Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Unique design structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

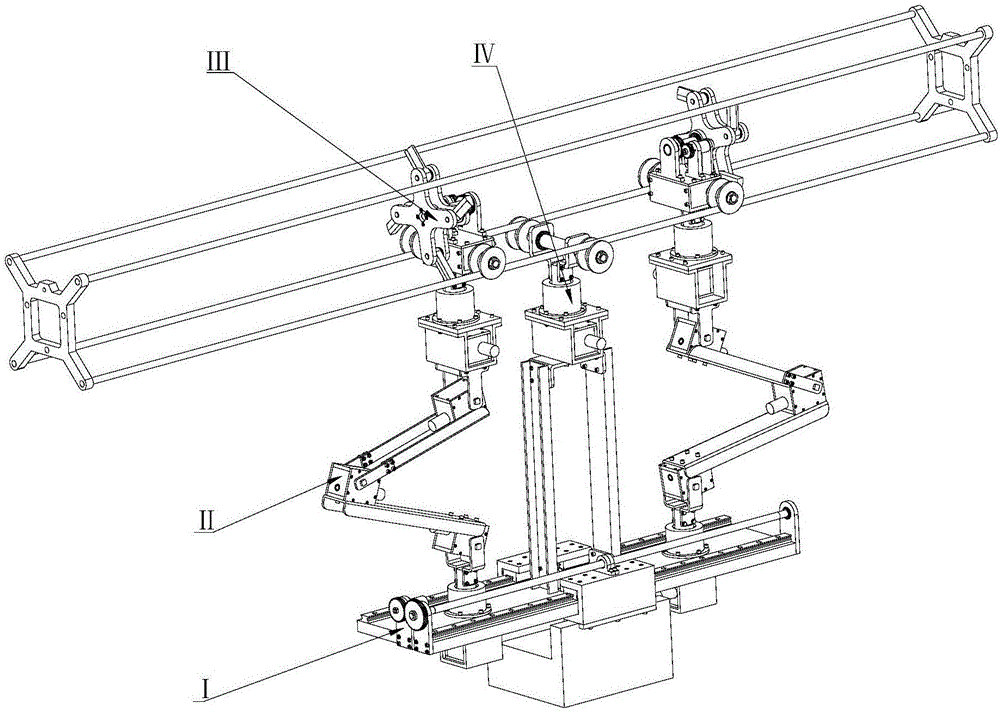

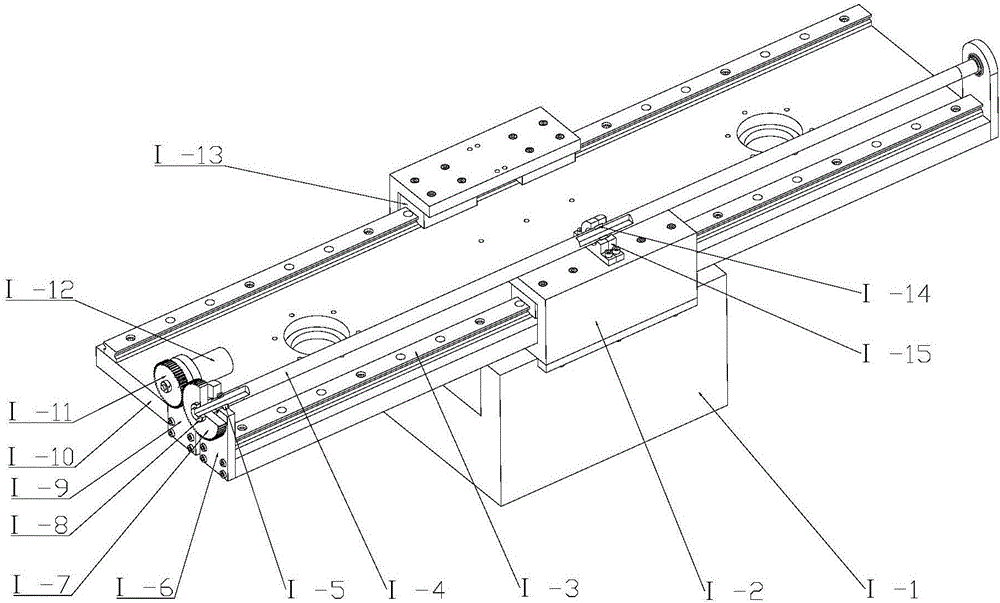

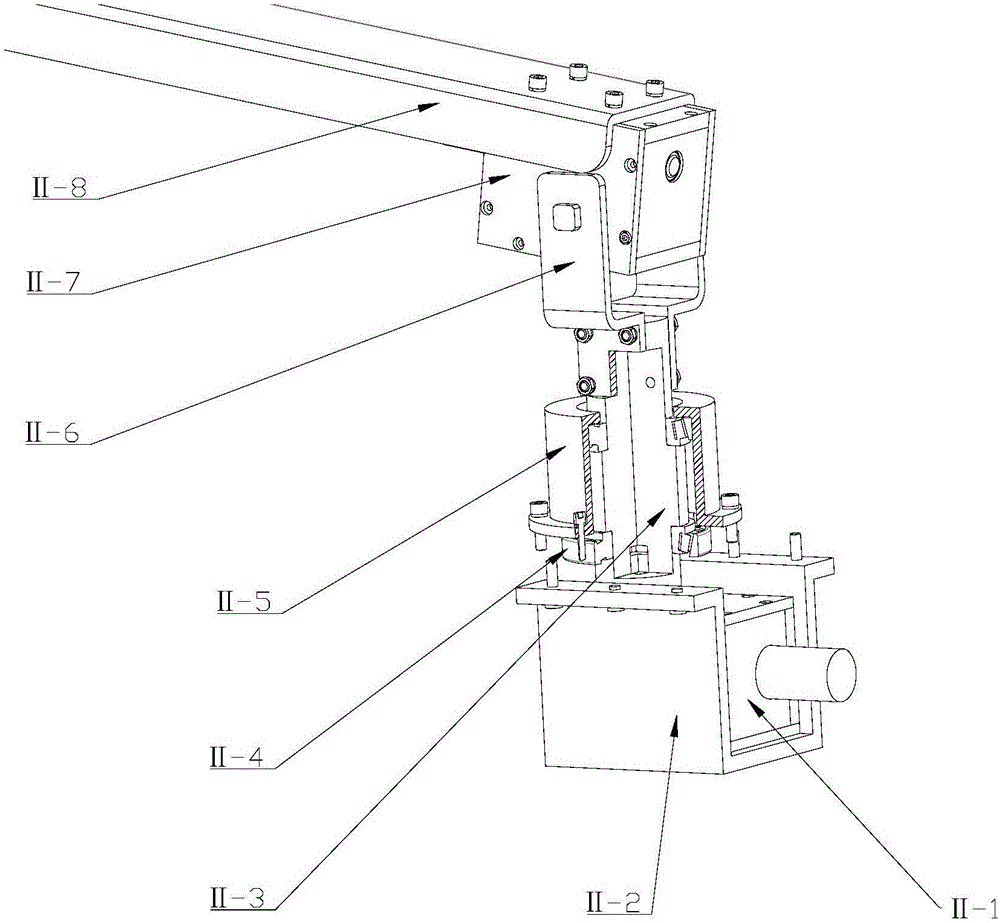

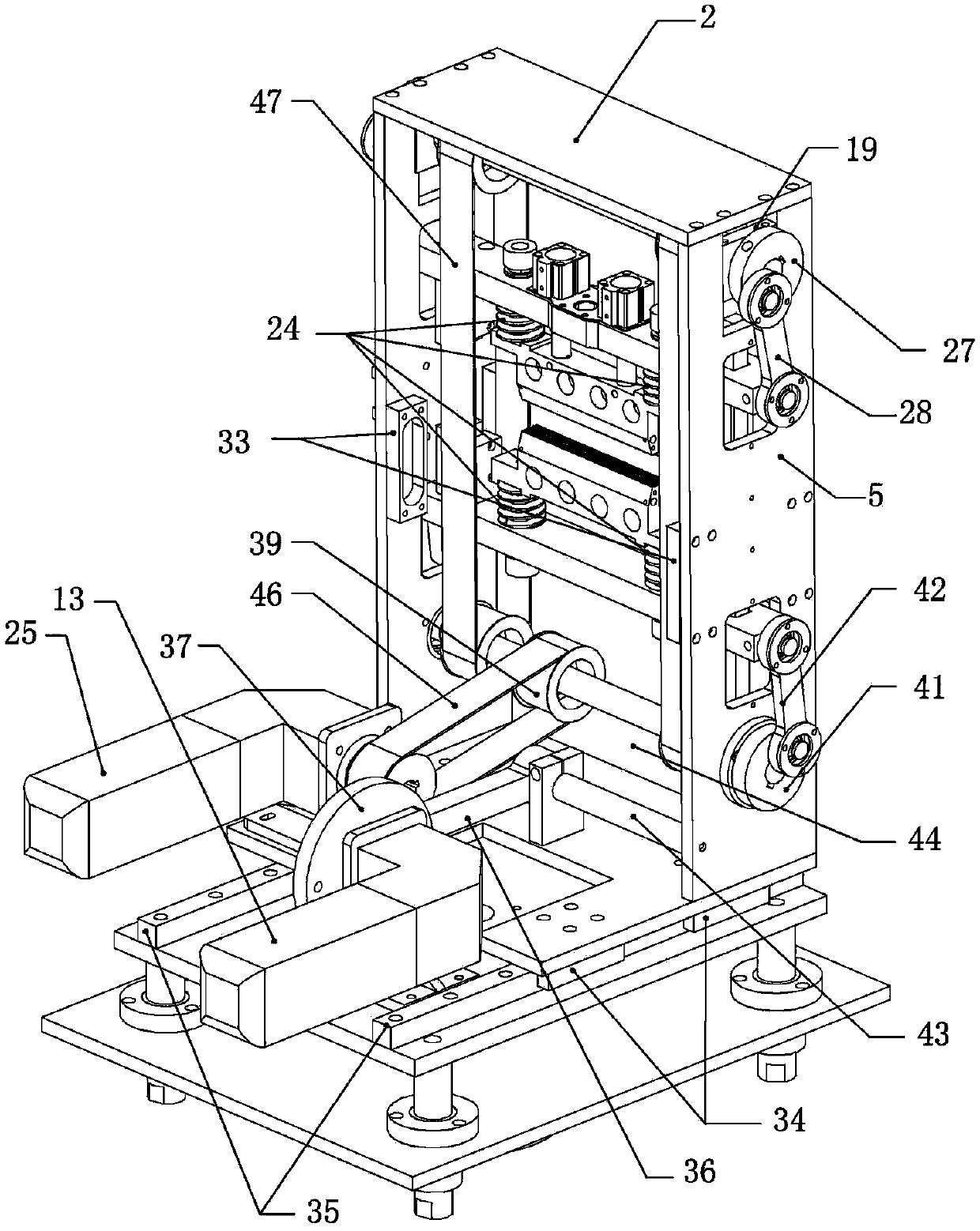

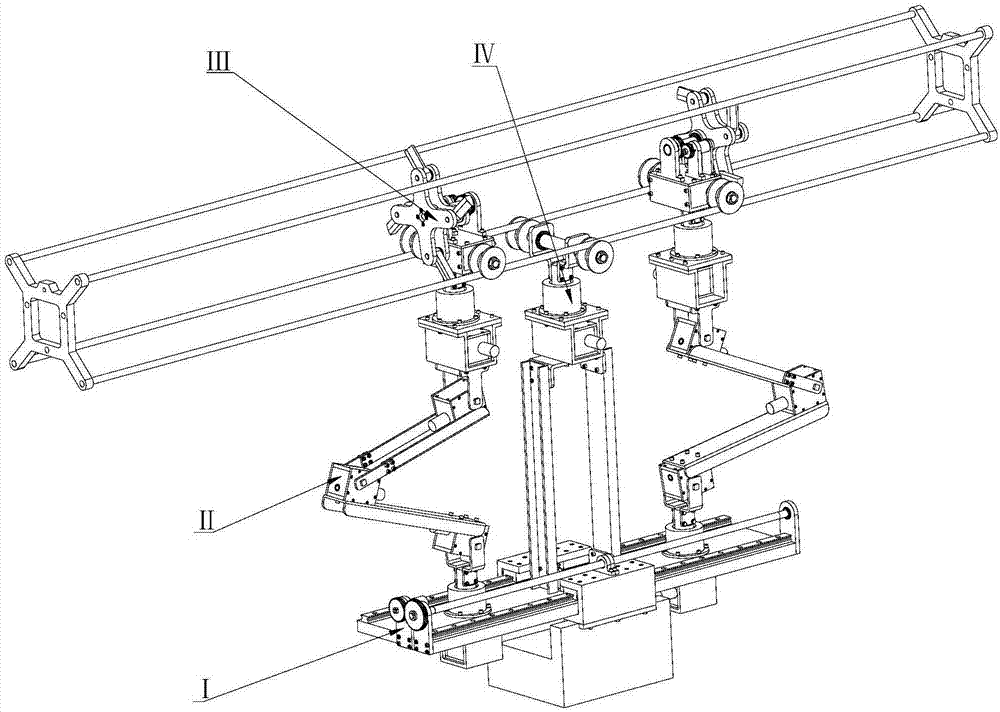

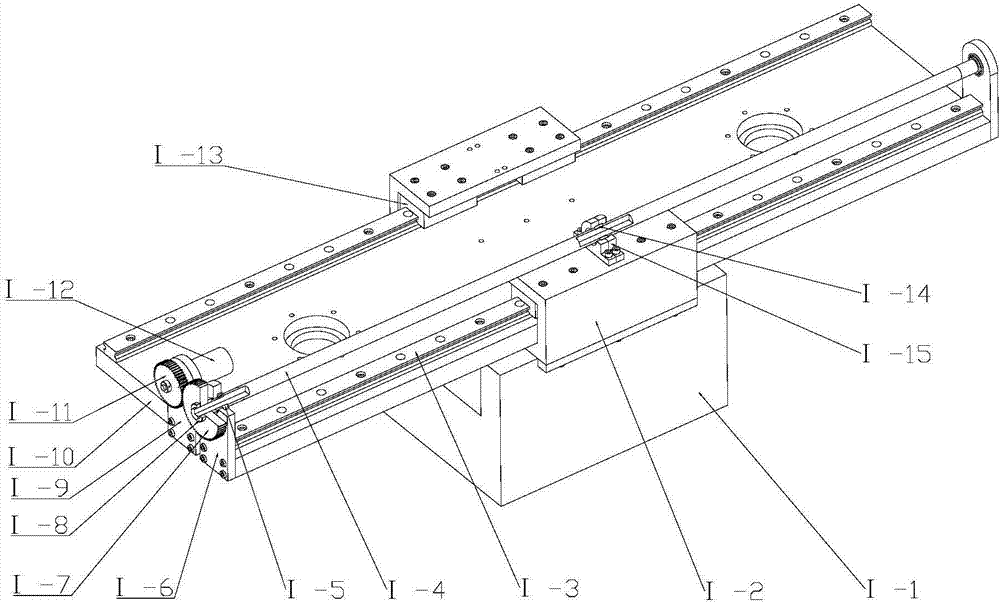

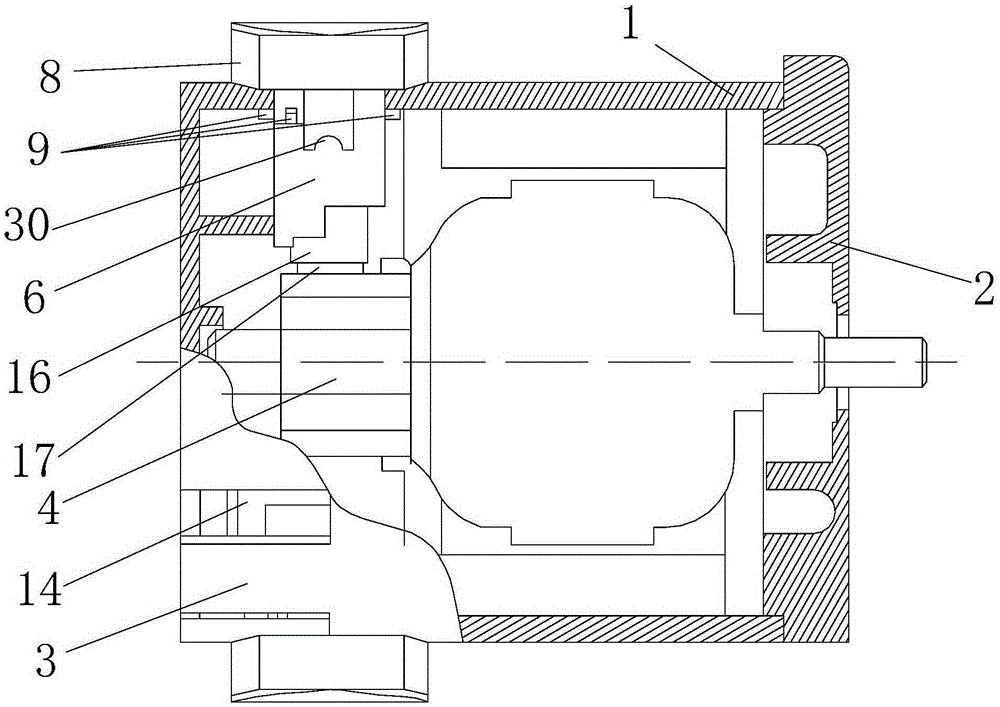

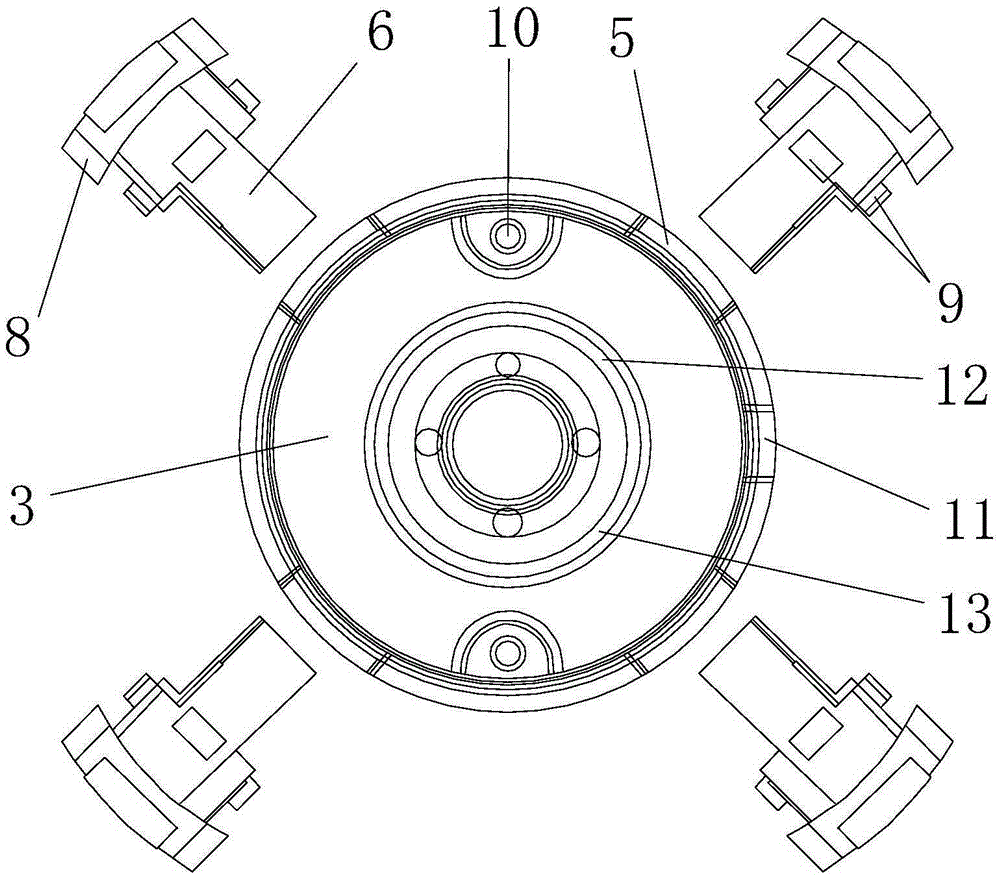

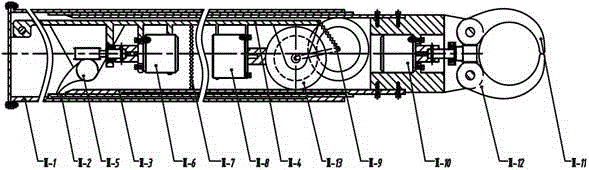

Deicing robot for four-cracking high-voltage power transmission line

ActiveCN106655060AReduce volumeImprove obstacle performanceOverhead installationEngineeringHigh pressure

The invention provides a deicing robot for a four-cracking high-voltage power transmission line. The deicing robot comprises a robot support platform, two six-degree of freedom arms, deicing devices and an intermediate support arm, wherein the two six-degree of freedom arms are arranged at two ends of the robot support platform. By employing the two six-degree of freedom arms and mutual matching of the two deicing devices and the intermediate support arm, the deicing task of a single-phase four-cracking high-voltage power transmission line can be achieved, and the deicing robot is generally applied to a power transmission line of 500Kv; the robot can clear the single-phase four-cracking power transmission line in one time, the deicing robot can cross a four-cracking impedance isolation rod and also can cross a pole tower, and three pole towers which are continuously crossed can be arranged in a straight line and also can be arranged in a broken line; the deicing robot can directly cross the pole tower and is unnecessary to interrupt deicing operation; and the deicing robot is light in weight and relatively small in volume.

