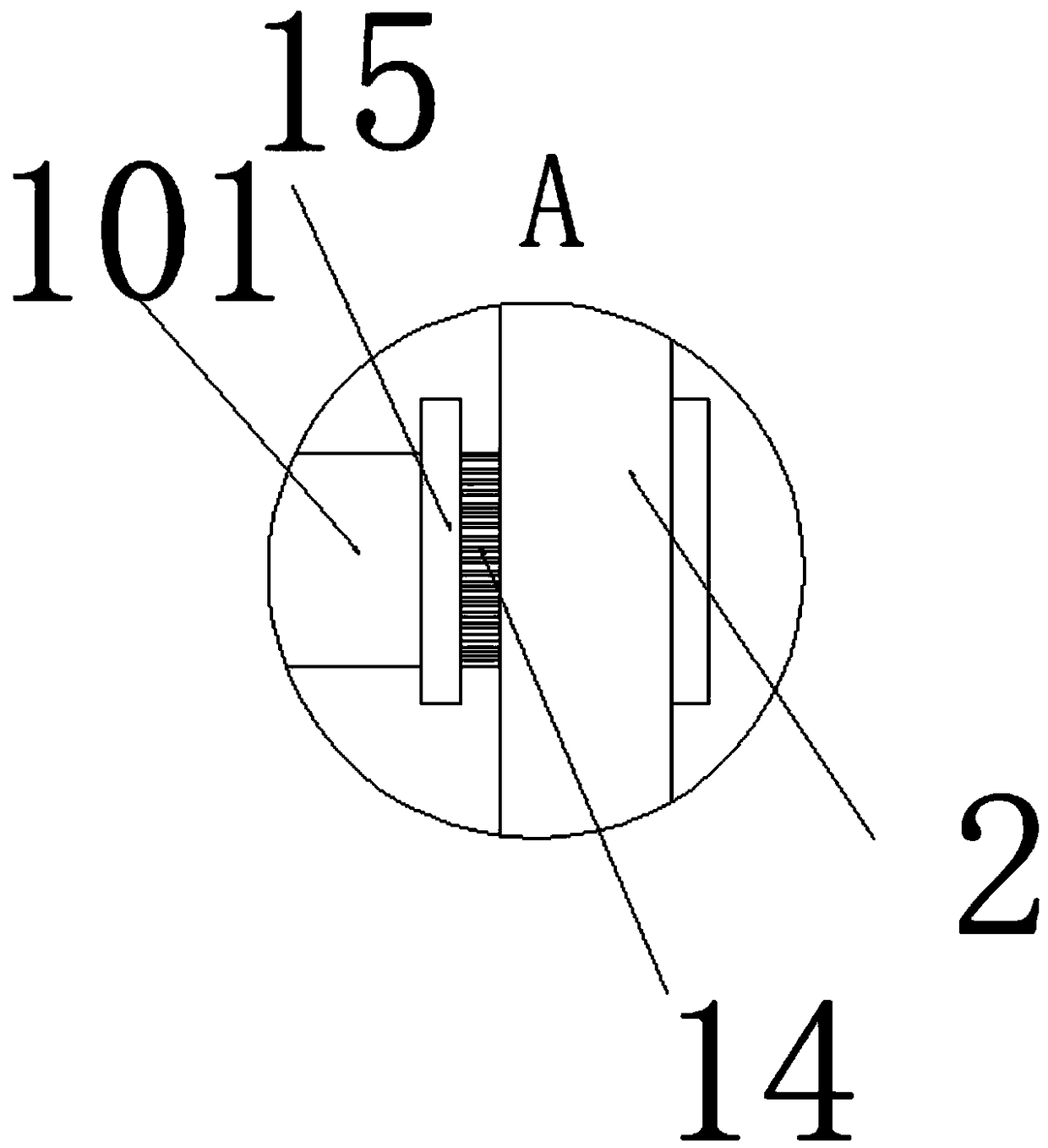

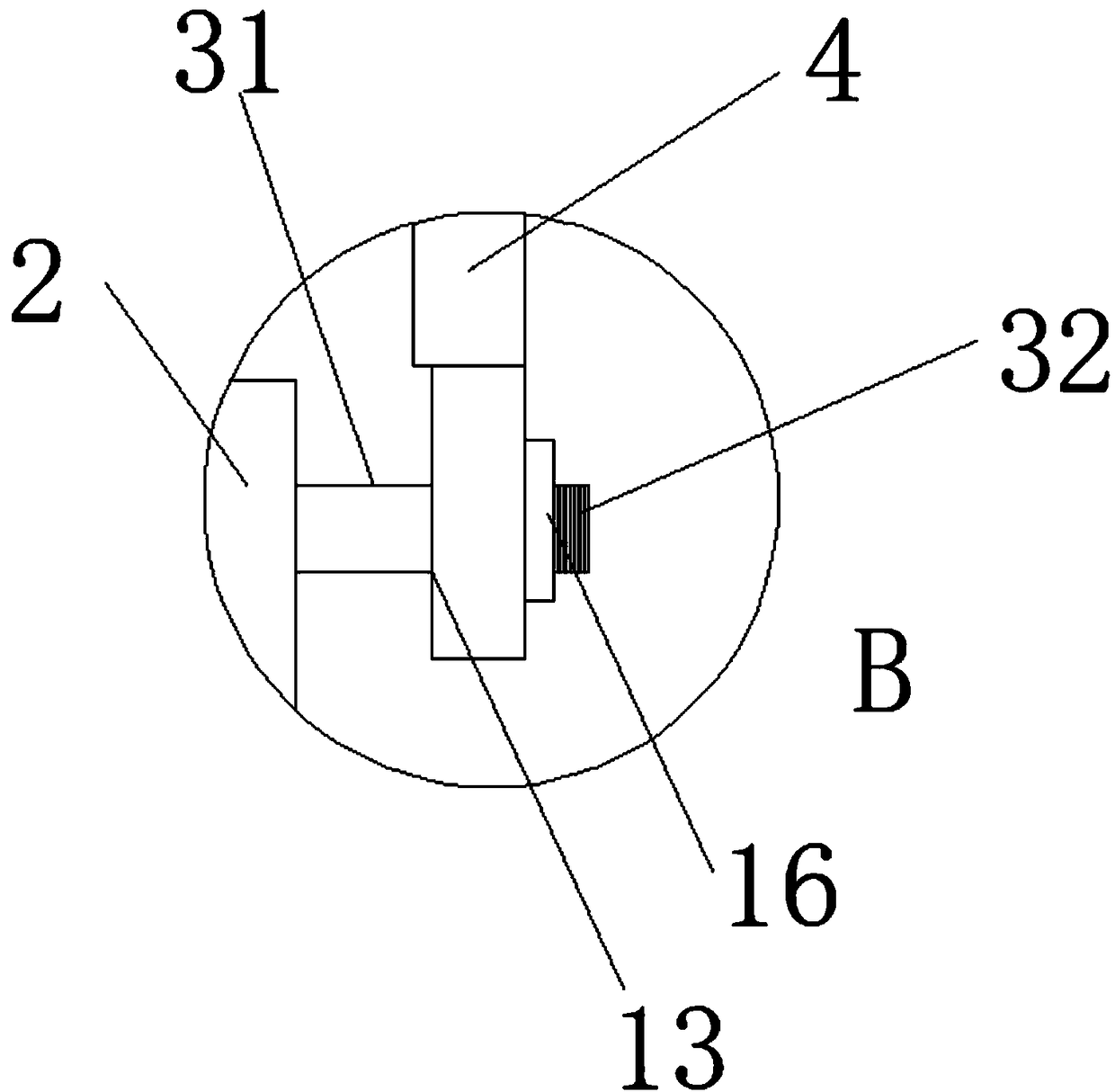

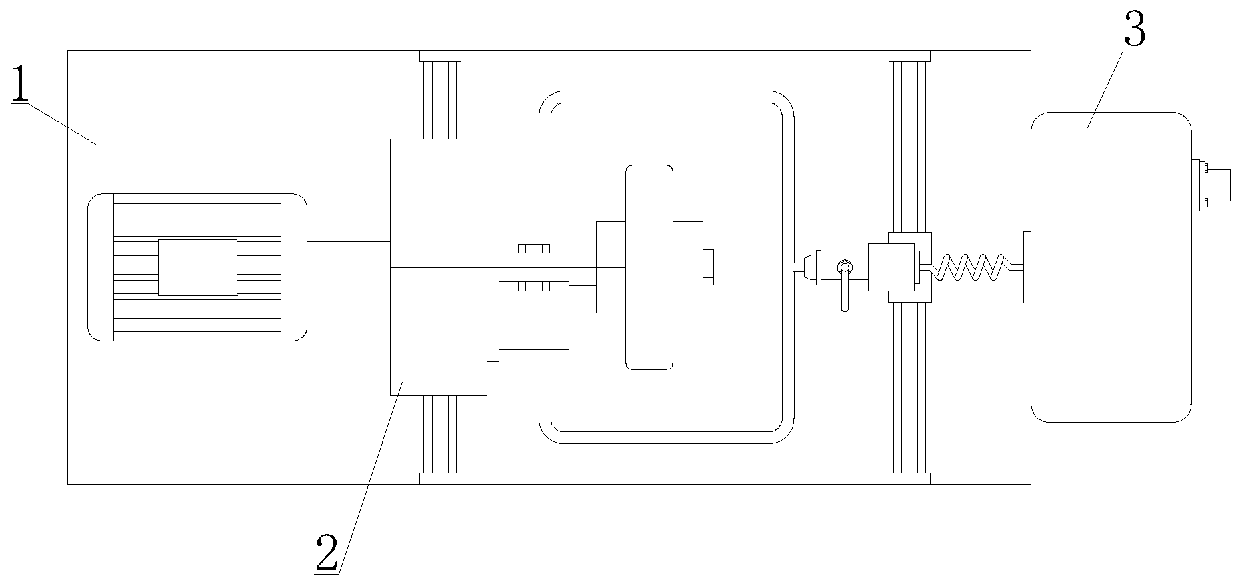

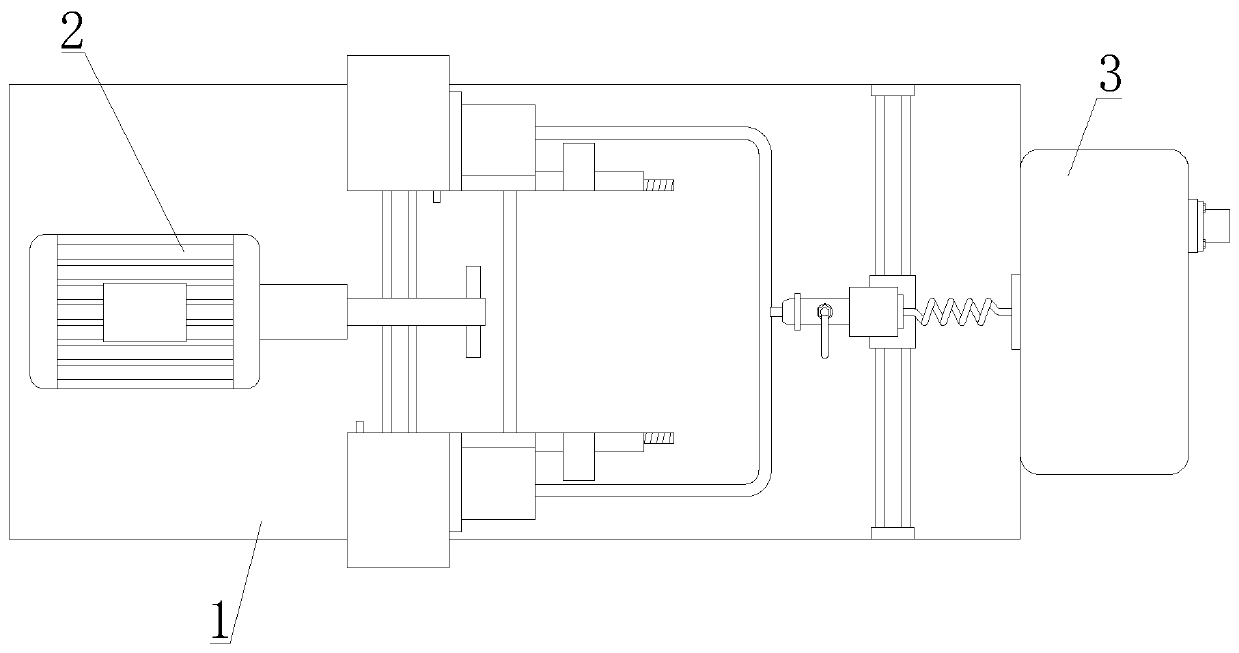

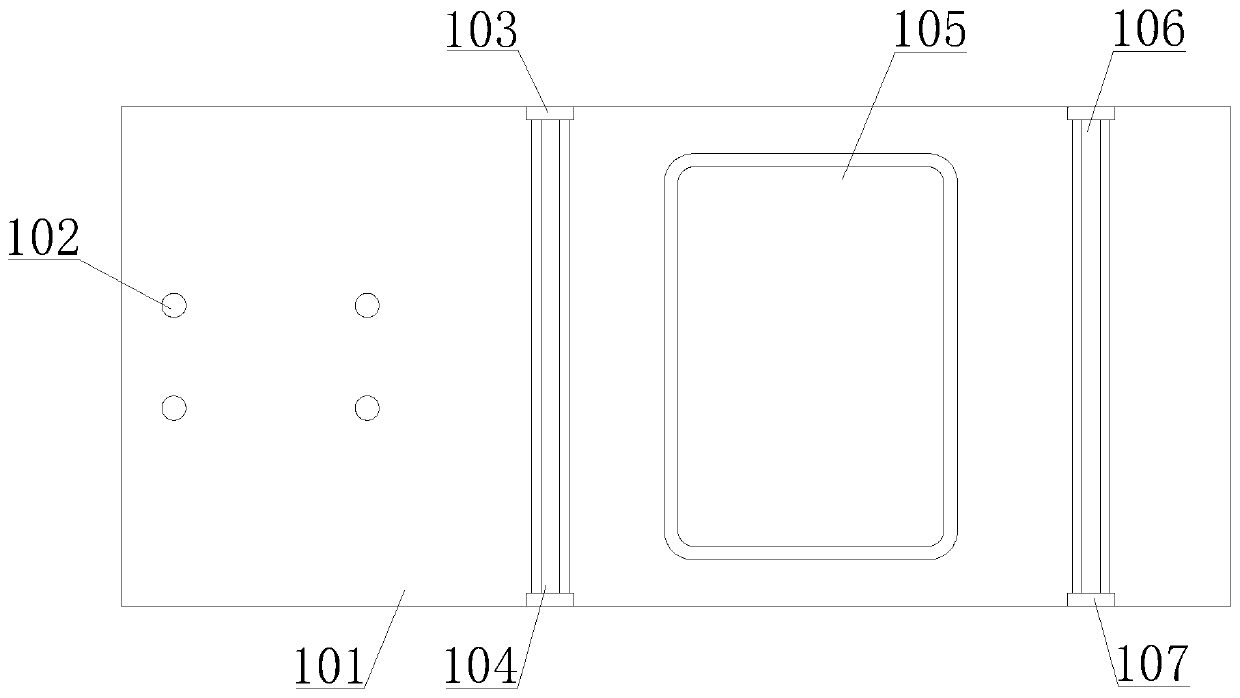

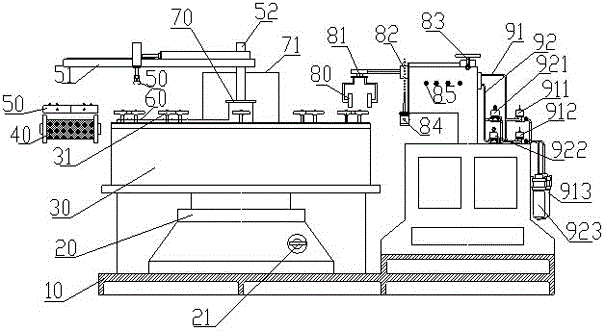

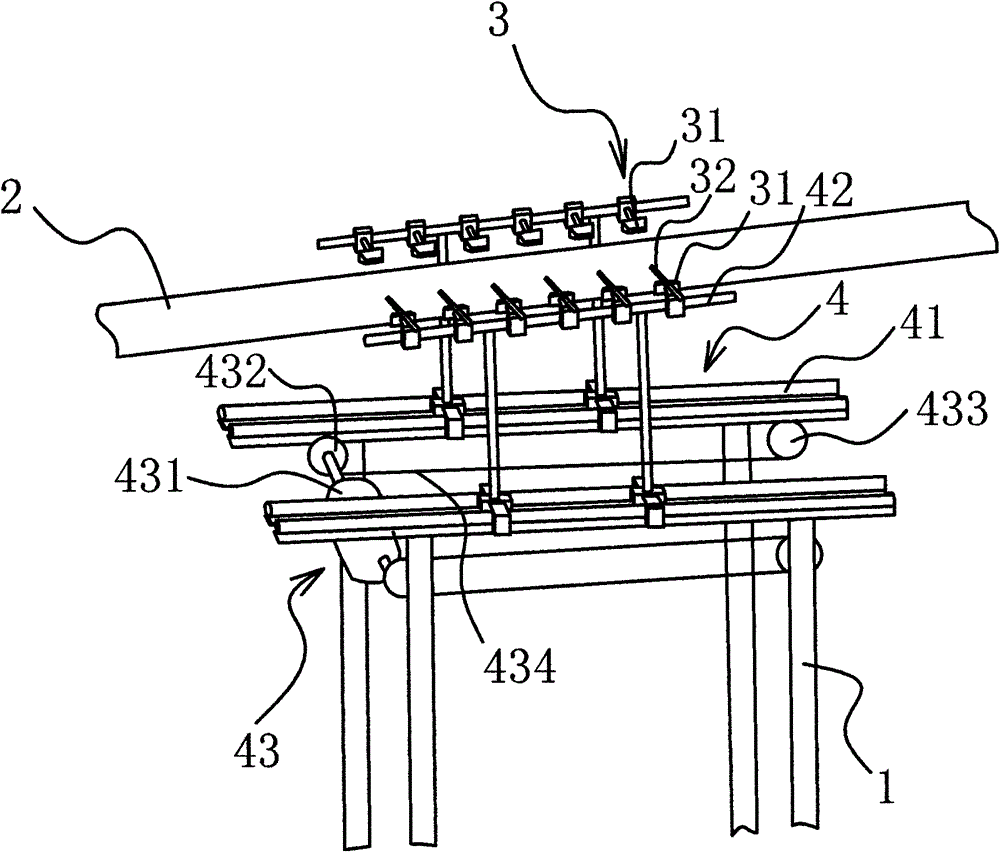

Quartz glass rod flame polishing and annealing device and method thereof

ActiveCN111825321AAvoid bendingAchieve the effect of annealingGlass productionThermodynamicsAuxiliary heating

The invention relates to a quartz glass rod flame polishing and annealing method which is characterized by comprising the following steps: S1, mobile terminal feeding: firstly, clamping a quartz glassrod and rotating the quartz glass rod at a constant speed; S2, preheating: turning on a main combustor, controlling the required temperature, controlling a flame operation table to transversely reciprocate, and preheating the quartz glass rod; S3, polishing and annealing: the height and the angle of the auxiliary flame nozzle and the hydrogen and oxygen supply amount of the auxiliary heating areaare adjusted in advance; each auxiliary flame nozzle is opened; and at the moment, the displacement speed controller is adjusted, the flame operation table drives the flame spray gun fixed to the flame gun frame to heat and polish the quartz glass rod at a constant speed, meanwhile, the distance between the auxiliary combustors and the hydrogen and oxygen amount of each combustor control the temperature to form a temperature gradient, the quartz glass rod can be slowly cooled, and the annealing effect is achieved. The method has the advantages of being good in production quality and high in production efficiency.

