Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Electronic scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

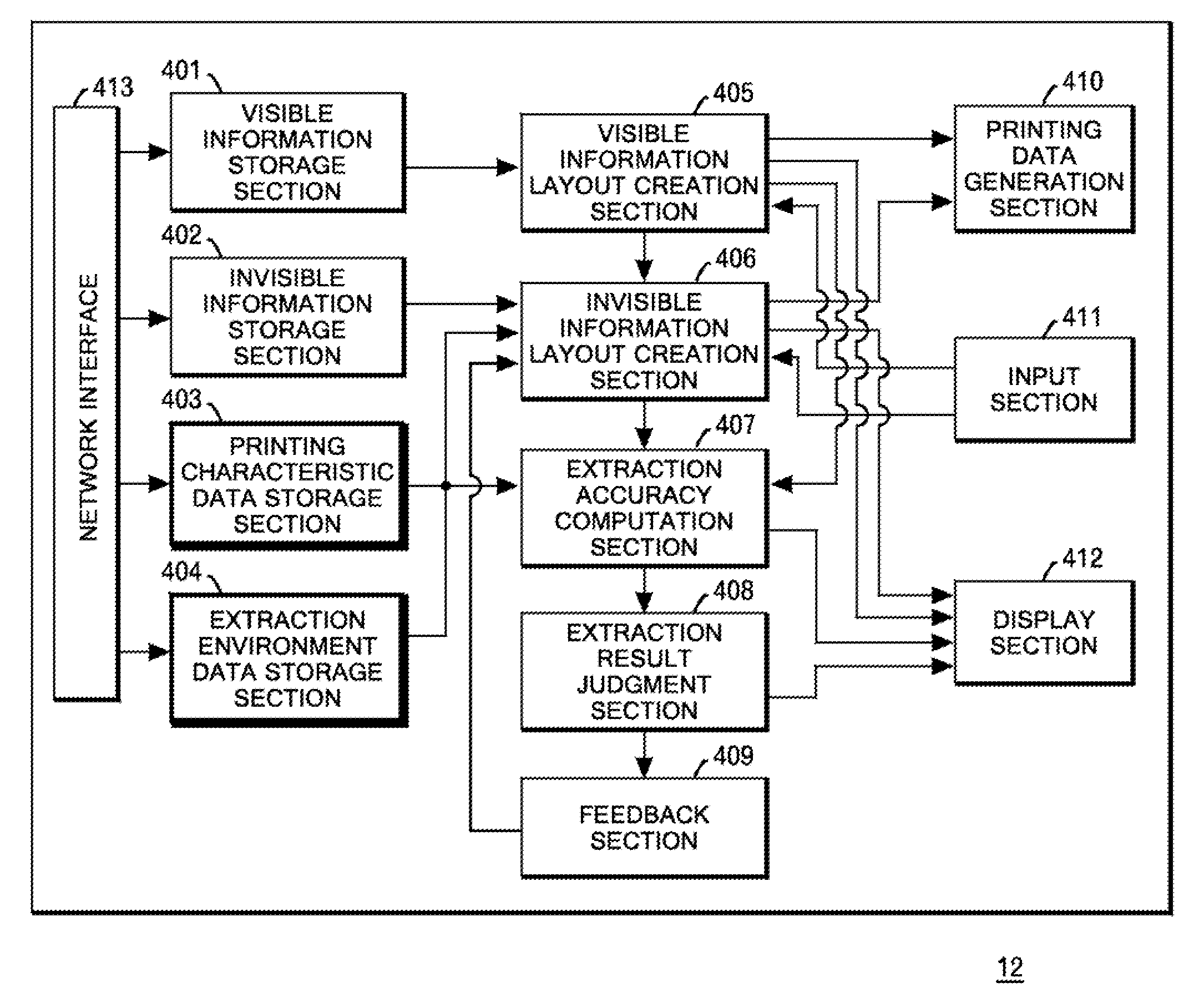

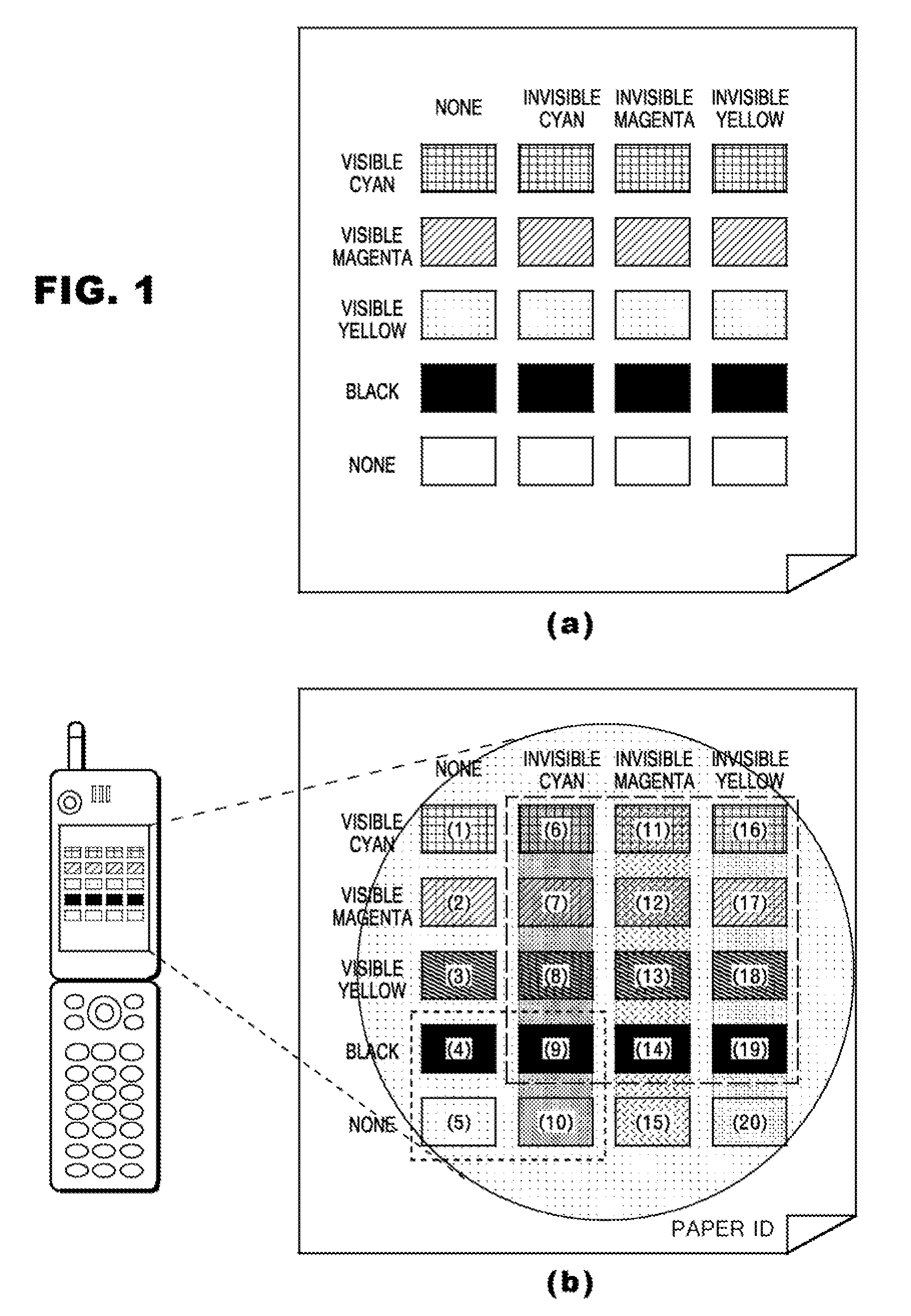

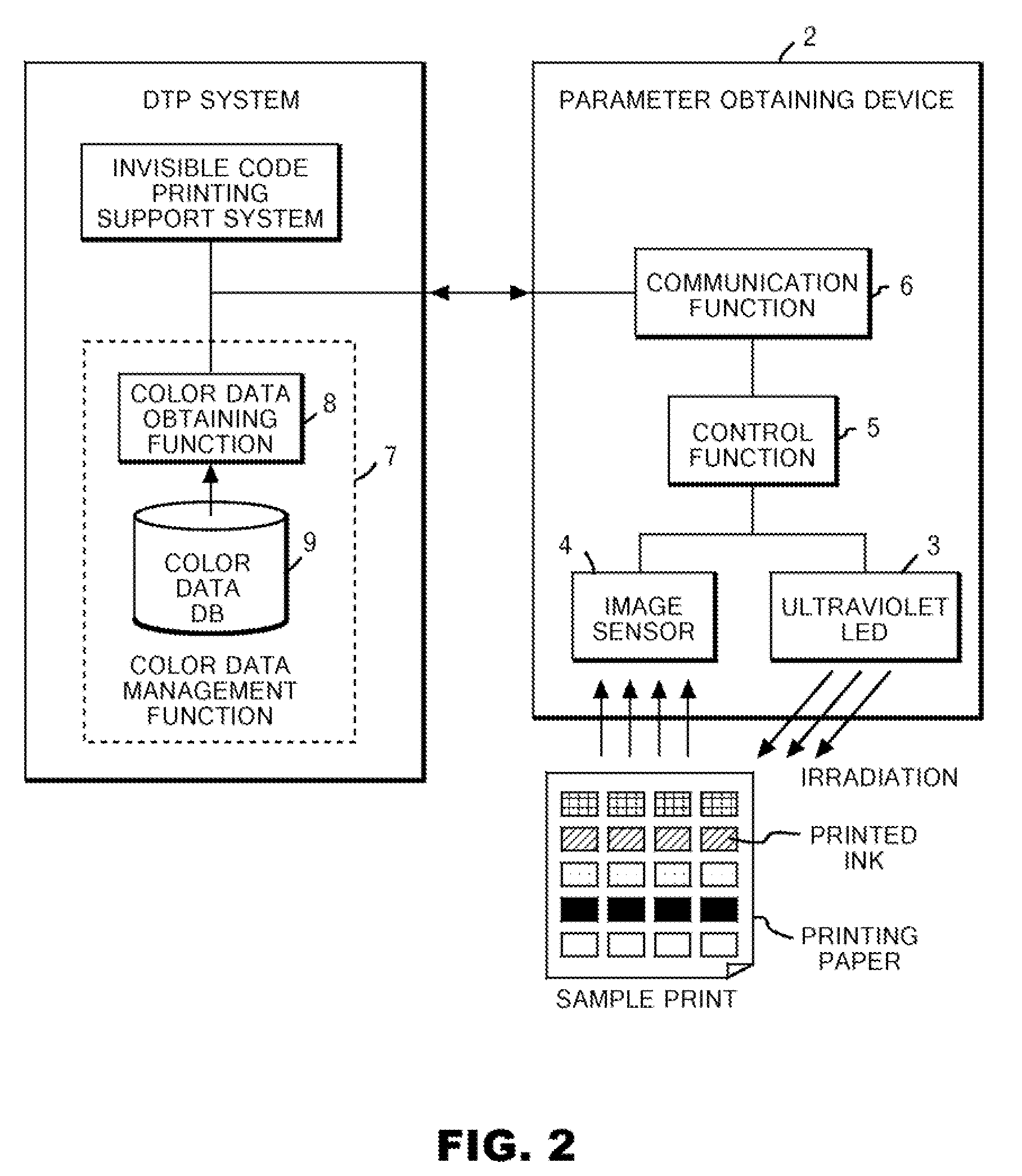

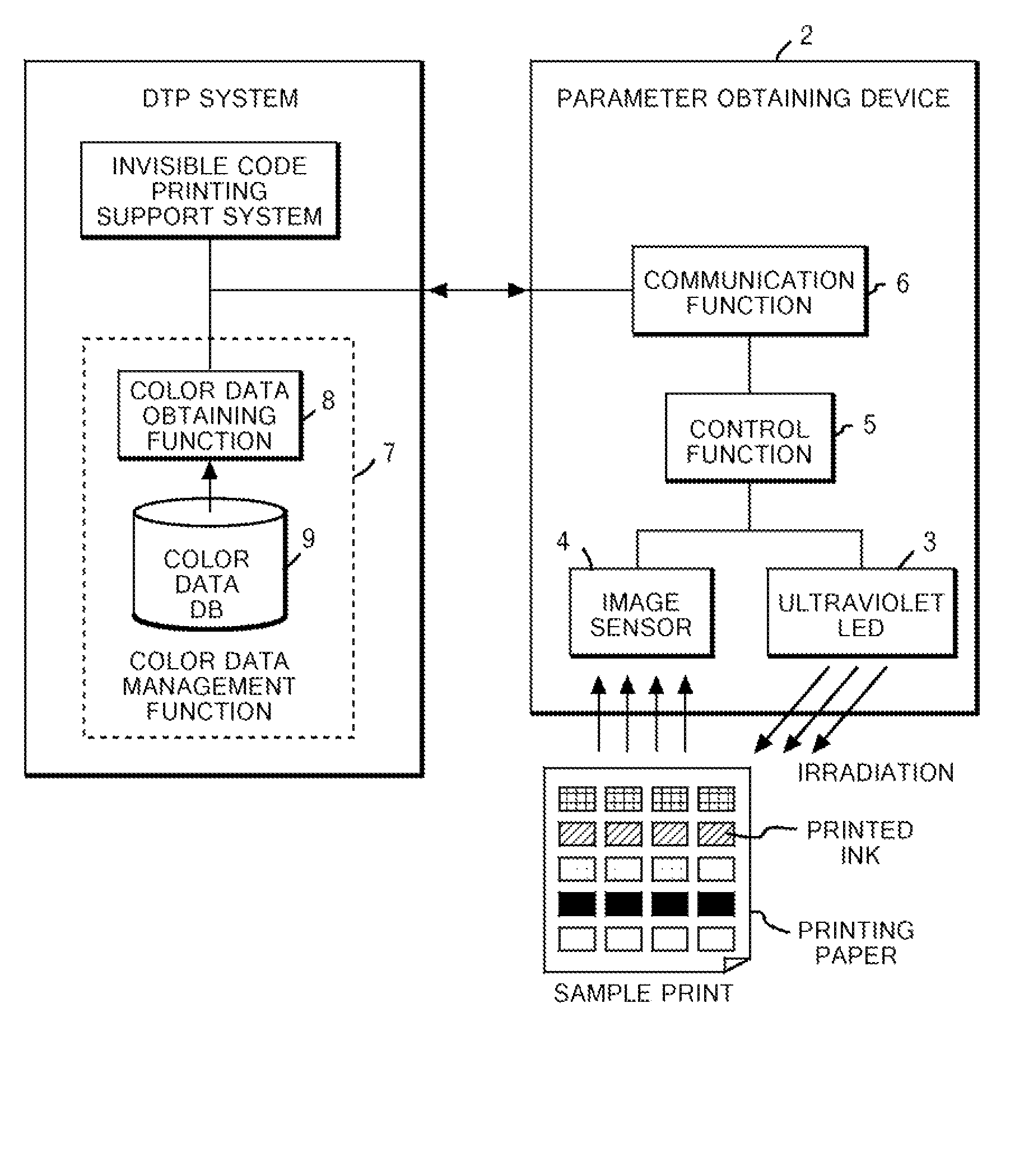

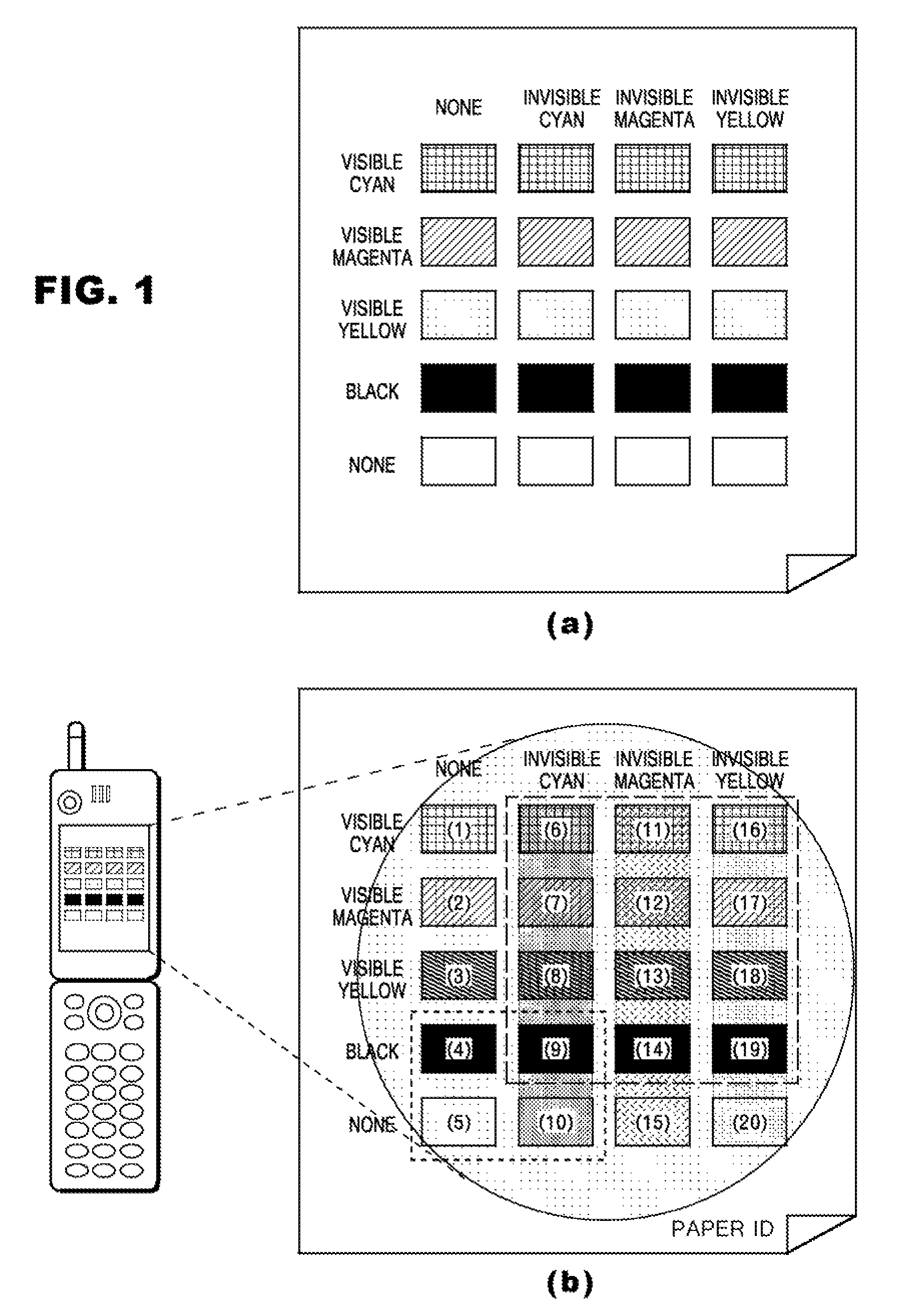

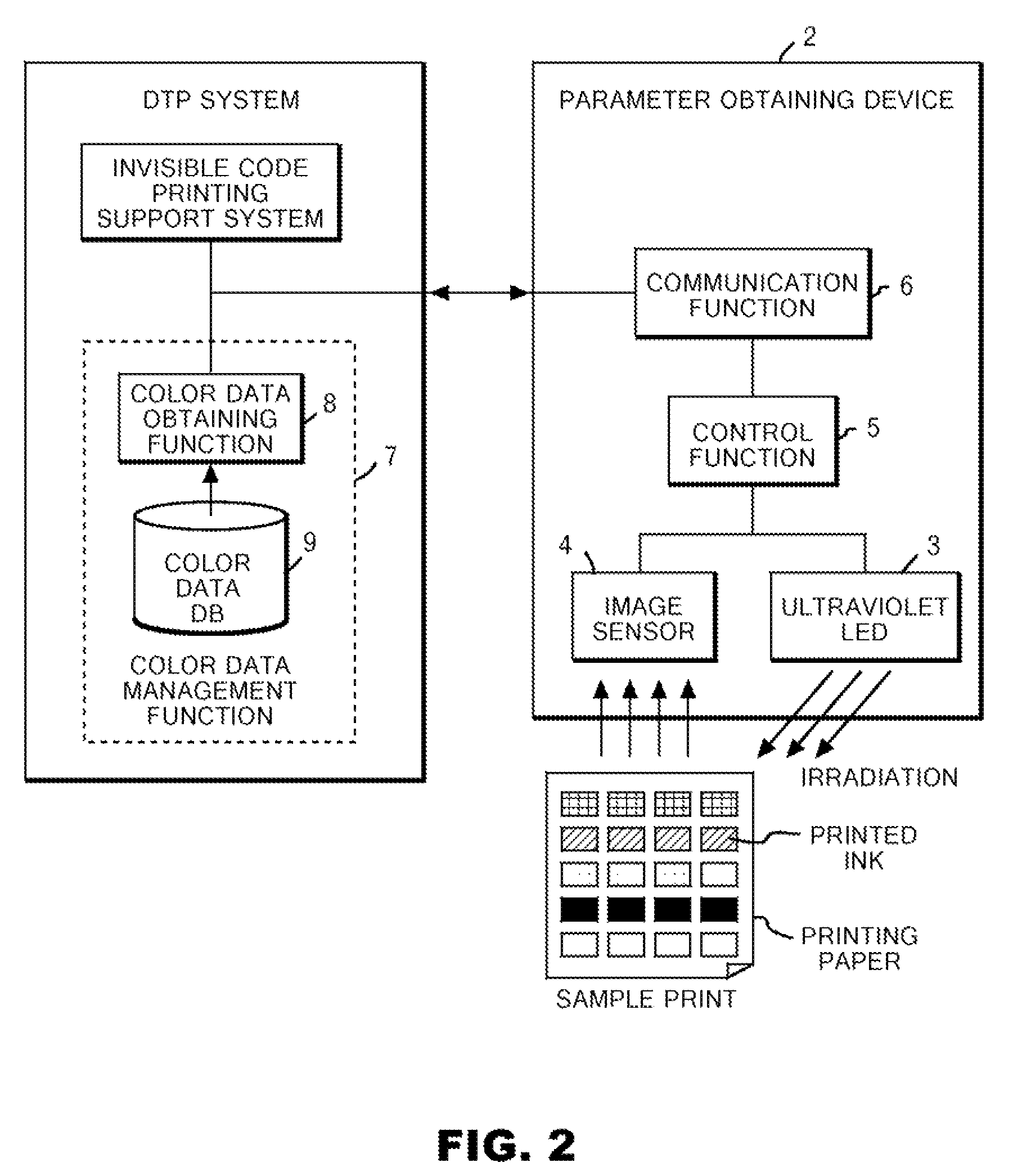

Method and system for obtaining parameter for simulation in invisible code printing support system

InactiveUS20080151280A1Improve accuracyEasy to carryDigital computer detailsVisual presentationOptical propertyUltraviolet

An image of a sample print printed to obtain parameters is picked up by using “a parameter obtaining device” that meets the standards of an instrument for the invention of “the electronic scrap system.” Then, the picked-up image is captured by a DTP system, and color data of a needed position are imported to a parameter DB. Thereby, parameters for simulation to be used in an invisible code printing support system can be easily inputted. Use of this method eliminates the necessity of figuring out parameters through experiments and the like, and of inputting these parameters as numerical values. In addition, since this method uses a physical medium and inks to be actually used, as they are, their optical characteristics, an influence of a blue component of invisible light emitted from an ultraviolet LED, and the like can be inputted all together as a picked-up image. Accordingly, it becomes possible to input parameters capable of accurately reproducing actual printed conditions, and thereby to produce printed materials providing high reading accuracy.

