Reciprocating type packaging machine

A reciprocating, packaging machine technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of different tensioning degrees of synchronous toothed belts or chains, unstable operation of cutting and packaging devices, and wear of synchronous mechanisms. To achieve the effect of beautiful product, long pressing time and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

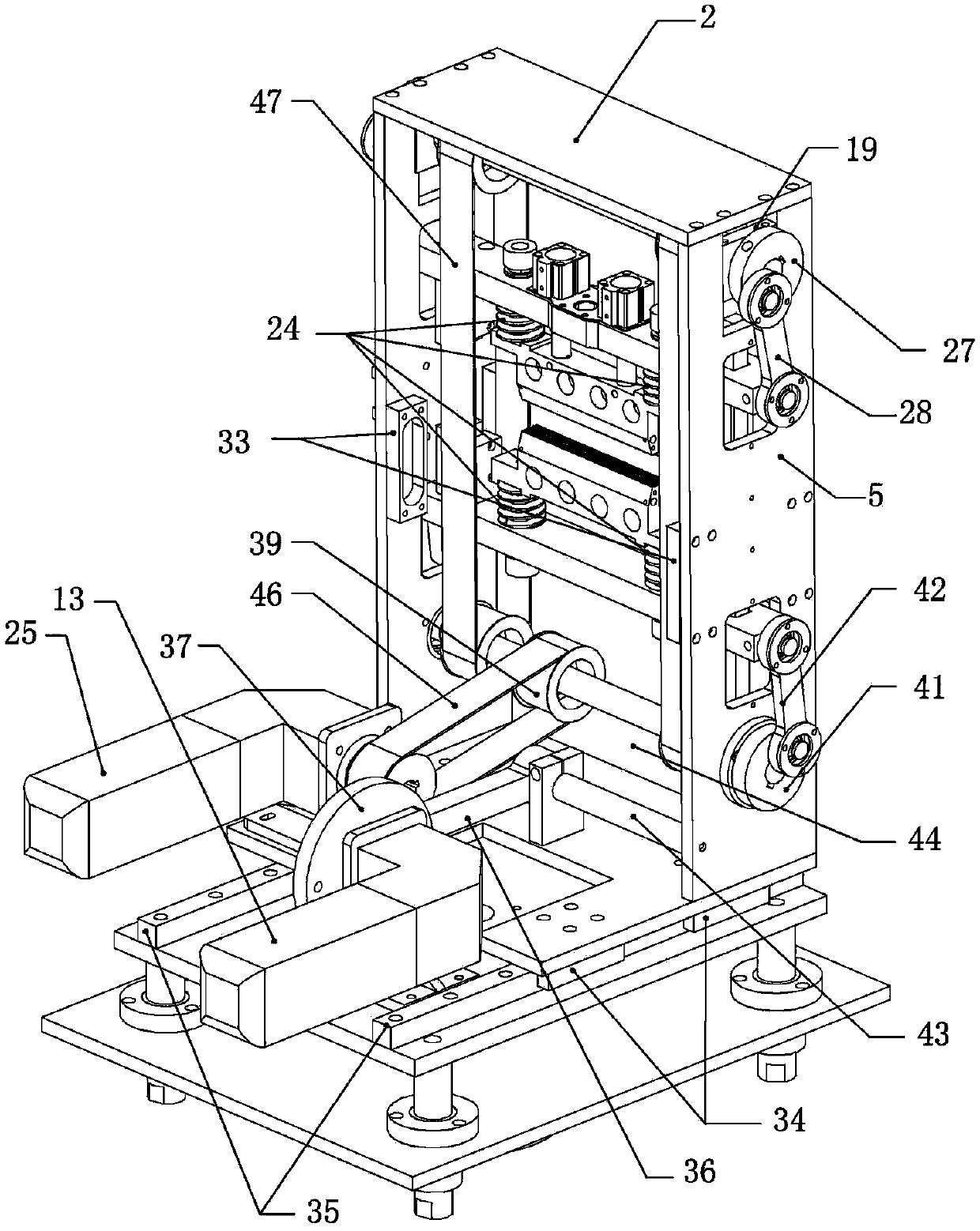

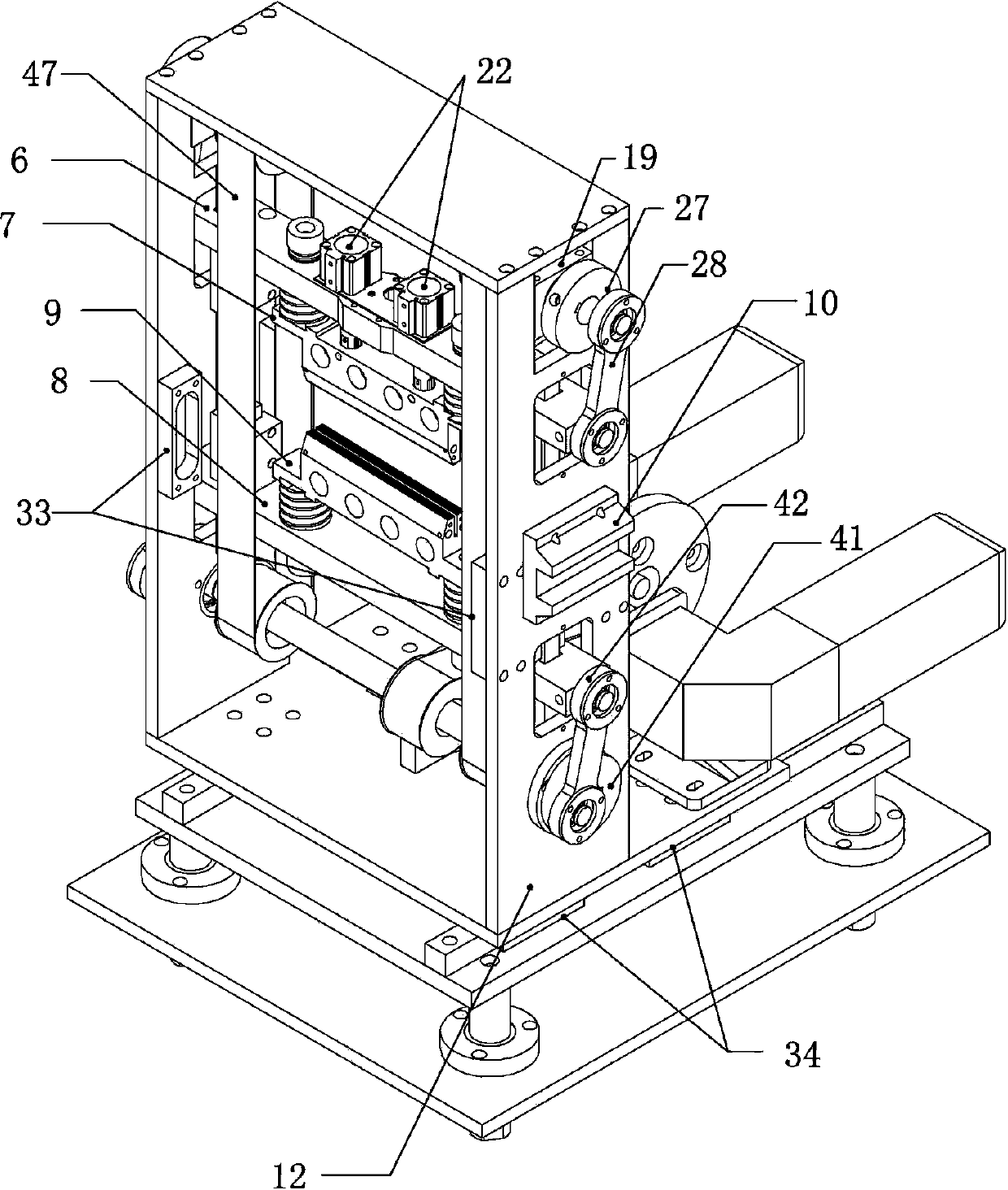

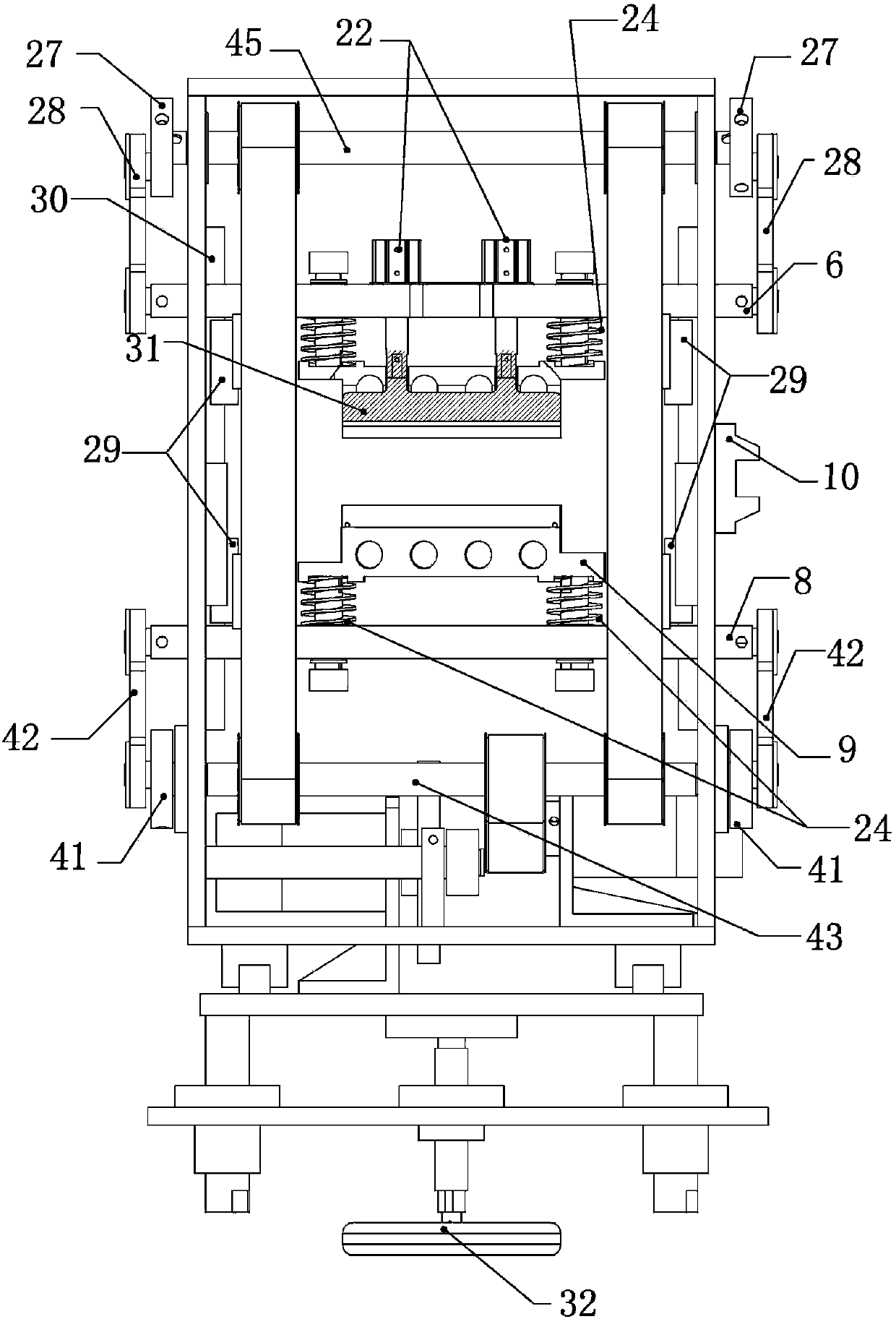

[0039] Embodiment 1: see Figure 1 to Figure 6 , a reciprocating pressing and cutting device, comprising a knife rest, a horizontal reciprocating movement mechanism of the knife rest, and a vertical reciprocating pressing and cutting opening mechanism of the upper and lower knife rests, and the horizontal reciprocating movement mechanism of the knife rest includes a horizontal reciprocating movement of the knife rest The driving motor, the horizontal reciprocating movement transmission assembly of the knife rest and the horizontal reciprocating movement guide