Owner:中建材衢州金格兰石英有限公司

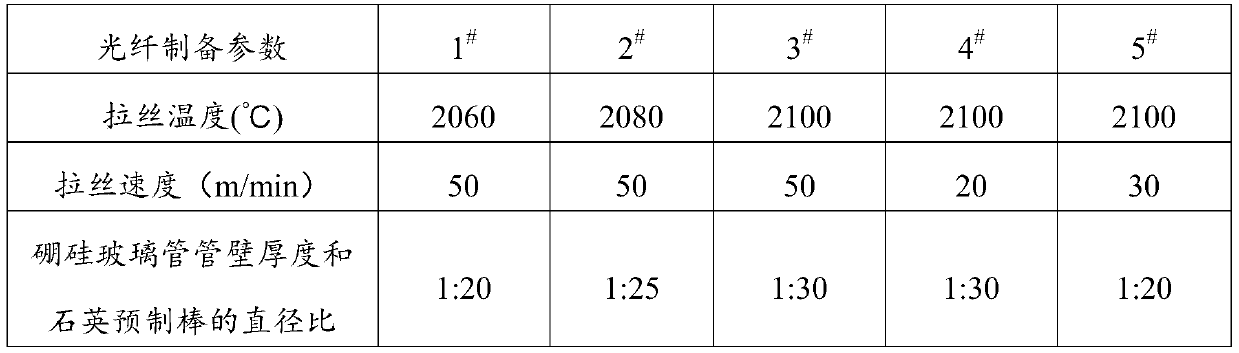

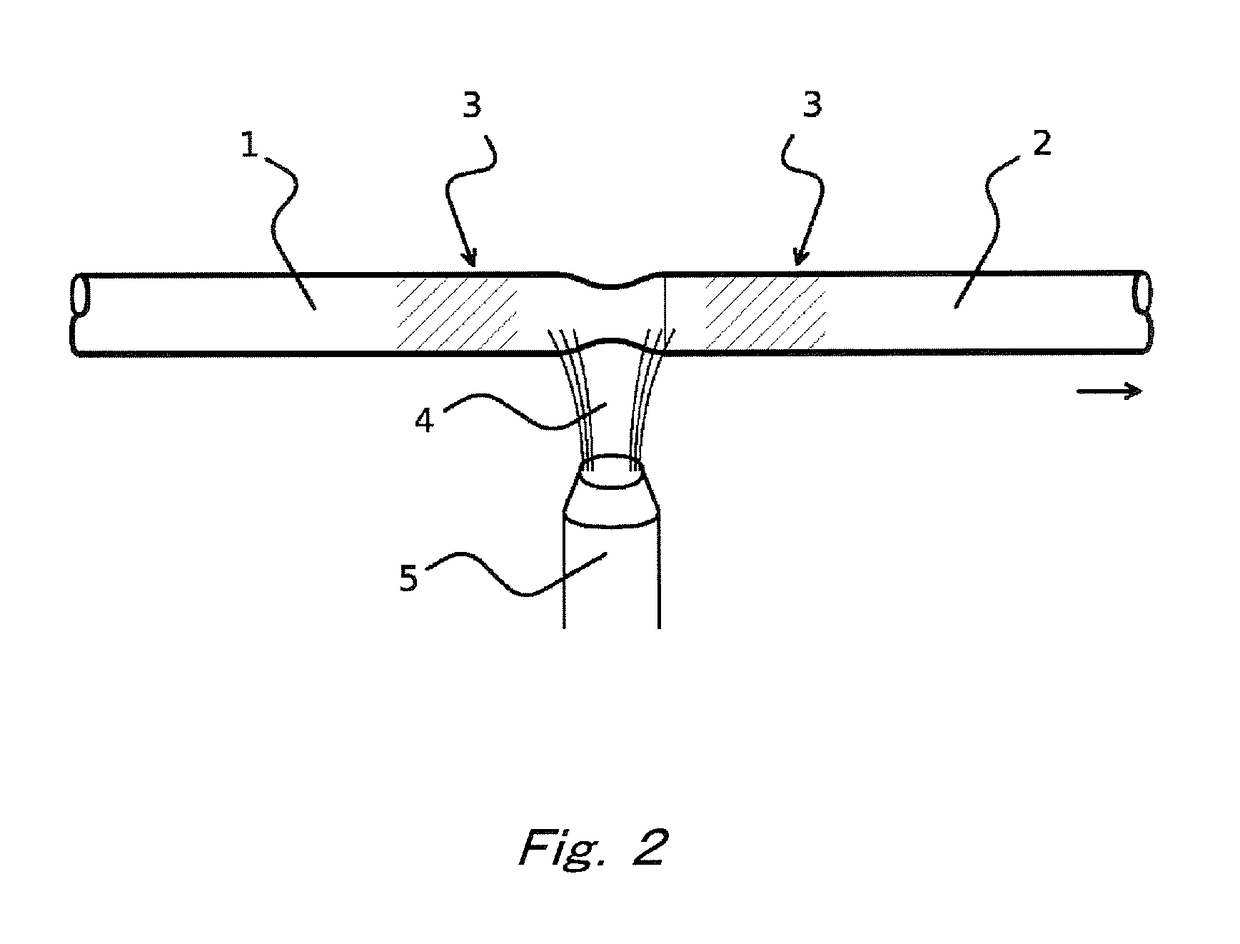

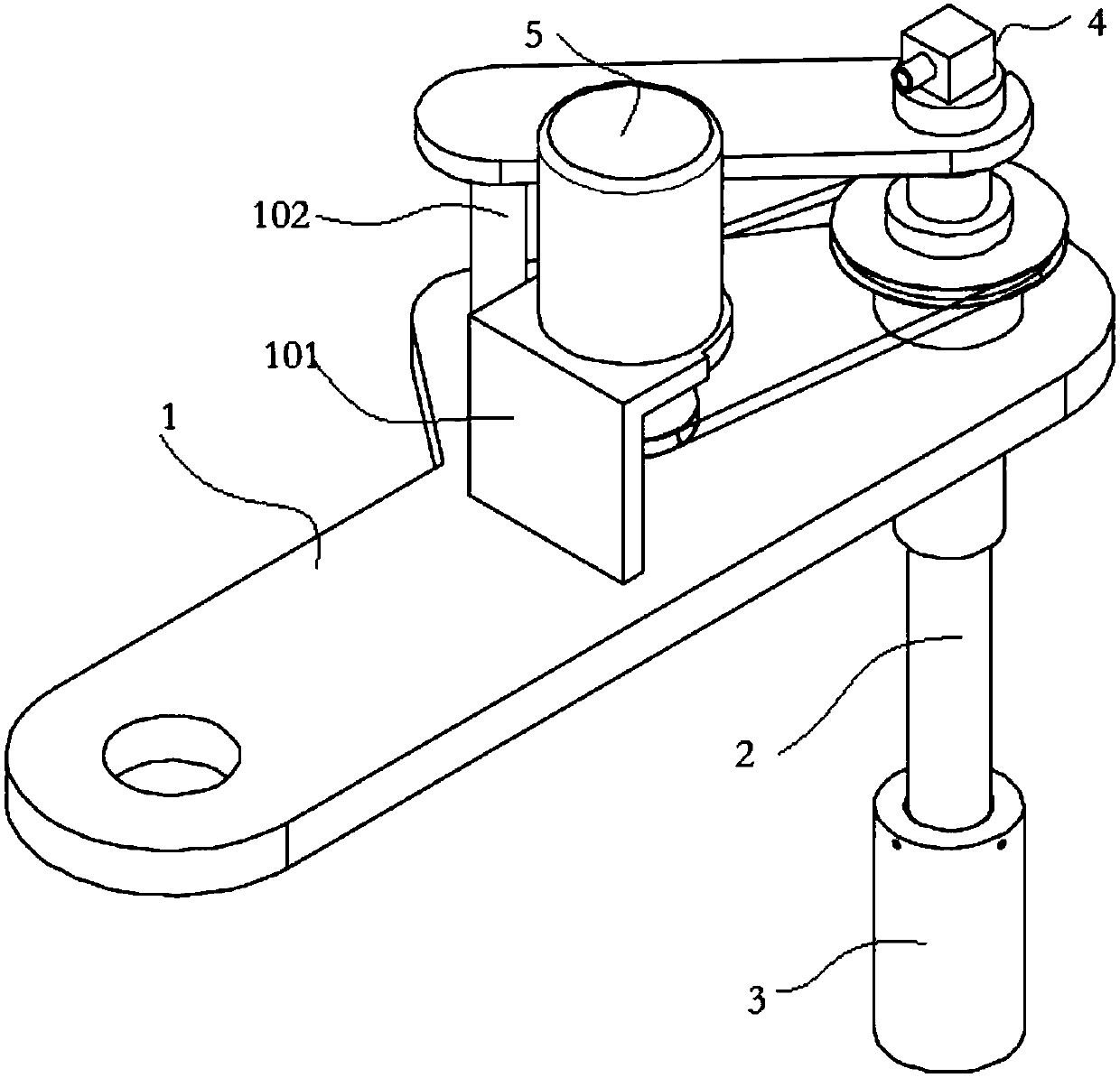

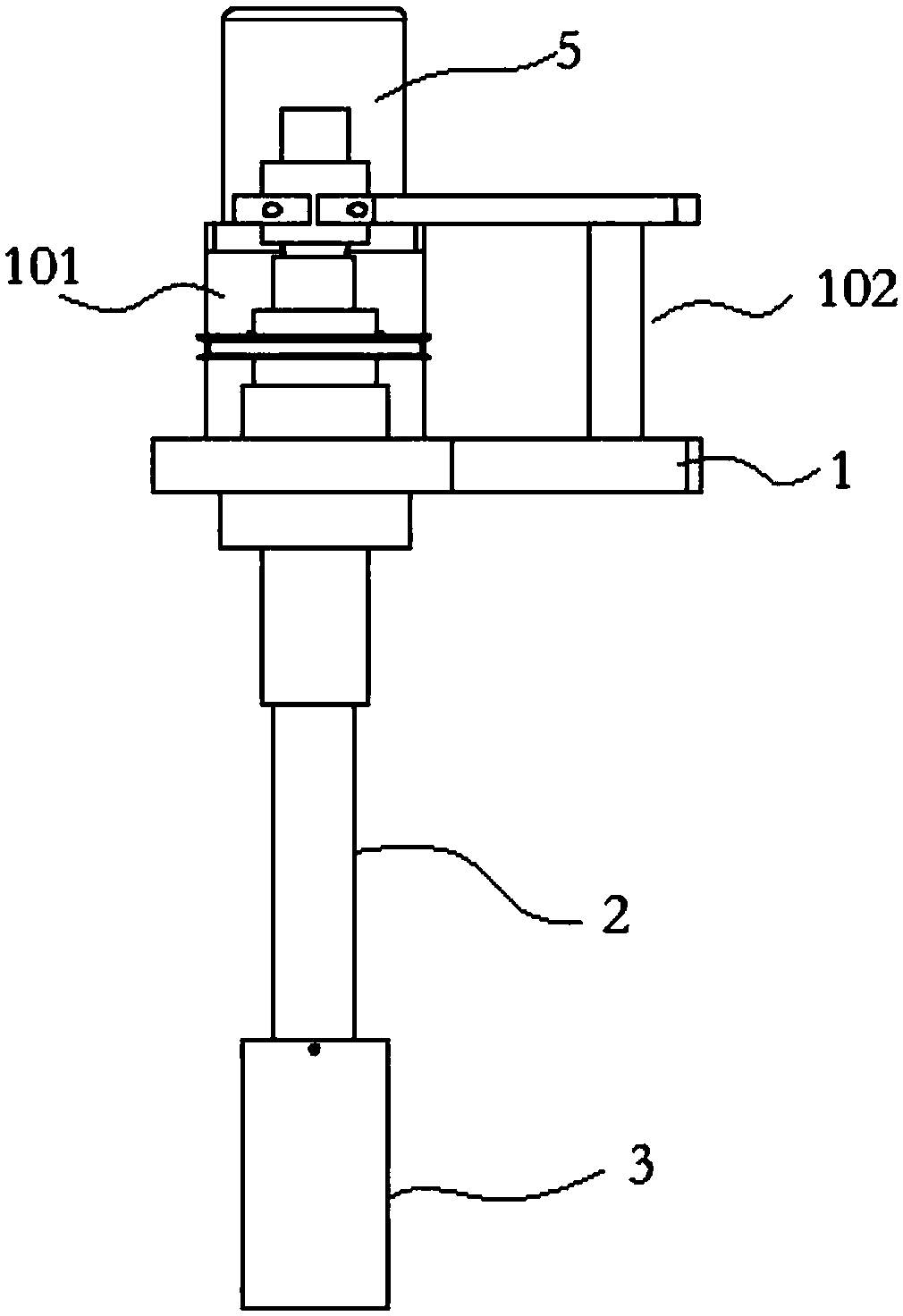

Preparation method of tensile optical fiber

ActiveCN111170628AOccasions that meet high-strength use requirementsHigh tensile strengthGlass making apparatusAcid etchingBorosilicate glass