Owner:HARBIN ENG UNIV

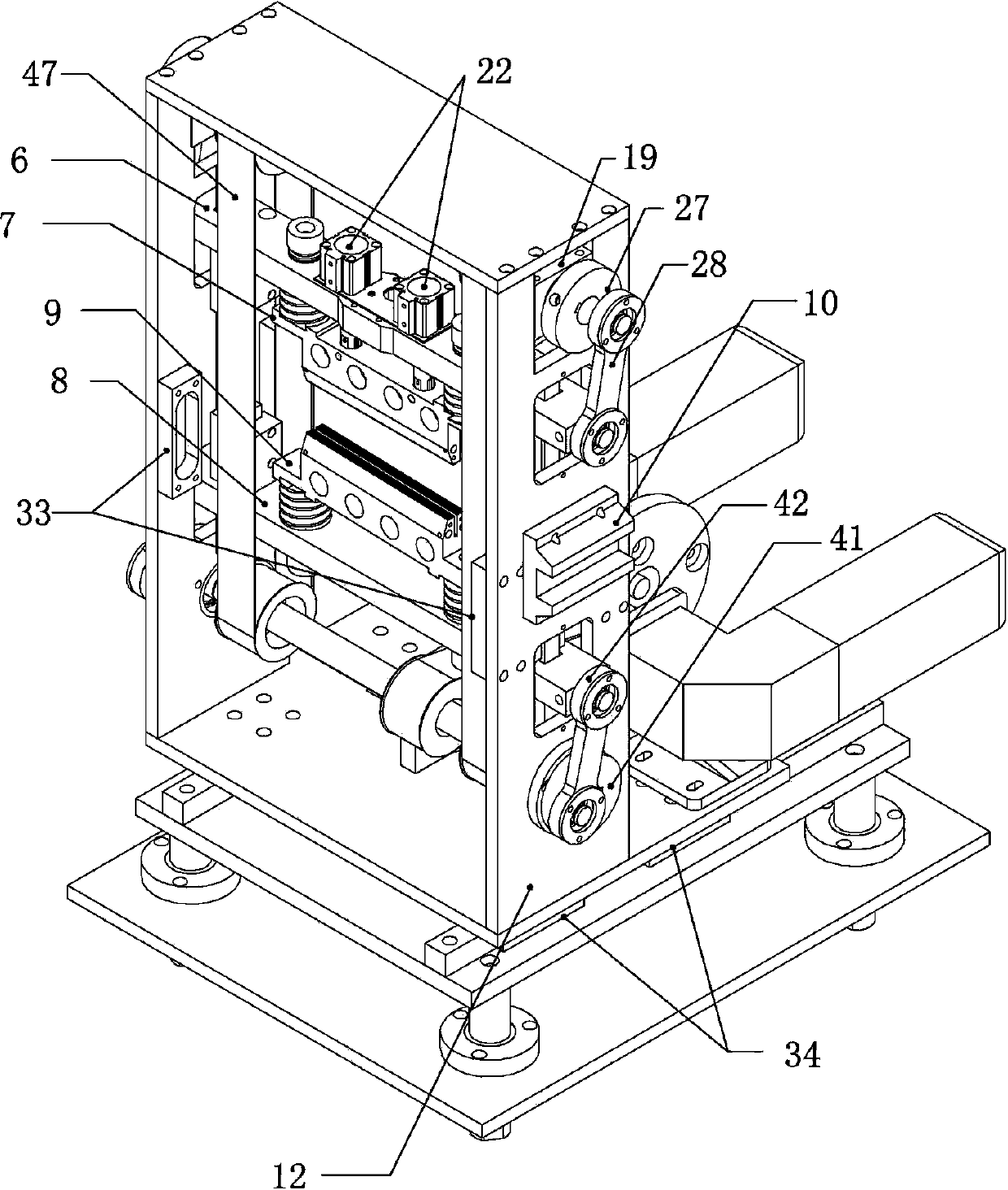

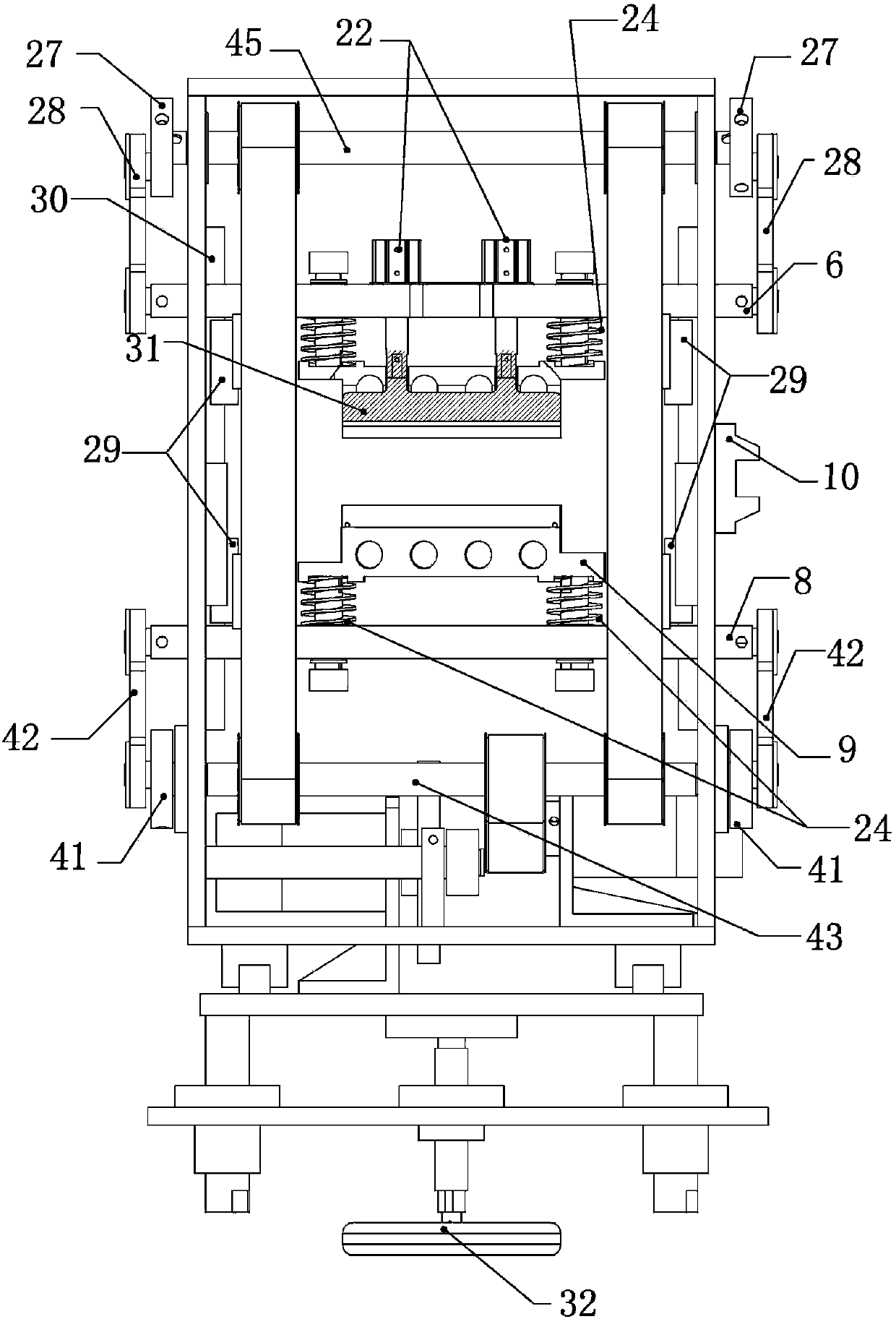

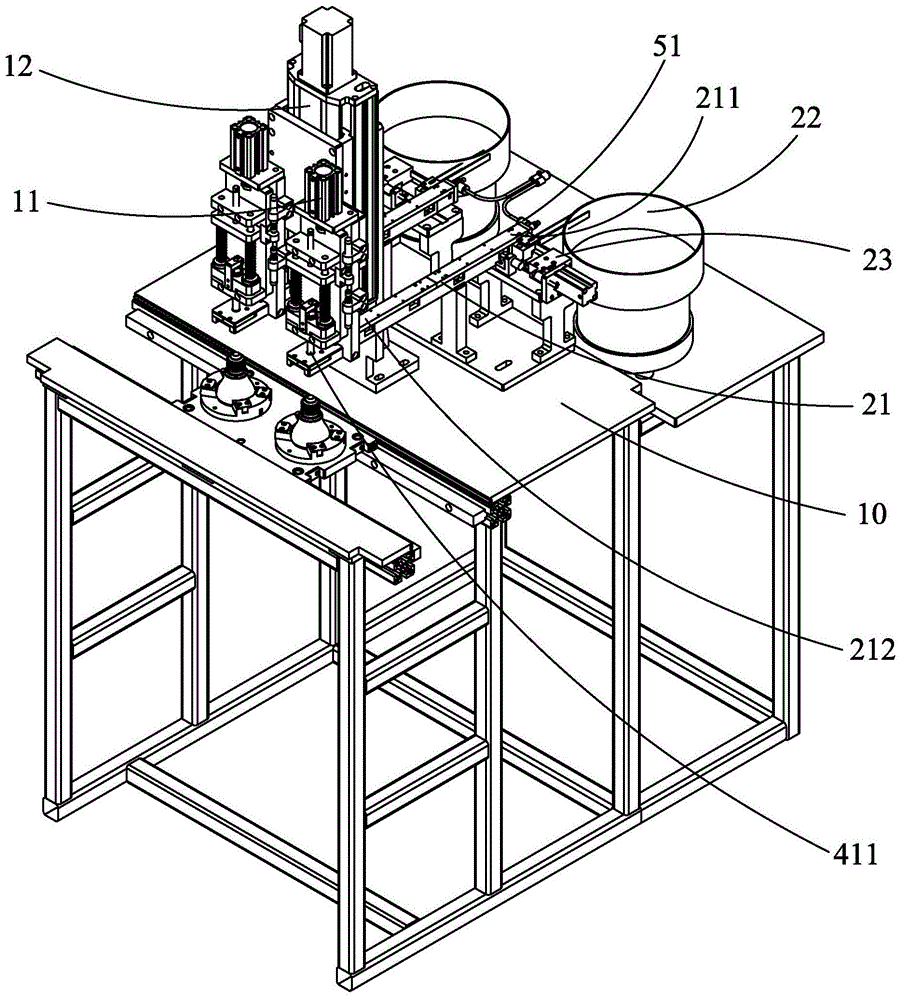

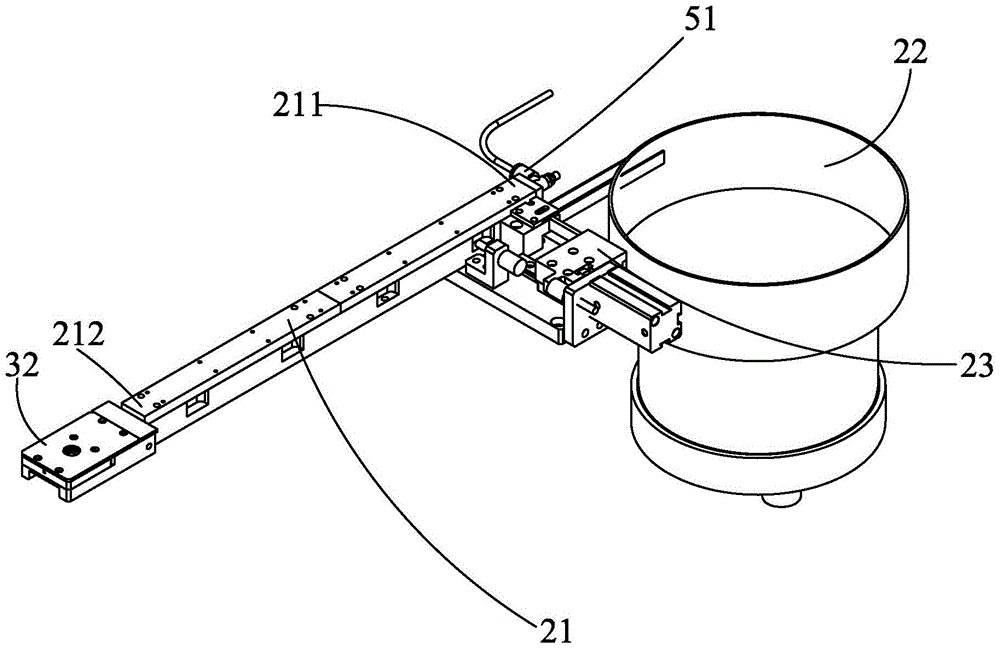

Reciprocating type packaging machine

InactiveCN104192368AUnique design structureIncrease productivityWrapper twisting/gatheringKnife holderPackaging machine

The invention relates to a reciprocating type packaging machine. The reciprocating type packaging machine comprises a packaging device and a packaging machine body. The packaging machine body comprises a material conveying platform, a rack, a packaging film coiling mechanism, a label pasting mechanism, a control touch screen, an adjusting bag manufacturing device, a back seal film-drawing mechanism, a flat-belt conveying belt and a sponge conveying belt. An air pressing device is arranged on the back side of the packaging device. A knife rest is installed on the rack, the knife rest does horizontal reciprocating movement through a knife rest horizontal reciprocating moving mechanism, and an upper knife holder and a lower knife holder are pressed together and separated in a reciprocating mode through an upper and lower knife holder vertical reciprocating pressing cutting and opening mechanism. According to the packaging machine, the knife rest horizontally reciprocates and the upper knife holder and the lower knife holder are pressed together and separated in the reciprocating mode through cams, the production efficiency is improved, the labor intensity is relieved, various packaging demands can be met, and the reciprocating type packaging machine is reasonable in design, simple in structure and easy to control.

Owner:陆丰机械(郑州)有限公司

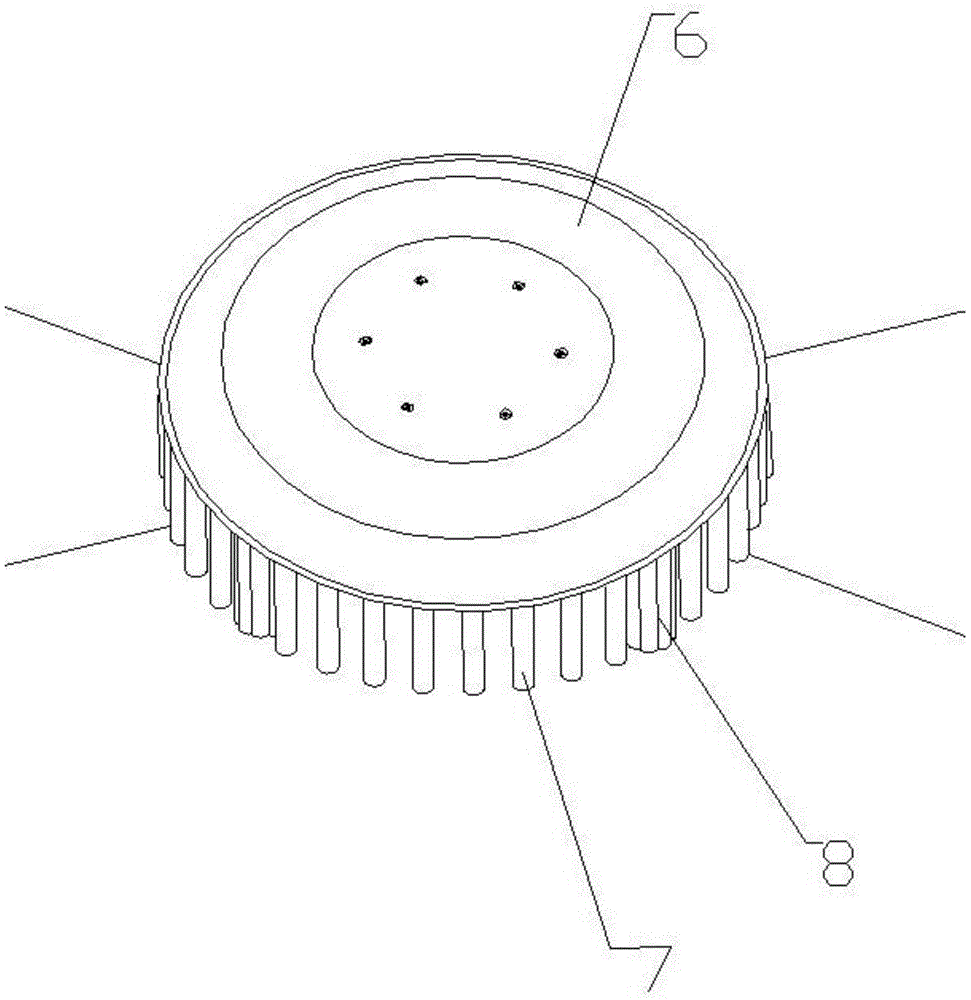

High-efficiency heat radiating LED (light emitting diode) lamp and manufacture method thereof

InactiveCN101871627AIncrease heatReduce light decay speedPoint-like light sourceSemiconductor/solid-state device detailsThermodynamicsEngineering

The invention discloses a manufacture method of a high-efficiency heat radiating LED lamp, which comprises the following steps: (1) manufacturing a strip-shaped PCB welding board, and evenly welding a plurality of LED lamps on the PCB welding board, wherein through holes are arranged on the PCB welding board below the LED lamps; (2) manufacturing a strip-shaped graphite radiator by adopting graphite and evenly arranging a plurality of heat conduction rivets on the graphite radiator, wherein the heads of the heat conduction rivets are projected on the graphite radiator, and the space between the two adjacent heat conduction rivets is equal to that between the two adjacent LED lamps on the PCB welding board; and (3) coating heat conduction paste on the upper surface of the graphite radiator and the tops of the heat conduction rivets, and fixing the graphite radiator with the upper surface upward to the lower surface of the PCB welding board, wherein the tops of the heat conduction rivets and the bottoms of the LED lamps are in contact to form a high-efficiency heat radiating structure. The invention also provides the high-efficiency heat radiating LED lamp manufactured by the method.

