Smelting method of electronic scraps

A technology of electronic waste and smelting methods, which is applied in the direction of improving process efficiency, etc., can solve problems such as high operation and maintenance and smelting costs, short service life of smelting equipment, and increased copper content in slag, so as to reduce heat input and reduce Energy consumption and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for smelting electronic waste, comprising the following steps:

[0035] Electronic scrap (Cu 8.80%, Sn 4%, Fe 8%, Au 10g / t, Ag 191g / t, Pd0.11g / t, Al 0.28%, Al 2 o 3 1.28%; SiO 2 28.88%), slagging agent and coal are mixed to obtain a mixed material, in which the slagging agent is made of copper smelting slag (Cu0.35wt%, TFe26.37wt%, SiO 2 33.60%, CaO 15.91%) and dolomite (CaO 56%). In the mixed material, the mass proportion of electronic waste is 44%, the mass proportion of slagging agent is 44%, and the mass proportion of coal is 12%.

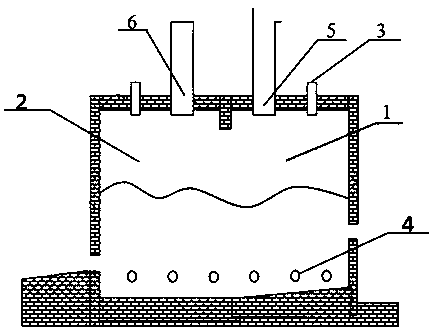

[0036]The above-mentioned mixed materials are added from the feed port 3 of the smelting zone of the blowing furnace on the oxygen-enriched side. Introduce high-concentration oxygen and low-concentration oxygen, wherein the concentration of high-concentration oxygen in smelting zone 1 is 65%, and the ratio of the oxygen supply volume to the mass of the mixed material is 855-1700m 3 氧气 / t 物料 , specifically 1000 m 3 氧气 / t...

Embodiment 2

[0040] A method for smelting electronic waste, comprising the following steps:

[0041] Electronic waste (Cu 55%, Sn 8%, Fe 12%, Au 5g / t, Ag 415g / t, Pt500g / t, Al 15%, SiO 2 8wt%), slagging agent and fuel (granulated coal and coke) are mixed to obtain a mixed material. Among them, the slagging agent is composed of limestone (CaO 90%) and silica (SiO 2 98%); in the mixed material, the mass proportion of electronic waste is 30%, and the mass proportion of fuel is 8%.

[0042] The above-mentioned mixed materials are added from the feeding port of the smelting zone of the oxygen-enriched side blowing furnace. During smelting, high-concentration oxygen and Low-concentration oxygen, in which the concentration of high-concentration oxygen in the smelting zone is 40%, and the ratio of the oxygen supply volume to the mass of the mixed material is 250-1100 m 3 氧气 / t 物料 , specifically 800 m 3 氧气 / t 物料 , the concentration of low-concentration oxygen in the fuming zone is 35%, the...

Embodiment 3

[0045] A method for smelting electronic waste, comprising the following steps:

[0046] Electronic waste (Cu 35%, Sn6%, Fe 8%, Au 5g / t, Ag 415g / t, Pt 500g / t, Al 15%, SiO 2 8wt%), slagging agent and coal are mixed to obtain a mixed material. Among them, the slagging agent is made of copper smelting slag (Cu 0.69wt%, TFe 42wt%, SiO 2 30%, CaO5%) and limestone; in the mixed material, the mass proportion of electronic waste is 55%, the mass proportion of slagging agent is 40%, and the mass proportion of fuel is 5%.

[0047] The above-mentioned mixed materials are added from the feeding port of the smelting zone of the oxygen-enriched side blowing furnace. During smelting, high-concentration oxygen and Low-concentration oxygen, in which the concentration of high-concentration oxygen in the smelting zone is 70%, and the ratio of the oxygen supply volume to the mass of the mixed material is 600-2100 m 3 氧气 / t 物料 , specifically 1500m 3 氧气 / t 物料 , the concentration of low-conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com