The invention relates to a preparation method of a tensile optical fiber, and aims to solve the problem that the strength of an existing optical fiber is difficult to meet use requirements in some special application fields. The preparation method comprises steps: a quartz preform is subjected to flame polishing and acid etching treatment; a thin borosilicate glass tube is sleeved on the outer layer of the quartz preform; then wire drawing is carried out, low-speed wire drawing is adopted, the wire drawing speed is controlled within the range of 10-50 m / min, gradient annealing treatment is carried out after the optical fiber comes out of afurnace mouth, a gradient annealing mode withgradually-changed temperature is adopted, finally coating is carried out. The optical fiber drawn through the method canmeetthe high-strength use requirement.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

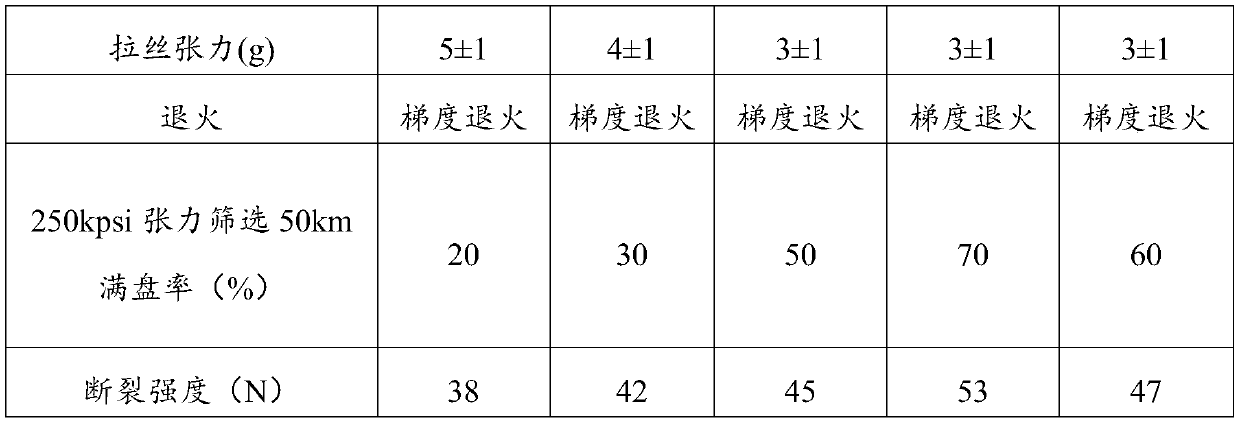

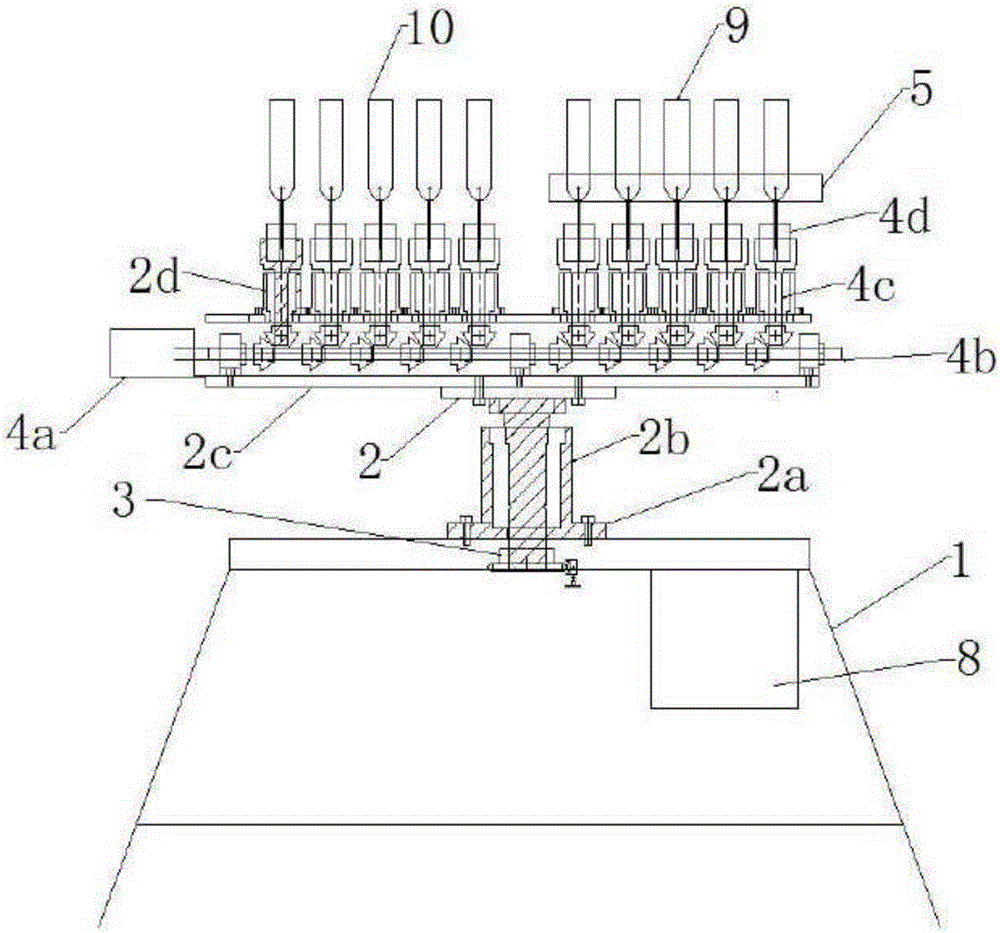

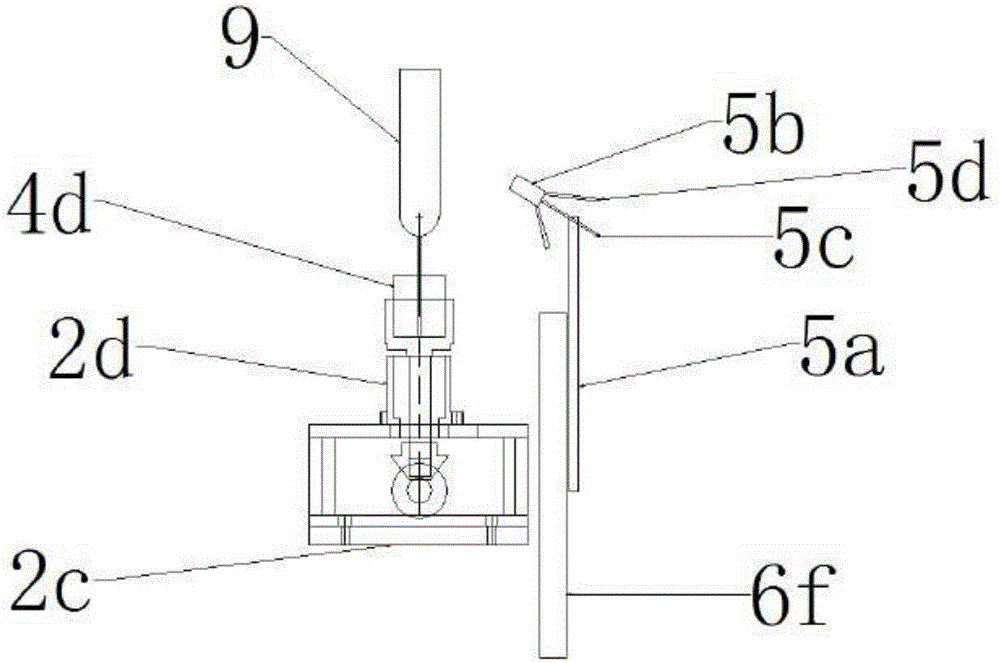

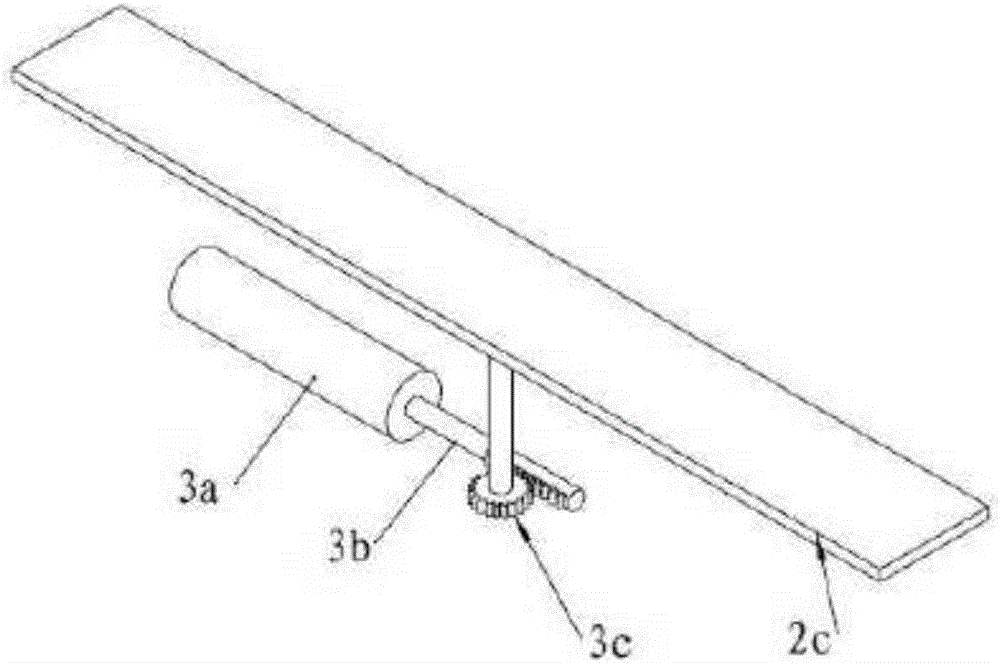

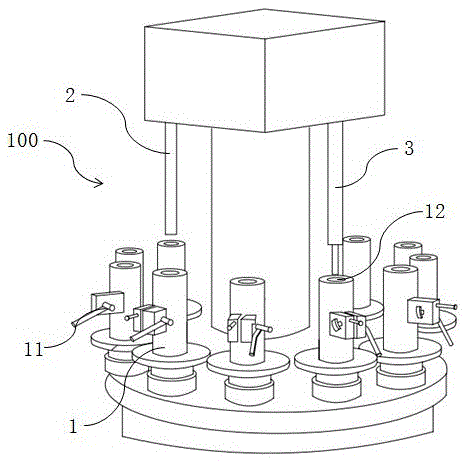

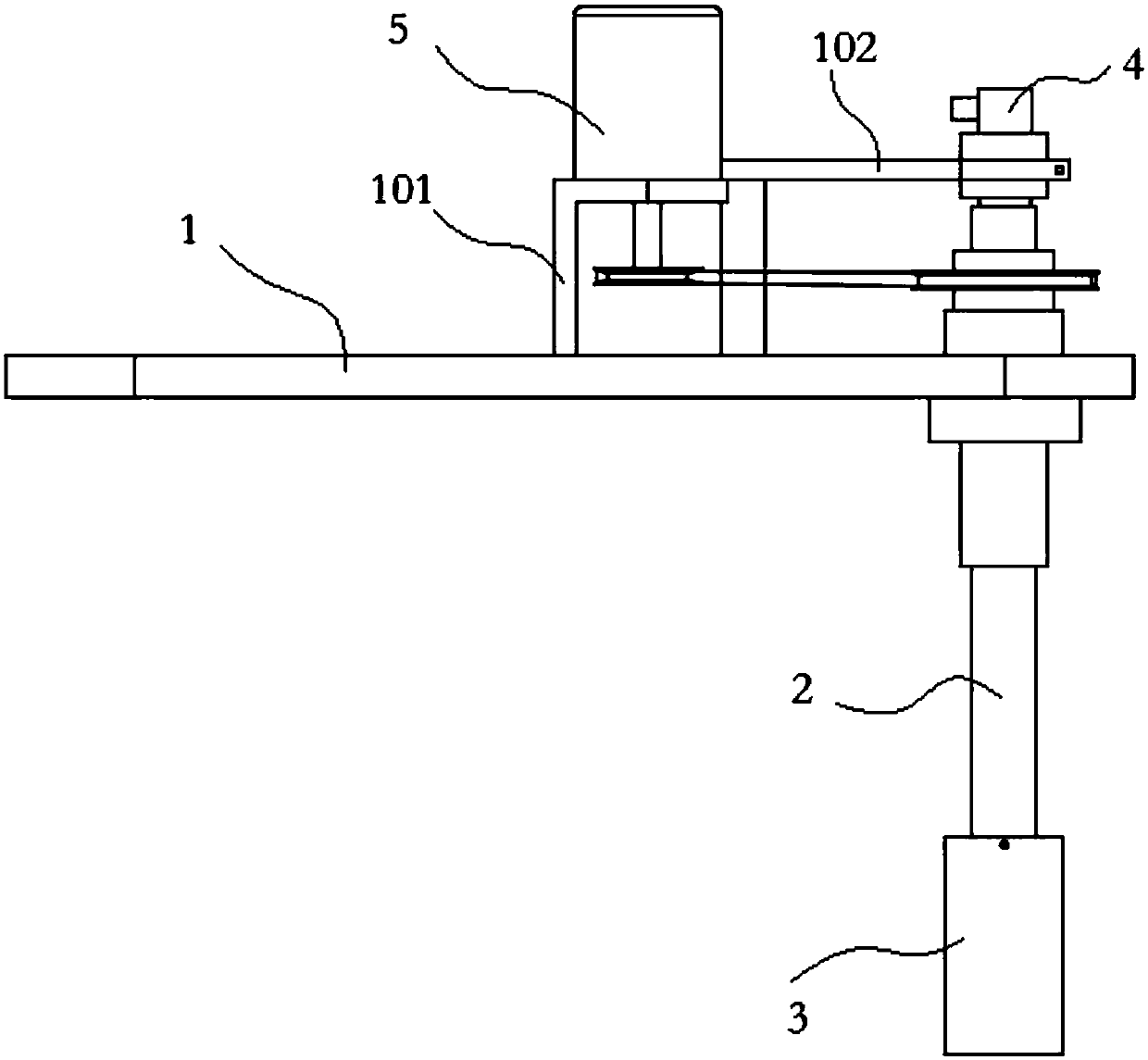

Automatic polishing machine with quartz furnace tube and polishing method

PendingCN109734296AMeet the requirements of automated processingIncrease productivityGlass shaping apparatusMechanical engineeringQuartz

The invention relates to an automatic polishing machine with a quartz furnace tube. The polishing machine is provided with the quartz furnace tube, a machine table, a first guide rail, a second guiderail, an internal flame gun rack, an external flame gun rack and a rotary table, wherein the machine table is the base of the whole polishing machine; the first guide rail is installed on the upper surface of the machine table; the second guide rail is installed on the side surface of the machine table; the internal flame gun rack is used for installing an internal flame gun installed on the firstguide rail through a sliding block and positioned on the axis of the quartz furnace tube, so that the internal flame gun can move along the first guide rail to carry out flame polishing on the innersurface of the quartz furnace tube; the external flame gun rack is used for installing an external flame gun, and the external flame gun rack is installed on the second guide rail through the slidingblock, so that the external flame gun can move along the second guide rail to carry out flame polishing on the outer surface of the quartz furnace tube; the quartz furnace tube is clamped by the fixture of the rotary table, and meanwhile, the quartz furnace tube performs axial rotary motion under the drive of a rotary table motor.