Owner:IBM CORP

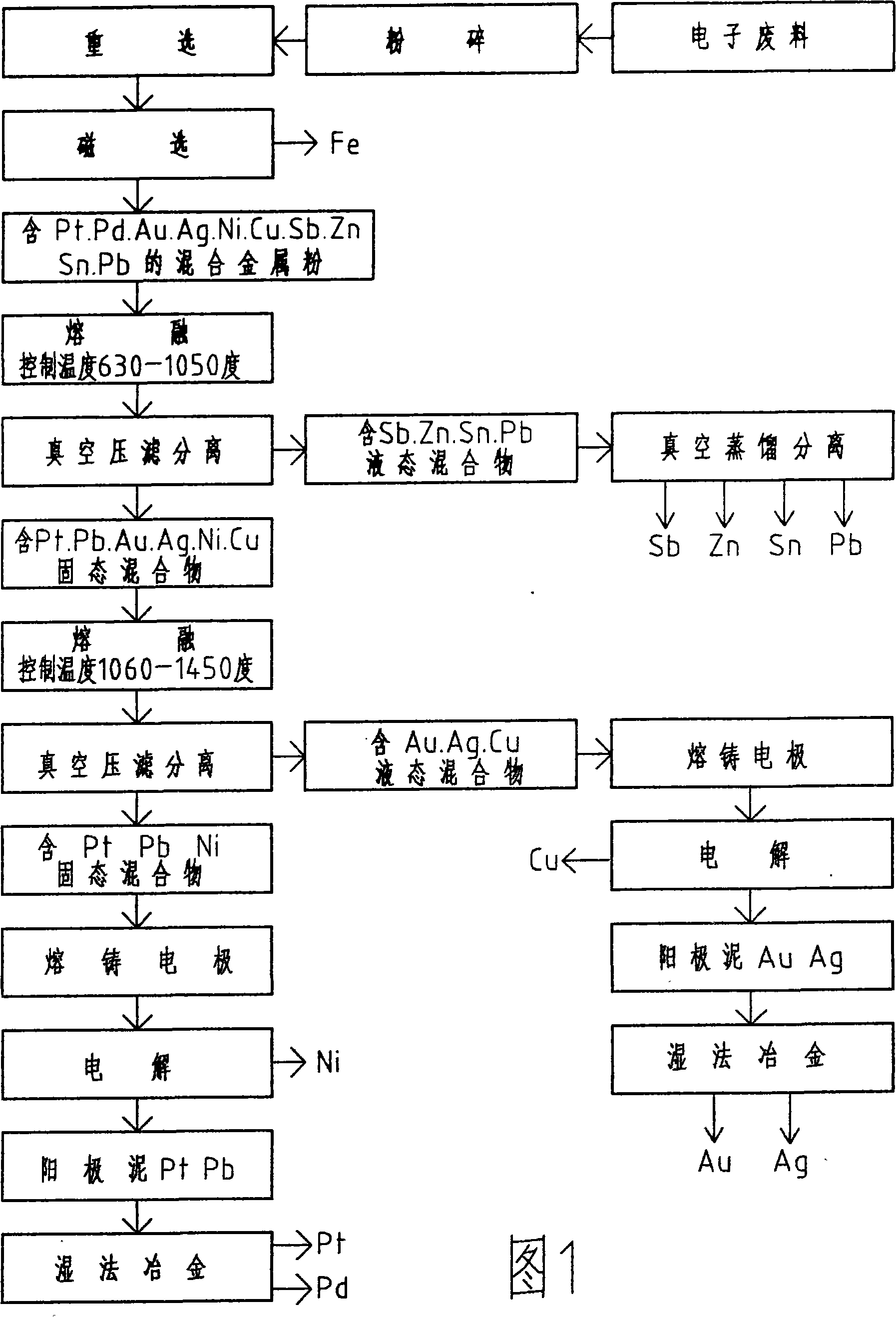

Process for recovering non-ferrous metal and noble metal from electronic waste material

InactiveCN101311280ALow costReduce energy consumptionPhotography auxillary processesProcess efficiency improvementElectrolysisHydrometallurgy

A method for reclaiming nonferrous metals and noble metals in electronic scrap belongs to the technical field of resourceful disposal for industrial waste. The method comprises the following steps: the electronic scrap is crushed and separated to get mixed metal powder containing Pt, Pd, Au, Ag, Ni, Cu, Sb, Zn, Pb and Sn; the powder is fused in two steps; after each step, the fused material is collected by vacuum press-filtering; then the fused material is separated by vacuum distillation separation method to obtain the Sb, Zn, Pb and Sn; the Cu and Ni are extracted by electrolysis; the Au, Ag, Pt and Pd are extracted by hydrometallurgy. The method has the advantages of more through separation and collection, complete recovery of various metals in the electronic scrap, low cost, low energy consumption and high efficiency.

Owner:董蜀希 +1

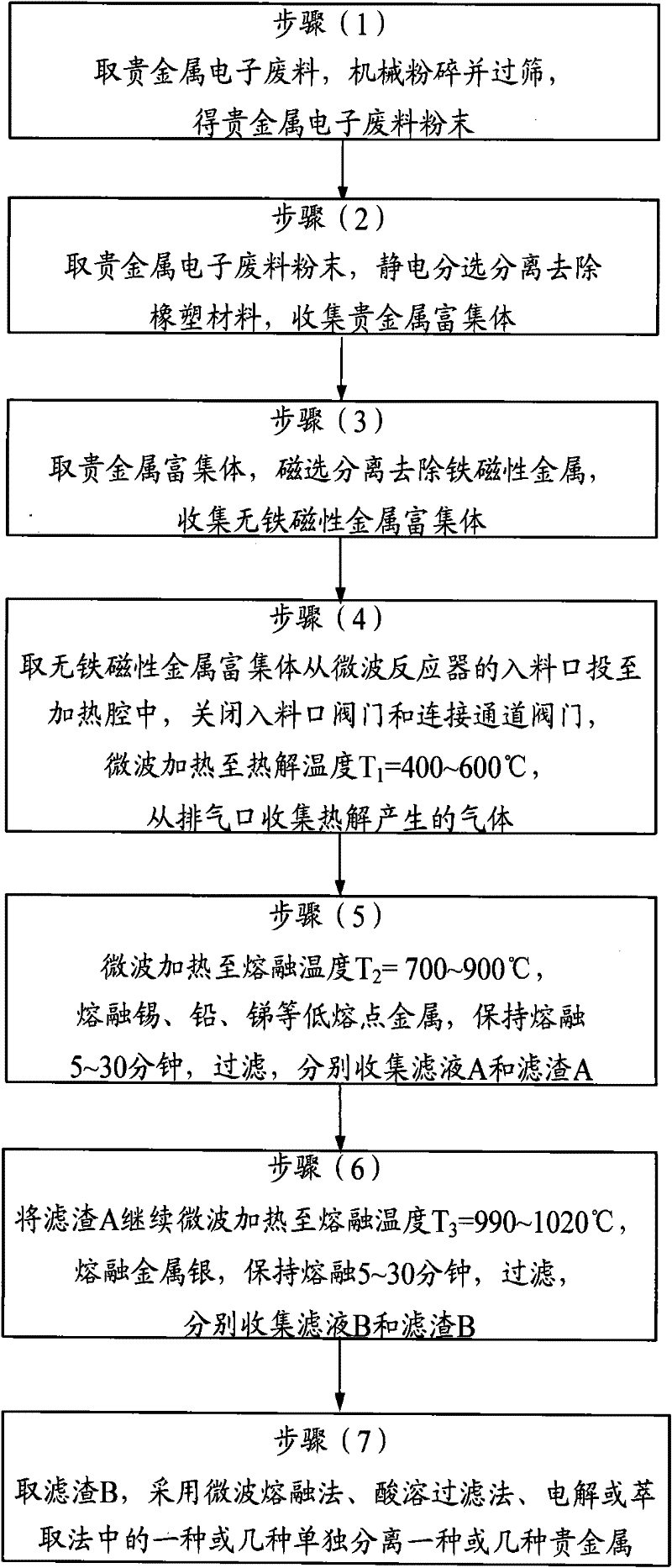

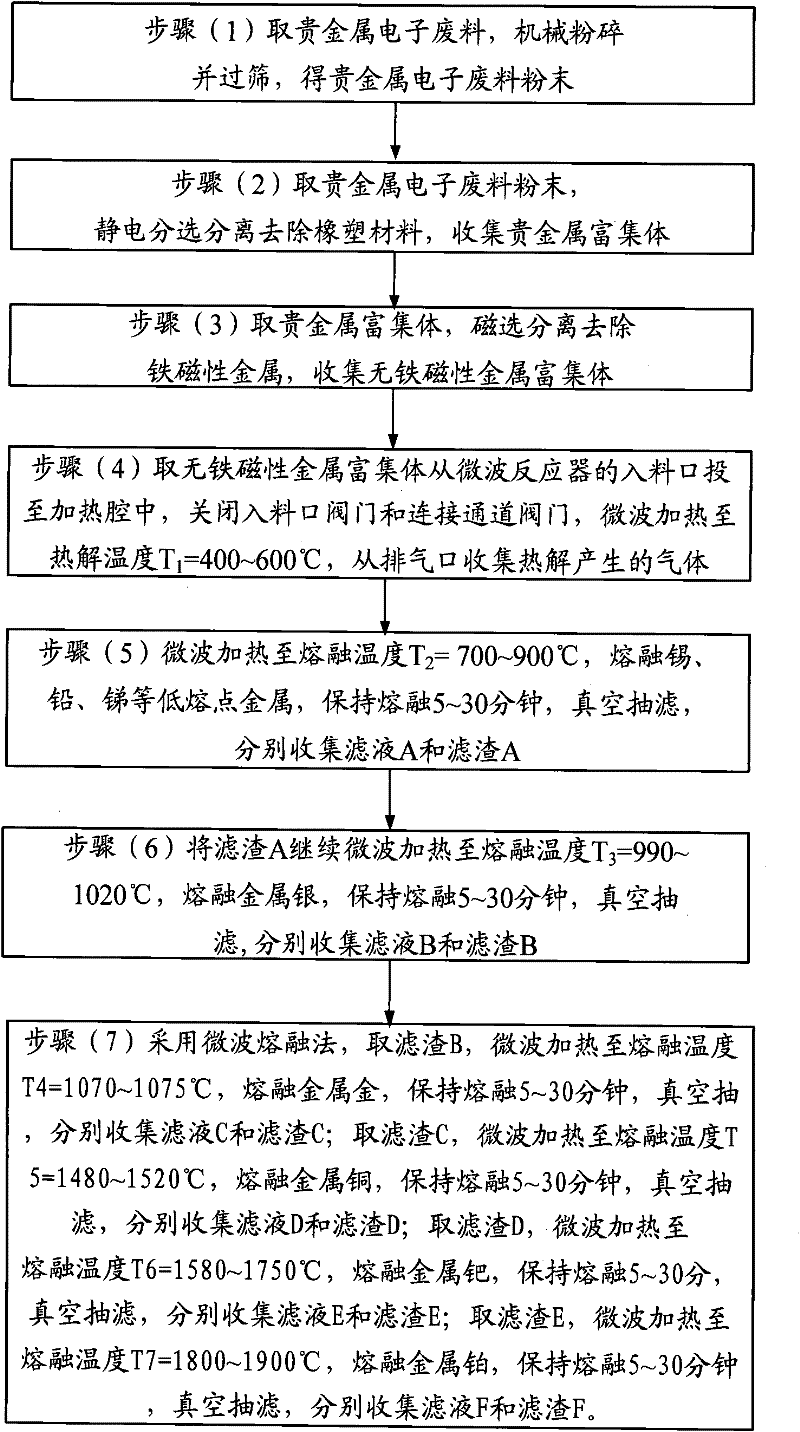

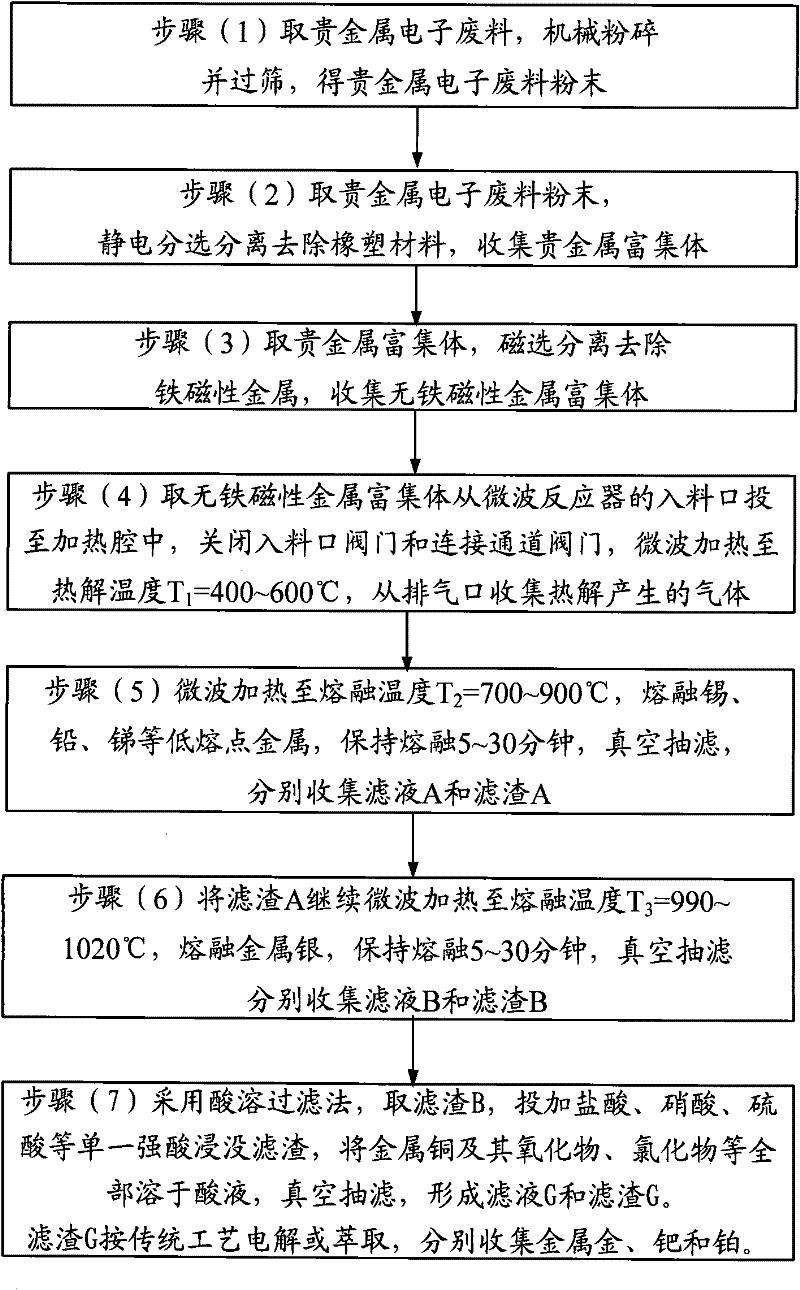

Method and device for recovering precious metals from precious metal electronic scraps