assembly of the knife rest. The moving transmission assembly pushes the tool holder to reciprocate horizontally along the horizontal reciprocating movement of the tool holder; the guide assembly reciprocates horizontally; the upper and lower knife seats are vertically reciprocated, pressed, cut, and opened; the upper and lower knife seats are vertically reciprocated, pressed, cut, and opened; , the vertical reciprocating ...

Embodiment 2

[0046] Example 2: see image 3 , in the above structure, the reciprocating pressing and cutting device also includes an auxiliary guide assembly for the horizontal reciprocating movement of the knife rest, and the auxiliary guide assembly for the horizontal reciprocating movement of the knife rest contains a chute block 10 fixed on the outer surface of the inner plate of the knife rest, and the chute block The 10-inner matching set is fixed on the horizontally arranged slide bar on the frame, and the two are slidably matched, or the guiding linear slider fixed on the outer surface of the inner plate of the tool holder slides with the horizontally arranged linear slide rail fixed on the frame Cooperate.

Embodiment 3

[0047] Embodiment 3: see Figure 7 , 8, a reciprocating packaging machine, including a conveying platform for packaged materials, a frame, a packaging film reel mechanism, a labeling mechanism, a control touch screen, a bag forming device, a back-sealing film pulling mechanism, a flat leather conveyor belt, and a sponge conveyor belt , compressed air device, reciprocating pressing and cutting device. The seat vertically reciprocates and presses the cutting and opening mechanism, and the horizontal reciprocating movement mechanism of the knife rest includes a horizontal reciprocating movement drive motor of the knife rest, a horizontal reciprocating movement transmission assembly of the knife rest and a horizontal reciprocating movement guide assembly of the knife rest, and the horizontal reciprocating movement of the knife rest The moving guide assembly is arranged under the bottom plate of the knife rest, and the drive motor for horizontal reciprocating movement of the knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com