Owner:戴建国

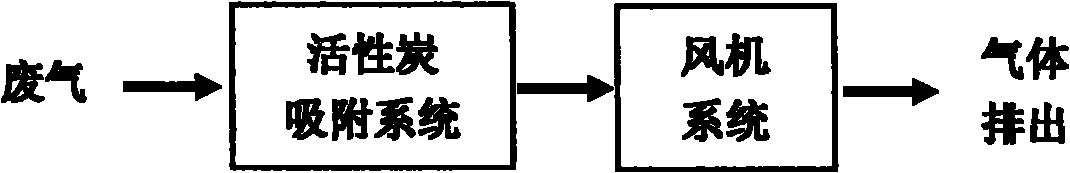

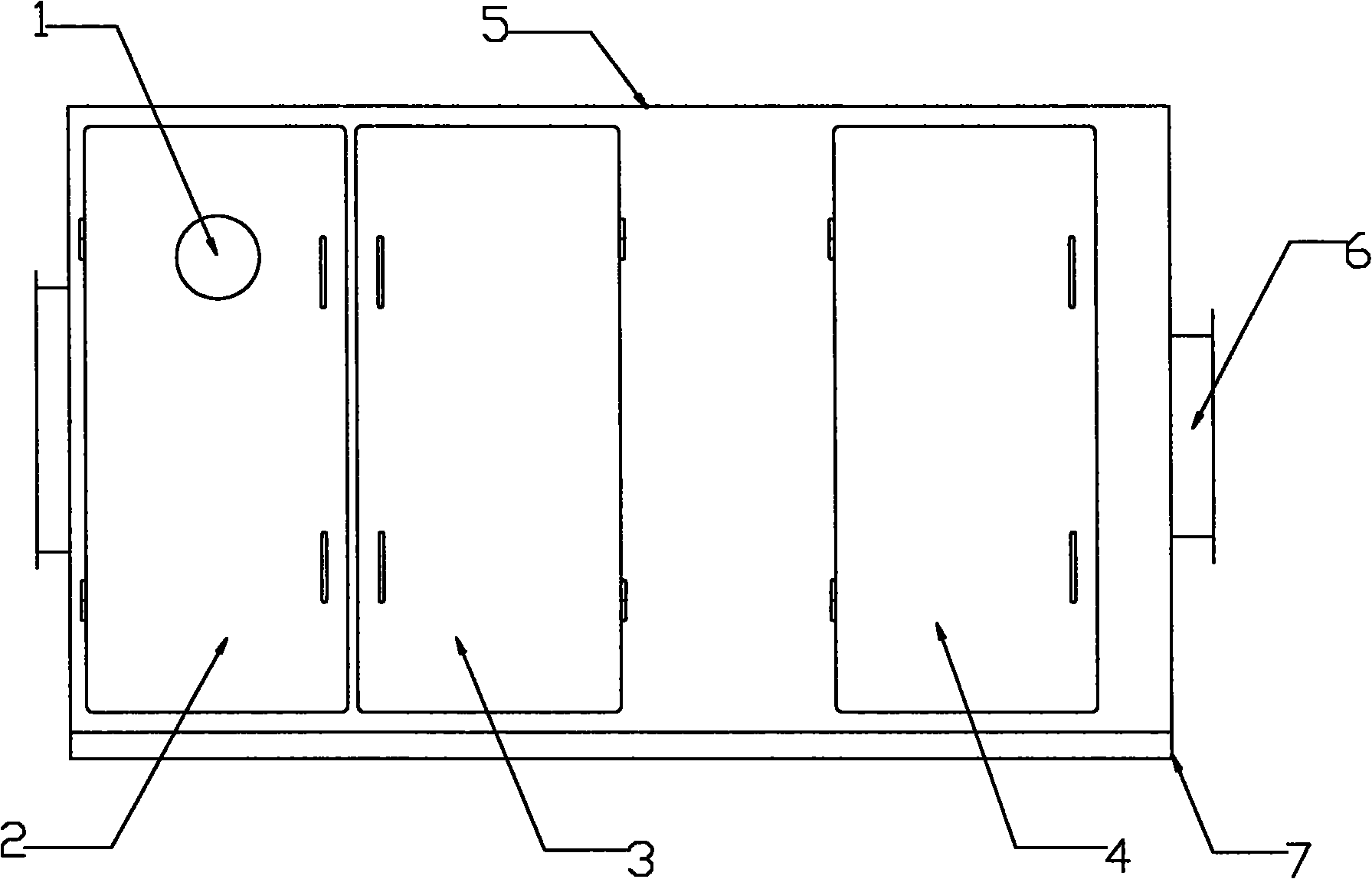

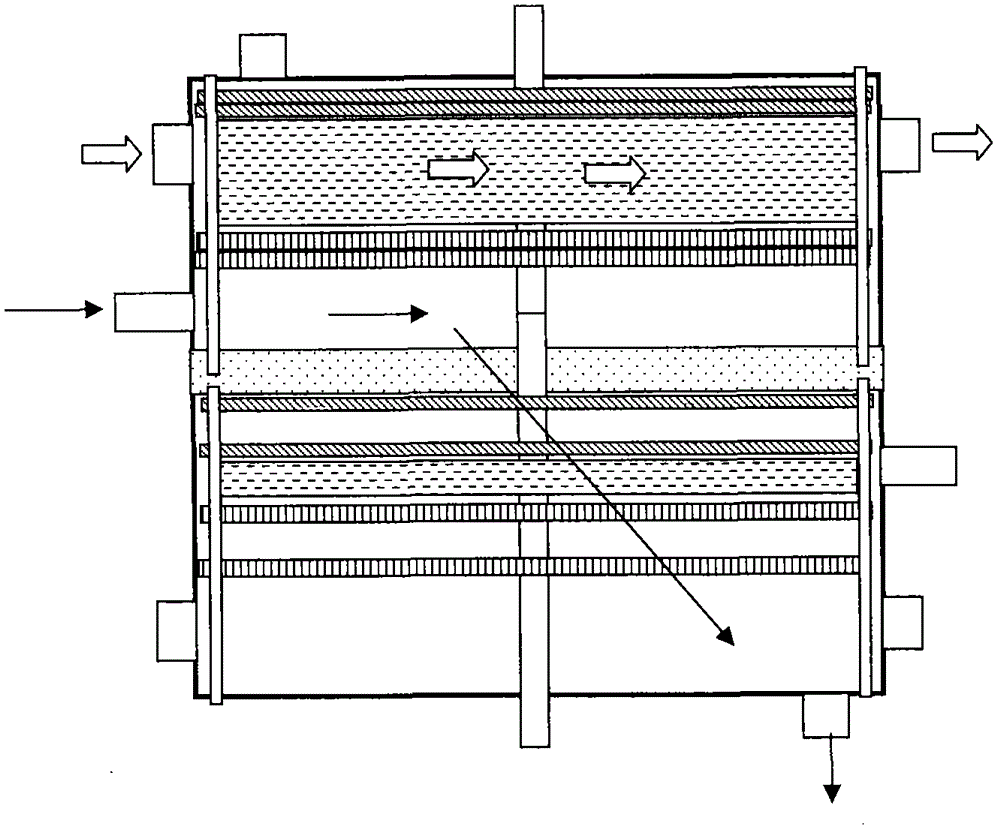

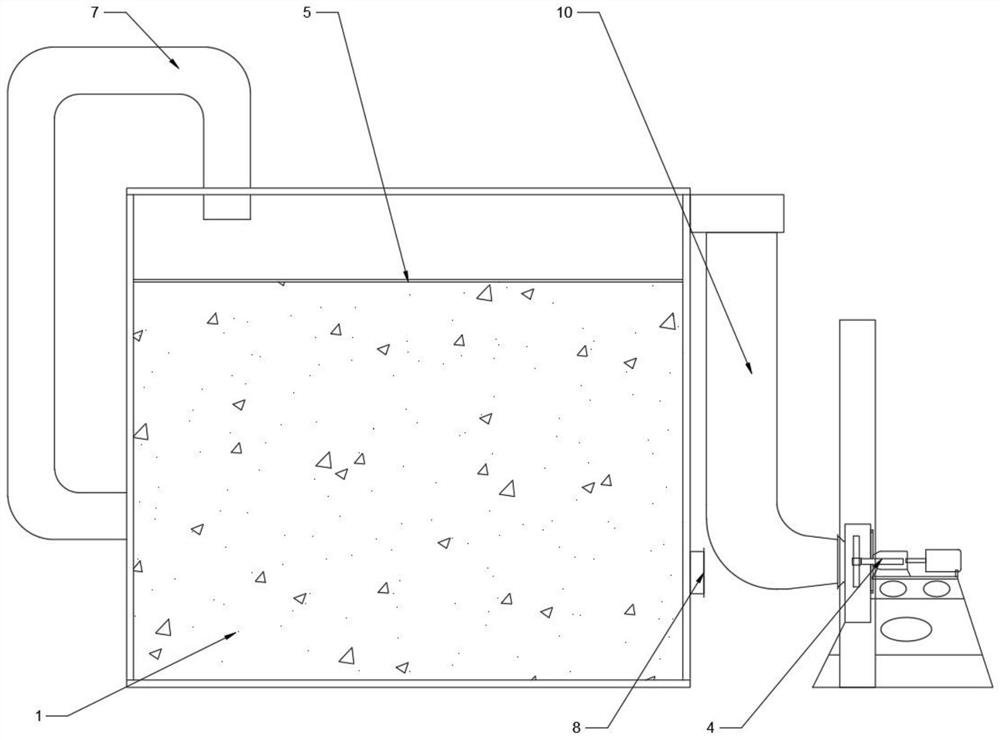

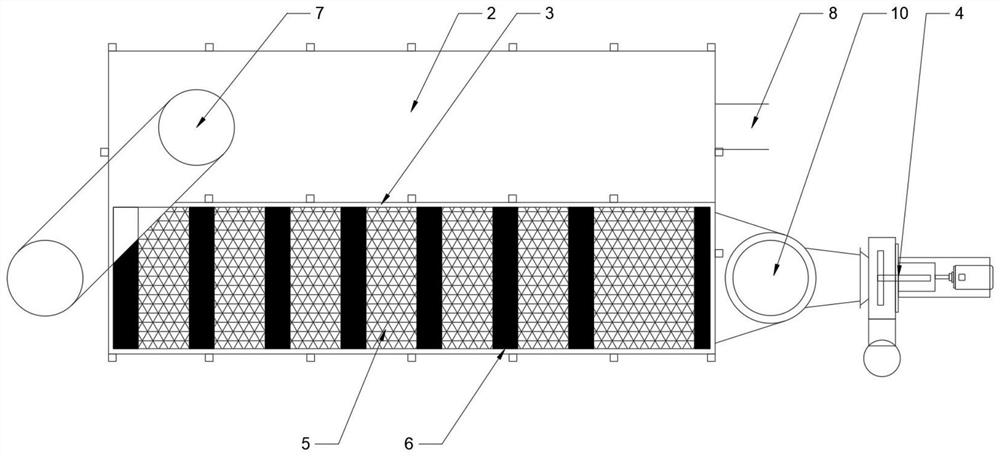

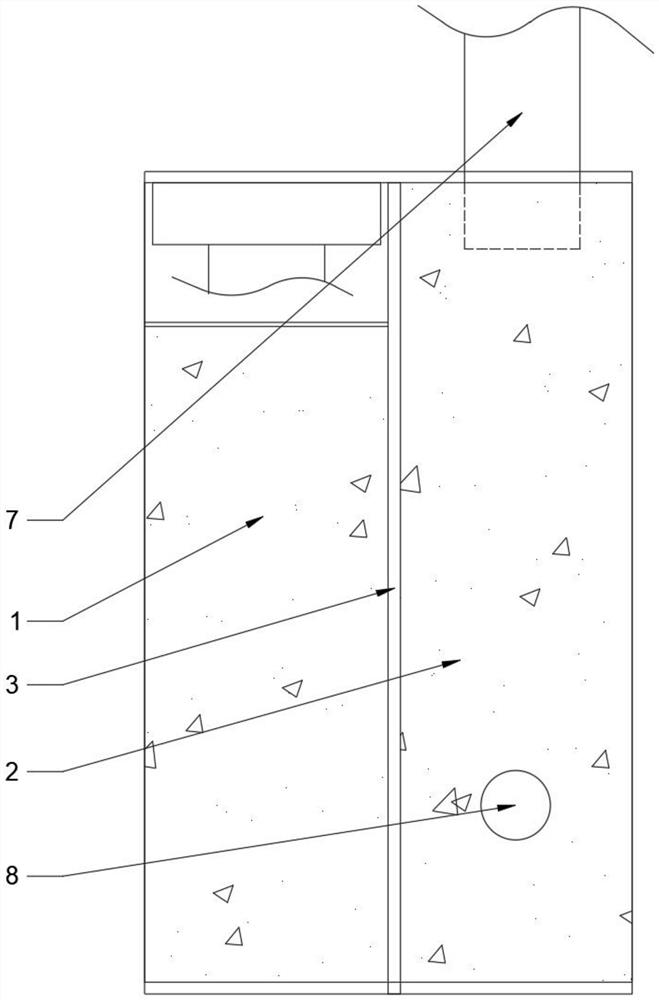

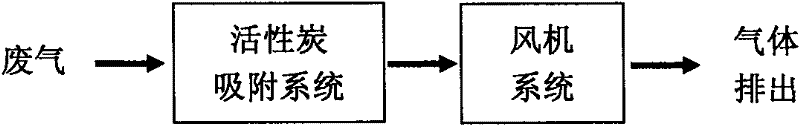

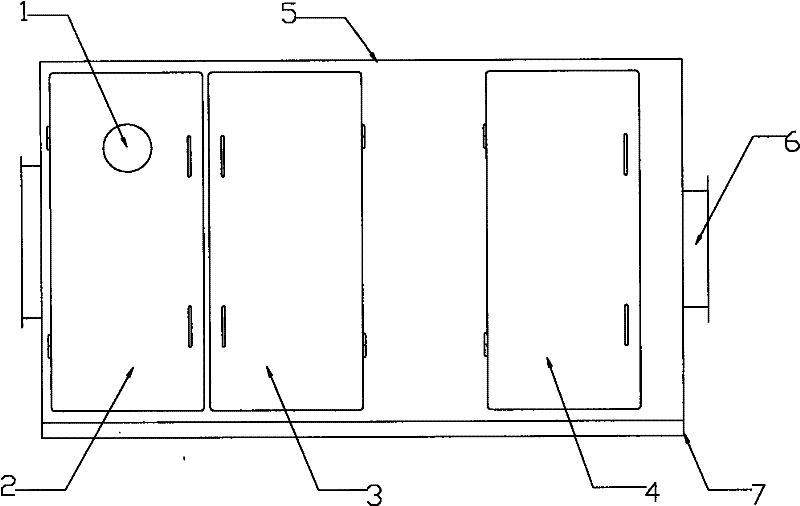

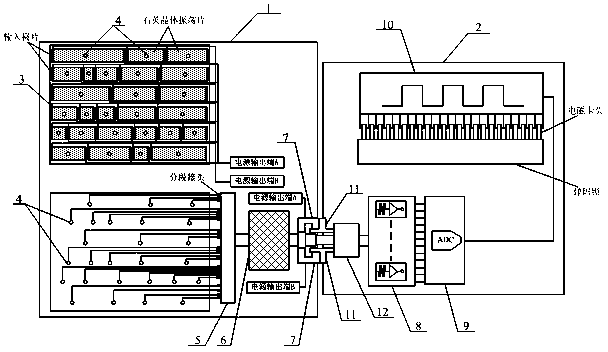

Method and device for treating volatile organic waste gas

InactiveCN101791512AReasonable designCompact structureDispersed particle separationLight activationDecomposition

The invention discloses a method and device for treating volatile organic waste gas. In the method, the volatile organic waste gas firstly enters into a flow rotating and gas distributing system containing a rotating flow tray which is provided with a plurality of cyclone vanes, then the gas which is subdivided by the flow rotating and gas distributing system subsequently enters into a light activation and advanced oxidation system to be irradiated by high power ultraviolet lamps, while radiation-induced decomposition is carried out on part of the waste gas, reactive oxygen is generated to oxidize the organics in the waste gas, after that, the waste gas uniformly passes through a high efficiency composite material adsorption system to be adsorbed by the high efficiency composite materials, and finally the waste gas is discharged from the waste gas outlet via an explosion-proof fan system. By the method, the efficiency and the rate of treating the volatile organic waste gas are improved, the harm of the waste gas to human health and the environment is weakened, the health of the experimental personnel is further protected and the working environment is improved.

Owner:中洁环淼(江苏)环境科技有限公司

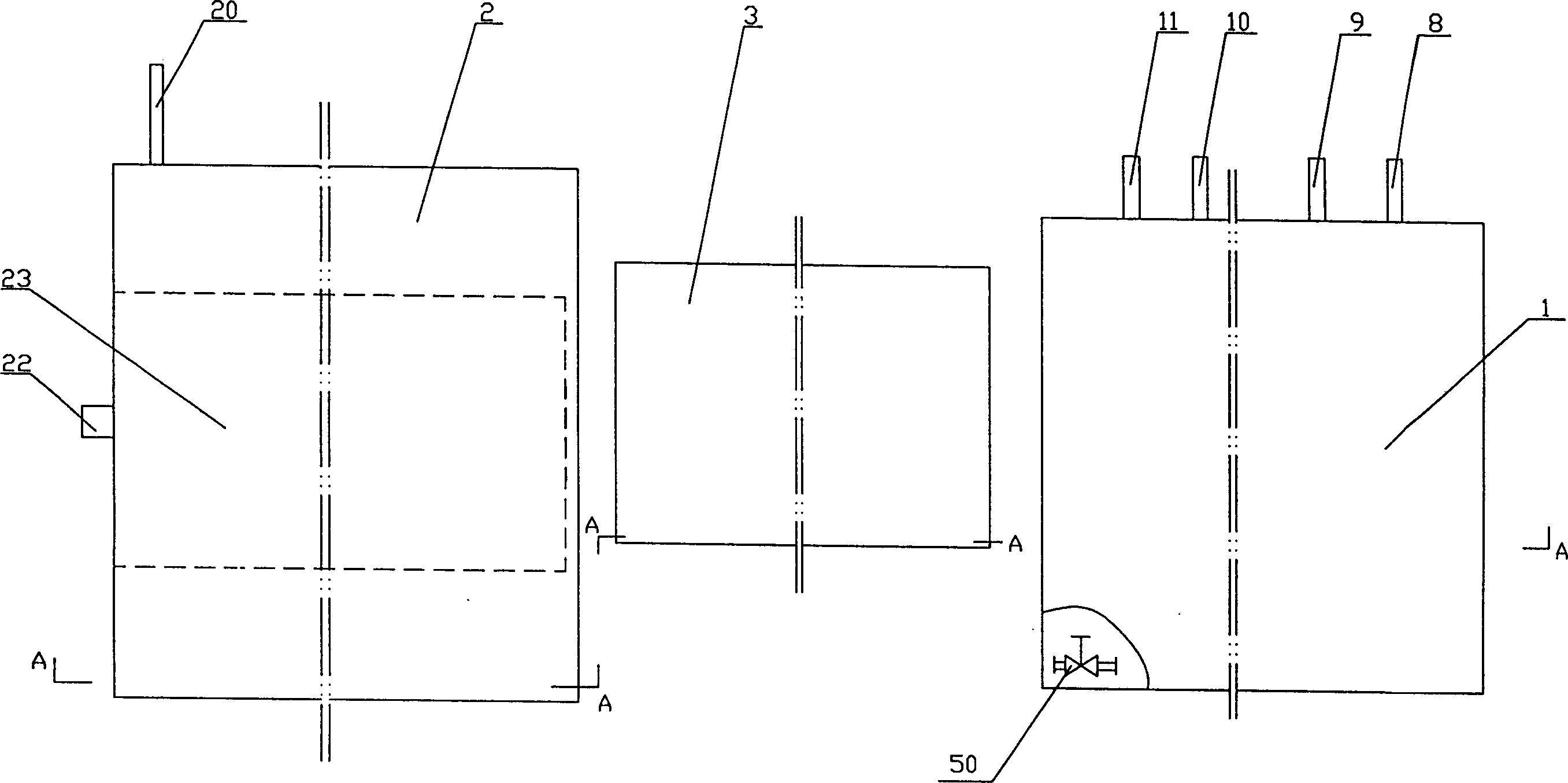

Multifunctional solar-energy seawater-desalinating and power-generating installation

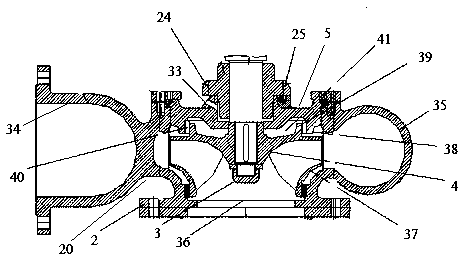

InactiveCN1843947AQuality improvementReduce the use of areaGeneral water supply conservationSeawater treatmentThermal insulationInlet valve

The invention relates to a solar energy multifunctional sea water desalination and power generation device, and it is characterized in that: multifunctional sea water desalination device comprises: box support, two-layer thermal insulation booth, heating device with solar energy, single-action sea water evaporator, sea water inlet, salt water inlet pipe, induced draft fan, steam cooling curtain, fresh water outlet pipe and fresh water collecting tank; solar pool comprises: two-layer thermal insulation booth, fresh water outlet pipe, fresh water collecting tank, salt water pool, salt pump and pool wall; solar power making device comprises: two-layer thermal insulation booth, box support, thermal insulation board, salt water outlet and inlet pipe, seawater outlet and inlet pipe, high pressure gas outlet valve, low pressure gas inlet pipe, high pressure gas outlet pipe, high pressure gas inlet valve, energy exchange device, refrigerant output valve, airturbine generator and air compressor. The said three parts form said seawater desalination and power generation device. The invention can not only use solar energy to make power and desalinate sea water, but also can get large amount of power and fresh with high quality and side product with high added value.