ActiveCN102441553AReduce manufacturing costHeating evenlySolid waste disposalPlastic recyclingMicrowave pyrolysisPlastic materials

The invention provides a method for recovering precious metals from precious metal electronic scraps, which includes the following steps: precious metal electronic scraps are mechanically ground, electrostatically separated and magnetically separated in advance, residual rubber and plastic materials are removed by microwave pyrolysis, microwaves are utilized to indirectly heat precious metal electronic scrap powder, so that the precious metal electronic scrap powder is quickly melted, and thereby precious metals can be sequentially separated and recovered from the lowest melting point of precious metal to the highest melting point of precious metal. The method has the advantages of uniform heating, high speed, energy saving, high efficiency, no pollution and low production cost, and is easy to control. The method also can be used for separating and recovering other ordinary metals with highly different melting temperatures, and is not limited by whether heated materials absorb microwaves or not. The invention also provides a corresponding device, the structure design of the device is reasonable, and the device can help to increase the reaction speed and separate solid from melt in the process of melting precious metals, and is convenient to automatically operate. The invention can recover precious metals in precious metal electronic scraps, so that the resources in scraps can be utilized to the max, and therefore the invention can bring great social and economic benefits.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Noble metalregeneration recovering method for electronic waste material

InactiveCN1458291ALow costAdvanced technologyProcess efficiency improvementRecovery methodSalt deposit

The noble metal regenerating and recovering method from electronic waste material includes pre-treatment of grinding, magnetically selecting and sieving to obtain noble metal containing powder; oxidation to loeaching through adding hydrochloric acid and complexing agent, dropping hydrogen peroxide while heating, leaching for at least 1.5 hr, eliminating superntant to obtain leaches liquid; addingiron powder into the leached liquid to obtain noble metal sludge via replacement; extracting from nobile metal sludge through leaching noble metal sludge, complex salt deposition, adding oxidant until producing chlorine and obtaining complex salt deposit; and purifying Pd. The present invention has the advantages of advanced technological process, low cost and high efficiency.

Owner:ZHEJIANG METALLURGICAL RES INST

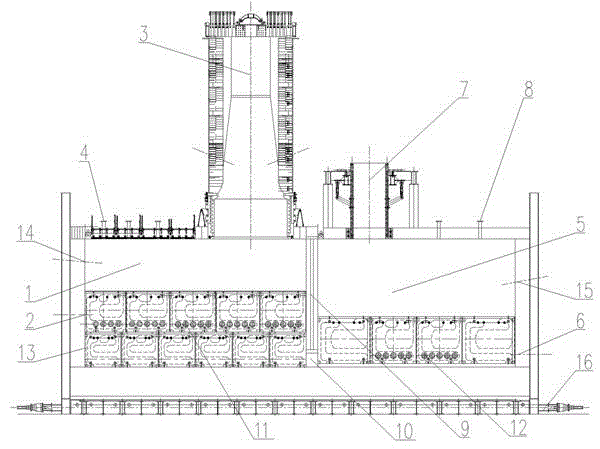

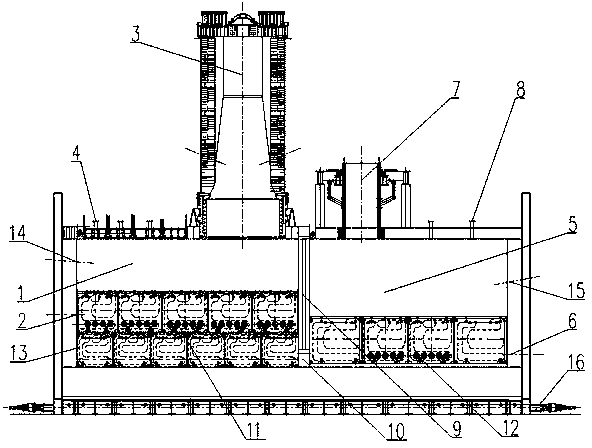

Side-blown continuous smelting process and device for electronic scrap

The invention discloses a side-blown continuous smelting process and device for electronic scrap. The smelting device is divided into a smelting area and a blowing area, wherein a water-cooled partition wall is arranged between the two areas; the lower end of the water-cooled partition wall exceeds an interface of slag and a metal layer, so that black copper flows in the blowing area through an opening on the lower part of the water-cooled partition wall; waste slag obtained from a smelting reaction is discharged from a wall slag tap at the end of the smelting area; and the furnace bottom is inclined from the smelting area to the blowing area, and crude copper obtained from the blowing reaction is discharged from a wall copper discharge opening at the end of the blowing area. According to flow of melt at the lower end of the partition wall, latent heat of the melt is efficiently utilized, and the smelting device has the characteristics of high efficiency and energy conservation; and moreover, a plurality of oxygen-enriched supply inlets are formed on a furnace wall on side faces of the furnace smelting area and the blowing area, the slag layer and the black copper layer are respectively stirred for reaction, and the thermodynamic and dynamic conditions of the reaction are greatly improved, so that the reaction is carried out at high efficiency, the operation time is shortened, the electronic scrap and copper-containing materials can be continuously smelted, crude copper is produced, and precious rare metals contained in the electronic scrap are enriched to the crude copper.

Owner:CHINA NERIN ENG

Recycling method for valuable metal in electronic waste

ActiveCN105349787AComprehensive processing flowEasy to handleProcess efficiency improvementSmelting processMixed materials

A recycling method for valuable metal in electronic waste includes the following steps that the electronic waste and a slag former are mixed to obtain a mixed material, wherein the electronic waste accounts for at least 10% of the mass of the mixed material; the mixed material is put into a smelting furnace for high-temperature smelting, wherein the smelting temperature is controlled to range from 1300 DEG C to 1450 DEG C, and the smelting time is longer than 10 min; and an oxidizing agent is added into the furnace in the high-temperature smelting process, and Cu-Sn alloy and furnace slag containing CaO and SiO2 are generated through smelting, wherein Fe accounts for less than 15% of the Cu-Sn alloy, and the CaO or SiO2 accounts for more than 0.25% of the furnace slag. The recycling method has the beneficial effects that the technological operation is simple, the waste is sufficiently utilized, the valuable metal recycling rate is high, energy consumption and cost are low, and the economic and environmental benefits are good.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

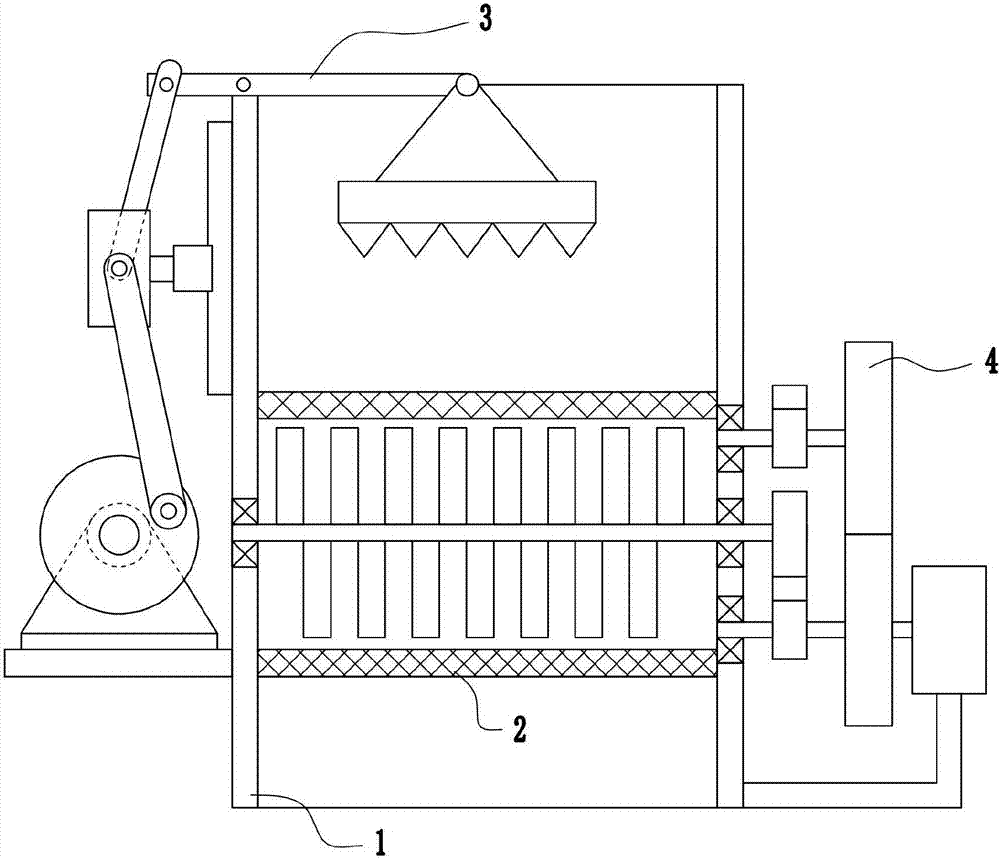

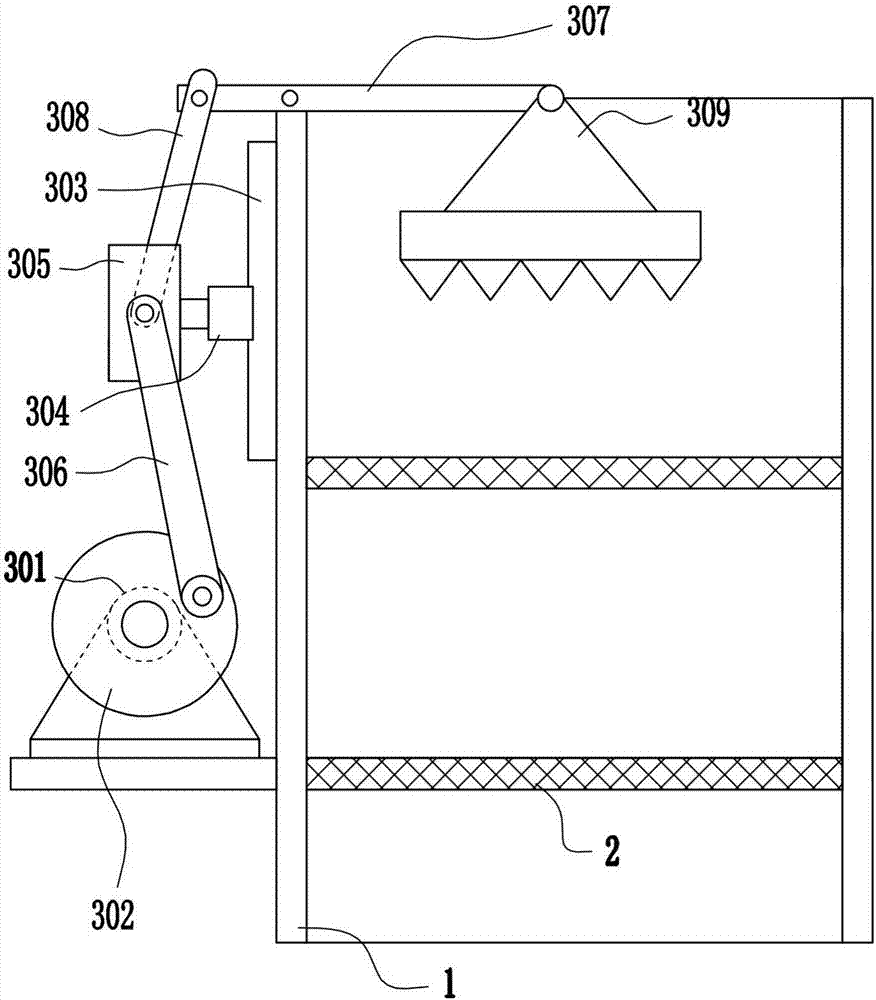

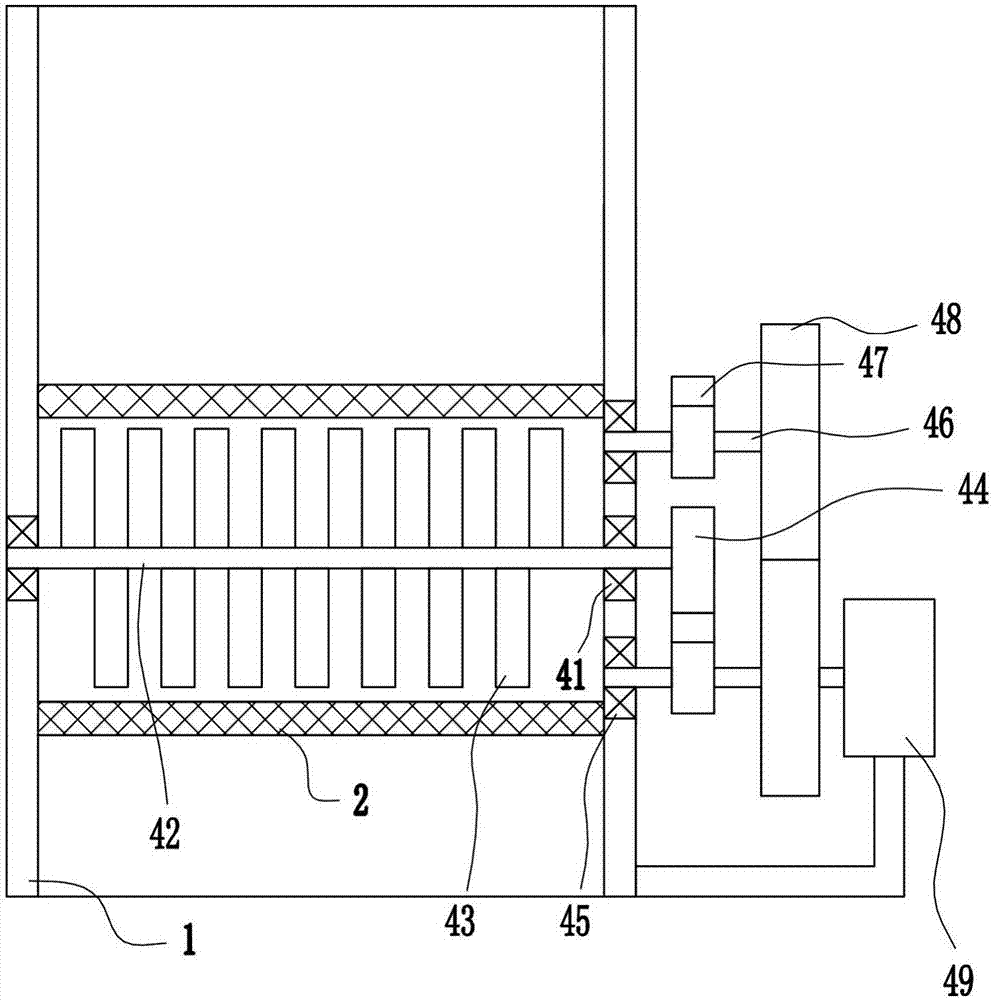

Multi-stage pulverizing device for electronic waste

The invention relates to a pulverizing device, and particularly relates to a multi-stage pulverizing device for an electronic waste. The technical problem to be solved by the invention is to provide the multi-stage pulverizing device for the electronic waste, and the multi-stage pulverizing device evenly pulverizes the waste and saves time and labor. In order to solve the technical problem, the invention provides the multi-stage pulverizing device for the electronic waste. The multi-stage pulverizing device for the electronic waste comprises a pulverizing frame, a primary-stage pulverizing mechanism is connected on the left side of the pulverizing frame, a secondary-level pulverizing mechanism is connected on the right side of the pulverizing frame, each of the upper side and the lower side of the interior of the pulverizing frame is connected with a filter screen, and sieve holes of the upper filter screen are larger than those of the lower filter screen. The invention designs the multi-stage pulverizing device for the electronic waste, the multi-stage pulverizing device for the electronic waste is provided with the primary-stage pulverizing mechanism so as to be favorable for saving time and labor when the electronic waste is pulverized, and the secondary-stage pulverizing mechanism is arranged.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Method and system for treating electronic scrap smoke

ActiveCN104383801AAchieve desulfurizationAchieve dehalogenationDispersed particle separationBromine/hydrogen-bromideBrominePhysical chemistry

The invention discloses a method and a system for treating electronic scrap smoke. The method comprises the following steps: (1) performing countercurrent contact between smoke and absorption liquid so as to obtain purified smoke and absorbed liquid; (2) filtering the absorbed liquid so as to obtain filtrate and filter residue; (3) mixing the filtrate with a heavy metal capture agent, and performing concentration treatment so as to obtain supernatant and filter residues containing heavy metals; (4) introducing chlorine into the supernatant, oxidizing bromide ions in the supernatant into molecular bromine, so as to obtain a reaction solution containing the molecular bromine; (5) distilling the reaction solution containing the molecular bromine so as to obtain bromine-containing gas; and (6) condensing the bromine-containing gas so as to obtain a bromine product and mixed gas. According to the method, the electronic scrap smoke can be effectively purified, the purified smoke can meet the national environmental protection standard, the bromine element can be efficiently recovered, the bromine extraction rate is over 90 percent, and the purity of the bromine product is over 99 percent.