Owner:SHANGHAI QIANGHUA IND CO LTD

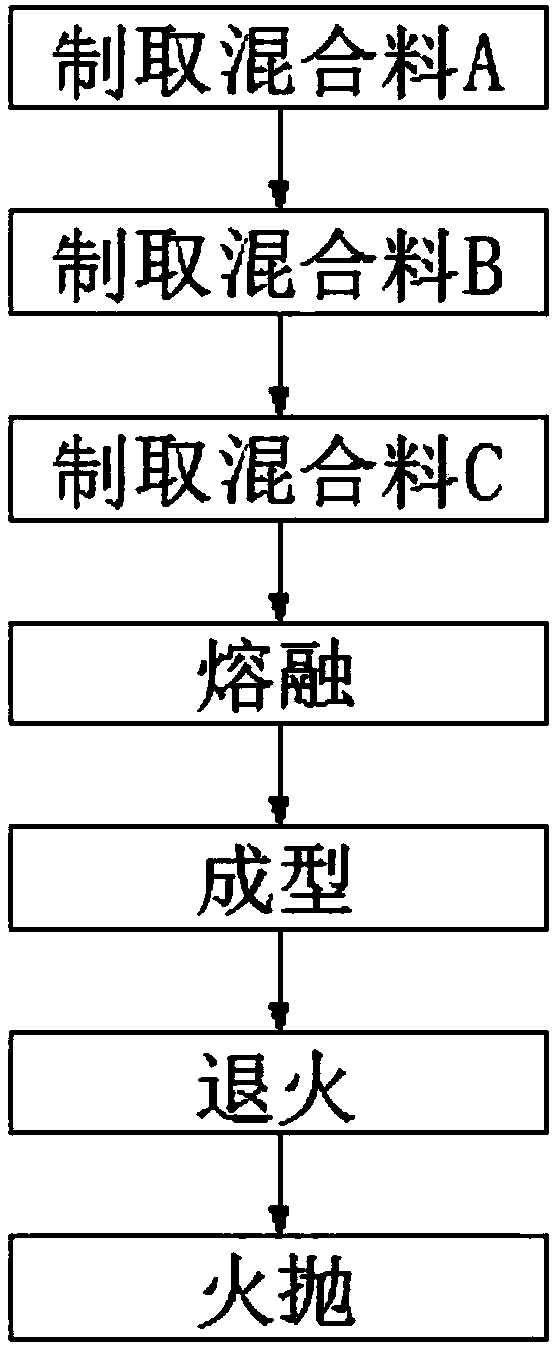

Production method of smooth-surface domestic glass ceramic

ActiveCN105819672AEliminate micro cracksEliminate burrsGlass pressing apparatusGlass productionGlass-ceramicFlame polishing

The invention discloses a production method of smooth-surface domestic glass ceramic. The production method is characterized by comprising the first step of semi-finished product production, the second step of product flame polishing treatment, the third step of product shaping and the fourth step of annealing treatment. According to the method, the produced domestic glass ceramic product has a smooth surface, tiny cracks in the surface of the product are basically eliminated, burrs and coarse surfaces at edges are eliminated, the edges are flat and smooth, the product is neat and free of deformation in appearance, and the quality of the product meets the GB / T30771 'domestic glass ceramic' standard requirement.

Owner:广东健诚高科玻璃制品股份有限公司

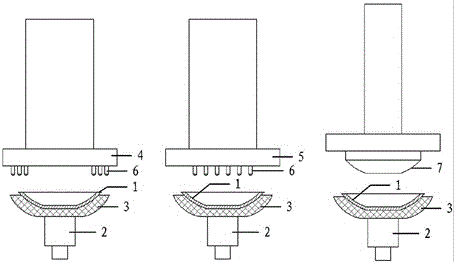

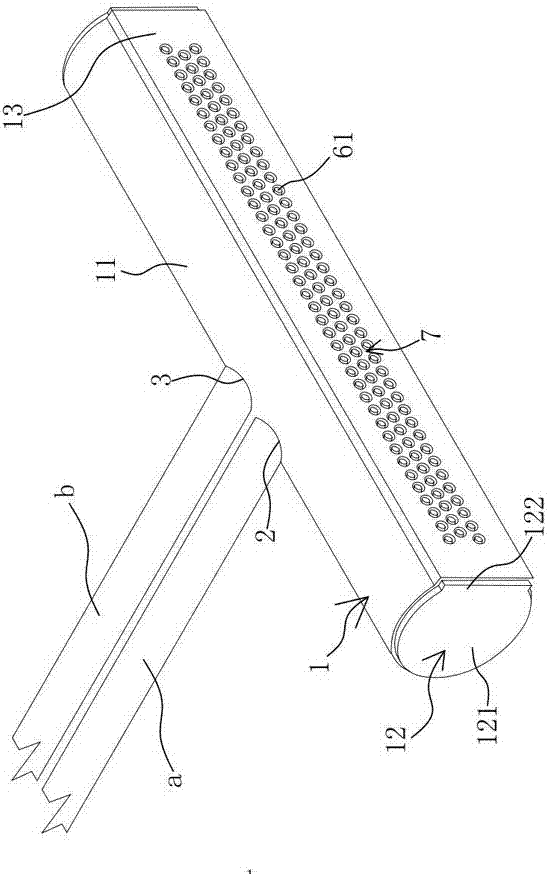

Quartz glass shell automatic flame polishing device

The invention is mainly applicable to polishing quartz glass shell and discloses a quartz glass shell automatic flame polishing device which comprises a rack, a flame head special for polishing, a quartz glass shell carrier, a quartz glass shell carrying vertical shaft, a machining lot switching mechanism, a quartz glass shell rotating mechanism, a flame head moving mechanism, a limiting feedback mechanism and a control mechanism. The quartz glass shell carrier is controlled through the machining lot switching mechanism to move machining products different in lot and on the quartz glass shell carrier into or out of a machining station, the machining products are rotated at a constant speed through the quartz glass shell rotating mechanism, workstations of the flame head are controlled through the flame head moving mechanism and the limiting feedback mechanism, and the machining process is controlled through the control mechanism. The quartz glass shell automatic flame polishing device can integrate four advantages of accurate moving of the flame head, rotating of workpieces, machining of multiple workpieces at one time and timely switching among different machining areas, and a new design idea is provided for flame polishing equipment in the field.