Owner:程显超

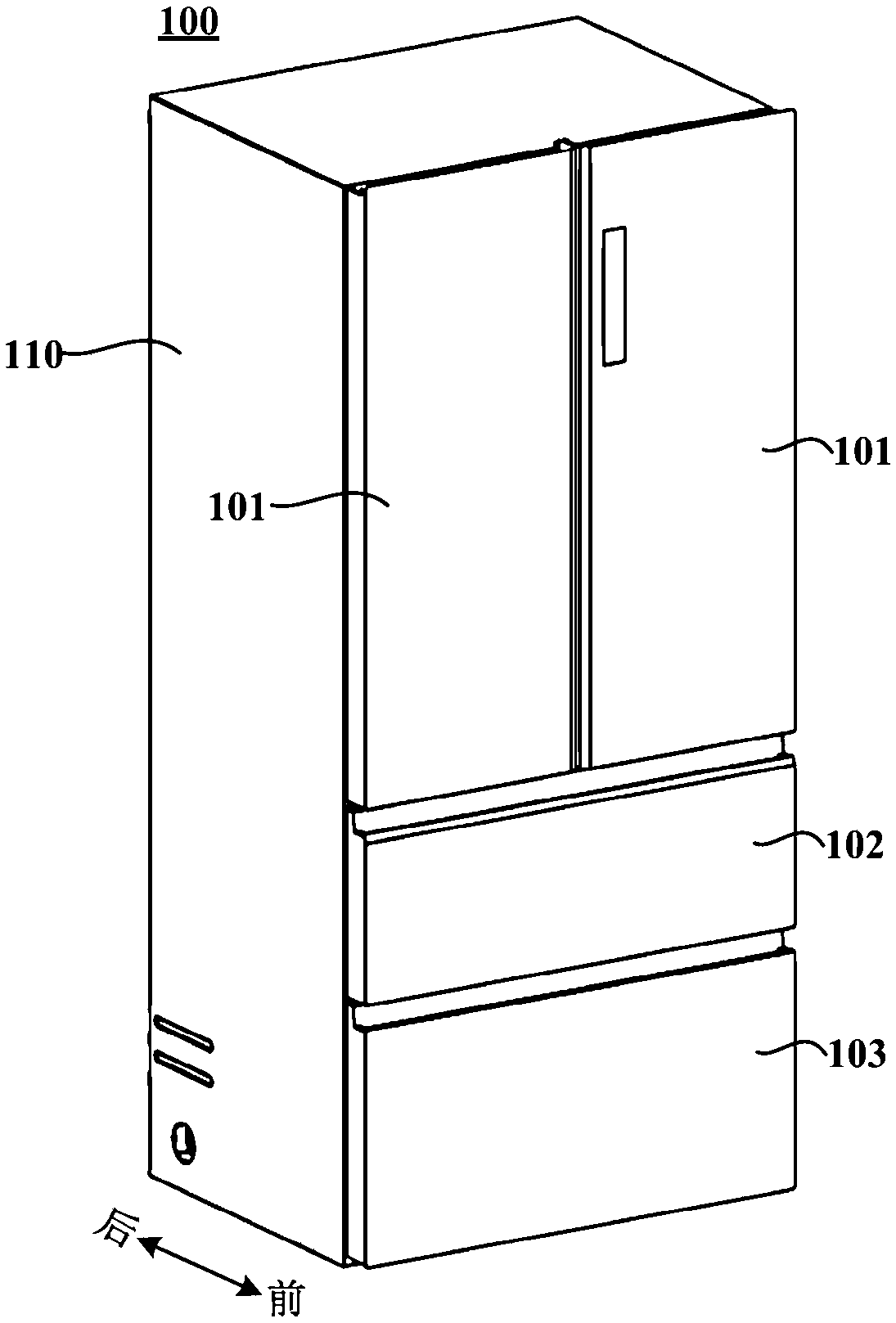

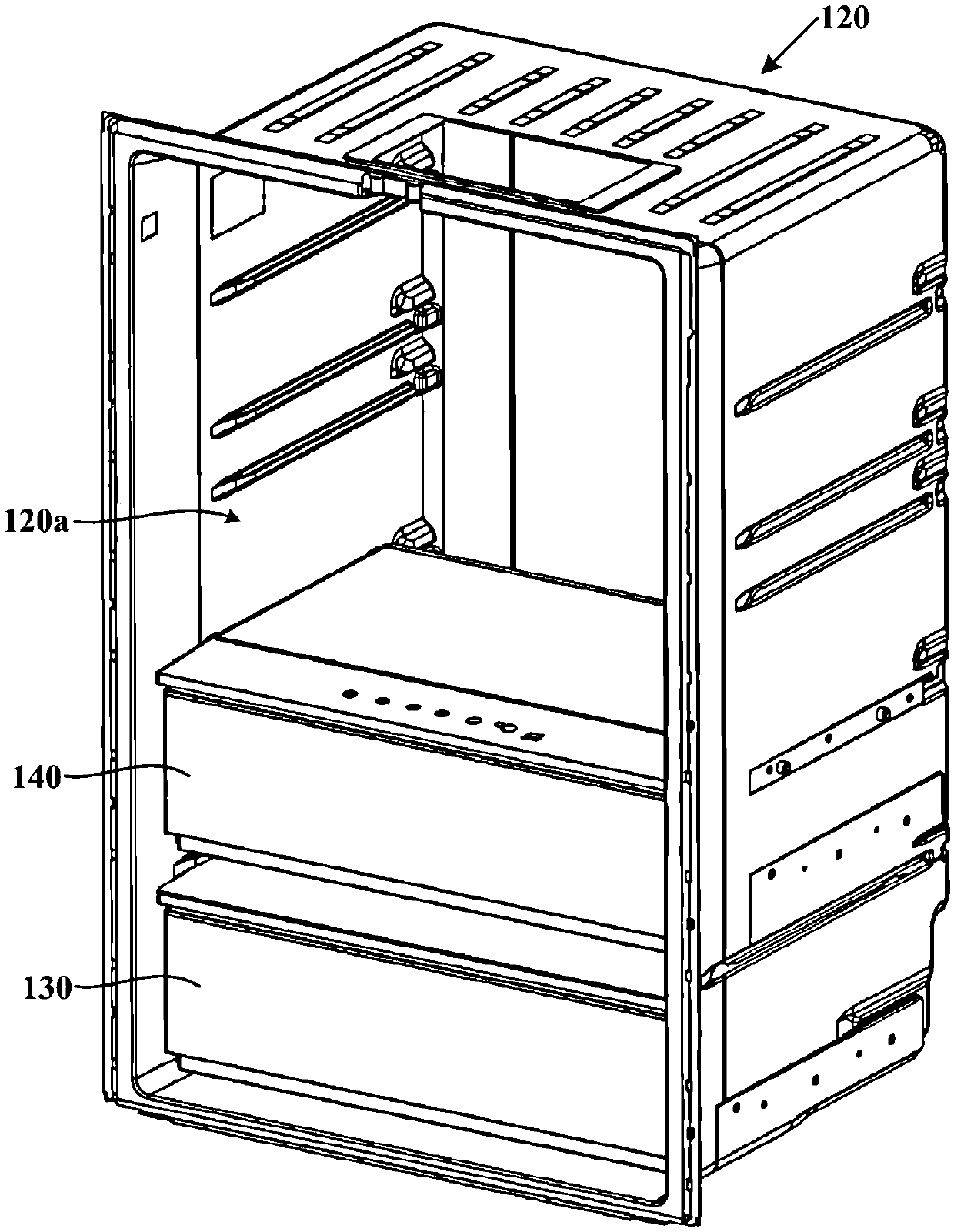

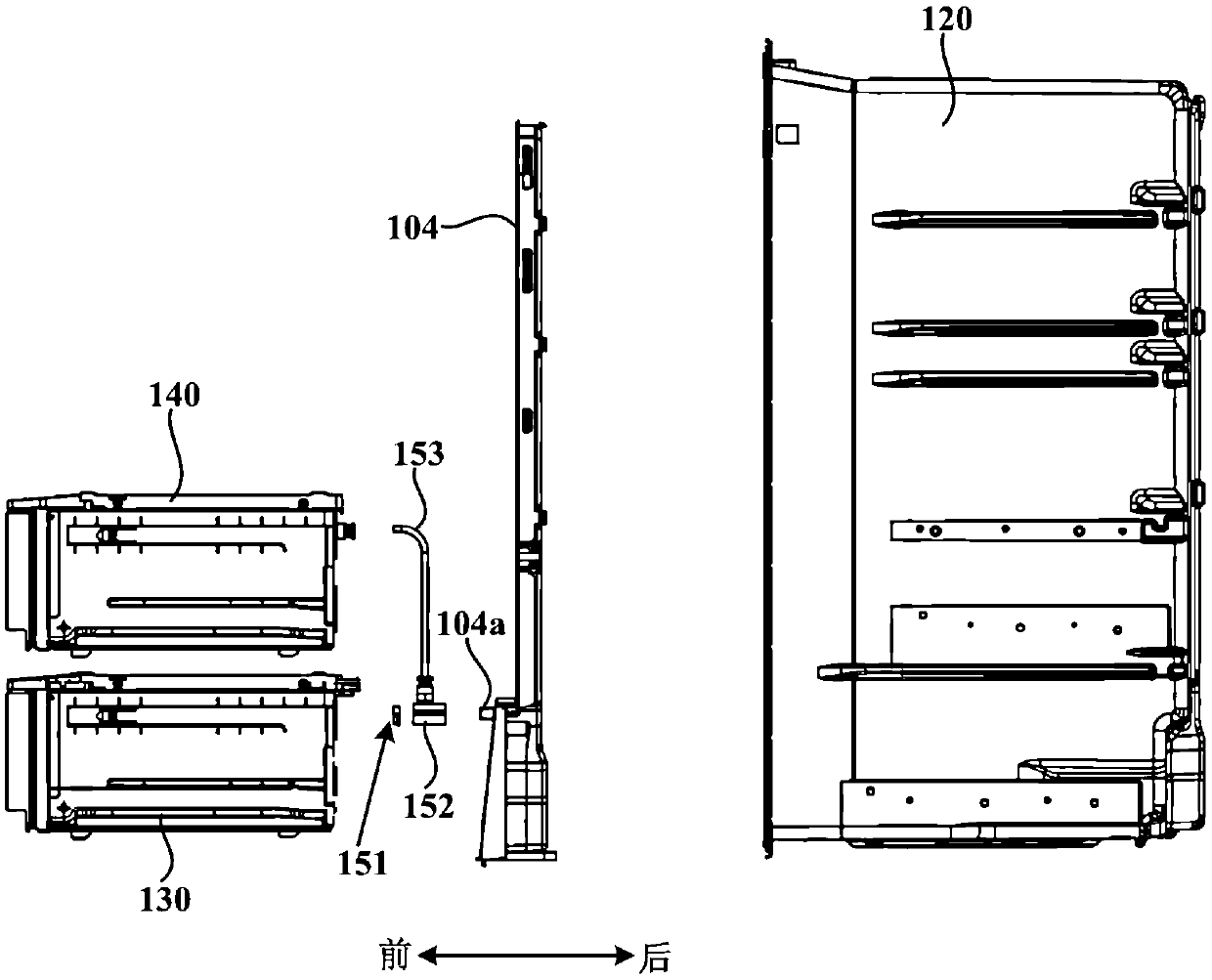

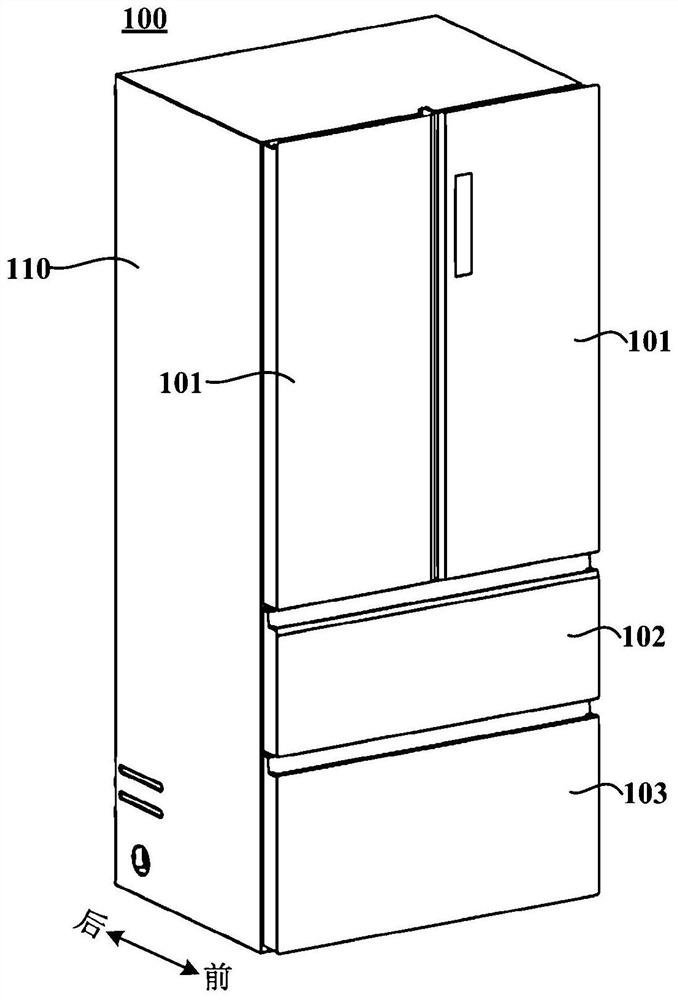

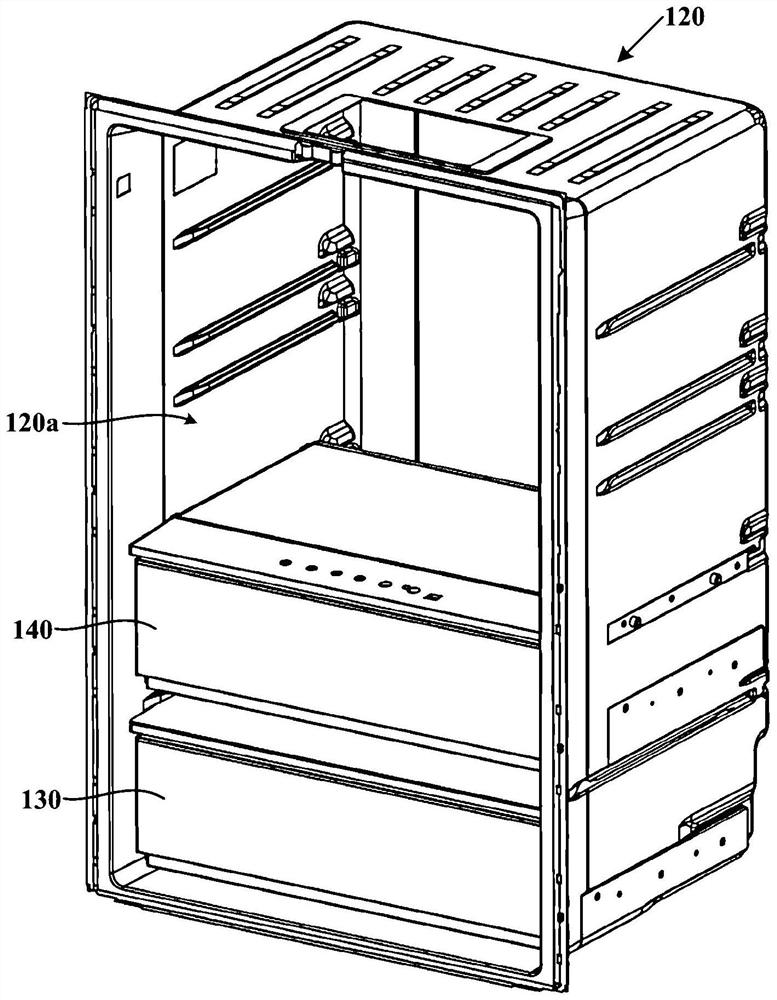

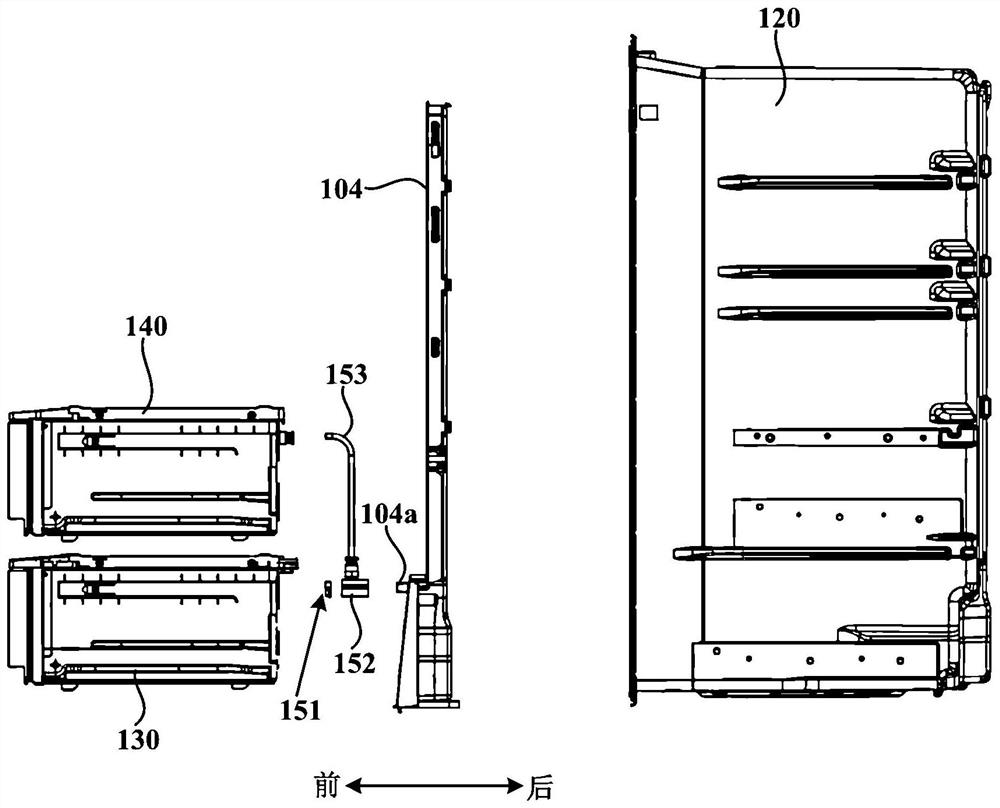

Refrigerating and freezing device

ActiveCN109737665ASolve the problem of complex structure and high costGuaranteed meat colorLighting and heating apparatusDomestic refrigeratorsNitrogenEngineering

The invention provides a refrigerating and freezing device. The device comprises a box body and a magnetic air separation unit; a storage space and an air supply air duct are defined in the box body,wherein the air supply air duct is used for conveying cold air flows to the storage space; a first storage container and a second storage container which are distributed at intervals are arranged in the storage space, and each of the first storage container and the second storage container is provided with an air inlet; the magnetic air separation unit is used for communicating an air outlet of the air supply air duct with the air inlet of the first storage container and the air inlet of the second storage container, and is configured to separate oxygen from nitrogen in the cold air flows so as to form the oxygen-enriched cold air flows and the nitrogen-enriched cold air flows; and the oxygen-enriched cold air flows are introduced into the first storage container to form an oxygen-enrichedfresh-keeping space in the first storage container, the nitrogen-enriched cold air flows are introduced into the second storage container to form a nitrogen-enriched fresh-keeping space in the secondstorage container, so that the quality, color and lustre of meat can be guaranteed, and nutrition loss can be reduced; and aerobic respiration intensity of fruits and vegetables can be reduced, so that deterioration of the fruits and vegetables can be inhibited, and nutrient loss can be reduced.