Owner:CHINA NERIN ENG

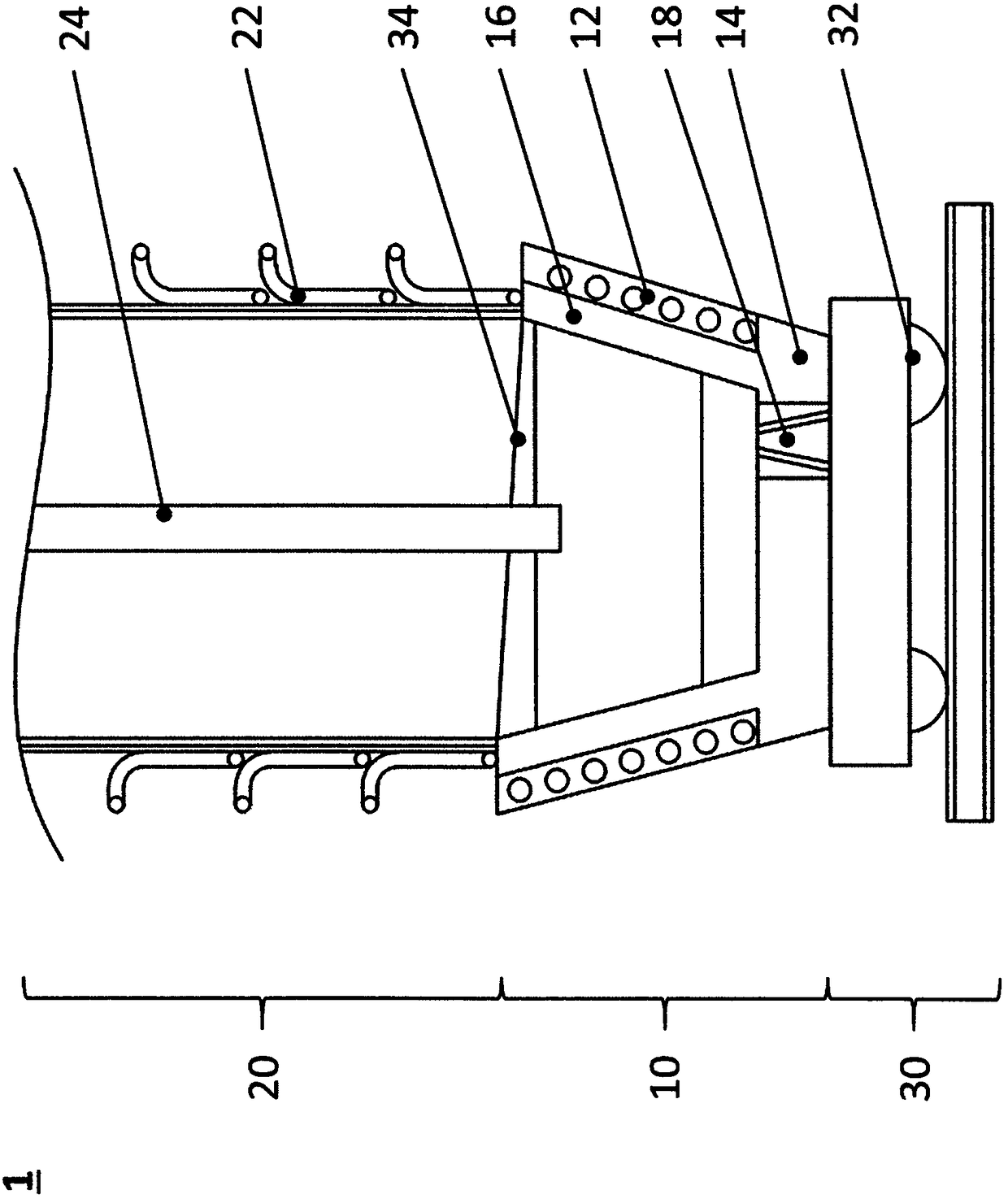

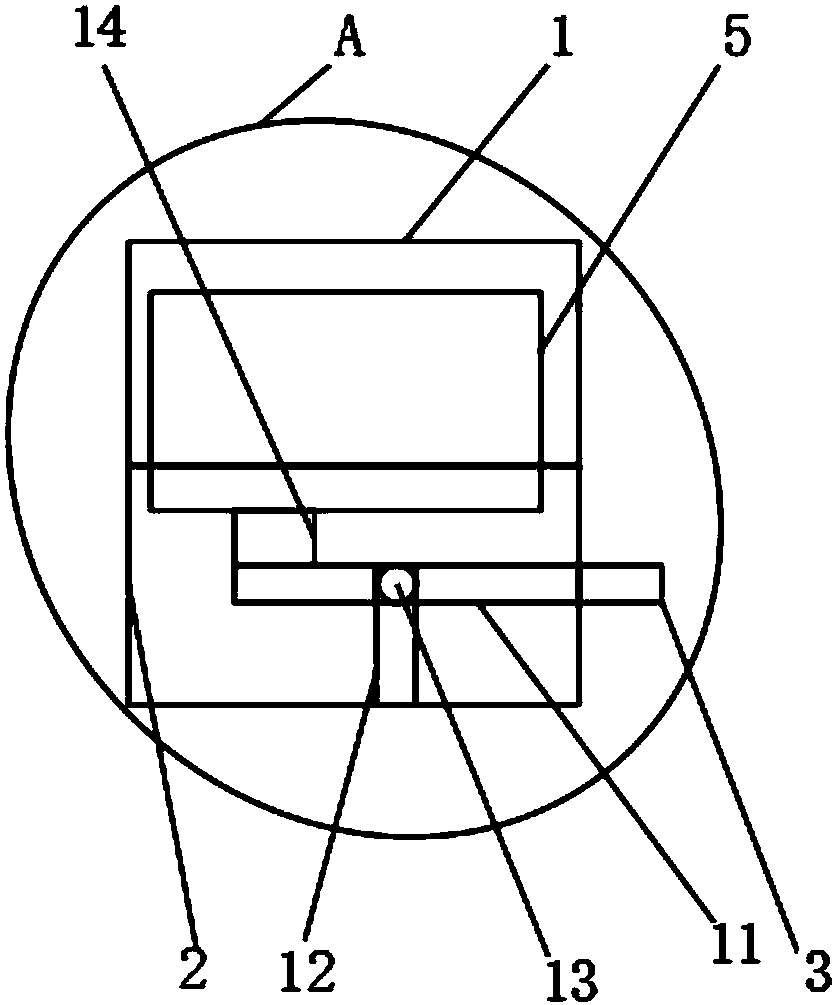

Sorting device and method

InactiveUS7866484B2Reduce transmissionPropagation delayGas current separationSortingVertical edgeEngineering

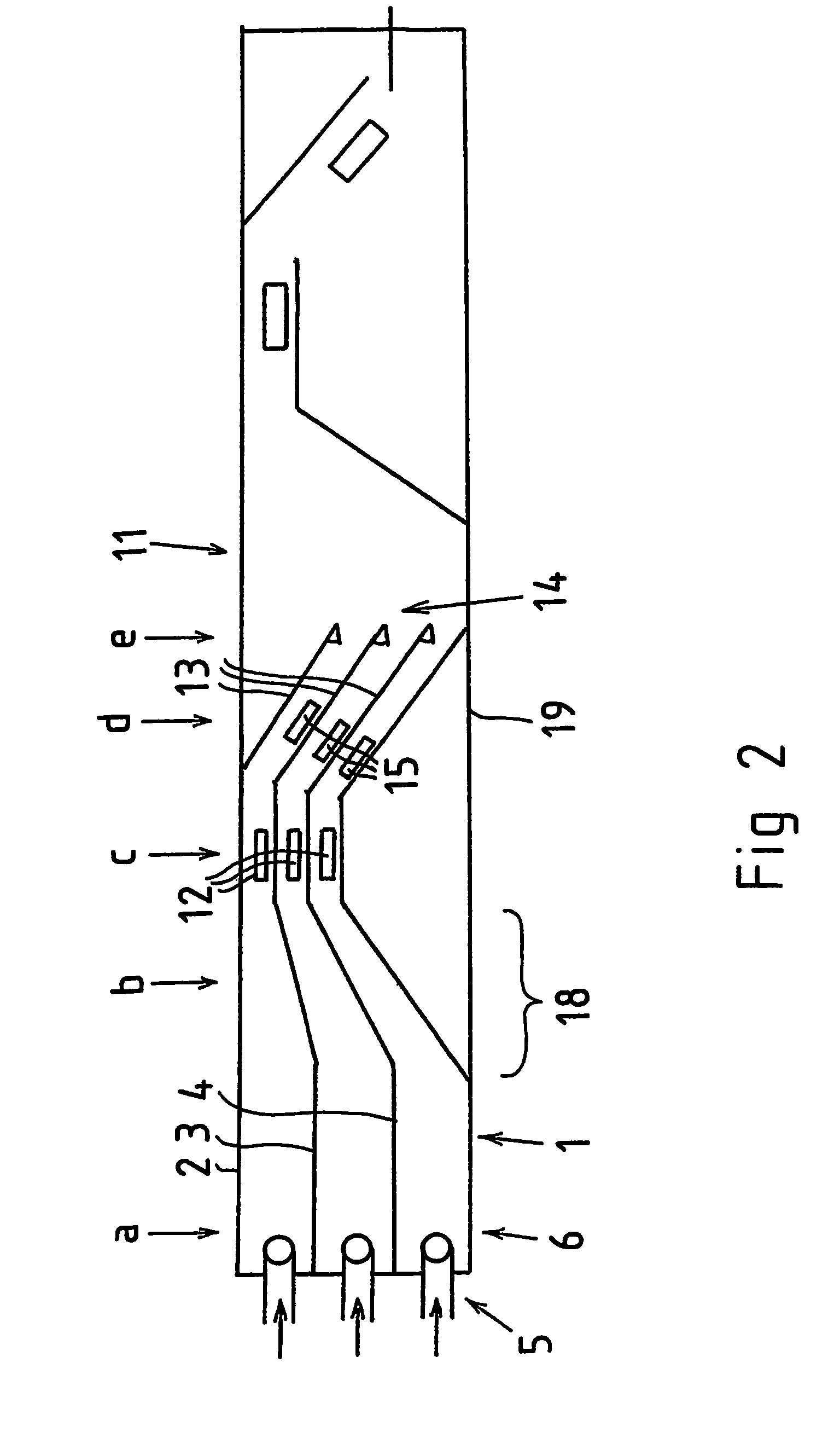

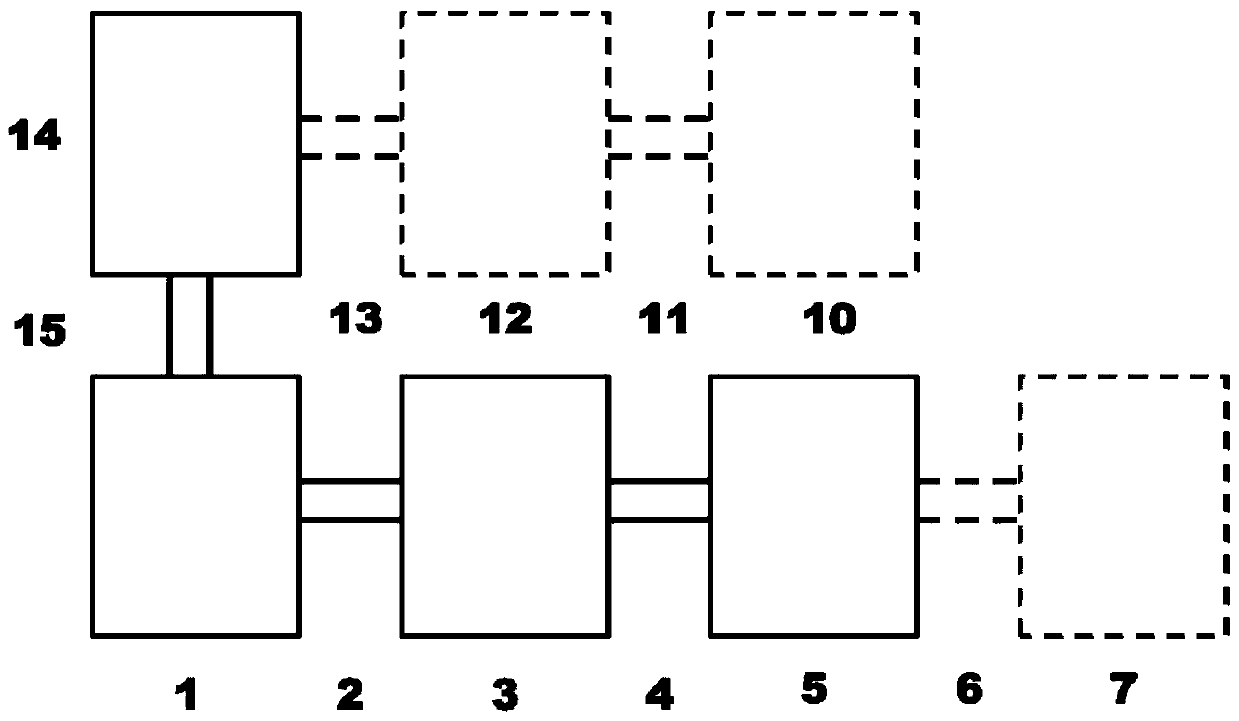

The invention relates to a sorting device and method for sorting granulated mass containing varied materials, such as granulated mass containing varied materials, such as granulated electronic scrap. According to the invention, the sorting device comprises a planar, elongated trough conveyor (1) having at least a first elongated and vertical edge (2, 3, 4); a feeding device (5) for feeding the mass into the first end (6) of the trough conveyor; a vibrator (9) provided with a motor (7) and an eccentric (8), whose rotation axis (10) is disposed in a plane deviating from the plane defined by the trough conveyor so that the mass proceeds obliquely forwards in the trough conveyor towards the first edge and second end (11); a first suction device (12) for removing the lightest surface portion of the mass near the edge, a guide (13) which is oblique with respect to the edge for bringing apart the mass flow from the edge; as well as a mechanical separator member (14) for dividing the mass flow into two parts.

Owner:RANTASALMEN SCEL

Palladium removing and copper extracting method for copper-based palladium plating electronic scraps

InactiveCN105219967AHigh recovery rateReduce manufacturing costProcess efficiency improvementChemistryScrap

The invention discloses a palladium removing and copper extracting method for copper-based palladium plating electronic scraps. The method comprises the steps that the copper-based palladium plating electronic scraps and a dedplating solution composed of a compounding agent, an oxidizing agent, a rate-accelerating additive and the like are mixed according to the proportion of 1:3-1:10, and react for 1-6 h at the temperature of 10-100 DEG C, a palladium plating layer is removed, and most of a copper base is kept; iron powder, zinc powder, cooper plates and the like which enter the deplating solution and are used for palladium are replaced, so that palladium is enriched again; palladium enriched objects are dissolved for liquid preparing, and palladium is separated through an extraction method; palladium strip liquor is refined to obtain palladium powder, the recover rate of palladium is 99%, and the purity of palladium is 99.95%-99.9%; little iron powder, zinc powder and the like which enter the deplating solution and are used for copper are deeply replaced to obtain active copper powder, and the active copper powder can replace iron powder, zinc powder and the like to be used as a replacement agent used for selectively replacing palladium in the deplating solution; and the copper base is subjected to smelting and ingot casting, raw copper is obtained and sold, the recover rate of copper is 95%, and the purity of copper is 98%. The method has the beneficial effects that the palladium deplating efficiency is high, damage to the copper base is small, palladium and copper are high in recovery rate, the method is simple and feasible, the amount of adopted reagent is low, production cost is low, and energy saving and environment friendliness are achieved.

Owner:云龙县铂翠贵金属科技有限公司

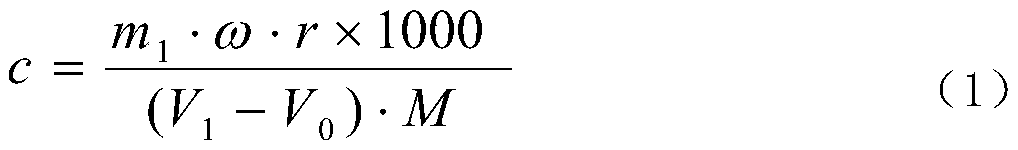

Analysis method for determining copper content in high-tin scrap copper ingots and crude copper

InactiveCN110361341AHigh precisionImprove accuracyChemical analysis using titrationPreparing sample for investigationDissolutionIngot

The invention discloses an analysis method for determining the copper content in high-tin scrap copper ingots and crude copper. Samples are dissolved by nitric acid, tin is precipitated by metastannicacid and separated, and the copper of the filtrate is determined by iodometr so that the precision and the accuracy of the analysis result can be enhanced. An efficient and accurate method for correction of copper by atomic absorption spectrometry after dissolution of filter residue is presented. The method has the advantages of simple operation, easy mastery, good precision, high accuracy and wide applicability and can provide accurate and reliable data support for production process index control, metal balance and trade settlement and meet the needs of production and trade and can also provide theoretical and data support for the formulation of industrial and enterprise standards for scrap copper ingots and crude copper produced by electronic scrap so as to effectively fill the blank of the copper analysis method for the scrap copper ingots and the crude copper produced by the electronic scrap.