Owner:武汉鑫友泰光电科技有限公司

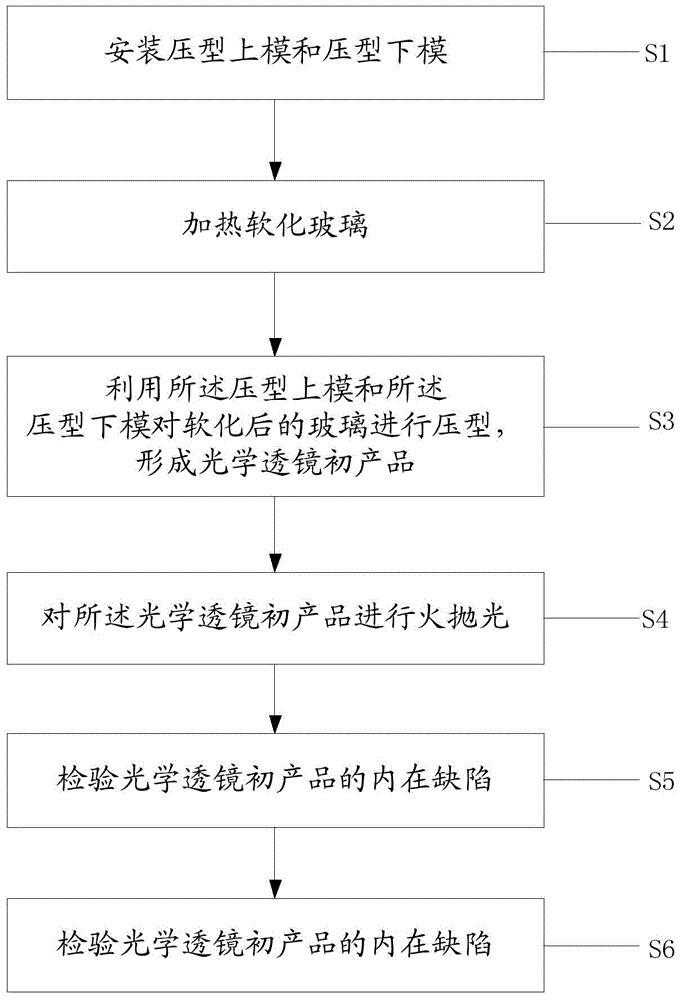

Manufacturing method for bright optical lens

InactiveCN105016606AReduce workloadImprove work efficiencyGlass pressing apparatusGlass productionProcessing costMaterials science

The application discloses a manufacturing method for a bright optical lens. The manufacturing method comprises: mounting a pressing upper mold and a pressing lower mold; heating and softening glass; profiling the softened glass by using the pressing upper mold and the pressing lower mold so as to form a preliminary product of the optical lens; performing flame-polishing on the preliminary product of the optical lens; inspecting inherent defects of the preliminary product of the optical lens; and carrying out cold processing on the preliminary product of the optical lens that does not have the inherent defects. According to the production method for bright optical lens provided by the invention, the working efficiency can be improved, and the labor cost and the processing cost of follow-up process are lowered.

Owner:雅安格纳斯光电科技有限公司

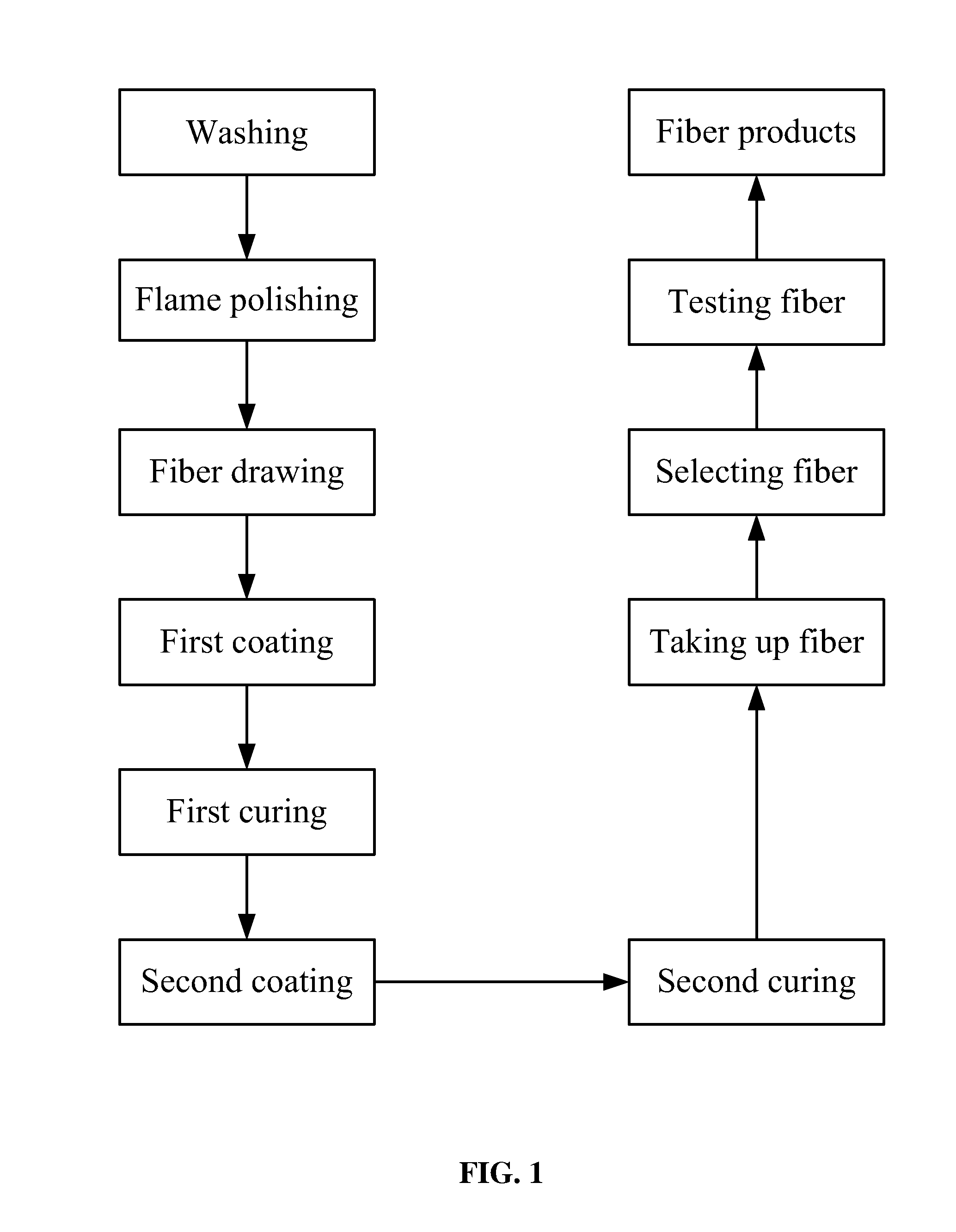

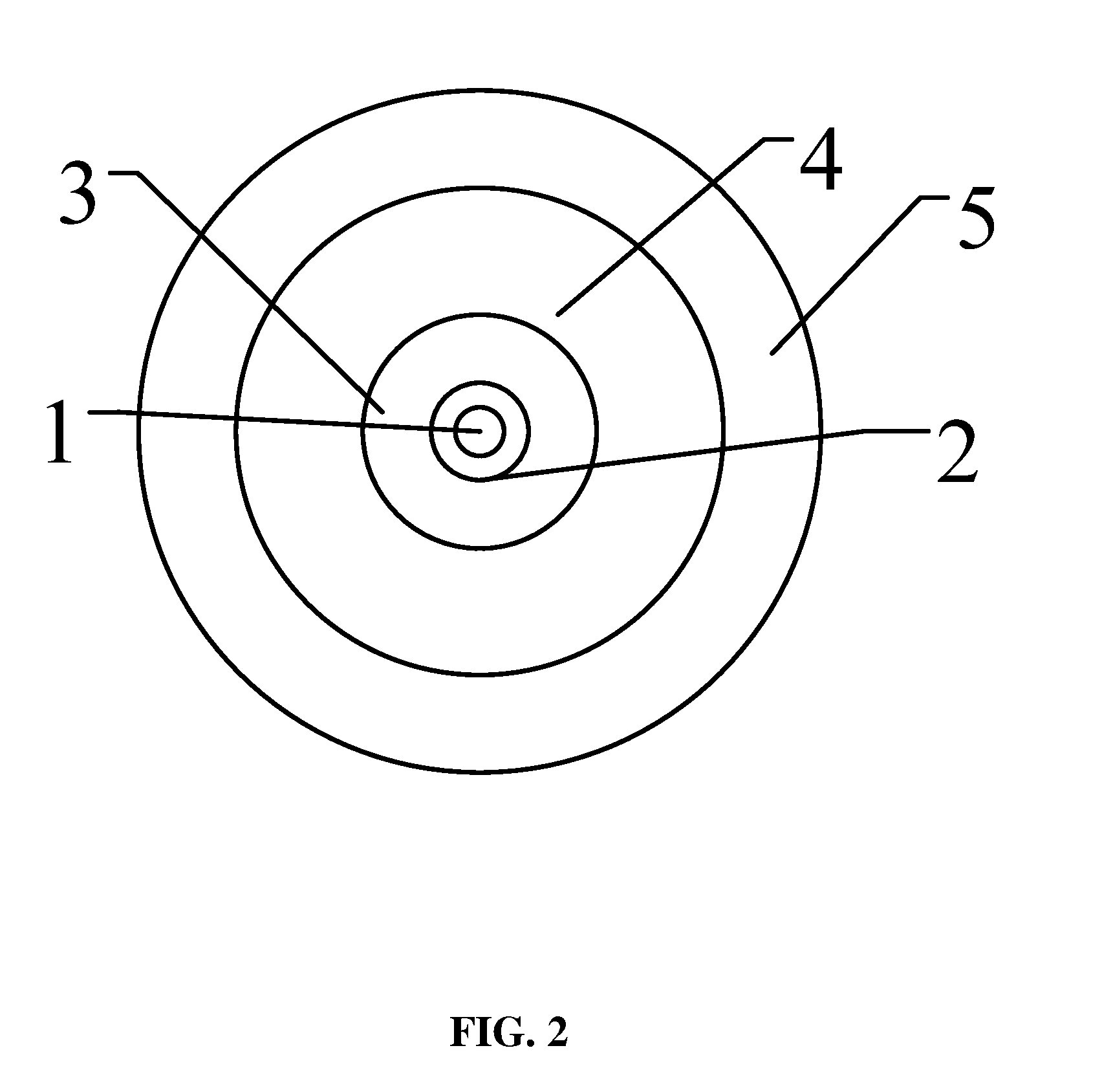

Method for producing high strength and long coiling length single-mode fiber for submarine cable

ActiveUS20110094268A1High strengthAvoid short lengthGlass optical fibreMaterial analysis using wave/particle radiationUV curingUltraviolet

Owner:ZHONGTIAN TECH FIBER OPTICS

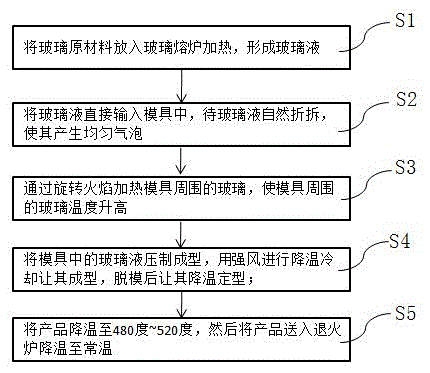

Forming method for bubble glass by means of flame polishing

InactiveCN105601089AReduce wasteIncrease profitGlass pressing apparatusGlass productionGlass furnaceMetal

The invention relates to a forming method for bubble glass by means of flame polishing. The forming method comprises the steps that 1, a glass material is put in a glass furnace for heating to form glass metal; 2, the glass metal is directly conveyed into a mold for natural bending and disassembling and then made to produce uniform bubbles; 3, a swirlflame is used for heating the glass around the mold to raise the temperature of the glass around the mold; 4, the glass metal in the mold is pressed and formed, a strong wind is used for cooling and shaping the glass metal, and the glass is subjected to cooling and setting after demolding; 5, the product is cooled to the temperature of 480 DEG C to 520 DEG C and then conveyed into an annealing furnace to be cooled to normal temperature. Through the forming method for the bubble glass by means of flame polishing and devices thereof, glass waste can be reduced, consumption of the glass material can be reduced, and the utilization rate of the glass is greatly increased; meanwhile, finished product production processes are reduced, cutting, grinding and manual polishing are not needed, and therefore the product cost is greatly lowered.