Owner:HAIER SMART HOME CO LTD

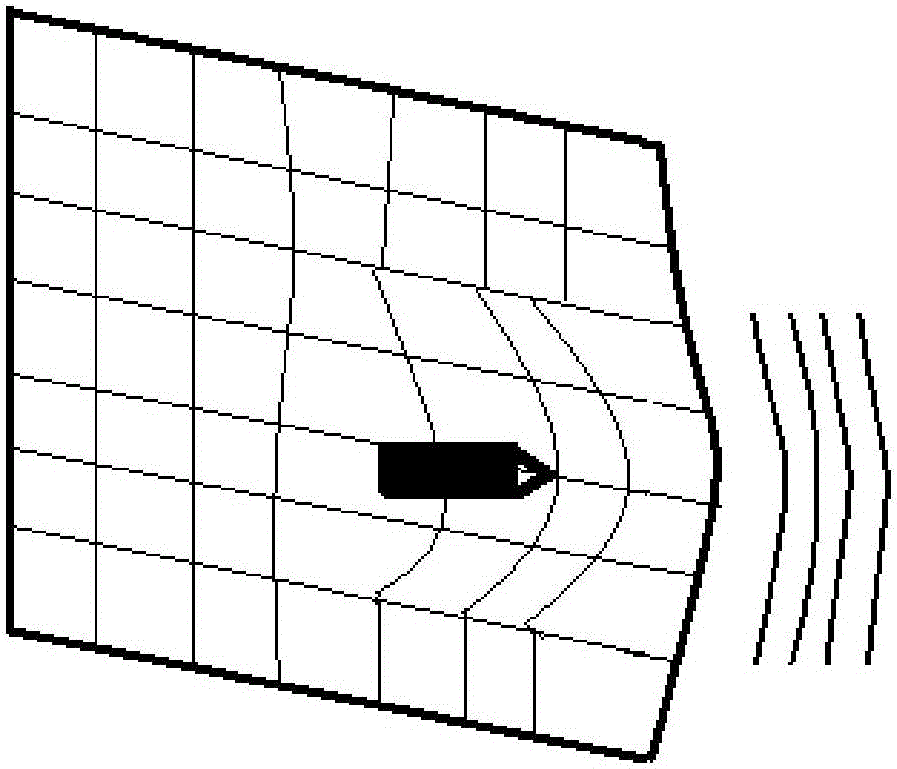

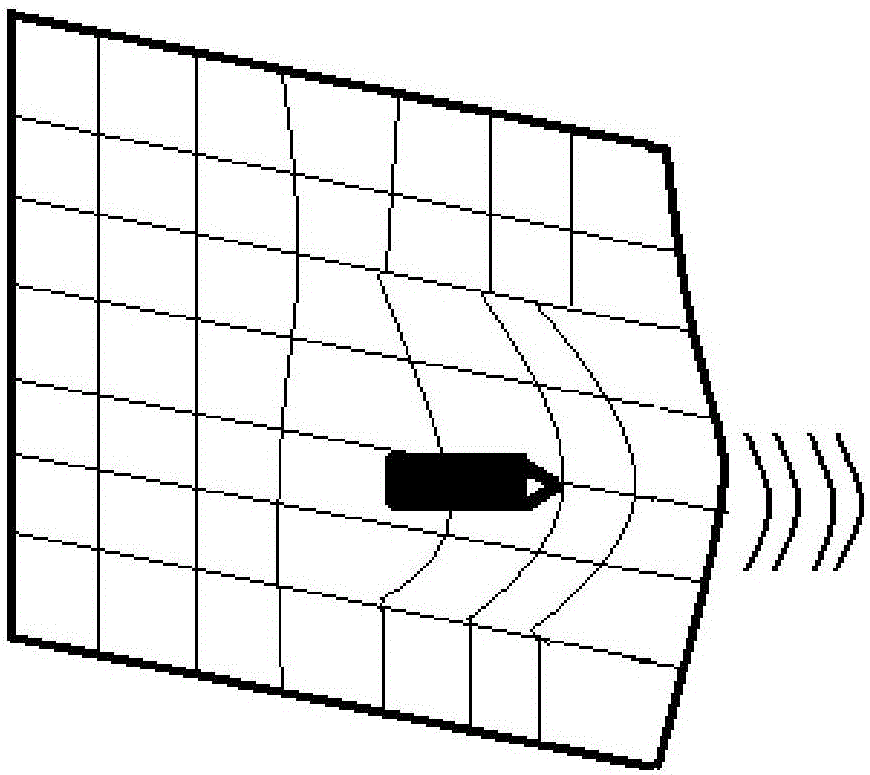

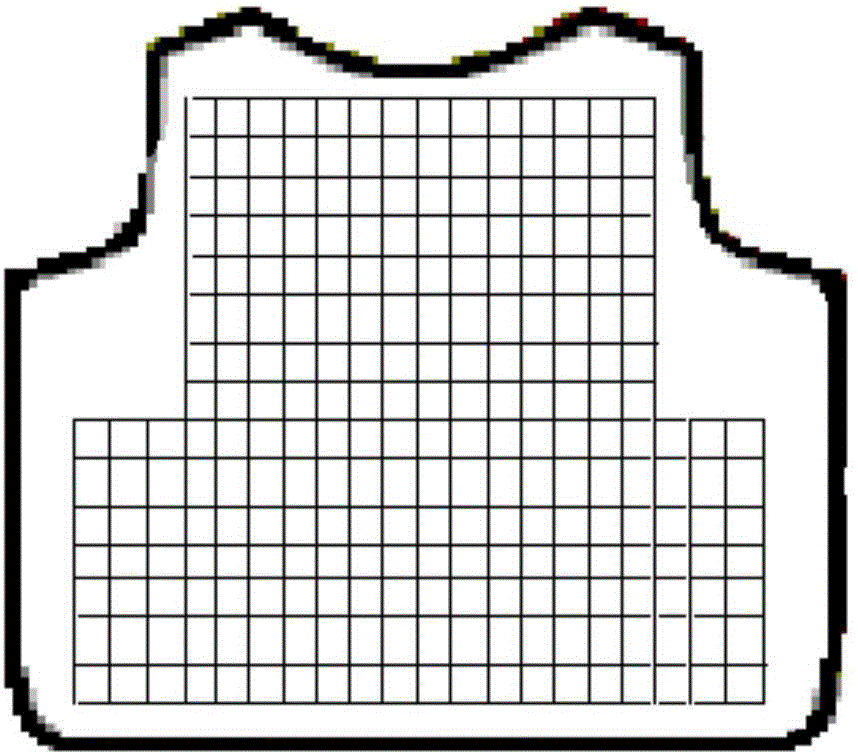

Novel light body armor with kinetic energy absorption structure

InactiveCN106123691AReduce post-maintenance costsReduce harmPersonal protection gearFiberEcological environment

A novel light body armor with a kinetic energy absorption structure comprises a coat, a body armor body, a lining and the kinetic energy absorption structure, wherein the coat is arranged on the outer side of the body armor body; the lining is arranged on the inner side of the body armor body; the body armor body is manufactured by processing high-performance fibers; the kinetic energy absorption structure adopts a design structure in which a fire-retardant liquid cooperates with an elastic sealing unit; the elastic sealing unit is filled with the fire-retardant liquid; and the kinetic energy absorption structure is movably mounted outside the lining. The biggest difference between the novel light body armor and a traditional buffer structure is that the novel light body armor can recover automatically and is reduced in later-stage maintenance cost; the novel light body armor is simple in structure, has a good kinetic energy absorption effect, forms a gentle large-area fluid kinetic energy impact on a human body, and reduces harm to the human body; and the novel light body armor is unique in design structure, reduces damage caused by compressed foam products to the ecological environment, and saves the costs of later-stage maintenance, storage and the like.

Owner:BEIJING PT PROTECTION TECH

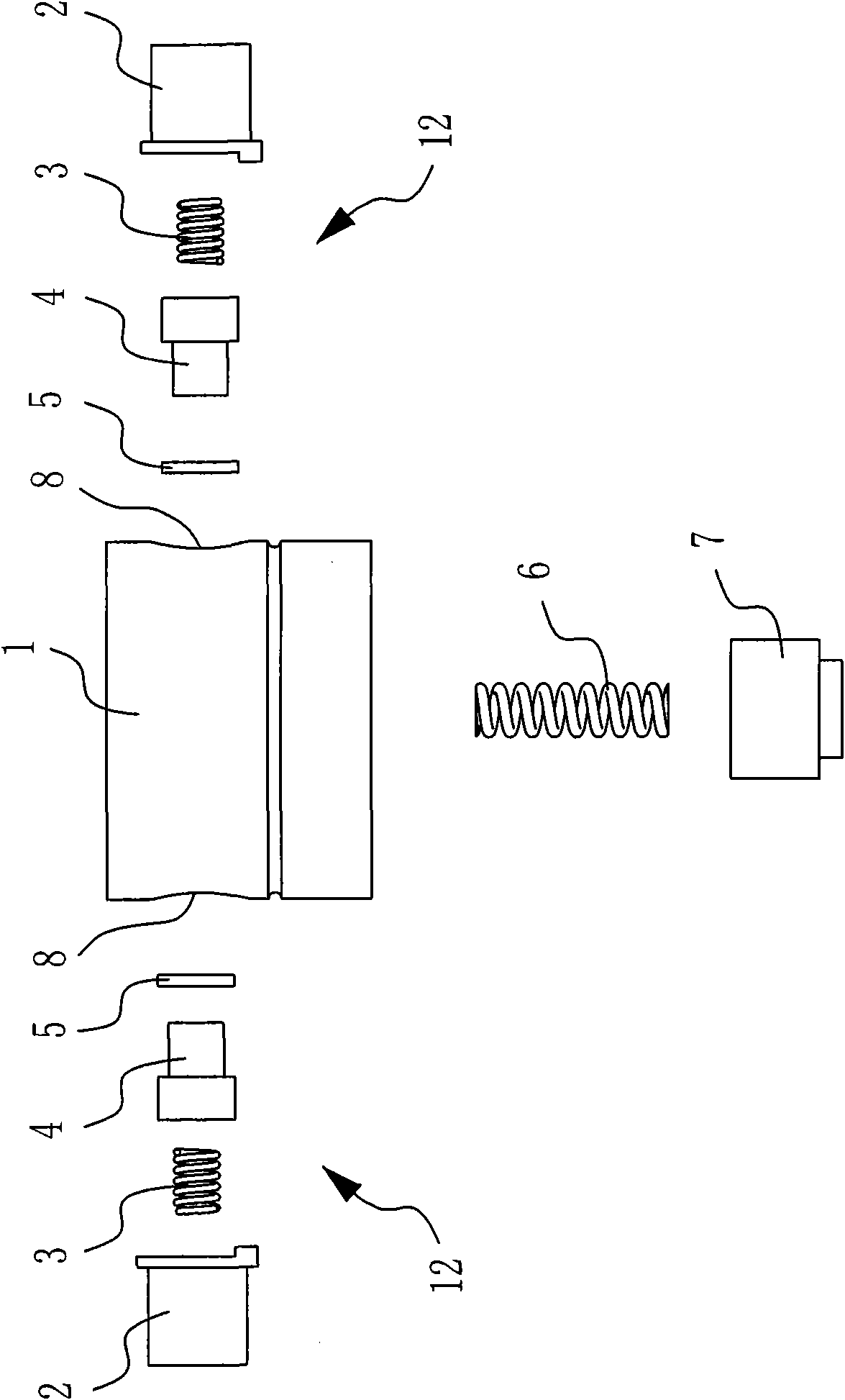

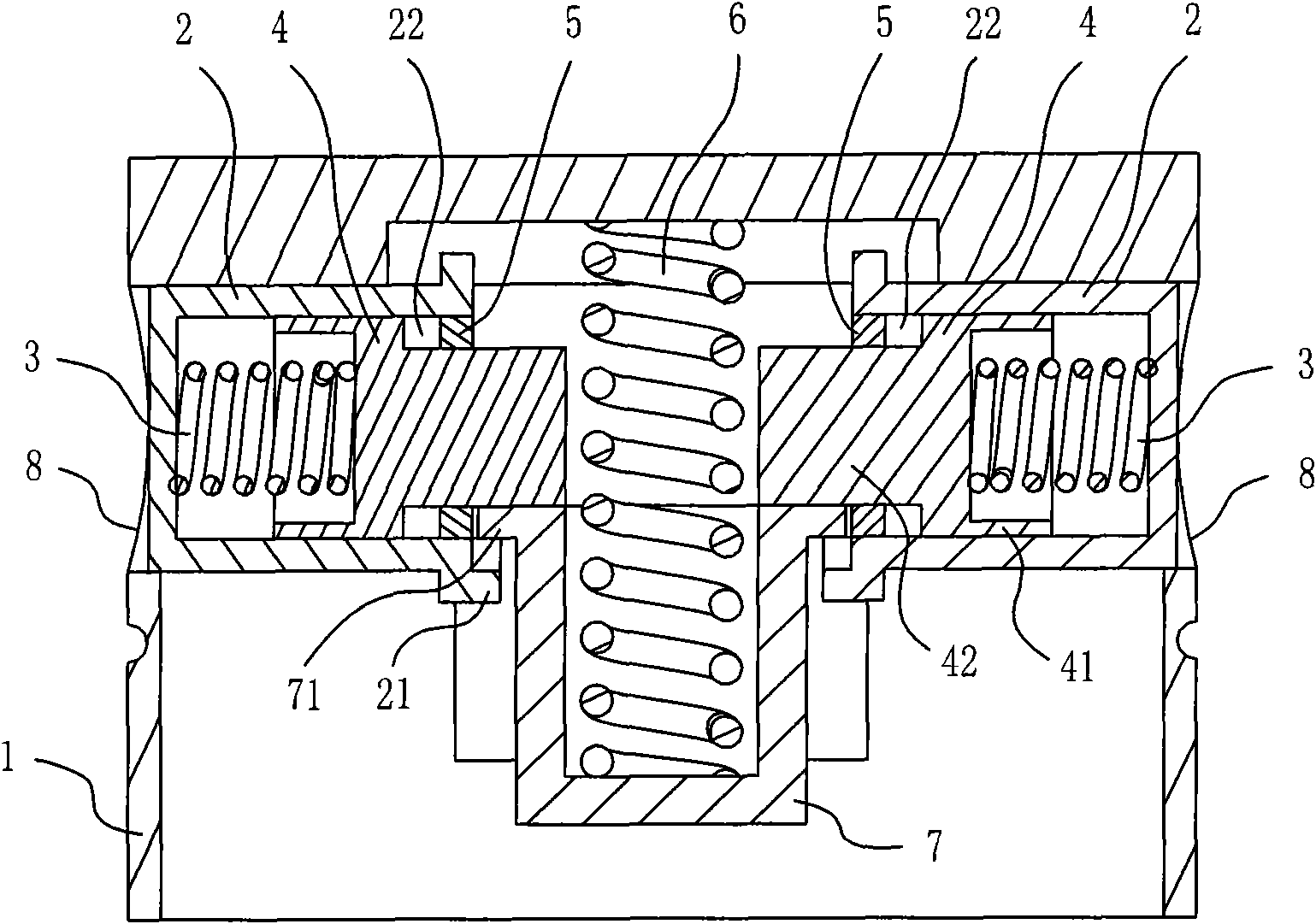

Cylinder-deactivation tappet device of engine

InactiveCN102400731AUnique design structureEmission reductionValve arrangementsOutput powerEngineeringCam

The invention relates to a cylinder-deactivation tappet device of an engine. The cylinder-deactivation tappet device comprises a shell, a bracket and lock pin components, wherein the shell covers a valve mechanism, the upper end of the shell is closed, and the shell is contacted with a cam; at least two openings are arranged on the side wall of the shell; the bracket is arranged inside the shell, and one end of the bracket is pressed against a valve rod of the valve mechanism by using a first elastic part which is clamped between the bracket and the shell; and the lock pin components are arranged in each opening and constructed to be in contact fit with the bracket during normal operation of the engine to keep the shell and the bracket from relatively moving, and during cylinder deactivation of the engine, the lock pin components are separated from the bracket to make the shell capable of moving relative to the bracket under the action of the cam. By adoption of the cylinder-deactivation tappet device of the engine, long-lift and zero-lift two-stage adjustment of valve lift can be realized, so that valve movement can be stopped when necessary so as to cause cylinder deactivation of the engine to reduce oil consumption and discharge of harmful gas; and an original tappet can be directly replaced with the cylinder-deactivation tappet device without replacement of a cylinder cover of the engine. Therefore, the cylinder-deactivation tappet device is good in technical expansibility and high in practical value.