Owner:江西华赣瑞林稀贵金属科技有限公司

Method for recovering precious metal from electronic waste

InactiveCN102925700AEfficient enrichmentReduce dosageProcess efficiency improvementElectric arc furnaceHydrometallurgy

The invention discloses a method for recovering precious metal from electronic waste. The method is simple in process, low in cost and capable of gathering the precious metal efficiently. The method includes the following steps: (1) preprocessed electronic waste, a trapping agent and a reducing agent are dried, smashed and mixed evenly; (2) the mixed materials are put in a graphite crucible and placed in a box-type resistance furnace or an electric-arc furnace, temperature rises, reduction is performed, gas is led in to perform protection, and water cooling is performed after reduction so as to enable the precious metal to enter alloys; (3) alloy phase containing the precious metal is immersed in base metal selectively to obtain precious metal enrichment; and (4) the precious metal enrichment is refined by using the hydrometallurgy technology to obtain platinum, palladium, rhodium products.

Owner:荣杨

Smelting method of electronic scraps

The invention discloses a smelting method of electronic scraps. The smelting method of electronic scraps comprises the following steps of 1) mixing the electronic scraps with a slag former and a fuelto obtain a mixed material; and 2) feeding the mixed material in an oxygen-enriched side converting furnace, separately introducing high concentration oxygen and low concentration oxygen in a smeltingarea and a fuming area in the oxygen-enriched side converting furnace, controlling the flue gas outlet temperatures of the smelting area and the fuming area to be 700-1250 DEG C, and performing smelting to produce Cu alloy and furnace slag, wherein the mass ratio of CaO to SiO2 in the furnace slag is larger than or equal to 0.30, the mass ratio of Fe to SiO2 is 0.05-1.0, and the content of Al2O3is smaller than or equal to 17%. The electronic scraps are smelted by adopting the oxygen-enriched side converting furnace of which the smelting area communicates with the fuming area, the high concentration oxygen and the low concentration oxygen are separately introduced in the smelting area and the fuming area, the condition that impurities enter the furnace slag after being sufficiently oxidized is ensured, loss of valuable metals (Cu, Sn and the like), caused after the valuable metals enter the furnace slag after being oxidized, is avoided, the separation efficiency of the impurities andthe alloy and the recovery rate of the valuable metal alloy are effectively improved, the separation difficulty of other impurities and the valuable metal alloy is reduced, and the smelting efficiencyis improved.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

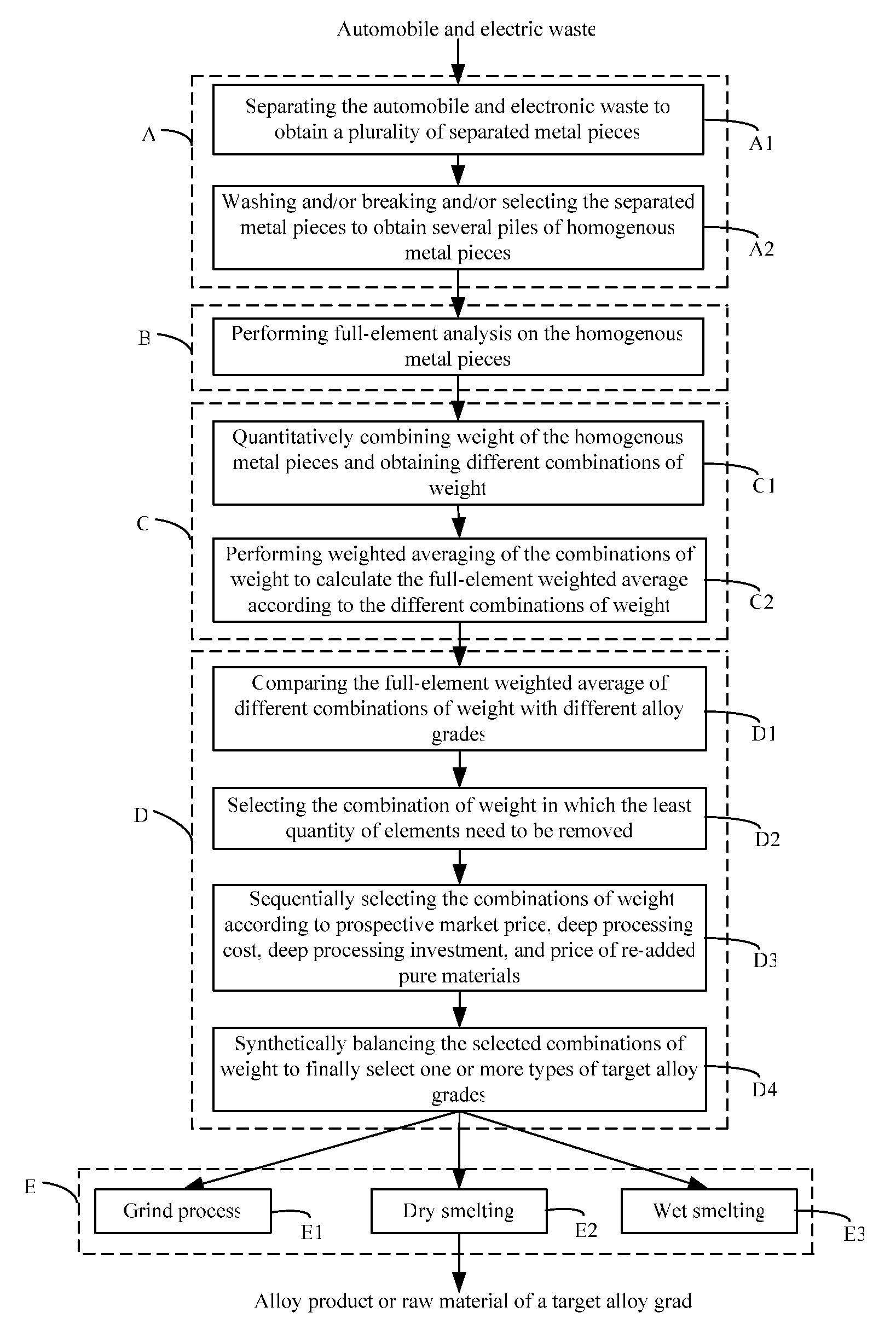

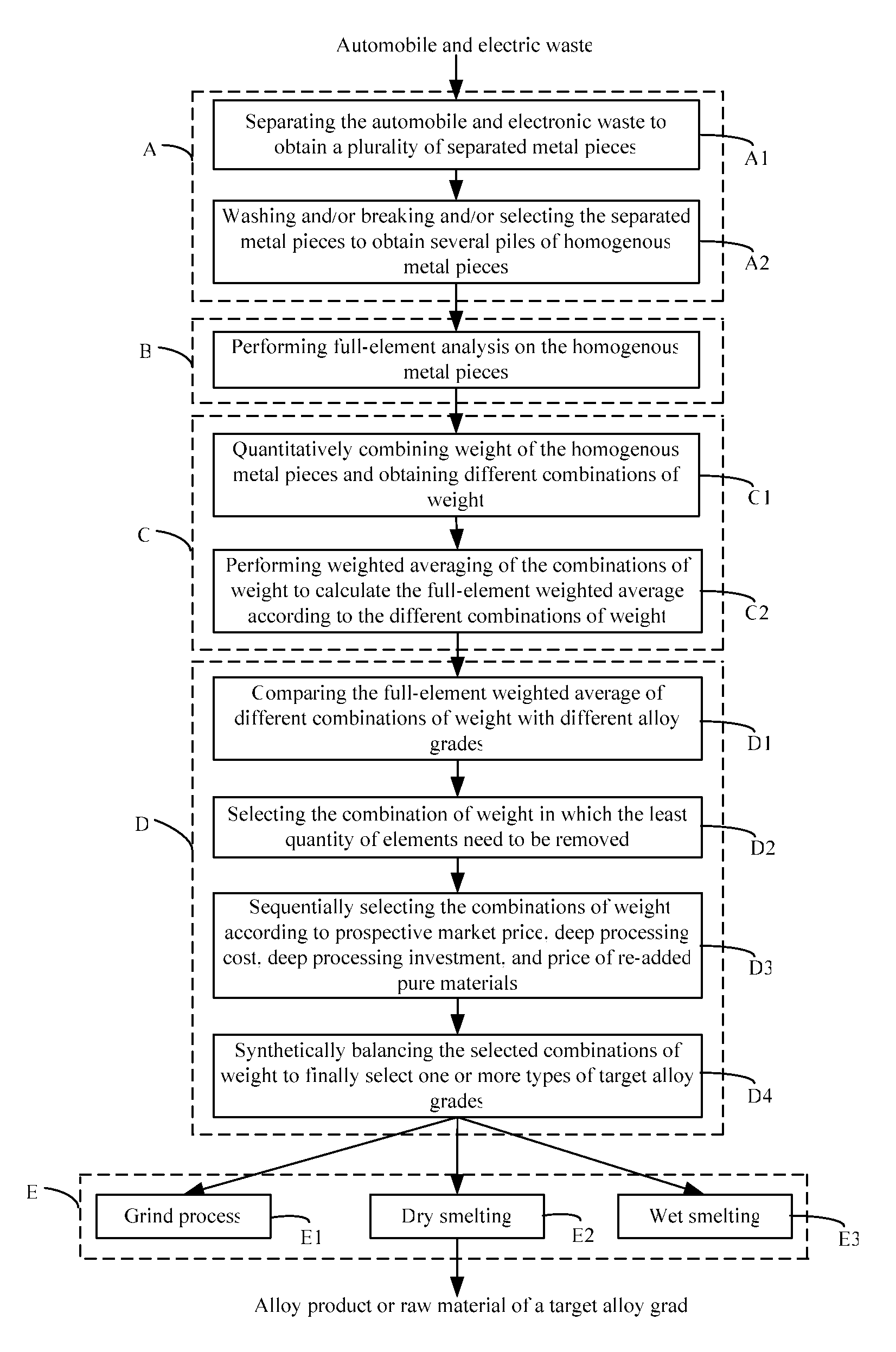

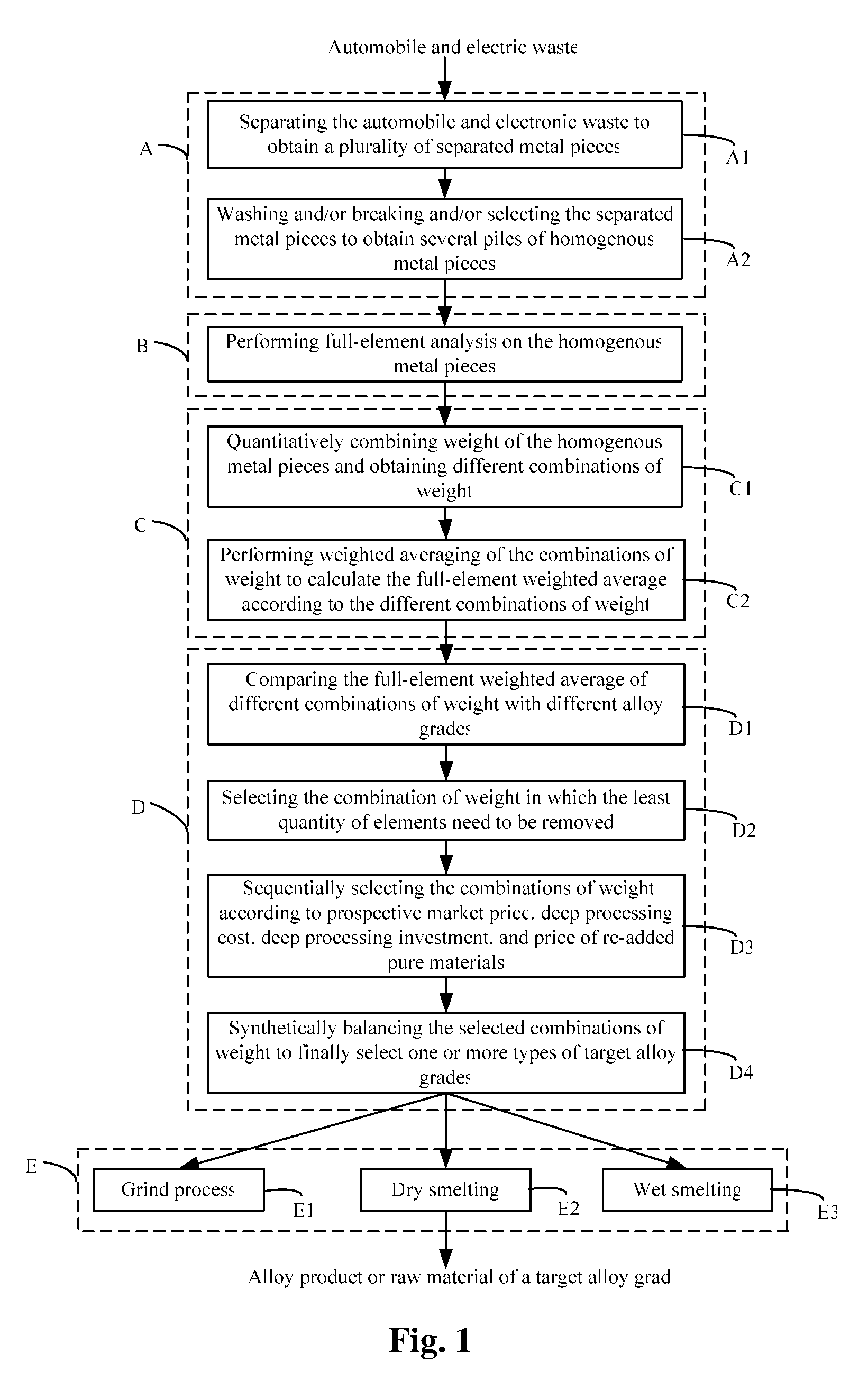

Methods for recovering metals from automobile scrap and electronic waste

ActiveUS20080282844A1Increase rangeReduce secondary pollutionSolid separationElectrostatic cleaningElemental analysisAlloy

A method of recovering the metal from automobile scrap and electronic waste. It includes separating the automobile scrap and the electronic waste to provide some metal pieces, washing and / or shredding and / or selecting said metal pieces to provide some groups of metal pieces having the same metal element, making a full-elemental analysis, comparing the weight of different metal pieces having the same metal element and attaining different combinations of value, weighted averaging the combination of value to calculate the full-elemental weighted average according to the different combinations of value, comparing said different full-elemental weighted averaging to different composite material, and finding a optimal set or some optimal sets, further disposing metal pieces according to the optimal set, and manufacturing alloy. Present invention has a lot of advantages, such as reducing pollution and cost, and processing more waste.

Owner:SHENZHEN GREEN ECO MANUFACTURE HI TECH CO LTD

Methods for recovering metals from automobile scrap and electronic waste

ActiveUS7740684B2Increase rangeReduce secondary pollutionSolid separationManufacturing convertersElemental analysisAlloy

A method of recovering the metal from automobile scrap and electronic waste. It includes separating the automobile scrap and the electronic waste to provide some metal pieces, washing and / or shredding and / or selecting said metal pieces to provide some groups of metal pieces having the same metal element, making a full-elemental analysis, comparing the weight of different metal pieces having the same metal element and attaining different combinations of value, weighted averaging the combination of value to calculate the full-elemental weighted average according to the different combinations of value, comparing the different full-elemental weighted averaging to different composite material, and finding a optimal set or some optimal sets, further disposing metal pieces according to the optimal set, and manufacturing alloy. Present invention has a lot of advantages, such as reducing pollution and cost, and processing more waste.

Owner:SHENZHEN GREEN ECO MANUFACTURE HI TECH CO LTD

Method for gold recovery and extraction from electronic waste or gold containing minerals, ores and sands

PendingCN111433377AUnderstand current contributionsLearn about current contributionsProcess efficiency improvementChemical reactionWaste material

A method for recovery of gold from gold-containing materials, such as electronic waste material, minerals and sands is described. The method includes crushing the gold containing material to obtain aparticulate material. The particulate material is then preheated in an oxygen- containing gas environment in a preheating zone. The method also includes mixing the oxidized particulate material with achlorine-containing material and treating the mixture in a reaction zone. The treatment is carried out by heating the mixture to provide thermal decomposition of the chlorine-containing material andproduce a chlorine-containing gas mixture, and by applying an electromagnetic field to the chlorine-containing gas mixture to provide ionization of chlorine. A volatile gold-containing chloride product, produced in the reaction zone as a result of a chemical reaction between gold and chlorine ions, is then cooled to convert the volatile gold- containing chloride product into solid phase gold-containing materials.