Owner:唐云国

Optical fiber glass base material manufacturing method and optical fiber glass base material

Provided is an optical fiber glass base material manufacturing method that includes flame polishing an outside of a starting base material that includes a core and a first cladding with an oxyhydrogen flame and then arranging a glass fine particle synthesis burner facing the starting base material, which rotates, moving the starting base material and the burner back and forth relative to each other along the starting base material, and depositing glass fine particles produced by hydrolysis of glass raw material in the oxyhydrogen flame as a porous glass layer of a second cladding, the method comprising synthesizing and depositing the glass fine particles under conditions in which a hydrogen flow rate during a first back and forth deposition pass performed immediately after supply of raw material is started is greater than a normal hydrogen flow rate.

Owner:SHIN ETSU CHEM IND CO LTD

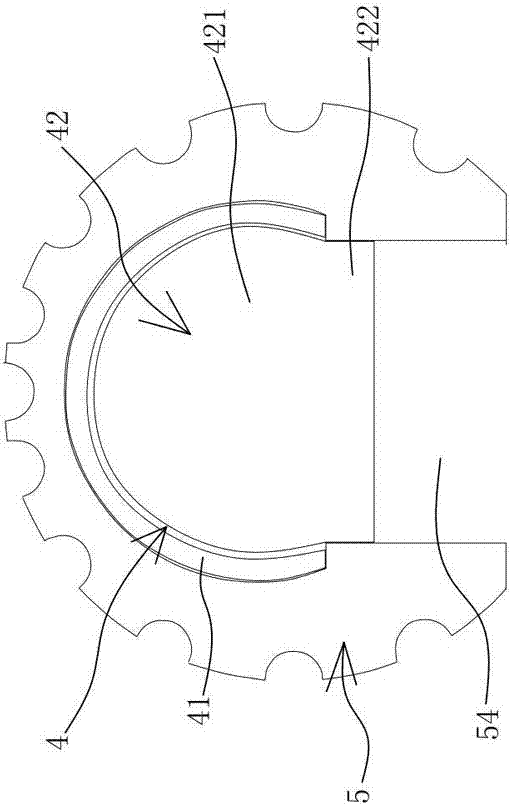

Flame polisher for polishing outer surface of glass cup and use method of flame polisher

The invention relates to glass cup production equipment, in particular to a flame polisher for polishing the outer surface of a glass cup and a use method of the flame polisher. The flame polisher comprises a polishing flame gun for polishing the glass cup, wherein the polishing flame gun is connected with a moving mechanism used for controlling movement of the polishing flame gun. The flame polishing equipment for glass cup production is provided, polishing operation of the glass cup is more intelligent through combination of mechanical components, and injury of conventional manual polishingto workers is also reduced.

Owner:芜湖万辰电光源科技股份有限公司

Flame polishing device and flame polishing process for production of temperable ultra-white glass

The invention discloses a flame polishing device and a flame polishing process for production of temperable ultra-white glass. The device comprises a processing base, a polishing wheel mechanism and aflame jetting mechanism, wherein the polishing wheel mechanism is installed on the upper left side of the processing base, the flame jetting mechanism is installed on the upper right side of the processing base, a fired tempered glass billet is placed on a polishing workbench, a polishing base and a front-end assembly are combined by properly adjusting the placing position, a bolt is mounted on aconnecting plate for fixing, a polishing wheel with proper parameters is selected to be mounted on a mounting shaft, a bolt is mounted on a fixing screw rod for fixing, a regulating valve on a gas conveying pipe is opened, a flame jet orifice jets flame, the flame jetting size is adjusted through an adjusting handle, and a rotating motor is started to drive the mounting shaft and the polishing wheel on the mounting shaft to rotate, so that the polishing wheel performs flame polishing process machining on the tempered glass billet in a flame spraying state, workers do not need to be in contactwith high temperature, and the flame polishing process is convenient to operate.

Owner:安徽晶晶玻璃制品有限公司

Method for preparing crystalline wine bottle cap

ActiveCN110526574AWith a sense of crystalBeautiful appearanceGlass pressing apparatusRefractive indexWine bottle

The invention relates to the field of package manufacturing of wine bottles and provides a method for preparing a crystalline wine bottle cap. The method provided by the invention comprises the stepsof batching, melting, pressing, flame polishing, annealer annealing, aftertreatment and the like. The crystalline wine bottle cap disclosed by the invention has the crystal clear sense of crystals, isattractive and generous in appearance and is very helpful to improving the grade of wine product packages. According to the crystalline bottle cap disclosed by the invention, the adopted crystallinematerial has very high transparency, refractive index and strength, so that the collection and ornamental values of wine products are increased sharply.

Owner:浙江富利华水晶科技有限公司

Manufacturing method of precise 3D glass plate

ActiveCN110963709AOvercoming rough heightOvercome costsGlass pressing apparatusGlass severing apparatusCompression moldingMetallurgy

The invention discloses a manufacturing method of a precise 3D glass plate. The method is characterized by comprising the following steps: S1, the preparation of glass water; S2, compression molding;S3, high-temperature flame polishing; S4, annealing; S5, detection; S6, fine trimming; S7, polishing; and S8, tempering. The invention further discloses the precise 3D glass plate manufactured according to the manufacturing method of the precise 3D glass plate. According to the manufacturing method of the precise 3D glass plate disclosed by the invention, traditional process glass processing is combined with an existing electronic 3D glass processing process, the precision which cannot be achieved by glass produced by a traditional pressing and pressure blowing method is achieved, the defectsthat a glass product blank obtained by roughening plain glass in existing electronic 3D glass processing is high in height, large in cost and low in amplitude can be overcome, and the method of the invention has the advantages of low cost, high precision, high product percent of pass, high production efficiency and long service life.

Owner:惠州佳铭光电有限公司

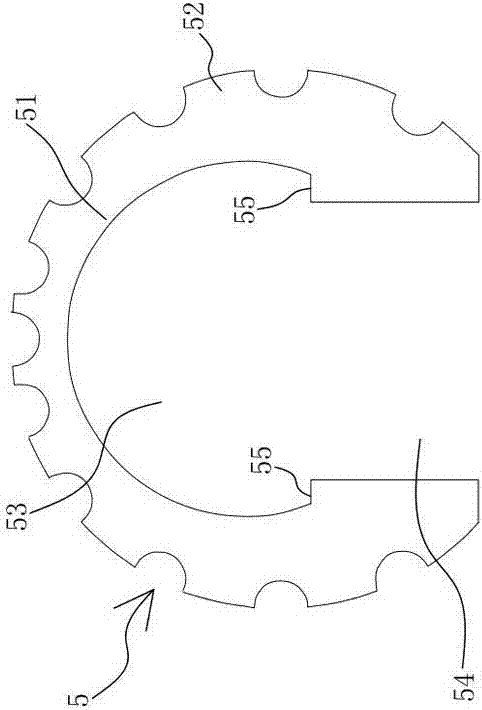

Glass container surface flame polisher

The invention relates to a glass container surface flame polisher, which comprises a base, wherein a drive mechanism is arranged on the base; a transmission and speed regulation mechanism is arranged on the drive mechanism; a plurality of working positions for placing a glass container to be processed are arranged on the transmission and speed regulation mechanism; a plurality of molding air blowers are arranged under the working positions; a burner device is arranged at one side of the working positions; a high temperature hood covers outside the burner device; a longitudinal burner matched with the burner device is suspended above the working positions, and is driven and positioned by a burner positioning and driving device; the burner positioning and driving device comprises a burner rotator, a burner automatic lifter and a burner high-low positioner; the burner positioning and driving device is connected with an oxygen pipeline and a natural gas pipeline. The technical scheme provided by the invention can realize rapid surface polishing on the glass container with flaws on the surface so as to enable the surface temperature of the glass container to be even, solve the problems such as deformation and cracking, and ensure the uniformity of the quality of the processed glass container to be good.

Owner:浙江长兴杭华玻璃有限公司

Glass bottle capable of resisting 1300 DEG C and being not deformed during high temperature flame polishing, and preparation method thereof

ActiveCN109721246AImprove heat treatment effectAvoid unprocessable situationsTherapeutic effectBottle

The invention belongs to the technical field of glass bottle processing, and discloses a glass bottle capable of resisting 1300 DEG C and being not deformed during high temperature flame polishing, wherein the glass bottle comprises: Al2O3, SiO2, BaO, Fe2O3, La2O3, MnO, Sb2O3, TiO2, ZnO, B2O3, As2O3, CaO, K2O, MgO, Na2O, SrO, Y2O3 and ZrO2. According to the present invention, when the temperaturereaches about 700-800 DEG C, the surface of the glass bottle is subjected to treatment and flame polishing, such that the heat treatment effect is good due to the soft exterior and the hard interior at this time, and the condition of incapability of being processed due to easy softening of the original glass bottle can be avoided.