Owner:SAIC MOTOR

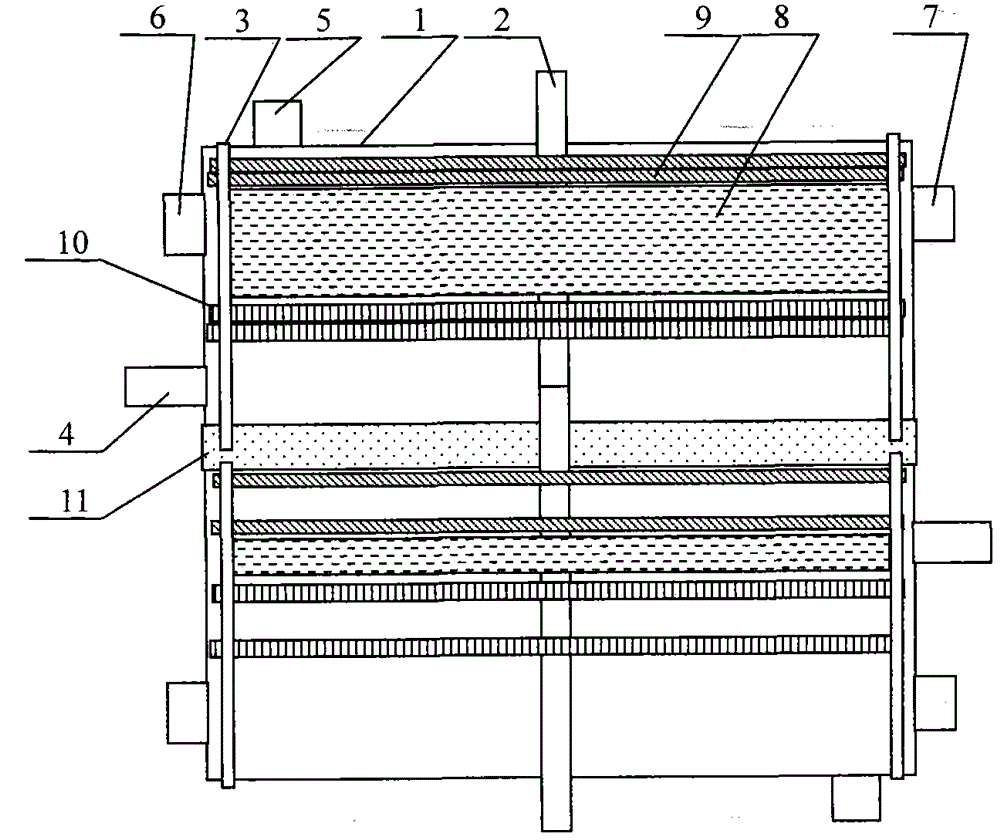

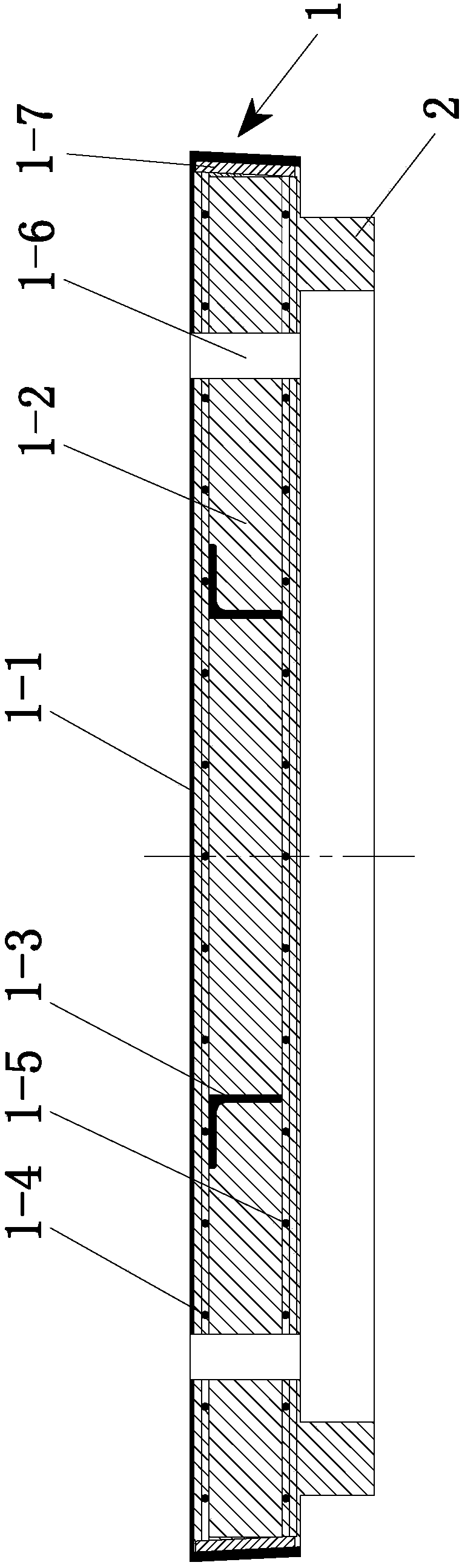

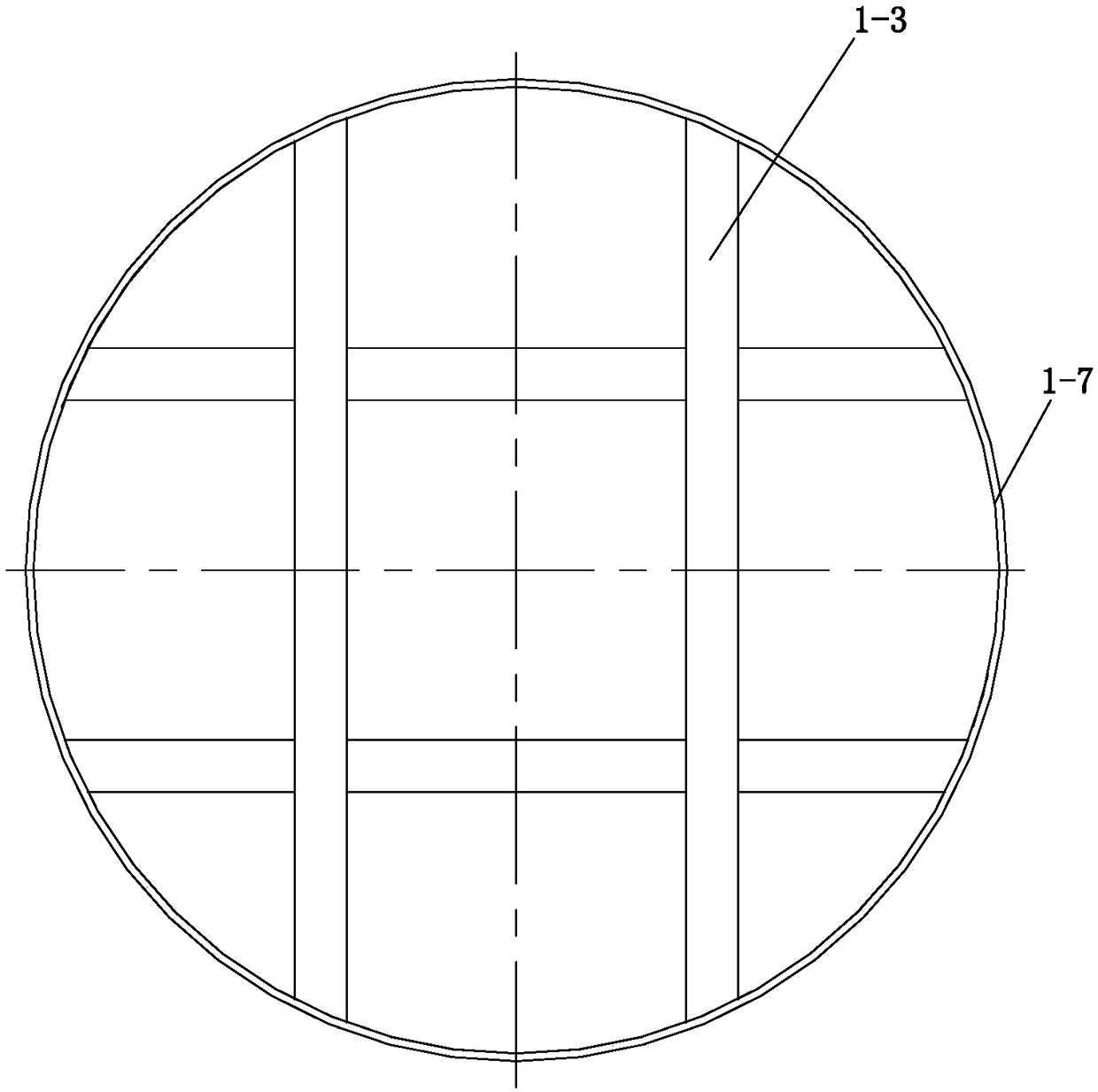

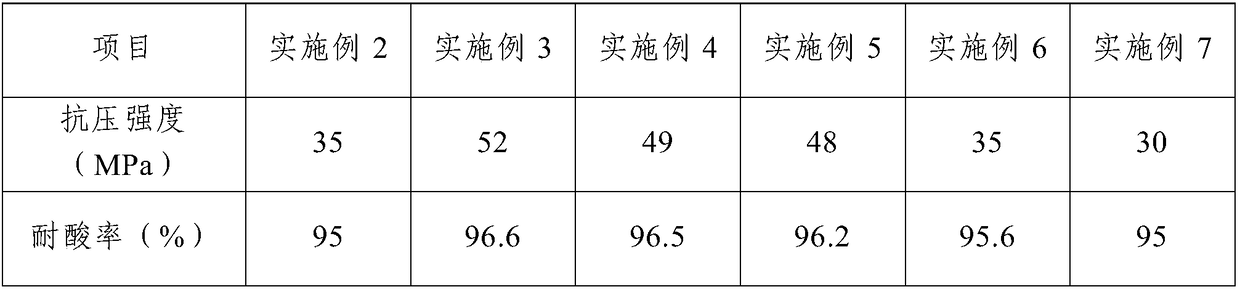

Seal type plate filter with cleanable filter core cross section

ActiveCN104587721AUnique design structureSimple structureStationary filtering element filtersClutchFineness

The invention discloses a seal type plate filter with a cleanable filter core cross section. A guide column (3) and a clutch rod (2) are longitudinally arranged in a box body (1), an outer closed pore plate pair (9), a filter core (8) and an inner closed pore plate pair (10) are sequentially and longitudinally arranged in the box body (1) in parallel from outside to inside along the guide column (3) and the clutch rod (2), the outer closed pore plate pair (9) and the inner closed pore plate pair (10) are respectively provided with at least two layers of parallel pore plates, longitudinal through holes are uniformly formed in each layer of pore plate, orthographic projections of holes in two adjacent layers of pore plates in a longitudinal direction are not mutually overlapped, the filter core is longitudinally compressed to be filtered when the pore plates are opened, and the filter is released for being transversely cleaned when fitted and closed, so that the long-term continuous and stable effect work of the whole plate filter is ensured, and equipment sealing and self-cleaning interaction works can be realized; meanwhile, the plate filter is special in design structure, simple and convenient to structure, convenient to operate, maintain and clean, economic and practical, small in volume, high in filtering efficiency, and excellent filtrate transparency and fineness.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

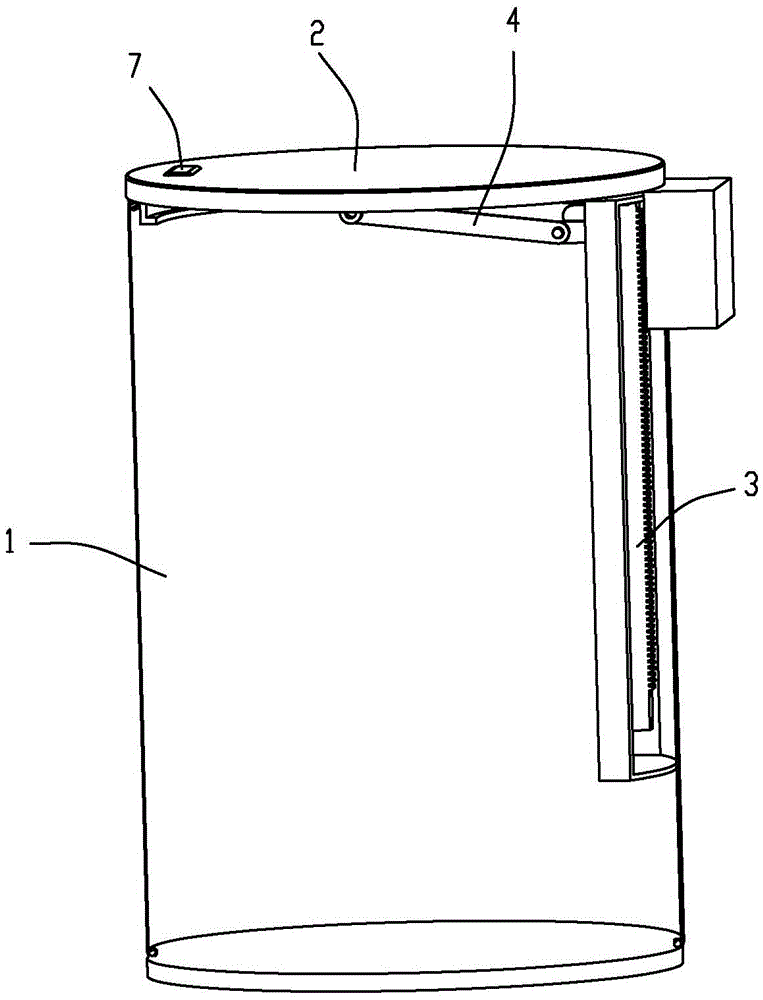

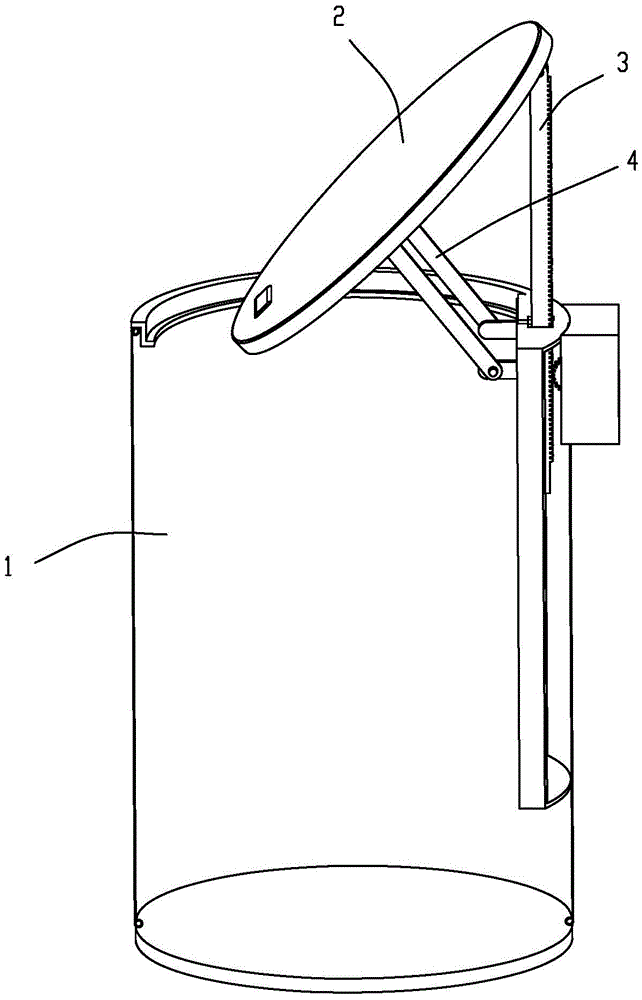

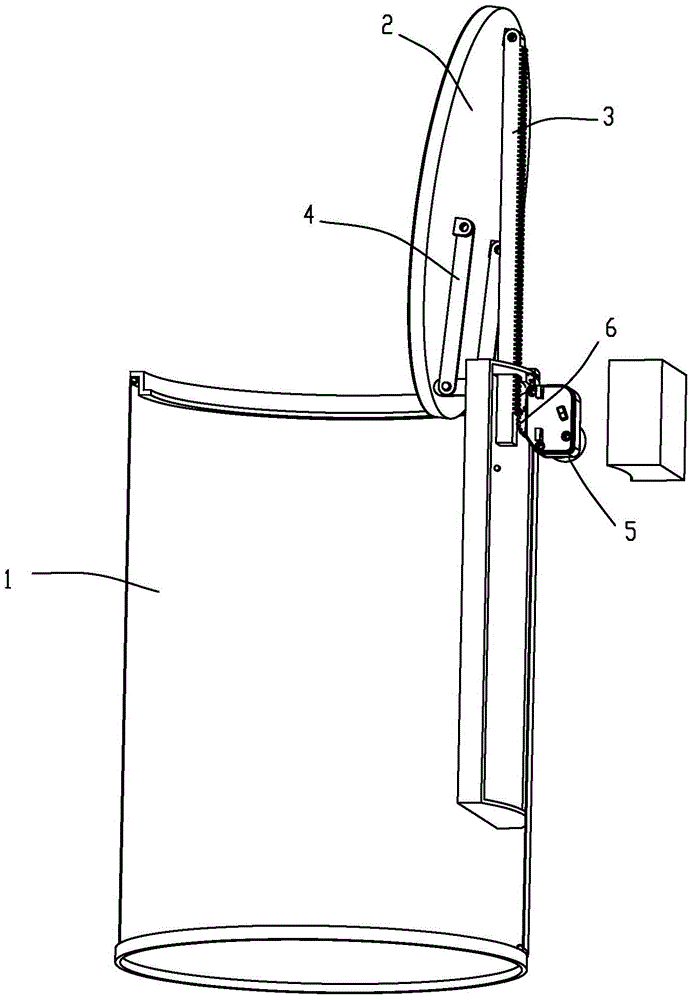

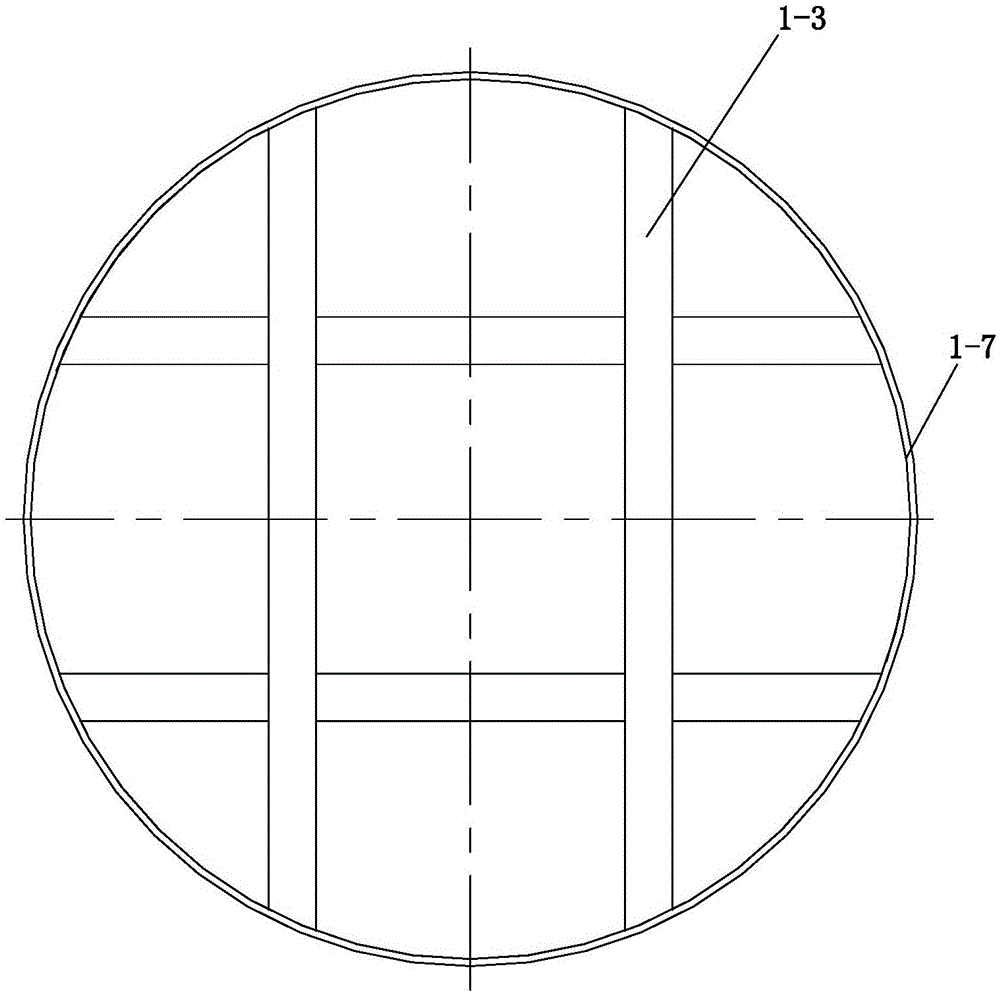

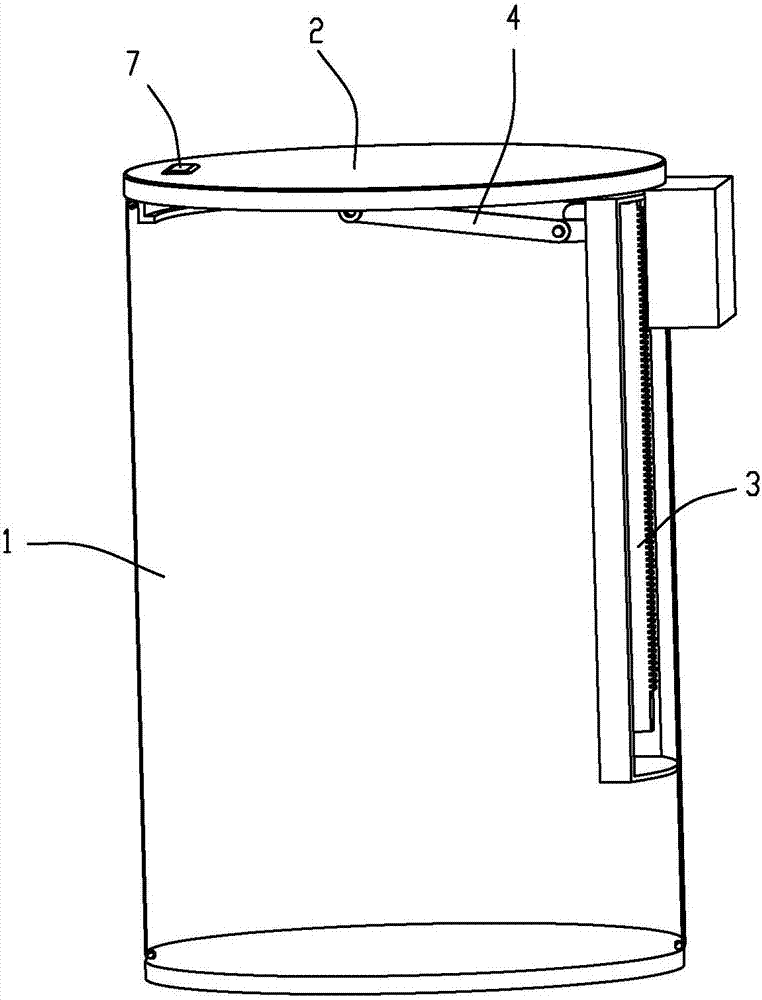

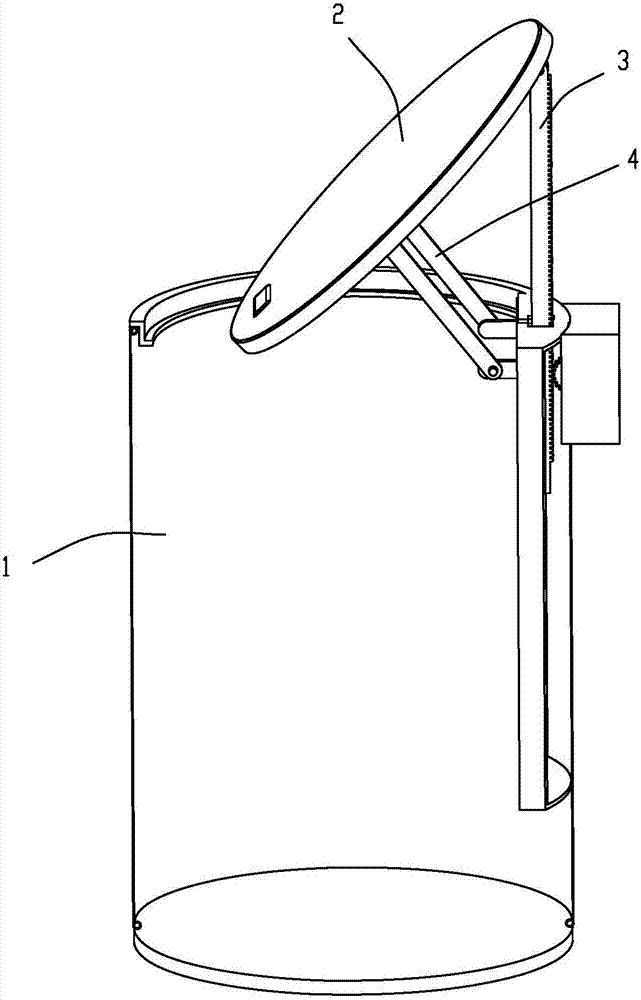

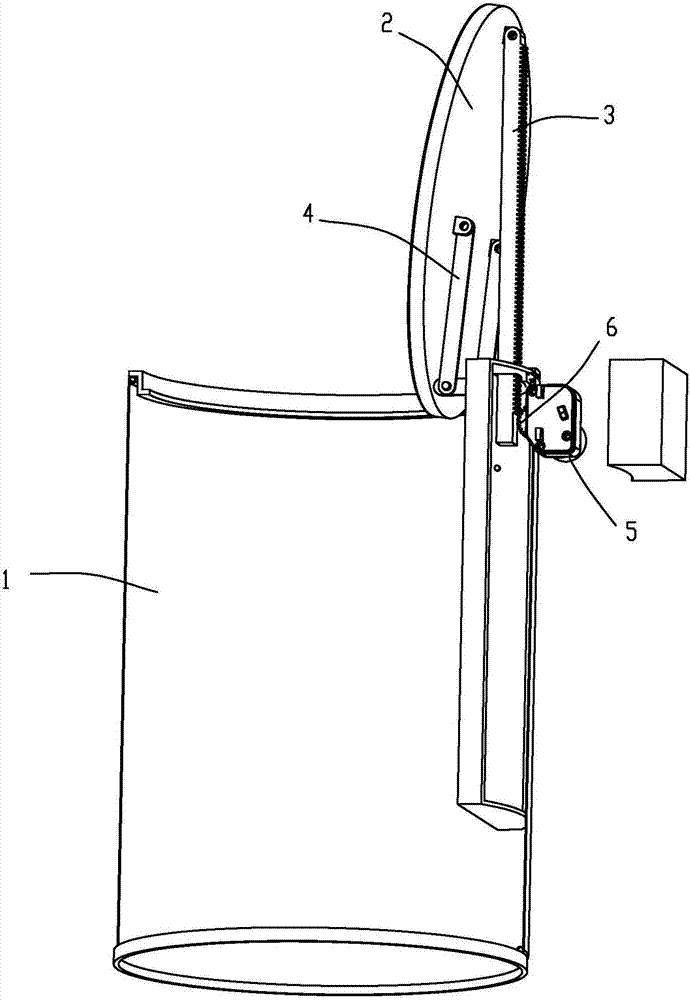

Novel garbage can cover opening structure

ActiveCN105600240AAvoid easily conflicting with the process of people throwing garbageUnique design structureRefuse receptaclesControl theoryMechanical engineering

The invention discloses a novel garbage can cover opening structure which comprises a can body and a can cover, the rear side of the can body is provided with a push rod which is driven by a drive device and can move up and down in the vertical direction, and the upper end of the push rod is in pin joint with the rear edge of the can cover; the bottom of the can cover is in pin joint with one or more swing arms, and the lower ends of the swing arms are in pin joint with the interior of the can body or a middleware in the can body; the push rod, the swing arms and the can cover move according to the following relation that when the push rod jacks upwards, the push rod pushes the rear edge of the can cover upward, meanwhile under the constraint of the swing arms, the front end of the can cover moves backwards simultaneously, and a backward cover opening process of the can cover is formed; when the push rod moves downwards, the push rod pulls the rear edge of the can cover downward, meanwhile under the constraint of the swing arms, the front end of the can cover moves forward simultaneously, and finally the cover closing state is formed. The novel garbage can cover opening structure is unique in design structure, the situation that directly upward cover opening of the garbage can is prone to collision with the process of throwing garbage of people is avoided, and the design structure is unique and more humanized.