Owner:YEDA RES & DEV CO LTD

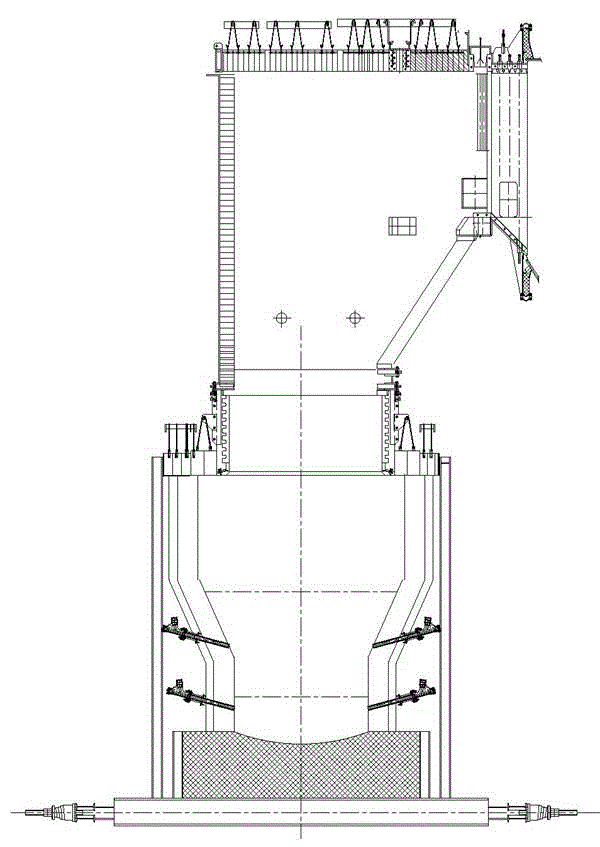

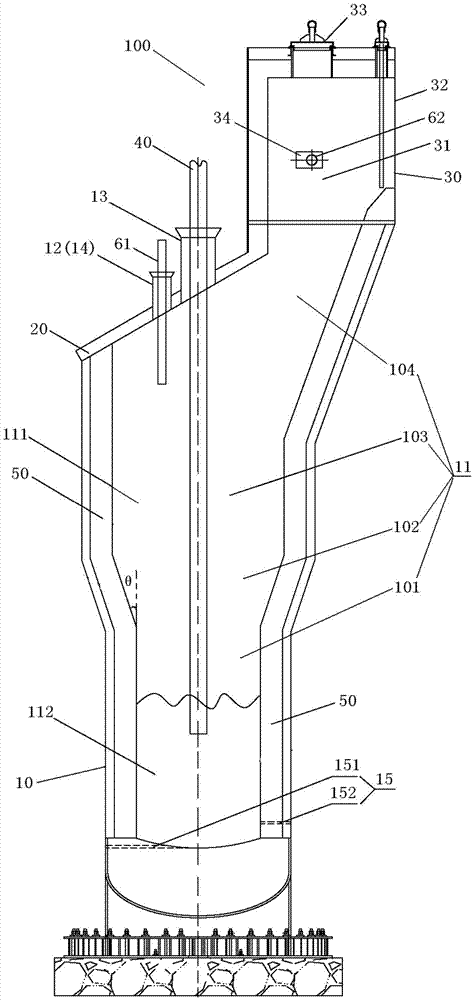

A side blowing continuous smelting device for electronic waste

The invention discloses a side-blown continuous smelting process and device for electronic scrap. The smelting device is divided into a smelting area and a blowing area, wherein a water-cooled partition wall is arranged between the two areas; the lower end of the water-cooled partition wall exceeds an interface of slag and a metal layer, so that black copper flows in the blowing area through an opening on the lower part of the water-cooled partition wall; waste slag obtained from a smelting reaction is discharged from a wall slag tap at the end of the smelting area; and the furnace bottom is inclined from the smelting area to the blowing area, and crude copper obtained from the blowing reaction is discharged from a wall copper discharge opening at the end of the blowing area. According to flow of melt at the lower end of the partition wall, latent heat of the melt is efficiently utilized, and the smelting device has the characteristics of high efficiency and energy conservation; and moreover, a plurality of oxygen-enriched supply inlets are formed on a furnace wall on side faces of the furnace smelting area and the blowing area, the slag layer and the black copper layer are respectively stirred for reaction, and the thermodynamic and dynamic conditions of the reaction are greatly improved, so that the reaction is carried out at high efficiency, the operation time is shortened, the electronic scrap and copper-containing materials can be continuously smelted, crude copper is produced, and precious rare metals contained in the electronic scrap are enriched to the crude copper.

Owner:CHINA NERIN ENG CO LTD

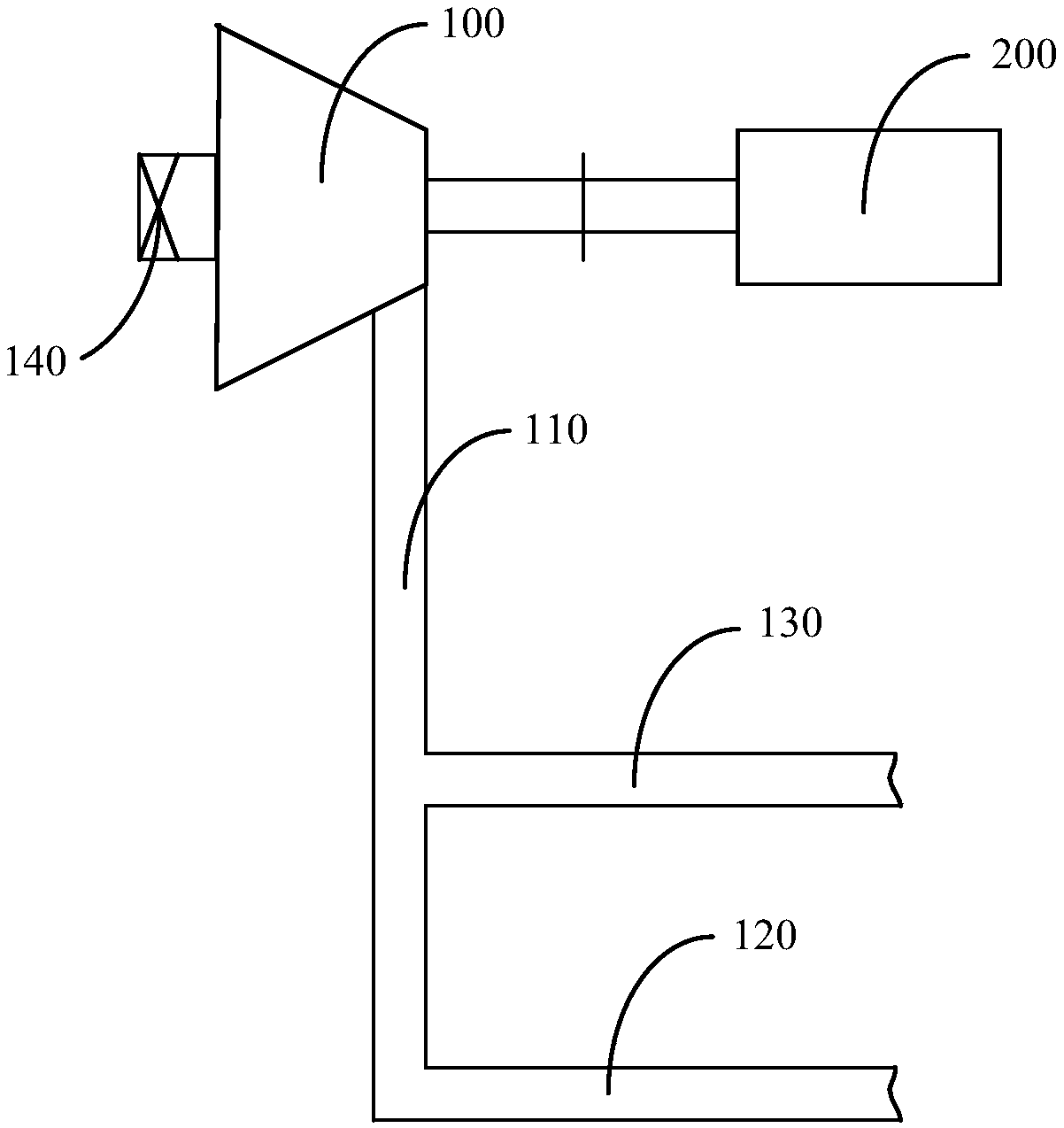

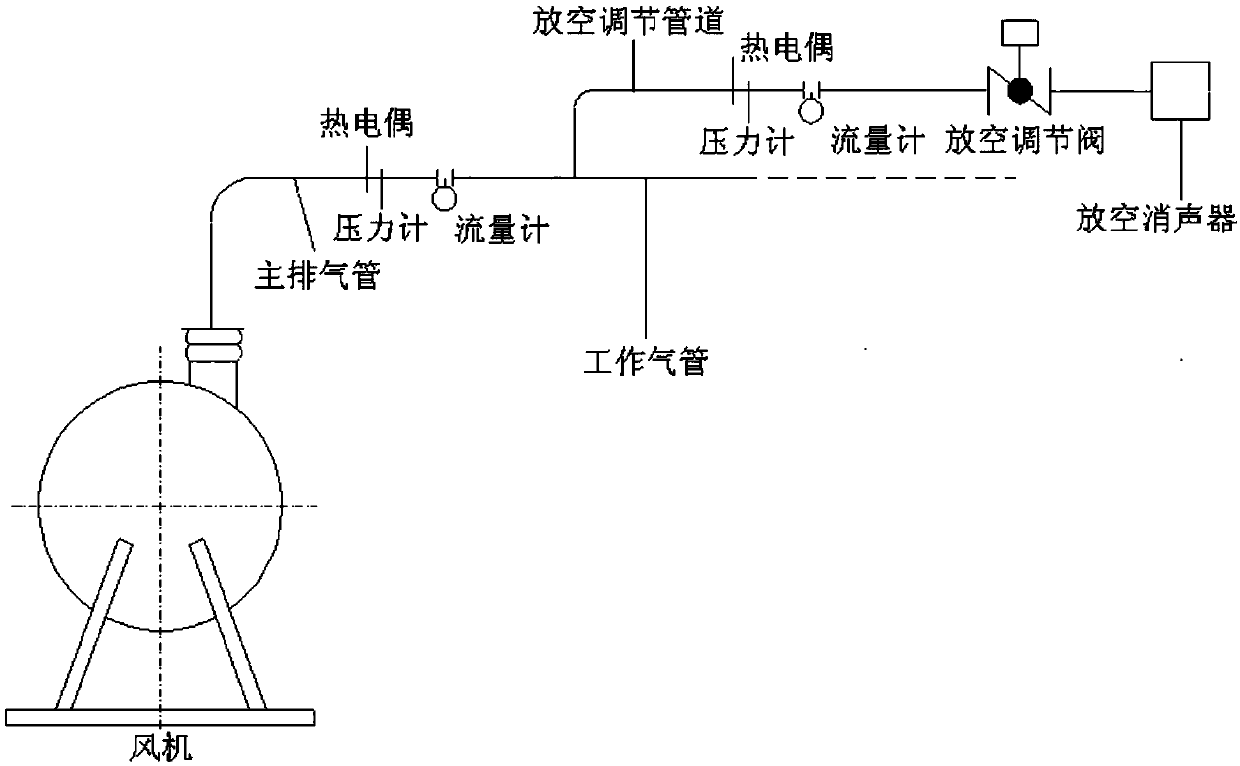

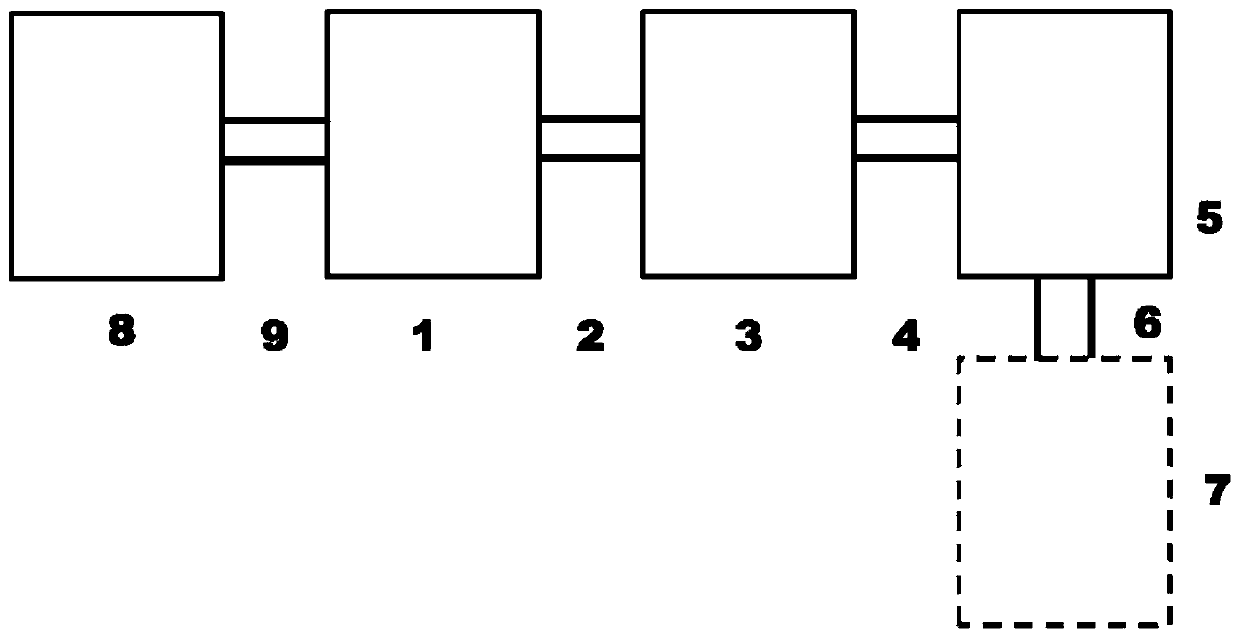

Fan control system and method based on electronic waste and complicated copper-based solid waste

ActiveCN111088427ALess investmentSolve the air volumePump controlProcess efficiency improvementAir volumeExhaust pipe

The invention discloses a fan control system and method based on electronic waste and complicated copper-based solid waste. The fan control system comprises a fan, a motor and a controller, wherein anemptying adjustment pipeline is connected to an air discharge pipe of the fan, the emptying adjustment pipeline is provided with a mass flow meter, a temperature measuring unit, a pressure meter andan emptying adjustment valve, the mass flow meter, the temperature measuring unit and the pressure meter are used for converting non-standard-condition flow into standard-condition flow, the motor isconnected with the fan and used for providing power for operation of the fan, the controller is connected with the temperature adjusting unit and the emptying adjustment valve and used for adjusting the temperature of the emptying adjustment pipeline through the temperature adjusting unit and linearly adjusting the emptying ratio through the emptying adjustment valve. The fan control system and method have the following advantages that the air volume needed by smelting with the electronic waste, the complicated copper-based solid waste and the like as raw materials can be effectively achieved,replacing the fan is not needed, so that investment of an enterprise is saved, the transformation period is shortened, normal production operation is guaranteed, and energy conservation and consumption reduction are achieved.

Owner:江西华赣瑞林稀贵金属科技有限公司

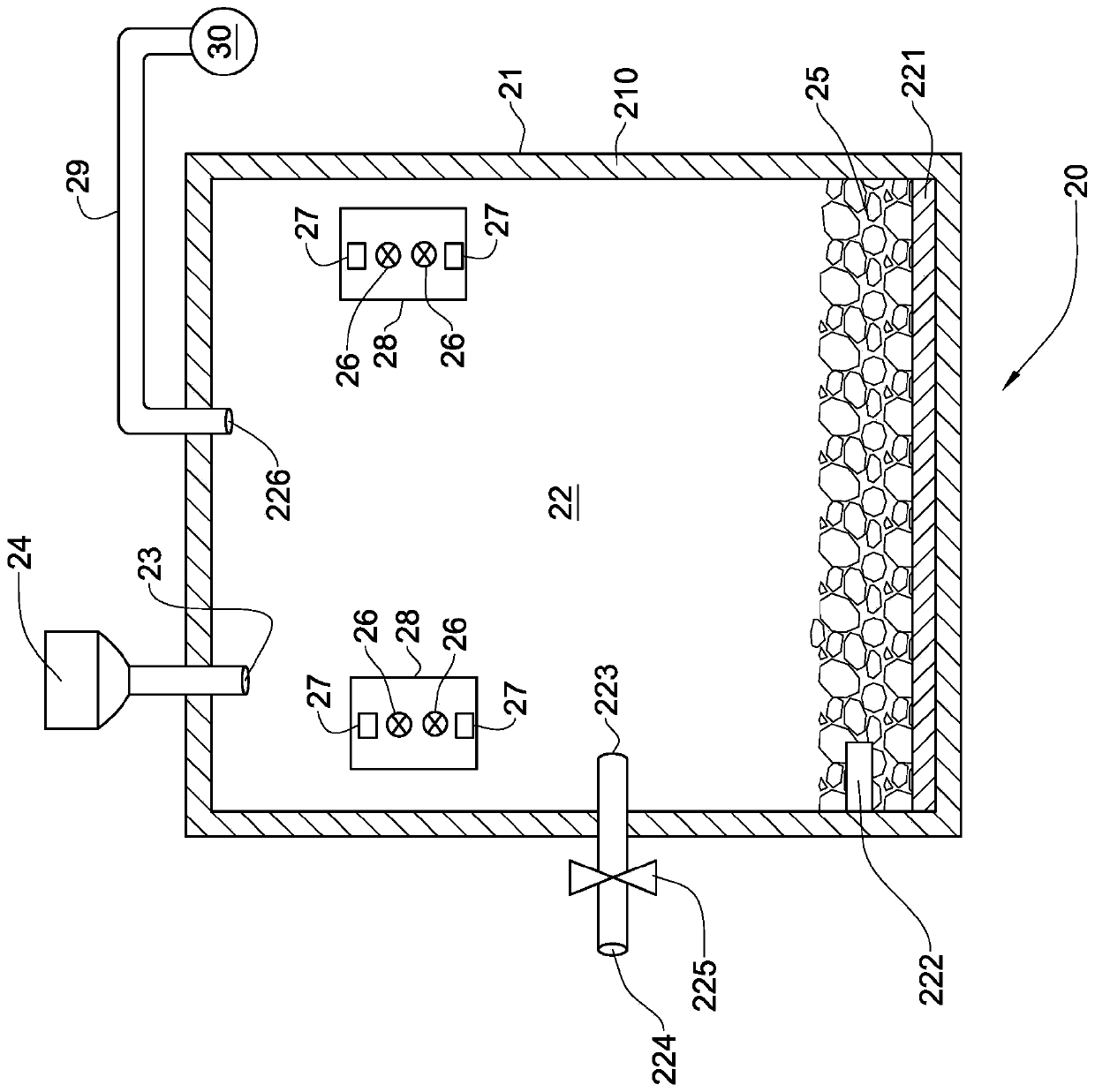

Apparatus and arrangement for the metallurgical treatment of electrical and/or electronic scrap or components and uses thereof and methods for the metallurgical treatment of electrical and/or electronic scrap or components

The present invention relates to an apparatus and an arrangement for the (pyro)metallurgical treatment of electrical and / or electronic scrap or components, which are in particular configured in such away that substantially uncontaminated electrical and / or electronic scrap or components thereof can be processed without impurities. The apparatus or the arrangement comprises a melting reactor, whichhas a cooling device. The present invention also relates to the use of the apparatus or the arrangement for the metallurgical treatment of electrical and / or electronic scrap or components and to theobtainment of raw copper or a precursor thereof. The present invention also relates to methods for the (pyro)metallurgical treatment of electrical and / or electronic scrap or components.