Owner:浙江晶华玻璃有限公司

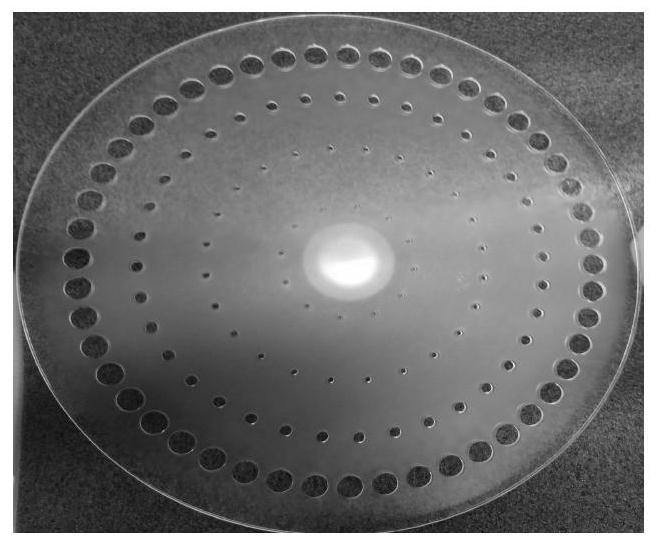

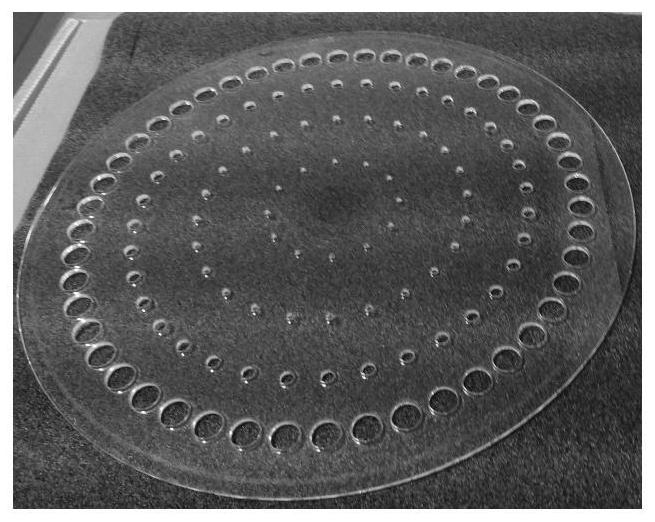

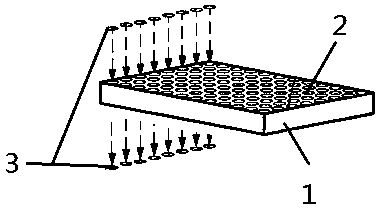

Quartz glass porous enzyme label plate manufacturing method and quartz glass enzyme label plate

PendingCN109116016ASmall coefficient of thermal expansionImprove temperature resistanceMaterial analysisHydrofluoric acidHardness

The invention relates to a quartz glass porous enzyme label plate manufacturing method and a quartz glass enzyme label plate prepared through the method. The preparation method comprises: preparing aquartz glass plate; cutting, and drilling holes; carrying out fine grinding; soaking with a 10-20% hydrofluoric acid solution, washing with water until achieving a neutral state, and drying; carryingout flame polishing; and annealing to remove stress until the quartz glass enzyme label plate is stress-free. According to the present invention, the prepared quartz glass enzyme label plate has advantages of high hardness, good chemical stability, repeated assembly use, energy saving and environmental protection, and is not limited by various conditions.

Owner:锦州明德石英玻璃有限公司

Glass container flame polishing machine

The invention relates to the technical field of glass processing, and especially relates to a glass container fire polishing machine, which solves technical problems in prior arts such as unreasonable design. The fire polishing machine comprises a frame, and a glass container conveyer belt arranged above the frame. The fire polishing machine is characterized in that: plural sets of fire polishing mechanism are arranged on the frame, wherein the fire polishing mechanisms are orderly arranged along the conveyer belt; each fire polishing mechanism is connected to the frame through an adjustable movable mechanism; the fire polishing mechanisms can move along the conveyer belt with the driving of the adjustable movable mechanism; while moving along the conveyer belt, the fire polishing mechanisms can be elevated in a vertical direction with the adjustable movable mechanism. Compared to prior arts, the glass container fire polishing machine has advantages of reasonable design, simple structure, high heat treatment temperature, and high speed. Meanwhile, flaws appeared during glass bottle production processes can also be solved by the machine. The processed glass containers have good surface fineness, no dust, and basically no pollution.

Owner:HANGZHOU ZHENHUA COSMETIC GLASS

Optical fiber base material machining method

ActiveUS10011516B2Surface state is deterioratedExtension of timeGlass fibre drawing apparatusGlass productionMachiningBiomedical engineering

Owner:SHIN ETSU CHEM IND CO LTD

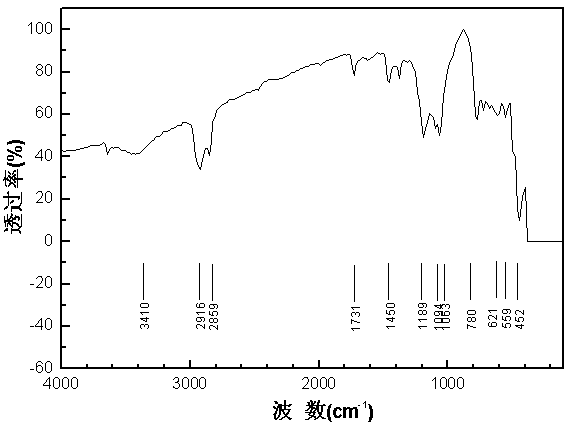

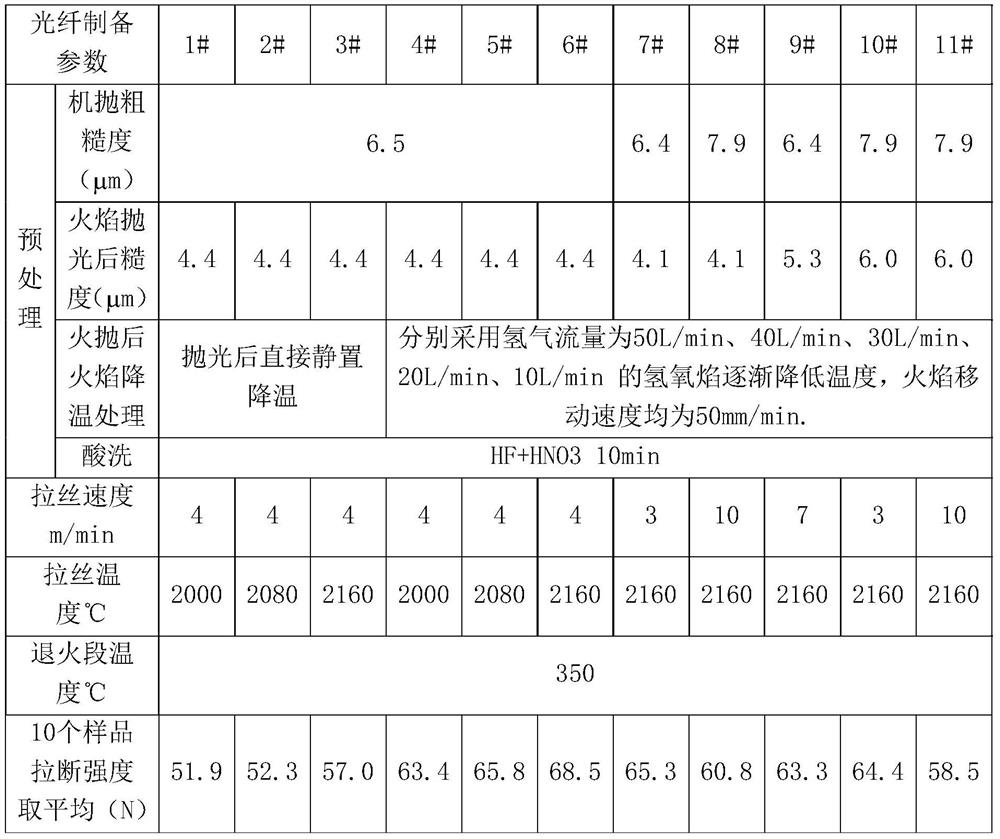

A kind of preparation method of high-strength silica optical fiber

ActiveCN113213748BHigh strengthEliminate temperature gradientsGlass making apparatusBare fiberHydrogen flow

The invention relates to a preparation method of silica optical fiber, in particular to a preparation method of high-strength silica optical fiber, which is used to solve the disadvantage that the strength of the existing silica optical fiber cannot meet the requirements of special application occasions. The preparation method of the high-strength silica optical fiber comprises the following steps: firstly, mechanically polishing a quartz preform with a diameter of 20-35 mm, the roughness after polishing is 6-8 μm, and then performing flame polishing, and the roughness after polishing is 4-6 μm , and then gradually reduce the heating temperature by gradually reducing the flow rate of hydrogen in the oxyhydrogen flame. After stopping the heating, let the quartz preform stand at room temperature, pickle the quartz preform and then draw it. The drawing speed is 3-10m / min , while annealing the bare optical fiber output from the exit of the drawing furnace, the length of the annealing section is 600mm, the annealing temperature is 300-500°C, and finally the bare optical fiber is coated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Flame polishing device for inner part of glassware

The invention discloses a flame polishing device for an inner part of glassware and relates to the technical field of glassware processing. The flame polishing device comprises a base, wherein a driving mechanism and a feeding mechanism are fixed on the base; the driving mechanism is used for driving a rotary shaft; a spraying nozzle is fixed at one end of the rotary shaft; a connecting part whichis matched with the driving mechanism is fixed at the other end of the rotary shaft; the inner part of the spraying nozzle is in thread matching with a flow guide cap; a flow guide barrel is arrangedon one end face of the flow guide cap; a gap is formed between the flow guide barrel and the inner surface of the spraying nozzle; flow guide through channels are uniformly distributed and opened onthe peripheral side face of the flow guide cap along the axial direction; one end of the flow guide cap is a groove. According to the flame polishing device disclosed by the invention, the driving mechanism and the feeding mechanism are used for carrying out flame polishing on the inner part of the glassware; flame of the feeding mechanism is uniformly distributed through the driving mechanism, sothat the inner part of the glassware is uniformly polished; one spraying nozzle is connected and is used for adjusting the spraying-out volume of the flame.

Owner:ANHUI KANGTAI GLASS IND TECH

Glass flame polishing gun

The invention provides a glass flame polishing gun, and belongs to the technical field of glass polishing equipment. The glass flame polishing gun solves the problem that design in the prior art is not reasonable. The glass flame polishing gun comprises a gas storage chamber, and a gas inlet hole formed in the gas storage chamber is connected with an outer main gas input pipe. The glass flame polishing gun is characterized in that an outer main oxygen input pipe penetrates an oxygen inlet outer hole in the gas storage chamber to be connected with the oxygen storage chamber in the gas storage chamber. The glass flame polishing gun has the beneficial effects that the oxygen storage chamber is arranged in the gas storage chamber and isolated from the gas storage chamber, the utilization rate of the work space is increased, and due to the arrangement that the other end of a spray pipe assembly slightly stretches out of a gas spraying port assembly arranged on the gas storage chamber, and the gas and oxygen are in an outer mixing mode, flame stiffness is improved, and fire return is not likely to happen; and through the arrangement of a tooth-shaped supporting assembly, the oxygen storage chamber is easy to dismount and mount on the gas storage chamber, and gas in the gas storage chamber flows smoothly without obstructions.

Owner:TONGXIANG HESHAN CRAFT GLASSWARE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com