Owner:江门市创和进出口有限公司

Multifunctional self-service car washer and billing method thereof

InactiveCN104108378AEasy to cleanConserve waterCleaning apparatus for vehicle exteriorsApparatus for hiring articlesComputer moduleSelf-service

The invention discloses a multifunctional self-service car washer and a billing method. The car washer comprises a control module, a water supplying module, a cleaning mixed liquid supplying module, a charging module, a billing module and a cleaning tool, wherein the cleaning tool comprises a water gun and a brush; the water gun and the brush are connected with the water supplying module and the cleaning mixed liquid supplying module through pipes; each of the water gun and the brush is provided with a selecting switch for selecting water or cleaning mixed liquid; the billing module comprises a water metering unit and a cleaning mixed liquid metering unit; and the water metering unit and the cleaning mixed liquid metering unit respectively meter the using amount of water and the using amount of cleaning mixed liquid independently. According to the scheme, the multifunctional self-service car washer is provided with the brush, a user can easily clean a car body, a cleaning effect of the multifunctional self-service car washer is far higher than a cleaning effect of a self-service car washer with a single water gun, and the washed car body is clean and does not have spots or marks; metering and billing on the water are separated from metering and billing on the cleaning mixed liquid, the water and the cleaning mixed liquid are billed respectively, waste is avoided, and environmental protection is facilitated; and the designed structure of the brush is unique, the brush is easy to use and can be used for cleaning the car body thoroughly, particularly, water and energy can be saved, the market prospect is wide, and the environmental protection significance is far-reaching.

Owner:朱国治

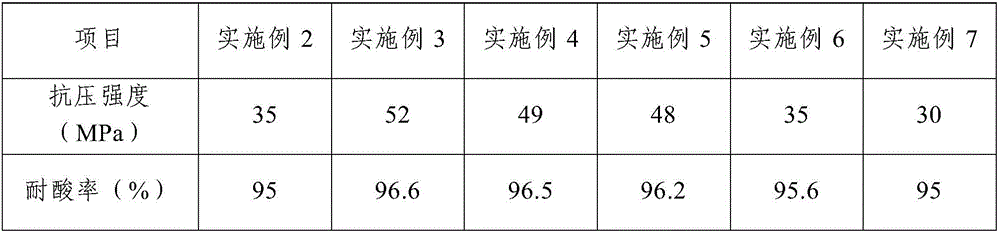

Anticorrosion recoverable well lid

ActiveCN106638698ASimple structureNovel and reasonable designArtificial islandsUnderwater structuresSulfurEngineering

The invention provides an anticorrosion recoverable well lid. The anticorrosion recoverable well lid comprises a lid body and a center band, wherein the lid body is shaped like a cake, the center band is located at the bottom of the lid body and is cylindrical, and the central axis of the lid body coincide with that of the center band; the lid body comprises a face layer and a lining layer, and a steel skeleton is arranged in the lining layer and comprises groined structural steel, an upper steel wire mesh arranged on the upper portion of the structural steel, a lower steel wire mesh arranged on the lower portion of the structural steel and a steel hoop arranged on the periphery of the structural steel; the face layer is arranged on the upper surface of the lining layer and the outer surface of the steel hoop and is made of fine mortar where modified sulfur is added, and the lining layer and the center band are made of thermoplastic concrete where modified sulfur is added. The anticorrosion recoverable well lid is novel and reasonable in structural design, simple in manufacturing process, excellent in corrosion resistance, compressive strength, extension strength and antifatigue life, wide in application range, high in practicability, good in use effect and convenient to popularize.

Owner:西安国蓝环保科技有限公司

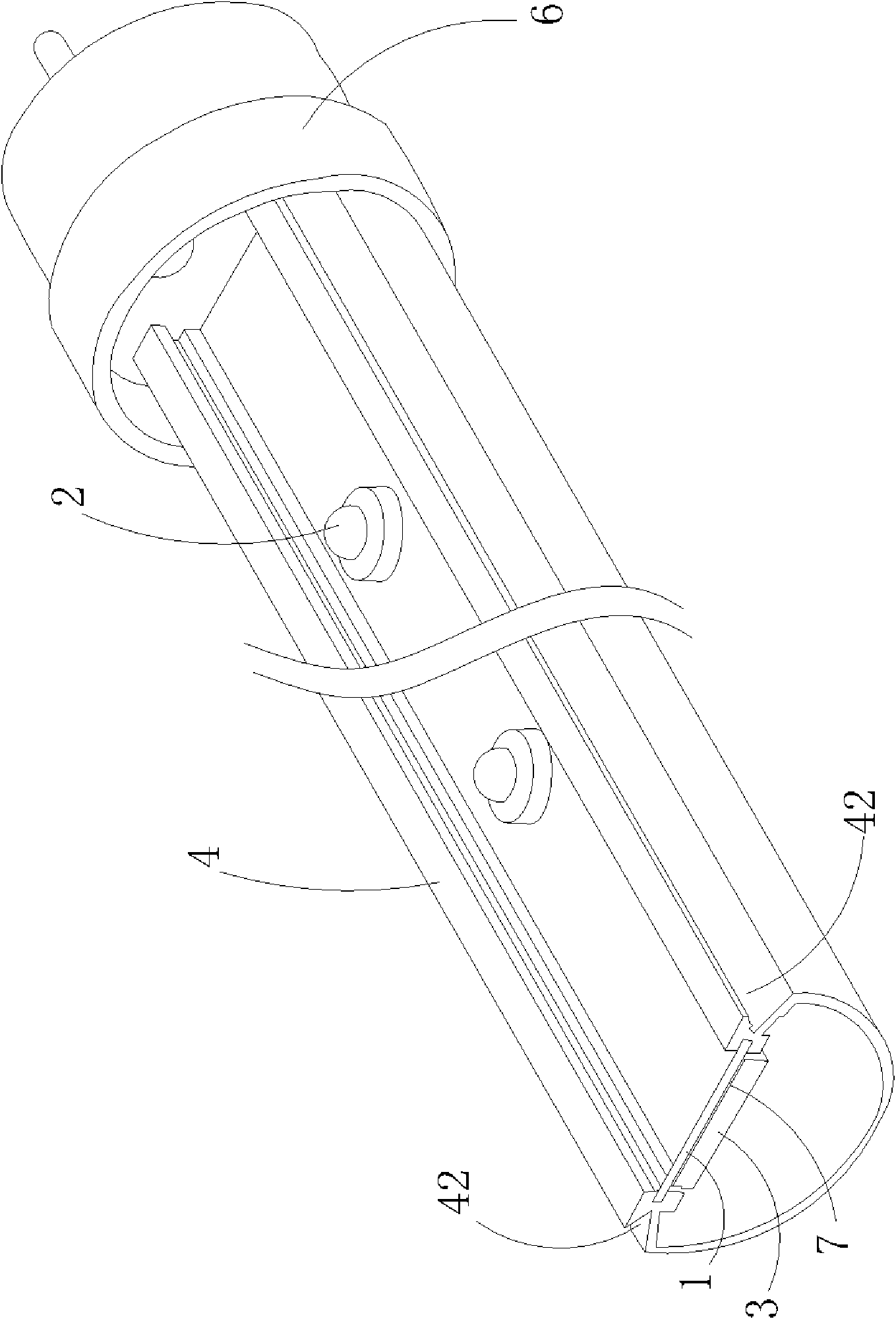

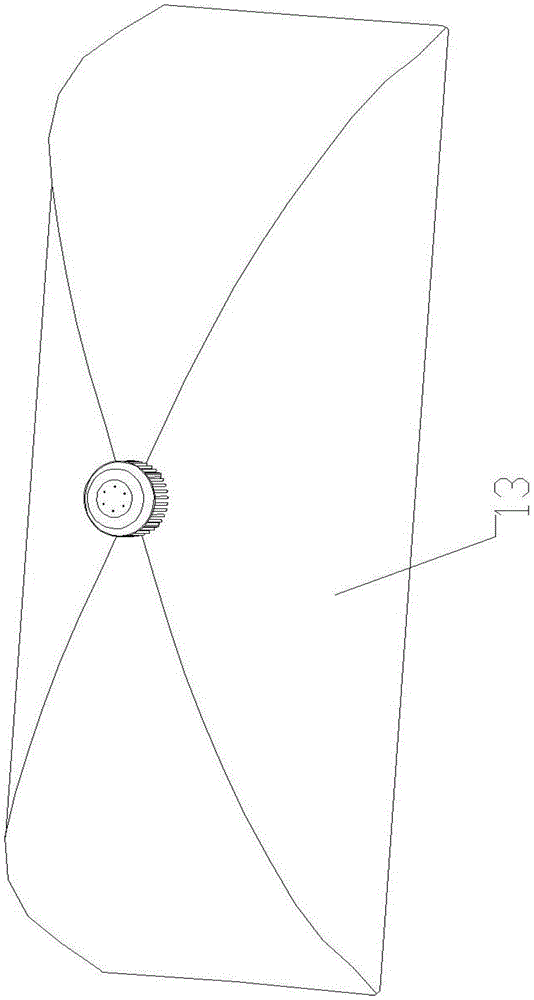

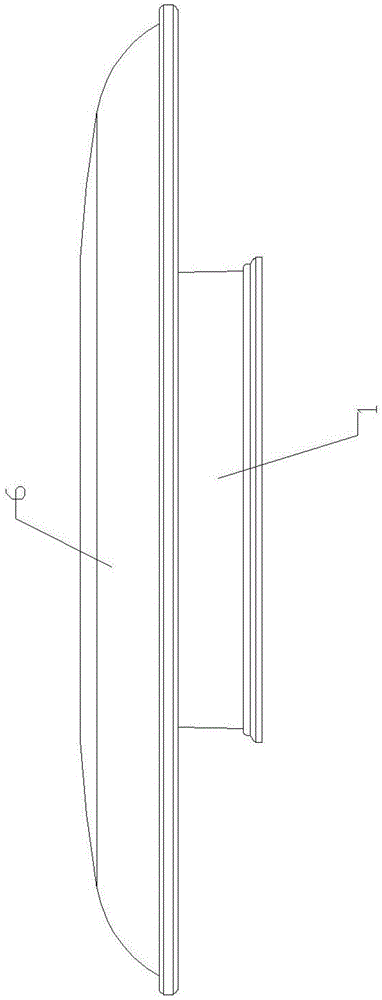

Fabric shade unfolding assisting mechanism for full-automatic automobile shade

ActiveCN104149588AAvoid residueAvoid accumulationRemovable external protective coveringsEngineeringPinion

The invention discloses a fabric shade unfolding assisting mechanism of a full-automatic automobile shade. The fabric shade unfolding assisting mechanism of the full-automatic automobile shade comprises an inner gear ring (2), multiple pinions (4) meshed with the inner gear ring (2), an outer gear ring (5) meshed with all the pinions (4), a top cover (6) movably combined with the outer gear ring (5) in a sleeved mode, and a plurality of brush strips (7) which are arranged on the edge of the top cover (6) in the circumferential direction and are used for smoothening the fabric shade so as to enable the fabric shade to be unfolded or folded smoothly, wherein a first one-way rotating structure is arranged on the outer gear ring (5) and the top cover (6), the outer gear ring (5) drives the top cover (6) to rotate in one direction through the one-way rotating structure when the fabric shade is unfolded, a second one-way rotating structure is arranged on the inner gear ring (2) and the top cover (6), the inner gear ring (2) drives the top cover (6) to rotate in one direction through the second one-way rotating structure when the fabric shade is folded, and the outer gear ring (5) and the inner gear ring (2) drive the top cover (6) to rotate in the same direction. The fabric shade unfolding assisting mechanism of the full-automatic automobile shade can assist in smooth unfolding and folding of the fabric shade, and impurities on the fabric shade can be removed when the fabric shade is folded.

Owner:胡建明

Novel liquid crystal display device capable of displaying timing clock and used for smoke exhaust ventilator

InactiveCN104575318AUnique display designUnique design structureDomestic stoves or rangesLighting and heating apparatusTectorial membraneCLOCK

The invention discloses a novel liquid crystal display device capable of displaying a timing clock and used for a smoke exhaust ventilator. The novel liquid crystal display device comprises a rectangular aluminum alloy panel and an aluminum alloy outer shell which are in buckle connection with each other, wherein protecting films are coated on the outer surfaces of the aluminum alloy panel and the aluminum alloy outer shell, and the protecting films comprise the following components by weight part: 0.6 parts of propylene glycol, 1-2 parts of barium soap of petrolatum oxide, 6-7 parts of nanometer silicon resins, 1-2 parts of sodium chloride, 2-3 parts of polycarboxylic sodium, 1-2 parts of alginic propylene glycol ester, 0.9 parts of dodecyltrimethylammonium and 1.1 parts of titanate. The novel liquid crystal display device provided by the invention has unique display design, structure design and protecting design; the protecting films are coated on the outer surfaces of the panel and the outer shell, so that the aluminum alloy panel and the aluminum alloy outer shell are prevented from being corroded, and a liquid crystal display control circuit board is prevented from being damped and corroded for a long term.

Owner:SUZHOU XINHANG MICROELECTRONICS

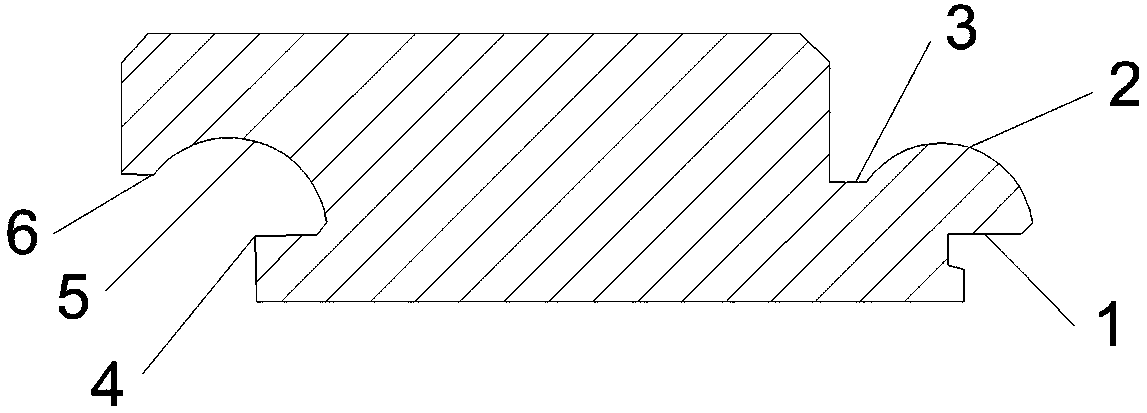

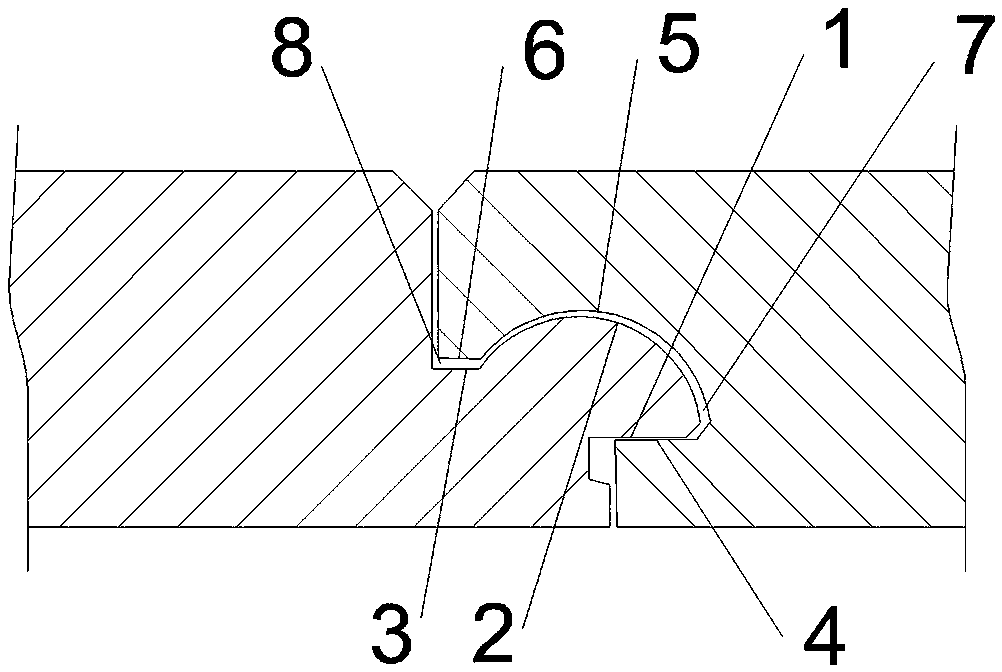

Floor and wallboard damp-proof arc lock catch structure

PendingCN111561125AStable structureUnique structureCovering/liningsFlooringRadial planeTongue and groove

The invention belongs to the technical field of building decoration materials, and relates to a floor and wallboard damp-proof arc lock catch structure. A special-shaped tenon structure and a special-shaped mortise structure which are matched with each other are arranged on the edges of the two opposite sides of a floor, the special-shaped tenon structure is a right semi-arc tenon and comprises atenon axial contact surface, a tenon positive semi-circular arc surface and a tenon radial contact surface from bottom to top; the special-shaped mortise structure matched with the special-shaped tenon structure is a mortise with a regular semicircle, and comprises a mortise axial contact surface, a mortise regular semicircle surface and a mortise radial contact surface from bottom to top, the left side between the special-shaped tenon structure and the special-shaped mortise structure is in radial plane contact; and the lower sides of the special-shaped tenon structure and the special-shapedmortise structure are in axial plane contact. According to the floor and wallboard damp-proof arc lock catch structure, the floor and the wallboard are unique in design structure, high in paving adaptability, capable of meeting paving of the ground with large height difference, resistant to damp, high in mounting firmness and large in tension.

Owner:DARE WOOD BASED PANEL GRP

Liquid crystal display device dedicated for extractor hood

InactiveCN104575319AUnique display designUnique design structureDomestic stoves or rangesLighting and heating apparatusPolyethylene oxideDivinylbenzene

The invention discloses a liquid crystal display device dedicated for an extractor hood. The liquid crystal display device dedicated for the extractor hood comprises a rectangular aluminium alloy panel and an aluminium alloy shell, wherein the rectangular aluminium alloy panel and the aluminium alloy shell are in buckled connection; the outer surfaces of the aluminium alloy panel and the aluminium alloy shell are coated with a protective film, wherein the protective film comprises the following components in parts by weight: 0.9 part of ethylene glycol, 0.4 part of heptadecenyl imidazoline alkenyl succinate, 8-9 parts of nanometer silicon resin, 1-2 parts of catechol, 2-3 parts of sodium dodecyl benzene sulfonate emulsion, 1-2 parts of divinylbenzene, 1.3 parts of alkylolamides polyethylene oxide epoxyethane ether and 0.8 part of calcium stearate. The liquid crystal display device has peculiar display design, structure design and protection design; the outer surfaces of the panel and the shell are coated with the protective film to prevent the aluminium alloy panel and the aluminium alloy shell from being corroded, and a liquid crystal display control circuit board is prevented from being damped or corroded for a long time.

Owner:SUZHOU XINHANG MICROELECTRONICS

Four-split high-voltage transmission line deicing robot

The invention provides a deicing robot for a four-cracking high-voltage power transmission line. The deicing robot comprises a robot support platform, two six-degree of freedom arms, deicing devices and an intermediate support arm, wherein the two six-degree of freedom arms are arranged at two ends of the robot support platform. By employing the two six-degree of freedom arms and mutual matching of the two deicing devices and the intermediate support arm, the deicing task of a single-phase four-cracking high-voltage power transmission line can be achieved, and the deicing robot is generally applied to a power transmission line of 500Kv; the robot can clear the single-phase four-cracking power transmission line in one time, the deicing robot can cross a four-cracking impedance isolation rod and also can cross a pole tower, and three pole towers which are continuously crossed can be arranged in a straight line and also can be arranged in a broken line; the deicing robot can directly cross the pole tower and is unnecessary to interrupt deicing operation; and the deicing robot is light in weight and relatively small in volume.