Owner:URBANGOLD GMBH

Method and system for obtaining parameter for simulation in invisible code printing support system

InactiveUS8035861B2Improve accuracyEasy to carryDigital computer detailsVisual presentationSupporting systemUltraviolet

An image of a sample print printed to obtain parameters is picked up by using “a parameter obtaining device” that meets the standards of an instrument for the invention of “the electronic scrap system.” Then, the picked-up image is captured by a DTP system, and color data of a needed position are imported to a parameter DB. Thereby, parameters for simulation to be used in an invisible code printing support system can be easily inputted. Use of this method eliminates the necessity of figuring out parameters through experiments and the like, and of inputting these parameters as numerical values. In addition, since this method uses a physical medium and inks to be actually used, as they are, their optical characteristics, an influence of a blue component of invisible light emitted from an ultraviolet LED, and the like can be inputted all together as a picked-up image. Accordingly, it becomes possible to input parameters capable of accurately reproducing actual printed conditions, and thereby to produce printed materials providing high reading accuracy.

Owner:INT BUSINESS MASCH CORP

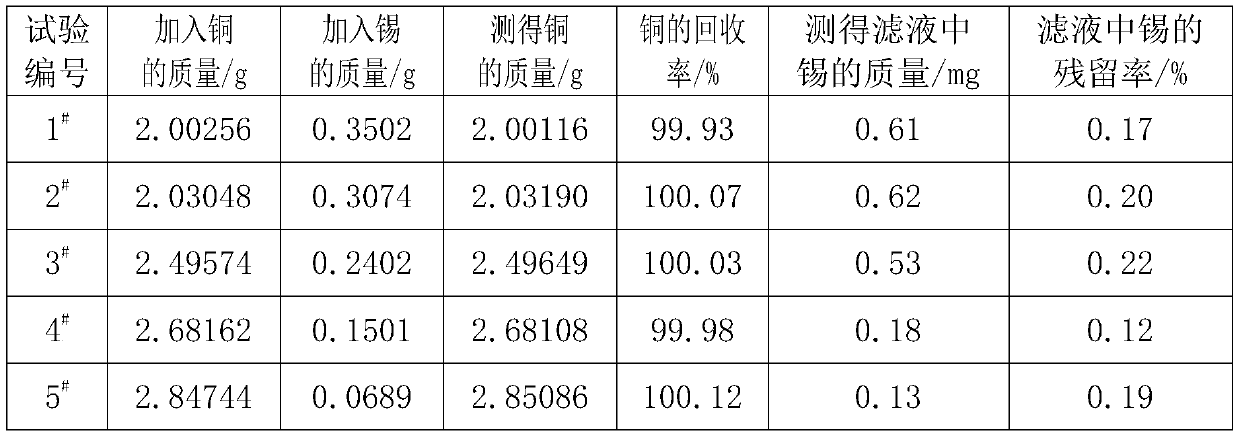

Smelting device and smelting method for electronic scraps

The invention discloses a smelting device and a smelting method for electronic scraps. The smelting device comprises a furnace body, a furnace top, a secondary combustion chamber and a spray gun, wherein a furnace hearth is defined in the furnace body; the furnace hearth is provided with an upper-end opening, and comprises a reaction region and a gas-phase region; a discharge hole is formed in the furnace body; the furnace top is connected with the furnace body and covers a part of the upper-end opening of the furnace hearth; a charge hole, a spray gun hole and a primary burner nozzle hole are formed in the furnace top; a secondary combustion chamber is defined in the secondary combustion chamber; a secondary burner nozzle hole is formed in the secondary combustion chamber; the secondary combustion chamber covers the other part of the upper-end opening, and the secondary combustion cavity communicates with the furnace hearth; a flue is arranged on the secondary combustion chamber, and the secondary combustion chamber is positioned at one side of a center line of the furnace hearth; and the spray gun is arranged in the spray gun hole in a penetrating mode, and the lower end of the spray gun extends into the reaction region. According to the embodiment of the invention, the smelting device for the electronic scraps can save fuels, improves smelting efficiency, and reduces emission of harmful gases.

Owner:CHINA NERIN ENG

Electronic scrap smelting device and smelting method

The invention discloses a smelting device and a smelting method for electronic scraps. The smelting device comprises a furnace body, a furnace top, a secondary combustion chamber and a spray gun, wherein a furnace hearth is defined in the furnace body; the furnace hearth is provided with an upper-end opening, and comprises a reaction region and a gas-phase region; a discharge hole is formed in the furnace body; the furnace top is connected with the furnace body and covers a part of the upper-end opening of the furnace hearth; a charge hole, a spray gun hole and a primary burner nozzle hole are formed in the furnace top; a secondary combustion chamber is defined in the secondary combustion chamber; a secondary burner nozzle hole is formed in the secondary combustion chamber; the secondary combustion chamber covers the other part of the upper-end opening, and the secondary combustion cavity communicates with the furnace hearth; a flue is arranged on the secondary combustion chamber, and the secondary combustion chamber is positioned at one side of a center line of the furnace hearth; and the spray gun is arranged in the spray gun hole in a penetrating mode, and the lower end of the spray gun extends into the reaction region. According to the embodiment of the invention, the smelting device for the electronic scraps can save fuels, improves smelting efficiency, and reduces emission of harmful gases.

Owner:CHINA NERIN ENG

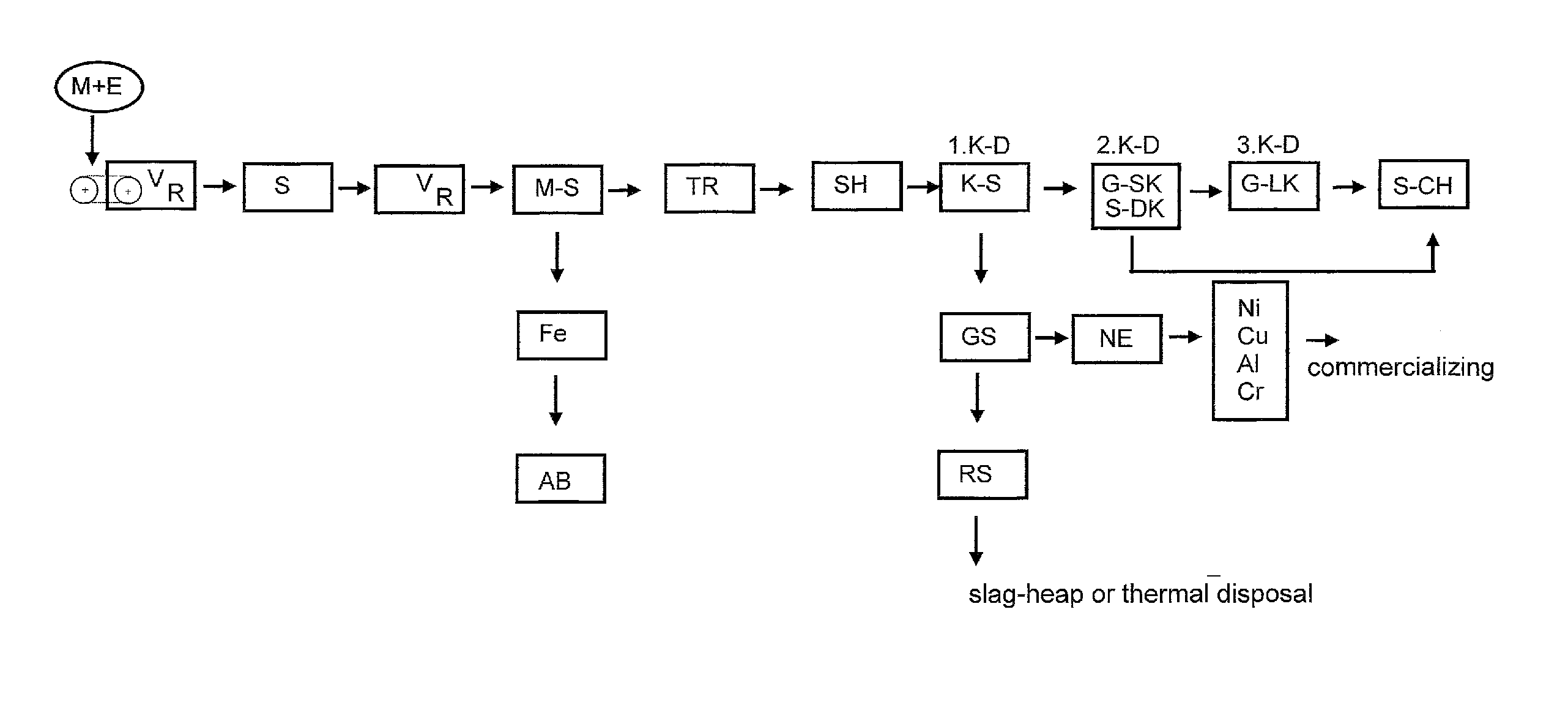

Recycling method for electronics scrap in order to obtain reusable materials while avoiding the release of harmful substances

ActiveUS8220729B2Avoid violationsLow costPlastic recyclingGrain treatmentsRecovery methodHazardous substance

Owner:KOSLOW ALEXANDER

Equipment and method for recycling gold by recycling electronic wastes

InactiveCN109939783AImprove the efficiency of degolding treatmentLow priceProcess efficiency improvementGrain treatmentsReducerEngineering

The invention belongs to the technical field of gold recovery, and discloses equipment for recycling gold by recycling electronic wastes. The equipment for recycling gold by recycling the electronic wastes comprises a crushing mechanism, a stirring mechanism and a filtering mechanism. The crushing mechanism comprises a shell, a feeding screw, two crushing rollers, a screening plate, a material pushing screw, a longitudinal baffle, a lifting screw and a first wedge-shaped block, wherein a feeding cylinder is longitudinally arranged in the shell, the feeding screw is longitudinally arranged at the upper end of the shell, the two crushing rollers are driven by a speed reducer to rotate oppositely, the screening plate is arranged in the shell and located below the two crushing rollers, the material pushing screw is used for pushing materials on the screening plate, the longitudinal baffle is longitudinally arranged in the shell, and the lifting screw is used for lifting the materials discharged from a first discharge port. The invention further discloses a method for recycling gold by recycling the electronic wastes, which can ensure that the particle diameter of the crushed electronicwastes collected by a second discharge port is controlled within a certain range, and the range is determined according to the hold diameter of the screening plate, so that the efficiency of gold separation treatment of the crushed electronic wastes in the stirring mechanism is improved.

Owner:孙祥

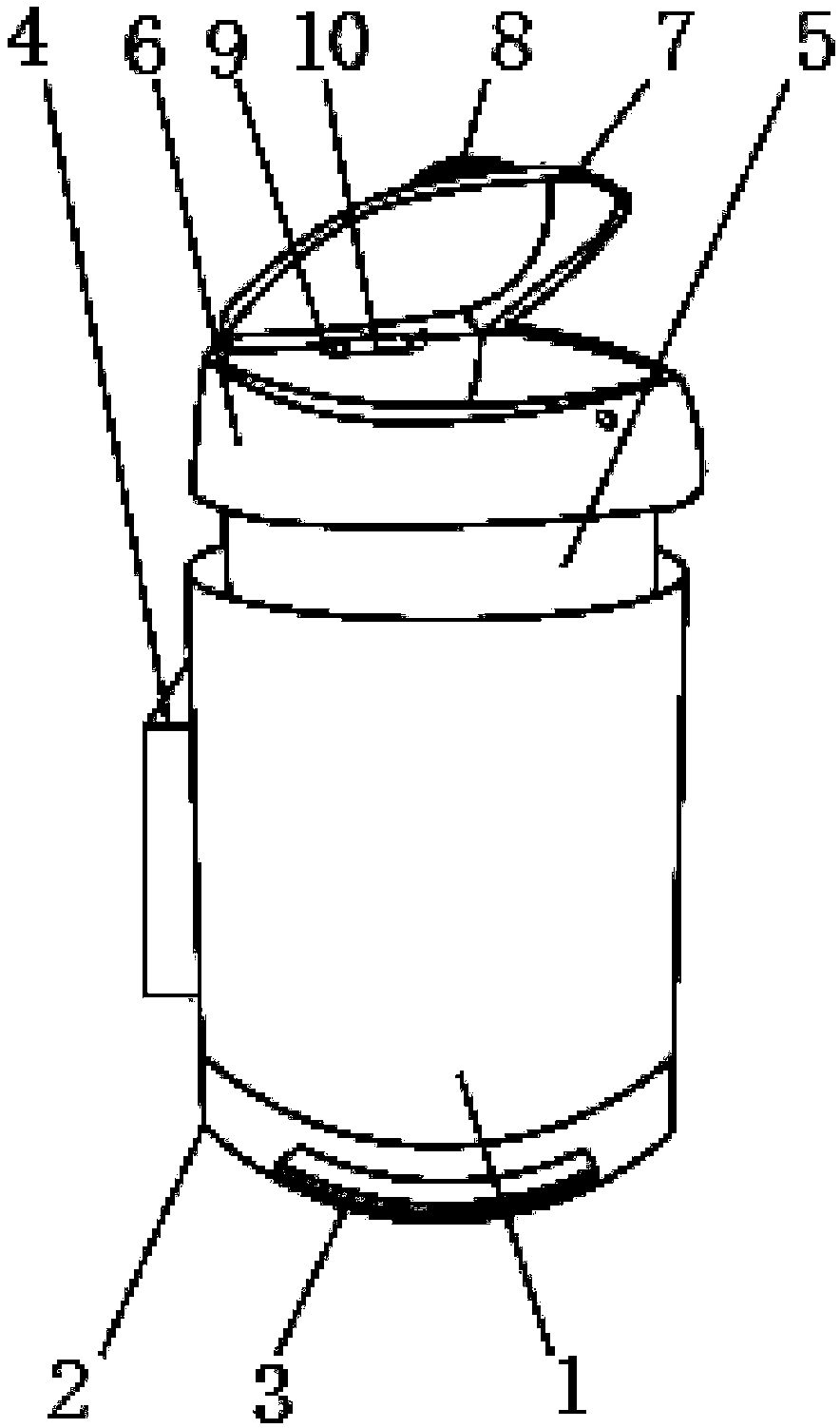

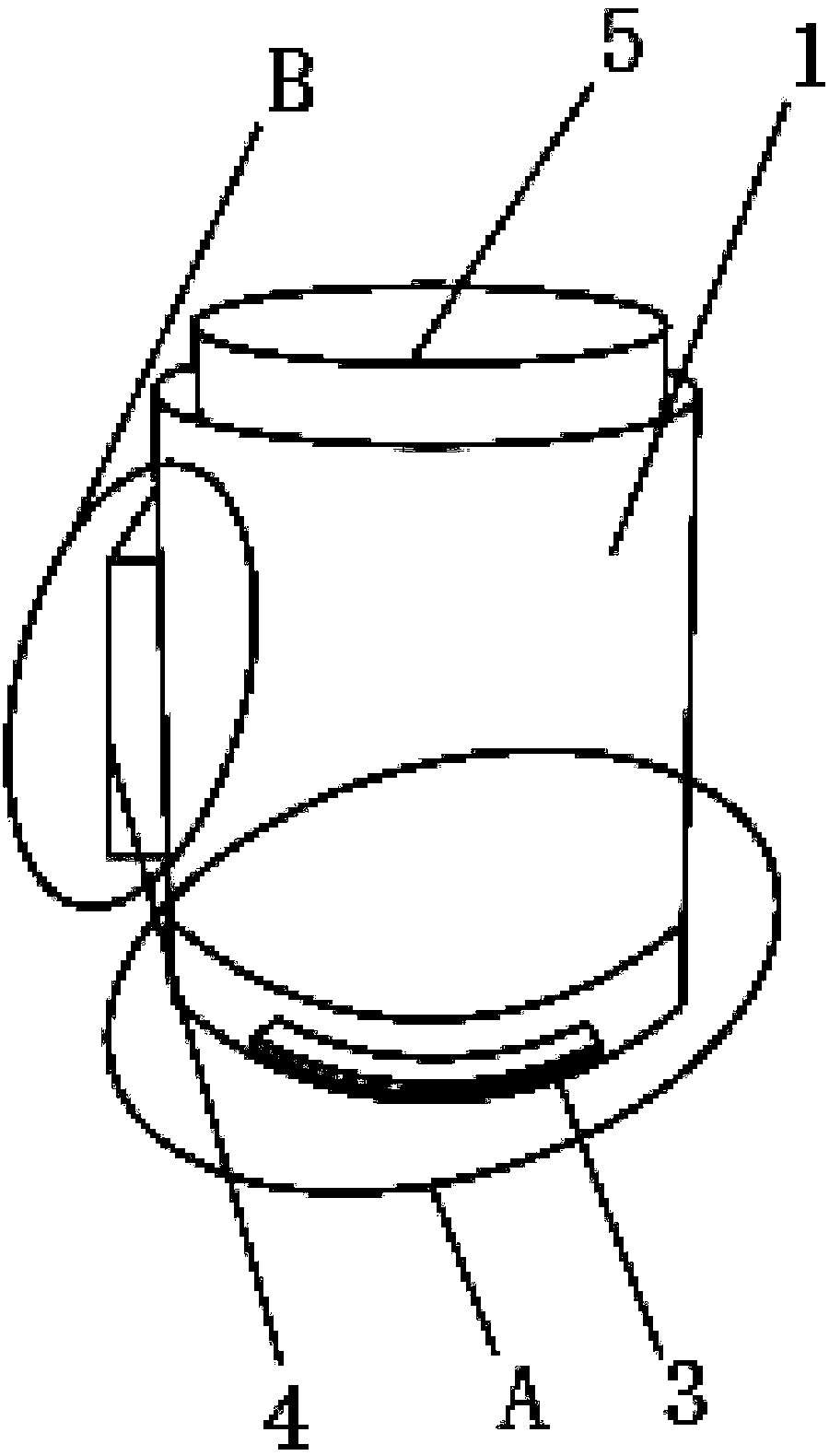

Recycling device for electronic discarded products

The invention relates to the field of waste recycling devices, in particular to a recycling device for electronic scrap products, which includes a stainless steel outer cylinder, a barrel cover and a rotating shaft. A non-slip base is fixedly installed on the outside of the lower end of the stainless steel outer cylinder, and the outer surface of the front end of the anti-slip base is A foot pedal is fixedly installed, a toolbox is fixedly installed on one side of the outer surface of the stainless steel outer cylinder, and a plastic inner cylinder is arranged inside the stainless steel outer cylinder, and an induction cover is movably installed on the upper surface of the rear end of the barrel cover. Moreover, a handle is provided on the outer surface of the upper end of the induction cover. A recovery device for scrapped electronic products according to the present invention is provided with a jacking mechanism, a tool box and a handle, and the staff can conveniently lift up the plastic inner cylinder to facilitate the dumping of scrapped products stored inside, and can accommodate simple electronic scraps. The equipment disassembly tool is convenient for the disassembly of electronic scrap products. When the induction effect of the induction cover fails, the induction cover can be lifted by the handle, which brings a better prospect of use.