Owner:HARBIN ENG UNIV

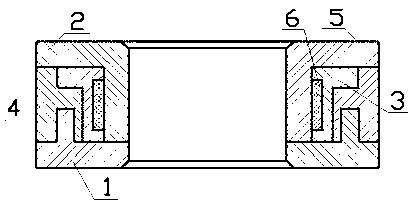

Submersible pump bearing

InactiveCN102996632AStable jobExtended service lifeRolling contact bearingsBearing unit rigid supportAgricultural engineeringRust

The invention discloses a submersible pump bearing comprising a bearing body arranged on a shaft, and a bearing cover, wherein the bearing body comprises an inner shaft sleeve, a middle layer and an outer shaft sleeve; one end of the inner shaft sleeve is contacted with the shaft; the other end of the inner shaft sleeve is vertical to the axis of the shaft; an annular baffle ring is arranged at the other end of the inner shaft sleeve; the middle layer is sleeved on the inner shaft sleeve; and a rolling body is arranged at the contact surface of the middle layer and the inner bearing, and the outer shaft sleeve is sleeved on the middle layer. The submersible pump bearing disclosed by the invention is an improvement mainly aiming at the problem that the bearing is oxidized and rusts because of working in water for a long period of time; and the bearing is relatively stable in the working process by the unique structure design and installation and the hermetic arrangement of a rotating part of the bearing. Therefore, the service life of the bearing is greatly improved.

Owner:张玮

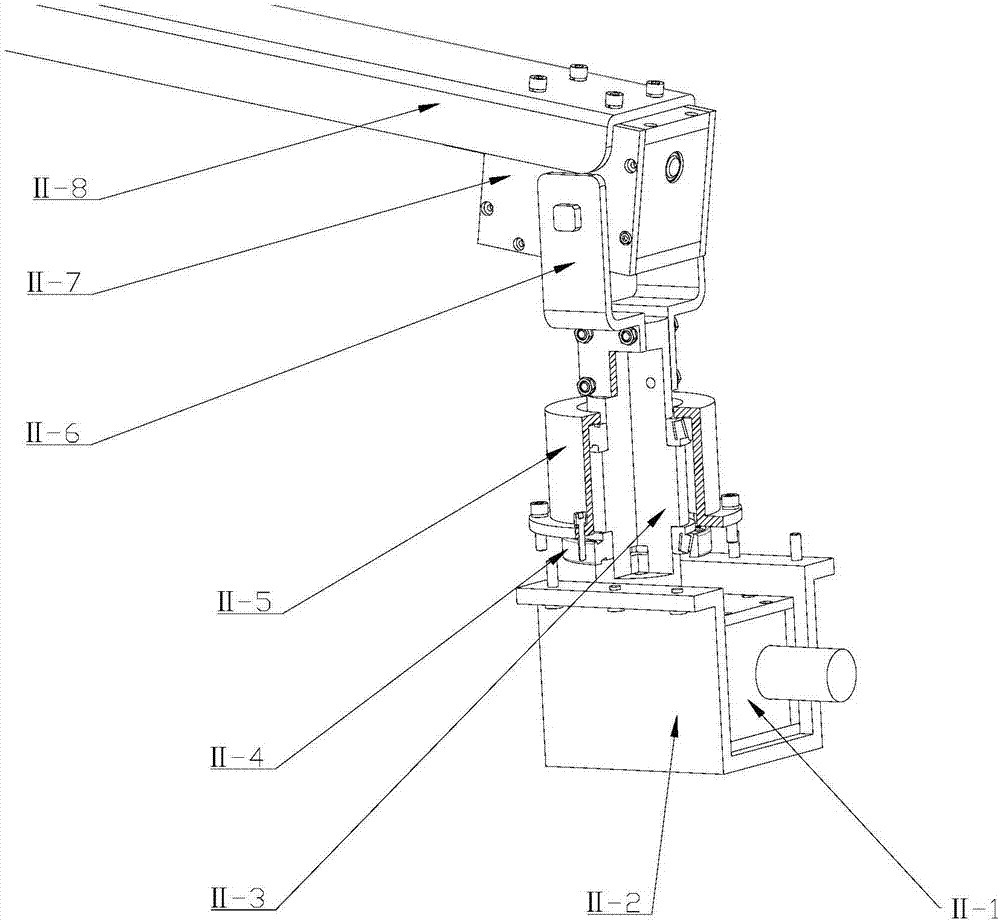

Air Nail Pressing Machine

ActiveCN104139432BPrevent rolloverUnique design structureStapling toolsNailing toolsEngineeringShort nail

The invention relates to a pneumatic conveying nail pressing machine. The pneumatic conveying nail pressing machine comprises a body, a feeding mechanism, a positioning mechanism, a nail pressing part and a pneumatic device, wherein the feeding mechanism, the positioning mechanism, the nail pressing part, the pneumatic device and the body are installed together. A feeding pipe in the feeding mechanism is internally of a T-shaped hollow passageway structure. The positioning mechanism comprises a base, a pressing ring and a cover body, wherein the pressing ring and the cover body are sequentially arranged on the base. The interior of the positioning mechanism is a profiling cavity after the base and the pressing ring are combined, and the cavity is communicated with the T-shaped passageway of the feeding pipe. At least three grooves are evenly distributed in the base in the radial direction of a round hole, and each groove is provided with a spring and a sliding jaw, wherein the spring and the sliding jaw are connected; the head of each sliding jaw is designed into a slope. Nails are conveyed in a pneumatic mode, the positioning mechanism with the special structure is designed, the pneumatic conveying nail pressing machine is especially suitable for nails with large-diameter nail heads and short nail points, the large-diameter nail heads are extruded downwards in the nail pressing process, and the nails are fixed through the design of the sliding jaws, so that the nails are well prevented from being laterally turned over, the work efficiency is improved, and the automation degree and the percent of pass of finished products are increased.

Owner:SHENZHEN HANJIANG AUTOMATION SCI & TECH CO LTD

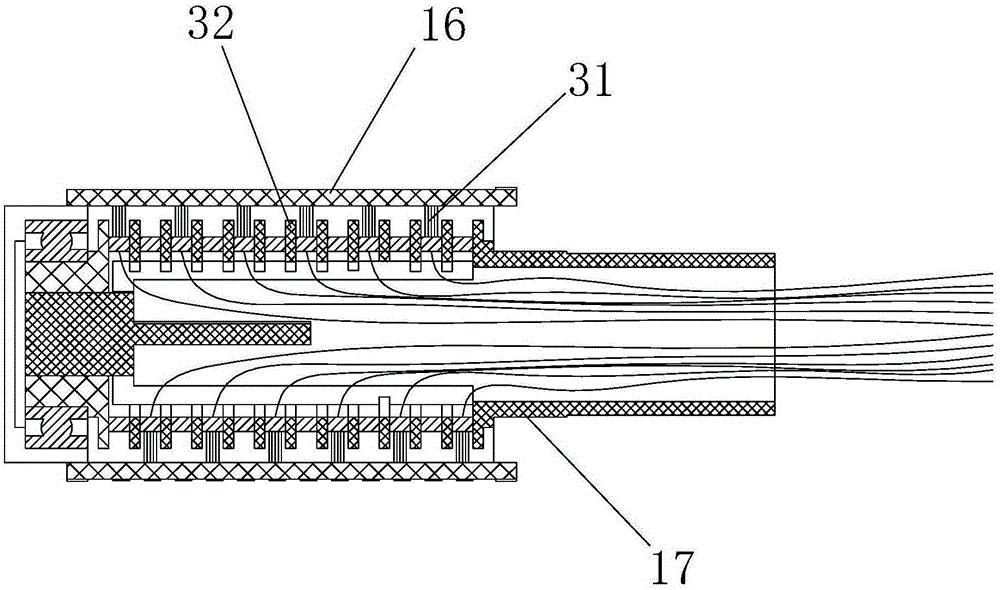

Motor provided with electric brushes

InactiveCN105262306AEasy to fixNot easy to looseRotary current collectorDC commutatorStatorEngineering

The present invention puts forward a motor provided with electric brushes, and solves the problem that an electric brush box in the prior art is not easy to replace, so that a motor is complicated in installation and troublesome in maintenance. The motor comprises a casing, a stator, a rotor and a commutator, wherein the casing consists of a shell, a front end cover and a rear end cover, each electric brush box is horizontally provided with a containing cavity therein, an electric brush assembly is detachably arranged in each containing cavity, each electric brush assembly comprises a brush carrier provided with a through hole and an electric brush arranged in the through hole, a plurality of conducting rings are uniformly distributed on the sidewall of the electric brush, a brush bristle hole is arranged between every two adjacent conducting rings, brush bristles are welded in the brush bristle hole, the brush bristles are formed by combination of a plurality of metal wires, one end of the brush bristle is contacted with the brush carrier, the other end of the brush bristle is fixedly connected with a wire, a tail end of the wire is connected with a limiting piece, the electric brush box penetrates the rear end cover of the motor, and a brush cover is rotatably fastened to the external part of the electric brush box. Through adoption of the motor of the present invention, the electric brush assembly can be conveniently disassembled at any time, thereby greatly simplifying maintenance work.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

A new type of trash can lid opening structure

ActiveCN105600240BAvoid easily conflicting with the process of people throwing garbageUnique design structureRefuse receptaclesEngineeringOpen structure

The invention discloses a novel garbage can cover opening structure which comprises a can body and a can cover, the rear side of the can body is provided with a push rod which is driven by a drive device and can move up and down in the vertical direction, and the upper end of the push rod is in pin joint with the rear edge of the can cover; the bottom of the can cover is in pin joint with one or more swing arms, and the lower ends of the swing arms are in pin joint with the interior of the can body or a middleware in the can body; the push rod, the swing arms and the can cover move according to the following relation that when the push rod jacks upwards, the push rod pushes the rear edge of the can cover upward, meanwhile under the constraint of the swing arms, the front end of the can cover moves backwards simultaneously, and a backward cover opening process of the can cover is formed; when the push rod moves downwards, the push rod pulls the rear edge of the can cover downward, meanwhile under the constraint of the swing arms, the front end of the can cover moves forward simultaneously, and finally the cover closing state is formed. The novel garbage can cover opening structure is unique in design structure, the situation that directly upward cover opening of the garbage can is prone to collision with the process of throwing garbage of people is avoided, and the design structure is unique and more humanized.

Owner:江门市创和进出口有限公司

Freezer

ActiveCN109737665BGuaranteed meat colorReduce the intensity of aerobic respirationLighting and heating apparatusDomestic refrigeratorsNutritionEngineering

Owner:HAIER SMART HOME CO LTD

Dedusting system special for scrap steel crushing

PendingCN114191923AGuaranteed tightnessGuaranteed to workHuman health protectionCombination devicesEnvironmental engineeringDust abatement

The special dust removal system comprises a dust removal cabin and a separation cabin, a separation wall is arranged between the dust removal cabin and the separation cabin, one side of the dust removal cabin is connected with a dust removal fan, dust raising filter cloth is arranged in the dust removal cabin and arranged at equal intervals, and a corridor is arranged at the interval of the dust raising filter cloth; the dust removal cabin is connected with the separation cabin through a pipeline, an air inlet is formed in one side of the separation cabin, and dust shoveling gates are arranged at the bottoms of the dust removal cabin and the separation cabin. Compared with the prior art, the dust removal system has the advantages that the problems of explosion, fire catching, heavy raised dust, pipeline blockage, dust discharging blockage, dirty finished products and the like of the dust removal system are solved.

Owner:唐山惠玛自动化工程技术有限公司

Method and device for treating volatile organic waste gas

InactiveCN101791512BReasonable designCompact structureDispersed particle separationUltravioletExhaust fumes

The invention discloses a method and device for treating volatile organic waste gas. In the method, the volatile organic waste gas firstly enters into a flow rotating and gas distributing system containing a rotating flow tray which is provided with a plurality of cyclone vanes, then the gas which is subdivided by the flow rotating and gas distributing system subsequently enters into a light activation and oxidation system to be irradiated by high power ultraviolet lamps, while radiation-induced decomposition is carried out on part of the waste gas, reactive oxygen is generated to oxidize the organics in the waste gas, after that, the waste gas uniformly passes through a composite material adsorption system to be adsorbed by the high efficiency composite materials, and finally the waste gas is discharged from the waste gas outlet via an explosion-proof fan system. By the method, the efficiency and the rate of treating the volatile organic waste gas are improved, the harm of the waste gas to human health and the environment is weakened, the health of the experimental personnel is further protected and the working environment is improved.

Owner:中洁环淼(江苏)环境科技有限公司

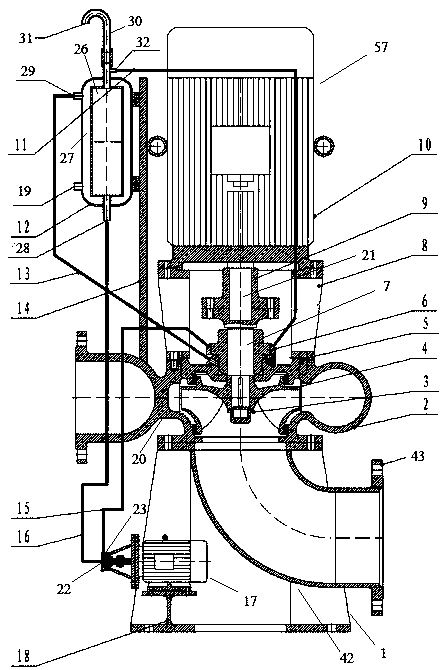

A non-leakage and anti-clogging oil-cooled circulating high-efficiency synchronous intelligent self-priming pump

ActiveCN108869315BUnique design structureHigh maintenance costPump componentsPriming pumpSlurryEngineering

The invention relates to the field of self-priming pumps, in particular to an oil-cooling circulation type synchronous intelligent self-priming pump with the features of leak-tightness, anti-cloggingperformance and high efficiency. The intelligent self-priming pump comprises a self-priming pump device and a filter device, and the self-priming pump device comprises a base, a pump body and a motor;the filter device comprises a filter vat, a filter screen and a flashboard. The intelligent self-priming pump can give full play to the unique performance advantages in reverse filling, high pressure, slurry and easy-to-wear media, and has the advantages of resistance to temperature, pressure and wear, leak-tightness, anti-clogging performance, high efficiency, long service life, less vulnerableparts, low maintenance cost, energy saving, consumption reduction and the like.

Owner:江苏创进泵阀制造有限公司

Frequency electromagnetic lockset

InactiveCN110580753AAvoid repetitionHigh degree of encryptionIndividual entry/exit registersElectronic accessVoltage converter

The invention discloses a frequency electromagnetic lockset comprising a key contact and a matched encryption lock end. The key contact includes a stepped segment selection crystal array, selected insertion electrodes, a segmented frequency output head, a segment code signal synthesizer and a lap joint contact. The matched encryption lock end includes a segment code signal frequency-to-voltage converter, an electromagnetic driving source selector and an elastic code switch. The selected insertion electrodes are inserted into different position segments of the stepped segment selection crystalarray; the segment frequency output head is connected to the selected insertion electrodes by a segmented joint; and a signal output terminal of the segmented frequency output head is connected to thesegment code signal synthesizer. The key contact is connected to a power output terminal and a signal input terminal of the matched encryption lock end through a lap joint; a signal input terminal isconnected to the segment code signal frequency-to-voltage converter; the segment code signal frequency-to-voltage converter is connected to the electromagnetic driving source selector; the electromagnetic driving source selector is connected to the elastic code switch by an electromagnetic head. The frequency electromagnetic lockset has advantages of high safety and low energy consumption; and repeatability of a mechanical lock and insecurity of the electronic access control lock are overcome.

Owner:HANGZHOU ZHIHUI TECH CO LTD

Liquid crystal display device specially used for induction cookers

InactiveCN104595945AGood corrosion resistanceUnique display designDomestic stoves or rangesLighting and heating apparatusEmulsionSurface plate

The invention discloses a liquid crystal display device specially used for induction cookers. The liquid crystal display device comprises a rectangular aluminium alloy panel and an aluminium alloy outer shell, which are connected by buckles, wherein the outer surfaces of the aluminium alloy panel and the aluminium alloy outer shell are coated with protective films; the protective films comprise the following components in parts by weight: 1.7 parts of propylene glycol, 1-2 parts of barium petroleum sulfonate, 15 parts of high-chlorinated polyethylene resin, 0.8 part of talcum powder, 1-2 parts of n-dodecanol ester, 2-3 parts of styrene-acrylic emulsion, 1-2 parts of ethylene glycol monostearate and 1.1 parts of zinc stearate. The liquid crystal display device has the advantages and beneficial effects that the liquid crystal display device has unique display design, structural design and protective design; the outer surfaces of the panel and the outer shell are coated with the protective films, thus preventing the aluminium alloy panel and the aluminium alloy outer shell from being corroded and ensuring liquid crystal display control circuit boards not to be affected with damp and corroded for a long term.

Owner:SUZHOU XINHANG MICROELECTRONICS

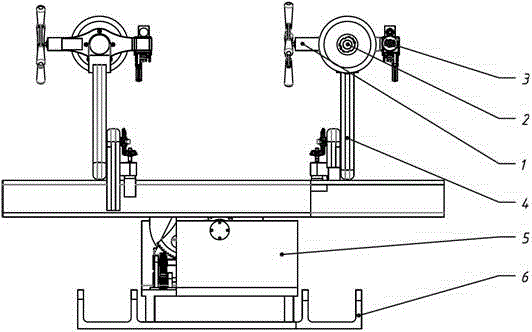

Cable deicing robot for transmission line

InactiveCN102709834BImprove work efficiencyRealize continuous operationCable installation apparatusEngineeringHigh tension line

The invention aims to provide a cable deicing robot for a transmission line, which comprises a main obstacle-crossing device, two deicing cars and two telescopic arms, wherein the two telescopic arms are respectively installed at the two end of the main obstacle-crossing device; and the two deicing cars are respectively installed on the two telescopic arms. The cable deicing robot has the beneficial effects that three cables are simultaneously deiced under the matching of the main obstacle-crossing device, the two telescopic arms and the two deicing cars on the two telescopic arms, the cable deicing robot can be applied to a 35 kV line, a 66 kV line, a 110 kV line and other high-tension lines on which the three cables are horizontally arranged, and the effect that one robot can simultaneously deice the three cables at one time is realized; and not only can obstacles on the cables be crossed, but also poles and towers can be crossed, so that the continuous operation on multiple lines is realized, and the situation that when reaching each pole and each tower, a line worker needs to repeatedly ascend the pole / tower to install and disassemble the robot is avoided.

Owner:HARBIN ENG UNIV

Liquid crystal display device for range hood

InactiveCN104595952AUnique display designUnique design structureDomestic stoves or rangesNon-macromolecular adhesive additivesEpoxyEngineering

The invention discloses a liquid crystal display device for a range hood. According to the liquid crystal display device, a sealant is arranged at multiple positions and consists of the following components in parts by weight: 0.2 part of quartz flour, 3-4 parts of gas phase silicon dioxide, 1-2 parts of tetrahydrofuran, 2-3 parts of diaryl secondary amine, 2-3 parts of gas phase white carbon black, 1-2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline, 22 parts of dimer acid modified epoxy resin, 2-3 parts of glycerol monostearate and 1-2 parts of isopropanolamine. The liquid crystal display device for the range hood, disclosed by the invention, is unique in display design, structural design and protective design; and the sealant is arranged at multiple positions to ensure that a liquid crystal display control circuit board cannot be damped and corroded for a long time, and can work effectively for a long time. The sealant can resist a high temperature of 100 DEG C and a low temperature as low as -24 DEG C.

Owner:SUZHOU XINHANG MICROELECTRONICS

An anti-corrosion recyclable manhole cover

ActiveCN106638698BSimple structureNovel and reasonable designArtificial islandsUnderwater structuresSulfurEngineering

The invention provides an anticorrosion recoverable well lid. The anticorrosion recoverable well lid comprises a lid body and a center band, wherein the lid body is shaped like a cake, the center band is located at the bottom of the lid body and is cylindrical, and the central axis of the lid body coincide with that of the center band; the lid body comprises a face layer and a lining layer, and a steel skeleton is arranged in the lining layer and comprises groined structural steel, an upper steel wire mesh arranged on the upper portion of the structural steel, a lower steel wire mesh arranged on the lower portion of the structural steel and a steel hoop arranged on the periphery of the structural steel; the face layer is arranged on the upper surface of the lining layer and the outer surface of the steel hoop and is made of fine mortar where modified sulfur is added, and the lining layer and the center band are made of thermoplastic concrete where modified sulfur is added. The anticorrosion recoverable well lid is novel and reasonable in structural design, simple in manufacturing process, excellent in corrosion resistance, compressive strength, extension strength and antifatigue life, wide in application range, high in practicability, good in use effect and convenient to popularize.

Owner:西安国蓝环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com