Owner:WUXI DACHENG TIANXIA INTELLIGENT TECH CO LTD XISHAN BRANCH

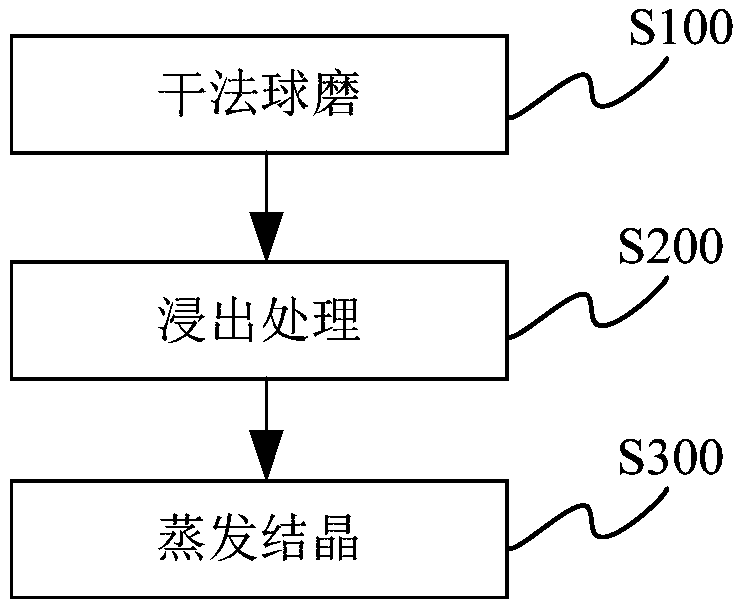

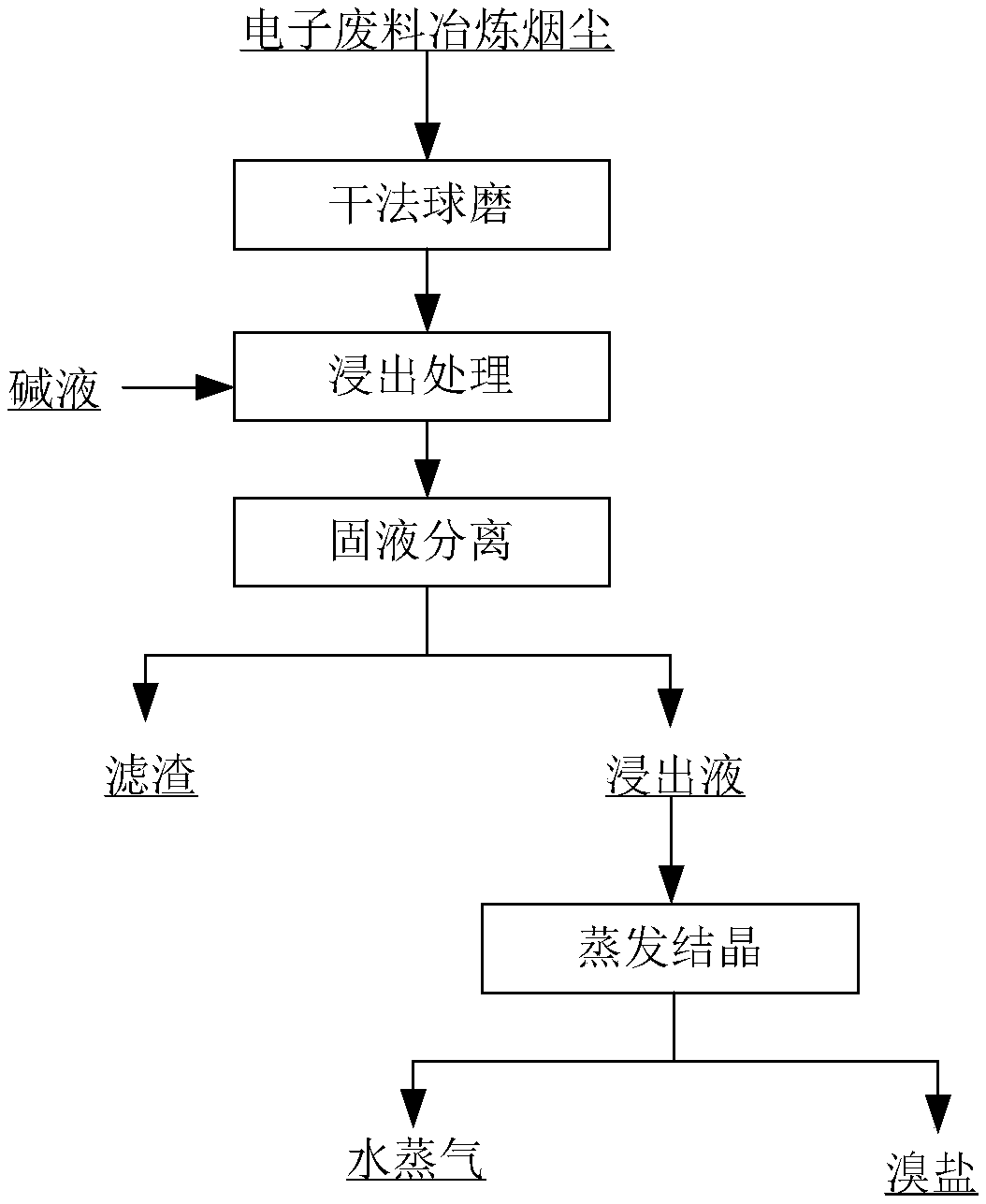

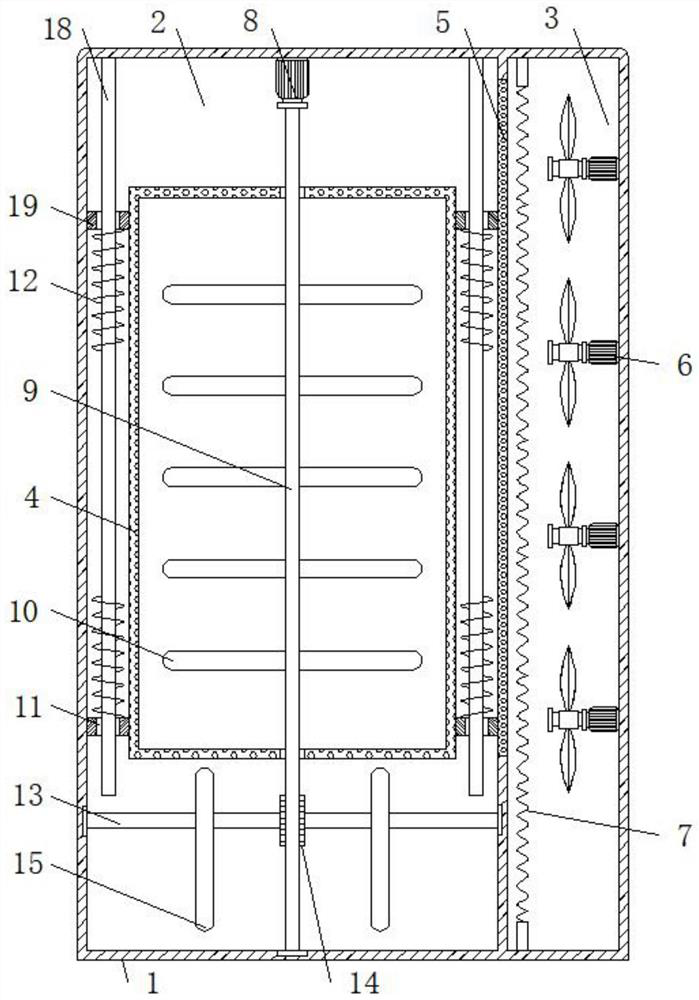

Method for recycling bromine in electronic waste smelting smoke dust through wet-process alkaline system

ActiveCN111170277ALow costShort processBromineProcess efficiency improvementPregnant leach solutionBromine

The invention discloses a method for recovering bromine in electronic waste smelting smoke dust by a wet alkaline system. The method comprises the following steps: carrying out dry ball milling on electronic waste smelting smoke dust to obtain ball-milled smoke dust; leaching the ball-milled smoke dust with an alkali liquor with a concentration of 1-5 mol / L according to a liquid-solid ratio of 1:(1-4) so as to obtain a leachate; and carrying out liquid-solid separation on the leachate, and carrying out evaporative crystallization on the obtained leachate to obtain a bromine salt or finely extracting bromine to obtain a liquid bromine product. The method has the advantages of high recovery efficiency, low cost, short flow and the like.

Owner:CHINA NERIN ENG +1

Recovery process of valuable components in waste thick film

InactiveCN111440948AEffective recyclingEmission reductionProcess efficiency improvementHemt circuitsAcid washing

The invention discloses a recovery process of valuable components in a waste thick film. The recovery process comprises the steps of disassembling a thick film circuit, specifically, the waste thick film circuit is disassembled from a product by a mechanical disassembling method; soaking and separating, specifically, the disassembled thick film circuit is soaked in an acidic medium to separate a metal plate from a thick film ceramic material in the thick film circuit, and a material after separating and removing the metal plate is filtered to obtain an insoluble electronic waste; performing ball milling and sorting, specifically, after the electronic waste is dried, the ball milling is carried out by using a ball mill, and ball-milled powder is separated by hydraulically power and gravityin a gravity mixer to separate the valuable components; and performing acid washing and impurity removal, specifically, the valuable components are recovered after acid treatment. According to the recovery process, a high-temperature alkali fusion method is replaced with a wet method, and the valuable components of the waste thick film are subjected to recycling treatment.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Method for dissolving and purifying precious metal from electronic waste

InactiveCN113403484AFast and efficient purification collectionImprove deposit progressProcess efficiency improvementPrecious metalElectronic scrap

The invention discloses a method for dissolving and purifying precious metal from electronic waste, relates to the technical field of comprehensive utilization of industrial solid waste. Aiming at the problem of poor utilization efficiency of the existing industrial solid waste,the following scheme is provided; the method for dissolving and purifying the precious metal from the electronic waste comprises the following steps of: mixing the electronic waste containing the precious metal with acid liquor; decomposing the electronic waste through acid liquor to obtain decomposition liquid containing precious metal; filtering and cleaning the obtained decomposition liquid; removing water-soluble impurities in the decomposition liquid to obtain precious metal powder; putting the obtained precious metal powder into corresponding drying equipment; and drying the precious metal powder through the drying equipment. According to the method for dissolving and purifying the precious metal from the electronic waste, the precious metal of the electronic waste in the industrial solid waste can be rapidly and efficiently purified and collected, the purification method is simple, processing equipment used for purification is convenient to use, and then the extraction and storage progress of the precious metal is effectively improved, and the recovery efficiency is high.

Owner:苏州市富荣环保科技有限公司

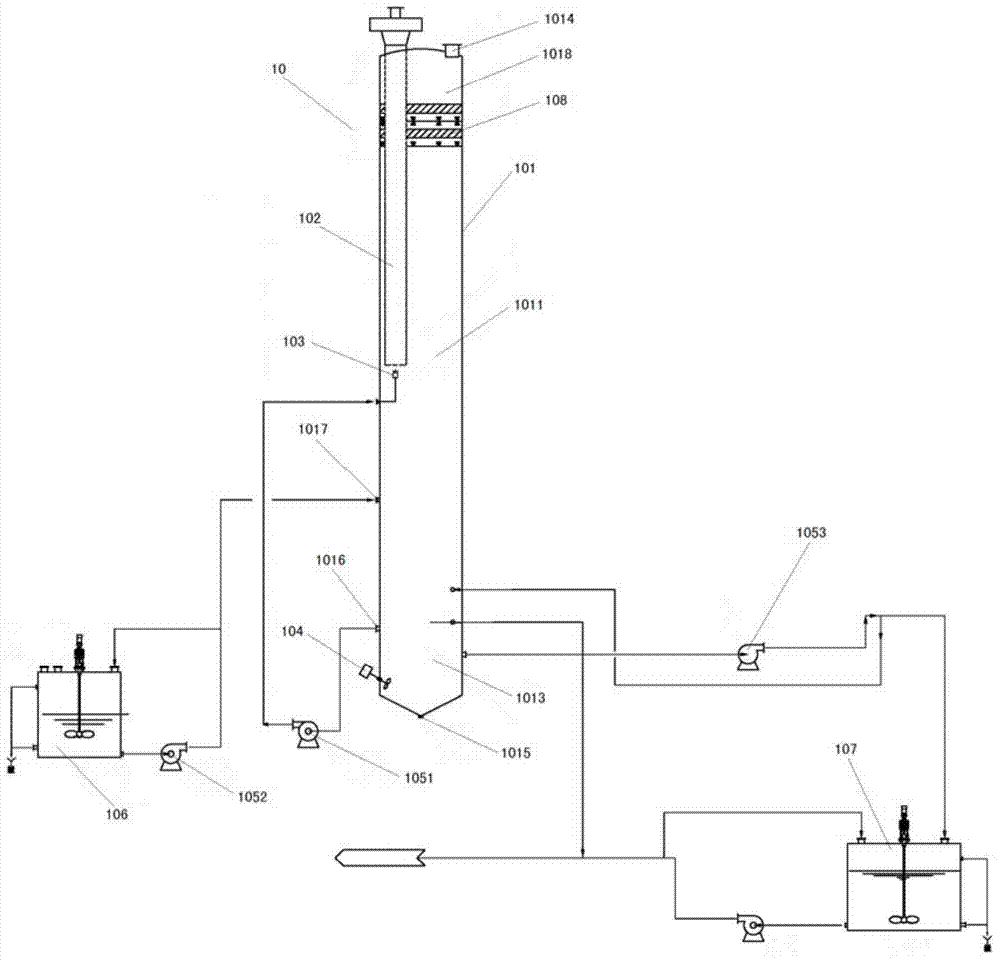

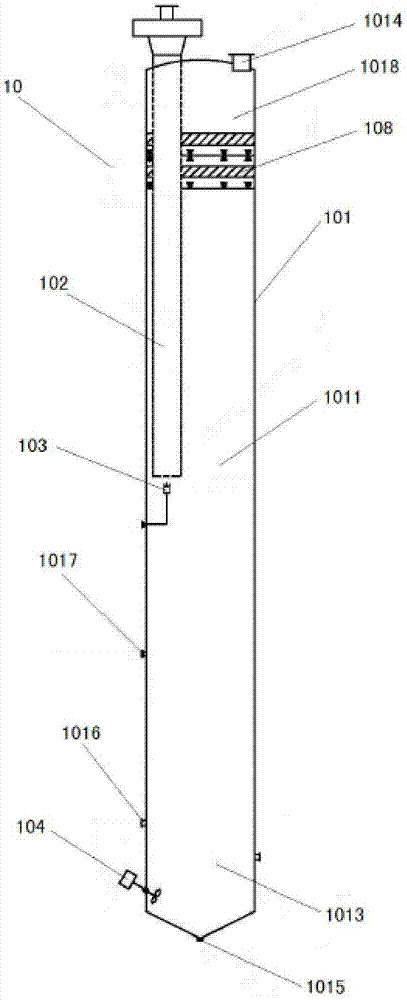

Dynamic wave system used for treating combustion flue gas of electronic waste material

The invention discloses a dynamic wave system used for treating combustion flue gas of an electronic waste material. The dynamic wave system comprises: a reaction tower, wherein a gas-liquid separation section is arranged in the reaction tower, and a purified flue gas outlet communicated with the gas-liquid separation section is arranged on the reaction tower; a reverse spraying pipe, wherein at least a part of the reverse spraying pipe is arranged in the reaction tower, and the reverse spraying pipe is provided with a flue gas inlet and an absorption slurry outlet communicated with the gas-liquid separation section; and a liquid inlet nozzle used for upwardly spraying an absorption liquid, wherein the liquid inlet nozzle is arranged in the reaction tower, has an upward opening and is located below the flue gas inlet. According to embodiments in the invention, the dynamic wave system used for treating combustion flue gas of the electronic waste material has the advantages of a substantial purifying effect, a good gas-liquid separation effect, etc.

Owner:江西华赣瑞林稀贵金属科技有限公司

Process for recovering metal from electronic waste

The invention relates to a method for recovering precious metals from electronic waste. In particular, bio-metallurgical techniques are utilised during the process. In a first aspect, the invention provides a method of recovering one or more target metals from electronic waste, the method comprising (a) a pre-processing step comprising removing at least a portion of non-target material from the electronic waste or grinding to a preselected size particle to give pre-processed electronic waste; (b) a dissolving step comprising contacting the pre-processed electronic waste with a lixiviant such that at least a portion of the target metal(s) dissolve into the lixiviant to produce a pregnant solution; (c) a biological absorption step comprising contacting a microorganism with the pregnant solution such that at least a portion of the target metal(s) ions is biologically absorbed to the microorganism wherein the microorganism becomes metal laden and the pregnant solution becomes barren; (d) aseparating step comprising substantially separating the metal laden microorganism from the barren solution; and (e) a recovery step comprising recovery of the target metal(s) from the metal laden microorganism. In particular embodiments, the target metal is gold.

Owner:MINT INNOVATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com